Page 1

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

effecta Lambda

Operation

Service

Installation

Rev. 07-01-07

Page 2

2

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Contents 2

Warranty 3

General 4

To the installer 5

Parts of the system 6

Parts of the system 7

The system 8

The components 9

The Laddomat valve 10

Connections in the tank 11

The control panel 12

Electrical installation 13

Environment 14

The rst re 15

Soot removal 16

Annual service 16

Troubleshooting 17

CE Mark 18

Innehållsförteckning

Page 3

3

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Effecta Products are guaranteed to be free of defects in materials and workmanship for two years

from the installation date. This applies to wear parts, such as seal, the main body of the boiler, ceramics and electrical components. This guarantee also covers original spare parts. Any faulty products

will be replaced or repaired at the discrimination of the retailer or Effecta. If a faulty product is

replaced, Effecta is entitled to replace it with a new or reconditioned product of the same or a similar type. Effecta gives a 5 year warranty on the remaining components. See the attached warranty

document.

If you have a complaint, you must contact Effecta before starting any servicing work. You must

submit your complaint without delay. You must always state the type of product, the date of purchase

and the serial number.

Otherwise the heating and plumbing industry´s current regulations apply in the case of complaints.

Guarantee terms:

The guarantee is valid on condition that:

• The boiler and the heating system have been installed in accordance with the installation

instructions and in a professional manner.

• The location where the product is installed is suitable for the purpose.

• The pellet burner used is recommended by Effecta.

The guarantee does not cover:

• The overall functioning of the heating system, costs incurred as a result of the heating system

being out of operation or the cost of the temporary replacement of products.

• Damage or injury caused by negligence during the installation or by operating the boiler in a

way which conicts with the installation and user instructions.

• Damage caused by abnormal wear, incorrect operation and maintenance.

• Damage caused by the boiler being positioned in an unsuitable location.

• Damage caused by vermin.

Date

Installer

Electrician

Warranty

Page 4

4

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

In General

Effecta Lambda is a woodred boiler with a suction fan. The boiler should be connected to one or

more accumulators, which are heated via a Laddomat valve. Warm water is taken from the top of the

boiler and is fed to the top of the tank. The return water is taken from the bottom of the tank and is fed

to the bottom of the boiler.

Domestic water

To get domestic water, the tank needs to be equiped with a coil.The tenperature of the water is regulated with a mixing valve.The amount of warmwater is dependent upon the temperature and size of

the tank.

Combustion

On the front of the boiler is two airinlets with dampers, which are controlled by two motors. The motors gets signals from the lambdacontrol depending on the amount of oxygen in the uegases. The system is designed to get as low output of harmful gases as possible. Normally you don´t need to change

the settings when you are burning different kinds of wood with different moisture content.

The system

Effecta Lambda should be connected to at least 1500l of accumulation volume. At installation, there

should always be a Laddomat valve connected.A woodred boiler that is connected to one or more

buffertanks will have a lot of advantages:

• The grate can always be fully loaded

• The user will have a long time between the warmups

• Prolonged lifespan

• The boiler is always used on maximum prestanda

• Efcency and envirinmental assets will be on top

You should always strive after a dimension of the accumulationsystem, so that you don´t need to make

more than one warmup a day.When you startup a new re,the fan will start to provide combustion air

and to prevent smoke from coming out of the reside. When the boiler has reached a temperature of

78degrees, the charging of the tank starts. The laddomat valve care for the statication in the tanks.

When the accumulators are heated, the pump and fan stops. The warm water in the tanks then heats

the radiators in the house, and the domestic water through a coil.

Page 5

5

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

To the installer

It´s now time for the installation of the boiler. Try to follow the examples we are describing for a safe

installation. After the installation, be careful to educate the end user of the boiler how the system is used

and maintained, this is to avoid unnecessary stops an problems.

Location

The boiler shall be placed on a rm foundation, try also to place the boiler as horizontally as possible,

this to avoid airpockets in the boiler. Keep in mind the laws and regulations regarding distances to combustible materials.

The boiler room

The boiler room shall be constructed according to current laws and regulation, if uncertain regarding this,

contact concerned authority. You need good ventilation in the boiler room to get the best performance of

the Woody Lambda.

The accumulator

It´s important that the accumulators are well isolated, this is to get as small heatlosses as possible. To get

a good comfort regarding the number of times you have to be in boiler room, you need at least 1500l of

accumulation volume.

The chimney

The chimney should have a diameter of at least 150mm,if you have a chimney with less diameter, Effecta

should be consulted before installation. The draft in the chimney should at low temperature be approx

15 pa. It´s important that the chimney is tested and approved by concerned authority before a new boiler

is installed. If the draft is to hefty a draft stabilator might be needed. If you have a tall chimney and a ue

gas temperature below 170degrees there is a risk of condensation, which in the long run can be harmful

to the chimney. Adequate temperature 1 metre from the vent of the chimney is 70-80degrees.

If the chimney is tall and wide it may result in to much draft which can lead to too much gasication and

too much re in the grate. This can be prevented by installing a draft stabiliser.

Page 6

6

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Laddomat 21

A Laddomat valve should always be mounted between boiler and

tank. It´s described further on page 10.

Automatic Shunt

It´s recomended to use an automatic shunt valve to control the ue

in the radiator circuit. It feels the temperature in a special place in

the house and regulates the temperature in the radiator circuit ue.

Using an automatic shunt will signicantly reduce the amount of

wood needed during a year, and your indoor climate comfort will

also improve.

Expansion Vessel

The expansion vessel normally is tested for 6bars. Highest working

temperature is 99degreees. The vessel has a preepressure of 2,5bar.

The volume should be approx. 10% of the total volume of the system. An open vessel should have a volume of 5% of the total.

Safety Valve

The safety valve will release when pressure exseeds 1,5bars. When it

opens water will drip out of it and the pressure goes down. Remember that the system is designed for a maximum pressure of 1,5bars,

and shall under no circumstanes be under higher pressure.

Shuntvalve

The shunt valve is mounted on the radiator circuit, and it´s designed

to mix the accumulatorwater and the return water from the radiator

to get the right temperature indoor. If mounting an automatic shunt

valve, read it´s instructions.

Components

Page 7

7

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Valve Combination

The valve combination is mounted on the domestic water circuit. It´s

purpose is to mix the hot water with cold before it reaches the water

taps. This is to avoid burns, and to keep the taps and seals from being destroyed by to hot water.

Piping

Normally copper is used for installing these systems. Piping between

boiler and accumulators should not be less 28mm. If the piping is

longer than 6 meters to the rst tank it´s recomended to use 35mm.

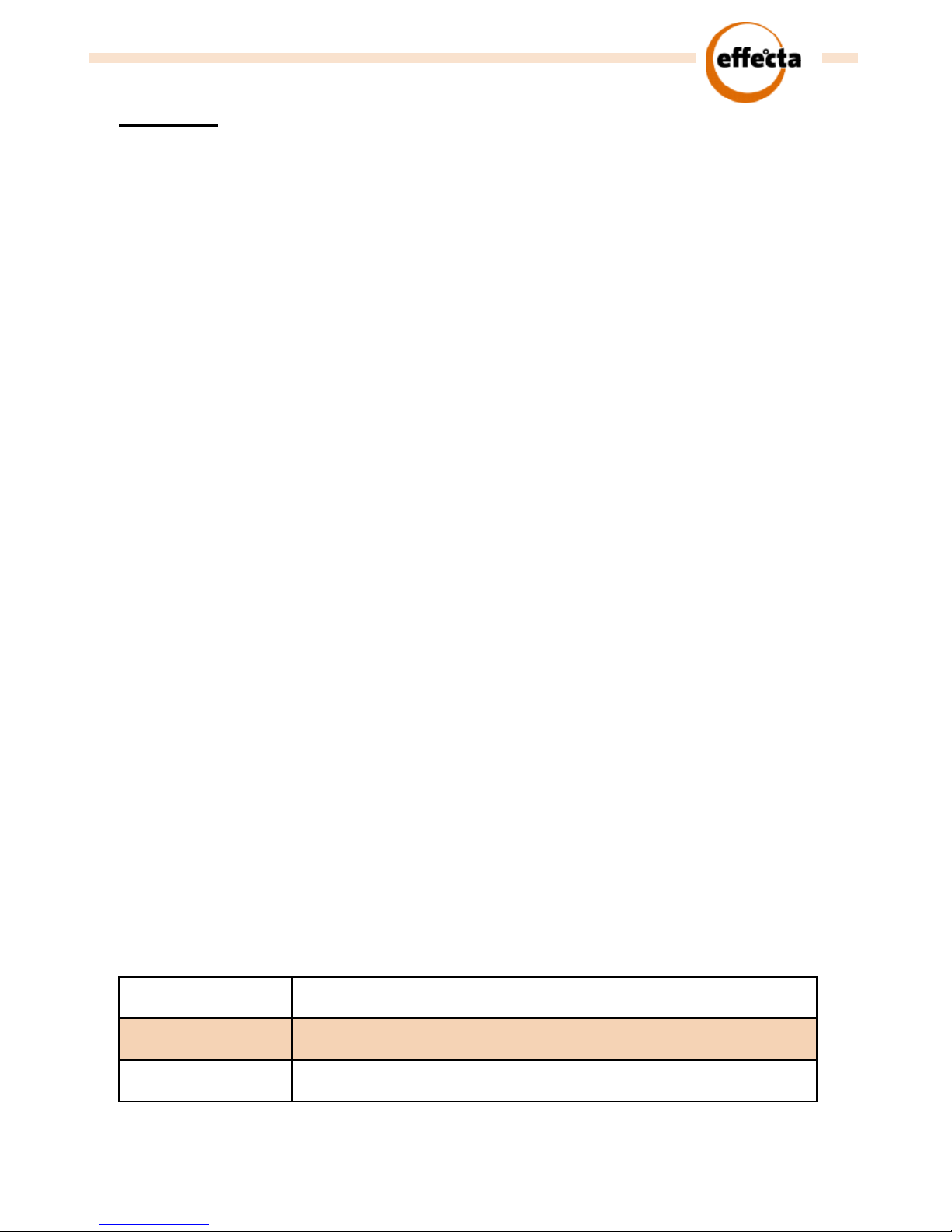

The Accumulator Tank

Effecta Lambda must always be connected to some sort of accumulator tank, where the energy is stored, and where the domestic water

and the warm water to the radiators is taken. The accumulator is

described more thorough on page 13.

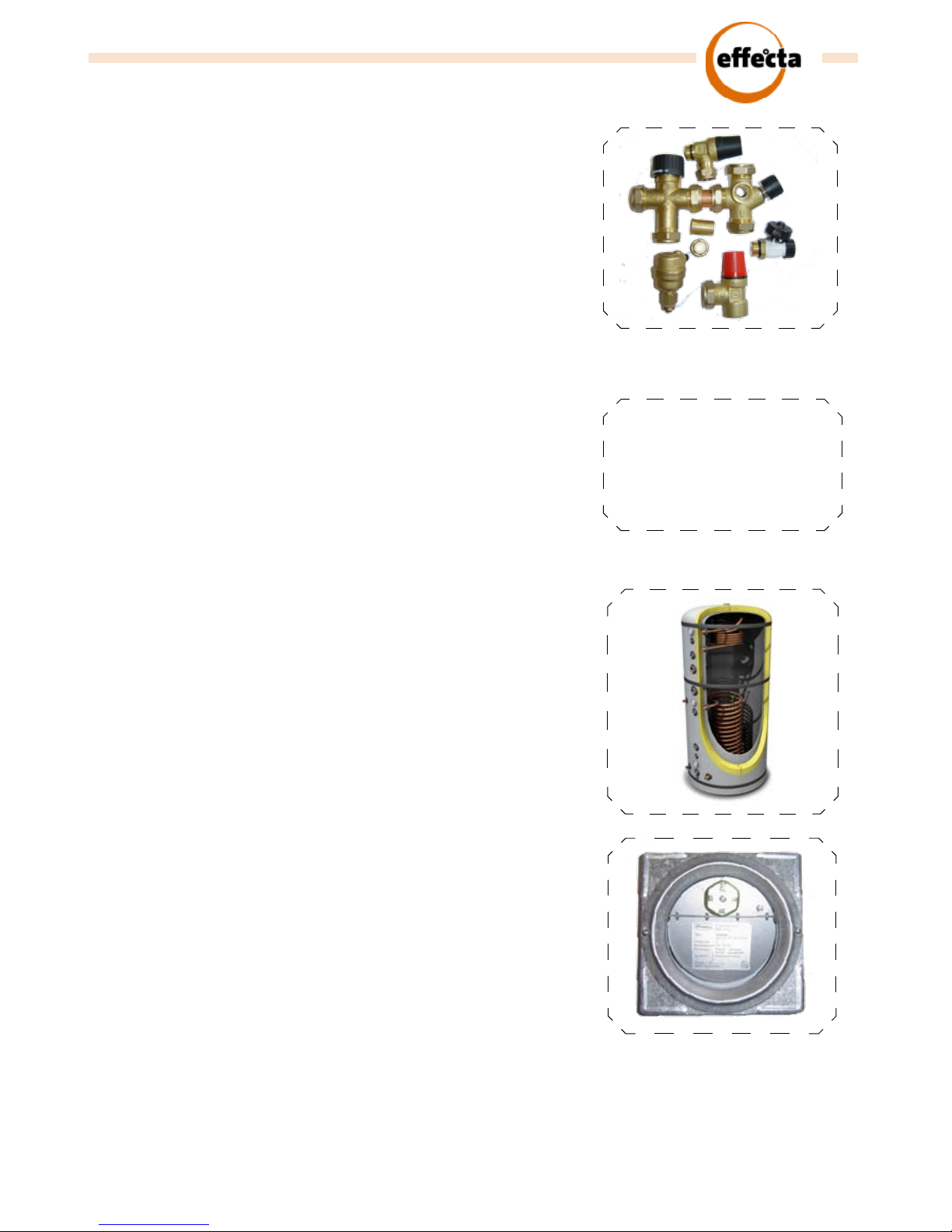

The Draft Stabiliser

If you have a tall and wide chimney, it´s possible that you have to

install a draft stabiliser. You might notice that you have an irregular

combustion, pufng sounds from the boiler. This happens when the

chimney sucks too much air through the boiler. The placement of the

draft stabiliser in the chimney should be approx. one meter above

the connection to the boiler. This is because you have an overpressure from the fan, and if you place the draft stabiliser too close to the

boiler you might have smoke coming out of the stabiliser.

OBS !

Tänk på att alltid isolera

rörledningar i systemet.

Page 8

8

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

1 Wood gasication boiler

2 Safety valve, 1,5bars

3 Laddomat valve

4 Electrical heater

5 Valve combination

6 Shunt valve with automatic motor

7 Outlet frfom safety valve

8 Suitable connection for an open expansion vessel

9 Suitable placement for air escape vent

10 Suitable connection for pressure vessel

11 Return water from the radiators

12

Domestic cold water inlet

Systemet

Page 9

9

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Page 10

10

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Page 11

11

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Component Component

1 Control panel 9 Ceramics

2 Grate hatch 10

Return from tank,

drain cock

3 Grate 11 Convection area

4 Primary air inlet 12 Flue gas fan

5 Secondary air inlet 13 Smoke pipe 150 mm

6 Inspection panel 14

Hot water outlet 1 1/

4”

7 Ash hatch 15 Soot hatch

8 Afterburner 16 Smoke pipe elbow (500x150x150)

Installation data Technical data

Height 1130 mm Output 35 kw

Width 650 mm Grate depth 540 mm

Depth 920 mm Grate volume 135 liters

Depth incl. smoke pipe 1150 mm Max. working pressure 1,5 bar

Weigth 420 kg Max. working temperature 100°

Electricity supply 230 volt Water volume 80 liter

Floor to centre smoke pipe 1340 mm Min. diameter chimney 150 mm

Placement of components

15

500 mm

16

Page 12

12

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Function Laddomat 21

1. Start; Before the boiler tem-

perature has reached 78degrees,

the thermovalve is closed, and the

valve for self cirkulation is closed

from the pump pressure.

2.

Heating phase; When the boi-

ler temperature exceeds 78degrees

the thermovalve begins to open and

mixes cold water from the tank.

Normally the temperature of the

return water to the boiler is about

70degrees and the hot water from

the boiler about 80-85degrees.

3. Final part; When the accumula-

tor is getting almost fully charged

the Laddomat, thanks to the unique

thermal valve, charges the accumulator completely by closing the

bypass opening.

4. Self circulation In the event of

a power failure the Laddomat immediatly starts charging the accumulator by self circulation. The

same happens if the pump breaks

down.

5 Thermal valve

6 Reverse circulation valve

7 Pump

8 Spring

9 Filling valve

Page 13

13

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Connections in Solar accumulator

15

1 Charging-Expansion 1 1/4” 9 Cold domestic water 22mmcu

2 Domestic water 22mm cu 10 Drain cock 1/2”

3 Warm water to radiators 1 1/4” 11 Water to solar panels 18mm cu

4 Connect to nr6 22mm cu 12 Thermometers 1/2”

5 Electrical heater 2” 13 Connection/Return radiators 1”

6 Connect to nr4 22mm cu 14 Water from solar panels 18mm cu

7 Allternativ return from radiators 1” 15 Sensor solar 1/2”

8 Sensor solar 1/2” 16 Alternative sensor 1/2”

16

OBS! detta är en standard tank och behöver ej vara exakt levererad.

Page 14

14

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

1 Control power supply ON/OFF

2 Overheating protection Stops the fan at boilertemperature 95º

3 Start (A) Start re (increase value)

4 Menu (B) Browse the menues (conrm)

5 Stopp (C) Stopps program (decrease value)

6 LCD Display Shows tamperatues, oxygen value, effectivity, etc. etc.

THE CONTROL PANEL

Page 15

15

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

230 VAC

12 volt

Traco, 2,1 amp

12 volt

+

+

T01

D1

D2

Red

Green

Grey

White

Yellow

Black

B3

S5

S4

Brown

Red

Yellow

Orange

Brown

Red

Yellow

Orange

-

-

V2

V1

L1

Electrical installation

S1 Power supply Incoming 230 VAC

T01 Overheating protection Mecanical overheating protection

B3 Fuse Fuse 2 amp

S4 Sensor ue gas Sensor TYP K

S5 Sensor boile temperatur Sensor TYP K

D1 Flue gas fan 230 VAC

D2

Pump laddomat 230 VAC

V1 Motor primary air 12 volt

V2

Motor secondary air 12 volt

L1 Lambdasond ---------------------------

S1

T01

+

-

Page 16

16

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

The surroundings

When you´re using a wood gasication boiler it´s important to re in a way that´s not harmful for the

environment or your neighbours. Take considerations in the following things:

The fuel

Effecta Lambda designed to be used with wood logs. The kind of tree species has no bigger importance

other than that birch, beech and oak have a higher efcency value than conifer. This means that the accumulator is heated faster with broad leaved trees than with coniferous trees.

Birch, beech and oak also have a slightly higher density than conifer, wich lead up to a bit more com-

pressed pile of wood in the grate which leads to a smoother gasication of the wood and a steadier

combustion.

When making a re, big and small logs should be mixed, with the largest on top in the grate. You

shouldn´t use only ne cloven wood or the opposite, only big logs.

Using only ne cloven wood can lead to a re with higher effect than the boiler is designed for. The

consequenses can be shortened lifespan of wear parts, such as ceramics, fan etc.

Using only bigger logs might lead to a re with low effect, with low ue gas temparature as aftermath.

This might lead up to damages on the chimney if you get condensation in it.

Never make a bonre with stuff that is harmful to the environment such as impregnated wood, domestic

waste, plastics or rubber etc.

Storage of the fuel

To ensure that the Effecta Lambda works in best possible way, the quality of the fuel must be good.

It´s important that the wood has the rigtht moisture, it should be somewhere around 15-20%. The logs

should be split into 5-15cm big bits, and the length should be 45-50cm. Never use logs longer than 5152cm, this will make the logs jam in the grate.

Try to use the sun and wind when storing the wood. If it´s to much dampness in the logs, the efcency

of the boiler will drop.

Cannibalisation

It is many years to come before your Effecta boiler is spent, but we ask you to follow the rules and regulation currently valid at the time for cannibalisation of your boiler.

Environment

Page 17

17

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Now it´s time to make a re. Remember that during the rst re, the boiler can appear to be slow and

it can be a bit hard to get a good combustion. This is because alla the metalsheets in the boiler are clean

and cooled by the boilerwater. Also the ceramics have some moiste in it which needs to dry out. This

uses extra energy and makes the re a little more slow.

During the rst warm ups there are also lots of air in the system, and this might lead to some strange

noices in the pipings and the boiler. This will dissapear after a few warm ups of the system.

The power supply should always be switched ”ON”

Put a handful of ne cloven wood in the bottom of the grate. Then put quite a lot of paper and put on

top of the pile. Push the button ”Start”, and then ignite. All hatches should be closed, except the grate

door which can be opened a little bit. You might have to try some small changes, i.e. closing the grate

door, etc, to get the best result.

When the re has started and it´s been burning for a while a glow should appeare in the bottom. Now

you can ll the grate with wood. Start by putting smaller bits in the bottom and increasing the size

further up in the grate. The better packed the logs are, the higher the efency and less emmisions you

will get.

When it has been burning for about 15 minitues, the ames should ll up the afterburner that you can

see in the inspection panel in the lower ash door. The boiler makes best use if it´s left alone withou in-

terfernce. If you open the grate door during a re there is risk for to much gasication which leads to

deterioation of the function.

If you are using very dry wood and have a powerful draft, you might hear a ”pufng” sound from the

dampers. This doesn´t deteriorate the combustion, but to avoid this you can install a draft stabiliser.

NOTE! On the occasion of second inlay there is a risk of smoke pooring out of the grate door. Therefore,

open the door cautiously to evacuate gas and smoke in the grate.

Making a re

The control

The Effecta Lambda´s combustion is controlled by a lambda sond, placed in the smoke pipe.

Start of a re cycle is done by pressing the button ”Start”, the dampers is than placed in a position to give

the right amount of air to the up start.

When the start is done and the ue gas temperature has reached a temperature of 100degrees, a measurment of the gases starts. The control strive after a preprogrammed value (13%) of co2, and moves the

dampers to achieve this. The lambda sond leaves a signal every second. +/- 0,5 %.

The button ”Stopp” interrupts the re and stops the fan and pump. The button ”Menu” gives you the opportunity to browse the menues.

The menues

• Calibration lambda sond: This should be done prior to the rst re, and there can be no re in the

grate when doing this.

• Tuning of lambda value: This is done by pressing + (A) stopp - (B). This can be changed if you

have big differenses in wood qualites.

• Sooting: After some time of using, a recommandation to soot the boiler will appear in the display.

Then clean the boiler and reset the control by pressing yes in the menu.

Page 18

18

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Sooting

To get the best performance from your Effecta boiler, it is important to clean it on regular basis. In

winter time it´s appropriate to clean it once a week, in summer once a month.

• Start by removing the stainless stick which lies on top of the

ceramics. Remove bits of logs and coal through the opening be tween the ceramics. The walls in the grate is usually covered with

a thin layer of tar. There is no need to remove this.

• Then remove the rear top plate and the ash hatch.

Remove the 7 turbulators and use the appurtenant

brush to clean the tubes.

• Then open the lower front door, pull out the afterburner and

empty it from ash. This should be done every third warm up

to get the most out your boiler. Then scrape out the dirt in the

space beneath the ceramics.

When cleaning the boiler, you might also clean the fan. Remove

the wing nuts at the fan and pull the fan out from the boiler.

Clean the wheel from dust and soot. If not properly cleaned the boiler will detoriate and burn

with lower efcency. Cleaning of the fan should normally be done 3-4 times/year.

Annual Service

Every year you should do a more thorough control of the

boiler, a good time to do this is before winter, when the

boiler will be used more frequently.

Start by controlling the combustion zone and ceramics. In

the interspace between the ceramics is metall plate with

holes (seen from under), remove dust and other objects.

Control the seals in the doors, they must not leak.

Remove the lambda sond and clean it from ash and soot.

Page 19

19

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Problem Possible faults Action

Smoke from the grate at start

up.

The fan is not running. Press ( Start ).

Smoke from closed doors Seals leaky Adjust doors, replace seals.

The fan doesn´t start Faulty control panel.

Overheating protection released.

Contact Effecta.

Press the reset pin under the

hat.

Tar in the convetion area. Too much soot in the grate.

Lambda sond dirty

Dampers faulty

Clean grate

Clean lambda sond

Contact Effecta

None or little heat is transferred to the accumulator.

Air in the system.

Poor wood.

Try to deair the system

Switch to better wood, or split

it ner.

The boiler gives less effect

and is hard to use

Moisty wood, to little

draft through the chimney.

The boiler needs to be cleaned.

Try wood with less moist.

Clean the boiler

The laddomat valve is banging or making strange noices,

poor ue through the system.

Air in the system,

To low pressure in the system

Try to deair the system

Increase pressure

The pressure is decreasing in

the system

You have a leak in the system.

Water have vaporised from the

open expansion vessel. Wrong

pre-pressure in the pressure

vessel.

Check for the leak.

Fill the system.

Adjust pressure.

Trouble shooting

Page 20

20

Effecta AB - Västra Rågdalsvägen 21 - 434 96 Kungsbacka - 0300 - 22320 - info@effecta.se

Försäkran om överensstämmelse:

Effecta Pannan AB

Västra rågdalsvägen 21

43496 Kungsbacka

Försäkran avser under eget ansvar produkten:

Effecta Woody: Vedpanna

Nummer: 02-756697-02

Direktiv:

89/336/EEG med tilläggen 92/31/EEG, 93/68/EEG (EMC)

73/23/EEG med tillägget 93/68/EEG (LVD)

97/23/EC (PED)

Harmoniserande standarder:

SS-EN 60204-1 Elektrisk utrustning för industrimaskiner -

Del 1: Allmänna fordringar kopplat till maskin och LVD.

SS-EN 50081-2 För emission-industri ( EMC –standard)

SS-EN 50082-2 För immunitet-industri (EMC- standard)

Kungsbacka 2004-12-12

Erik Andersson

Effecta Pannan AB

Page 21

Loading...

Loading...