Page 1

MTT 3600 (2.15 cu.in)

en

OPERATOR’S INSTRUCTION MANUAL

fr

MANUEL D’UTILISATION ET D’ENTRETIEN

es

MANUAL DE INSTRUCCIONES

Page 2

WARNING! – This saw is for tree service operators only. Use without

proper training can result in severe injuries.

ATTENTION! – L’emploi de cette tronçonneuse est réservé aux

opérateurs du secteur de l’entretien des espaces. L'utilisation sans une

formation adéquate peut provoquer des blessures extrêmement graves.

¡ATENCIÓN! - Esta motosierra es sólo para personal adiestrado en el

mantenimiento de los árboles. El uso sin un adiestramiento adecuado

puede causar daños físicos de extrema gravedad.

Page 3

1

1 3 52

4 6

7 8 9

10

3

1

6

2

15

8

7

18

5

16

11

13

12

3

2

17

9

4

14

4

B

A

5

6

E

H

L

F

N

G

D

C

M

Page 4

7

8

L

11

13

9

10

12

14

D

CLOSE

OPEN

Page 5

15

18 19

16

20

17

22

21

Page 6

0,5 mm

CMR7A

23

24

26

28

C

C

A

27

29 30

25

B

C

Page 7

English 5

Français 29

Español 55

Page 8

Page 9

INTRODUCTION

To correctly use the chain saw and prevent

accidents, do not start work without having first

carefully read this manual. You will find

explanations concerning the operation of the

various parts plus instructions for necessary

checks and relative maintenance.

Note: Illustrations and specifications in this

manual may vary according to Country

requirements and are subject to change

without notice by the manufacturer.

THE OPERATOR’S MANUAL

Your operator’s manual is for your protection.

READ IT. Keep it in a safe place for reference.

Know what you are doing before you begin

assembly of the unit. Proper preparation and

upkeep go hand-in-hand with satisfactory

performance of the saw and safety.

Contact your dealer or the distributor for your

area if you do not understand any of the

instructions in this manual.

In addition to the operating instructions, this

manual contain paragraphs that require your

special attention.

Such paragraphs are marked with the symbols

described below:

Warning: where there is a risk of an accident or

personal injury or serious damage to property.

Caution: where there is a risk of damaging the

machine or its individual components.

WARNING - To ensure safe and correct

operation of the chainsaw, this operator's

manual should always be kept with or near

the machine. Do not lend or rent your

chainsaw without the operator's instruction

manual.

WARNING: Allow only persons who

understand this manual to operate your

chainsaw.

CONTENTS

1. UNDERSTANDING SAFETY LABELS __ 5

2. CHAIN SAW COMPONENTS _________ 5

3. SAFETY RULES ___________________ 6

4. ASSEMBLING THE BAR AND CHAIN __ 13

5. STARTING _______________________ 15

6. STOPPING THE ENGINE ____________ 18

7. USE ____________________________ 18

8. MAINTENANCE ___________________ 20

9. STORAGE ________________________ 26

10. TECHNICAL DATA _________________ 27

11. TROUBLE SHOOTING CHART _______ 28

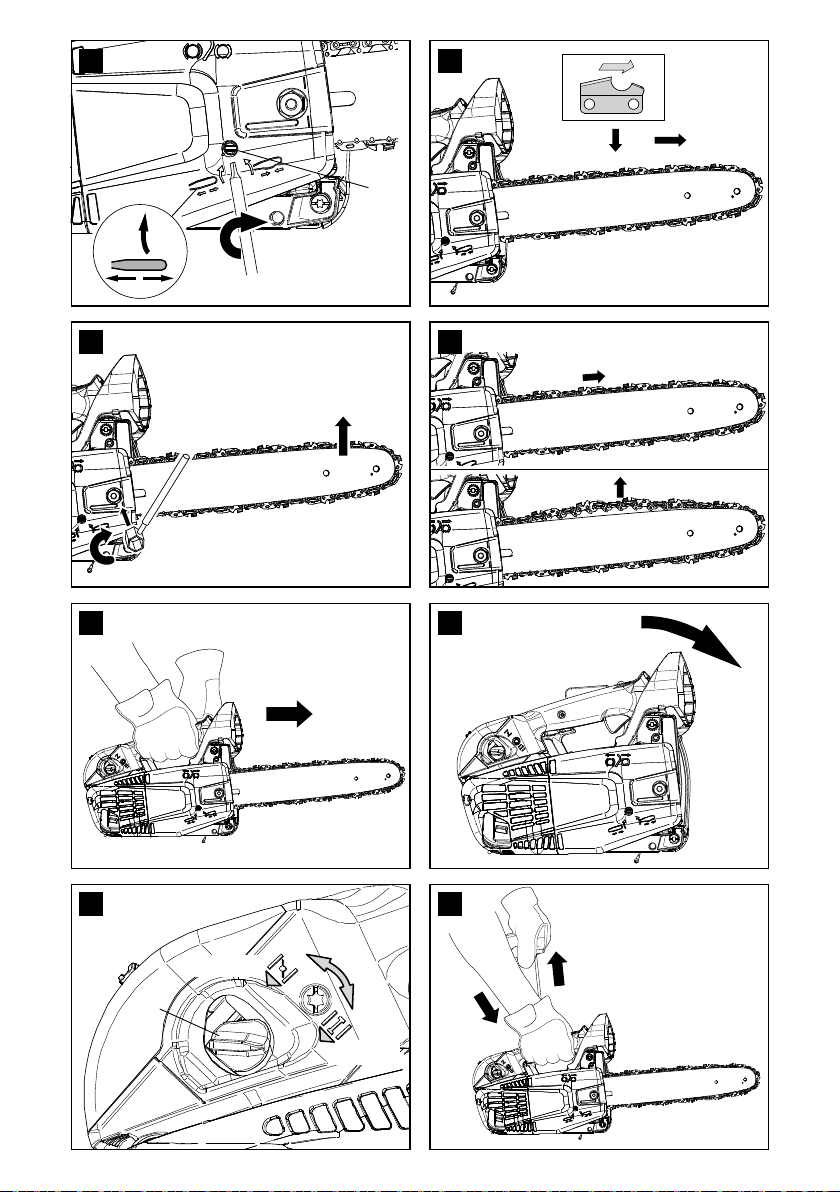

1. UNDERSTANDING SAFETY LABELS

(Fig.1)

1. This symbol indicates Warning, and Caution.

2. WARNING! Beware of Kickback. Avoid bar

nose contact.

3. Wear safety strong shoes or boots having

skid-proof sole and anti-piercing insert.

4. Your manual contains special messages to

bring attention to potential safety concerns,

machine damage as well as helpful operating

and servicing information. PLEASE READ ALL

THE INFORMATION CAREFULLY TO AVOID

INJURY AND MACHINE DAMAGE.

5. Wear eye, hearing and head protection when

operating this equipment.

6. Always hold saw properly with both hands.

7. Primer bulb

8. Chain brake, activated (right). Chain brake,

not activated (left).

9. WARNING! The surface can be hot!

2. CHAIN SAW COMPONENTS (Fig. 2)

1. Choke lever

2. Throttle trigger

3. Throttle trigger lockout

4. Carburetor adjustment screws

5. Inertial brake lever

6. Exhaust muffler

7. Chain

8. Guide bar

9. Air filter cover

10. STOP button

11. Fuel tank cap

12. Starter handle

13. Oil tank cap

14. Primer bulb

15. Lateral chain tensioner screw

16. Front handle

17. Rear handle

18. Bar cover

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

5

Page 10

3. SAFETY RULES

State and Local Requirements

en

The engine is NOT equipped with a Spark Arrester

System complying with the requirements of SAE

GB

Recommended Practice J335 and California Codes

4442 and 4443. All national forest land and land

F

managed by the states of California, Maine,

Washington, Idaho, Minnesota, New Jersey and

Oregon require internal combustion engines to

D

be equipped with a spark arrester screen by

law. Other states and federal agencies are

E

enacting similar regulations.

Operating this engine in a state or locale where

NL

such regulations apply, could result in a violation

of the law.

P

Note: When using a chainsaw for logging

purposes, refer to Code of Federal

GR

Regulations, Parts 1910 and 1928.

TR

CZ

SK

RUS

UK

PL

WARNING: The ignition system of your

unit produces an electromagnetic

field of a very low intensity. This field may

interfere with some pacemakers. To reduce

the risk of serious or fatal injury, persons with

pacemaker should consult their physician

and the pacemaker manufacturer before

operating this tool.

WARNING: Muffler surfaces are very

hot during and after operation of the

chain saw, keep all body parts away from the

muffler. Serious burns may occur if contact is

made with the muffler.

H

WARNING: Exposure to vibrations

through prolonged use of gasoline

LV

powered hand tools could cause blood

vessel or nerve damage in the fingers, hands,

EST

and wrists of people prone to circulation

disorders or abnormal swellings. Prolonged

use in cold weather has been linked to blood

LT

vessel damage in otherwise healthy people. If

symptoms occur such as numbness, pain, loss

RO

of strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or wrists,

discontinue the use of this tool and seek

medical attention.

WARNING: The engine exhaust from

this product contains chemicals known

to the State of California to cause cancer,

birth defects or other reproductive harm.

Operate your chainsaw outdoors only in a well

ventilated area.

SAFETY RULES FOR TREE SERVICE CHAIN SAW

This chain saw for tree service is a specialized

chain-saw of limited weight designed for use

by a trained and competent operator for

pruning and dismantling standing tree

crowns.

A trained operator is a person who has

competence and knowledge in:

- the use and particular hazards associated with

using a chain-saw (for tree service work),

- the precautions to be taken to limit these

hazards including wearing recommended

personal protective equipment (PPE).

Due to the special compact handle design,

there is an increased risk of injury.

For this reason these special chainsaws should

be used only for work in a tree by persons who

are trained in special cutting and working

techniques and who are properly secured (lift

bucket, ropes, safety harness).

For all other cutting work forestry chain saws

(with wider spaced handles) must be used.

In addition to the safety instructions listed in

the following pages of the manual, when

using a tree service chain saw take special

attention to the following instructions:

• The specially shaped handgrip on the

machine calls for particular care when dealing

with kickback.

• Extreme care should be taken at the end of a

cutting operation in relation to the machine

suddenly dropping. This eventuality is difficult

to control with this type of handgrip.

• Attention should be paid to chain sliding.

Instead of penetrating the tree trunk, the

chain may slide forward and the operator will

not be able to fully control this action.

• Tree maintenance operators must be trained

in the correct operative techniques

concerning safety at work, i.e.: headgear,

6

Page 11

safety harnesses, cables and spring-clips, as

well as all of the other safety devices that are

normally used and must be trained

professionally in tree climbing.

• Pay attention to wires while working; always

keep distance from them.

• Release machine from hook point while

refuelling.

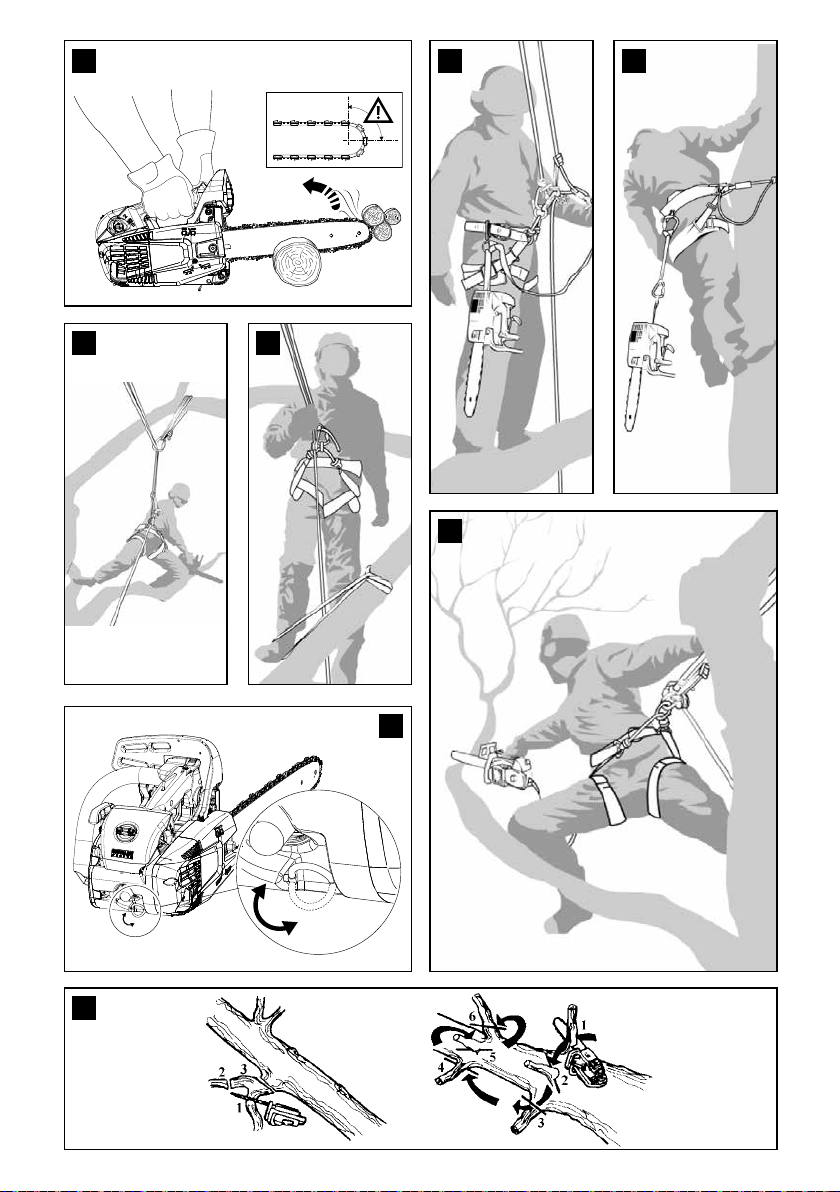

WORKING WITH TREE SERVICE CHAIN-SAWS

FROM A ROPE AND HARNESS

This chapter sets out working practices to reduce

the risk of injury from tree service chainsaws

when working at height from a rope and harness.

While it may form the basis of guidance and

training literature, it should not be regarded as a

substitute for formal training.

General requirements working at height

Operators of tree service chainsaws working at

height from a rope and harness should never

work alone. A competent ground worker trained

in appropriate emergency procedures should

assist them.

Operators of tree service chainsaws for this work

should be trained in general safe climbing and

work positioning techniques and shall properly

equipped with harnesses, ropes, strops,

karabiners and other equipment for maintaining

secure and safe working positions for both

themselves and the saw.

Preparing to use the saw in the tree

The chainsaw should checked, fuelled, started

and warmed up by the ground worker before it is

sent up to the operator in the tree.

The chainsaw should be fitted with a suitable

strop for attaching to the operator’s harness

(Fig. 16):

a) choke the strop around the attachment point

on the rear of the saw (Fig. 21);

b) provide suitable karabiners to allow indirect

(i.e. via the strop) and direct attachment (i.e. at

the attachment point on the saw) of saw to

the operators harness;

c) ensure the saw is securely attached when it is

being sent up to the operator;

d) ensure the saw it secured to the harness

before it is disconnected from the means of

ascent.

The possibility to attach the unit on the operators

belt greatly reduces the risk of machine damage

during aerial work. Stop the machine when it is

attached to the operator.

The saw should only be attached to the

recommended attachment points on the harness.

These may be at mid-point (front or rear) or at the

sides. Where possible attaching the saw to centre

rear mid-point will keep it clear of climbing lines

and support its weight centrally down the

operator’s spine (Fig. 17).

When moving the saw from any attachment

point to another, operators should ensure it is

secured in the new position before releasing it

from the previous attachment point.

Using the chainsaw in the tree

An analysis of accidents with these saws during

tree service operations shows the primary cause

as being inappropriate one-handed use of the

saw. In the vast majority of accidents, operators

fail to adopt a secure work position which allows

them to hold both handles of the saw. This results

in an increased risk of injury due to:

- not having a firm grip on the saw if it kicks

back;

- a lack of control of the saw such that it is more

liable to contact climbing lines and operators

body (particularly the left hand and arm)

- losing control from insecure work position

resulting in contact with the saw (unexpected

movement during operation of the saw)

Securing the work position for two-handed

use

To allow the operator to hold the saw with both

hands, they should as general rule, aim for secure

work position where they are operating the saw

at:

- hip level when cutting horizontal sections;

- solar plexus level when cutting vertical

sections.

Where the operator is working close into vertical

stems with a low lateral forces on their work

position, then a good footing may be all that is

needed to maintain a secure work position.

However as operators move away from the stem,

they will need to take steps to remove or

counteract the increasing lateral forces by, for

example, a re-direct of the main line via a

supplementary anchor point or using an

adjustable strop direct from the harness to a

supplementary anchor point (Fig. 18).

Gaining a good footing at the working position

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

7

Page 12

can be assisted by use of a temporary foot stirrup

created from an endless sling (Fig. 19).

en

Starting the saw in the tree

When starting the saw in the tree, the operator

GB

should:

a) apply the chain brake before starting;

F

b) hold saw on either the left or right of the body

when starting:

1) on the left side hold the saw with either the

D

left hand on the front handle or the right hand

on the rear handle and thrust the saw away

E

from the body while holding the pull starter

cord in the other hand;

2) on the right side, hold the saw with the right

NL

hand on either handle and thrust the saw

away from the body while holding the pull

starter cord in the left hand.

P

The chain brake should always be engaged

before lowering a running saw onto its strop.

GR

Operators should always check the saw has

sufficient fuel before undertaking critical cuts.

TR

One-hand use of the chainsaw

Operators should not use tree service chainsaws

CZ

one-handed in place of unstable work

positioning or in preference to a handsaw when

cutting small diameter wood at the branch tips.

SK

Tree service chainsaws should only be used onehanded where:

RUS

- the operator cannot gain a work position

enabling two-handed use; and

- they need to support their working position

UK

with one hand; and

- the saw is being used at full stretch, at right

PL

angles to and out of line with the operator’s

body (Fig. 20).

Operators should never:

H

- cut with the kickback zone at the tip of the

chainsaw guide bar

LV

- ‘hold and cut’ sections

- attempt to catch falling sections.

EST

Freeing a trapped saw

If the saw should become trapped during cutting,

LT

operators should:

- switch off the saw and attach it securely to the

tree inboard (i.e. towards the trunk side) of the

RO

cut or to a separate tool line;

- pull the saw from the kerf whilst lifting the

branch as necessary;

- if necessary, use a handsaw or second chain

saw to release the trapped saw by cutting a

minimum of 30 cm away from the trapped saw.

Whether a handsaw or a chainsaw is used to free

a stuck saw, the release cuts should always be

outboard (toward the tips of the branch), in order

to prevent the saw being taken with the section

and further complicating the situation.

Basic Safety Precautions

· Read this manual carefully until you

completely understand and can follow all

safety rules, precautions, and operating

instructions before attempting to use the unit.

· Restrict the use of your saw to adult users who

understand and can follow safety rules,

precautions, and operating instructions found

in this manual. Minors should never be allowed

to use a chainsaw.

· Do not handle or operate a chain saw when

you are fatigued, ill, or upset, or if you have

taken alcohol, drugs, or medication. You must

be in good physical condition and mentally

alert. Chain saw work is strenuous. If you have

any condition that might be aggravated by

strenuous work, check with your doctor before

operating a chain saw. Be more cautious before

rest periods and towards the end of your shift.

· Keep children, bystanders, and animals a

minimum of 35 feet (10 meters) away from the

work area. Do not allow other people or

animals to be near the chain saw when starting

or operating the chain saw.

· Major cases of chainsaw accidents happen

when the chain hits the operator. While

working with the chainsaw, always use safety

protective approved clothing. The use of

protective clothing does not eliminate injury

risks, but reduces the injury effects in case of

accident. Consult your trusted supplier to

choose equipment in compliance with

legislation. The clothing must be proper and

not an obstacle. Wear adherent anti-cut

clothing. Anti-cut jackets, dungarees and

leggings are ideal. Do not wear clothes,

scarves, ties or bracelets that may get stuck in

wood or twigs. Tie up and protect long hair

(example with foulards, cap, helmets, etc.).

Safety shoes or boots having skid-proof

sole and anti-piercing insert. Wear

protective helmet in places where there can

be falling objects. Wear protective goggles

or face screens! Use protections against

8

Page 13

noises: for example noise reduction ear

guards or earplugs. The use of protections for

the ear requests much more attention and

caution, because the perception of danger

audio signals (screaming, alarms, etc.) is

limited. Wear anti-cut gloves.

· Only loan your saw to expert users who are

completely familiar with saw operation and

correct use. Give other users the manual with

operating instructions, which they have to read

before using the saw.

· Check the chain saw each day to ensure that

each device, whether for safety or otherwise, is

functional.

· Never use a damaged, modified, or improperly

repaired or assembled chain saw. Do not

remove, damage or deactivate any of the

safety devices. Only use bars of the length

indicated in the table (page 12). Always replace

bar, chain, hand guard, or chain brake

immediately if it becomes damaged, broken or

is otherwise removed.

· Carefully plan your sawing operation in

advance. Do not start cutting until you have a

clear work area, secure footing, and, if you are

felling trees, a planned retreat path.

· All saw service, other than the operations

shown in the present manual, have to be

performed by competent personnel.

· The chain saw must only be used for cutting

wood. It is unadvisable to cut other types of

material.

· It is unadvisable to hitch tools or applications

to the P.t.o. that are not specified by the

manufacturer.

Fuel Handling

WARNING: Gasoline is an extremely

flammable fuel. Use extreme caution

when handling gasoline or fuel mix. Do not

smoke or bring any fire or flame near the fuel

or the chainsaw.

· To reduce the risk of fire and burn injury,

handle fuel with care. It is highly flammable.

· Mix and store fuel in a container approved for

gasoline.

· Mix fuel outdoors where there are no sparks or

flames.

· Select bare ground, stop engine, and allow to

cool before refueling.

· Loosen fuel cap slowly to release pressure and

to keep fuel from escaping around the cap.

· Tighten fuel cap securely after refueling. Unit

vibration can cause an improperly tightened

fuel cap to loosen or come off and spill

quantities of fuel.

· Wipe spilled fuel from the unit. Move 10 feet

(3 m) away from refueling site before starting

engine.

· Never attempt to burn off spilled fuel under

any circumstances.

· Do not smoke while handling fuel or while

operating the saw.

· Store fuel in a cool, dry, well ventilated place.

· Never place the saw in a combustible area such

as dry leaves, straw, paper, etc.

· Store the unit and fuel in an area where fuel

vapors cannot reach sparks or open flames

from water heaters, electric motors or switches,

furnaces, etc.

· Never take the cap off the tank when the

engine is running.

· Never use fuel for cleaning operations.

· Take care not to get fuel on your clothing.

· Don’t refuel when you are in a tree; refuel only

on a secure ground or on a platform.

Operation and Safety

Warning: Always hold the chain saw with

both hands when the engine is running.

Use a firm grip with thumbs and fingers

encircling the chain saw handles.

· Keep all parts of your body away from the saw

chain when the engine is running.

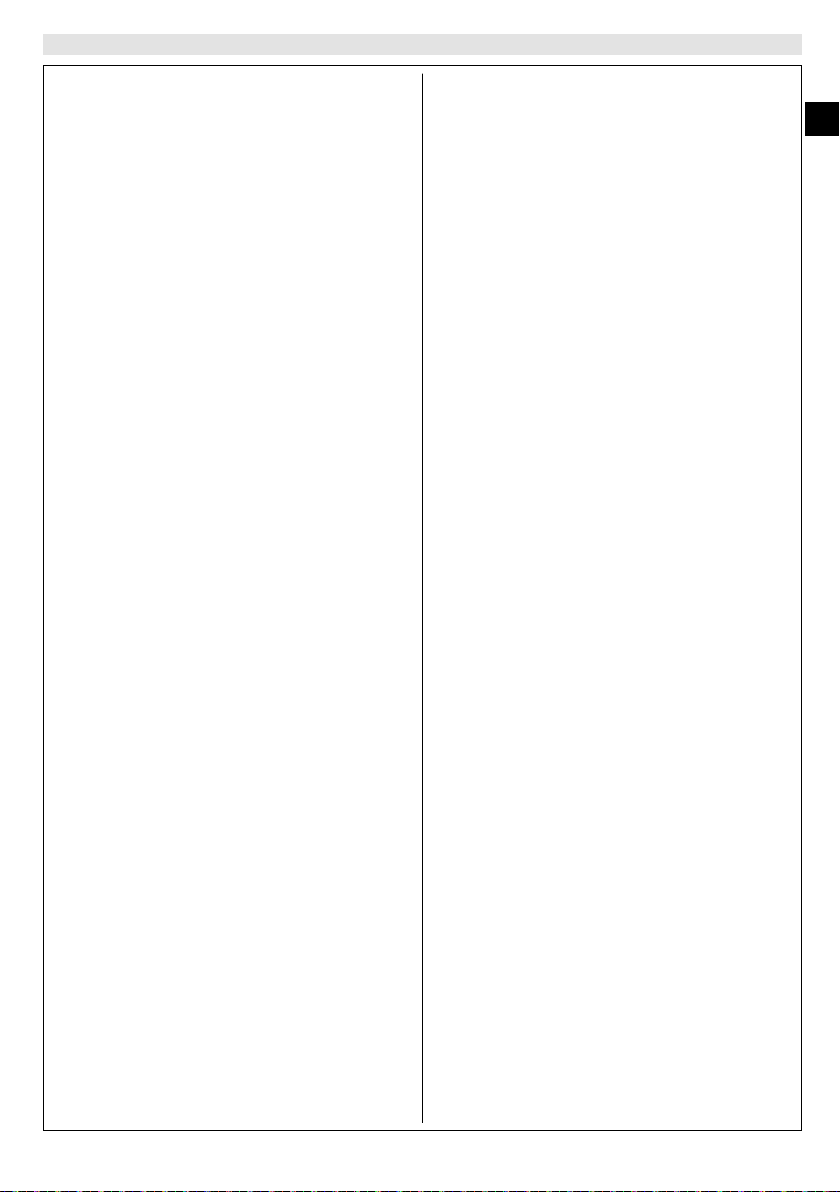

· Always carry the chain saw with the engine

stopped and chain brake engaged, the guide

bar and saw chain to the rear, and the muffler

away from your body. When transporting your

chain saw, use the appropriate guide bar

scabbard (Fig. 29). When transporting in a

vehicle, keep chain and bar covered with the

chain guard. Properly secure your saw to

prevent turnover, fuel spillage and damage to

the saw.

· Apply chain brake prior to any repositioning of

the operator in the cutting area.

· Do not operate a chain saw with one hand!

Serious injury to the operator, helpers,

bystanders, or any combination of these

persons may result from one-handed

operation. A chain saw is intended for two-

handed use.

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

9

Page 14

· Before you start the engine, make sure the saw

chain is not contacting any object. Never try to

en

start the saw when the guide bar is in a cut.

· Shut off the engine before setting down the

saw. Do not leave the engine running

GB

unattended.

· As an additional safety precaution, apply the

chain brake prior to setting down the saw.

F

· Only use the chain saw in well-ventilated

places, do not operate the chain saw in

D

explosive or flammable atmospheres or in

closed environments. Beware of carbon

monoxide poisoning.

E

· Do not operate saw from a ladder. Always cut

in a safe position.

NL

· Do not put pressure on the saw at the end of

the cut. Applying pressure can cause you to

lose control when the cut is completed.

P

· Do not cut near electric cables.

· Keep the handles dry, clean, and free of oil or

GR

fuel mixture.

· When the chain saw is running, grip the front

handle firmly with your left hand and the back

TR

handle with your right hand.

· When cutting a limb that is under tension, be

CZ

alert for springback so you will not be struck

when the tension in the wood fibre is released.

· Take great care when cutting small branches or

SK

shrubs which can block the chain, be thrown

back towards you or cause you to lose your

RUS

balance.

· Never cut with the chain saw above shoulder

height.

UK

· Never start up the chain saw without the chain

cover fitted.

PL

Precautions Against Kickback

H

LV

EST

LT

WARNING: Avoid kickback which can

result in serious injury. Kickback is the

backward, upward or sudden forward motion

of the guide bar occurring when the saw chain

near the upper tip of the guide bar contacts

any object such as a log or branch, or when

the wood closes in and pinches the saw chain

in the cut. Contacting a foreign object in

the wood can also result in loss of chain saw

control.

RO

· Rotational Kickback can occur when the

moving chain contacts an object at the upper

tip of the guide bar. This contact can cause the

chain to dig into the object, which stops the

chain for an instant. The result is an extremely

fast, reverse reaction which kicks the guide bar

up and back toward the operator (Fig. 15).

· Pinch-Kickback can occur when the wood

closes in and pinches the moving saw chain in

the cut along the top of the guide bar and the

saw chain is suddenly stopped. This sudden

stopping of the chain results in a reversal of the

chain force used to cut wood and causes the

saw to move in the opposite direction of the

chain rotation. The saw is driven straight back

toward the operator.

· Pull-In can occur when the moving chain

contacts a foreign object in the wood in the

cut along the bottom of the guide bar and the

saw chain is suddenly stopped. This sudden

stopping pulls the saw forward and away from

the operator and could easily cause the

operator to lose control of the saw.

Avoid Pinch-Kickback:

· Be extremely aware of situations or

obstructions that can cause material to pinch

the top of or otherwise stop the chain.

· Do not cut more than one log at a time.

· Do not twist the saw as the bar is withdrawn

from an undercut when bucking.

Avoid Pull-In:

· Always begin cutting with the engine at full

speed and the saw housing against wood.

· Use wedges made of plastic or wood. Never

use metal to hold the cut open.

Reduce the Risk of Kickback

Recognize that kickback can happen.

With a basic understanding of kickback,

you can reduce the element of surprise which

contributes to accidents.

· Never let the moving chain contact any object

at the tip of the guide bar.

· Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc. Eliminate or avoid any obstruction

that your saw chain could hit while you are

cutting through a particular log or branch.

· Keep your saw chain sharp and properly

tensioned. A loose or dull chain can increase

the chance of kickback occurring. Follow

manufacturer’s chain sharpening and

maintenance instructions. Check tension at

10

Page 15

regular intervals with the engine stopped,

never with the engine running. Make sure the

chain brake nuts are securely tightened after

tensioning the chain.

· Begin and continue cutting at full speed. If the

chain is moving at a slower speed, there is

greater chance of kickback

occurring.

· Cut one log at a time.

· Use extreme caution when re-entering a

previous cut.

· Do not attempt cuts starting with the tip of the

bar (plunge cuts).

· Watch for shifting logs or other forces that

could close a cut and pinch or fall into chain.

· Use the Reduced-Kickback Guide Bar and LowKickback Chain specified for your saw.

Maintain Control

· Keep a good, firm grip on the saw with both

hands when the

· engine is running and don’t let go. A firm grip

will help you reduce kickback and maintain

control of the saw. Keep the fingers of your left

hand encircling and your left thumb under the

front handlebar. Keep your right hand

completely around the rear handle whether

you are right handed or left handed. Keep your

left arm straight with the elbow locked.

· Position your left hand on the front handlebar

so it is in a straight line with your right hand on

the rear handle when making bucking cuts.

Never reverse right and left hand positions for

any type of cutting.

· Stand with your weight evenly balanced on

both feet.

· Stand slightly to the left side of the saw to keep

your body from being in a direct line with the

cutting chain.

· Do not overreach. You could be drawn or

thrown off balance and lose control of the saw.

· Do not cut above shoulder height. It is difficult

to maintain control of saw above shoulder

height.

Kickback Safety Features

WARNING: The following features are

included on your saw to help reduce the

hazard of kickback; however, such features

will not totally eliminate this dangerous

reaction. As a chain saw user, do not rely only

on safety devices. You must follow all safety

precautions, instructions, and maintenance in

this manual to help avoid kickback and other

forces which can result in serious injury.

· Reduced-Kickback Guide Bar, designed with a

small radius tip which reduces the size of the

kickback danger zone on the bar tip. A

Reduced-Kickback Guide Bar has been

demonstrated to significantly reduce the

number and seriousness of kick-backs when

tested in accordance with safety requirements

for gasoline powered chain saws as set by ANSI

B175.1 - 2000.

· Low-Kickback Chain, designed with a

contoured depth gauge and guard link that

deflect kickback force and allow wood to

gradually ride into the cutter. Low-Kickback

Chain has met kickback performance

requirements when tested on a representative

sample of chain saws below 3.8 cubic inch

displacement specified in ANSI B175.1 - 2000.

· Front Hand Guard, designed to reduce the

chance of your hand contacting the chain as

your hand slips off the front handlebar.

Chain Brake

Chain brakes are designed to rapidly stop the

chain from rotating. When the chain brake lever

/ hand guard is pushed toward the bar, the chain

should stop immediately. A chain brake does

not prevent kickback.

Chain brake should be cleaned and tested daily.

Clean the chain brake per the Maintenance-Chain

Brake Section and test per the Operation-Chain

Brake Operation Section.

WARNING: Even with proper maintenance,

the correct operation at the chain brake

under field conditions can not be certified.

WARNING: WE DO NOT REPRESENT AND

YOU SHOULD NOT ASSUME THAT THE

CHAIN BRAKE WILL PROTECT YOU IN THE

EVENT OF A KICKBACK. DO NOT RELY UPON

ANY OF THE DEVICES BUILT INTO YOUR SAW.

YOU SHOULD USE THE SAW PROPERLY AND

CAREFULLY TO AVOID KICKBACK.

Reduced-Kickback Guide Bar and LowKickback Chain

Reduced-kickback guide bars and low-kickback

saw chains reduce the chance and magnitude of

11

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

Page 16

kickback and are recommended. Your saw has a

low kickback chain and bar as original

en

equipment. Repairs on a chain brake should be

made by an authorized servicing dealer. Take

your unit to the place of

GB

purchase if purchased from a servicing dealer, or

to the nearest authorized service dealer.

F

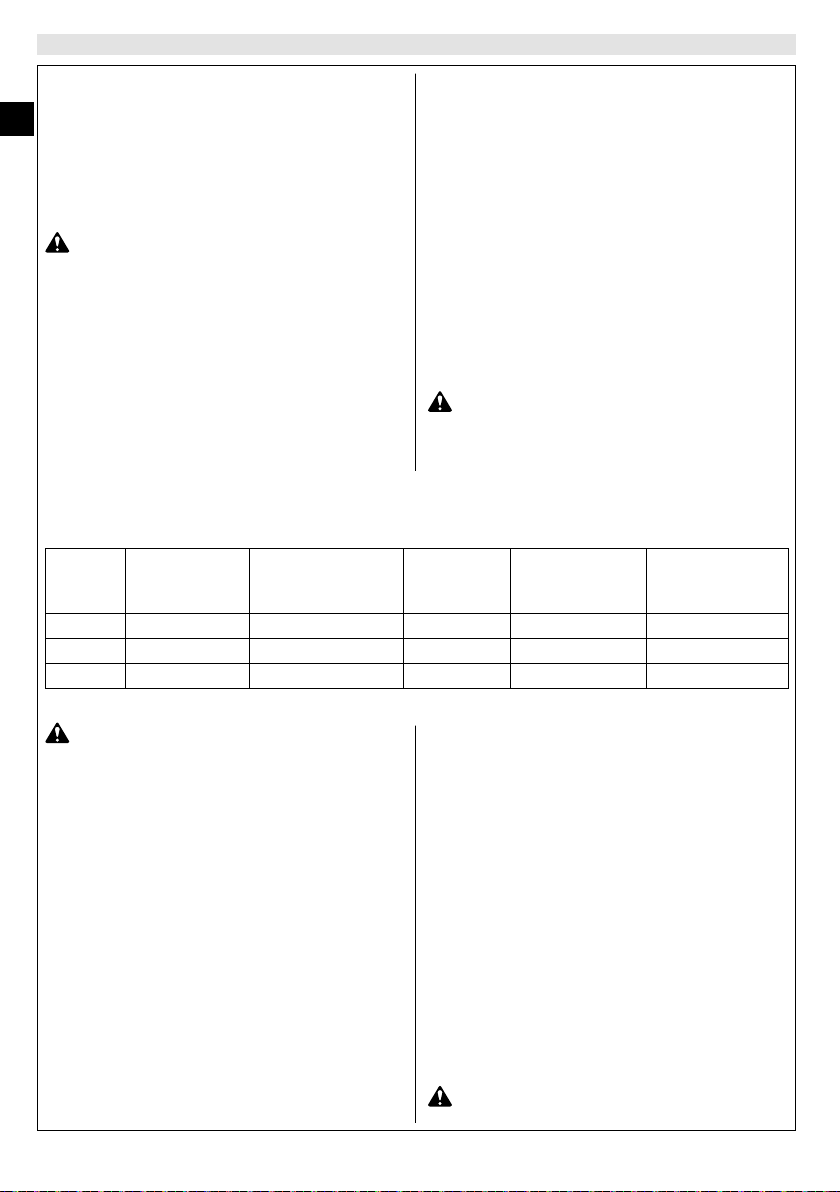

WARNING: Computed kickback angle

(CKA) listed on your saw and listed in

D

the CKA table below represents angle of

kickback your bar and chain combinations

will have when tested in accordance with CSA

E

(Canadian Standards Association) and ANSI

standards. When purchasing replacement bar

NL

and chain, considerations should be given

to the lower CKA values. Lower CKA values

represent safer angles to the user, higher

P

values indicate more angle and higher kick

energies. Computed angles represented

GR

Recommended bar and chain combination

TR

3/8” x .050” Low Prole Chain

CZ

LENGTH EFCO BAR P/N OREGON BAR P/N CHAIN TYPE

SK

RUS

12” EUSA50018 120SDEA041 91PX 91PX045X 27°

14” EUSA50000 140SDEA041 91PX 91PX052X 30°

16” EUSA50001 160SDEA041 91PX 91PX057X 35°

indicate total energy and angle associated

without activation of the chain brake during

kickback. Activated angle represents chain

stopping time relative to activation angle of

chain break and resulting kick angle of saw.

In all cases lower CKA values represent a

safer operating environment for the user. The

following guide bar and chain combinations

meet kickback requirements of CSA Standards

Z62.1, Z62.3, & ANSI B175.1 when used on

saws listed in this manual. Use of bar and

chain combinations other than those listed is

not recommended and may not meet the CKA

requirements per standard.

WARNING: Do not mount a bow guide on

any Efco chainsaw. The risk of kickback

is increased with a bow guide because of the

increased kickback contact area.

EFCO CHAIN

P/N (SAME AS

OREGON)

CKA WITHOUT

CHAIN BRAKE

UK

PL

H

LV

EST

LT

RO

WARNING: The computer derived angles

of par. 5.11 of ANSI B 175.1 – 2000 may

bear no relationship to actual kickback bar

rotation angles that may occur in real life

cutting situations.

In addition, features designed to reduce

kickback injuries may lose some of their

effectiveness when they are no longer in their

original condition, especially if they have

been improperly maintained.

Compliance with par. 5.11 of ANSI B 175.1 –

2000 does not automatically mean that in a

real life kickback the bar and chain will rotate

at most 45°.

Precautions to Reduce Vibration Risk

· The chain saw is provided with anti-vibration

(AV) system; never alter or modify it.

· Wear gloves and keep your hands warm.

· Keep the saw chain sharp and the saw,

12

including the AV system, well maintained. A

dull chain will increase cutting time, and

pressing a dull chain through wood will

increase the vibrations transmitted to your

hands.

· Maintain a firm grip at all times, but do not

squeeze the handles with constant, excessive

pressures, take frequent breaks. All the above

mentioned precautions do not guarantee that

you will not sustain whitefinger disease or

carpal tunnel syndrome. Therefore, continual

and regular users should monitor closely the

condition of their hands and fingers. If any of

the above symptoms appear, seek medical

advice immediately.

Maintenance Precaution

WARNING: Never operate a chain saw that

is damaged, improperly adjusted, or is

Page 17

not completely and securely assembled.

· Be sure that the saw chain stops moving when

the throttle control trigger is released. If the

saw chain moves at idle speed, the carburetor

may need adjusting, see Operation-Carburetor

Adjusting Section. If the saw chain still moves

at idle speed after adjustment has been made,

contact a Servicing Dealer for adjustment and

discontinue use until the repair is made.

WARNING: All chain saw service, other

than items in the Operator's Manual

maintenance instructions, have to be

performed by competent chain saw service

personnel. (If improper tools are used to

remove the flywheel or clutch, or if an

improper tool is used to hold the flywheel in

order to remove the clutch, structural damage

to the flywheel could occur which could

subsequently cause the flywheel to burst and

serious injury could result.)

· Never modify your saw in any way.

· Keep the handles dry, clean, and free of oil or

fuel mixture.

WARNING: Use only accessories and

replacement parts recommended.

· Never touch the chain or attempt to service

the saw while the engine is running.

· Never use fuel for cleaning operations.

· Keep the chain saw in a dry place, off the

ground with the chain guard on and the tanks

empty.

· If your chain saw is no longer usable, dispose

of it properly without damaging the

environment by handing it in to your local

Dealer who will arrange for its correct disposal.

· Replace immediately any safety device when

damaged or broken.

WARNING: The muffler and other parts

of the engine (e.g. fins of the cylinder,

spark plug) become hot during operation

and remain hot for a while after stopping the

engine.

To reduce risk of burns do not touch the

muffler and other parts while they are hot.

4. ASSEMBLING THE BAR AND CHAIN

WARNING: Check the chain tension

frequently when operating the chain

saw. Never touch or adjust the chain while

the engine is running. The saw chain is very

sharp, always wear protective gloves when

performing maintenance to the chain.

1 Ensure that the chain brake is not set by

pulling the chain brake lever / hand guard

towards the front handle as shown in Fig. 3.

Refer to Safety-Chain Brake and OperationChain Brake Sections for additional

information.

2. Remove the bar nut (A, Fig. 4) and the clutch

cover (B).

3. Remove and discard the plastic shipping

spacer (C, Fig. 5) that has been installed on

the bar studs in place of the bar for

shipping purposes.

4. Adjust the chain tensioning pin (D) fully

towards the brake band by turning the chain

tensioning screw (L) counterclockwise as

shown in inset (Fig. 5).

5. The guide bar (F) contains a bar stud slot that

fits over the bar studs (N). The guide bar also

contains two chain tensioning pin holes (G)

and two lubrication holes, one per side. The

bar is reversible and either tensioning pin hole

may be utilized with the chain tensioning pin.

6. Place the guide bar (F) onto the bar studs (H)

as shown in Fig. 5.

7. Position the guide bar (F) tip through the

chain (H) loop as shown in Fig. 6. The cutters

on the top of the guide bar should face

toward the bar nose, in the direction of the

chain rotation. See insert (M) in Fig. 8.

8. Fit the chain (H) over the rim sprocket (E) and

into bar groove.

CAUTION: Severe damage can occur to the

rim sprocket, clutch drum, guide bar and

chain, if the chain is not correctly seated into

the rim sprocket.

9. Replace the clutch cover (B). Turn the chain

tensioning screw (L) clockwise (as shown in

Fig. 7) until the chain tensioning pin (D) fits

into the chain tensioning pin hole (G). Install

the bar nut (A). Tighten the bar nut finger

tight only. The bar must be free to move for

tension adjustment.

13

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

Page 18

CAUTION: Failure to ensure that the chain

tensioning pin is in the chain tensioning

en

pin hole will result in severe damage to the

chain saw during reassembly of the clutch

cover.

GB

NOTE: If the clutch cover does not slide on

F

freely, check that the chain brake is not

engaged. To disengage chain brake with

clutch cover removed, grasp clutch cover as

D

shown in Fig. 3 and pull back on chain brake

lever / hand guard.

E

10. Remove all slack from chain by turning the

NL

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

chain tensioning screw (L) clockwise,

assuring that the chain seats into the bar

groove during tensioning.

P

11. Lift the tip of the guide bar up to check for

sag, see Fig. 10. Release the tip of the guide

bar, and turn the chain tensioning screw (L)

1/2 turn clockwise. Repeat this process until

sag does not exist.

12. Hold the tip of the guide bar up and tighten

the bar nuts

securely as shown in Fig. 9.

13. Chain is correctly tensioned when there is no

slack on the underside of the guide bar, the

chain is snug, but it can be

turned by hand without binding, see Fig. 10.

Ensure that the chain brake is not set.

NOTE: If chain is too tight, it will not rotate.

Loosen bar nuts slightly and turn adjusting

screw 1/4 turn counterclockwise. Lift the tip of

the guide bar up and retighten bar nuts.

WARNING: Check the chain tension

frequently when operating the chain

saw. Never touch or adjust the chain while

the motor is running. The saw chain is very

sharp, always wear protective gloves when

performing maintenance to the chain.

WARNING: The replacement chain

must have the same or lower kickback

characteristics as that originally supplied.

WARNING: If the saw is operated with a

loose chain, the chain could jump off the

guide bar and result in serious injury.

WARNING: Never start the saw with the

sprocket cover loose.

CHAIN TENSION

WARNING: Never touch or adjust the

chain while the motor is running. The saw

chain is very sharp, always wear protective

gloves when performing maintenance to the

chain.

1. Stop the engine before setting the chain

tension. Loosen the guide bar nuts slightly,

turn the chain tensioning screw clockwise to

tension the chain. Refer to AssemblyAssembling the Bar and Chain Section.

Retighten guide bar nuts. A cold chain is

correctly tensioned when there is no slack on

the underside of the guide bar, the chain is

snug, but it can be turned by hand without

binding. For warm chain, see Item 3.

2. Chain must be retensioned whenever the

flats on the drive link tangs hang out of the

bar groove.

3. During normal saw operation, the

temperature of the chain will increase. The

drive link tangs of a correctly tensioned warm

chain will hang approximately .050” (1.25

mm) out of the bar groove. To help determine

the correct warm chain tension, the tip of the

combination wrench can be used as a guide.

CAUTION: Chain tensioned while warm,

may be too tight upon cooling. Check the

"cold tension" before next use.

CAUTION: A new chain has to be

retensioned more often than one that

has been in use for some time.

Breaking-in the Chain

New chains will stretch and must be tightened

frequently.

Lift the chain out of the bar groove and lubricate

the bar groove with additional oil. Place the chain

saw on a piece of cardboard or scrap plywood.

Start the chain saw (refer to the OperationStarting Engine Section) and allow it to run at

moderate speed for approximately one (1)

minute. Stop the engine. Check that the oil

pump is working properly. The cardboard should

have excess oil from the chain rotation if the oil

pump is working properly. Adjust the chain

14

Page 19

tension (refer to Operation-Chain Tension

Section). Start the saw again and make a few cuts

in a log to heat up the chain. Stop the engine and

re-adjust chain again. Repeat this process until

the chain retains proper warm tension

adjustment in Operation-Chain Tensioning

Section. Never touch the ground with the

chain.

Bucking Spike

WARNING: Your chain saw is fitted with a

bucking spike. The bucking spike is very

sharp and can cause injury. Be extremely

careful when working near the bucking spike.

5. STARTING

FUELING

This product is powered by a 2-cycle engine and

requires pre-mixing gasoline and 2-cycle oil.

Pre-mix unleaded gasoline and 2-cycle engine oil

in a clean container approved for gasoline.

RECOMMENDED FUEL: THIS ENGINE IS

CERTIFIED TO OPERATE ON UNLEADED GASOLINE

INTENDED FOR AUTOMOTIVE USE WITH AN

OCTANE RATING OF 89 ([R + M] / 2) OR HIGHER.

Mix 2-cycle engine oil with gasoline according to

the instructions on the package.

We strongly recommend the use of 2% (1:50)

Efco two cycle engine oil, which is specifically

formulated for all air-cooled two-stroke engines.

The correct oil / fuel proportions shown in the

table are suitable when using the Efco PROSINT

2 and EUROSINT 2 or an equivalent high-quality

engine oil (JASO specification FD or ISO

specification L-EGD).

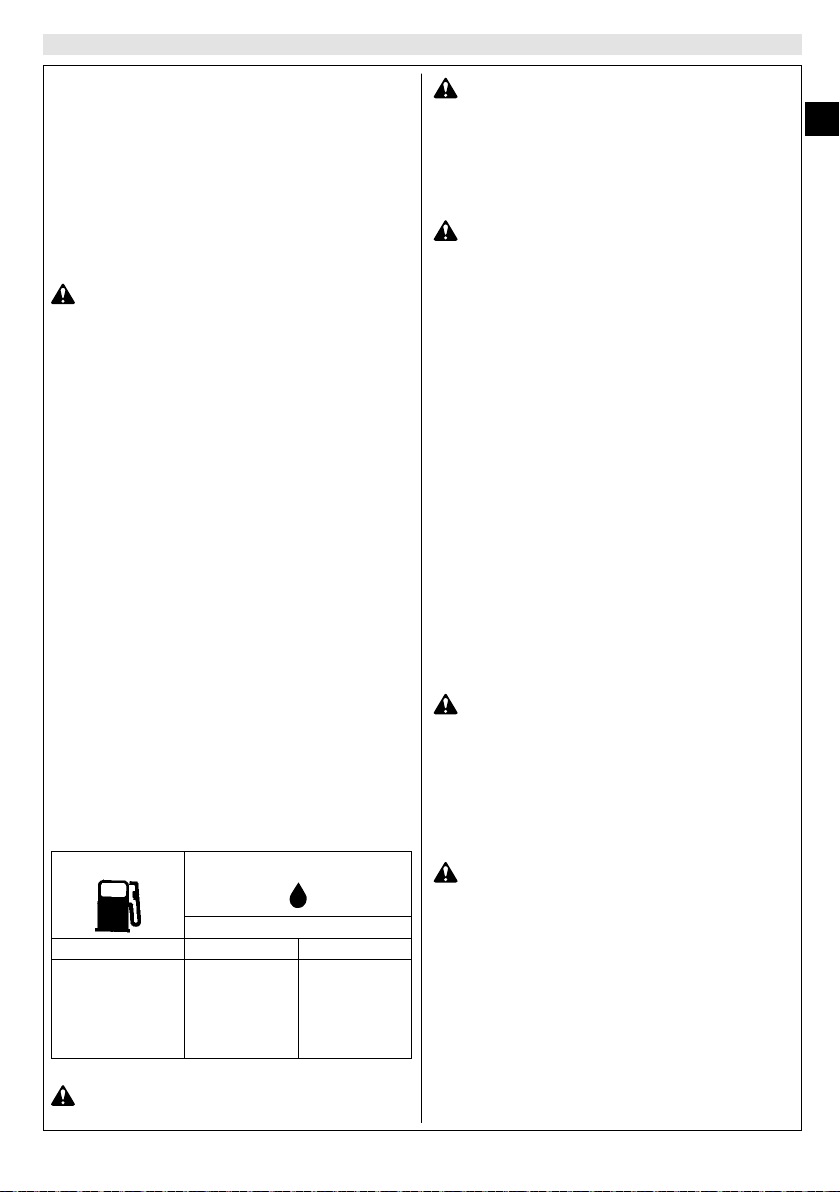

GASOLINE OIL

2% - 50:1

ℓ ℓ

1

5

10

15

20

25

CAUTION: DO NOT USE AUTOMOTIVE OIL

OR 2-CYCLE OUTBOARD OIL.

0,02

0,10

0,20

0,30

0,40

0,50

(cm3)

(20)

(100)

(200)

(300)

(400)

(500)

CAUTION:

- Match your fuel purchases to your

consumption; don’t buy more than you

will use in one or two months;

- Store gasoline in a tightly-closed

container in a cool, dry place.

CAUTION - For the mixture, never use a

fuel with an ethanol percentage higher

than 10%; gasohol (mixture of gasoline and

ethanol) up to 10% ethanol or E10 fuel are

acceptable.

When using an Oxygenated Gasoline a good

practice of Fuel Management is necessary.

Gasoline Oxygenated with alcohol readily takes/

up water when it is present; the water may be

condensed out of humid air or be a contaminant

in the fuel system, including tank.

The use of Oxygenated Gasoline may cause the

occurrence of vapor-lock easier.

NOTE - Prepare only the quantity of mixture

required for immediate use; do not leave fuel in

the tank or a container for a long time. Were

commend the use of the additive Emak ADDITIX

2000 code 001000972 if the mixture is to be

stored for 12 months.

Alkylate gasoline

CAUTIONS – Alkylate fuels have different

density than normal fuel. Therefore

engines, set with normal fuel, need different H

jet regulation to avoid critical issues. For this

operation it’s necessary turned at a Licensed

Service Dealer.

FILLING THE TANK

WARNING: Follow safety instruction for

fuel handling. Always shut off engine

before fuelling. Never add fuel to a machine

with a running or hot engine. Move at least 3

m from refuelling site before starting engine.

DO NOT SMOKE!

1. Clean surface around fuel cap to prevent

contamination.

2. Loosen fuel cap slowly.

3. Carefully pour fuel mixture into the tank.

Avoid spillage.

4. Prior to replacing the fuel cap, clean and

15

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

Page 20

inspect the gasket.

5. Immediately replace fuel cap and hand

en

tighten. Wipe up any fuel spillage.

GB

NOTE: It is normal for smoke to be emitted

from a new engine during and after first use.

F

WARNING: Check for fuel leaks, if any

are found, correct before use. Contact a

D

Servicing Dealer if necessary.

E

Chain Oil System

The bar and chain require continuous lubrication.

NL

Lubrication is provided by the automatic oiler

system when the oil tank is kept filled. Lack of oil

P

will quickly ruin the bar and chain. Too little oil

will cause overheating shown by smoke coming

GR

from the chain and/or discoloration of the bar. In

freezing weather oil will thicken, making it

TR

necessary to thin bar and chain oil with a small

amount (5 to 10%) of Diesel Fuel or kerosene. Bar

and chain oil must be free flowing for the oil

CZ

system to pump enough oil for adequate

lubrication.

SK

RUS

UK

PL

H

LV

EST

LT

RO

CAUTION: Never use waste oil. Always use

biodegradable lubrificant that is specific

for bar and chain and that is better for the

environment and chainsaw’s parts.

CAUTION: Do not use dirty, used or

otherwise contaminated oils. Damage

may occur to the oil pump, bar, or chain.

WARNING: Do not use waste oil! Medical

studies have shown that renewed contact

with waste oil can cause skin cancer.

1. Fill the oil tank every time engine is fueled.

Chain saw should use approximately one tank

of oil per tank of fuel.

2. The automatic oil pump is a positive

displacement pump operated through gears

driven off the clutch drum assembly.

The pump will not oil at idle speeds.

Preparation for Cutting

Proper Grip on Handles.

Refer to Safety Section for appropriate Safety

Equipment.

1. Wear non-slip gloves for maximum grip and

protection.

WARNING: Hold the saw firmly with both

hands. Always keep your LEFT HAND on

the front handlebar and your RIGHT HAND on

the rear (throttle) handle, so that your body is

to the left of the chain line. Never use a crosshanded grip, or any stance which would place

your body or arm across the chain line. Lefthanders should follow these instructions too.

2. Maintain a proper grip on the saw whenever

the engine is running. The fingers should

encircle the handlebar and the thumb is

wrapped under the handlebar. This grip is

least likely to be broken (by a kickback or

other sudden reaction of the saw). Any grip in

which the thumb and fingers are on the same

side of the handle, is dangerous because a

slight kick of the saw can cause loss of control.

WARNING:

Proper Cutting Stance

- Weight should be balanced on both

feet - feet on solid ground.

- Keep arm with elbow locked in a

"straight arm" position to withstand

any kickback force.

- Your body should always be to the left

of the chain line.

- Thumb on underside of handlebar.

Basic Cutting Procedure

Practice cutting a few small logs using the

following technique to get the "feel" of using

your saw before you begin a major sawing

operation.

1. Take the proper stance in front of the wood

with the saw idling.

2. Accelerate the engine to full throttle just

before entering the cut by squeezing the

throttle trigger.

3. Begin cutting with the saw against the log.

16

Page 21

4. Keep the engine at full throttle the entire time

you are cutting.

5. Allow the chain to cut for you; exert only light

downward pressure. If you force the cut,

damage to the bar, chain, or engine can result.

6. Release the throttle trigger as soon as the cut

is completed, allowing the engine to idle. If

you run the saw at full throttle without a

cutting load, unnecessary wear or damage

can occur to the chain, bar, and engine.

7. Do not put pressure on the saw at the end of

the cut.

Work Area Precautions

WARNING: Cut only wood or materials

made from wood. Do not cut metal,

plastics, masonry, or non-wood building

materials.

· Never allow children to operate your saw. Only

allow others to use this chainsaw who have

read this Operator's Manual or received

adequate instructions for the safe and proper

use of this chain saw.

· Keep everyone - helpers, bystanders, children,

and animals a safe distance from the cutting

area. During felling operations, the safe

distance should be a least twice the height of

the largest trees in the felling area. During

bucking operations, keep a minimum distance

of 35 feet (10 m) between workers.

· Always cut with both feet on solid ground to

prevent being pulled off balance.

· Do not cut above chest height, as a saw held

higher is difficult to control against kickback

forces.

· Do not fell trees near electrical wires or

buildings. Leave this operation for

professionals.

· Cut only when visibility and light are adequate

for you to see clearly.

· Do not cut from a ladder, this is extremely

dangerous. Leave this operation for

professionals.

· Stop the saw if the chain strikes a foreign

object. Inspect the saw and repair parts as

necessary.

· Keep the chain out of dirt and sand. Even a

small amount of dirt will quickly dull a chain

and increase the possibility of kickback.

· Stop the engine before setting the saw down.

· Be particularly cautious and alert while

wearing hearing protection because such

equipment may restrict your ability to hear

sounds indicating danger (calls, signals,

warnings, etc).

· Be extremely cautious when working on slopes

or uneven ground.

· When a chain saw is being used, a fire

extinguisher should be available.

·

WARNING – Never start the saw engine

without the bar, chain and clutch cover

(chain brake) assembled - or else the clutch can

come loose and cause personal injuries.

STARTING THE ENGINE

WARNING: Keep body to the left of the

chain line. Never straddle the saw or

chain, or lean over past the chain line. The

chain brake must be engaged when starting

the saw.

· Place the chain saw on level ground and

ensure that no objects or obstructions are in

immediate vicinity which could come in

contact with the bar and chain. Hold the front

handle firmly with the left hand and put your

right foot onto the base of the rear handle, see

Fig. 14.

· Set the chain brake by pushing the chain brake

lever / hand guard forward (towards the bar),

to the Brake Position as shown in Fig. 12. Refer

to Safety-Chain Brake and Operation-Chain

Brake Sections for additional information.

· Slowly push the purge bulb 6 to 8 times (14,

Fig. 2).

· Pull the choke lever (D) to the fully extended

position (

· Pull the starter rope until the first firing of the

engine is heard (no more than five (5) pulls). A

new unit may require additional pulls.

· Push the choke lever (E) completely in the

OPEN position, as shown in Fig. 13.

· Pull the starter rope until the engine starts.

· Immediately after the engine has started,

depress the throttle trigger lockout (3, Fig. 2),

quickly squeeze and release the throttle trigger

(2). Place chain brake lever / hand guard into

the run position as shown in Fig. 3. Refer to

Safety-Chain Brake and Operation-Chain Brake

Sections for additional information.

· When pulling the starter rope, do not use the

full extent of the rope as this can cause the

), as shown in Fig. 13.

CLOSE

17

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

Page 22

rope to break. Do not let starter rope snap

back. Hold the handle and let the rope rewind

en

slowly.

GB

D

NL

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

WARNING: Do not cut material with the

choke/fast idle lever at the FULL CHOKE

position. Do not operate your chainsaw with

F

the starting throttle lock engaged. Cutting

with the starting throttle lock engaged does

not permit the operator proper control of the

saw or chain speed.

E

NOTE - STARTING WARM ENGINE:

Follow above starting instructions, but do not

use the Full Choke position for start up again.

To set fast idle for warm engine starting, pull

choke out completely and push back in to the

P

original Run Position.

WARNING: Weather conditions and

altitude may affect carburetion. Do not

allow bystanders close to the chain saw while

adjusting the carburetor.

WARNING: Never attempt to start the

chainsaw when the guide bar is in a cut

or kerf.

Breaking-in the Engine

The engine reaches the maximum power after

5-8 hours of activity.

During this period of breaking-in do not make

the machine function idly at full throttle, to avoid

excessive functioning stress.

CAUTION! – During the braking-in period

do not vary the carburetion to obtain a

presumed power increment; the engine can

be damaged.

Difficult Starting (or starting a flooded

engine)

The engine may be flooded with too much fuel if

it has not started after 10 pulls. Flooded engines

can be cleared of excess fuel by following the

warm engine starting procedure listed above.

Starting could require pulling the starter rope

handle many times depending on how badly the

unit is flooded. If engine fails to start refer to the

TROUBLESHOOTING TABLE (page 28).

Engine is Flooded

If you did not move the choke lever to warm

start, quickly enough after the engine began to

fire, the combustion chamber is flooded.

· Pry off the spark plug boot.

· Unscrew and dry off the spark plug.

· Open the throttle wide.

· Pull the starter rope several times to clear the

combustion chamber.

· Refit the spark plug and connect the spark

plug boot, press it down firmly.

· Set the choke lever to warm start (OPEN) –

even if engine is cold.

· Now start the engine.

6. STOPPING THE ENGINE

Release the throttle lever (2, Fig. 2) and let

the engine return to idle. Turn off the engine,

pushing the STOP button (10).

Do not put the chain saw on the ground

when the chain is still moving.

CAUTION: The chain contracts as it cools

down. If it is not slackened, it could

damage the crankshaft and bearings.

Pre-operation checking

WARNING: THE SAW CHAIN SHOULD

NEVER TURN AT IDLE. Turn the idle speed

screw “T” counterclockwise to reduce the idle

RPM and stop the chain, or contact a Servicing

Dealer for adjustment and discontinue use

until the repair is made.

Serious personal injury may result from the

saw chain turning at idle.

7. USE

Chain Brake Operation

Refer to Safety-Chain Brake Section before

use.

The chain brake operating condition should be

checked prior to each use as follows:

1. Start the engine and grasp front and rear

handles securely with both hands.

2. Pull the throttle trigger to bring the chain saw

up to full speed. Using the back of your left

hand, engage the chain brake by pushing the

18

Page 23

chain brake lever / hand guard toward the bar

while the chain is rotating rapidly.

3. The chain brake should engage and stop the

chain immediately, if not, take the saw to a

Servicing Dealer for repair and discontinue

use until the repair is made.

4. Reset the chain brake back into the run

position by grasping the guide bar side (right

side from operator's position) of the chain

brake lever / hand guard and pull toward the

front handle until an audible click is heard. See

Fig. 3.

WARNING: If chain brake does not stop

the chain immediately, take the saw to a

Servicing Dealer for repair prior to use.

WARNING: An improperly maintained

chain brake may increase the time needed

to stop the chain after activation, or may not

activate at all.

WARNING: This chainsaw equipped with

a top handle is designed specifically

for tree surgery and maintenance. Due to

the special handle design (closely spaced

handles), there is an increased risk in its

use. For this reason this special chainsaw

should be used only for work in a tree by

persons trained in special cutting and working

techniques. This type of chainsaw cannot be

used for felling operations; for this reason,

this manual does not contain instructions for

felling. For bucking and other operations on

ground the use of a normal forest chainsaw is

highly recommended.

WARNING: During bucking operations

always stand on the uphill side so that the

cut-off section of the log can not roll over you.

WARNING: If saw becomes pinched or

hung in a log, don’t try to force it out. You

can lose control of the saw resulting in injury

and/or damage to the saw. Stop the saw,

drive a wedge of plastic or wood into the cut

until the saw can be removed easily. Restart

the saw and carefully reenter the cut. Do not

attempt to restart your saw when it is pinched

or hung in a log.

WARNING: Do not stand on the log being

cut. Any portion can roll causing loss of

footing and control. Do not cut in an area

where logs, limbs, and roots are tangled.

Drag the logs into a clear area before cutting

by pulling out exposed and cleared logs first.

Bucking with a Wedge

If the wood diameter is large enough for you to

insert a soft bucking wedge without touching

the chain, you should use the wedge to hold the

cut open to prevent pinching.

Logs Under Stress

Make the first bucking cut 1/3 of the way through

the log and finish with a 2/3 cut on the opposite

side. As the log is being cut, it will tend to bend.

The saw can become pinched or hung in the log

if you make the first cut deeper than 1/3 of the

diameter of the log.

Give special attention to logs under stress to

prevent the bar and chain from pinching.

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

Bucking

Bucking is the term used for cutting a fallen tree

to the desired log length.

· Cut only one log at a time.

WARNING: Support small logs on a saw

horse or another log while bucking. Never

allow another person to hold the log while

cutting and never hold the log with your leg

or foot.

WARNING: Keep a clear cutting area. Make

sure that no objects can contact the guide

bar nose and chain during cutting, this can

cause kickback (Fig. 15).

Types of Cutting Used

Overbucking

Begin on the top side of the log with the bottom

of the saw against the log; exert light pressure

downward.

Underbucking

Begin on the under side of the log with the top of

the saw against the log; exert light pressure

upward. During underbucking, the saw will tend

to push back at you. Be prepared for this reaction

and hold the saw firmly to maintain control.

WARNING: Never turn saw upside down

to undercut. The saw cannot be controlled

19

H

LV

EST

LT

RO

Page 24

in this position. Always make your first cut

on the compression side of the log. The

en

compression side of the log is where the

pressure of the log’s weight is concentrated.

GB

Limbing and Pruning

WARNING: Be alert for and guard against

F

kickback. Do not allow the moving chain

to contact any other branches or objects at

the nose of the guide bar when limbing or

D

pruning. Allowing such contact can result in

serious injury.

E

· Work slowly, keeping both hands on the saw

with a firm and proper grip. Maintain secure

NL

footing and balance.

· Keep the tree between you and the chain while

P

limbing. Cut from the side of the tree opposite

the branch you are cutting.

· Do not cut from a ladder, this is extremely

GR

dangerous. Leave this operation for

professionals.

TR

· Do not cut above chest height as a saw held

higher is difficult to control against kickback.

· Be alert for springback. Watch out for branches

CZ

that are bent or under pressure. Avoid being

struck by the branch or the saw when the

SK

tension in the wood fibers is released.

· Keep a clear work area. Frequently clear

branches out of the way to avoid tripping over

RUS

them.

UK

PL

H

WARNING: Only persons especially

trained in tree service operations are

allowed to climb into a tree to limb or

prune. Do not stand on ladders, platforms,

a log or in any position which can cause you

to lose your balance or control of the saw.

cutting techniques described in BUCKING

WITHOUT A SUPPORT.

· Always use an overcut to cut small and freely

hanging limbs. Undercutting could cause limbs

to fall and pinch the saw.

Pruning Operation

· When pruning trees it is important not to make

the flush cut next to the main limb or trunk

until you have cut off the limb further out to

reduce the weight. This prevents stripping the

bark from the main member.

· Underbuck the branch 1/3 through for your

first cut, your second cut should overbuck to

drop the branch off.

· Now make your finishing cut smoothly and

neatly against the main member so the bark

will grow back to seal the wound.

WARNING: If the limbs to be pruned are

above chest height, hire a professional to

perform the pruning.

Springpoles

A springpole is any log, branch, rooted stump, or

sapling which is bent under tension by other

wood so that it springs back if the wood holding

it is cut or removed. On a fallen tree, a rooted

stump has a high potential of springing back to

the upright position during the bucking cut to

separate the log from the stump. Watch out for

springpoles. They are potentially dangerous.

WARNING: Springpoles are dangerous

and could strike the operator, causing

the operator to lose control of the chain saw.

This could result in severe or fatal injury to

the operator.

LV

Limbing Operation (Fig. 22)

· Always limb a tree after it is cut down. Only

then can limbing be done safely and properly.

EST

· Leave the larger limbs underneath the felled

tree to support the tree as you work.

LT

· Start at the base of the felled tree and work

toward the top, cutting branches and limbs.

Remove small limbs with one cut.

RO

· Keep the tree between you and the chain. Cut

from the side of the tree opposite the branch

you are cutting.

· Remove larger, supporting branches with the

20

8. MAINTENANCE

Chain Maintenance

Use only Dual Raker low-kickback chain on this

saw. This fast-cutting chain will provide kickback

reduction when properly maintained.

For smooth and fast cutting, raker chain needs to

be maintained properly. The chain requires

sharpening when the wood chips are small and

powdery, the chain must be forced through the

wood during cutting, or the chain cuts to one

side. During maintenance of your chain, consider

Page 25

the following:

1. Improper filing angle of the side plate can

increase the risk of a severe kickback.

2. Raker (depth gauge) clearance: Too much

increases the potential for kickback; not

enough decreases cutting ability.

3. If cutter teeth have hit hard objects such as

nails and stones, or have been abraded by

mud or sand on the wood, have

Servicing Dealer sharpen chain.

4. In rare instances drive tangs could flare

resulting in chain not rotating freely. Replace

chain if necessary.

NOTE: Inspect the rim sprocket for wear or

damage when replacing the chain. If signs of

wear or damage are present in the areas, have

the rim sprocket replaced by a Servicing Dealer.

How to Sharpen the Cutters

Be careful to file all cutters to the specified angles

and to the same length, as fast cutting can be

obtained only when all cutters are uniform.

1. Wear gloves for protection. Tighten the chain

tension enough that the chain does not

wobble. Do all of your filing at the mid-point

of the bar. See Operation-Chain Tension.

2. Use a 3/16" diameter round file and holder.

3. Keep the file level with the top plate of the

tooth. Do not let the file dip or rock.

4. Using light but firm pressure, stroke towards

the front corner of the tooth. Lift file away

from the steel on each return stroke.

5 Put a few firm strokes on every tooth. File all

left hand cutters in one direction. Then move

to the other side and file the right hand

cutters in the opposite direction. Occasionally

remove filings from the file with a wire brush.

CAUTION: Dull or improperly sharpened

chain can cause excessive engine speed

during cutting which may result in severe

engine damage.

WARNING: It is absolutely essential to

comply with the angles and dimensions

specified below. If the saw chain is incorrectly

sharpened – and in particular if the depth

gauge is set too low – there is a risk of

increased kickback of the chainsaw, with

resulting risk of injury.

Failure to replace or repair damaged chain can

cause serious injury.

The saw chain is very sharp, always wear

protective gloves when performing

maintenance to the chain.

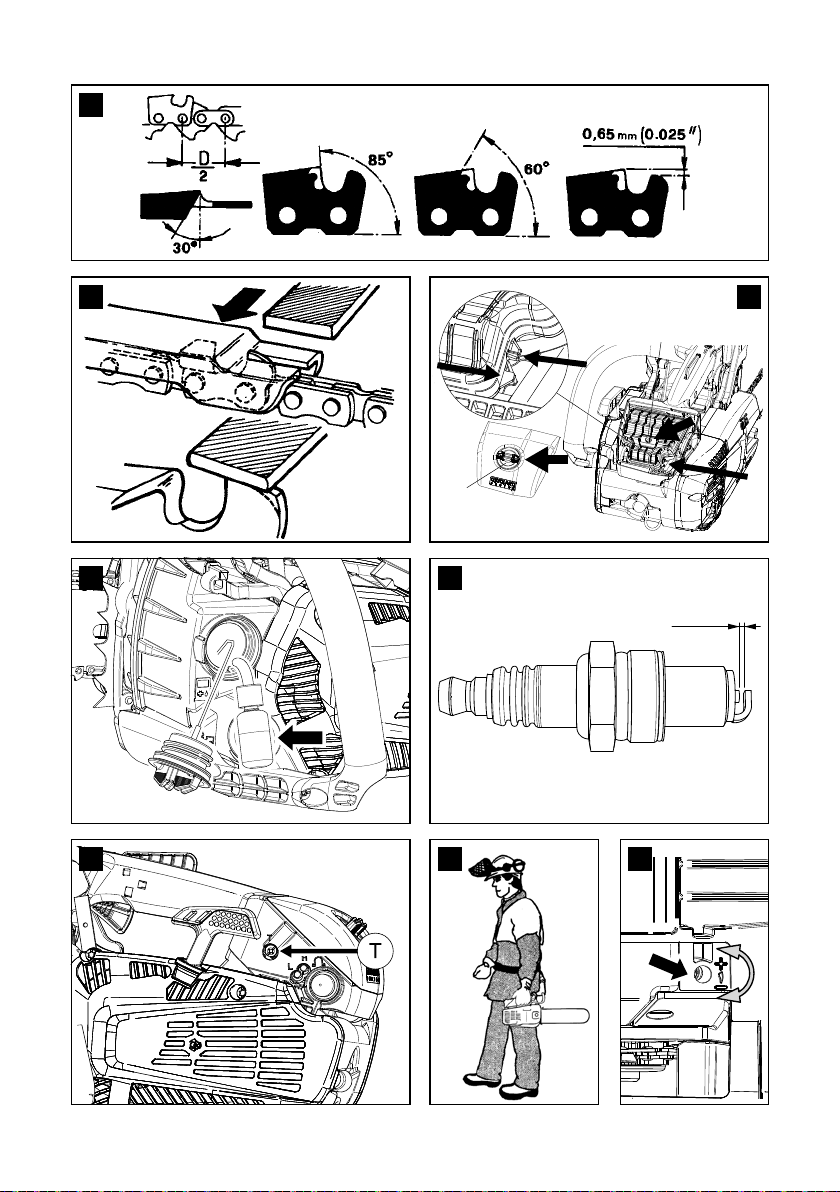

Top Plate Angle

File holders are marked with guide marks to align

file properly to produce correct TOP PLATE

ANGLE.

G) CORRECT- 30°

H) LESS THAN 30° - For Cross Cutting.

I) MORE THAN 30°- Feathered Edge Dulls

Quickly.

Side Plate Angle (Fig. 23)

J) CORRECT- 85° - 90°

Produced automatically if correct diameter

file is used in file holder.

K) “HOOK”- “Grabs” and dulls quickly. Increases

potential of KICKBACK.

Results from using a file with diameter too

small, or file held too low.

L) BACKWARD SLOPE- Needs too much feed

pressure, causes excessive wear to bar and

chain.

Results from using a file with diameter too

large, or file held too high.

Depth Gauge Clearance

1. The depth gauge should be maintained at a

clearance (Fig. 23) between .025 (0.65 mm)

and .024" (0.6 mm). Use a depth gauge tool for

checking the depth gauge clearances.

2. Every time the chain is filed, check the depth

gauge clearance.

Use a Flat File and a Depth Gauge Jointer to

lower all gauges uniformly (Fig. 24).

P) FLAT FILE

Q) DEPTH GAUGE JOINTER

Depth gauge jointers available in .020" to

.035" (0.5 mm to 0.9 mm). After lowering each

depth gauge, restore original shape by

rounding the front. Be careful not to damage

adjoining drive links with the edge of the file.

CAUTION: After sharpening, clean

the chain thoroughly, remove filings

or grinding dust – lubricate the chain

thoroughly.

21

en

GB

F

D

E

NL

P

GR

TR

CZ

SK

RUS

UK

PL

H

LV

EST

LT

RO

Page 26

Guide Bar Maintenance

Every day of use, reverse the guide bar on the

en

saw to distribute the wear for maximum bar life.

The bar should be cleaned every day of use and

checked for wear and damage.

GB

Feathering or burring of the bar rails is a normal

process of bar wear. Such faults should be

F

smoothed with a file or stone as soon as they

occur.

A bar with any of the following faults should

D

be replaced:

• Wear inside the bar rails which permits the

E

chain to lay over sideways.

• Bent guide bar.

• Cracked or broken rails.

NL

• Spread rails.

In addition, guide bars with a sprocket at their tip

P

must be lubricated periodically with a grease

syringe to extend the guide bar life.

Turn the guide bar and check that the lubrication

GR

holes and chain groove are free from impurities.

TR

WARNING - Never mount a new chainsaw

on a worn sprocket.

CZ

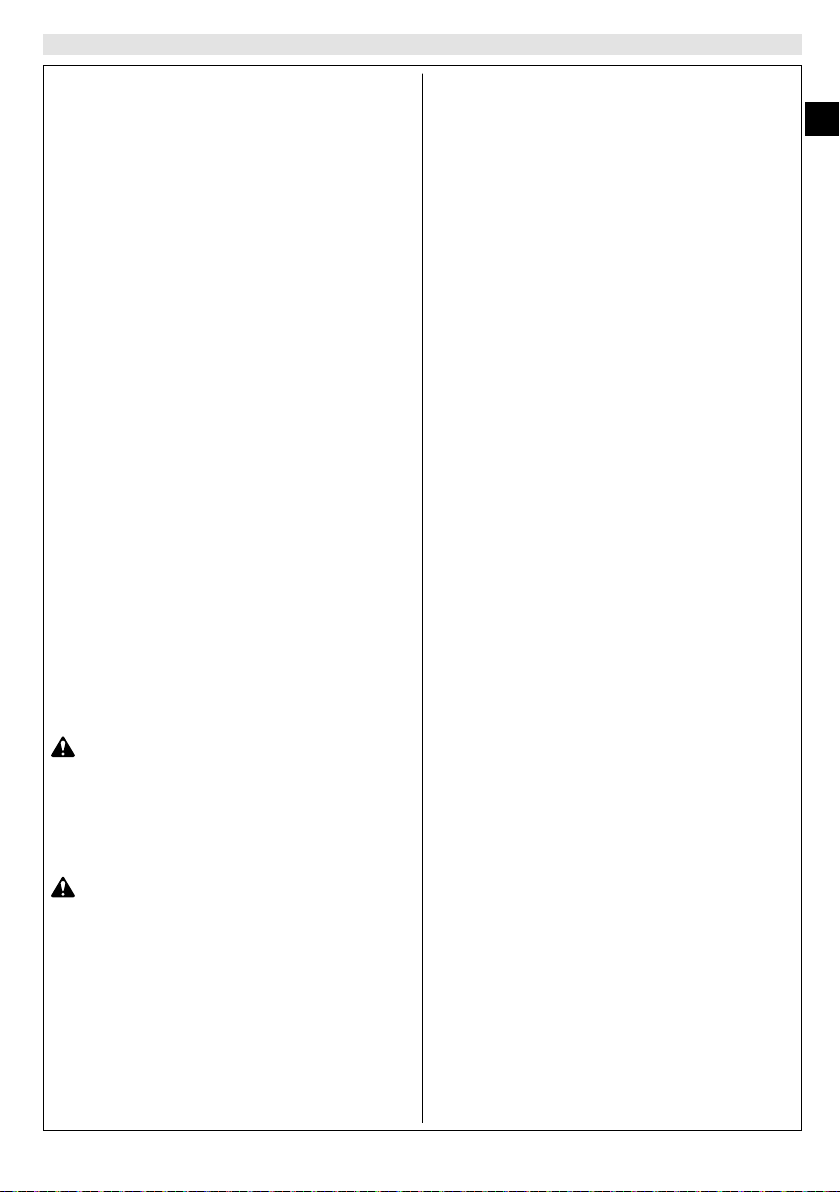

AIR FILTER

SK

RUS

UK

PL

H

LV

EST

LT

RO

WARNING: Do not clean filter in

gasoline or other flammable solvent to

avoid creating a fire hazard or producing

harmful evaporative emissions.

Completely loosen the air filter cover knob (A,

Fig. 25) by turning counterclockwise, remove air

filter cover and check the air filters (B) each day.

Clean filter with soapy water, rinse and dry

thoroughly prior to installing. Reinstall the air

filters into cover. Place the air filter cover onto the

chain saw. Tighten the air filter cover knob

securely.

A used air filters can never be completely

cleaned. It is advisable to replace your air filters

with a new one after six month of operation.

CAUTION: Never run the engine without

the air filters, serious damage could

result.

Make sure the air filters is correctly placed in

the air filter cover before reassembly.

Always replace damaged filters.

Do not clean a filters with a brush.

FUEL FILTER - Check the fuel filter periodically.

Replace it if too dirty (Fig. 26).

OIL PUMP (automatic/adjustable) - Flow

adjustment is pre-set by the manufacturer. Oil

flow can be adjusted by the operator according

to specific requirements by means of the special

adjusting screw (Fig. 30). Oil flow occurs only

when the chain is moving.

WARNING - Never use scavenge oil.

STARTING UNIT - Use a brush or compressed

air to keep the cooling louvers of the starter

assembly free and clean.

WARNING: The coil spring is under tension

and could fly apart causing serious

injuries. Never try to disassembly or modify it.

ENGINE - Clean the cylinder & flywheel fins

with compressed air or a brush periodically.

Dangerous overheating of engine may occur due

to impurities on the cylinder.

WARNING: Never run the saw without all

the parts, including the drivecase cover

and starting housing, securely in place.

Because parts can fracture and pose a

danger of thrown objects, leave repairs to

the flywheel and clutch to trained Servicing

Dealers.

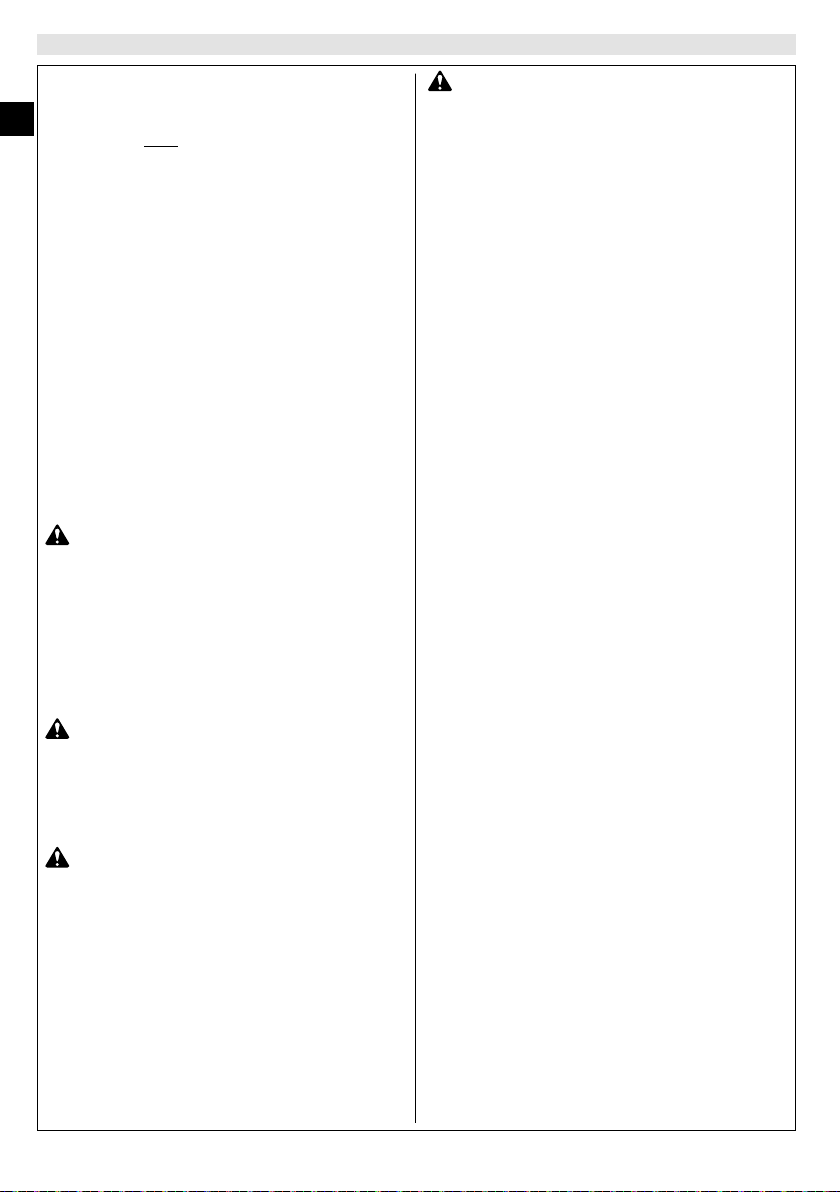

SPARK PLUG - Clean the spark plug and check

the electrode gap periodically (Fig. 27).

Use NGK CMR7A or of other brand with the same

thermal grade.

WARNING: Never test the ignition system

with ignition wire connector removed

from spark plug or with unseated spark

plug, since uncontained sparking may cause

a fire. A loose connection between spark

plug terminal and ignition wire connector in

the boot may create arcing that could ignite

combustible fumes and cause a fire.

Use only resistor type spark plugs of the

approved range.

Factors such as:

- too much oil in fuel mix;

- dirty air filter;

- unfavourable running conditions, e.g.

operating at part load;