Page 1

Rev. JG.012-01-02

INSTALLING

MAINTENANCE

SERVICE

ASSEMBLY

EFFECTA KOMPLETT

Page 2

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

2

We at Effecta would like to thank you for putting your trust in us when choosing your new

boiler. The ”Effecta Komplett” has been developed to give you maximum performance, comfort

and quality. In order to get the best results from your boiler, we suggest that you follow the

recommendations in this installation guide.

Checking your delivery

Check that the boiler has not been damaged during transportation. If the boiler has been

damaged, you must report this to the transportation company immediately.

Your safety

If you discover any faults or defects in our products, it is important that you report them as

quickly as possible to your installation engineer, so that the fault can be rectified. Make sure

that there are no flammable materials close to the boiler, to help prevent risk of fire. You must

use your own judgement when operating the pellet boiler. Remember that the hatches and some

surfaces can get hot. You must take caution to avoid being burnt.

The user

It is the user´s responsibility to operate the boiler according to our instructions. If you do not

operate and maintain your boiler correctly, the environmental impact of the boiler will be greater,

it´s efficency will be reduced and the service life of some components will be shorter. If there

is anything that you are not sure about, please contact your installation engineer or Effecta for

advice.

Warranty

The warranty takes effect from the date on which the boiler is installed. The supplied installation

form must be completed and returned to Effecta. You can find the other guarantee terms on

(page 3).

▀

Scope of delivery

Please check all components delivered.

The standard delivery as follows:

- Effecta Komplett boiler

- Cleaning handle with brush

- Rake with scraper

- Fluetube with draught stabiliser

- Turbulators, 8pcs.

- Drain cock

- Shunt valve (mounted)*

- Electrical heater 3-9 kW (mounted)

- Valve combination

- Room thermostat

- Flow sensor

- Flue gas sensor

- Boiler temp sensor

* not delivered with Effecta without coil

▀

Introduction

Page 3

3

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

System data:

▀

Warranty

Installer:

Date:

Electrical installer:

Effecta products are guaranteed to be free of defects in materials and workmanship for two years

from the installation date. This applies to wear parts, such as seals, the main body of the boiler and

electrical components. This guarantee also covers original spare parts. Any faulty products will be

replaced or repaired at the discrimination of the retailer or Effecta. If a faulty product is replaced,

Effecta is entitled to replace it with a new or reconditioned product of the same or a similar type.

Effecta is liable for the costs of any servicing or repairs. Effecta gives a 5 year guarantee on the

remaining components. See the attached guarantee document.

If you have a complaint, you must contact Effecta before starting any servicing work.You must

submit your complaint without delay. You must always state the type of product, the date of

purchase and the serial number.

Otherwise the heating and plumbing industry's current regulations apply in the case of complaints.

Guarantee terms:

The guarantee is valid on condition that:

- The boiler and the heating system have been installed in accordance with the installation instructions

and in a professional manner.

- The location where the product is installed is suitable for the purpose.

The guarantee does not cover:

- The overall functioning of the heating system, costs incurred as a result of the heating system

- being out of operation or the cost of the temporary replacement of products.

- Damage or injury caused by negligence during the installation or by operating the boiler in a

way which conflicts with the installation and user instructions.

- Damage caused by abnormal wear, incorrect operation and maintenance.

- Damage caused by the boiler being positioned in an unsuitable location.

- Damage caused by vermin.

Page 4

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

4

▀

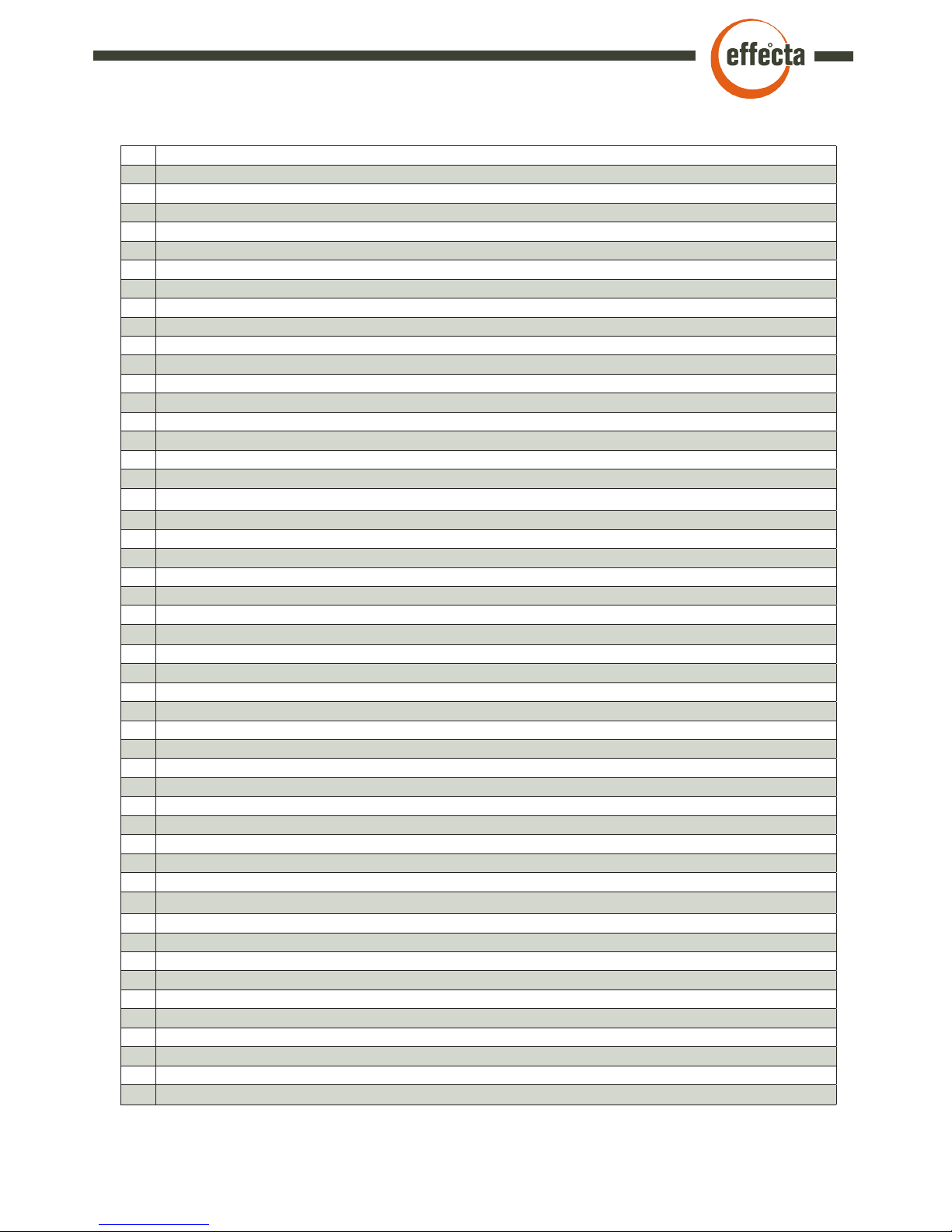

Contents

2 Introduction

2 Scope of delivery

3 Warranty

3 Terms of warranty

3 System data

4 Contents

5 In general

5 Symbols in this document

6 To the installer

7 The components

7 Exploded view, burner

8 Safety and function

9 The safety systems

10 Placement of components

11 The fuel

11 The chimney

12 Cleaning system boiler

13 Cleaning system burner

14 The mothterboard

15 1,2 or 3 Phase connection

16 Electrical connection

17 The menu system

18 The menu system

19 The menu system

20 The menu system

21 The menu system

21 Alarms at disruption

21 Ignition phase of the burner

22 First start

22 Tuning the boiler

23 Tuning the burner

24 Hot water

24 Valve combination

25 Shunt control

26 Adjustment of heating curves

27 Examples of curves

28 Mounting the auger

28 Mounting and adjusting of the draft stabilasor

29 Replacing the combustion fan

30 Servicing the flame detector

30 Overheated droptube

31 Charging the igniter

32 Cleaning the air box and outer tube

32 Mounting and adjusting of the draft stabilasor

33 Service and cleaning

34 Trouble shooting

34 The sensors

35 Documentation of settings

36 Dimensions

37 Hyudralic scheme

Page 5

5

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

The Boiler

Effecta Complete is a boiler which is to be fueled with wood pellets. No other kind of fuel is

allowed to be used. Not logs or oil.

Disassembly and disposal

It will be many years before your Effecta boiler is worn out, but it is important that you follow

the regulations in force at the time concerning disassembly and disposal of your boiler.

The fuel

The boiler should normally burn 6/8 mm fuel pellets which come either in 16 kg sacks or

are supplied by bulk truck. If you have built a bulk storage container, you should follow the

current recommendations to ensure that the quality of the pellets does not deteriorate. Never

use pellets which do not meet European pellet standards, as this may result in problems in

operating the burner.

▀

In general

Information

This symbol is shown with info to the installer which can be important to know and

understand. Neglecting these informations can be harmful to the prestanda in the product.

▀

Symbols in this document

Warning

This symbol is shown when the installer or user must be careful in the handling of the

product. Neglecting these warnings can result in damage to the product or personal injury.

Dangerous electricity

This symbol means that extra caution should be taken. Otherwise serious personal injury

might occur. When maintaining the product where this symbol is present the power must

be disonnected. All electrical wiring must be done by a proffesional.

Page 6

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

6

▀

To the installer

It is time to install the Effecta Komplett pellet boiler. Please follow the examples we provide for

a safe installation. After installation, be sure to instruct the customer on how the heating system

and the boiler work, in order to avoid unnecessary complications in the future.

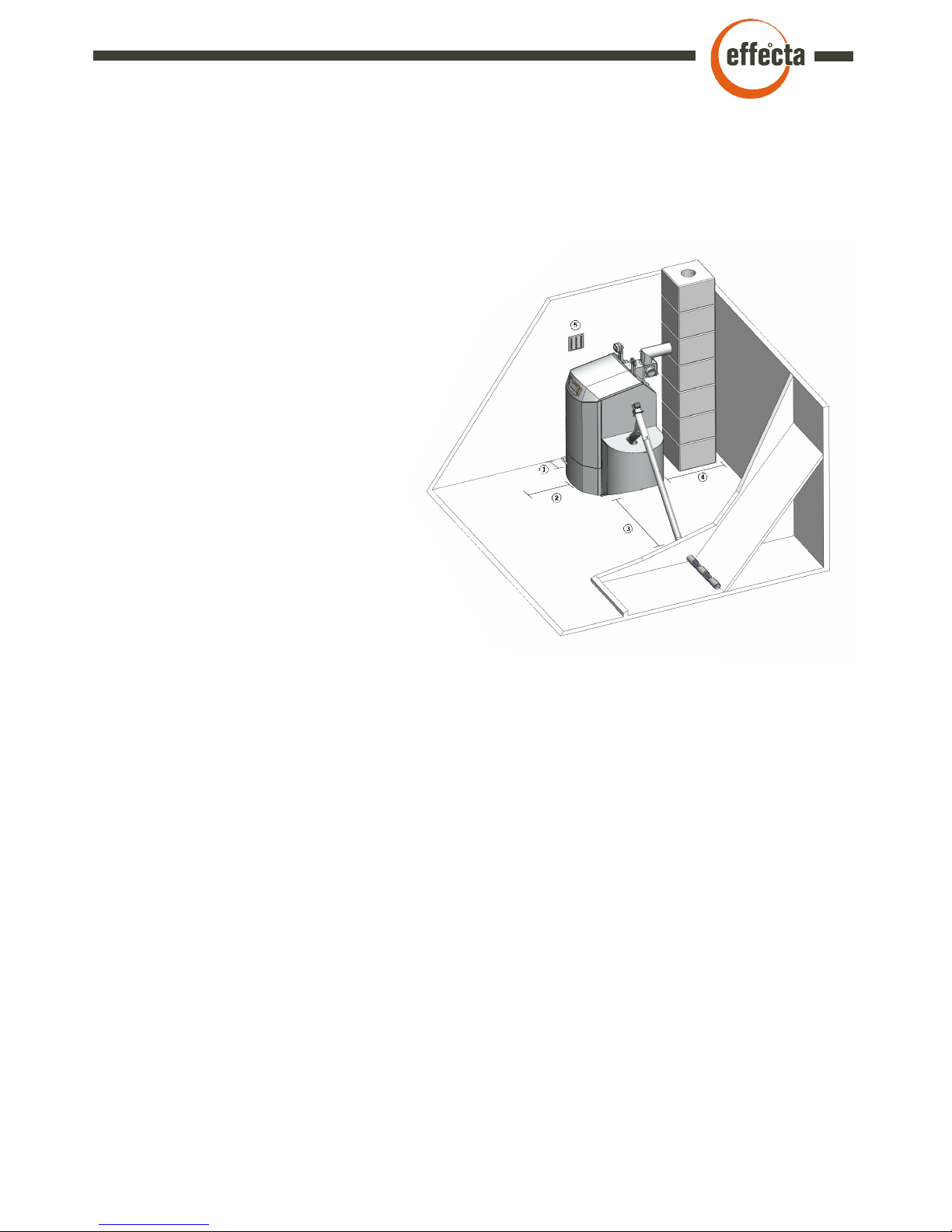

Set up

The boiler is positioned so that the surface

temperature of flammable building material does

not exceed 80°C. The boiler should be positioned

at least 15 cm (1) from the wall. The distance

from the smoke valve to a flammable wall with

ignition protective covering must be at least

30 cm (4). In order to clean the boiler, a

minimum clear space of 1 metre (2) is

required in front of the boiler and on

the side at the convection section and

at any inspection panel in the chimney.

A passage with a minimum width of 0.5

(3) m is required along one of the long

sides of the boiler. The pellet hopper

aint alowed to stand closer than 120 cm

from the boiler.

The boiler room

The boiler must be installed in a boiler room or

boiler house. The ceilings and walls must be fitted

with ignition protective covering and the floor must

be made of non-combustible material. Minimum ceiling

height at the boiler is 2 metres. The boiler room or boiler house must be equipped with a fresh air

intake with the minimum dimensions 150 x 150 (5.) mm or with a sufficiently large free sectional

area to avoid low pressure in the boiler room. It must be impossible to close the air intake.

Chimney

The chimney should have a diameter of at least 120 mm. If your chimney is smaller, Effecta

should be consulted before installation. The draught in the chimney should be about 15 pa at

low temperatures. It is important that the chimney is tested and approved by a certified chimney

sweep before a new boiler is installed. If the chimney has a strong draught, a draught controller

(see page 32) may need to be installed for good boiler operation. If you have a tall chimney and

an outgoing flue gas temperature below 170°C, there is a risk of condensation in the chimney,

which can damage the chimney in the long term. A suitable temperature is 70-80°C one metre

down into the chimney. Ask your local chimney sweep for help to measure the temperature. If the

chimney is tall and has a large area, a draught that is too strong may mean high levels of flue gas

and overignition in the firebox. If this is the case, a draft stabiliser must be installed.

Page 7

7

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

The shunt valve

The shunt valve controls the heat supply from the boiler to the radiator circuit. Effecta Complete

is fitted with motorised shunt control. The room temperature can be adjusted on a scale on the

thermostat. An automatic system will significantly reduce fuel consumption and provide a more

comfortable environment.

The valve combination

The mixing valve is used to ensure that the temperature of the hot water in your shower and

elsewhere in the house is comfortable. Set the system to the temperature you want by turning

the thermostat between +/-.

The burner

The burner is mounted on the left or right side. The burner heats the water in the boiler which

provides heat to the domestic and hot water.

The turbulators

In the tubes in the convective part hangs the turbulators. The turbulator`s function is to reduce

the heat in the flue gases on behalf of the temperature in the boiler. They must always be fitted

in the boiler. If the flue gas temperature should be to low, the turbulators can be cut off. Always

contact the installer before doing this.

The sealings

The seals on the hatches must be checked every year. If the hatches do not seal properly, the

efficiency and the combustion process of the boiler will deteriorate.

▀

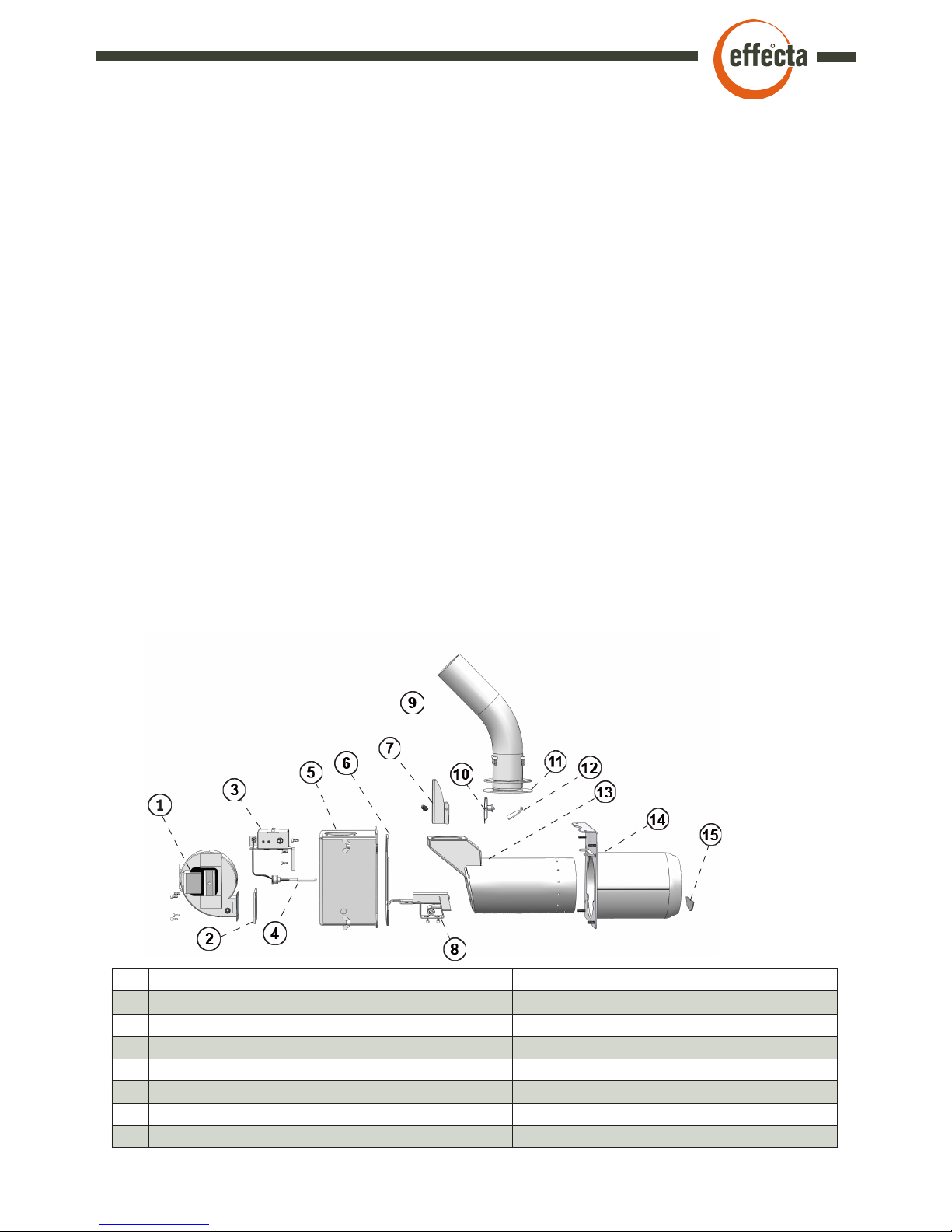

The components

1. Combustion fan 9. Feeding tube

2. Fan seal 10. Overheating protection

3. Electrical console 11. Seal feeding tube

4. Flame detector 12. Pellet retarder

5. Rear housing 13. Inner tube

6. Rear housing seal 14. Outer tube

7. Cover overheating protection 15. Stop plate

8. Ignition console

▀

Exploded view, burner

Page 8

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

8

▀

Safety and function

Before using the product, the owner and/or other user must read and understand the content in

this manual. The directions must be followed. This is to make sure that the product is functioning

correctly and accidents and injuries are avoided. Incorrect use or incorrectly tuning can result in

damages to property and personal injury or lacking function in the product. The boiler room where

the product is installed, the chimney and other components must be approved according to current

legislations.

The commisioning of the product must be made by a proffesional, according to Effectas directions

and current legislations. Controls and tuning of the product should be made by a proffesional.

A chimney sweeper should also be contacted when commisioning the product. The electrical

connections must be done by a professional, according to Effectas instructions in this manual.

The casing outside of the burner must always be fitted on the boiler when the boiler is connected to

the electrical power. Before cleaning and maintenance of the product, make sure it is disconnected

from the power line.

It is strictly forbidden to open any doors when the burner is igniting. If any door or hatch is opened

when the burner is running, great caution must be taken. Any kind of interferance or using of other

than original spare parts can result in damage to the product or person. It also removes Effecta

from any liability.

This manual should be kept during the whole life span of the product. Any updates will be reported

on the Effecta web page: www.effecta.se.

Page 9

9

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

The flexi pipe between burner and auger

The flexi pipe prevents any fire coming in to the hopper. It is made from a heat sensitive material

which melts if it gets to hot. If replaced, a new must be ordered from Effecta.

The overheating protection on the feeding tube

It stops the feeding if the fan temperatures gets to high. Reset is made manually.The cover must

always be in place when connected to main power.

Flame sensor

The flame sensor monitors the fire in the burner. If light is missing for a set time during fire the

burner stops and goes into cooling phase.

Overheating protection on the boiler

There is an overheating protection on the boiler which cuts the power to both the boiler and the

burner if the temperature in the boiler exceeds 95°C.

Compressed air cleaning system

In this cleaning system there are three different safety devices.

1. The motherboard controls the time the compressor can run.

2. There is a pressure switch that stops the compressor at a preset pressure.

3. A safety valve wich releases air if pressure exceeds 9bars.

Power outage

After a power outage the control system remembers where in the sequence the burner was. If it

was in the ”Run” mode, the fan blows for four minutes to burn out any pellet rests. Then it goes

into normal mode.

▀

The safety systems

Page 10

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

10

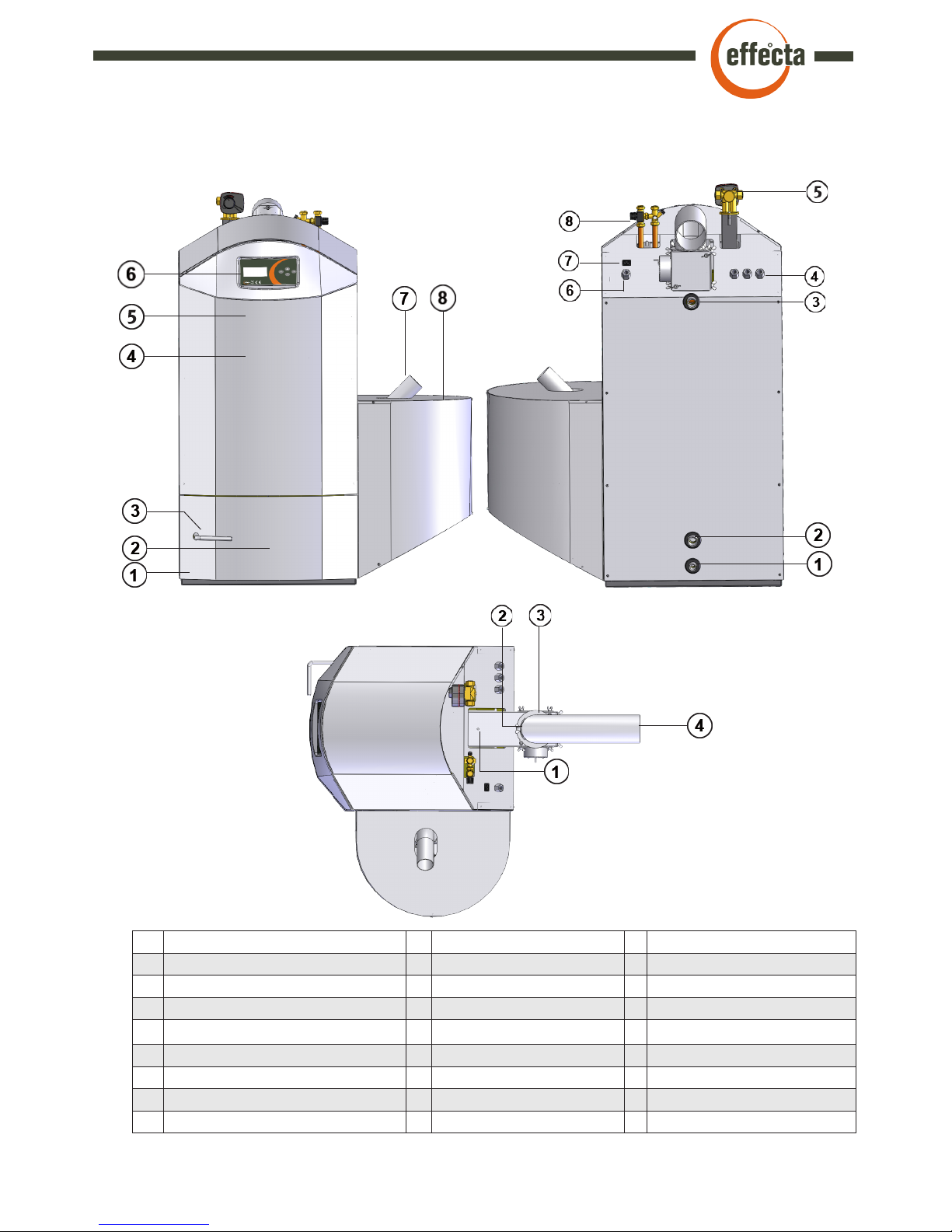

▀

Placement of the components

Front Back Topp

1 Adjustable feet 1 Drain tap 1/2” 1 Hole for measuring instruments

2 Soot door 2 Return hot water circuit 1” 2 Sootdoor flue pipe

3 Handle soot door 3 Flow hot water circuit 1” 3 Sootdoor 3 pc.

4 Cover plate electricity 4 Hoses electrical wiring 4 Flue pipe

5 Over heat protection (behind front) 5 Shunt valve

6 Display 6 Hose for sensor

7 Feeding tube pelletburner 7 Connector feedmotor/auger

8 Protective cover 8 Mixing valve

Page 11

11

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

Wood pellet is made by sawdust, a byproduct from from handling woods. Wood contains lignin

that makes the pellet hard without any glue or other binder used.

On the market there are several different kinds of pellet. The quality and energy can be different

between them. The diameter is 6 or 8mm, the normal length is between 5 and 30mm. Pellet with

high quality has a density of 600-750 kg/m3. The moist content is 5-9% in weight.

Oil has an energy content of 9,9kW/kg and wood logs about 4,0kW/kg. Wood pellet has 4,75,0kW/kg in energy content. To maintain a good combustion the pellet should be stored in a

dry place and be protected from dirt. Pellet is delivered in sacks with 16kg content or in bulk by

truck.

Effecta Complete can handle most of the different types of wood pellet that is 6-8mm. The quality

should meet european standards. Good pellet with small amount of dust and an even quality

helps to reach good combustion, less maintenance of the product and also less environmentally

harmful emissions.

The worse quality of the fuel, the more cleaning and maintenance of the product.

▀

The fuel

The amount of pellet fed into the burner should be controlled every time the pellet brand or quality is changed. If the deviation is more than 0,5kg/hour compared to the numbers in the ”Warranty and Installation”

paper, the burner should be tuned.

Inspection

We recommend that the local chimney sweeper inspect and give advices and guidances regarding any necessary steps needed to be taken regarding the chimney and the boilers connection

to it. Some issues needed to be considered:

Dimensions

Suitable dimensions are from about ca Ø120 to Ø160 mm for a steel construction and about

140x140 mm for a bricked. The length of the chimney should be so that a draft of 15-20 Pa is

reached during operation.

A much larger/smaller flue might be needed to be adjusted to receive a proper draft. If a new

installation of the flue is done, the chimney manufacturer can give advice regarding the dimensioning. Generally speaking, a flue used for burning oil works for firing pellet in the same power

range. The draft stabiliser attached to the flue tube should always be used if nothing else is stated

from Effecta.

The flue gas temperature should be checked.

The temperature in the flue directly after the boiler in the flue should be about 160 - 200ºC.

With a tall and big chimney there is a risk of condensation which can lead to corrosion and/or

frost damages. To control this you can check the temperature 1 meter down from the top of the

chimney. The temperature should be at least 80ºC in the end of a burning session. Suggestions

for actions to be taken if needed is e.g. insulate the chimney or mount a steel pipe inside the

chimney. This will increase the temperature in the flues without effecting the efficeny of the boiler.

Other actions are increasing the power output of the burner or removing/cutting off turbulators.

This will however decrease the burners efficency some. The draft stabiliser helps keeping the

chimney free from condensation by ventilating it.

▀

The chimney

Page 12

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

12

The solenoid

The solenoid is mounted on the right side of the soot

hatch on the top of the boiler. The solenoid flips the

turbulators up and down to keep the tubes clean.

1 Solenoid

2 Lifting shaft

3 Flipper

4 Suspension

5 Turbulator

The turbulators

The turbulators in the tube helps reducing the flue

gas temperature and also cleaning the tubes when

pulled up and down.

▀

Cleaning system boiler

Function and service

Cut the power to the boiler before servicing. The solenoid is mounted on the boiler to keep

the convective part clean. It is controlled from the menu ”Cleaning” on the control panel. It

can be set to work/not work in different times during the day.

Suspension

On every suspension there are two turbulators

that is removed when cleaning the tubes with

a brush.

Lifting shaft

The shaft is pulled up by the magnet making the

turbulators also being pulled up.

Flipper

Flips when the solenoid activates.

Page 13

13

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

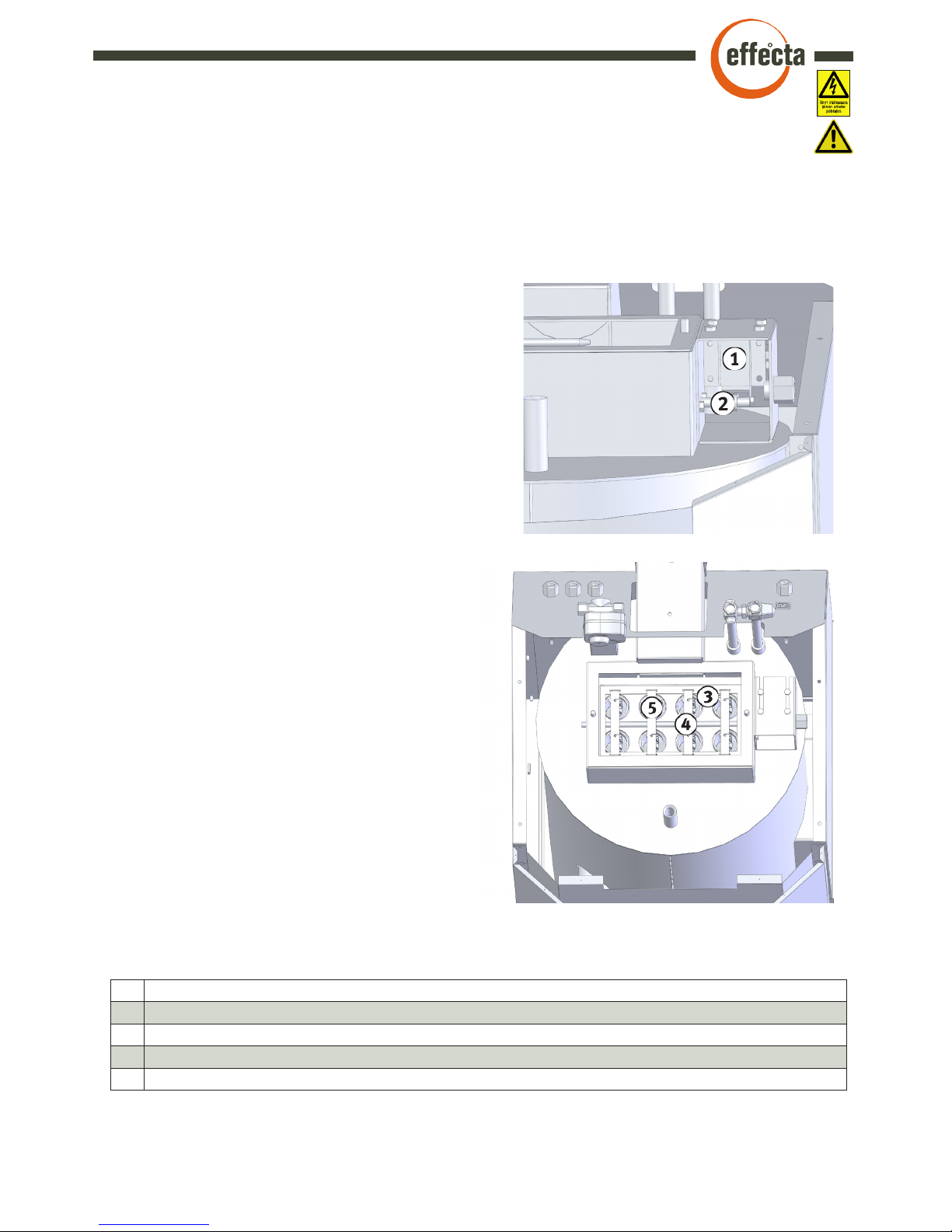

Cleaning system burner

Function and service

Cut the power to the boiler before servicing. Next to the burner a air compressor is mounted that provides pressurised air for cleaning the burner. This is done by letting high pressure air into the burner after the burner has made a heating cycle. The compressor build up

a pressure in the air container which is released into the burner in one blast. This is made

four times and all ashes and pellet rests are blown out into the firebox. In the menu ”Service” the settings are made.

The compressor

The compressor creates a pressure in the

container. The compressor has a life span of

at least 2500 hours. It might then need to be

serviced. Effecta provides a renovating kit.

Air container

The air container stores the air before it is

released into the burner.

1 Compressor

2 Solenoid

3 Silencer

4 Pressure Switch

5 Safety valve

6 Non return valve

7 Air container

8 Capacitor

The pressure gauge

Displays the pressure in the air container.

The safety valve

The safety valve prevents the pressure to exceed

9bars by releasing air if the pressure switch fails.

The pressure switch

It stops the compressor at a pre-set value.

Normally 7 bars. This is also adjustable.

Non return valve

Makes the air stay in the container and not putting

pressure on the compressor.

Page 14

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

14

▀

The motherboard

G1 Temp sensor boiler NTC 22 kΩ

G2 Sensor flue gas PT1000

G3 Extern control

G4

G5 Sensor accumulator tank low NTC 22 kΩ

G6 Sensor accumulator tank high NTC 22 kΩ

G7 Sensor, radiator flow NTC 22 kΩ

G8 Flame sensor

1U. Connection to display board

2U. Connection electricity board

1. Outdoor sensor

2. Outdoor sensor

3. Room sensor (6)

4. Room sensor (1)

5. Room sensor (4)

6. Not used

+ --

- --

PE Incoming Ground

N Incoming zero

Li Incoming phase 6,3 A/230 VAC

PE Ground

N Zero

11 Radiator pump 2A/230 VAC

12 Shunt motor

N Zero

13 Shunt motor 2A/230 VAC

PE Ground

N Zero

14 Solenoid valve AERO 2A/230 VAC

PE Ground

N Zero

15 Compressor 2A/ 230 VAC

PE --

N --

16 Solenoid valve tube cleaning 2A/230 VAC

N Zero

17 Loading pump 2A/230 VAC

Remember to always cut the power to the controller before starting any work on it.

All electrical work should be done by a certified electrician, for everyones safety.

Check so that the marking of the

prom is set at the correct side.

Before shifting a e-prom make sure to write down all the settings that has been done to

the boiler. This since all the changes that has been done will be lost.

While mounting the e-prom make

sure that the ”legs” isn´t damaged.

Page 15

15

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

1, 2 or 3 Phase connection

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

011-07-01

50-12-11

E.A

G8

G7

G6

G5

G4

G3

G2

G1

EL

17

N

16

N

PE

15

N

PE

14

N

PE

13

N

12

11

N

PE

L1

N

PE

M

NEUTRAL

OPEN

CLOSE

LOW VOLTAGE

HIGH VOLTAGE 230 VAC

L1 REQUIRED FOR FUNCTION

AND 3KW IMMERSER

N

Ground

6 1 4

DISPLAY CARD

CHARGE PUMP

COMPRESSOR

SHUNTMOTOR

RADIATOR PUMP

OVER HEAT PROTECTION 95 ˚C

POWER GRID 230 V

BLUE

BROWN

YELLOW/GREEN

BLUE

BROWN

YELLOW/GREEN

YELLOW/GREEN

BROWN

BLUE

EXPANSION CARD EL. HEATER

ROOM SENS.

N

L1

EL 2a EL 2b

EL 1b

EL 1a

L2

L2 OPTIONAL

PROM

M

TUBE CLEANING

M

BLUE

BROWN

YELLOW/GREEN

L3 OPTIONAL

EL 3a EL 3b

L3

51

52

53

54

55

56

57

58

AMPERE METERS

JOINT

123456+

-

OUTDOOR SENS.

RC 482

Display

YELLOW/GREEN

BROWN

BLUE

SOLENIOD VALVE

24

23

22

21

N

YELLOW/GREEN

M

FAN MOTOR

IGNITOR

O.H

PROTECTION

FALL SHAFT

EARTH CENTER SOCKET

EARTH CENTER PIN

FEEDER MOTOR

PALE BLUE

6.2.5.

4.3.1.

M

CIRCUIT DIAGRAM

EFFECTA KOMPLETT

ELECTRICAL HEATER 3+3+3 KW

N

BOILER PROBE

FLUE GAS PROBE

EXTERN CONTROL

ACC. HIGH

ACC. LOW

FLOW SENSOR

FLAME SENS.

Page 16

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

16

▀

Electrical connection

When it’s time to do the electrical connection you need to remove the front casing which

are in front of the motherboard. On the backside of the boiler there are four (1) hoses that

ends in the front of the boiler (5). Those shall be used to connect the sensors and electrical cables. Don’t put the low and high voltage in the same hose. When you remove the

front casing you unscrew the three screws that hold the

plastic panel in place (2). Don’t forget to disconnect the

cable to the display. To loosen the front cover you need

remove the upper (3) screws all the way. Then lift the

casing up.

Then connect the input voltage to the card’s ports, according to wiring diagram on previous page.

NOTE! The boiler must be filled with water before the wiring begins.

Current sensors

If you’re electrical system

have a problem to provide

enough electricity to the electrical heater and the house at

the same time you can install

current sensors that lower the

power to the electrical heater

if its necessary. This is done

by distributing the power to the

building’s different phases.

Connection of current sensors

To mesure the power you must

install one current sensor to

each incoming phase in the

house. This must be done directly in the electrical central.

Connect the sensors to a cable

with the area of 0,5mm2 to the

circuit board. In the menu “electrical heater” you set the max power that’s

allowed on the fuses in your house.

Page 17

17

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

The menu system

+

‹

-

‹

Boiler temp.

Fluetemp

Status: Standby

FV

--- %f

75°C

175°C

13:17:44

Start dose

Supp. dose

Oper. dose high

Oper. dose low

Run start dose

Run supp. dose

Run oper. dose

Fill feeder

Clean at

On

Off

Interval

Number clean

Clean pause

Cleaning conv..

Fluegas

Max time burner

Ext. contr. closed / open

Quick start

Chimney fan

►

Number starts

Igniter

Oper. pellets

Clean number

Reset info

65s

10s

22%

7%

no

no

no

no

09:00

21:00

1

4

13s

3st

90°C

3h

No

Boiler temp G1

Fluegas

El.heater

Acc.tank high G6

Acc.tank Low G5

Room temp

Status: Standby

FV

--- %f

75°C

175°C

3 kW

55°C

65°C

21.5 (20.0)°C

13:17:44

►

Burner

Fan

Feeder

Temperature set

Information

Service

Installation

Off

VER: 1.10

Weekday

Time

Calibrate sensors

Function test

Alarms

English

►

Mon

00:00

►

►

55

%

10%

No

Fan highspeed

Fan lowspeed

Fan lowspeed

►

►

►

►

24 (45)

Komplett

Room sensor

Room temp

Flow.temp

Radiator pump

Max flow temp

Max room temp

Min room temp

Heating from

Outdoor temp.

Heat curve

Slope

Adjustment

Energy saver

►

06 _ _ _ _ 22

06 _ _ _ _ 22

06 _ _ _ _ 22

06 _ _ _ _ 22

06 _ _ _ _ 22

06 _ _ _ _ 22

06 _ _ _ _ 22

Lowering temp.

Mon

Tue

Wedn

Thu

Fri

Sat

Sun

- 5 °C

►

►

Both

20.0 (18.2)°C

50°C

Yes

60°C

25°C

15°C

16°C

-8°C

40°C

0

°C

Yes

- +

82

0 :00

►

System settings

Temp.El.

Shunt control

Product

El.heater

100st

10h

100h

130st

no

Ign. sequence 1

Ign. sequence 2

Ign. sequence 3

Miss ign.

Stopp start phase

Stopp oper phase

Flame sensor

Igniter

Feeder

Fan

Compersson

Solenoid valve

Test cleaning

Convection clean

Shunt motor (+/-)

El. heater

Radiator pump

Loading pump

0%

0

0

0%

0

0

0

0

0

0

0

0

►

23

12

3

0

0

2

►

Sensor T1

Sensor T2

Sensor T3

Sensor T4

Sensor T5

Sensor T6

Sensor T8

Sensor T8

►

0°C

0°C

0°C

0°C

0°C

0°C

0°C

0°C

Temp level

Temp down °C/6 min

►

20°C

5°C

6 ( 9) kW

11 (16)

0h

0h

El.heater

El. step (A-B-C)

Fuse A

Runtime 6 kW

Runtime 3 kW

Level start

Level oper

Time oper.

Time phase out

60%

25%

60s

80s

►

0s

10s

50%

180s

120s

Testblow start

Phase out

Fan pre oper.

Clean phase out

Ramp phase out

Fan ingition

Flame sensor

Quick start

►

Operation settings

System settings

Other settings

►

►

75°C

85°C

75°C

55°C

65°C

80°C

90°C

55°C

90°C

Boiler temp G1

Stop

Start

Acc.tank high G6

Acc.tank low G5

Stop G5

Max G6

Start G6

Max G1

Page 18

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

18

▀

Menu system

Current boiler temp. G1

Fluetemp

Acc. tank high G6

Acc. tank low G5

Room temp

Status

Operation settings

Boiler temp

Current temperature of the flue gases G2

Current temp of the acc. tank top. (Only shown when sensor is installed)

Current room temperature. (Only shown when installed and activated in software.)

Current burner mode. (Ignition-Running-Cooling-Standby-Off)

Settings for burner.

System setups

Settings for heating systems.

Other settings

Remaining settings.

►

►

►

El. heater

Current effect of the electrical heater in the boiler.

FV ---%

Setting of the fan speed in full effect oper. mode.

Fan lowspeed

Fan highspeed

Setting of the fan speed in low effect oper. mode.

Temperature set

►

Fan lowspeed

Low effect mode active: (YES/NO)

Fan

Temperature set

Information

Service

Installation

Burner

Feeder

Burner mode (on/off)

Settings for the fan of the burner.

Settings of the augers feeding control.

Settings for the burners operation temp.

Operations log of the burner.

Menu for burner service settings.

Settings for automatic cleaning etc.

Oper. dose high

Oper. dose low

Run start dose

Run operation dose

Fill feeder

Run supp. dose

Supp. dose

Start dose

Start dose size, measured according to (page 23).

Size of support dose, dose is given between ignition and running mode.

Size of the high effect feeding dose (page 23).

Size of the low effect feeding dose (page 23).

Test run of start dose for measuring. Only available in burner mode off.

Test run of supp. dose for measuring. Only available in burner mode off.

Test run of operation dose for measuring. Only available in burner mode off.

Activates auger feeding for 15 minutes. Only available in burner mode off.

Start

Acc.tank high G6

Acc.tank low G5

Max G6

Start G6

Stop

Boiler temp G1

Stop G5

Max G1

Shows the boiler temp, start/stop sensor with overheating function.

Temperature when the burner goes to standby mode.

Temperature when the burner starts up from standby mode.

When loading acc. tank, sensor G6 should be installed at the tank top of the

primary tank. The sensor starts the burner at set temp.

When loading acc. tank, sensor G5 should be installed low or at the bottom of

the primary tank. The sensor stops the burner at set temp.

Temperature when burner starts.

Temperature when burner stops.

Maximal allowed temperature G6, tank overheated.

Maximal allowed temperature in the boiler.

Feeder

►

Fan

►

Current temp of the acc. tank bottom. (Only shown when sensor is installed)

Current strength (brightness) of flame in boiler.

Page 19

19

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

Menu system

Information

►

Oper. pellets

Clean number

Igniter

Number starts

Displays the number of burner starts been done

Displays the number of hours ignitor has been lit.

Displays the number of hours the burners been running.

Displays the number of times the AERO unit has cleaned the burner.

Reset info

Resets the information above.

Service

►

Off

Interval

On

Clean at phase out

Option if cleaning should be done prior to or after the running cycle.

Time when AERO cleaning is allowed (ON).

Time when AERO cleaning is not allowed (OFF).

Choice of how often the AERO cleaning is to be done.

Number clean

The amount of blows in a cleaning cycle.

Clean pause

Cleaning at

Max time burner

Extern control

Time between each blow in a cleaning cycle.

Temperature when flue tubes is cleaned.

Max operation time of the burner before pause with AERO cleaning.

Choice of external START/STOP control to the boiler. The control could be

done either by NC or NO connection.

Installation

►

Fan pre oper.

Clean phase out

Phase out

Testblow start

Seconds the fan blows before ignition phase. Detection of ”old” flame.

Seconds the ignitor is active after the flame sensor has approved start value.

The fan speed before operation phase.

Time that the fan afterblows before standby or cleaning.

Ramp phase out

Time that the fan decreases it´s speed after running cycle.

Quick start

►

Temp down - min

Temp down - °C

Degrees temp shall fall before burner goes to quick start.

The time in which the temp. shall fall before burner activates quick start.

Flame sens

Quick start

►

►

Flame sensor

►

Time oper

Level oper

Level start

Time phase out

Set value where the burner goes from ignition mode to operation mode.

Lowest approved value in operation mode. If lower: ”ALARM BURNER”

Time before ”ALARM BURNER” when flame sensor lower than level oper.

Time the fan goes to max speed.

Menu options for the flame sensor.

Menu options for the quick start function.

Cleaning conv..

The amount of pulls of the solenoid valve for the flue tubes.

Page 20

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

20

▀

Menu system

►

Setting of current weekday

Function test

Givare G2

Time

Calibration of each sensor +/- 4 °C

Test mode of the products different functions.

Givare G1

Calibrate sensors

Setting of current time

Option to calibrate/adjust all the sensors connected.

Other settings

Givare G3

Givare G4

Givare G5

Weekday

Alarms

Language

►

►

►

Alarm log

Choice of system language

Givare G6

Givare G7

Givare G8

Flow. temp.

Option of set value of the room temperature

Radiator pump

On/Off control of radiator pump.

Max flow temp

Maximum allowed temperature to the flow.

Energy saver

The amount of degrees to be lowered at choosen times.

El. step 3-6-9

Fuse A

El. heater 6 kW

Choose between different effects on the electrical heater. 1 phase is maximum 3kW

El. heater 3 kW

Log of runtimes of the different electrical heating steps.

Heating off

Outdoor temp when heating turns off. Rad. pump is runned 1min/2hours.

Outdoor temp

Outdoor temperature at the outdoor sensor

Heat curve

Option of slope to the heat curve (page 27).

Max room temp.

Maximum allowed room temp.

Min room temp

Minimum allowed room temp. Shunt opens full at set temp.

Min flow temp

Room temp

Minimum allowed flow temp.

Room sensor

Option of control, (ROOM, OUTDOOR or BOTH.

El. heater

Current load to the fuse in Amps.

►

Shunt control

►

Temp. to radiator/underfloor heating G7.

Slope

Adjustment

Lowering temp.

►

►

►

Option of adjustment to the heat curve (page 27).

The heating curve for the heating control (page 27).

06 _ _ _ _ 22

06 _ _ _ _ 22

Mon

Tue

Weekly schedule of lowering the indoor temp/ flow temp at choosen times. Please

note that for instance underfloor heating is slow and therefore takes time to reheat.

Options for energy saver (such as day/time/temp control.

Options for the electrical heater.

Options for the shunt control

►

Calibrate sensors

Page 21

21

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

Ignitor

Activates the auger/feeder.

Flame sensor

Feeder

Fan

Compressor

Solenoid valve

Test cleaning

Convection cleaning

Function test of the flame sensor. Must be illuminated to test function.

Activates ignitor, the fan starts at 40% to protect the ignitor.

Activates electrical heater.

Activates the fan

Activates and tests the full AERO cleaning cycle.

Activates the shunt motors open or close, +/-

Activates the radiator pump.

Stop start

Ign sequence 1

Stop operation

Registration of which ignition sequence the boiler goes to operation mode.

►

Function test

Shunt motor

Radiator pump

Loading pump

El. heater

Activates the loading pump for another unit such as Laddomat.

Activates compressor for cleaning.

Activates/opens solenoid valve for cleaning.

Activates the flue cleaning.

►

Alarms

Ign sequence 2

Ign sequence 3

If there is a failure during ignition phase alarm will show: ”ALARM IGNITION”

If there is a failure during normal operation alarm will show: ”ALARM BURNER”

▀

Alarm at disruption

Alarm

Burner

There has been a problem during operation phase. Most likely

problem is that the pellets is out. Flame sensor can also be

covered by soot.

Alarm

Ignition

The burner has missed the ignition phase, most likely problem

is poorly adjusted starting dose. Also check the ignitor in the

function test.

Alarm

Flue gas

The flue gas temperature has been above 320°C. This is a extrmely high temperature, please check that the automatic cleaning

is working (function test). Also check the flue gas sensor.

Alarm

Boiler temp.

The temperature of the boiler has been abov it´s max value. Normally this can happen from the heat after the combustion cycle.

Try to lower the stopping temeprature if the problem reoccurs.

▀

Ignition phase of the burner

The adjusted start dose is given to

the combustion chamber.The ignitor

is lit for 30 seconds. The fan ramps

in three cycles.

If the flame sensors doesn´t detect

a flame the burner gives a support

dose. The fan ramps up in three

cycles.

If the flame sensors still doesn´t

detect a flame the burner gives a

support dose. The fan ramps up in

three cycles.

If the flame sensor detects lights

the burner goes to operation

mode in seq 1.

If the flame sensor detects lights

the burner goes to operation mode

in seq 3.

If the flame sensor detects

lights the burner goes to operation mode in seq 2.

If there is no light in seq 3 ”ALARM

START” will be showm in display.

▀

Menu system

Page 22

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

22

►

▀

First start

▀

Tuning the boiler.

The boiler is only roughly set from the factory. Before first start an easier tuning must be done.

Then the boiler can be started and the combustion can be controlled and fine tuned with a flue

gas analyzer. After a couple of week in service, a check of the flue gas values should be done.

►

The values shown in the menues earlier are good for a startup of the boiler. Then

fine tuning is needed.

►

►

►

►

Start with the settings by entering the boilers menu (page 17.).

Temperature settings

The start and stop temperatures for the burner is set in the menue ”TEMPERATURE

SETT.” The start temperature should not be set below 75°C, there might be problem

with hot water running out. This is of course depending on which boiler being used.

Temperature el.heater

Set the temperature for the electrical heater to start if there would accure a fault or the

pellet should run out. Set the temperature 5-10°C below the burners start temperature.

Cleaning of tubes

Set the time when the cleaning of the tubes should be activated.

Clock

In this menu, the same as ”Cleaning”, the time is set. If there is a power outage, unfortunately the clock has to be set again.

Shunt

Set the desired indoor temperature. Do this by turning the room thermostat. There is

no value on the knob, the value is changed on the display on the boiler. The thermostat

should be placed in an open space without interferences by heat from e.g a stove or

cold draft. Sometimes the heating system might need to be trimmed by turning the thermostats on the radiators in different rooms.

El. heater

Here you set what effect the electrical heater should have if activated. You can choose

3 or 6kW, or both. If both is set to active the effect will be 9000W. Remember to check

that the fuses in the house can handle the power to the electrical heater.

Page 23

23

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

Tuning the burner

►

►

►

►

►

Fill screw

Start with filling the auger by setting ”FILL SCREW”. The auger will run for 15 min. Put a

bucket under the outlet to prevent pellet from falling out. It is important that the auger is

filled properly, therefore it is a good idea to tap it with for example a rubber mallet during

the filling.

The fan

The rpm for the fan is set in the menue ”FAN”. The rpm is dependent upon the operation

dose set. For the best efficiency a flue gas analyzer should be used. We recommend

12% CO2 in the flue gases. You also choose if the low power option should be activated.

Which might be good if for example there is a small amount of water in the boiler.

Start dose

The feeding of the pellet is the most important part in the system for a good combustion

and function. Set the start dose by activating the ”RUN START DOSE”. It is important

that the start dose is correct and it should be controlled when the burner has been running

a number of hours. The amount of pellet fed when running the start dose should be about

3,5 dl. If the burner fails to start, the dose can be increased a bit, and if it smokes a lot

during startup it might be decreased a bit.

Operation dose

The operation dose is set in the menue ”RUN OPER.DOSE”. Weigh the pellet that is fed

through the auger and adjust the power according to the diagram below. Never run the

burner at a higher power than needed, it is harder to maintain best efficiency at higher

power.

Service

In this menue the settings is deciding how and when the burner should be cleaned with the

compressed air. The less time the cleaning is set to be prevented, the better. There will be

fewer times/year the burner needs to be cleaned manually if the compressor is allowed

to do the work. Here is also the maximum time set for the burner to be running before

it cleans itself. It goes into cooling phase and cleans and then startup again. When the

settings are made, set the burner to ”ON”, and the first start will take place if there is a

heating need from the boiler.

Power kW 12,5 15 17,5 20 22,5 25 27,5 30

Amount of fuel kg/h 2,6 3,1 4,7 4,1 4,7 5,2 5,7 6,25

Doses calculated with pellet with the energy content 4.8 kWh/kg.

If ”RUN OPER.DOSE” is set, the auger will feed small doses of pellet for 6 minutes in

the same way as when it is running normally. Weigh the pellet fed to get the right power. 6

minutes is equal to 1/10 of 1 hour. If you set the burner on 20 kW it should have 410 g as

operation dose.

Page 24

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

24

▀

Valve combination

The valve combination is there so the hot water temperature doesn’t get to scalding temperature. In order

to increase the temperature turn (1) against +. You

may also need to tune the flow valve (6) to reduce

the flow through the coil. There is a safety valve (9)

that releases the water out of overflow tube (10) if the

pressure in the hot water circuit is too high. Note that

overflow pipe should always have drainage to a floor

drain.

1 Temperature control 6 Flow control valve

2 Hot water 7 Mixing valve

3 Cold water 8 Vent pipe

4 Hot water out 9 Safety valve

5 Cold water in 10 Overflow pipe

▀

Hot water

Hot water is produced in a copper coil. There are flanges on the

outside on the coil for best heat absorption. The cold incoming

water is mixed with the heated water from the coil in the mixing

valve (1). The mixing valve includes a thermostat where you set

the temperature on the outgoing water. If you don’t run the boiler

with pellet there also is a possibility to heat the hot water with the

electrical heater which should be set to 70°C for good hot water

comfort. If the operating temperature of the burner or electrical

heater is too low, the coil will not deliver the quantity of hot water

as desired for larger amounts.

When hot water is prepared in a coil, legionella bacteria cannot

occur.

Page 25

25

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

Room sensor

If the room sensor is used it is recommended to be installed in a open space near the center

of the house. The sensor shouldn´t be interfered by draught, doors, sunlight directly to it or

other heat sources since it then will block the entire heating output to the house.

Loosen the control wheel by

pulling outwards. The loosen

the screw to open the box.

6 Connected to number 3 on the main board 4 Connected to number 5 on the main board

2 Not used 1 Connected to number 4 on the main board

▀

Shunt control

In the menu ”shunt control” there are different options of controls; indoor sensor, outdoor

sensor or both in combination.

Outdoor sensor

If a outdoor sensor is used this should be mounted on the facad of the house. It is important

the sensor is mounted on the north side of the house. Make sure that the sensor isn´t

disturbed from solar insolation. It is recommended that the sensor is mounted about 2 metres

from ground level and if possible protected from water and such.

1 Connected to 1 on the main board

2 Connected to 2 on the main board

Loosen the screw and split the

casing. It is then possible to

mount the box to the wall.

Page 26

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

26

▀

Adjustments of heating curves

The appropriate heating curve is essential in order to have to right indoor temperature. The

heating curve needs to be adjusted to the specific energy demands of the house it is installed

in. All houses have different demands, which could give that one house would need a 25˚C flow

at a outdoor temperature of +-0˚C while another house needs 45˚C.

Adjustment to the heating curve is done in the menu “Shunt control”. In this menu it is possible to alter both the slope and the adjustment to the curve. To find and adjust the correct

heating curve it is important that the following points are fulfilled:

- The outdoor temperature must not be higher than +5˚C

- Energy saver function must be switched off.

- Valves on the radiators must be fully open.

- Radiators must be checked and in function.

It is normal that during the first heating season changes must be done several times in order

to find the right setting for the house. When the right setting is found there is no need for any

changes for years to come. This is the greatness with an outdoor sensor. To start out with

something as a rule of thumb we could recommend these initial settings:

- Houses with underfloor heating in concrete. “Slope 35”

- Well insulated low energy house with low temp. radiators. “Slope 40”

- A high temp. radiator system in a older house with poor insulation. “slope 55”

Example of slope:

If the slope is set to 50˚C this is the temperature sent to the flow at a outdoor temperature of

-15˚C.

Example of adjustment:

When an adjustment is done to the slope this is done parallel to the curve. Meaning that if an

adjustment of 5˚C is done. This happens for the whole slope.

Page 27

27

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

Example of curves

A too low heating curve will result in that the house will not have the correct indoor

temperature

-30 -25 -20 -15 -10 -5 0 5 10 15 20 25

80

70

60

50

40

30

20

Temperature flow

Slope

The heating curve chosen in the software is the temperature

to the flow at -15˚C outdoor temperature. Therefore the flow

temperature will change with the outdoor temperature.

Outdoor temperature

-30 -25 -20 -15 -10 -5 0 5 10 15 20 25

80

70

60

50

40

30

20

Outdoor temperature

Temperature flow

Adjustment

Slope 50˚C, adjustment +5˚C

Slope 50˚C with no adjustment

! If it is cold outdoors (cold winter) and the room temperature is too low. Increase the slope

with 1-2˚C

! If it is cold outdoors (cold winter) and the room temperature is too high. Decrease the

slope with 1-2˚C

! If it is warm outdoors (average autumn/spring) and the indoor temperature is too low.

Increase the adjustment with 1-2˚C

! If it is warm outdoors (average autumn/spring) and the indoor temperature is too high.

Decrease the adjustment with 1-2˚C

! Wait at least 24 hours between adjustments and changes due to slow response of heating.

When a adjustment of 5˚C is done, the heating curve is

adjusted at all outdoor temperature with 5˚C.

Page 28

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

28

▀

Mounting the auger

Ø75, 1.7 and 2.5 m, mounting in Mafa Micro, Mini or Mini Storage.

Make sure the helix spiral is 15-25 mm inside the plastic tube (1). Adjust by loosening the

clamp (2) and move the plastic tube to the correct dimensions.

Adjust the store location so that the feed screw is properly positioned over the burner, with

a tilt of between 30 - 45 °. Mount a hook in the ceiling above the auger for hanging it in the

strap. (min. Ø6, not included).

Insert the auger into the store pipe, it shall rest entirely on the store lid (3). Secure Mafa

storage lid with 2 short screws (4), alt. used a hose clamp (5) as a stop. Hang the auger on

the hook with the strap. Install appropriate flexi hose and make the final adjustment to the

burner. Move the screw and the storage so that the hose reduction can be pressed in to the

drop pipe. The tube should not be stretched or squashed.

Check inside the store that the auger intake is completely visible. Adjust, if necessary, by

loosening the clamp (2) and rotate the plastic tube to the correct position. First select the

pipe location in the longitudinal direction so that the former adjustment does not change.

Make sure the clamp is applied and tightened before the auger is in operation. Connect the

power cable to the burners connector.

The spiral must stay just outside or in line with

the tube (not adjustable). Insert the auger 420

mm of the store pipes, mount hose clamps (5)

to stop. Check inside the store that the auger

intake is completely visible. Adjust and hang up

as described for Ø75 feed screw.

Install the screw engine in the flange of the screw.

The M8-screw with distance tube should stay in

the motor plate to lock the motor from rotating.

Be sure the locking screw in flange is in the

groove on the motor shaft and tighten. Connect

the power cable to the burner.

Ø90 steel, 1.7 and 2.3 m, mounting in Mafa Micro, Mini or Mini Storage.

Page 29

29

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

Replacing the combustion fan

When a fan has been replaced, a new analyze of the flue gas should be done. The RPM

can vary between fans.

Disconnect the power supply to the boiler. Loosen the three wing nuts and lift the cover up.

Disconnect the power supply to the burner. Loosen the power cable to the burner, cable to the

flame sensor and the air supply if its connected. (let the ignition element stay remain in the

ignition device). Note the electrical routing and attachment of all cables.

Disconnect power leads from the fan by pulling out the pins (1). Remove the four screws (screw

3 mm) and remove the fan (2). Install the new fan. Make sure the conduit to the ignition element

cable, is in place.

Replace the ignition device according to the ”change of ignition elements.” Attach the wires

to the igniter and thermal protection and flame sensor with cable ties in the mounting bracket.

Page 30

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

30

▀

Changing and/or servicing the flame detector

It is important that the cables are connected the same way to burner as they were, otherwise it will display 100% light all the time and the burner will be faulty.

Disconnect the power supply to the boiler.

Loosen the three wing nuts and lift the cover

up. Note how the flame sensors are coated

and remove the cable tie from the mounting

bracket. Disconnect the terminal block of the

flame sensor (1) by pulling it straight back.

Then loosen the burner from the outer tube by

loosening the four wing nuts (2) Then loosen the

nut that holds the flame sensor in place inside

the house. Then take the flame sensor out and

replace with the new. Reassemble in reverse

order. When cleaning the flame sensor, use a

damp cloth after you loosened the burner from

the burner tube.

▀

Overheated feeder tube

On the feeder tube of the pellet burner there is a heat protection. This turns out to protect against backfires. If the protection tripped, the voltage disappear to the auger. The cause of

overheating is usually due to large back pressure in the boiler,

which in turn usually depends on:

- Burner tube is full of soot.

- The boiler is full of soot.

- The chimney is too narrow.

- The burner is set to high power.

Reset the protection by loosen the bracket wich is placed in

front of the overheating protection (1). Then press the reset

button (2) and you will hear a click when it is restored.

If the protection is activated again, we recommend that you

contact your installer to review the function and settings.

Page 31

31

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

Changing the igniter.

Disconnect the power supply to the boiler. Loosen the three wing nuts and lift the cover up.

Loosen the power cable of the burner, the cable to the flame sensor and the air supply. (1)

Remove the four bolts (2) wich are holding the burner housing against the end plate of the

mantle. Angle the burner housing and pull it upwards/backwards so that the feeder tube loosens

from the burner. Then detach the pipe to purging by unscrewing the quick connector on the

outside of the rear housing. Then disconnect the ignition element wires on the terminal block

located under the metal lid of the connection box (3). Remove the ignition device from the rear

housing (two screws on the bottom of the burner (4). Ignition element cap is removed (5) and

the element is pulled out of the square tube.

Slide the new element in the square tube. Push to lie on the outer edge of the square tube (6).

Install the clamp and tighten the screws with moderate force, so that the element is not going

to fly back and forth.

Insert the ignition device in the rear housing. The cables should be pulled out through the fan’s

cable access. Connect the cables on the terminal. Secure the two cables to each other with

a cable tie. Reassemble in reverse order, wait to fasten ignition device in the burner until the

burner is mounted together with the mantle. Push the ignition device to the burner tube and

tighten the two bolts. Check that the square tube is in the middle of the hole in the burner tube.

When you re-mount bracket for

ignition element and compressed

air pipe, you must be careful

that it is pushed as far forward

as possible to the burner tube.

If there is a gap in between can

ignition of the pellet be difficult

and cleaning impaired.

Page 32

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

32

▀

Cleaning the rear housing and outer tube

After a period of heating up, there will be dust and soot from the burner´s

inner and outertube. These must be removed to avoid deterioration

in combustion and function. We recommend that the cleaning is

done after about 6 tons of pellets consumption. After the cover

is removed, start by loosening the

four wing nuts (1) wich are holding

the burner in place and then unload

according to description. Then pull

out the inner tube (2) and clean

from ash and soot. It is important

that the holes are not clogged with

soot, as these are essential to good

combustion. Then clean the outer

tube (3) from the soot and pellet

residues. Reassemble in reverse

order.

▀

Mounting and adjusting of the draft stabiliser.

A draft stabiliser makes sure that a constant and stable draft is achieved. Also condensation

in the chimney is avoided.

Adjusting the balancing shaft

To adjust this shaft, loosen the two screws a bit and turn the shaft so that it is horisontally when

the hatch is closed. Then fasten the screws.

Adjusting the draft

By moving the counterweight along the balanceshaft, the draft needed to open the hatch is

adjusted. About 1Pa per 2mm.(fig.2) The hatch is preset at about 1Pa. A professional should

measure the draft and make the adjustments.

Functions

Tigex draft stabiliser opens the hatch just as much as needed depending on the current draft.

The draft varies a lot depending on the chimney, weather and also if the burner is running or

not. This means that the hatch can be open alot, a little or closed, depending the situation.

Page 33

33

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

Service and cleaning

Cut the power to the boiler before starting the service. We recommend a good service/cleaning

of the burner and boiler 2-3 times a year. Do as follows for best result and minimizing the

chances for failures.

Sweeping range

1. Firepbox, if necessary, or at about 3 tons of pel lets consumption.

2. Burner tubes after 3 tons of pellets consumption.

3. Convection part 3 tons of pellets consumption.

3. Without automatic cleaning every other week in

winter.

4. Soot box if necessary.

5. Smoke box after 3 tons of pellets consumption.

6. Flue pipe after 3 tons of pellets consumption.

7. The burner’s outer tube 6 tons of pellets con sumption.

8. Flame detector after 6 tons of pellets consumption

(page 30)

Cleaning the firebox

Cleaning the firebox is done through the ash door on the front. The easiest way is to use some type

of ash cleaner. If you do not have access to a an ash cleaner, remove the ash with a scrape and keep

it in a fireproof bin. Remember that ashes can contain hot particles for a long time and may not be

stored near flammable materials.

Cleaning the burner

Remove the ash contained in the burner tube, this is done either through the firepbox with the supplied

scraper or by taking the burner tubes apart outside the boiler, which sometimes can be the easiest

way.

Cleaning of convection

Cleaning of the tubes is done with the included brush, lifting the turbulators acc. (page 12). It is

important for the efficiency that these are cleaned thoroughly at the service.

Cleaning of ash and flue

Soot box, which is placed above the tubes must be emptied of ash, if the soot box is full, the flue gas

has no place to escape out through the chimney and you will receive a disruption. Also clean the flue

tube that goes to the chimney, when it is not certain that the chimney sweep do it.

The burner’s outer / innertube

The space between the outer - inner tube must be cleaned out of dust and particles after about 6 tons

of pellets consumption (page 32)

Page 34

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

34

▀

Trouble shooting

The burner does not ignite - Incorrect start dose

- Igniter faulty

- Igniter console poorly attached

- Inner tube filled with ashes

- Adjust start dose

- Replace igniter

- Adjust the console

- Clean the burner

The burner ”puffs” at start - Incorrect start dose - Adjust start dose

High temp protection on

feeding tube activated

- Low draft

- Inner tube filled with ashes

- Control the draft

- Clean the burner

Inner tube fills up with ashes - Poor combustion

- The burner cleaning malfunctioning

- Contact your installer

- Contact your installer

Ashes are totally black - Poor combustion - Contact your installer

Poor hot water capacity - Low temperature in the boiler

- To high flow in the pipes

- Set the burners ”Stop” temperature higher

- Adjust the flow on the mixing valve

- Changing the water tap

Low/high indoor temperature - Incorrect set thermostat

- Sensor untrimmed

- Placement of thermostat in a bad place

- Adjust thermostat

- Trim sensor (page17)

- Move the sensor to a better place

Soot in the boiler room - Leaking seals - Contact your installer

Alarm (flue gas) - Sooty boiler

- Poor combustion

- Broken sensor

- Clean the boiler

- Contact your installer

- Contact your installer

No heat on radiators - Shunt motor broken

- Thermostat set to low

- Contact your installer

- Adjust thermostat

White smoke from the chimney - Low flue gas temperature

- To big chimney

- Rain water in the chimney

- Cut turbulators/increase power

- Contact a professional

- Mount a rain hood

Fault Cause Action

There are actions that the end user can take to fix a stop. However, a professional should always be

adviced before doing any adjustments.

-10°C 960 ohm 60°C 1232 ohm

0°C 1000 ohm 70°C 1271 ohm

10°C 1039 ohm 80°C 1309 ohm

20°C 1077 ohm 90°C 1347 ohm

30°C 1116 ohm 100°C 1385 ohm

40°C 1155 ohm 120°C 1461 ohm

50°C 1194 ohm 140°C 1535 ohm

If the cables are lengthened, use these cables:

- For a length up to 15m 2 x 0,5m²

- For a length up to 50m 2 x 0,75m²

- Do not place these cables together with main cables(high voltage).

The value of the resistance on the Pt1000 sensors is measured with ohm meter. Disconnect the

sensor from the motherboard in order to measure. Remember that the sensors need good connection in order to get a correct result.

▀

The sensors

Page 35

35

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

▀

Documentation of settings

Before you commision the boiler system we ask you to fill out the different values set in the menues.

This is important for the future services and makes it easier in the communication between the

customer and the installer and between the installer and Effecta.

Parameters Value

Start temperature burner

Stop temperature burner

Fan speed

Temperature electrical heater

Power electrical heater

Operation dose

Start dose

Flame sensor start

Flame sensor running

Acc.tank high G6

Acc.tank low G5

Stopp G5

Max G6

Start G6

Max G1

Settings in buffer system

Parameters Value

CO2 content

CO (ppm)

Flue gas temperature

Negative pressure in the flue (pa)

Prestanda

Parameters Value

Basic settings

2011 2012 2013 2014 2015

Tillverknings år. / Manufacturing year

Tillverkare / Manufactory

Hersteller / Fabricants

Modell / Model

Typ / Modéle

Godkänd enl. / Approved by

Zugelassen nach / Approuvé á

Miljöklass / Emission class

Emissionsklasse / Classe d’émission

Max drifttemp. / Max temp. (C)

Max. Betriebstemp. / Temp d’opération max

Elinstallation / Electrical supply

Strom / Branchement électrique (VAC)

El-patron / Electrical heater (kW)

El-Patrone / El-cartouche

Vattenvolym / Water volume

Wasserinhalt / Contenance d`eau (litre)

Tillverknings nr / Manufacturing number

Herstell Nr / Numéro de fabrication

Effecta Energy Solutions AB

Effecta Komplett

EN-303-5

3

100

230/380~50Hz

3 - 9

183

Effecta AB - Sweden - Kungsbacka - www.effecta.se

Max drifttryck / Max pressure

Max Betriebsdruck / Pression maximum (bar)

1,5

Tillverknings månad / Manufacturing month

1 2 3 4 5 6 7 8 9 10 11 12

Effekt / Heat output

Heizleistung /Puissance nominale (kW)

20 30

The label is placed on the outer casing on the burner. Here

you can see the production number, month and year.

▀

Type plate

Page 36

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

36

▀

Dimensions

EFFECTA KOMPLETT 20 KW

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

011-12-15

V50-04-47

E.A

TECHNICAL DATA

1. FLOW HOT WATER 1”

2. RETURN HOT WATER 1”

3. DRAIN COCK 1/2”

EXPLANATIONS

Width

Depth incl. smoke pipe

Height

Weight

Maximum pressure

Flue tube angle (extra)

Flue tube diameter

Floor to cc smoke pipe

Water Volume

Recommended draft

Min. schimney area

Electrical connection

Sheet thickness mantle

Sheet thickness grate

Firebox volyme

Firebox depth

Power max

Max operating temperature

1075 mm

1050 mm

1450 mm

295 kg

1,5 bar

120 mm

180 mm

1430 mm

183 liter

15 pa.

120 mm

230/380 VAC

4 mm

4 mm

106 liter

500 mm

20 kW

99 gr

Page 37

37

Effecta AB Västra Rågdalsvägen 21 434 99 Kungsbacka Sweden +46-300 - 22320 info@effecta.se

PRINCIPAL SCHEME

EFFECTA KOMPLETT WITH HOT WATER CURCUIT

AND RADIATOR.

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

010-12-13

V50-05-56

E.A

COMPONENTS

8.

1. ROOM THERMOSTAT

2. RADIATOR VALVE

3. RADIATOR PUMP

4. REFILL

5. SHUNT WITH SHUNTMOTOR

6. MIXING VALVE

7. EXPANSION VESSEL WITH SAFETY VALVE 1,5 BAR

8. DRAIN COCK

9. DIRT FILTER

HEAT CURCUIT

3.

7.

Domestic water

6.

9.

4.

5.

2.

1.

2.

COLD WATER

HOT WATER

▀

Hyudralic scheme

Page 38

Loading...

Loading...