Page 1

INSTALLATION

MAINTENANCE

SERVICE

ASSEMBLY

EFFECTA LAMBDA 60

Rev. 012-02-09

Page 2

2

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

Contents 2

Warranty 3

In general 4

To the installer 5

Components 6

Components 7

System components 8

Components placement 9

The first firing 10

Menu 11

Function laddomat 12

Sleeve placement on solar accumulator tank 13

Electrical scheme 14

Cleaning and service 15

Cleaning 16

Hydraulic scheme 17

Measurements 18

Ceramics 19

Door adjustment 20

Rotate door 22

Air dampers and converter 23

Trouble shooting 24

CE approval 25

▀

Contents

Page 3

3

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

Products from Effecta are guaranteed free of defects with regards to materials and workmanship

for two years for wear parts such as gaskets, pumps, ceramics and electrical components from

the date of installation. The wood boiler’s welded body has a warranty period of five years. This

warranty also includes original spare parts. Any defective products are replaced or repaired as

per assessment by the retailer concerned, or by Effecta. When replacing a faulty product, Effecta

reserves the right to replace it with a new one or a renovated one of the same or equivalent

type.

In the case of a complaint, Effecta must be contacted before any servicing begins. Complaints

must be made promptly. A complaint must always describe the type of product, date of purchase

and serial number.

Otherwise, in the case of a complaint, the HVAC industry’s current regulations apply.

Warranty conditions:

The warranty requires that:

- Installation of the product and the heating system have been done according to the

installation instructions and have been performed professionally.

- The location where the product is installed is designed to make it suitable for this end.

The warranty does not cover:

- The heating system’s overall operation, downtime costs or costs for temporary replacement of

the product.

- Damage caused by negligence during the installation, usage which is contrary to the installation

and user instructions.

- Damage caused by abnormal wear, improper care or improper maintenance.

- Damage that occurs due to placement in an unsuitable location.

- Damage caused by vermin.

- Damage that occurs due to cold.

Facility data:

To be completed when the system is installed / serial number is located on the product label on

top of the boiler and on the front of the accumulator tanks.

Date:

Installer:

Serial number:

Electrical installer:

▀

Warranty

Page 4

4

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

In general

Effecta Lambda 60 is a wood fired boiler with a induced-draught fan. The boiler should be

connected to one or more accumulators, which are heated via a Laddomat valve. Hot water is

taken from the top of the boiler and is fed to the top of the tank. The return water is taken from

the bottom of the tank and is fed to the bottom of the boiler.

Hot water preparation

For hot water storage, the accumulator tank must have a built-in hot water coil or equivalent.

The temperature of the hot water is adjusted by means of a mixing valve. The amount of hot

water that can be tapped depends on the accumulator tank temperature, size and the incoming

cold water flow.

Combustion

On the front of the boiler is two air inlets with dampers, which are controlled by two motors.

The motors gets signals from the lambda control depending on the amount of oxygen in the flue

gases. The system is designed to get as low output of harmful gases as possible. Normally you

don´t need to change the settings when you are burning different kinds of wood with different

moisture content.

The system

Effecta Lambda should be connected to at least 3000l of accumulation volume. At installation,

there should always be a Laddomat valve connected. A wood fired boiler that is connected to

one or more accumulator tank will have a lot of advantages:

• The loading compartment can always be fully loaded

• The user will have a long time between the warm-ups

• Long life-span

• The boiler is always used on maximum performance

• Efciency and environmental assets will be on top

Always try to select an accumulator tank size that will allow you to fire no more than once a

day. When a new firing commences, the boiler fan starts up in order to provide combustion air

and prevent smoke emission. When the boiler reaches a temperature of 78°C, the accumulator

tank starts to charge, and the charging equipment ensures that this is done using layering.

When the accumulator tank is heated, the fan and the charging pump stop. The warm water in

the accumulator tank then heats the house via a shunt valve or automatic shunt. The hot water

is controlled with a mixing valve.

Storage of the fuel

To ensure that the Effecta Lambda works in best possible way, the quality of the fuel must be

good. It´s important that the wood has the right moisture, it should be somewhere around 1520%. The logs should be split into 5-15cm big bits, and the length should be 45-50cm. Never

use logs longer than 51-52cm, this will make the logs jam in the loading chamber.

Try to use the sun and wind when storing the wood. If it´s to much dampness in the logs, the

efficiency of the boiler will drop.

Dismantling and disposal

It is many years to come before your Effecta boiler is worn out, but we ask you to follow the

rules and regulation currently valid at the time for dismantling and disposal of your boiler.

Page 5

5

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

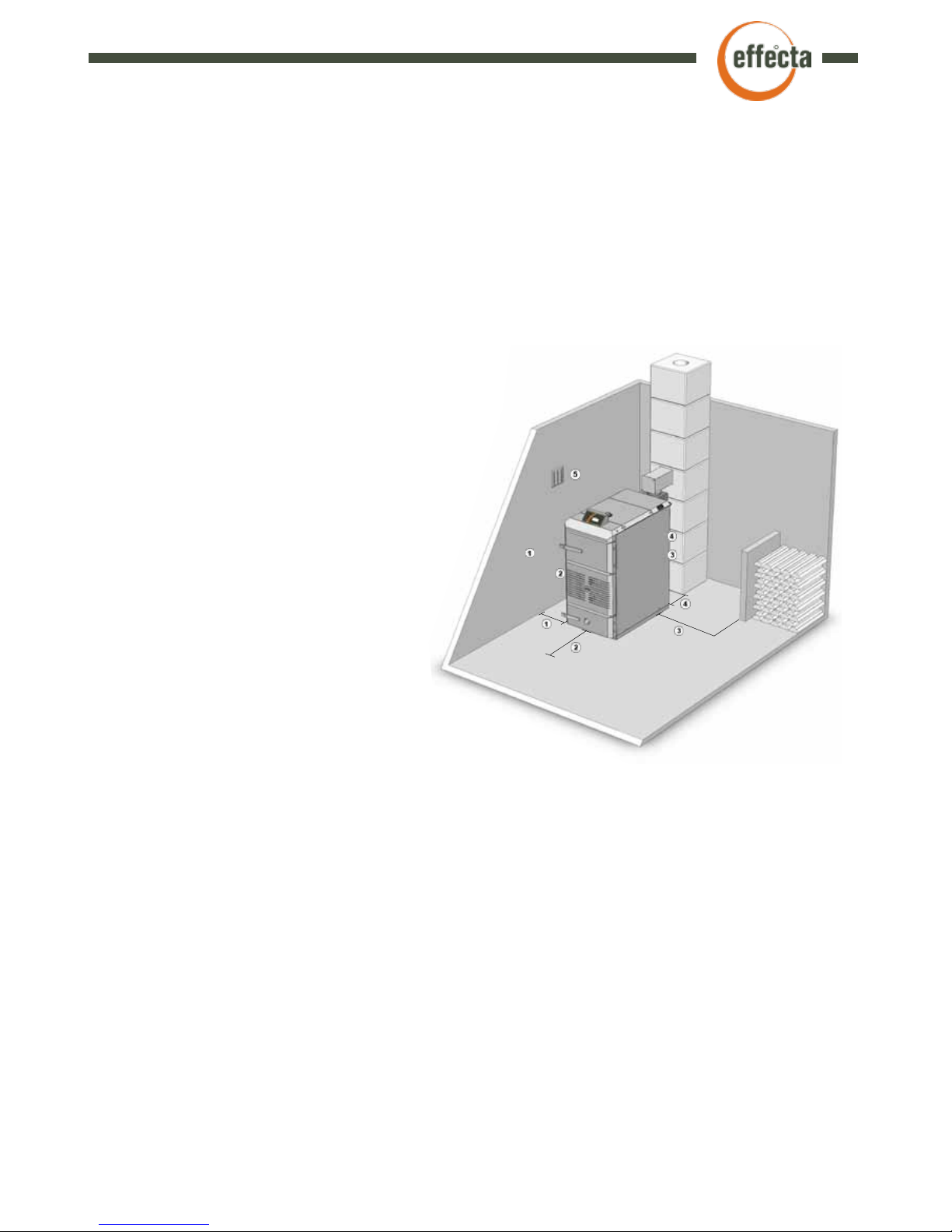

To the installer

It is time to install the Effecta Lambda wood boiler. Please follow the examples we provide for a

safe installation. After installation, be sure to instruct the customer on how the heating system

and the boiler work, in order to avoid unnecessary complications in the future.

Set up

The boiler is positioned so that the surface temperature of flammable building material not

exceed 80°C. The boiler should be positioned at least 15 cm (1.) from the wall. The distance

from the smoke connection to a flammable wall with ignition protective covering must be at least

30 cm (4.). In order to clean the boiler, a minimum clear space of 1 metre (2.) is required in front

of the boiler and on the side at the convection section

and at any inspection panel in the chimney. A passage

with a minimum width of 0.5 (3.) m is required along

one of the long sides of the boiler.

The boiler room

The boiler must be installed in a boiler room or

boiler house. The ceilings and walls must be

fitted with ignition protective covering and

the floor must be made of non-combustible

material. Minimum ceiling height at the boiler

is 2 metres. The boiler room or boiler house

must be equipped with a fresh air intake

with the minimum dimensions 150 x 150

(5.) mm or with a sufficiently large free

sectional area to avoid low pressure in

the boiler room. It must be impossible to

close the air intake.

Accumulator tank

Be sure that the accumulator tanks are well insulated.

For the Effecta Lambda to function as optimally as possible, an accumulator

tank volume of 3000-5000 liters is required.

Chimney

The chimney should have a diameter of at least 150 mm. If your chimney is smaller, Effecta

should be consulted before installation. The draught in the chimney should be about 15 pa at

low temperatures. It is important that the chimney is tested and approved by a certified chimney

sweep before a new boiler is installed. If the chimney has a strong draught, a draught stabiliser

(see page 24.) may need to be installed for good boiler operation. If you have a tall chimney and

an outgoing flue gas temperature below 170°C, there is a risk of condensation in the chimney,

which can damage the chimney in the long term. A suitable temperature is 70-80°C one metre

down into the chimney. Ask your local chimney sweep for help to measure the temperature. If

the chimney is tall and has a large area, a draught that is too strong may mean high levels of

flue gas and overignition in the loading compartment. If this is the case, a counterdraught door

must be installed.

Page 6

6

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

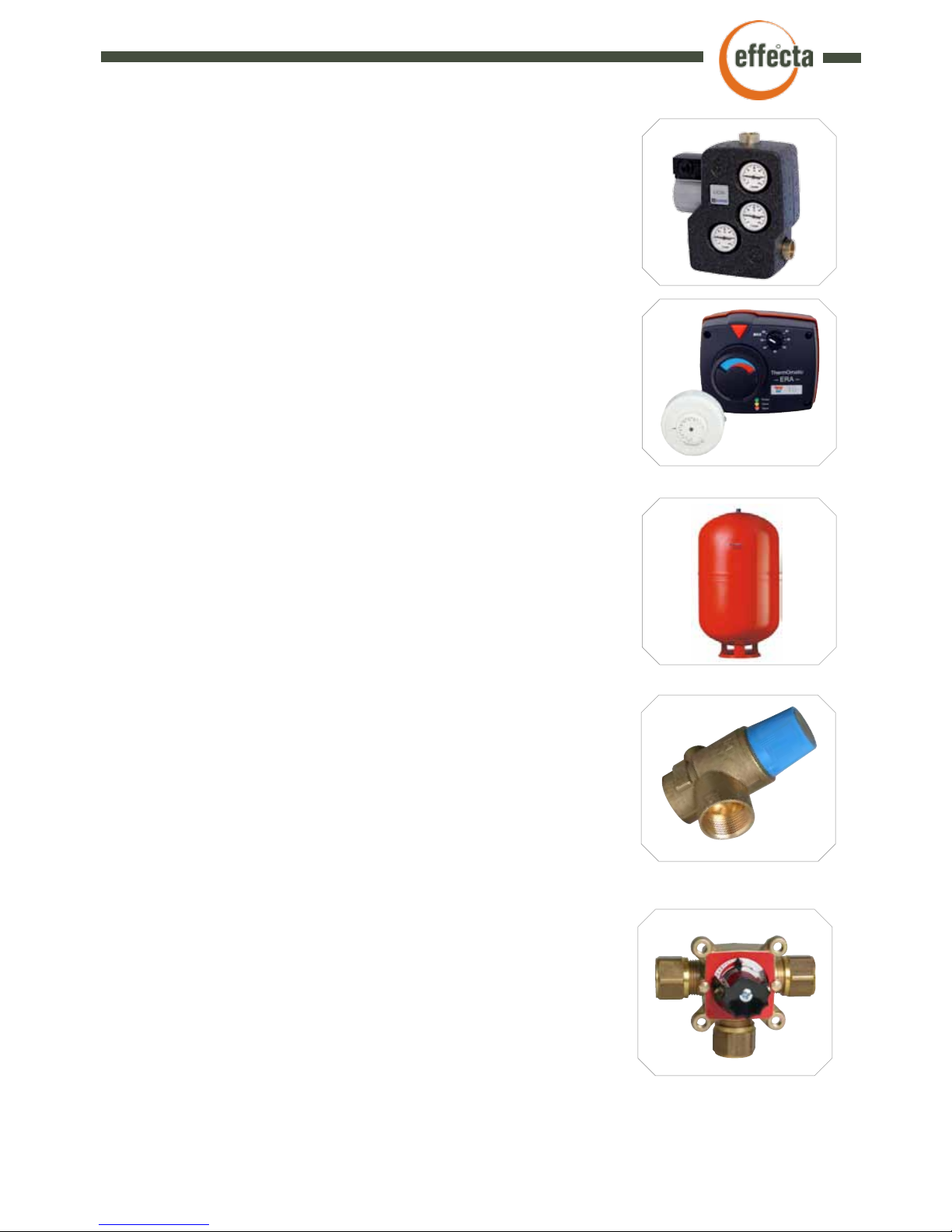

Laddomat 21-100 or equivalent

A Laddomat valve should always be mounted between boiler and

tank. It´s described further on page 12.

Automatic Shunt

The installation of a shunt automatic system on the radiator

circuit is always recommended. The automatic system senses

the temperature in a suitable location in the house and adjusts

the incoming temperature on the radiator circuit accordingly.

This measure can reduce your wood consumption by as much as

25 % and will improve your heat comfort level..

Expansion Vessel

The expansion vessel normally is tested for 6 bars. Highest

working temperature is 99°C. The vessel has a prepressure

of 2,5 bar. The volume should be approx. 10-12% of the total

volume of the system. An open vessel should have a volume of

5% of the total.

Safety Valve

The safety valve will release when pressure exceeds 1,5 bars.

When it opens, water will drip out of it and the pressure goes

down. Remember that the system is designed for a maximum

pressure of 1,5 bars, and shall under no circumstances be under

higher pressure.

Shunt valve

The shunt valve is to be mounted on the radiator circuit, and it´s

designed to mix the accumulator water and the return water from

the radiator to get the right temperature indoor. If mounting an

automatic shunt valve, read it´s instructions.

▀

Components

Page 7

7

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

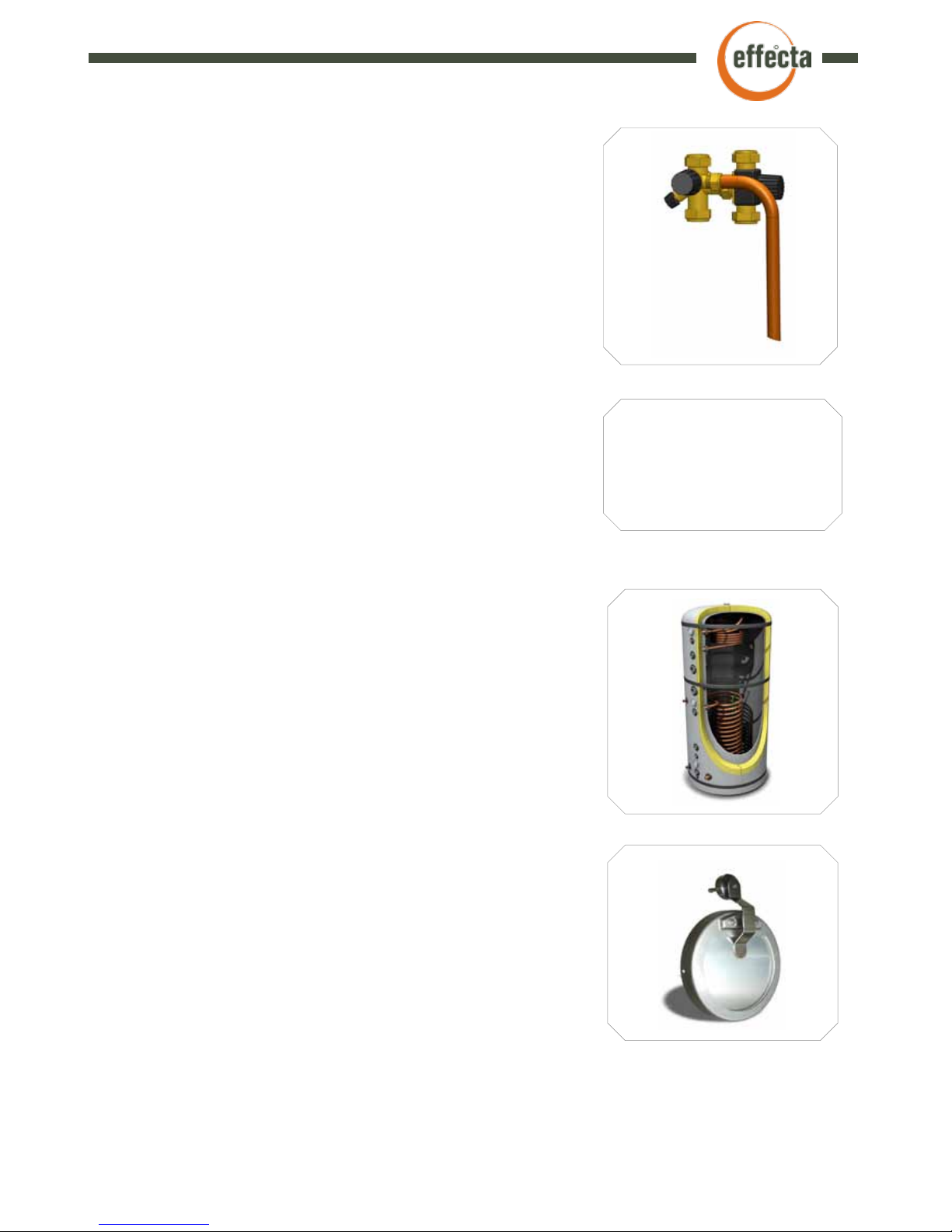

Valve Combination

The valve combination is mounted on the domestic water

circuit. It is purpose is to mix the hot water with cold before

it reaches the water taps. This is to avoid burns, and to keep

the taps and seals from being destroyed by to hot water.

Piping

Normally, copper piping is used for installing these systems.

Piping between boiler and accumulators should not be less

35mm. If the piping is longer than 6 meters to the first tank

it´s recommended to use 42mm.

The Accumulator Tank

Effecta Lambda must always be connected to some sort of

accumulator tank, where the energy is stored, and where the

domestic water and the hot water to the radiators is taken.

The accumulator is described more thorough on page 13.

The Draft Stabiliser

If you have a tall and wide chimney, it is possible that you

have to install a draft stabiliser. You might notice that you

have an irregular combustion, puffing sounds from the boiler.

This happens when the chimney sucks too much air through

the boiler. The placement of the draft stabiliser in the chimney

should be approx. one meter above the connection to the

boiler. This is because you have an overpressure from the

fan, and if you place the draft stabiliser too close to the boiler

you might have smoke coming out of the stabiliser.

NOTICE!

Remember to insulate all of the

pipes in the boiler room.

▀

Components

Page 8

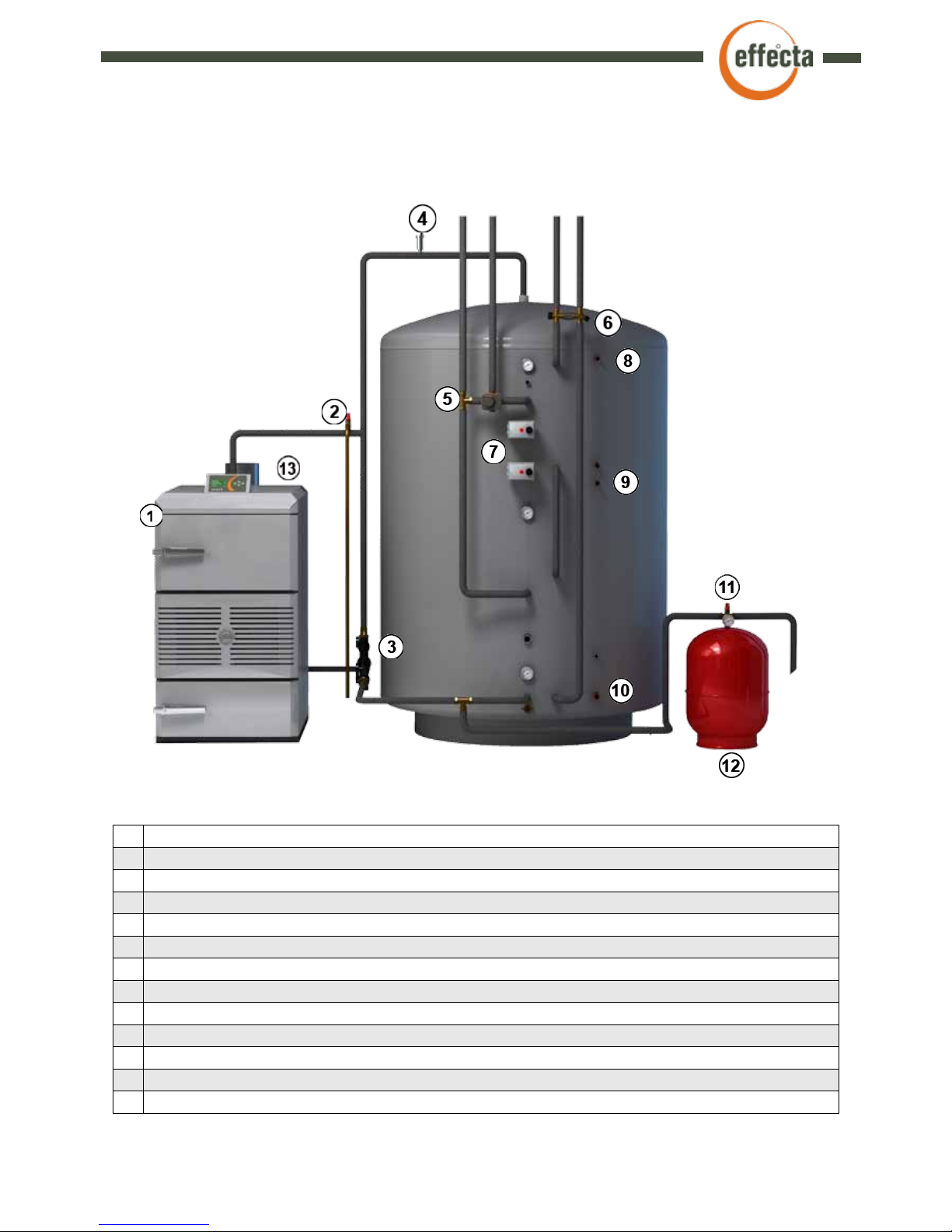

1 Wood log boiler Effecta Lambda 60

2 Safety valve

3 ESBE LTC 100 laddomat valve or similar

4 Air outlet

5 Automatic shunt valve

6 Valve combination for hot water

7 Electrical heaters

8 Possible connection from solar collectors

9 Possible connection from solar collectors

10 Return to solar collectors

11 Safety valve combination

12 Expansion vessel (at least 10% of the volume in the system)

13 Cooling coil (optional)

▀

System components

8

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka +46 (0)300 - 22320 - export@effecta.se

Page 9

9

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

Front Back Top

1 Inspection glass 1 Drain tap ½” 1 Control switch

2 Handle combustion chamber 2 Return pipe 1 ½” 2 Incoming pipe 1 ½”

3 Combustion chamber 3 Wing nut for detaching fan 3 Flue connection

4 Air intake 4 Splice connector fan 4 Cover plate for soot door

5 Damper motors (behind plate) 5 Fan 5 Sensor boiler temp

6 Handle loading compartment 6 Connecting box 6 Flue sensor

7 Loading compartment 7 Thermal protection

8 Control panel 8 Power supply for fan

9 Lambda sensor

▀

Component placement

Page 10

10

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

Remember that during the first firing the boiler can feel sluggish and tough to fire. This is because

all the metal surfaces in the boiler are clean and cooled against the boiler water, the ceramics also

has some moisture that needs to dry. This uses energy from the wood, so the boiler can feel a bit

sluggish.

During the first firing, there is also a lot of oxygen in the water so it can sound as if it is simmering

in the boiler. This will go away when the system has been heated a few times.

The control switch should always be switched on. Place a handful of finely chopped dry wood at

the bottom of the loading compartment. Then take plenty of paper and place on top of the wood.

- Press button (A / startup) to start the fan and the charging pump, then ignite.

The lower door must be shut and the loading compartment door can be ajar but it can also be

closed. Test the way that suits you best. When the wood has ignited and there is a bed of embers,

the loading compartment can be filled with wood. Start by adding smaller pieces of wood at the

bottom and increase the size the further up in the loading compartment you go. Remember to stack

the wood carefully. It is important to get the best possible effect of the firing. When it has burned for

about 15 minutes, the flame will fill the bowl that you see in the inspection glass in the lower door.

The boiler burns at its best if the combustion is left on its own. It is therefore not appropriate to stir

the in the box during firing. If you open the door during firing, there is a risk of flashover in the box,

with poorer function as a result.

If you burn a lot of dry wood and have a strong draught in the chimney, you may hear a whispering

sound in the air dampers. This does not impair the boiler combustion or function, but to avoid this

you have to install a draft stabiliser that maintains a stable draught in the chimney.

NOTE: In case of a second insertion, there is a small risk of smoke emission. Therefore, wait until

the flue reaches a temperature just above 100°C. Open the door carefully to release any gas and

smoke from the loading compartment if necessary.

▀

The first firing

▀

Firing cycle

Start

Press the (START) button.

Fan and charging pump start,

the lambda probe is heated.

The dampers are adjusted

to Primary 70 % open and

Secondary 30 % open.

Operating phase

When the flue gas reaches

100°C , the dampers start to

regulate to achieve the set co²

level. The probe detects a value

every 20 seconds and adjusts

when the difference is + / - 0.5

% from the set value. If the co²

level must be increased, the

primary 10 % opens and the

secondary is reduced by 10 %.

If co² levels must be reduced,

the reverse occurs.

Reducing fire

When the co² level goes

down below 8 %, the

secondary damper shuts off

completely. And when the

flue gas temperature is below

90°C, the fan and circulation

pump shut off. The damper

closes completely. In order

to prevent downdrafts.

Safety

If the water jacket overheats

during firing, a protection will

stop the fan electronically

at 95°C. If the temperature

remains high, a mechanical

thermal protection is initiated.

This must be reset manually.

►

►

►

▬

Page 11

11

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Menus

Showing carbon dioxide concentration, becomes

active at a flue temperature of 100°C.

Primary air damper is open 70%

Turning off the boiler.

Menu for firing

Boiler 47°C

Flue 45°C

B:stop

C:menu

P

_

S

_

CO

2

=

__.__ %

Secondary air damper is open 30%

Calibration of

Lambda sensor?

C:Next

A:Yes

Menu for adjustments

Calibration ongoing

Setting for

desired Co

2

: 13,5 %

C:Next

B:Top

A:Down

Total time: 143h

After cleaning 18h

Has cleaning been done?

C:No

B:Yes

Calibration must be

done before the first

firing. I.e. there must be

no fire in the boiler.

Total operating time

for the boiler.

Displays the operating

time after cleaning.

Press to reset.

C

C

A

Fired with / Running on pellets

C:No / NoB:Yes / Yes

C

C

The pump stops when ue = 85°C

B

The pump starts when ue

= 95°C

C:Next B:Top

A:Down

C:Next B:Top

A:Down

C

Use the fan

B:No / No

A:Yes / Yes

C

Charging pump start

temperature.

Charging pump stop

temperature.

In the case of a weak

draught, the boiler fan

can be used for pellets

burning.

Normally the concentration does not change. If the

wood is extremely dry, it can be reduced or the reverse in the case of damp wood.

Has cleaning been done?

C:NoB:Yes /

C

Effecta Woody Lambda

Boiler 47°C

Flue 45°C

A:start

C:menu

P

_

S

_

Starts the boiler

Indicates boiler temp.

Indicates flue

gas temp.

Damper status.

Damper status.

Entry menu.

Page 12

12

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Function Laddomat 21-100

5 Thermal valve

6 Check valve for natural circulation

7 Circulation pump

8 Spring with housing

9 Filling valve for the system

1. Start-up when the boiler

temperature is below 78°C, the

cartridge has not opened, the

beam for self-circulation is tight

against the accumulator tank due

to pump pressure.

2. Operational phase when

the boiler temperature exceeds

78 °C, the cartridge opens

and mixes cold water from the

accumulator tank. Boiler water

return temp is normally about

70°C. At 90°C from the boiler,

the Laddomat normally gives

66°C back to the boiler.

3. Final phase When the

accumulator tank is fully charged,

hot water will enter on the cold

side of the Laddomat. Then the

plunger opens fully toward the

accumulator tank and closes the

pipe toward the top of the boiler.

All flow now goes to the

accumulator tank. This feature

is important for the accumulator

tank to charge fully.

4. Self-circulation In the

event of loss of electricity or

failure of the circulation pump,

the check valve is opened for

self-circulation. This will normally

prevent boiling unless the

accumulators are fully charged or

the piping presents an obstacle

for circulation.

Page 13

13

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Sleeve placement in solar accumulator tank

165

215

306

376

584

714

866

946

1075

1274

1456

1534

1616

150

1889

1

3

4

6

7

8

9

10

11

12

14

15

5

13

2

16

18

19

17

20

21

ACKUMULATOR 750 BBS

MÅTT OCH PLACERING

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

010-05-22

V50-05-67

E.A

EXPLANATION

1. SWEEP 1500 X 750 MM

2. 1 1/4”70 MM / CHARGE

3. 1/2” 45 MM / THERMOMETER

4. 1/2” 45 MM / SENSOR SOLAR

5. 1 1/4”70 MM / DOCKAGE / FLOW RADIATOR

6. 2” ELECTRICAL HEATER

7. 2” ELECTRICAL HEATER

8. 1/2” 45 MM / THERMOMETER

9. 1 1/4”70 MM / DOCKAGE

10. 1/2” 45 MM / THERMOMETER

11. 1”70 MM / RETURN UNDERFLOOR HEATING

12. 1/2” 45 MM / SENSOR SOLAR

13. 1/2” 45 MM / THERMOMETER

14. 1 1/4”70 MM / RETURN BOILER / DOCKAGE

15. 1/2” 70 MM / DRAIN

16. 22 MM CU / HOT WATER OUT

17. FRAMES WITH 18

18. FRAMES WITH 17

19. COLD WATER IN

20. 18 MM CU / SOLAR COLLECTORS RETURN

21. 18 MM CU / SOLAR COLLECTORS FLOW

Page 14

14

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

ELECTRICAL DIAGRAM

EFFECTA LAMBDA 35/60

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

011-12-20

50-12-08

E.A

L1

N

Ground

CHARGE PUMP

OH 95 ˚C

POWER 230 V

LAMBDA SENSOR

BLACK

GREY

BLUE

WHITE

RED

BROWN

BROWN

ORANGE

YELLOW

RED

BROWN

ORANGE

YELLOW

RED

M

M

RED

RED

M

DAMPER PRIMARY

DAMPER SECUNDARY

FUSE 2A

GREEN

GREEN

---

---

N N N

L1

N

+-

+ +

+

N

M

FAN MOTOR

CONDENSER

FLUEGAS

BOILER TEMPERATURE

POTENTIOMETER

CONTROL SWITCH

L1

1. 2.

4. 5.

CONVERTER

N

BLUE

BLUE

BLUE

N

L1

PELLET BURNER

NOT STANDARD CONNECTION

OH 95 ˚C

▀

Electrical installation

Page 15

15

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Cleaning and service

Afterburner chamber and combustion chamber

The afterburner chamber (1) is located

behind the lower door. It is important to

keep it clean for maximum power and

performance. The chamber slides on two

rails under the ceramics tray. Pull out

and empty the chamber from soot and

ashes approximately every third firing.

When you do a major cleaning, scrape the

space under the ceramics clean as well

as the whole space where the afterburner

chamber is located. Do not forget to reach

all the way into the back where the ashes from

the tubes collect.

Tubes

In order to clean the tubes, lift the rear top plate

(1.), then loosen the wing nuts (2.), that keep the

soot door in place (3.). Remove the 12 spirals

from the tubes (4.), and use the supplied brush to

clean the tubes.

Loading compartment

Start by removing the grate sticks (1.) located at the bottom

of the ceramics. Scrape off the charcoals and ash down into

the slits in the ceramics. The loading compartment walls (2.)

normally have a thin layer of tar, this is normal and does not

need to be scraped off. Do not forget to check that there are

no ashes in the hole where the primary air (3.) is released

into the loading compartment.

Cleaning interval

1. Loading compartment, 40 hours firing.

2. Tubes 40 hours firing.

3. Afterburning chamber,15 hours firing.

4. Fan about 3 times a year.

5. Cleaning lambda sensor once per year.

6. Air distributor secondary air, 40 hours firing.

7. Combustion chamber, 40 hours firing.

8. Check the gaskets once per year.

9. Flue connection and elbow, 40 hours firing.

10. The holes where the primary air is released, once

per year.

Page 16

16

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

Lambda sensor

The lambda sensor is located in the flue

connection and measures the oxygen content

in the flue gas. Once a year the Lambda probe

should be unscrewed from its bracket and

cleaned from any soot that has amassed. Use a

brush. Do not tap it against anything, then it will

brake.

Fan

In normal wood consumption, you should clean

the fan three times a year. Loosen the wing nuts

(1.) located at the back of the fan housing. Pull

out the fan, clean the fan wings (2.) from dust

and soot. If the fan is not cleaned, the boiler

will lose power, resulting in slower heating and

lower combustion.

Secondary air

In the air gap where the flame is drawn down,

there is a metal plate with holes (1.) Clean the

plate after about 40 hours firing. Brush / scrape

away the dust and ashes. If the holes become

clogged up, combustion will deteriorate

significantly.

(In the picture the lower door is viewed from an

angle from below)

▀

Cleaning

Gaskets

The door gaskets must fit tightly against the

frame, if the doors leak the boiler heats less

efficiently. Make sure that the doors' gaskets

seal tightly against the frames. If the gaskets do

not seal tightly, the boiler will burn less efficiently.

If the doors need to be adjusted, see (p. 20).

Page 17

17

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Hydraulic scheme

EFFECTA LAMBDA 60 ACCUMULATOR

AND SOLAR

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

010-05-22

V50-05-77

E.A

EFFECTA ST2

RADIATORS

30.

2.

27.

1.

31.

28.

29.

5.

16.

1. AIR SEPARATOR

2. SENSOR SOLAR (T1)

3. CIRCULATION PUMP RADIATOR

4. BIVALENT SHUNT

5. AIR SEPARATOR

6. LOADING / DOCKING

7. THERMOMETER

8. SENSOR SOLAR ( T2 )

9. RADIATOR SEK / DOCKING

10. ELECTRICAL HEATER

11.TERMOMETER

13. RADIATOR PRIMARY / DOCKING

14.POSSIBLE SENSOR

15. RETURN RADIATOR

16. SENSOR SOLAR ( T3 )

17. THERMOMETER

18. RETURN BOILER

19. HOT WATER OUT

20. CONNECT TO 21

21. CONNECT TO 20

22. COLD WATER IN

23. LOADING SOLARS HIGH

24. RETURN SOLAR LOW

25. LOADING SOLAR LOW

26. RETURN SOLAR LOW

27. 3-WAY VALVE / ALT. THERMAL VALVE (61)

28. 3-WAY VALVE / ALT. THERMAL VALVE (48)

29. CIRKULATION PUMP SEK. SOLAR

30. DRAIN COCK

31. EXPANSIONS VESSEL WITH SAFETY GROUP

32.THERMAL VALVE WITH PUMP

33. SAFETY VALVE 1,5 BAR

34. MIXING VALVE

35. EXPANSIONS VESSEL WITH SAFETY GROUP

3.

34.

19.

22.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

17.

18.

23.

24.

25.

26.

4.

21.

20.

6.

35.

RC

ACCUMULATOR

33.

WOODY LAMBDA 60

32.

EXPLANATION

COLD WATER

Page 18

18

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

EFFECTA LAMBDA 60

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

011-10-11

V50-04-46

E.A

TECHNICAL DATA

1. FLOW ACCUMULATOR 1 1/2”

2. RETURN ACCUMULATOR 1 1/2”

3. DRAIN COCK 1/2”

LEGEND

Width

Depth incl. Flue connect.

Height

Weight

Maximum pressure

Flue angle (extra)

Smoke pipe diameter

Floor to cc flue conncet.

Water volume

Log length

Recommended draft

Min. chimney area

Electrical connection

Sheet tickness mantle

Sheet tickness firebox

Loading volume

Loading compart. depth

Power fan

Power

Max. operating temp.

Firebox opening

Rec. tankvolume

750 mm

1330 mm

11340 mm

540 kg

1,5 bar

150x180x630 mm

180 mm

1365 mm

135 liter

500 mm

15 pa.

180 mm

230 VAC

4 mm

5 mm

195 liter

550 mm

100 W

60 kW

99 gr

490x310 mm

3000-5000 liter

▀

Measurements

Page 19

19

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Ceramics

1 Grate stick

2 Top left

3 Top right

4 Distribution plate secondary air

5 Bottom left

6 Bottom right

7 Afterburner chamber

8 Widener lower

9 Widener upper

The ceramics tray is installed in the loading compartment. The purpose of the ceramics is to

separate the different combustion zones in the boiler. It is important to monitor the tray since

it is a wear part. In normal conditions, the ceramics tray will last for 6-8 years. When the tray is

used up, combustion and efficiency deteriorate significantly.

Page 20

20

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Door adjustment

1. Adjustments in depth

If the gasket does not seal tightly against the hinge

side, loosen the two bolts that hold the hinge in place

of the door frame. Release the bolts around two turns

and adjust the door inwards to tighten the lid and inverted to release the pressure on the gasket.

2. Vertical displacement

To centre the gasket on the door frame in height,

loosen the two bolts on the outside of door. Release

the bolts around two turns and adjust the door.

Approval of the door locking

If the gasket does not seal tightly on the handle side,

loosen the two bolts (1.) that hold the bracket in place.

Loosen around two turns and slide the latch inwards to

tighten the lid and outward to release the pressure. If

the door handle is not in the vertical position with the

flip closed, you can adjust the bolt (2.) up or down to

change position.

There are a number of ways to adjust the hatch. In the pictures below you can see the hinge

on the door. After some use, some adjustments maybe is needed so the gaskets do not draw

extra air to the boiler.

3. Adjustment sideways

To centre the gasket on the door frame to the side,

loosen the two above the number of millimetres that

the adjustment needs. Tighten the short side door with

two bolts.

Page 21

21

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Rotate the door

As standard Effecta Lambda is delivered with door hinges on the right side. If you need to replace the door hanging follow instructions below.

Upper hatch

1. Start by loosening the two M12 bolts that hold the hatch in the against the frame. Remember to have a shelter over the hatch to avoid scratches in the paint with continued work.

2. Also loosen the two M12 bolts that hold the locking device in place. The new lock is supplied with boiler, the existing is not to be used.

3. Remove the two M12 bolts that hold the thermal insulation in place. Manage the insulation

carefully as it easily gets splinters.

4. Remove the two door gaskets.

5. Then remove the two small bolts that hold the angle (6) which is the upper insulation strip

in place.

6. Reassemble the thermal insulation into the two holes located above the original holes. Replace gaskets and then finally the angle plate. Remember not to twist gasket when refitting.

Lower hatch

The lower door is rotated by following step (1-2).

Page 22

22

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

1 Damper motor 5 Set screw

2 Stop pin 6 Motor shaft

3 Air damper 7 Bracket motor

4 Distance 8 Air box

▀

Air dampers

To access the damper loosen the four screws holding the

cover plate in front damper motors in place. Open the two

doors to access the screws.

▀

Converter

Under the middle roof of the boiler there is a

converter which supplies the circuit boards with

power. The power level is preset at the factory,

but sometimes an adjustment may be needed. If

so, the light flashes on the display. Features such

as fans can also be affected at low voltage. Adjust

the brightness using the knob (1.) located on the

converter clockwise 1-3 mm. If the LED (2.) is not

lit, the converter is probably not functioning.

Page 23

23

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - export@effecta.se

▀

Trouble shooting

Problem Possible errors Action

There is smoke emission during ignition.

The fan is turned off. Press ( start new firing ).

Smoke is seeping through the doors. A gasket is leaking. Adjust the doors.

The fan will not start. An electronics malfunction.

Thermal protection switched on.

Contact the factory.

The fan will not stop. The boiler has not had a flue gas

temperature higher than 100°C during

firing.

The boiler will stop within 1 hour.

Tar in the convection section. A sooty loading compartment.

The Lambda sensor needs cleaning.

Damper motor defective.

Clean the boiler.

Clean the Lambda sensor.

Contact the factory.

Little or no heat is transferred to the

accumulator tank.

Probably air in the system.

Poor quality wood.

Fill the system thoroughly.

Change to dryer wood, or chop the

wood into smaller pieces.

The boiler has a low output and is

sluggish.

Moist wood or too little draught in the

chimney.

The boiler may need to be cleaned.

Try drier wood.

Clean the boiler and fan.

The charge pump creaks or thumps,

and sometimes stops pumping.

Probably air in the system.

Low system pressure.

Follow the Laddomat instructions.

Increase the pressure.

The pressure drops in the system. There is a leak in the system. The wa-

ter in the vessel has evaporated.

Wrong first pressure in the pressure

vessel.

Fill up with water and ventilate.

Adjust the pressure.

The CO ² level is abnormally high. The lift dampers have shifted. Adjust the dampers.

The CO ² level is abnormally low. The lift dampers have shifted, the fire is

extinguished.

Adjust the dampers, check the fire.

The air dampers do not start regulating.

Flue gas temperature is below 100°C,

and the fire is extinguished. Deficient

flue gas sensor.

Check the fire.

Noise from the fan. The cooling wing scrapes against the

boiler. The bearings in the fan have run

out.

Check the cooling wing on the shaft

between the motor and fan. Contact

your installer.

The display is blinking. Low or high voltage to the circuit board. Adjust the converter.

High flue gas temperature. Soot in the tubes. Clean the boiler.

CO2 is not changing from 17-21% Dirty lambda sensor or broken

Electrical connections faulty

Clean the sensor

Check all connections

To run without sensor press A and B at

the same time. Then the dampers open

50/50 and the sensor is not used. Contact your retailer or Effecta for service

Page 24

Declaration of conformity:

Effecta Pannan AB

Västra rågdalsvägen 21

SE-434 99 Kungsbacka

The declaration refers to the responsibility of the product:

Effecta Woody: Wood boiler

Number: 02-756697-02

Directive:

89/336/EEC with supplements 92/31/EEC, 93/68/EEC (EMC)

73/23/EEC with the supplement 93/68/EEC (LVD)

97/23/EC (PED)

Harmonised standards:

SS-EN 60204-1 Electrical equipment for industrial machines -

Part 1: General requirements related to the machine and LVD.

SS-EN 50081-2 For emission industry (EMC standards)

SS-EN 50082-2 For immunity industry (EMC standards)

Kungsbacka 12-12-2004

Erik Andersson

Effecta AB

Loading...

Loading...