Page 1

Rev. HA. 015-02-18

COMISSIONING GUIDE

QUICK START GUIDE

EFFECTA KOMPLETT III

20-25-35 kW

Page 2

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

2

This guide will not replace the service and/or user manual of the product. The guide is only

designed to be a help on first start up of the product as well as a guide through the commissioning process.

All parts and menus of this document is described in depth in the product manual.

▀

Introdction

▀

Symbols in the document

Note!

The icon is shown when a important notice of the products needs to be understood.

High voltage

When the icon is shown extra caution needs to be taken since live parts of the boiler is possible to contact without them being isolated. Personal injury or even death may occur! All

installations must be done by a trained professional and comply with current building redulations.

Hot surfaces

The icon is shown when there is risk for personal scaldings or burns.

Page 3

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

3

P. 2 Introduction

P. 2 Symbol description

P. 3 Table of content

P. 4 Check list before powering up the unit

P. 5 Controller

P. 6 Controller setup - fan

P. 7 Controller setup - feeder

P. 8 Calibration of feed rate - Auger model

P. 9 Calibration of feed rate - Auger model

P. 10 Calibration of feed rate - Integrated fuel store model

P. 11 Calibration of feed rate - Integrated fuel store model

P. 12 Calibration of feed rate - Vacuum fed model

P. 13 Calibration of feed rate - Vacuum fed model

P. 14 Calibration of feed rate - Vacuum fed model

P. 15 Calibration of feed rate - Vacuum fed model

P. 16 Controller setup - effect output

P. 17 Controller setup - date / time

P. 17 Controller setup - function test

P. 18 Back end protection

P. 19 Heating circuits

P. 20 Heating circuits

P. 21 Heating circuits

P. 22 Documentation

▀

Table of content

Page 4

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

4

Water content

Before powering up the system with electrical mains please ensure that all the boiler is filled with

water. All pumps controlled by the boiler needs to be in water filled heating circuits where there is

no blockages from circulation.

Doors

All doors and cleaning accesses needs to be closed and sealed before powering up.

Flue / chimney

The boiler must be connected to a approved flue system to evacuate smoke gasses before powering up the boiler.

Fuel feeding

Depending on what fuel feed option the boiler is equipped with the fuel feed system needs to be

completed before power up as well as the storage filled with pellets.

When above is confirmed please allow electrical mains to the boiler.

▀

Check list before electrical power feed

Page 5

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

5

Language

Choose desired language by pressing any of the

flags on the screen.

If change of language is desired please open OTHER SETTINGS where language change can be done

again.

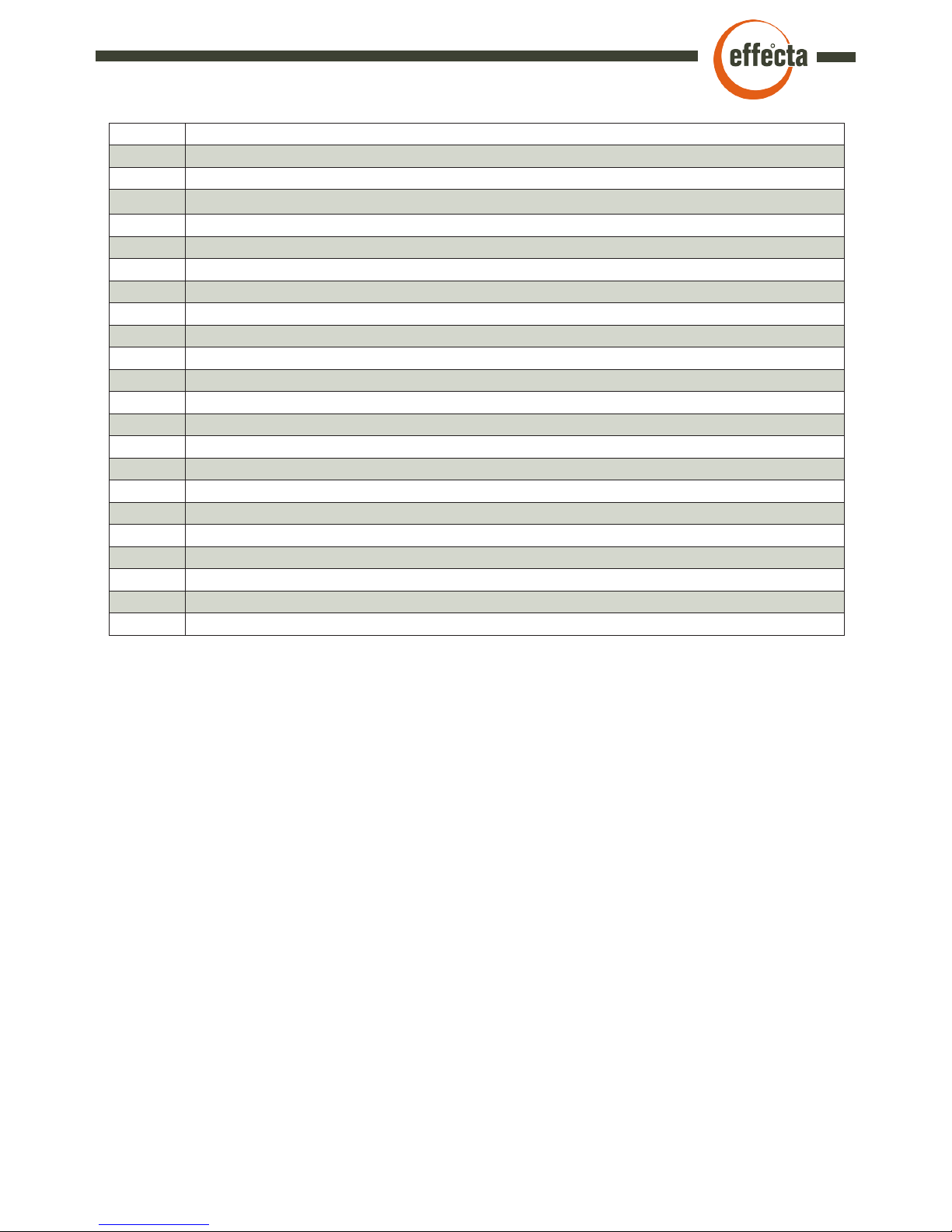

Home screen

On the home screen there is a image of the boiler

with temperature readings of the flue, flow of first

heating circuit and boiler temperature.

A CO2 vaule is displayed (only in operation phase) if

the a lambda probe is used.

A flame icon indicates the flame value visual inside

the boiler in percent.

If the electrical heater is used and applicable to the

system a current consumption will be displayed.

At the bottom part a operating mode will normally be

displayed for instance; Ignition, pre operation, operation phase etc.

Main menu

When pressing the touch display three icons will appear. In this quick start guide you will be asked to

enter the different menus in order to do different settings.

▀

Control display

Page 6

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

6

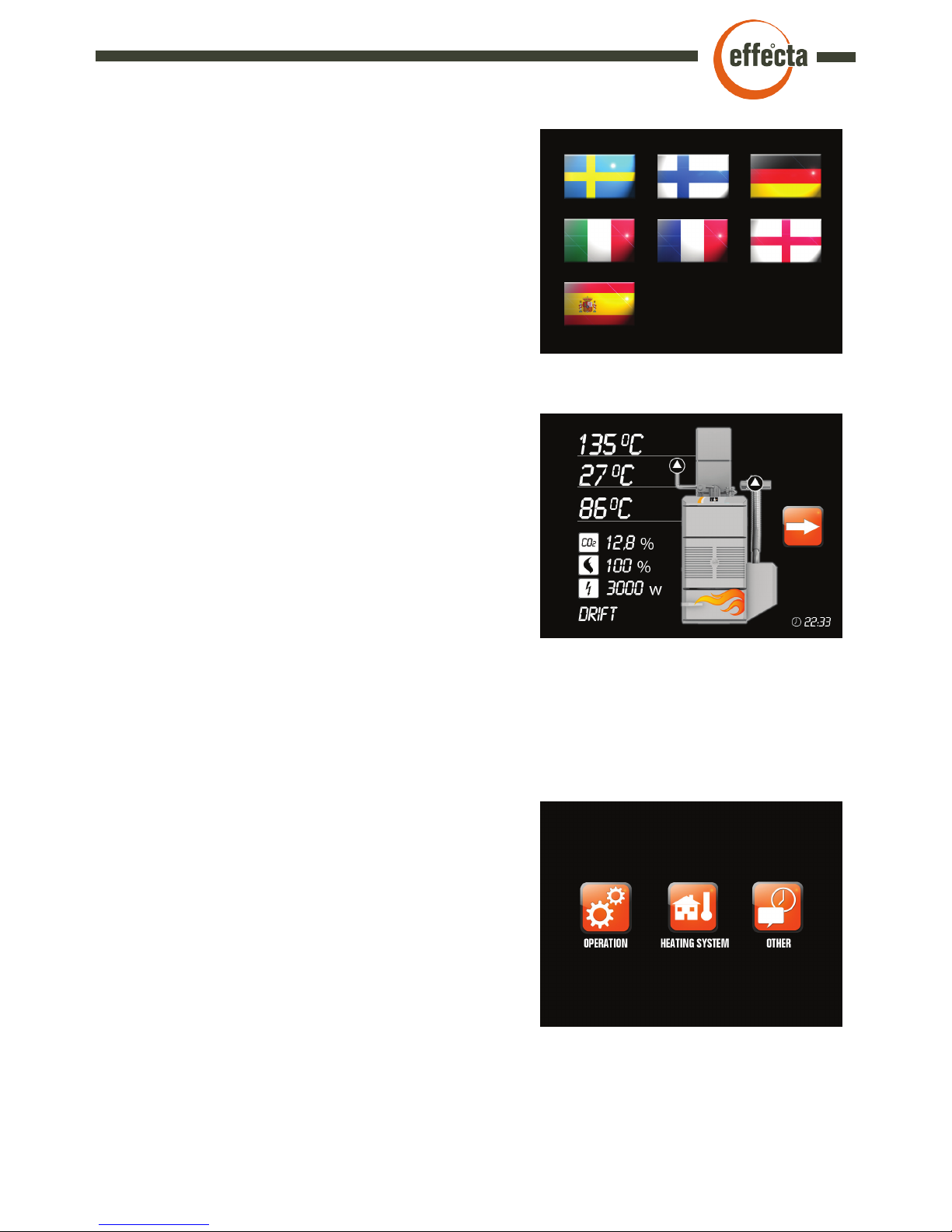

Controller setup

Press anywhere on the display and then press the OPERATION icon.

Operation settings menu:

Use the + and - buttons together with OK and the Return

key to navigate the menu system.

- Confirm that burner is set to OFF.

Fan menu:

Enter the FAN menu, a passcode is required which is

2233. The fan values are set up during operation with

a flue analyzer according to the installation manual. We

can however recommend the following values to get the

boiler operating enough to be able to measure with a flue

analyzer:

The ”Fan burner low” parameter is set to ON if you which

to have the low power output mode activated. We recommend to have it activated on a Komplett III Light which direct feeds any heating circuit without a accumulator tank.

Please leave the menu by pressing the Return key repeatedly until the home screen appears.

▀

Program setup - fan

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

VER: 3.0

Operation settings

20kW 25kW 35kW

Fan burner 55% 65% 55%

Flue boiler 65% 75% 90%

Fan burner

Flue boiler

Fan burner low

Fan alarm

Fan alarm

Fan

65%

75%

Off

Tacho

5s

Page 7

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

7

▀

Program setup - feeder settings

Calibration of feed dose

The most critical part of the commissioning is to calibrate the feed doses of pellets correctly. It is

therefore of outmost importance that it is done precisely and according to this manual. If the feed

doses isn´t setup according to our recommendations the boiler will deliver a faulty output which

can damage the system and it will most likely also result in unstable operation of the product.

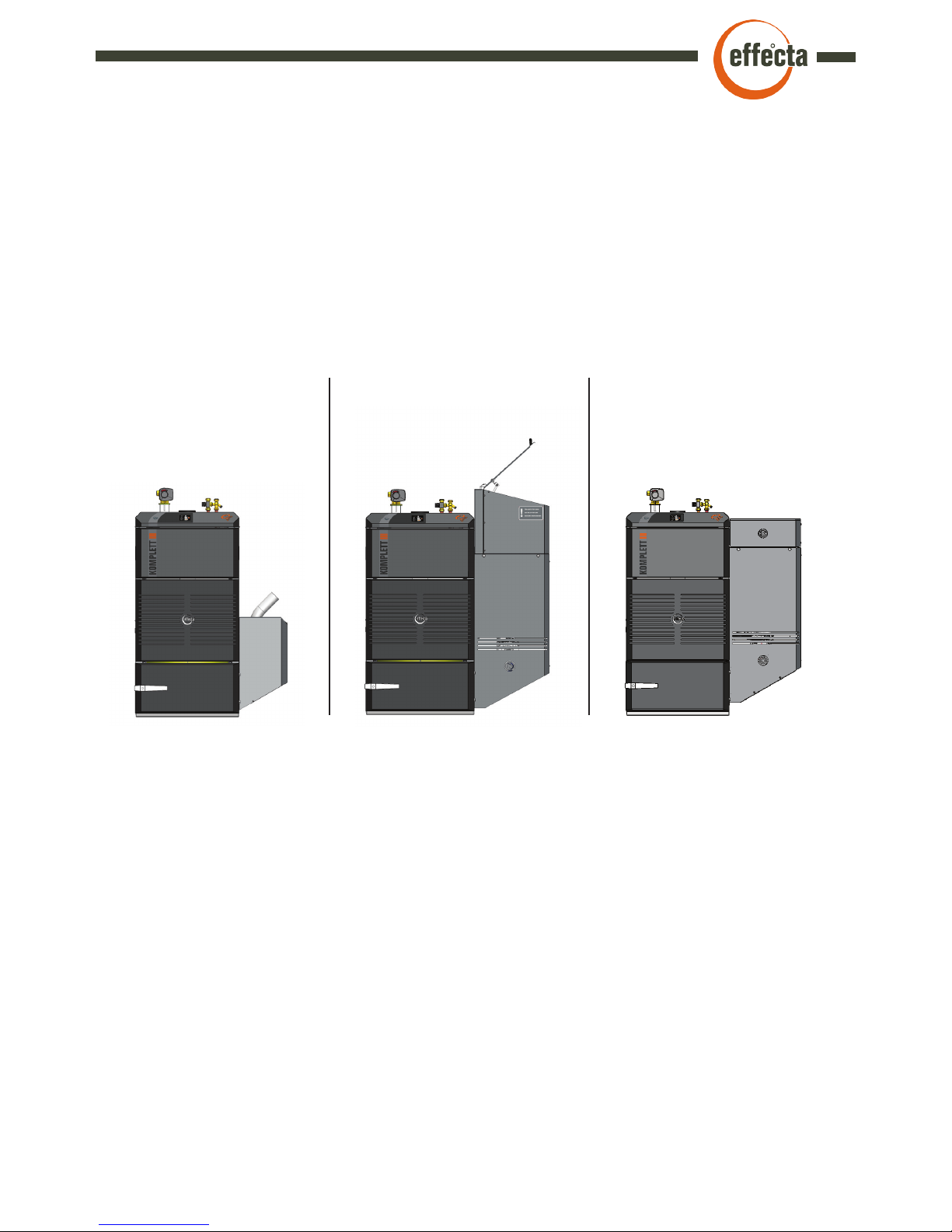

Auger fed model

The calibration process is described on

page 8-9.

Suction model

The calibration process is described on

page 12-15.

Integrated fuel store model

The calibration process

is described on page

10-11.

Page 8

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

8

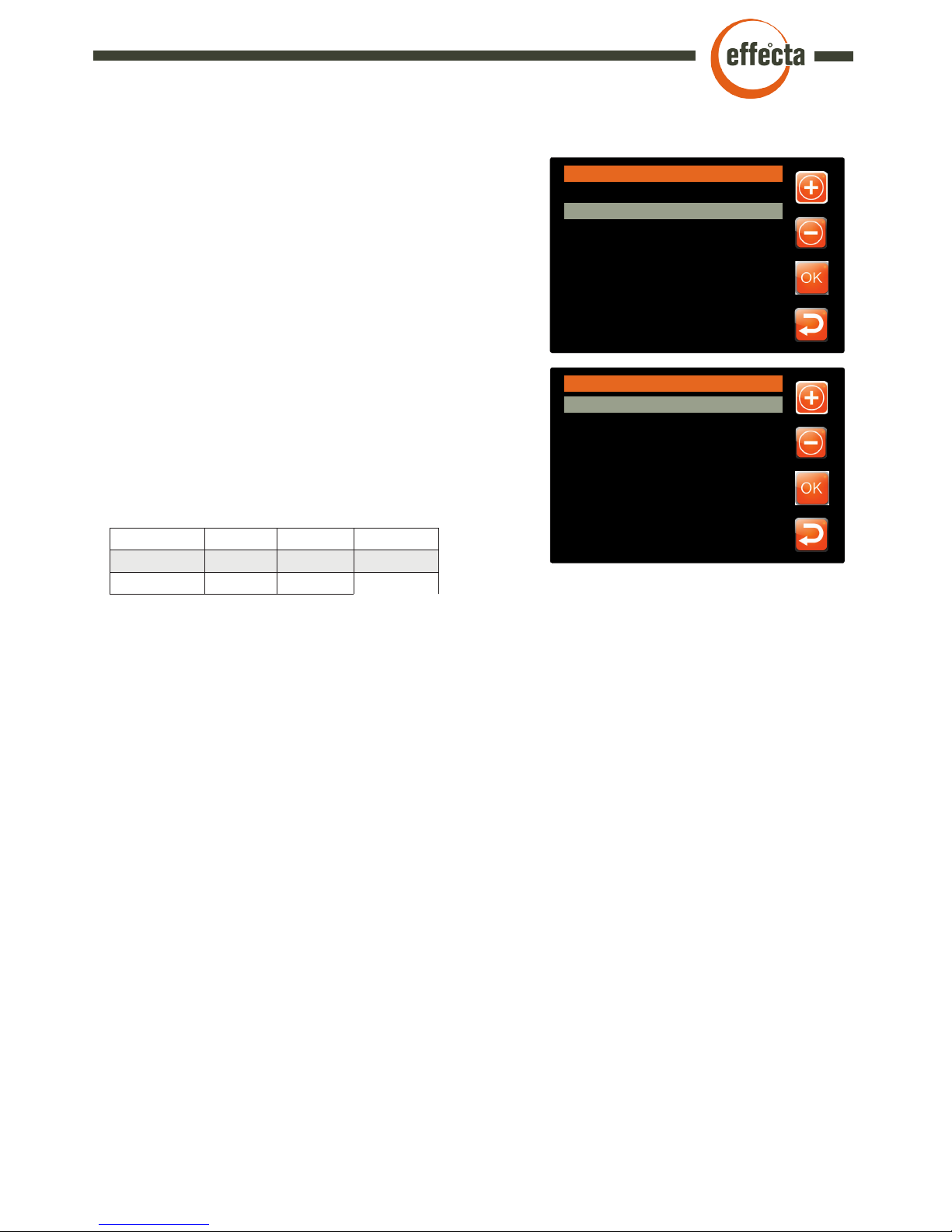

Controller setup

Press anywhere on the display and then press the OPERATION icon.

Operation settings menu:

Use the + and - buttons together with OK and the Return

key to navigate the menu system.

- Confirm that burner is set to OFF.

Feeder menu:

Enter the FEEDER SETTINGS menu.

Change the pellets diameter to 6 or 8 mm. pellets.

▀

Calibration of feed dose - Auger version

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

VER: 3.0

Operation settings

Start dose

Support dose

Pellets diameter

Run start dose

Run supp. dose

Run oper. dose

Feeder settings

50s

10s

6

No

No

No

A correctly adjusted start dose is one of the most critical and important steps of a

comissioning process. If the start dose is incorrect it will give the wrong output on the

boiler which might create operational issues, excessive wear on parts and even be

dangerous in extreme situations.

Calibration of feed dose with a auger fed boiler:

If the boiler is attached to a external feeding auger the start dose value needs to be veriefied according to the below information.

Remove the black plastic hose which connects the feeding auger with the burner unit. Place

some sort of container underneath the plastic hose to collect the pellets that will be fed during a

auger filling procedure.

The hole down the fall shaft to the burner (where the black plastic hose where connected originally) needs to plugged temporarily in order to be able to build under pressure in the fire box and

allow the auger to feed in test mode.

Enter the OPERATION menu and then INSTALLATION menu. Activate the FILL FEEDER function

which will force feed pellets for 15 minutes. Meanwhile the auger is filling up tap the auger repeatedly to ensure that it is packed with fuel. When pellets comes out at the end of the auger the fill

feeder should be set back to NO and then directly back to ON to have a full 15 minutes feed of

pellets to make sure enough pellets is in the auger. Collect the pellets in a bag or container during

this 15 minute feed. Do not stop the feeding process, it is critical to have a properly packed and

filled auger in order to calibrate the feed rate in the next step.

Page 9

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

9

Setting the start dose

When the auger is properly packed and full enter the

OPERATION menu and open the FEEDER SETTINGS

menu and then press RUN START DOSE.

Collect the pellets being fed during the test start dose

process. It should be exactly 40cl. If it is less increase the

amount of seconds of the start dose and run another test

It the start dose is greater than 40cl decrease the amount

of seconds for the start dose and then run the test start

dose again.

Keep testing until the start dose being fed is exactly 40cl.

When this step has been processed the boiler is to be

reassembled again by putting the fall shaft hose back in

to the burner.

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

VER: 3.0

Operation settings

Start dose

Support dose

Pellets diameter

Run start dose

Run supp. dose

Run oper. dose

Feeder settings

50s

10s

6

No

No

No

If the feeder isn´t running it is likely that under pressure over the boiler isn´t sufficient.

Make sure that the burner fall shaft is plugged at all time when the black plastic fall

hose is out of the burner.

▀

Calibration of feed dose - Auger version

Page 10

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

10

Controller setup

Press anywhere on the display and then press the OPERATION icon.

Operation settings menu:

Use the + and - buttons together with OK and the Return

key to navigate the menu system.

- Confirm that burner is set to OFF.

Feeder menu:

Enter the FEEDER SETTINGS menu.

Change the pellets diameter to 6 or 8 mm. pellets.

▀

Calibration of feed dose - Integrated fuel store version

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

VER: 3.0

Operation settings

Start dose

Support dose

Pellets diameter

Run start dose

Run supp. dose

Run oper. dose

Feeder settings

50s

10s

6

No

No

No

A correctly adjusted start dose is one of the most critical and important steps of a

comissioning process. If the start dose is incorrect it will give the wrong output on the

boiler which might create operational issues, excessive wear on parts and even be

dangerous in extreme situations.

Calibration of feed dose with a boiler equipped with a integral fuel store:

If the boiler is equipped with a intergrated fuel store on any side the start dose value needs to be

veriefied according to the below information.

Remove the front and/or side casing of the fuel store. The internal fuel store and burner unit will

be visual. Remove the black plastic hose which connects the feeding auger with the burner unit.

Place some sort of container underneath the plastic hose to collect the pellets that will be fed

during a auger filling procedure. (See illustration on page 11. for further information)

The hole down the fall shaft to the burner (where the black plastic hose where connected originally) needs to plugged temporarily in order to be able to build under pressure in the fire box and

allow the auger to feed in test mode.

Enter the OPERATION menu and then INSTALLATION menu. Activate the FILL FEEDER function

which will force feed pellets for 15 minutes. Meanwhile the auger is filling up tap the auger repeatedly to ensure that it is packed with fuel. When pellets comes out at the end of the auger the fill

feeder should be set back to NO and then directly back to ON to have a full 15 minutes feed of

pellets to make sure enough pellets is in the auger. Collect the pellets in a bag or container during

this 15 minute feed. Do not stop the feeding process, it is critical to have a properly packed and

filled auger in order to calibrate the feed rate in the next step.

Page 11

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

11

Setting the start dose

When the auger is properly packed and full enter the

OPERATION menu and open the FEEDER SETTINGS

menu and then press RUN START DOSE.

Collect the pellets being fed during the test start dose

process. It should be exactly 40cl. If it is less increase the

amount of seconds of the start dose and run another test

It the start dose is greater than 40cl decrease the amount

of seconds for the start dose and then run the test start

dose again.

Keep testing until the start dose being fed is exactly 40cl.

When this step has been processed the boiler is to be

reassembled again by putting the fall shaft hose back in

to the burner.

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

VER: 3.0

Operation settings

Start dose

Support dose

Pellets diameter

Run start dose

Run supp. dose

Run oper. dose

Feeder settings

50s

10s

6

No

No

No

If the feeder isn´t running it is likely that under pressure over the boiler isn´t sufficient.

Make sure that the burner fall shaft is plugged at all time when the black plastic fall

hose is out of the burner.

▀

Calibration of feed dose - Integrated fuel store version

The plastic hose is the fall shaft for pellets

in to the burner and should be removed in

order to collect and measure the amount

of pellets being fed.

Page 12

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

12

Controller setup

Press anywhere on the display and then press the OPERATION icon.

Operation settings menu:

Use the + and - buttons together with OK and the Return

key to navigate the menu system.

- Confirm that burner is set to OFF.

Feeder menu:

Enter the FEEDER SETTINGS menu.

Change the pellets diameter to 6 or 8 mm. pellets.

Change the start dose value to 48s which will get you

reasonably close to the correct start dose value.

▀

Calibration of feed dose - Suction version

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

VER: 3.0

Operation settings

Start dose

Support dose

Pellets diameter

Run start dose

Run supp. dose

Run oper. dose

Feeder settings

50s

10s

6

No

No

No

A correctly adjusted start dose is one of the most critical and important steps of a

comissioning process. If the start dose is incorrect it will give the wrong output on the

boiler which might create operational issues, excessive wear on parts and even be

dangerous in extreme situations.

Page 13

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

13

Filling the internal storage

Press anywhere on the display and then press the OPERATION icon.

Operation settings menu:

Use the + and - buttons together with OK and the Return

key to navigate the menu system.

- Confirm that burner is set to OFF.

Installation menu:

Enter the INSTALLATION menu.

Scroll down to SUCTION SYSTEM and press OK.

Suction system menu:

In the suction system menu scroll down to FILL STORAGE and set the function to ON.

The filling process will now begin.

NOTE: There is a delay time until the vacuum motor comes. It will take 2-3 minutes until the turbine comes on

and with a empty storage it can take up to 15 minutes

until it is fully filled.

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

Operation settings

Advanced

Fill feeder

Effect High speed

Effect low sepped

Testblow start

Phase out

Fan Pre oper.

Fan low pre oper.

Clean Phase out

Flame Sens

Quick Start

Lam,bda probe

Suction System

Cascade

Installation

>

NO

15kW

0kW

0s

10s

40%

50%

12s

>

>

>

>

>

▀

Calibration of feed dose - Suction version

Filling interval

Night blockage

Clean int. storage

Fill Storage

0 (4)h

On

1 (25)h

Off

Suction system

If the feeder isn´t running it is likely that under pressure over the boiler isn´t sufficient.

Make sure that the burner fall shaft is plugged at all time when the black plastic fall

hose is out of the burner.

Page 14

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

14

Calibration of feed dose on a boiler equipped with a suction unit:

When the on board pellets storage has been filled it is time to calibrate the feed rate.

Remove the front casing of the fuel store. The internal fuel store and burner unit will be visual.

Remove the fall shaft connection by removing the elbow coming out from the storage. For reference see illustration on page 15.

Place a container underneath the hole to the feeding opening where the elbow used to connect

to the storage to collect the pellets that will be fed during a auger filling procedure.

The hole down the fall shaft to the burner (where the black plastic hose where connected originally) needs to plugged temporarily in order to be able to build under pressure in the fire box and

allow the auger to feed in test mode.

Enter the OPERATION menu and then INSTALLATION menu. Activate the FILL FEEDER function

which will force feed pellets for 15 minutes. Meanwhile the auger is filling up tap the auger repeatedly to ensure that it is packed with fuel. When pellets comes out at the end of the auger the fill

feeder should be set back to NO and then directly back to ON to have a full 15 minutes feed of

pellets to make sure enough pellets is in the auger. Collect the pellets in a bag or container during

this 15 minute feed. Do not stop the feeding process, it is critical to have a properly packed and

filled auger in order to calibrate the feed rate in the next step.

▀

Calibration of feed dose - Suction version

A correctly adjusted start dose is one of the most critical and important steps of a

comissioning process. If the start dose is incorrect it will give the wrong output on the

boiler which might create operational issues, excessive wear on parts and even be

dangerous in extreme situations.

Page 15

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

15

Setting the start dose

When the auger is properly packed and filled enter the

OPERATION menu and open the FEEDER SETTINGS

menu and then press RUN START DOSE.

Collect the pellets being fed during the test start dose

process. It should be exactly 40cl. If it is less increase the

amount of seconds of the start dose and run another test

It the start dose is greater than 40cl decrease the amount

of seconds for the start dose and then run the test start

dose again.

Keep testing until the start dose being fed is exactly 40cl.

When this step has been processed the boiler is to be

reassembled again by putting the fall shaft hose back in

to the burner.

NOTE: A good value to begin with is 48s for the start

dose. It will take the initial tests close to 40cl. of feed

rate.

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

VER: 3.0

Operation settings

Start dose

Support dose

Pellets diameter

Run start dose

Run supp. dose

Run oper. dose

Feeder settings

48s

10s

6

No

No

No

If the feeder isn´t running it is likely that under pressure over the boiler isn´t sufficient.

Make sure that the burner fall shaft is plugged at all time when the black plastic fall

hose is out of the burner.

▀

Calibration of feed dose - Suction version

The elbow connecting the fall shaft with

the on board storage. Remove it by unwinding the two M8 nuts.

Page 16

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

16

Temperature set

Press OPERATION and then open TEMPERATURE SET

menu.

In the temperature set menu you will set the desired stop

and start temperature of the burners on/off to heat the

water volume within the boiler. Our recommendation is to

have on at 65

°C and off at 75°C.

These temperatures is not at all the same or in communication with the heating circuits used to heat the house.

It is only the internal temperature within the boiler body.

▀

Program setup - temperature set

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

Operation settings

Boiler temp G1

Stop temp.

Start temp.

Temperature set

50°C

80°C

70°C

Effect output

Press OPERATION and then open the INSTALLATION

menu.

Scroll down to Effect high speed and set the boilers high

speed output at the desired effect. Never use a higher

output than the rating of the product!

If the boiler also will be used with a low power output the

Effect low speed needs to be set. We recommend it to be

50% of the boilers maximum rated output.

Burner

Fan

Feeder settings

Temperature set

Information

Service

Installation

Off

Operation settings

Advanced

Fill feeder

Effect high speed

Effect low speed

Testblow start

Phase out

Fan pre oper.

Fan low pre oper.

Installation

>

No

20kW

0kW

0s

10s

40%

50%

▀

Program setup - effect output

Never use a higher output than the maximum rated output of the product!

Page 17

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

17

Date & time

Press OTHER and then open the WEEKDAY menu.

Set the correct date and then press return to get back to

the Other setting menu.

Press TIME to open the menu for the clock. Set the correct local time.

▀

Program setup - date & time

Weekday

Time

Calibr. sensors

Function test

Alarms

English

Start guide

Other settings

Flame sens

Igniter

Feeder

Fan

Compressor

Solenoid valve

Test air clean

Convection clean

Shunt motor 1 (+/-)

Radiator pump 1

Shunt motor 2 (+/-)

Radiator pump 2

Function test

0%

Off

Off

100%

Off

Off

Off

Off

Off

Off

Off

Off

Function test of shunt motors

Press OTHER and then open the FUNCTION TEST menu.

Depending on what functions the boiler have been delivered with a different view will appear in the function test

menu.

Test the following functions:

Shunt motor 1 (also 2 and 3 if applicable) needs to controlled so that they open in the right direction. Press +/and check that they very slowly open in the right direction.

Note that it can be either clockwise or counterclockwise

depending on how the shunt valve has been set up. If the

motor is operating in the wrong direction the power freed

phases needs to be switched.

▀

Program setup - function test

>

>

>

>

>

>

>

Weekday

Time

Calibr. sensors

Function test

Alarms

English

Start guide

Other settings

>

>

>

>

>

>

>

Page 18

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

18

Back end protection

If one or more heating circuits is connected to the

connections at the back of the boiler the back end

protection function must be enabled at all times.

NOTE: Warranty is void unless the back end protection

function is enabled.

▀

Back end protection

Backend prot.

Temp G1 min

Max flow temp.

Backend prot.

Yes

60 °C

20 °C

Back end protection

Press anywhere on the controller and then open the HEATING SYSTEM menu.

Depending on what sensors has been connected to the

boiler and what program options the system has been

set up with the HEATING SYSTEM menu will appear differently. The one illustrated is displayed if one sensor G7

is attached and the programmer is set to a constant flow

temperature.

In the shunt control menu scroll down to BACKEND PROT

and press OK. In the BACKEND PROT menu make sure

that the function is set to YES.

Recommended settings:

Temp G1 min: 60°C

Max flow temp: 20°C

Description of function:

The first parameter (Temp G1 min) is the temperature

within the boiler where the Backend protection function

will be enabled. In the above example the function will be

activated when the temperature drops below 60°C. The

function will then restrict the flow temperature down to

the Max Flow temp which in the above example is set to

20°C. Since the draw of hot water is limited to a minimum

while the backen protection function is active the boiler

temperature (G1) will then rise and when the boiler temperatures reaches 61°C the shunt motor will slowly start

to open again.

▀

Program setup - back end protection

Program

Flow temp.

Radiator pump

Constant flow

Enegy saver

Backend prot.

Shunt control 1

Constant flow

22 (20)°C

On

60°C

>

Yes

Boiler warranty is void if the backend protection function isn´t activated when heating

circuits are connected to the back connections of the boiler.

Page 19

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

19

Setting up the heating circuits

All Komplett III can control up to three individual heating circuits with a great variety of programs

as well as day/time set back. To set up the heating circuits it is important to have the project documentation available in order to set the system up as it has been sold originally.

The layout and controls can be done in more than fifty ways and we will in this document try to

explain the basic functions. Please use the users manual as reference if deeper information is

needed.

For the circuits to work you need the following components installed:

▀

Heating circuits

Components for heating circuits Amount used per heating circuit

Shunt valve 3 way 1 pcs. per heating circuit

Shunt motor 120s ESBE 1 pcs. per heating circuit

Flow sensor, article 301701 1 pcs. per heating circuit

Outdoor sensor, article 301702 1 pcs. common for all available heating circuits.

Room sensor, article 30171 1 pcs. per heating circuit

Heating system menus

The flow sensors enables and activates the menus for

each heating circuit. The first flow sensor needs to be

connected to G7 on the main board in order to activate

heating circuit one. The second and third heating circuit

is controlled from the expansion board and are at port G9

and G10.

NOTE: If the flow sensor for the desired heating circuit

isn´t connected the menu for the circuit will not appear in

the controller!

A electrical diagram is available in the full manual for the

Komplett III boilers.

▀

Activating the heating system menu

Program

Flow temp.

Radiator pump

Constant flow

Enegy saver

Backend prot.

Shunt control 1

Constant flow

22 (20)°C

On

60°C

>

Yes

Room

If the program ROOM is choosen the shunt motor will regulate the shunt valve to maintain a certain

room temperature getting it´s reference from the room sensor. One room sensor is used for each

heating circuit using this program. The active sensors in this set up is the flow sensor and room

sensor.

It is possible to use the ENERGY SAVER function to set back the room temperature with the desired amount of degrees on two different times each individual weekday.

Recommended to use when: The building uses radiators and the room sensor is placed in a location where it isn´t affected by direct sunlight or chill from doors opening and closing. It should be

placed in a central location of the building and not on a outer wall.

Not recommended to use when: The building uses radiant floor heating / under floor heating.

▀

Heating program options

Page 20

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

20

Outdoor

If the program OUTDOOR is choosen the shunt motor will regulate the shunt valve to maintain a

certain room temperature getting it´s reference from the outdoor sensor. The temperature to the

flow is determined with the help of a heating curve and adjustment in the program. This is also

known as weather compensation. The same outdoor sensor can be used for all three heating

circuits running on the same program option. The active sensors in this set up is the flow sensor

and the outdoor sensor.

It is possible to use the ENERGY SAVER function to set back the flow temperature with the desired amount of degrees on two different times each individual weekday.

Recommended to use when: The building uses radiators or underfloor heating.

NOTE: The outdoor sensor must be placed on a north facing wall to function properly!

Both

If the program BOTH is choosen the shunt motor will regulate the shunt valve to maintain a certain

room temperature getting it´s reference from the outdoor sensor. The temperature to the flow is

determined with the help of a heating curve and adjustment in the program. This is also known as

weather compensation. The same outdoor sensor can be used for all three heating circuits running

on the same program option.

The difference between to the program BOTH and the program OUTDOOR is that the room

sensor will correct the temperature to the flow with 5

°C for every °C the room temperature is off.

Example: If a desired room temp is set at 20

°C and the actual room temperature is 19°Cthe tem-

perature to the flow will raise with 5

°C until the difference between desired room temperature and

the actual room temperature is 0

°C.

The active sensors in this set up is the flow sensor, room sensor and the outdoor sensor.

It is possible to use the ENERGY SAVER function to set back the flow temperature with the desired amount of

°C on two different times each individual weekday.

Recommended to use when: The building uses radiators or underfloor heating.

NOTE: The outdoor sensor must be placed on a north facing wall to function properly, the room

sensor needs to be placed at a central location of the house where direct sunlight or chill from

doors doesn´t interfere with the room temperature.

Constant

If the program CONSTANT is choosen the shunt motor will regulate the shunt valve to maintain a

constant temperature to the flow getting it´s reference from the flow sensor.

The active sensors in this set up is the flow sensor.

It is possible to use the ENERGY SAVER function to set back the flow temperature with the desired amount of

°C on two different times each individual weekday.

Recommended to use when: Any case where a separate heating controller is used.

▀

Heating program options

Page 21

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

21

Cylinder

If the program CYLINDER is choosen the shunt motor will regulate the shunt valve to maintain a

constant temperature to the flow getting it´s reference from the flow sensor. This is a very simple

way to control the temperature going to a remote cylinder where there is no possibility to connect

a sensor measuring the actual cylinder temperaure.

The active sensors in this set up is the flow sensor.

It is possible to use the ENERGY SAVER function to set back the flow temperature with the desired amount of

°C on two different times each individual weekday.

Recommended to use when: The cylinder is very remote without possibility to connect a sensor.

Cylinder 2

If the program CYLINDER 2 is choosen the shunt motor will regulate the shunt valve to maintain

a set temperature in the cylinder. The cylinder sensor is connected on port G17 on the expansion

board.

The active sensors in this set up is the flow sensor and a sensor in the cylinder.

It is possible to use the ENERGY SAVER function to set back the flow temperature with the desired amount of

°C on two different times each individual weekday.

Recommended to use when: Always when a cylinder is used where a sensor can be wired back

to the boiler.

Hydraulic schematics

For hydraulic references please see the full manual for the Komplett III.

▀

Heating program options

Page 22

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - 0300 - 22320 - info@effecta.se

22

▀

Customer details and information

User name:

User adress:

Installing company:

Effectas order no:

Serial no:

Commissioning engineer:

Boiler start temp G1 °C

Boiler stop temp G1 °C

Boiler start temp. G6 (only when G5 & G6 is active) °C

Boiler stop temp. G5 (only when G5 & G6 is active) °C

Max G6 (only when G5 & G6 is active) °C

Max G1 (only when G5 & G6 is active) °C

Start dose value S

Start dose measured value cl.

Fan burner %

Flue boiler %

Fan burner low On/Off

Fan burner low (if low effect On) %

Flue boiler (if low effect On) %

Effect high speed kW

Effect low speed (if activated) kW

Back end protection Yes/No

SEND A COPY TO EFFECTA: gunilla@effecta.se

▀

Customer details and information

Loading...

Loading...