Effecta Komplett III Owner's Manual

Rev. JG. 014-09-03

INSTALLING

MAINTENANCE

SERVICE

ASSEMBLY

20

25

35

Light

20

25

35

EFFECTA KOMPLETT III

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

2

We at Effecta would like to thank you for putting your trust in us when choosing your new

boiler. The ”Effecta Komplett III” has been developed to give you maximum performance,

comfort and quality. In order to get the best results from your boiler, we suggest that you

follow the recommendations in this installation guide.

Checking your delivery

Check that the boiler has not been damaged during transportation. If the boiler has been

damaged, you must report this to the transportation company immediately.

Your safety

If you discover any faults or defects in our products, it is important that you report them as

quickly as possible to your installation engineer, so that the fault can be rectified. Make sure

that there are no flammable materials close to the boiler, to help prevent risk of fire. You must

use your own judgement when operating the pellet boiler. Remember that the hatches and

some surfaces can get hot. You must take caution to avoid being burnt.

The user

It is the user´s responsibility to operate the boiler according to our instructions. If you do

not operate and maintain your boiler correctly, the environmental impact of the boiler will be

greater, its efficency will be reduced and the service life of some components will be shorter.

If there is anything that you are not sure about, please contact your installation engineer or

Effecta for advice.

Warranty

The warranty takes effect from the date on which the boiler is installed. The supplied

installation form must be completed and returned to Effecta. You can find the other guarantee

terms on (page 3).

▀

Scope of delivery

Please check all components delivered.

The standard delivery as follows:

- Effecta Komplett III boiler

- Cleaning handle with brush

- Rake with scraper

- Fluetube

- Draft stabiliser (optional)

- Turbulators, 8pcs.(mounted)

- Drain cock

- Shunt valve + motorized shunt control, not in ”Light” version

- Electrical heater 3-9 kW (mounted), not in ”Light” version

- Thermostatic mixer valve, not in ”Light” version

- Room thermostat, optional in ”Light” version

- Outdoor sensor, optional in ”Light” version

▀

Introduction

3

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

System data:

▀

Warranty

Installer:

Date:

Electrical installer:

Effecta products are guaranteed to be free of defects in materials and workmanship. The main

body has a 5 year warranty against leakage of water and all other parts have a 2 year warranty.

The warranty also covers original spare parts. Any faulty products will be replaced or repaired at

the discrimination of the retailer or Effecta. If a faulty product is detected, Effecta is entitled to

replace it with a new or reconditioned product of the same or a similar type.

If you have a complaint, you must contact your retailer before starting any servicing work.You

must submit your complaint without delay. You must always state the type of product, the date of

purchase and the serial number.

Otherwise the heating and plumbing industry's current regulations apply in case of complaints.

Guarantee terms:

The guarantee is valid on condition that:

- The boiler and the heating system have been installed in accordance with the installation instructions

and in a professional manner.

- The location where the product is installed is suitable for the purpose.

The guarantee does not cover:

- The overall functioning of the heating system, costs incurred as a result of the heating system

being out of operation, or the cost of the temporary replacement of products.

- Damage or injury caused by negligence during the installation or by operating the boiler in a

way which conflicts with the installation and user instructions.

- Damage caused by abnormal wear, incorrect operation and maintenance.

- Damage caused by the use of non-original spare parts.

- Damage caused by the boiler being positioned in an unsuitable location.

- Damage caused by vermin.

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

4

▀

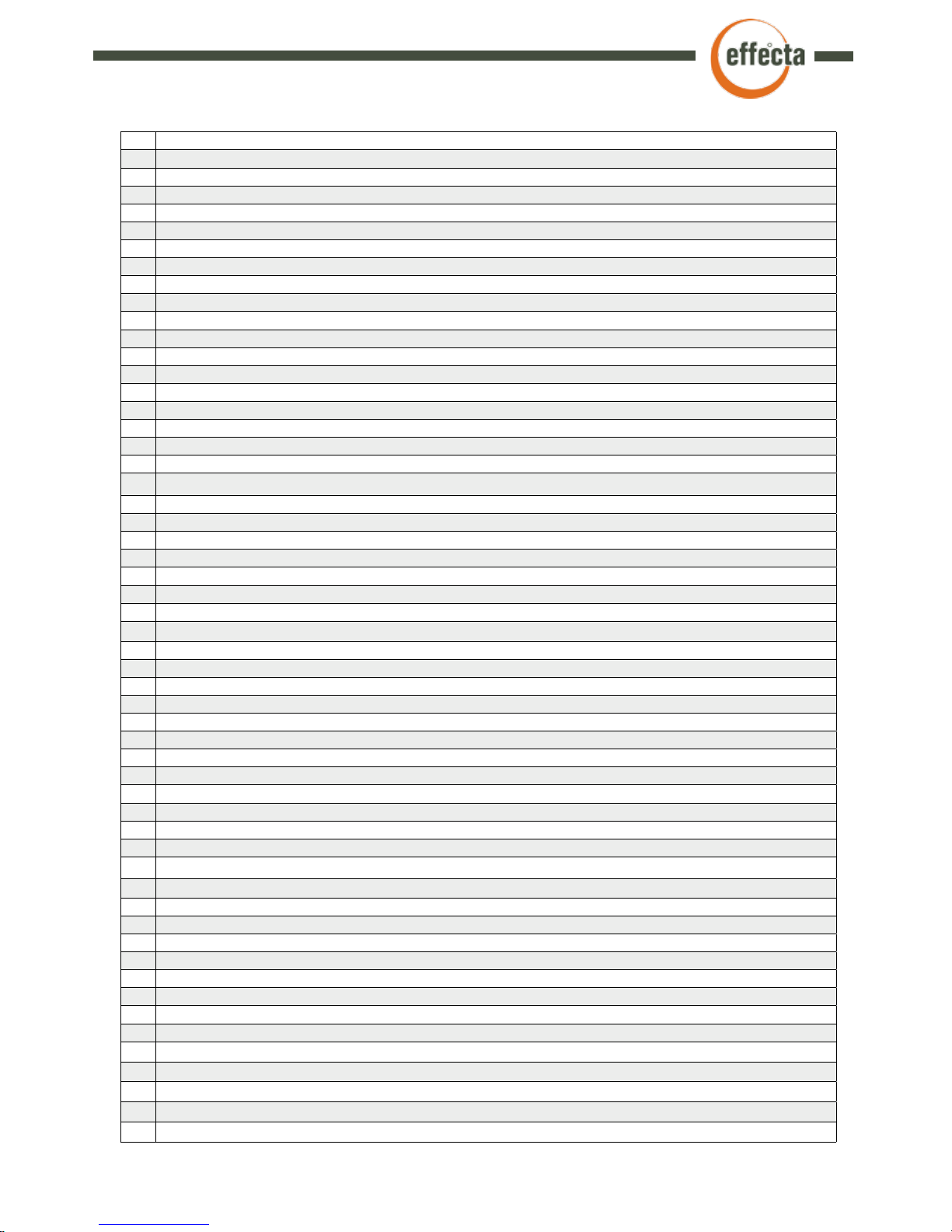

Contents

2 Introduction

2 Scope of delivery

3 Warranty

3 Terms of warranty

3 System data

4 Contents

5 In general

5 Symbols in this document

5 UK Clean Air Act

6 To the installer

7 The components

7 Exploded view, burner

8 Safety and function

9 The safety systems

10 Placement of components

11 The fuel

11 The chimney

12 Cleaning system boiler

13 Cleaning system burner

14 The mothterboard

15 1,2 or 3 Phase connection

16 Connection expansion boards

17 Electrical connection

18 The menu system

19 The menu system

20 The menu system

21 The menu system

22 The menu system

22 Alarms at disruption

22 Ignition phase of the burner

23 First start

23 Tuning the boiler

24 Tuning the burner

25 Hot water

25 Valve combination

26 Shunt control

27 Adjustment of heating curves

28 Examples of curves

29 Service and cleaning

30 Replacing the combustion fan

31 Servicing the flame sensor

31 Overheated fall shaft

32 Charging the igniter

33 Cleaning the rear housing and outer tube

33 Mounting and adjusting of the draft stabiliser

34 Mounting the auger

35 Trouble shooting

35 The sensors

36 Documentation of settings

37 Dimensions

38 Technical data

39 Hydraulic scheme

40 Hydraulic scheme extra hot water

41 Hydraulic scheme buffer system

42 CE

5

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

The Boiler

Effecta Komplett III is a boiler which is to be fueled with wood pellets. No other kind of fuel is

allowed to be used. Not logs or oil.

Disassembly and disposal

It will be many years before your Effecta boiler is worn out, but it is important that you follow

the regulations in force at the time concerning disassembly and disposal of your boiler.

The fuel

The boiler should burn 6 mm pellets which come either in sacks or are supplied by bulk truck.

If you have built a bulk storage, you should follow the current recommendations to ensure that

the quality of the pellets does not deteriorate. Never use pellets which do not meet European

pellet standards, as this may result in problems in operating the burner.

▀

In general

Information

This symbol is shown with info to the installer which can be important to know and

understand. Neglecting this information can affect the performance of the product.

▀

Symbols in this document

Dangerous electricity

This symbol means that extra caution should be taken otherwise serious personal injury

might occur. When maintaining the product where this symbol is present the power must

be disconnected. All electrical wiring must be done by a Professional and comply with

current building regalation.

▀

United Kingdom ”Clean Air Act”

Under the Clean Air Act local authorities may declare the whole or part of the district of the

authority to be a smoke control area. It is an offence to emit smoke from a chimney of a building, from a furnace or from any fixed boiler if located in a designated smoke control area. It is

also an offence to acquire an ”unauthorised fuel” for use within a smoke control area.

Unless it is used in an ”exempt” appliance (”exempted” from the controls which generally apply in the smoke control area). The Secretary of State for Environment, Food and Rural Affairs

has powers under the Act to authorise smokeless fuels or exempt appliances for use in smoke

control areas in England. In Scotland and Wales this power rests with Ministers in the devolved

administrations for those countries. Separate legislation, the Clean Air (Northern Ireland) Order

1981, applies in Northern Ireland. Therefore it is a requirement that fuels burnt or obtained for

use in smoke control areas have been ”authorised” in Regulations and that appliances used to

burn solid fuel in those areas (other than ”authorised” fuels) have been exempted by an Order

made and signed by the Secretary of State or Minister in the devolved administrations.

Your local authority is responsible for implementing the Clean Air Act 1993 including designation and supervision of smoke control areas and you can contact them for details of Clean Air

Act requirements”

Effecta Komplett has been recommended as suitable for use in smoke control areas when burning wood pellet.

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

6

▀

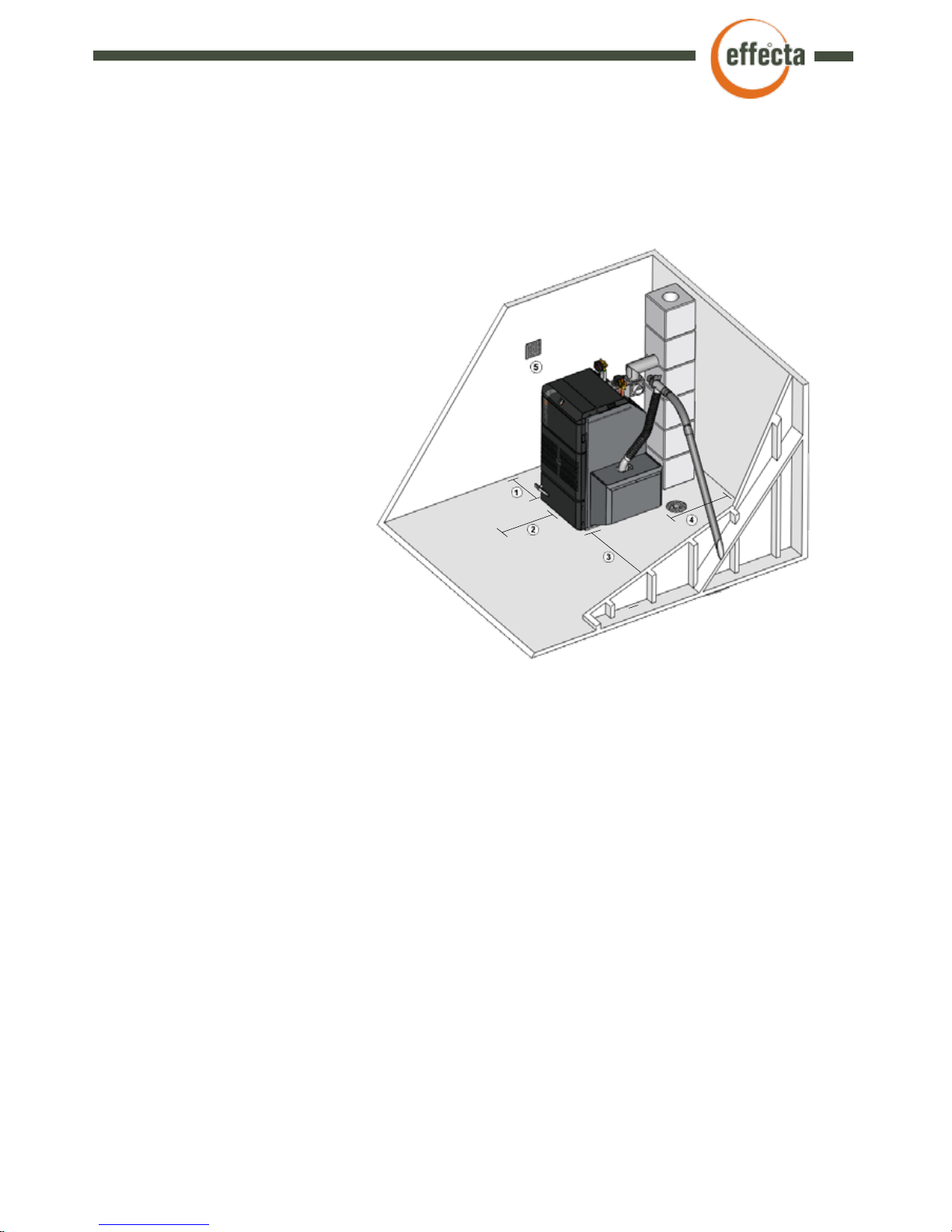

To the installer

It is time to install the Effecta Komplett III pellet boiler. Please follow the examples we provide

for a safe installation. After installation, be sure to instruct the customer on how the heating

system and the boiler work, in order to avoid unnecessary complications in the future. Please

fill out ”Documentation of Settings”(pg35).

Set up

The boiler is positioned so that the

surface temperature of flammable

building material does not exceed

80°C. The boiler must be placed on a

non combustible floor, for example

concrete or tiles. The boiler should

be positioned at least 15 cm (1)

from the wall. The distance from

the flue tube on the boiler to

a flammable wall with ignition

protective covering must be

at least 30 cm (4). In order to

clean the boiler, a minimum

clear space of 1 metre (2)

is required in front of the

boiler and on the side at the

convection section and at

any inspection panel in the

chimney. A passage with a

minimum width of 0.5 (3)

m is required along one of

the long sides of the boiler. Check the regulations of your country in order to place the pellet

hopper on a approved distance from the boiler.

The boiler room

The boiler must be installed in a boiler room or boiler house. The ceilings and walls must

be fitted with ignition protective covering and the floor must be made of non-combustible

material. Minimum ceiling height at the boiler is 2 metres. The boiler room or boiler house

must be equipped with a fresh air intake with the minimum dimensions 150 x 150 (5.) mm or

with a sufficiently large free sectional area to avoid low pressure in the boiler room. It must be

impossible to close the air intake.

Chimney

The draught in the chimney should be about 15 pa at low temperatures. It is important that

the chimney is tested and approved by a HETAS approved installer before a new boiler is

installed. If the chimney has a strong draught, a draught controller (see page 32) may need

to be installed for good boiler operation. If you have a tall chimney and an outgoing flue gas

temperature below 170°C, there is a risk of condensation in the chimney, which can damage

the chimney in the long term. A suitable temperature is 70-80°C one metre down into the

chimney. Ask your local chimney sweep for help to measure the temperature. If the chimney

is tall and has a large area, a draught that is too strong may mean high levels of flue gas and

overignition in the ash compartment. If this is the case, a draft stabiliser must be installed.

7

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

The shunt valve

The shunt valve controls the heat supply from the boiler to the radiator circuit.

Effecta Komplett III is fitted with motorised shunt control. The room temperature can be

adjusted on a scale on the thermostat. An automatic system will significantly reduce fuel usage

and provide a more comfortable environment.

The thermostatic mixer valve

The mixing valve is used to ensure that the temperature of the hot water in your shower and

elsewhere in the house is comfortable. Set the system to the temperature you want by turning

the thermostat between +/-.

The burner

The burner is mounted on the left or right side. The burner heats the water in the boiler which

provides heat to the domestic and hot water.

The turbulators

In the tubes in the heat exchanger hangs the turbulators. The turbulator`s function is to transfer

heat from flue gas to boiler water. They must always be placed in the boiler. If the flue gas

temperature should be to low, the turbulators can be cut off. Always contact the installer before

doing this.

The sealings

The seals on the hatches must be checked every year. If the hatches do not seal properly, the

efficiency and the combustion process of the boiler will deteriorate.

▀

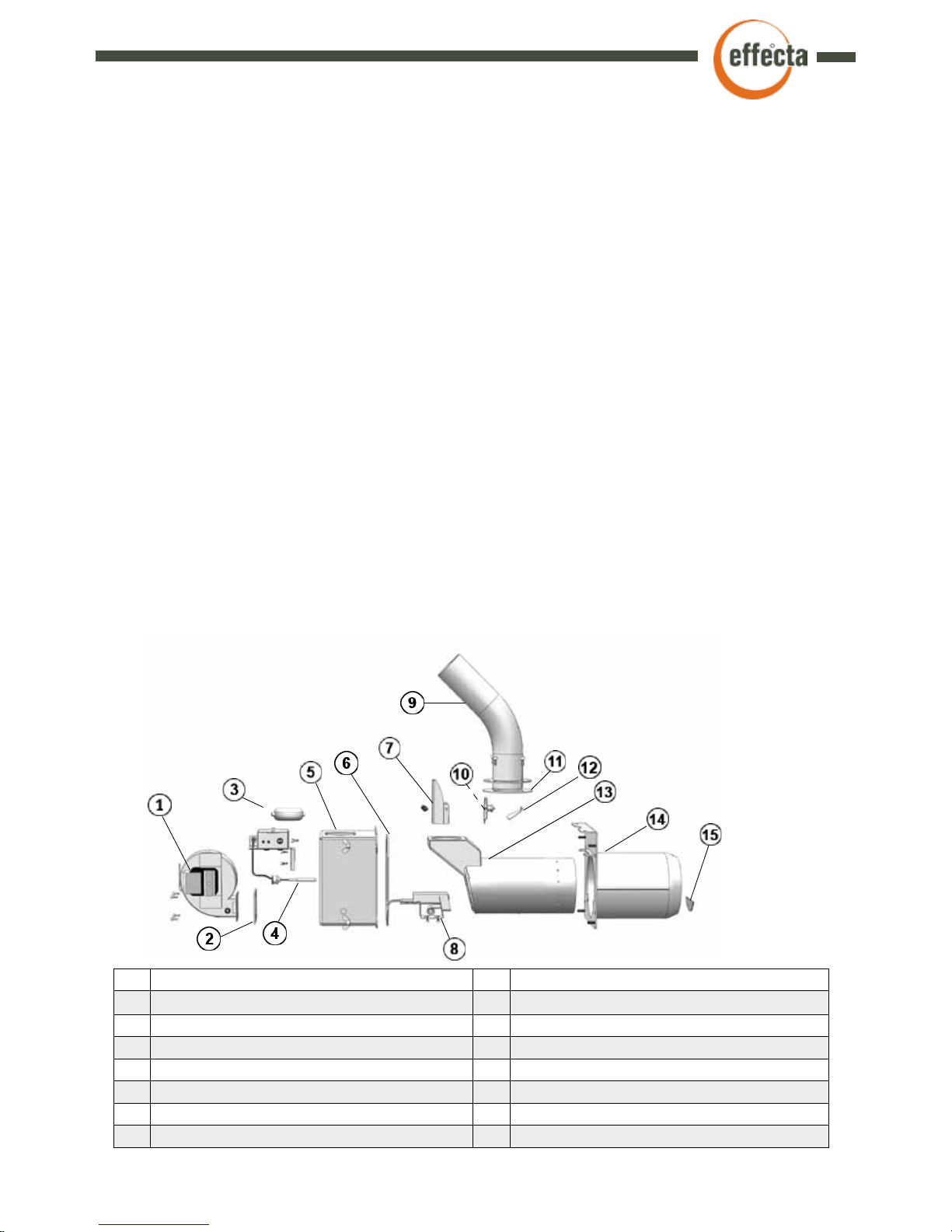

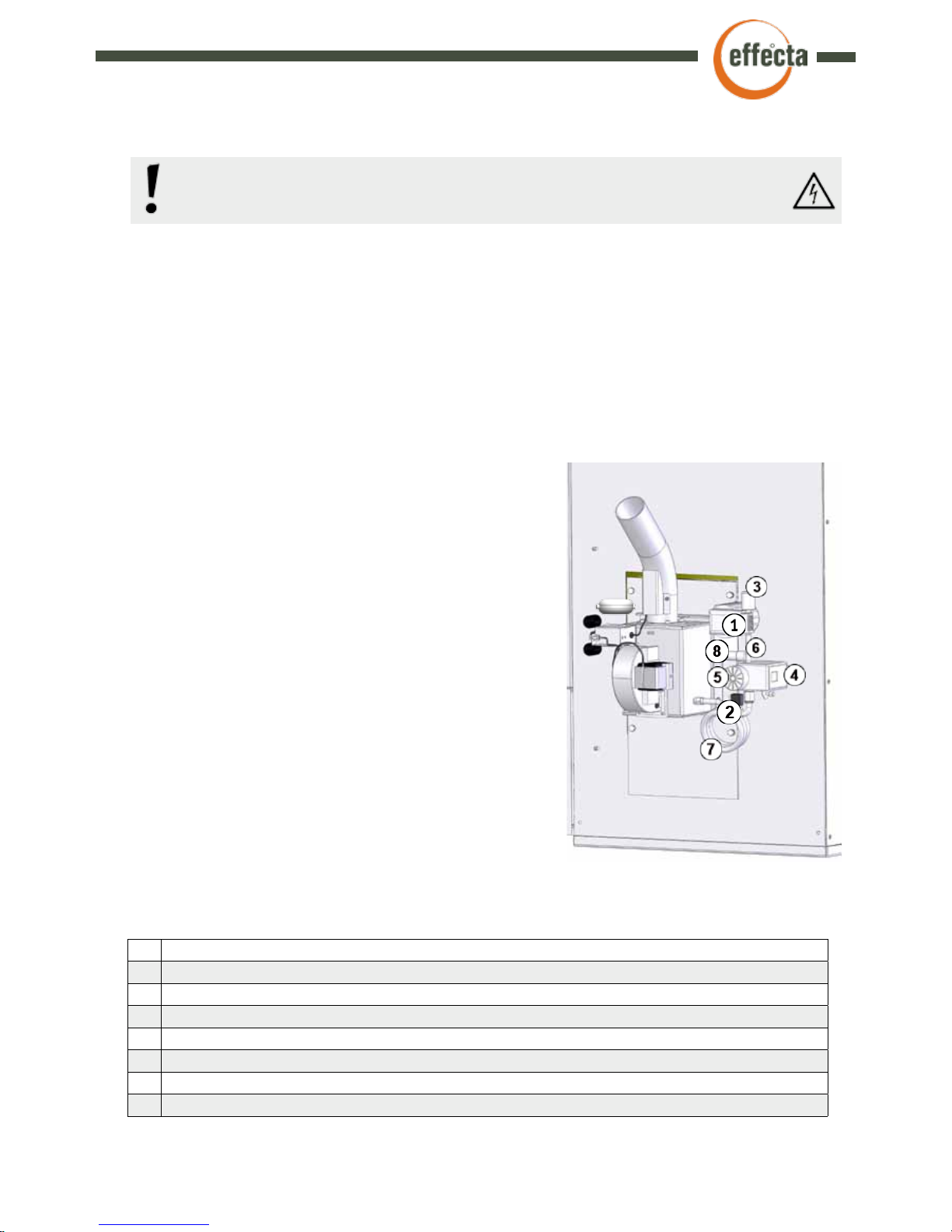

The components

1. Combustion fan with tachometer 9. Fall shaft

2. Fan seal 10 Overheating protection

3. Under pressure switch 11 Seal for fall shaft

4. Flame sensor 12 Pellet retarder

5. Rear housing 13 Inner combustion tube

6. Rear housing seal 14 Outer combustion tube

7. Cover for overheating protection 15 Stop plate

8. Ignition console

▀

Exploded view, burner

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

8

▀

Safety and function

Before using the product, the owner and/or other user must read and understand the content

in this manual. The directions must be followed. This is to make sure that the product is

functioning correctly and accidents and injuries are avoided. Incorrect use or burner adjustment

can result in damage to property and personal injury or poorer performance in the product.

The boiler room where the product is installed, the chimney and other components must be

approved according to current legislation.

The commisioning of the product must be made by a professional, according to Effectas

directions and current legislations. Controls and tuning of the product should be made by a

professional. A chimney sweeper should also be contacted when commisioning the product.

The electrical connections must be done by a qualified electrician, according to Effectas

instructions in this manual.

The casing outside of the burner must always be fitted on the boiler when the boiler is

connected to the electrical power. Before cleaning and maintenance of the product, make sure

it is disconnected from the main power.

It is strictly forbidden to open any doors when the burner is igniting. If any door or hatch is

opened when the burner is running, great caution must be taken. Any kind of interference or

using of other than original spare parts can result in damage to the product or person. It also

removes Effecta from any liability.

It is strictly forbidden to make any changes or alterations on the boiler without prior approval

from Effecta. If any changes are made, the safety functions, or any other function, might not

work as it is supposed to, and all warranties and liabilites from Effecta are cancelled.

This manual should be kept during the whole life span of the product. Any updates will be

reported on the Effecta web page: www.effecta.se.

9

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

The overheat protection on the fall shaft

This stops the feeding if the fan temperatures gets too high. Reset is made manually.The cover

must always be in place when connected to main power. It only cuts the power to the auger.

Flame sensor

The flame sensor monitors the flame in the burner. If the flame disappear for a set time during

operation the burner stops and goes into cooling phase.

Overheat protection on the boiler

There is overheat protection on the boiler which cuts the power to both the boiler and the burner

if the temperature in the boiler exceeds 95°C.

Power outage

After a power outage the control system remembers where in the sequence the burner was. If it

was in the ”Run” mode, the fan blows for four minutes to burn out any pellet rests. Then it goes

into normal mode.

Under pressure switch

If the under pressure in the combustion chamber is lost, the auger stops and no more pellets is

fed into the burner. If the soot door not is closed, the under pressure is lost and the burner will

switch off. The auger starts when underpressure is obtained again.

▀

The safety systems

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

10

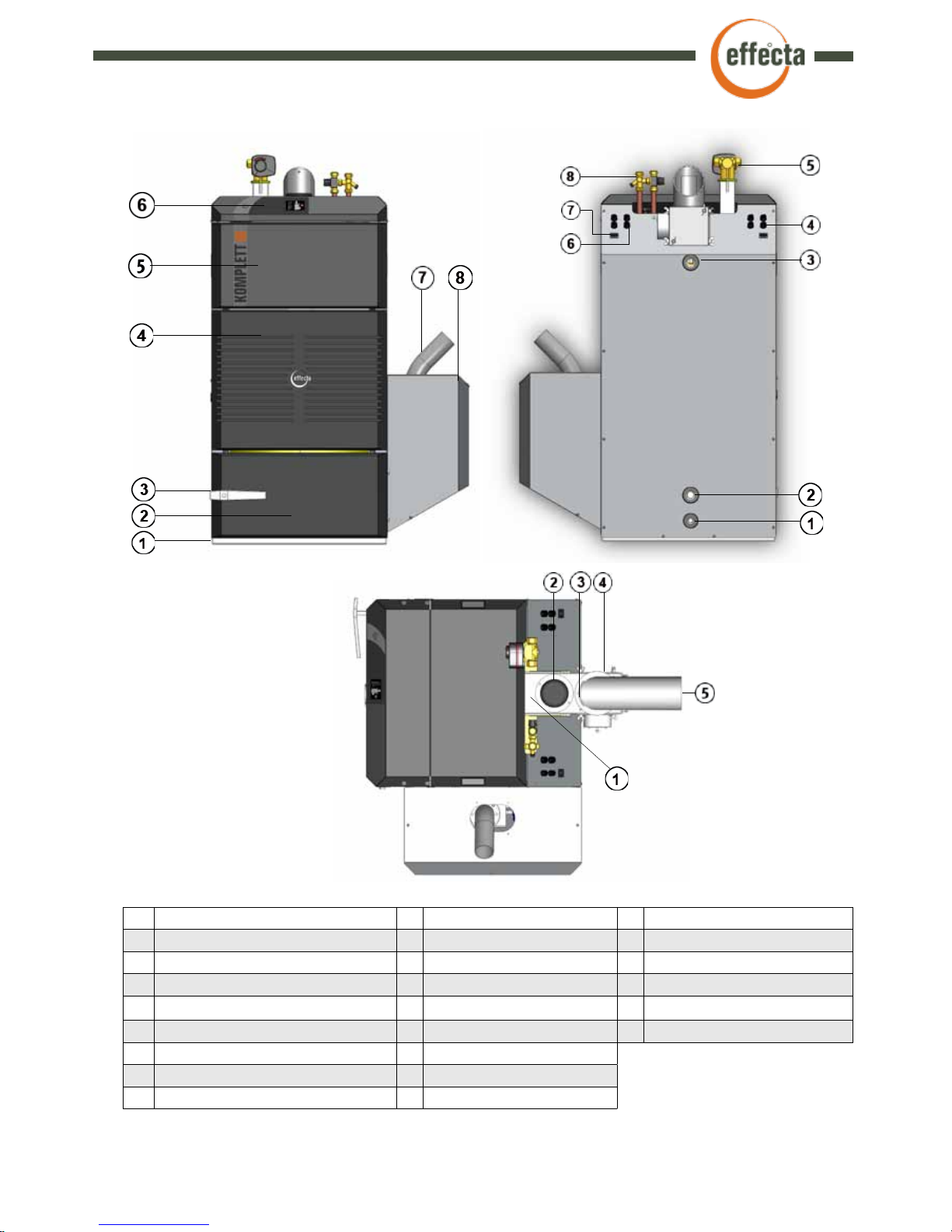

▀

Placement of the components

Front Back Top

1 Adjustable feet 1 Drain cock 1/2” 1 Flue gas measuring point

2 Soot door 2 Return hot water circuit 1” 2 Flue fan

3 Handle soot door 3 Flow hot water circuit 1” 3 Soot door flue tube

4 Front cover 4 Hoses electrical wiring 4 Soot door 3 pc.

5 Over heat protection (behind front) 5 Shunt valve * 5 Flue tube

6 Display 6 Conduit for sensor

7 Fall shaft pellet burner 7 Connector feedmotor/auger

8 Protective cover 8 Mixing valve * for hot water

* Not on model Komplett Light

11

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

Wood pellet is made of sawdust, a byproduct from handling wood. Wood contains lignin that

makes the pellet hard without any glue or other binder used.

There are several different kinds of pellet on the market. The quality and energy can be

different between them. The diameter is 6-8mm, the normal length is between 5 and 30mm.

Pellet with high quality has a density of 600-750 kg/m3. The moist content is 5-9% in weight.

Oil has an energy content of 9,9kWhr/kg and wood logs about 4,0kWhr/kg. Wood pellet has

4,7-5,0kWhr/kg in energy content. To maintain good combustion the pellets should be stored

in a dry place and be protected from dirt. Pellets are delivered in sacks with 10-15kg content

or in bulk by truck.

Effecta Komplett III can handle most of the different types of wood pellet that is between

6-8mm, but in UK only 6mm should be used. The quality should meet DIN+ standards. Good

pellet with small amount of dust and an even quality helps achieve good combustion, less

maintenance of the product and also less environmentally harmful emissions.

The worse quality of the fuel, the more cleaning and maintenance of the product.

▀

The fuel

The amount of pellets fed into the burner should be controlled every time the pellet brand or quality is

changed. If the deviation is more than 0,5kg/hour compared to the numbers in the ”Warranty and Installation” paper, the burner should be tuned.

Inspection

We recommend that the local chimney sweeper inspect, give advice and guidance regarding

any necessary steps needed to be taken regarding the chimney and the boilers connection to

it. The detailed method of installation must be in accordance with building regulations.

Some issues needed to be considered:

Dimensions

Suitable dimensions are from about ca Ø120 to Ø160 mm for a steel construction and about

140x140 mm for a bricked. The length of the chimney should be so that a draft of 15-20 Pa is

reached during operation.

A much larger/smaller flue might be needed to be adjusted to receive a proper draft. If a new

installation of the flue is done, the chimney manufacturer can give advice regarding the dimensioning. The draft stabiliser attached to the flue tube should always be used if nothing else is

stated from Effecta.

The flue gas temperature should be checked.

The temperature in the flue directly after the boiler in the flue should be about 160 - 200ºC. In

low power mode around 100-120ºC. With a tall and big chimney there is a risk of condensation

which can lead to corrosion and/or frost damages. To control this you can check the temperature 1 meter down from the top of the chimney. The temperature should be at least 80ºC at

the end of a burning session. Suggestions for actions to be taken if needed is e.g. insulate the

chimney or mount a steel pipe inside the chimney. This will increase the temperature in the flues

without effecting the efficeny of the boiler. Other actions are increasing the power output of the

burner or removing/cutting off turbulators. This will however decrease the burners efficency

some. The draft stabiliser helps keeping the chimney free from condensation by ventilating it.

▀

The chimney

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

12

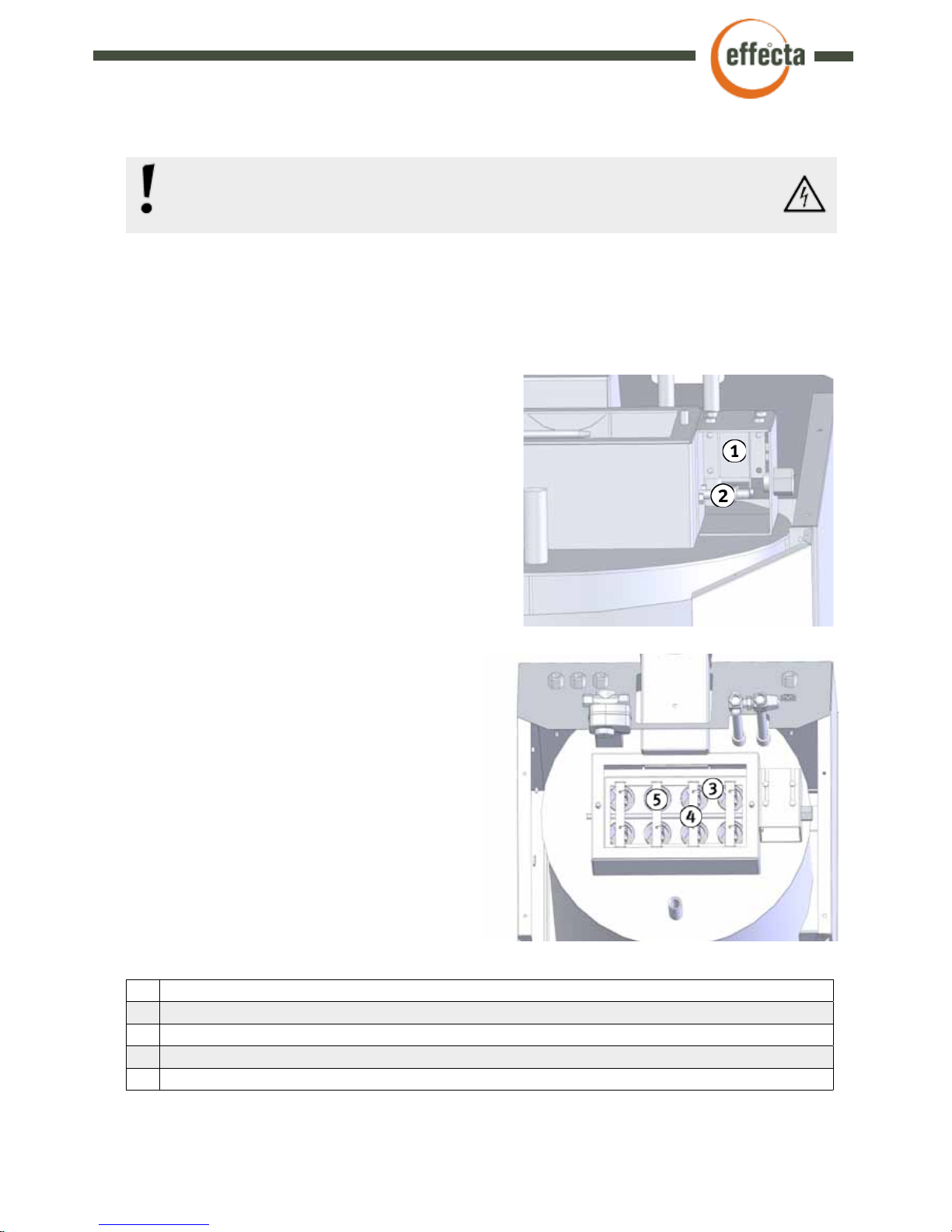

The magnet motor

The magnet motor is mounted on the right side of

the soot hatch on the top of the boiler. The magnet

motor rotates the lift shaft up and down to keep the

tubes clean.

1 Magnet motor

2 Lifting shaft

3 Flipper

4 Suspension

5 Turbulator

The turbulators

The turbulators in the tube help by reducing the flue

gas temperature and also cleaning the tubes when

pulled up and down.

▀

Cleaning system boiler

Function and service

Cut the power to the boiler before servicing. The magnet motor is mounted on the boiler to

keep the convective part clean. It is controlled from the menu ”Cleaning” on the control

panel. It can be set to work/not work in different times during the day.

Suspension

On every suspension there are two turbulators

that are removed when cleaning the tubes with

a brush.

Lifting shaft

Rotating the lift shaft lifts the turbaltors

Flipper

Flips when the magnet motor activates.

Remember to always cut the power to the boiler before starting any work on

it. All electrical work should be done by a certified electrician, for everyones

safety.

13

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

Cleaning system burner

Function and service

Cut the power to the boiler before servicing. Next to the burner an air compressor is

mounted that provides pressurised air for cleaning the burner. This is done by letting high

pressure air into the burner after the burner has made a heating cycle. The compressor

builds up a pressure in the air container which is released into the burner in one blast. This

is done four times and all ash and pellet remains are blown out into the ash compartment.

The settings are made in the ”Service” menu.

The compressor

The compressor creates a pressure in the

container. The compressor has a life span of at

least 2500 hours.

Air container

The air container stores the air before it is

released into the burner.

1 Compressor

2 Solenoid

3 Silencer

4 Pressure Switch

5 Safety valve

6 Non return valve

7 Air container

8 Capacitor

The pressure gauge

Displays the pressure in the air container.

The safety valve

Prevents the pressure exceeding 9bars by releasing

air if the pressure switch fails.

The pressure switch

Stops the compressor at a pre-set value.

Normally 7 bars. This is also adjustable.

Non return valve

Keeps the air in the container and prevents

pressure on the compressor.

The cover of the burner must be screwed tight after service. Under no

circumstances should it be possible to lift it off by hand.

Loading...

Loading...