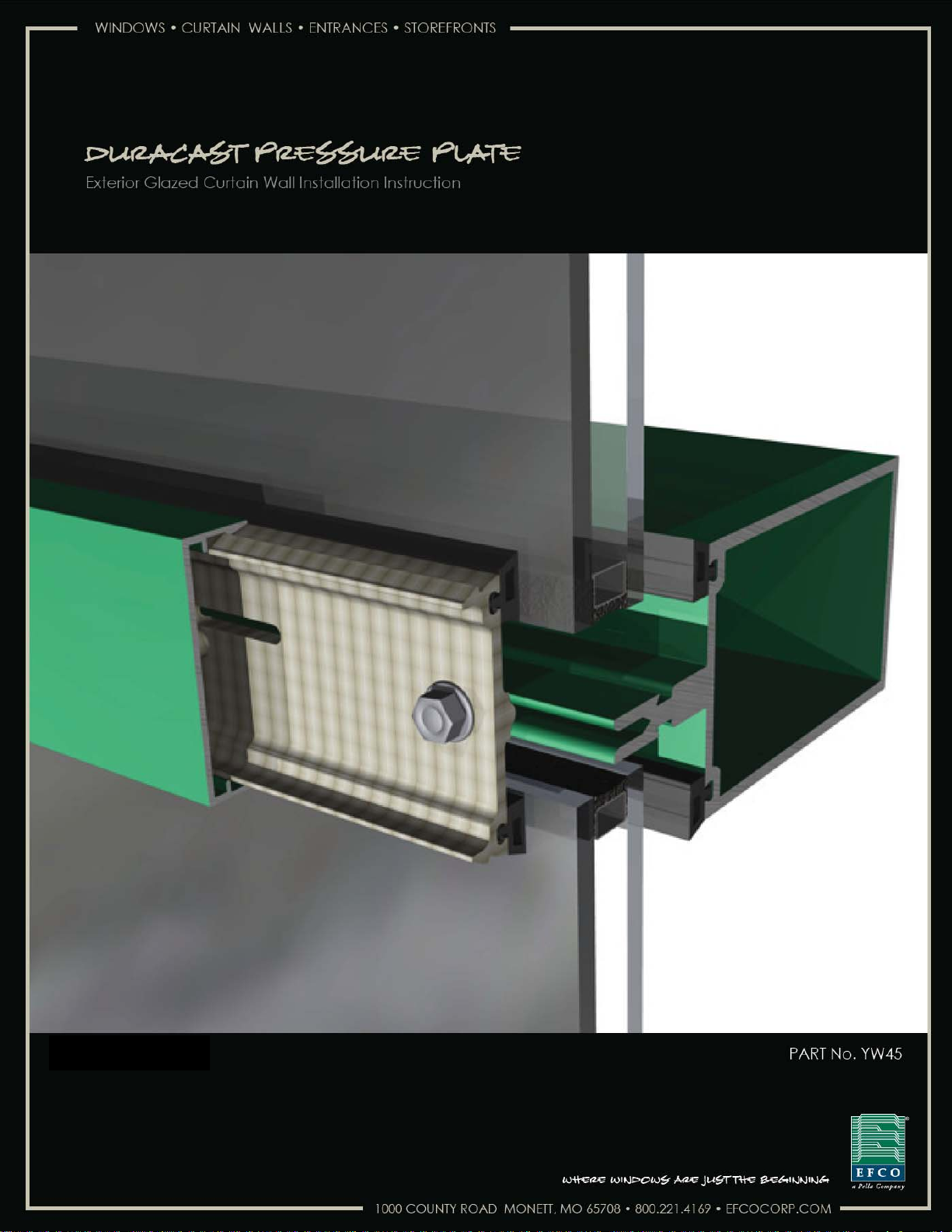

Page 1

Duracast Pressure Plate Installation Instructions

December 2011

EFCO CORPORATION 12/5/2011 PART NO. YW45

Page 2

Duracast Pressure Plate Installation Instructions

TABLE OF CONTENTS

S-5600 / S-5900 DURACAST PRESSURE PLATE

SECTION PAGE

I. General Notes and Guidelines…………………………………………. 3-4

II. Glazing Preparation & Installation…………………………..………. 5

III. Pressure Plate Installation……………………………………..………. 6-10

IV. Vertical Splice Joints………………………………………………………. 11

V. Exterior Cover Installation…………...………………………………… 12

Minimizing Condensation

Note: Please reference EFCO's "Understanding Condensation" brochure which can be obtained

through your EFCO representative.

Condensation will form on any surface when unfavorable conditions (interior temperature and

relative humidity and exterior temperature) are present. When the formation of excessive condensation

is a concern, it is highly recommended that a design professional is utilized to perform an analysis of

the shop drawings to recommend the best possible installation methods. Please contact your EFCO

representative for information on EFCO's Thermal Analysis Services.

Many current installation practices lead to an increase in the possibility of the formation of

condensation. Though not all inclusive, the list of examples below illustrates conditions under which

condensation is likely to occur:

1. Bridging system thermal break with non-thermally broken metal flashing or lintels that

are exposed to the exterior

2. System exposure to cold air cavities

3. Interior relative humidity levels not maintained at recommended levels, see EFCO’s

“Understanding Condensation” brochure

4. Inadequate separation between system and surrounding condition at perimeter

5. Product combinations during the shop drawing stage that result in bridging thermal

breaks of one or all products involved

Note: These installation instructions are a supplement to the approved final shop

drawings and are to be used in conjunction with those drawings.

EFCO CORPORATION 6/2012 PART NO. YW45

2

Page 3

Duracast Pressure Plate Installation Instructions

Section I: General Notes and Guidelines

I. HANDLING / STORING / PROTECTING DURACAST - The following precautions are

recommended to assure early acceptance of your products and workmanship.

A. HANDLE CAREFULLY - Store with adequate separation between components so

the material will not rub together. Store the material off the ground. Protect materials against weather elements and other construction trades.

B. KEEP MATERIAL AWAY FROM WATER, MUD, AND SPRAY - Prevent cement,

plaster, and other materials from contacting with and damaging the finish. Do not

allow moisture to be trapped between the finished surface and the wrapping material.

C. PROTECT MATERIALS AFTER ERECTION - Wrap or erect screens of plastic

sheeting over material. Cement, plaster, terrazzo, and other alkaline materials are

very harmful to the finish and are to be removed with soap and water before hardening. Under no circumstances should these materials be allowed to dry or permanent staining will occur.

D. CUTTING OF DURACAST - Duracast can be cut with a standard miter saw using

a carbide blade; however, the life of the blade life will be shortened significantly

due to the high glass content of Duracast. For best results use a diamond tipped

or concrete blade for extended blade life.

II. GENERAL GUIDELINES - The following practices are recommended for all installations:

A. REVIEW APPROVED SHOP DRAWINGS – Become thoroughly familiar with the

project. Shop drawings govern when conflicting information exists in these installation instructions.

B. INSTALL ALL FRAMING MATERIAL PLUMB, LEVEL, AND TRUE – Proper

alignment and relationships to benchmarks and column centerlines, as established

by the architectural drawings and the general contractor, must be maintained.

C. The sequence of erection should be coordinated with the project superintendent to

prevent delays and minimize the risk of material damage. Note: If preset an-

chors are required, coordinate and supervise anchor placement with the

general contractor.

D. Verify that all job site conditions and accompanying substrates receiving the instal-

lation are in accordance with the contract documents. If deviations occur, notification must be given IN WRITING to the general contractor and differences resolved before proceeding further with the installation in the questionable area.

EFCO CORPORATION 6/2012 PART NO. YW45

3

Page 4

Duracast Pressure Plate Installation Instructions

SECTION I: GENERAL NOTES and GUIDELINES

F. Follow EFCO framing installation and glazing instructions.

G. Verify contents of all material shipments received upon their arrival. Verify quantity

and correct finishes. NOTIFY EFCO IMMEDIATELY OF ANY DISCREPANCIES

OR DAMAGE THAT MAY HAVE OCCURRED.

H. Throughout these instructions the term “SEALANT” will appear. For the purposes of

these instructions, sealant is to be defined as the following:

SEALANT - A weather resistant, gunnable liquid filler which when cured provides a

resilient, flexible (± 50% movement capability) air and water seal between similar

and dissimilar materials.

All sealant must meet ASTM C 920, CLASS 50.

BUTYL SEALANT- A non-skinning, non-hardening material (NAAMM Reference Standard 5C-1).

NOTE: All sealant must be compatible with all surfaces on which adhesion is re-

quired, including other sealant surfaces. All frame surfaces should be clean,

dry, dust, and frost free. If a primer is required, it must be applied to clean

surfaces. All perimeter substrates shall be clean and properly treated to receive sealant.

This system is designed and has been tested to utilize butyl or silicone sealants at all internal joineries, i.e., joint plugs, gasket intersections, etc.

Regardless of the sealant used, the customer should contact the sealant

manufacturer to determine compatibility and adhesion. Follow sealant manufacturer's proper application procedures and quality assurance programs for

weather sealing.

Maintain caulk joints as shown in the approved shop drawings. Unless

specified otherwise, most sealant manufacturers recommend a 3/8” minimum perimeter caulk joint. A 3/4” minimum joint is recommended at the

head condition to accommodate thermal expansion and contraction.

Anchoring surfaces of perimeter construction must be level and plumb within

the adjustable limits of the head, jamb, and sill framing.

EFCO CORPORATION 6/2012 PART NO. YW45

4

Page 5

Duracast Pressure Plate Installation Instructions

Section II: Glazing Prep. & Installation

Note: All anchors must be “FIXED” before glazing installation begins.

5600 Series — Outside Glazed Installation

A. Seal and install Joint plugs per Installation Instruction

Preparation

B.

Install Setting Blocks, Infill Glazing Material, Temporary Retainers, and Side Blocks per

Installation Instruction

. DO NOT install a Thermal Isolator as indicated in Steps 1A and 1B.

Y302 - Section VII: Glazing Installation, Steps #3 thru #5.

5900 Series — Outside Glazed Installation

A. Seal and install Joint plugs per Installation Instruction

cation.

B. Install Glazing Adaptors / Mullion Gaskets per Installation Instruction

Glazing Adaptors / Mullion Gaskets.

C.

Install Setting Blocks, Infill Glazing Material, and Anti-Walk Blocks ONLY per Installation

Instruction

Gaskets

Plate. See

Y350 - Sections VIII: Setting Blocks / Anti-Walk Blocks / Pressure Plate

. Follow the instructions in this document for the installation of the Pressure

Section III - Pressure Plate Installation

Y302 - Section VI: Glazing

Y350 - Sections VI: Joint Plug Appli-

Y350 - Sections VII:

EFCO CORPORATION 6/2012 PART NO. YW45

5

Page 6

Duracast Pressure Plate Installation Instructions

Section III: Pressure Plate Installation

Note: All anchors must be “FIXED” before glazing installation begins.

STEP #1 Perimeter Pressure Plate Preparation

A. If not using a Perimeter Adaptor skip to Step #2

B. Align the Perimeter Adaptor the Pressure plate and install using a rubber

mallet or hammer every 2 to 3 feet. The adaptor should be installed flus h

with each end of the pressure Plate.

C. When installing the exterior gasket material as described in step #2, one

gasket should be installed in the pressure plate and the second gasket

installed in the Perimeter Adaptor.

Install Perimeter adaptor with

mallet every 2 to 3 feet.

Align Perimeter adaptor to pressure

plate. The Pressure Plate and

Adaptor should both be flush at the

each end.

Install glazing gaskets per step

#2. One gasket should be

located in the adaptor and one

in the pressure plate

EFCO CORPORATION 6/2012 PART NO. YW45

6

Page 7

Duracast Pressure Plate Installation Instructions

Section III: Pressure Plate Installation

Note: All anchors must be “FIXED” before glazing installation begins.

STEP #2 Pressure Plate Preparation

A. Remove exterior gasket material from the reel and allow to relax and

shrink.

B. Insert glazing gaskets into the pressure plates. For horizontals, gaskets

should extend 1/4” beyond each end of the pressure plate. For vertical

single story applications, gaskets should be flush with both ends of the

pressure plate. For vertical multi-story applications, gaskets should extend

1” beyond the top end of the pressure plate and flush with the bottom end

of the pressure plate.

Horizontal Pressure Plate

Horizontal Pressure Plate

Vertical Pressure

Plate

Typical horizontal gasket

extended ¼” each end.

Typical horizontal gasket

extended ¼” each end.

STEP #3 Joint Plug Face Sealing

A. Apply sealant to the face of

the joint plugs prior to installation of vertical and horizontal pressure plates.

Typical vertical

gasket cut flush

top and bottom.

Vertical at multistory, gasket

extended 1” at

top only

Apply sealant to face

of all joint plugs

EFCO CORPORATION 6/2012 PART NO. YW45

7

Page 8

Duracast Pressure Plate Installation Instructions

Section III: Pressure Plate Installation

STEP #4 Install Pressure Plate

A. First attach the vertical pressure plates and then the horizontal pressure

plates into position using stainless steel hex washer head screws (refer to

Table #1 for screw size based on Curtain Wall Series). Locate screws in

the first complete pre-punched hole

on each end of the pressure plate no

more than 3.5” from the end. Refer

to the final approved shop drawings

for screw spacing.

B. Torque screws to 80 inch-pounds.

C. In cold Weather, first torque all

pressure plate screws to 40 inch-

pounds. Once all four sides have

been clamped down, torque all

screws to 80 inch-pounds.

D. When possible, work from the center

outward on horizontals and from the

sill upward on verticals.

E. Glazier should always place screws in

pre-punched holes immediately above and below each horizontal. This will

provide maximum control of pressure on mullion plugs that provide a criti-

cal sealing function.

F. The pressure plate should extend 3” past any splice (see Section IV:

Vertical Splice Joints).

Pressure Plate End

Incomplete Hole

Hex washer head

screw in first

complete hole

(see Table #1).

Table #1

CurtainWall

Series ScrewSize&Type

5600 #13x5/8"S.S.HexWasherHeadScrew

5900 ¼"x1"S.S.HexWasherHeadScrew

Place screws in holes

immediately above and

below all horizontals

EFCO CORPORATION 6/2012 PART NO. YW45

8

Page 9

Duracast Pressure Plate Installation Instructions

Section III: Pressure Plate Installation

STEP #4 Install Pressure Plate (continued)

F. For curtain wall systems that utilize vertical covers 1” in depth and over,

attach a Roll Pin Support on the vertical

at each horizontal. This will allow the

application of a roll pen after cover

installation to prevent slippage.

G. For curtain wall systems that utilize

horizontal covers 1” in depth and over,

attach a Roll Pin Support at the

mid-span of the horizontal.

Roll Pin Support located

at each horizontal when

vertical cover depth 1”

and over.

Weep

Note: Orient horizontal pressure

plates such that the weeps are

located above the mullion tongue

Note: Horizontal pressure plates are

¼” shorter than horizontal mullions.

The glazier should center the horizontal

pressure plate on the mullion before

installation.

EFCO CORPORATION 6/2012 PART NO. YW45

9

Page 10

Duracast Pressure Plate Installation Instructions

Section III: Pressure Plate Installation

STEP #5 Seal Pressure Plate Ends

A. Seal all joints between the vertical and horizontal pressure plates with

sealant to provide a water and airtight joint.

Seal joint between

horizontal and vertical

pressure plates.

EFCO CORPORATION 6/2012 PART NO. YW45

10

Page 11

Duracast Pressure Plate Installation Instructions

5600 Series — Outside Glazed Installation

5900 Series — Outside Glazed Installation

Section IV: Vertical Splice Joints

A. Vertical splices should be assembled per

Splice Joints

locations and overlaps.

A. Vertical splices should be assembled per

Joints

and overlaps.

including location of pressure plate and cover splice joint locations

including location of pressure plate and cover splice joint

Y302 - Section VIII: Vertical

Y350 - Section V: Vertical Splice

EFCO CORPORATION 6/2012 PART NO. YW45

11

Page 12

Duracast Pressure Plate Installation Instructions

5600 Series — Outside Glazed Installation

5900 Series — Outside Glazed Installation

Section V: Exterior Cover Installation

A. Vertical and horizontal covers should be installed per Installation Instruc-

tion

Y302 - Section IX: Exterior Cover Installation.

required they should be located such that the pins engage the

Roll Pin Supports applied in Section III, Step #3 of this

instruction.

A. Vertical and horizontal covers should be installed per Installation Instruc-

tion

Y350 - Section X: Exterior Cover Installation.

required they should be located such that the pins engage the

Roll Pin Supports applied in Section III, Step #3 of this

instruction.

Note, if roll pins are

Note, if roll pins are

EFCO CORPORATION 6/2012 PART NO. YW45

12

Loading...

Loading...