Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Italiano 3

English 23

Français 42

Deutsch 63

Español 84

Slovensky 105

Português 125

Ελληνικα 146

Türkçe 167

Česky 187

Pуccкий 207

Polski 228

Page 7

TRANSLATION OF ORIGINAL INSTRUCTIONS

INTRODUCTION

For correct use of the machine and to avoid

accidents, do not start working until you have

re ad this manua l careful ly. You will find

explanations concerning the operation of the

various parts plus instructions for necessary

checks and relative maintenance.

NOTE: The descriptions and illustrations

contained in this manual are not binding. The

ma nu fa ct ur er re se rv es th e ri gh t t o

und ertake any mo dificat ions it deems

necessary without revising this manual.

In addition to the operating instructions, this

manual contains paragraphs that require your

special attention. Such paragraphs are marked

with the symbols described below:

WARNING: where there is a risk of an accident

or personal, even fatal, injury or serious damage

to property.

CAUTION: where there is a risk of damaging the

machine or its individual components.

WARNING

RISK OF HEARING DAMAGE

IN NORMAL CONDITIONS OF USE, THIS

MACHINE MAY EXPOSE THE OPERATOR TO A

PERSONAL DAILY NOISE LEVEL EQUAL TO OR

HIGHER THAN

85 dB (A)

CONTENTS

1. SAFETY PRECAUTIONS (precautions

for using the machine safety)

2. SYMBOLS AND SAFETY WARNINGS

(explanations on how to identify the

machin e and the me aning of t he

symbols)

3. MAIN COMPONENTS (position of the

main parts that make up the machine)

4. ASSEMBLY (explanations on how to

remove the packaging and assemble

detached parts)

5. STARTING 26

6. STOPPING THE ENGINE 29

7. USING THE MACHINE 29

8. TRANSPORTING 32

23

25

25

25

9. MA IN TE NA NCE ( all i nf or mat io n

required to keep the machine at peak

efficiency)

10. STORAGE 35

11. ENVIRONMENTAL PROTECTION

(advice on using the machine in ways

that respect the environment)

12. TECHNICAL DATA (a summary of the

main specifications of the machine)

13. DECLARATION OF CONFORMITY 40

14. WARRANTY CERTIFICATE (a summary

of the warranty conditions)

15. TROUBLESHOOTIN G (helps you to

quickly solve any problems you may encounter while using the machine)

1. SAFETY PRECAUTIONS

WARNING

- The machine, when used correctly, is a

us ef ul a nd e ff ec tiv e to ol ; i f use d

inc orrect ly or witho ut the nece ssary

pr ecau tio ns, it can be dan gero us. To

ensure your safety and comfort, always

observe the safety instructions given here

below and throughout this manual.

- E x po s ur e t o v i br at i on s t h ro ug h

prolo nged use of combus tion enginedriven tools could cause blood vessel or

nerve damage in the fingers, hands, and

wr ists of pe ople prone to cir cul atio n

di so rd er s o r a bn or ma l s we ll in gs .

Prolonged use in cold weather has been

li nk ed t o b loo d ves se l da ma ge i n

otherwise healthy people. If symptoms

occur such as numbne ss, pain , loss of

strength, change in skin colour or texture,

or loss of feeling in the fingers, hands, or

wrists, discontinue the use of this tool and

seek medical attention.

- T he ig nit ion s yst em of your m ach ine

produces an electromagnetic field of very

low intensity. This field could interfere

with certain pacemakers. To reduce the

risk of serious or fatal injury, persons with

pacemakers should consult their doctor or

the m anufact urer o f th e p acem aker

before using this machine.

33

36

37

40

41

GB

23

Page 8

WARNING: National regulations may limit

GB

the use of the machine.

1 - Do not operate the machine unless you

have received specic instruction on its use.

First time users must familiarise themselves

thoroughly with the operation of the

machine before working in the eld.

2 - The machine must only be used by adults

in good physical condition who are familiar

with the operating instructions.

3 - Never use the brush cutter when you are

tired or fatigued or if you have taken alcohol,

drugs or medication.

4 - Wear appropriate clothing and safety articles

such as: boots, heavy-duty trousers, gloves,

protective eyewear, ear protection and

protective helmet. Use clothing which is

close-tting but comfortable.

5 - Do not allow children to use the brush cutter.

6 - Do not allow other people to remain within

15 metres during brush cutter use .

7 - Before using the brush cutter, make sure

that the blade xing bolt is well-tightened.

8 - The brush cutter must be equipped with

the cutting accessories recommended by

the manufacturer (look pag. 38).

9 - Never use the brush cutter without the blade

guard or the head.

10 - Before starting the engine, make sure that

the blade is free to move and is not in contact

with any foreign objects.

11 - Every now and then while working, stop

the engine and check the blade. Replace it

at the rst sign of cracks or breaks.

12 - Only use the machine in well-ventilated

places, do not use in explosive or ammable

atmospheres or in closed environments.

13 - Never touch the blade or attempt any

maintenance work while the engine is

running.

14 - It is prohibited to t any device other than

that supplied by the manufacturer.

15 - Do not use a machine that has been

damaged, badly repaired, improperly

assembled or modied. Do not attempt to

remove or bypass any of the safety devices.

Only use cutting attachments indicated in

24

the table.

16 - All labels with health hazards must be kept

in good conditions. In case of damage or

deterioration, immediately substitute them

(Fig. 24).

17 - Do not utilize the ma chine for uses

different from the ones specified in the

manual (see pag. 29).

18 - Never leave the machine unattended with

the engine running.

19 - Do not start the engine with the arm not

mounted.

20 - Check the brush cutter daily to be sure that

components and safety devices are full

functioning properly.

21 - Do not attempt to carry out operations

or repairs that are not part of the normal

maintenance. See the authorised dealer.

22 - When disposing of the machine at the

end of its u seful l ife, think o f the

environment. Take your old unit to your

dealer who will be able to dispose of it in

a proper manner.

23 - Only experienced p ersons who are

familiar with the operation and safe use of

this machine should use it. If you lend the

blower to someone, also give them the

instruction manual and ensure that they

read it before using the machine.

24 - All saw service, other than the operations

shown in the present manual, should be

performed by competent personnel.

25 - Keep this manual on hand and consult it

before each use of the tool.

26 - Please note that the owner or the user is

responsible for any accidents or damage to

third parties or their property.

WARNING

- Never use a machine with faulty safety

eq ui pm en t. Th e ma ch in e’ s s af et y

e qu ip me nt mu st b e c he ck ed a nd

maintained as described in this section. If

your machine fails any of these checks

contact an Authorised Service Centre to

get it repaired.

- Any use of the machine not expr essly

en vi sa ge d in t hi s m anu al i s t o be

Page 9

co nsi der ed impro per and therefore a

source of risk to people and property.

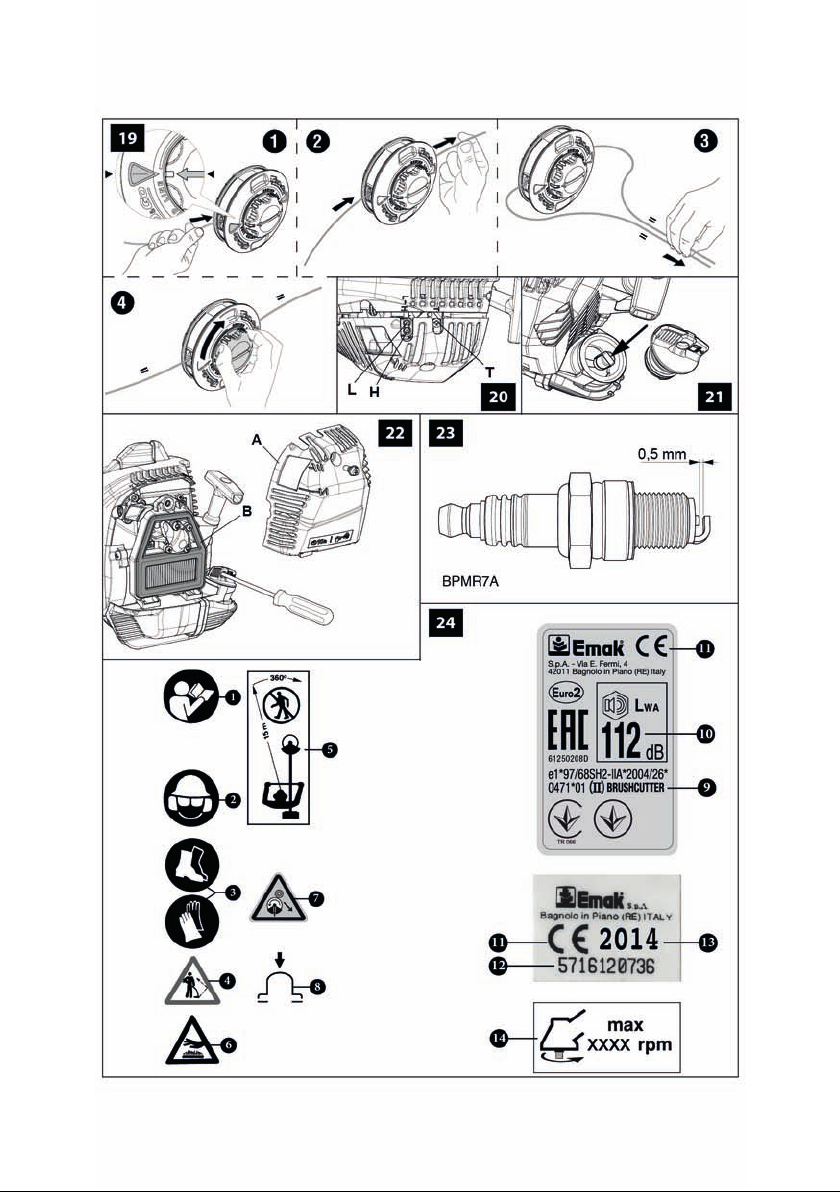

2. SYMBOLS AND SAFETY WARNINGS (Fig.24)

1 - Read operator’s instruction book before

operating this machine.

2 - Wear head, eye and ear protection.

3 - Wear strong boots and gloves when cutting

with metal or plastic blades.

4 - Be aware that objects can be thrown.

5 - Keep bystanders away 15 m.

6 - WARNING! – The surface can be hot!

7 - Warning! Kickback it’s danger.

8 - Purge Bulb.

9 - Type of machine: BRUSH CUTTER.

10 - Guaranteed sound power level.

11 - CE conformity marking.

12 - Serial number.

13 - Year of manufacture.

14 - Max. speed of output shaft, RPM

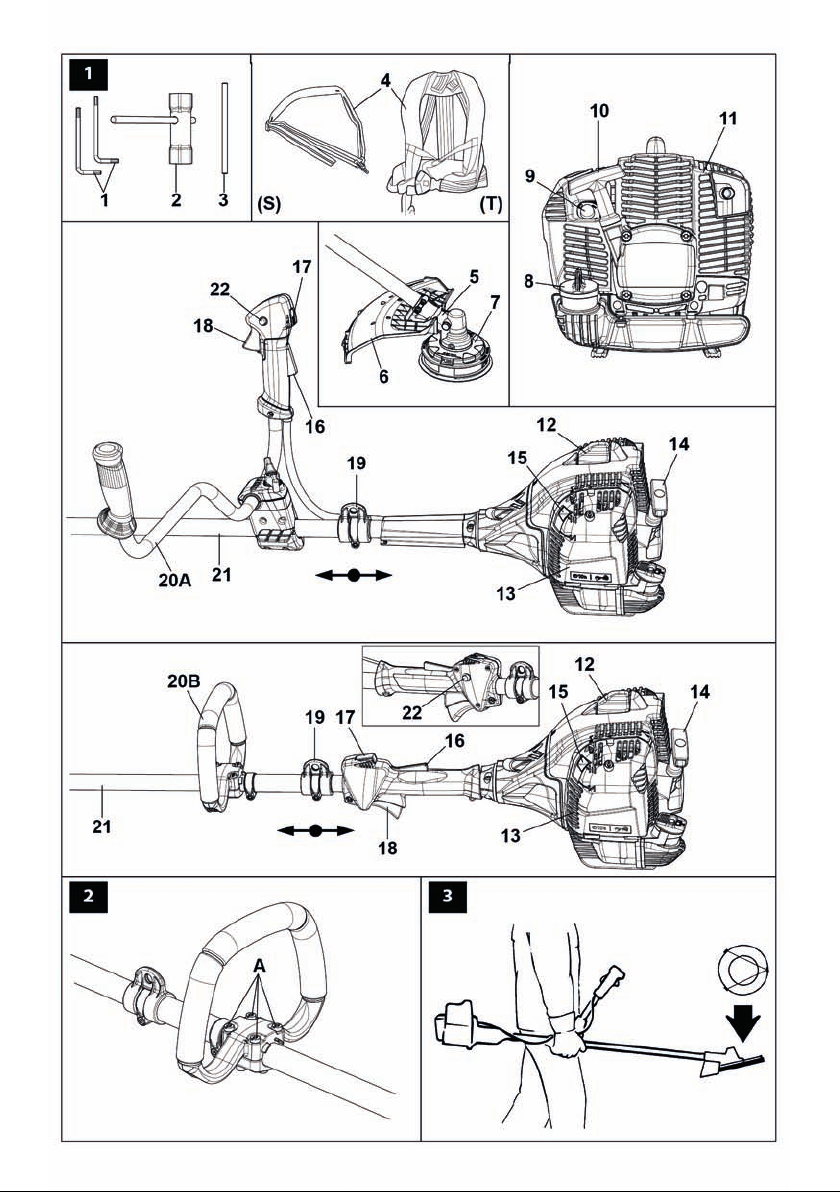

3. MAIN COMPONENTS (Fig.1)

1÷3 - Tools supplied

4 - Harness

5 - Bevel gear

6 - Curved guard

7 - Nylon line head

8 - Fuel tank cap

9 - Purge Bulb

10 - Carburettor adjustment screws

11 - Muer guard

12 - Spark plug

13 - Air lter

14 - Starter Handle

15 - Choke Lever

16 - Throttle trigger lockout

17 - STOP button

18 - Throttle lever

19 - Harness attachment

20 - Handle

21 - Shaft arm

22 - Button half-throttle

4. ASSEMBLY

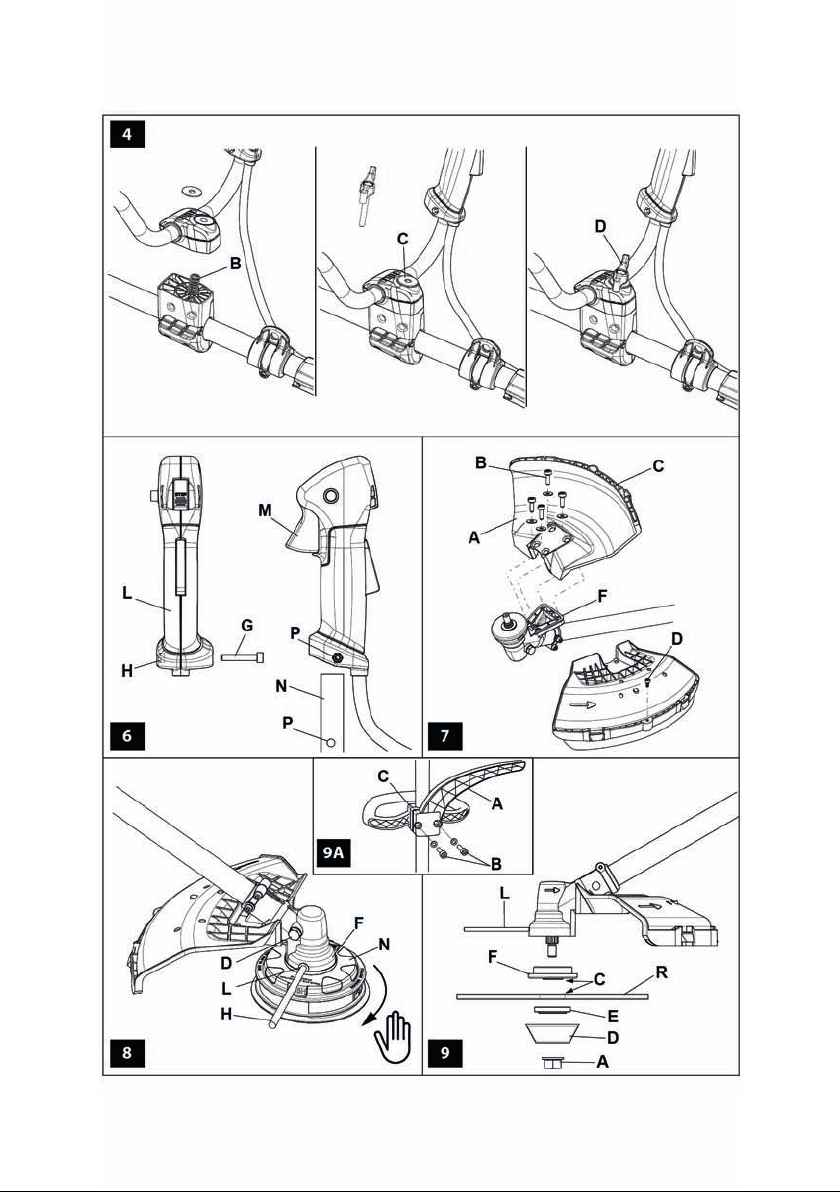

FITTING THE SAFETY GUARD (Fig.7)

Fit the blade guard (A) to the shaft arm with screws

in a position allowing the operator to work safely (B).

NOTE: use the guard (C) only with nylon head.

Secure the guard (C) to the protection (A) by

means of the screw (D).

FITTING THE NYLON LINE HEAD (Fig. 8)

Put the upper (F) ange in place. Put the head xing

pin (H) in the appropriate hole (L) and tighten the

head (N) anti-clockwise by hand.

FITTING THE DISK (Fig. 9)

Fix the blade (R) onto the upper ange (F) making

sure that the rotation direction is correct.

Fix the lower ange (E), the cup (D) and tighten bolt

(A) anti-clockwise.

Put the pin provided in the appropriate hole (L)

to block the blade and allow the bolt (A) to be

tightened to 2.5 kgm (25 Nm).

WARNING – Collar (see arrows C, Fig.9)

must locate in blade’s mounting hole.

FITTING THE HANDLE (Fig. 2)

Fit the handle onto the shaft arm and secure it

using screws (A). The handle position is calculated

depending on the requirements of the operator.

ASSEMBLING THE SAFETY BOOM (Fig. 9A)

When using the disc instead of nylon line head, it

is necessary to set up the “safety boom”. Fix the

boom (A) under the attachment (C) of handle (20B,

Fig. 1) by means of the screws (B). Taking care to

verify the “safety boom” being on the left side of

the brushcutter.

ASSEMBLING THE BIKE HANDLE (Fig. 4)

- To x the handle, insert the spring (B) and washer

(C)

- Line up the handlebar at a right angle to the

drive tube.

- Then tighten the clamp with the screw (D)

MOUNTING THE CONTROL HANDLES (Fig. 6)

- Loosen the screw (G, Fig.6). The nut (H) remains

in the control handle (L).

- Push the control handle (L) (throttle trigger M

25

GB

Page 10

must point toward the gearbox) onto the bike

handle (N) so that the holes (P) line up.

- Insert screw (G) and tighten down rmly.

GB

WARNING: M ake sure that al l

components are connected properly and all

screws tightened.

APPROVED POWER TOOL ATTACHMENTS

The following Emak attachments may be mounted

to the basic power tool:

EH 25 Hedge trimmer (adjustable) (1) (2)

EH 50 Hedge trimmer (adjustable) (1) (2)

EP 100 Pole pruner (2)

EP 120 Pole pruner (2)

PREPARING TO WORK

HARNESS (4S, Fig. 1)

Correct adjustment of the harness permits the

brush cutter to be properly balanced and at an

appropriate height from the ground (Fig. 10).

- Put on the single harness.

- Hook the brush cutter to the harness using the

hook (A, Fig. 10).

- Position the hook (19, Fig. 1) to obtain the best

brush cutter balance.

- Position the buckle to obtain the correct brush

cutter height.

CORRECT ADJUSTMENT OF THE HARNESS

DS 3500 T - BC 350 T models

1. Put on the double harness (4T, Fig.1).

2. Fasten the waist buckle (A, Fig.12) and adjust

by tightening the top belt strap (B) until

comfortable.

3. Fasten the chest buckle (C).

4. Adjust the shoulders by tightening the two

straps (D, Fig.13) until comfortable. With this

type of harness, the weight of the machine can

be distributed between shoulders and waist

according to the preference of the operator.

5. Adjust the chest strap (E, Fig.12).

6. Hook the brushcutter to the harness with the

snap (A, Fig.10).

7. Adjust the carrying height by shortening or

lengthening the belt straps (H-L, Fig.14). The

correct distance between the belt and the

snap can be measured as in Fig.10. This

adjustment will also help to distribute the

weight of the brushcutter so that it stays

comfortably balanced during operation.

WARNING! – When using wood-cutting

blades (22-60-80 teeth) a double harness with

quick-release mechanism must be worn.

26

(1) Safety boom (A, Fig.9A) must be assembled

under the loop handle.

(2) Not approved for use with bike handle units

(DS 3500 T - BC 350 T).

5. STARTING

FUELING

WARNING: Gasoline is an extremely

ammable fuel. Use extreme caution when

handling gasoline or fuel mix. Do not smoke

or bring any re or ame near the fuel or the

unit.

· To reduce the risk of fire and burn injury,

handle fuel with care. It is highly flammable.

· Mix and store fuel in a container approved for

gasoline.

· Mix fuel outdoors where there are no sparks or

flames.

· Select bare ground, stop engine, and allow to

cool before refueling.

· Loosen fuel cap slowly to release pressure and

to keep fuel from escaping around the cap.

· Tighten fuel cap securely after refueling. Unit

vibration can cause an improperly tightened

fuel cap to loosen or come off and spill

quantities of fuel.

· Wipe spilled fuel from the unit. Move 3 metre

away from refueling site before starting

engine.

· Never attempt to burn off spilled fuel under

any circumstances.

· Do not smoke while handling fuel or while

operating the unit.

· Store fuel in a cool, dry, well ventilated place.

Page 11

· Never place the machine in a combustible

area such as dry leaves, straw, paper, etc.

· Store the unit and fuel in an area where fuel

vapors cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

· Never take the cap off the tank when the

engine is running.

· Never use fuel for cleaning operations.

· Take care not to get fuel on your clothing

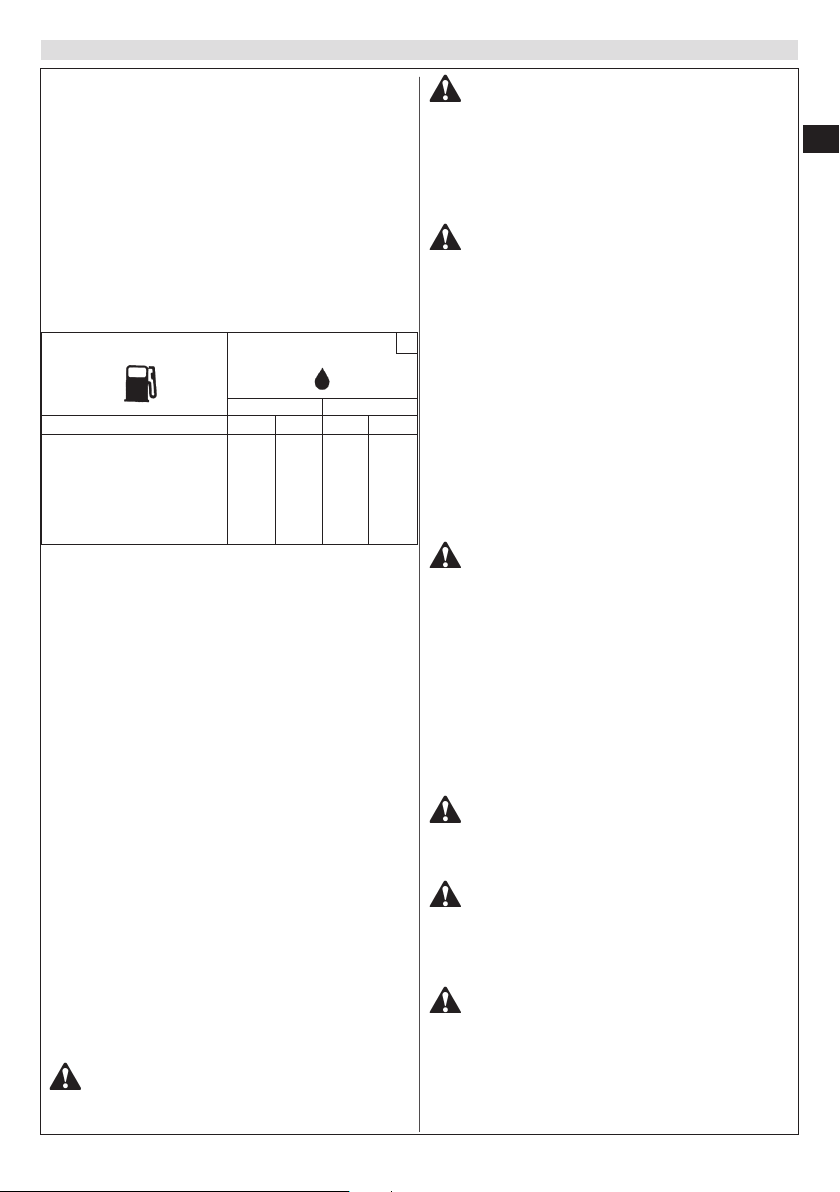

GASOLINE

l

1

5

10

15

20

25

2%-50 : 1

l (cm

0,02 (20)

0,10 (100)

0,20 (200)

0,30 (300)

0,40 (400)

0,50 (500)

OIL

4%-25 : 1

3

) l (cm3)

0,04 (40)

0,20 (200)

0,40 (400)

0,60 (600)

0,80 (800)

1,00 (1000)

This product is powered by a 2-cycle engine and

requires pre-mixing gasoline and 2-cycle oil.

Pre-mix unleaded gasoline and 2-cycle engine

oil in a clean container approved for gasoline.

RECOMMENDED FUEL: THIS ENGINE IS

CERTIFIED TO OPERATE ON UNLEADED

GASOLINE INTENDED FOR AUTOMOTIVE USE

WITH AN OCTANE RATING OF 89 ([R + M] / 2) OR

HIGHER.

Mix 2-cycle engine oil with gasoline according to

the instructions on the package.

We strongly recommend the use of 2% (1:50)

Efco - Oleo-Mac two cycle engine oil, which is

specifically formulated for all air-cooled twostroke engines.

The correct oil / fuel proportions shown in the

table (Fig. A) are suitable when using the

PROSINT 2 and EUROSINT 2 or an equivalent

high-quality engine oil (JASO specification FD

or ISO specification L-EGD). When oil

specifications are NOT equivalent or unknown

use 4% (1:25) oil / fuel mixing ratio.

CAUTION: DO NOT USE AUTOMOTIVE

OIL OR 2-CYCLE OUTBOARD OIL.

CAUTION:

- Match your fuel purchases to your

consumption; don’t buy more than you will

use in one or two months;

- Store gasoline in a tightly-closed container

in a cool, dry place.

CAUTION - For the mixture, never use a

fuel with an ethanol percentage higher than

10%; gasohol (mixture of gasoline and

ethanol) up to 10% ethanol or E10 fuel are

acceptable.

A

NOTE - Prepare only the quantity of mixture

required for immediate use; do not leave fuel in

the tank or a container for a long time. Were

commend the use of the additive Emak ADDITIX

2000 code 001000972 if the mixture is to be

stored for 30 days.

Alkylate gasoline

CAUTIONS – Alkylate fuels have

different density than normal fuel. Therefore

engines, set with normal fuel, need different

H jet regulation to avoid critical issues. For

this operation it’s necessary turned at a

Licensed Service Dealer.

Filling the tank

stir the mixture well before refuelling.

STARTING

Before starting the engine, make sure

that the blade is free to move and is not in

contact with any foreign objects.

The cutting attachment must not rotate

when the engine is idling. Otherwise contact

an Authorized Service Center to carry out a

check and x the problem.

WARNING: Hold the brush cutter rmly

with both hands. Always keep your body is to

the left of tube. Never use a cross-handed grip.

Left-handers should follow these instructions

too.

Keep a proper cutting stance.

GB

27

Page 12

Over exposure to vibrations can result in

blood-vessel or nerve injury to persons

GB

suering with blood circulation problems. Seek

medical attention if you experience physical

symptoms such numbness, lack of feeling,

reduction in normal strength, changes in the

colour of the skin. These symptoms normally

appear in the fingers, hands or wrists.

Before starting the engine, make sure that the

throttle lever works freely.

WARNING: Follow safety instruction for

fuel handling. Always shut off engine before

fuelling. Never add fuel to a machine with a

running or hot engine. Move at least 3 m from

refuelling site before starting engine. DO

NOT SMOKE!

1. Clean surface around fuel cap to prevent

contamination.

2. Loosen fuel cap slowly.

3. Carefully pour fuel mixture into the tank.

Avoid spillage.

4. Prior to replacing the fuel cap, clean and

inspect the gasket.

5. Immediately replace fuel cap and hand

tighten. Wipe up any fuel spillage.

WARNING: Check for fuel leaks, if any

are found, correct before use. Contact a

Servicing Dealer if necessary.

Engine is Flooded

- Engage a suitable tool in the spark plug boot.

- Pry off the spark plug boot.

- Unscrew and dry off the spark plug.

- Open the throttle wide.

- Pull the starter rope several times to clear the

combustion chamber.

- Refit the spark plug and connect the spark

plug boot, press it down firmly.

- Set the choke lever to OPEN position – even

if engine is cold.

- Now start the engine.

2) Pull the choke lever (15, Fig.1) in the CLOSE

position (A, Fig.15)

3) Pull the throttle lever (18, Fig. 1) and stop it

at half-throttle by pressing the button (22),

then release the lever (18).

4) Place the brush cutter on the ground in a

stable position. Check that the blade is free.

Holding the brush cutter down (Fig.15A), pull

the starter rope until the rst kick over of the

engine is heard (no more than 3 pulls). A new

unit may require additional pulls.

5) Push the choke lever (15, Fig.1) in OPEN

position (B, Fig.15).

6) Pull the starter cord to start the engine. Once

the machine is started, warm up the machine

for about few seconds, without touch the

throttle lever. The machine could need more

seconds to warm up with cold weather or at

high altitudes. Finally, push the throttle lever

(18, Fig.1) for deactivate the half-throttle.

CAUTION:

- Never wrap the starter cord around your

hand.

- When pulling the starter rope, do not

use the full extent of the rope as this can

cause the rope to break.

- Do not let starter rope snap back. Hold the

starter handle (14, Fig.1) and let the rope

rewind slowly.

WARNING: Once the engine is warmed

up do not use the choke to start up again.

WARNING: Use the semi-acceleration

device only in the phase of starting the engine

to cold.

BREAKING-IN THE ENGINE

The engine reaches the maximum power after

5÷8 hours of activity.

During this period of breaking-in do not use the

engine at wide open throttle without load, to avoid

excessive functioning stress.

STARTUP PROCEDURE

1) Slowly push the purge bulb 4 times (9, Fig.1).

28

WARNING! - During the breaking-in

period do not vary the carburetion to obtain a

Page 13

presumed power increment; the engine can be

damaged.

NOTE: It is normal for smoke to be emitted

from a new engine during and after first use.

6. STOPPING THE ENGINE

Set the throttle lever to idle position (18, Fig. 1)

and wait a few seconds to let the engine cool o.

Turn o the engine, pushing the ON/OFF switch

(17).

7. USING THE MACHINE

PROHIBITED USE

WARNING: Avoid kickout which can

result in serious injury. Kickout is the

sideward or sudden forward motion of the

machine occurring when the blade contacts

any object such as a log or stone, or when the

wood closes in and pinches the saw blade in

the cut. Contacting a foreign object can also

result in loss of brush cutter control.

WARNING! - Always follow the safety

precautions. The brush cutter must only be

used to trim grass material. Cut wood only with

appropriate saw blade. Do not cut metal,

plastics, masonry, or non-wood building

materials. Do not use the brush cutter as a lever

to lift, move or break objects, nor lock it on

xed supports. It is forbidden to apply tools or

applications that are not the ones indicated by

the manufacturer onto the brush cutter’s power

take-o.

WARNING: When using rigid blades,

avoid cutting close to fences, sides of

buildings, tree trunks, stones or other such

objects that could cause the brush cutter to

kick out or could cause damage to the blade.

We recommends use of the nylon line heads

for such jobs. In addition, be alert to an

increased possibility of ricochets in such

situations.

Never use the brushcutter for trimming

hedges.

WARNING: If the blade loosens after

being properly tightened, stop work

immediately. The retaining nut may be worn

or damaged and should be replaced. Never

use unauthorized parts to secure the blade. If

the blade continues to loosen, see your

dealer. Never use the brushcutter for

trimming hedges.

Work Area Precautions

• Always cut with both feet on solid ground to

prevent being pulled off balance.

• Make sure you can move and stand safely.

Check the area around you for possible

obstacles (roots, rocks, branches, ditches, etc.)

in case you have to move suddenly.

• Do not cut above chest height, as a brush

cutter held higher is difficult to control against

kickout forces.

• Do not work near electrical wires. Leave this

operation for professionals.

• Cut only when visibility and light are adequate

for you to see clearly.

• Do not cut from a ladder, this is extremely

dangerous.

• Stop the brush cutter if the blade strikes a

foreign object. Inspect the blade and brush

cutter; repair parts as necessary.

• Keep the blade out of dirt and sand. Even a

small amount of dirt will quickly dull a blade

and increase the possibility of kickout.

• Stop the engine before setting the brush

cutter down.

• Be particularly cautious and alert while

wearing hearing protection because such

equipment may restrict your ability to hear

sounds indicating danger (calls, signals,

warnings, etc).

• Be extremely cautious when working on

slopes or uneven ground.

GB

WARNING: Never use of a brush cutter

above ground level or with the cutting

attachment perpendicular to the ground.

WARNING: Never use rigid blades when

cutting in stony areas. Thrown objects or

damaged blades may result in serious or fatal

29

Page 14

injury to the operator or bystanders. Watch

out for thrown objects. Always wear approved

eye protection. Never lean over the cutting

GB

attachment guard. Stones, rubbish, etc. can

be thrown up into the eyes causing blindness

or serious injury. Keep unauthorised persons

at a distance. Children, animals, onlookers

and helpers should be kept outside the safety

zone of 15 m. Stop the machine immediately

if anyone approaches. Never swing the

machine around without first checking

behind you to make sure no-one is within the

safety zone.

obstacles (roots, rocks, branches, ditches, etc.)

in case you have to move suddenly. Take great

care when working on sloping ground.

4. Switch off the engine before moving to

another area.

5. Never put the machine down with the engine

running.

• Always use the correct equipment.

• Make sure the equipment is well adjusted.

• Organise your work carefully.

• Always use full throttle when starting to cut

with the blade.

• Always use sharp blades.

Working Techniques

General Working Instructions

WARNING: This section describes the

basic safety precautions for working with

clearing saws and trimmers. If you encounter

a situation where you are uncertain how to

proceed you should ask an expert. Contact

your dealer or your service workshop. Avoid

all usage which you consider to be beyond

your capability. You must understand the

difference between forestry clearing, grass

clearing and grass trimming before use.

Basic safety rules

1. Look around you:

• To ensure that people, animals or other things

cannot affect your control of the machine.

• To ensure that people, animals, etc., do not

come into contact with the cutting attachment

or loose objects that are thrown out by the

cutting attachment.

WARNING: Do not use the machine

unless you are able to call for help in the

event of an accident.

2. Do not use the machine in bad weather, such

as dense fog, heavy rain, strong wind, intense

cold, etc. Working in bad weather is tiring and

often brings added risks, such as icy ground,

etc.

3. Make sure you can move and stand safely.

Check the area around you for possible

30

WARNING: Neither the operator of the

machine nor anyone else may attempt to

remove the cut material while the engine is

running or the cutting equipment is rotating,

as this can result in serious injury. Stop the

engine and cutting equipment before you

remove material that has wound around the

blade as otherwise there is a risk of injury.

The bevel gear can get hot during use and

may remain so for a while afterwards. You

could get burnt if you touch it.

WARNING: Sometimes branches or

grass get caught between the guard and

cutting attachment. Always stop the engine

before cleaning.

Check before starting

• Check the blade to ensure that no cracks have

formed at the bottom of the teeth or by the

centre hole. Discard a blade if cracks are

found.

• Check that the support flange is not cracked

due to fatigue or due to being tightened too

much. Discard the support flange if it is

cracked.

• Ensure the locking nut has not lost its captive

force. The tightening torque of the locking nut

should be 25 Nm.

• Check that the blade guard is not damaged or

cracked. Replace the blade guard if it is

cracked.

WARNING: Never use the machine

Page 15

without a guard or with a defective guard.

Never use the machine without the

transmission shaft.

Forestry clearing

• Before you start clearing, check the clearing

area, the type of terrain, the slope of the

ground, whether there are stones, hollows etc.

• Start at whichever end of the area is easiest,

and clear an open space from which to work.

• Work systematically to and fro across the area,

clearing a width of around 4-5 m on each pass.

This exploits the full reach of the machine in

both directions and gives the operator a

convenient and varied working area to work

in.

• Clear a strip around 75 m long. Move your fuel

can as work progresses.

• On sloping ground you should work along the

slope. It is much easier to work along a slope

than it is to work up and down it.

• You should plan the strip so that you avoid

going over ditches or other obstacles on the

ground. You should also orient the strip to

take advantage of wind conditions, so that

cleared stems fall in the cleared area of the

stand.

Grass clearing using a grass blade

• Grass blades and grass cutters must not be

used on woody stems.

• A grass blade is used for all types of tall or

coarse grass.

• The grass is cut down with a sideways,

swinging movement, where the movement

from right-to-left is the clearing stroke and the

movement from left-to-right is the return

stroke. Let the left-hand side of the blade

(between 8 and 12 o’clock) do the cutting.

• If the blade is angled to the left when clearing

grass, the grass will collect in a line, which

makes it easier to collect, e.g. by raking.

• Try to work rhythmically. Stand firmly with

your feet apart. Move forward after the return

stroke and stand firmly again.

• Let the support cup rest lightly against the

ground. It is used to protect the blade from

hitting the ground.

• Reduce the risk of material wrapping around

the blade by following these instructions:

1. Always work at full throttle.

2. Avoid the previously cut material during the

return stroke.

• Stop the engine, unclip the harness and place

the machine on the ground before you start to

collect the cut material.

Grass trimming with a trimmer head

CAUTION: Do not work with mowing

line longer than the intended diameter. With

a properly mounted guard, the built-in cutter

will automatically adjust the line to its proper

length. Overly long lines can overload the

engine, resulting in damage to the clutch

mechanism and nearby parts.

Trimming

• Hold the trimmer head just above the ground

at an angle. It is the end of the cord that does

the work. Let the cord work at its own pace.

Never press the cord into the area to be cut.

• The cord can easily remove grass and weeds

up against walls, fences, trees and borders,

however it can also damage sensitive bark on

trees and bushes, and damage fence posts.

• Reduce the risk of damaging plants by

shortening the cord to 10-12 cm and reducing

the engine speed.

Clearing

• The clearing technique removes all unwanted

vegetation. Keep the trimmer head just above

the ground and tilt it. Let the end of the cord

strike the ground around trees, posts, statues

and the like.

CAUTION: This technique increases the

wear on the cord.

• The cord wears quicker and must be fed

forward more often when working against

stones, brick, concrete, metal fences, etc., than

when coming into contact with trees and

wooden fences.

• When trimming and clearing you should use

less than full throttle so that the cord lasts

GB

31

Page 16

longer and to reduce the wear on the trimmer

head.

GB

Cutting

• The trimmer is ideal for cutting grass that is

difficult to reach using a normal lawn mower.

Keep the cord parallel to the ground when

cutting. Avoid pressing the trimmer head

against the ground as this can ruin the lawn

and damage the tool.

• Do not allow the trimmer head to constantly

come into contact with the ground during

normal cutting. Constant contact of this type

can cause damage and wear to the trimmer

head.

Sweeping

• The fan effect of the rotating cord can be used

for quick and easy clearing up. Hold the cord

parallel to and above the area to be swept and

move the tool to and fro.

• When cutting and sweeping you should use

full throttle to obtain the best results.

WARNING: Never cut, when visibility is

poor or in very high or low temperatures or in

freezing weather.

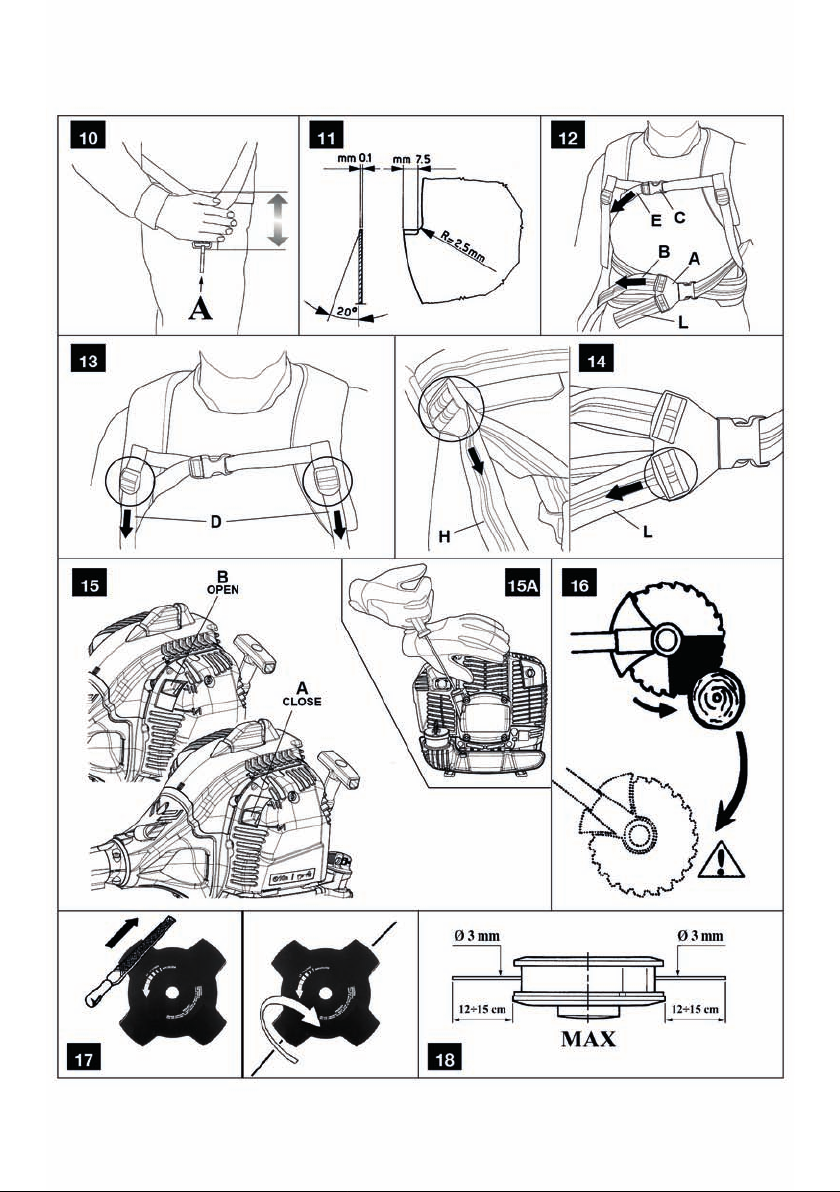

Forestry clearing using a saw blade

• The risk of kickout increases with increasing

stem size. You should therefore avoid cutting

with the area of the blade between 12 o’clock

and 3 o’clock (Fig.16).

• To fell to the left, the bottom of the tree should

be pushed to the right. Tilt the blade and bring

it diagonally down to the right, exerting firm

pressure. At the same time push the stem using

the blade guard. Cut with the area of the blade

between 3 o’clock and 5 o’clock. Apply full

throttle before advancing the blade.

• To fell to the right, the bottom of the tree

should be pushed to the left. Tilt the blade and

bring it diagonally up to the right. Cut with the

area of the blade between 3 o’clock and 5

o’clock so that the direction of rotation of the

blade pushes the bottom of the tree to the left.

• To fell a tree forwards, the bottom of the tree

should be pulled backwards. Pull the blade

backwards with a quick, firm movement.

• If the stems are tightly packed, adapt your

walking pace to suit.

• If the blade jams in a stem, never jerk the

machine free. If you do this the blade, bevel

gear, shaft or handlebar may be damaged.

Release the handles, grip the shaft with both

hands and gently pull the machine free.

Using the circular saw blade

WARNING: Circular saw blades are suitable

for thinning brush and cutting small trees up

to a diameter of 5 cm. Do not attempt to cut

trees with larger diameters, since the blade

may catch or jerk the clearing saw forward.

This may cause damage to the blade or loss of

control of the clearing saw which may result

in serious injury.

WARNING: A saw blade can only be used in

connection with the proper guard (see table

pag.38) a twin handle and double harness

with release mechanism.

Brush cutting with a saw blade

• Thin stems and brush are mown down. Work

with a sawing movement, swinging sideways.

• Try to cut several stems in a single sawing

movement.

• With groups of hardwood stems, first clear

around the group. Start by cutting the stems

high up around the outside of the group to

avoid jamming. Then cut the stems to the

required height. Now try to reach in with the

blade and cut from the centre of the group. If it

is still difficult to gain access, cut the stems

high up and let them fall. This will reduce the

risk of jamming.

8. TRANSPORTING

TRANSPORTION

Carry the brush cutter with the engine o and with

the protective blade cover on (Fig. 3).

ATTENTION: Fit the disk protection p.n.

4196086 as shown (Fig. 3) before transporting or

storing the brushcutter.

32

Page 17

9. MAINTENANCE

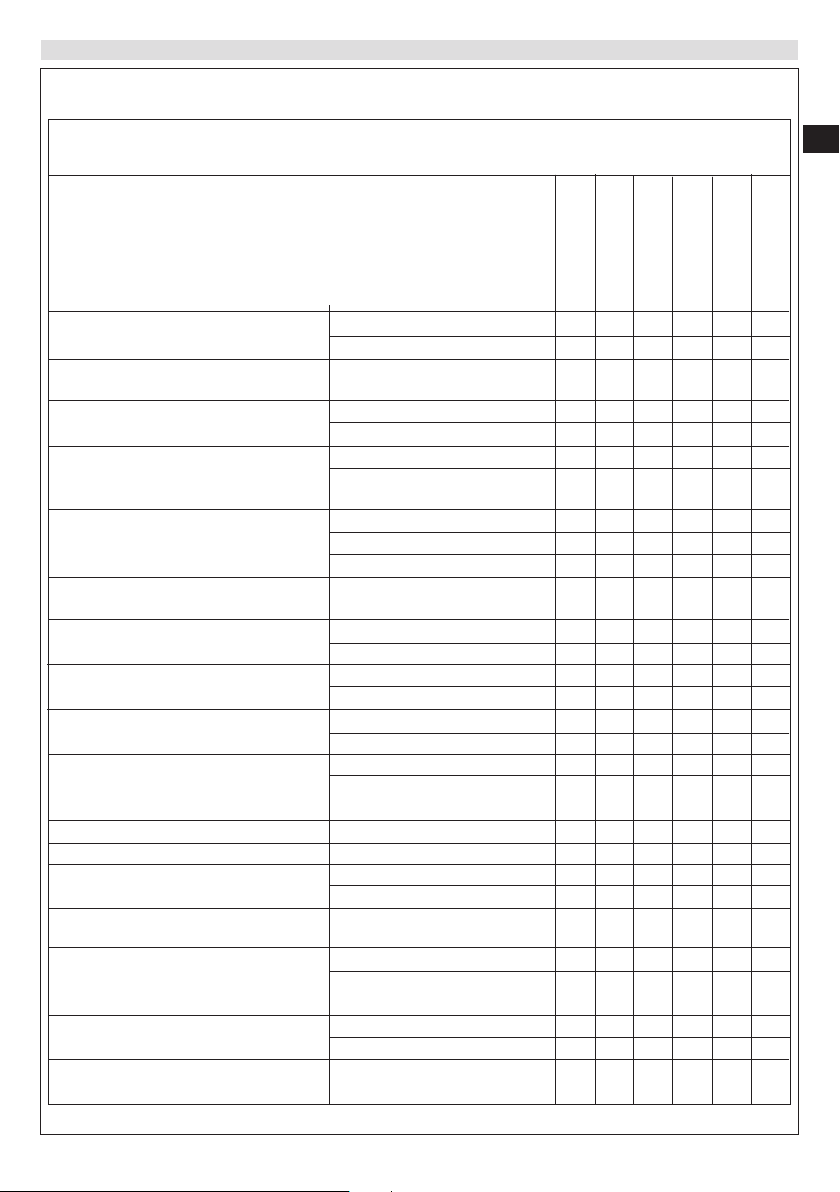

Maintenance Chart

Please note that the following maintenance intervals apply for normal operating conditions only. If your daily work

requires longer than normal or harsh cutting conditions are present, then the suggested intervals should be shortened

accordingly.

Complete Machine

Controls (STOP button, Choke Lever, Throttle

Trigger, Trigger interlock)

Fuel Tank

Fuel Filter and tube

Cutting Attachments

Bevel Gear

Clutch Drum

Cutting Attachments Guard

All Accessible Screws and Nuts (Not Adjusting Screws)

Air Filter

Cylinder Fins

Starter System Vents

Starter Rope

Carburetor

Spark Plug

Vibration Mounts

Cutting Attachments nuts and screws

Inspect (Leaks, Cracks, and Wear)

Clean after finishing daily work

Check Operation

Inspect (Leaks, Cracks, and Wear)

Clean

Inspect

Clean, Replace Filter Element

Inspect (Damage, Sharpness, and Wear)

Check Tension

Sharpen

Inspect (Damage, Wear and Grease Level)

Inspect (Damage, Wear and Grease Level)

Replace

Inspect (Damage, and Wear)

Replace

Inspect

Retighten

Clean

Replace

Clean

Clean after finishing daily work

Inspect (Damage, and Wear)

Replace

Check Idle (Cutting Attachments must not

rotate at idle)

Check Electrode Gap

Replace

Inspect (Damage, and Wear)

Replace by Dealer

Check that the locking nut of the cutting

equipment is tighten correctly

GB

Faulty

Monthly

Before Each Use

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

As Required

If Damaged or

x

x

x

x

x

x

x

x

x

x

x

x

x

1 year or 100 hrs.

6 mouths or 50 hrs.

x

x

x

x

x

33

Page 18

BLADE SHARPENING 234 TOOTH

1. Blades are reversible: when one side is no

GB

longer sharp, the blade can be turned over

and used on the other side (Fig. 17).

2. Blades are sharpened using a at single-cut

le (Fig. 17).

3. To maintain the correct balance, le all cutting

edges uniformly.

4. If the blades are not sharpened correctly, this

can set up abnormal vibrations in the machine

and cause the blades themselves to break

ultimately.

BLADE SHARPENING (8 TOOTH

Always check the general condition of the blade.

Correct sharpening permits the maximum

performance of the brush cutter. To sharpen the

teeth, use a le or grindstone and proceed with

light touches, respecting the corners and the

dimensions shown in Fig. 11.

SHARPENING THE SAW BLADE

• See the cutting attachment packaging for

correct sharpening instructions.

A correctly sharpened blade is essential for

working efficiently and to avoid unnecessary

wear to the blade and clearing saw.

• Make sure that the blade is well supported

when you file it. Use a 5.5 mm round file.

• The filing angle is 15°. File alternate teeth to

the right and those in between to the left. If

the blade has been heavily pitted by stones it

may be necessary to dress the top edges of

the teeth with a flat file, in exceptional cases. If

so, this should be done before filing with a

round file. The top edges must be filed down

by the same amount for all the teeth.

WARNING! – The wrong type of cutter or

an incorrectly sharpened blade will increase the

risk of kickback. Check mower blades for

deterioration or cracks, and replace if damaged.

WARNING: Never repair damaged

cutting attachments by welding,

straightening or modifying the shape. This

may cause parts of the cutting tool to come

off and result in serious or fatal injuries.

NYLON LINE HEAD

Only use line of the same diameter as the original

to avoid overloading the engine (Fig. 18).

In order to get more line out of the cutting head,

tap it lightly on the ground while working.

Note: Never hit the nylon head against hard spots

such as concrete or stones, it could be dangerous.

Replacing the nylon line on the LOAD&GO

trimmer head (Fig.19)

1. Cut 6.0 m of nylon line Ø 3.0 mm.

2. Align the arrows and insert the line into the

trimmer head (Fig. 19.1) until it is released from

the opposite side (Fig.19.2).

3. Divide the line into two equal parts (Fig. 19.3)

and then load the trimmer head by turning the

knob (Fig. 19.4).

WARNING! – Always wear protective

gloves during maintenance operations. Do not

carry out maintenance with the engine hot.

AIR FILTER

Every 8-10 working hours, remove the cover (A,

Fig. 22), clean the lter (B).

Blow with compressed air, at a distance.

Replace if dirty or damaged. The engine runs

irregularly if the lter is clogged, with consequent

higher consumption and lower performance.

FUEL TANK

Check fuel lter periodically. A dirty lter can cause

dicult starting and lower engine performance.

To clean lter proceed as follows: remove it from

fuel lling hole. Replace it (Fig. 21) if too dirty.

ENGINE

Clean cylinder ns with a brush or compressed

air periodically. Dangerous overheating of engine

may occur due to impurities on the cylinder.

SPARK PLUG

Clean spark plug and check electrode distance

periodically (Fig. 23). Use Champion NGK BPMR7A

or of other brand with the same thermal grade.

GEAR HOUSING

Every 30 working hours, remove screw (D, Fig. 8)

34

Page 19

on the gear housing and check the quantity of

grease. Do not use more than 10 grams. Use high

quality molybdenum bisulde grease.

Never use fuel for cleaning operations.

CARBURETOR

Before adjusting the carburetor, clean the air lter

(B, Fig. 22) and warm up the engine. This engine

is designed and manufactured in order to comply

with the applicable 97/68/EC, 2002/88/EC and

2004/26/EC Directive. The carburetor (Fig. 20)

is designed to permit only the adjustement

of L and H screws in a range of 1/4; the quarter

round the hall range admissible for L and H ± 1/8

screws is determined by the manufacturer and

you can not modify it.

WARNING: Don’t try to force the screws

outside the range!

Idle screw T is adjusted in order to ensure a good

safety margin between idle running and clutch

engagement.

Screw L must be adjusted so that the engine

promptly responds to sharp accelerations and

gives good idle operation.

Screw H must be adjusted so that the engine gives

maximum power during the cutting phase.

WARNING: With the engine idling (2800

rpm), the blade should not rotate. We

recommend that you have your nearest

authorised dealer or service workshop carry

out any carburettor adjustments.

WARNING: Weather conditions and

altitude may aect carburation.

MUFFLER

WARNING! - This muer is tted with a

catalytic converter needed for the engine to be in

compliance with the emissions requirements.

Never modify or remove the catalytic converter:

failure to do so is a violation of law.

WARNING! - Muers tted with catalytic

converters get very hot during use and remain

so for some time after stopping. This also

applies at idle speed. Contact can result in burns

to the skin. Remember the risk of re!

CAUTION! -

must be replaced. If the muffler frequently

becomes blocked, this could be an indication that

the efficiency of the catalytic converter is limited.

WARNING: Do not operate your brush

cutter if the muffler is damaged, missing or

modified. An improperly maintained muffler

will increase the risk of fire and hearing loss.

EXTRA MAINTANANCE ADVISABLE

It is advisable to inspect the machine by a

specialized technician at an authorized service

network at t he e nd of se ason, if us ed

intensively, and every two years if with normal

use.

ATTENTION: All maintenance operations

not reported in this manual must be carried

out by an authorized Service Center.

To ensure steady and regular brush cutter

operation, remember that parts must only be

replaced with ORIGINAL SPARES.

Any unauthorized changes and/or use

of non-original replacement parts may result

in serious injury or death to the operator or

third parties.

10. STORAGE

If the machine is to be stored for long periods:

- Drain and clean the fuel tank in a well-ventilated

area. To drain the tank, start the engine and

wait until the fuel is exhausted and the engine

stops (leaving fuel mixture in the carburettor

could damage the membranes).

- The procedures for returning the machine to

service following winter storage are the same as

for starting up during everyday use (page 26).

- Follow all the maintenance regulations

previously described.

- Clean the brush cutter completely and lubricate

the metallic parts.

If the muffler is damaged, it

GB

35

Page 20

- Remove, clean and lubricate the blade to

prevent rusting.

- Remove the blade xing anges, clean, dry

GB

and lubricate the bevel gear seat.

- Empty the fuel tank and put the cap back on.

- Thoroughly clean the cooling slots and the air

lter (B, Fig. 22).

- Store the brush cutter in a dry place, preferably

not in direct contact with the oor and away

from heat sources.

11. ENVIRONMENTAL PROTECTION

Environmental protection should be a priority of

conside rable importance when using the

machine, for the benefit of both social cohesion

and the environment in which we live.

- Try not to cause any disturbance to the

surrounding area.

- Scrupulously comply with local regulations

and provisions for the disposal of waste

materials after mowing.

- Scrupulously comply with local regulations

and provisions for the disposal of oils, petrol,

batteries, filters, deteriorated parts or any

elements which have a strong impact on the

environment. T h is wa s te mu s t not be

disposed of as normal waste, it must be

separated and taken to specified waste

disposal centres where the material will be

recycled.

Demolition and disposal

When the machine reaches the end of its service

life, do not dispose of it into the environment;

instead take it to a waste disposal centre.

Most materials used in the manufacture of the

ma chine are recyclable; all metals (s teel,

aluminium, brass) can be delivered to a normal

recycling station. For information contact your

local waste recycling service. Waste disposal

must be carrie d out with respect for the

environment, avoiding soil, air and water

pollution.

In all cases, applicable local legislation must

be complied with.

36

Page 21

12. TECHNICAL DATA

GB

Displacement

Engine

Power

Min. rpm

Maximum speed of output

spindle

Engine speed at maximum

output spindle speed

Fuel tank capacity

Primer carburetor

Antivibration system

Cutting width

cm

kW

min

min

min

cm

cm

DS 3500 S - BC 350 S

3

36.3

DS 3500 T - BC 350 T

2 stroke EMAK

1.4

-1

-1

-1

3

2800

8.500

11.700

600 (0.6 l)

Yes

Yes

42

Weight without cutting tool

and guard

kg

6.9

7.4

37

Page 22

GB

Recommended cutting attachments

Model Cutting attachments Guards

DS 3500

BC 350

DS 3500

BC 350

DS 3500

BC 350

DS 3500

BC 350

DS 3500

BC 350

DS 3500

BC 350

DS 3500 T - BC 350 T P.N. 4095635AR P.N. 4174279

DS 3500 T - BC 350 T P.N. 4095066AR P.N. 4174279

* protection p. n. 4174283A not needed

P.N. 63129003

P.N. 63129004

P.N. 63019018

P.N. 63019017

P.N. 4095673AR

P.N. 4095674AR

P.N. 4095638AR

P.N. 4095563AR

P.N. 4095565AR

P.N. 4095065AR

P.N. 61042035A

P.N. 61042036A

P.N. 61042035A

P.N. 61042036A

P.N. 61042035A

P.N. 61042036A

P.N. 61042035A

P.N. 61042036A

P.N. 61042035A

P.N. 61042036A

P.N. 61042035A

P.N. 61042036A

*

*

*

*

WARNING!!!

Using an incorrect cutting attachment increases the risk of accidents! Only use the

recommended cutting attachments and guards and follow the manufacturer’s sharpening

instructions.

38

Page 23

DS 3500 S - BC 350 S DS 3500 T - BC 350 T

GB

Pressure level

Uncertainty

Measured sound

power level

Uncertainty

Guaranteed

sound power

level

Vibration level

Uncertainty

dB (A)

dB (A)

dB (A)

dB (A)

dB (A)

m/s

m/s

EN 11806

EN 22868

2000/14/EC

EN 22868

EN ISO 3744

2000/14/EC

EN 22868

EN ISO 3744

EN 11806

2

EN 22867

EN 12096

2

EN 12096

LpA av

L

WA

96.5 91.5 91.5 91.5

3.0 3.0 3.0 3.0

110.0 106.0 106.0 106.0

2.0 2.0 2.0 2.0

112.0 108.0 108.0 108.0

5.5 (sx)

5.2 (dx)

2.5 (sx)

1.1 (dx)

5.2 (sx)

4.6 (dx)

1.3 (sx)

1.1 (dx)

3.1 (sx)

4.1 (dx)

3.4 (sx)

2.4 (dx)

4.4 (sx)

4.4 (dx)

2.4 (sx)

2.1 (dx)

*

*

- Weighted average values: 1/2 minimum rpm, 1/2 at full load (head) or 1/2 racing (blade).

*

39

Page 24

13. DECLARATION OF CONFORMITY

The undersigned, Emak spa via Fermi, 4 - 42011 Bagnolo in

Piano (RE) ITALY declares under its own responsibility that

GB

the machine:

1. Category: brushcutter/grass trimmer

2. Brand Efco, Type DS 3500 S - DS 3500 T

Brand Oleo-Mac, Type BC 350 S - BC 350 T

3. Serial ID 246 XXX 0001 ÷ 246 XXX 9999 (DS 3500 S - BC 350

S) - 249 XXX 0001 ÷ 249 XXX 9999 (DS 3500 T - BC 350 T)

conforms to the requirements of Directives:

2006/42/CE - 2000/14/CE - 2004/108/CE - 97/68/CE - 2004/26/

CE, conforms to the provisions of the following harmonized

standards:

EN 55012 - EN ISO 11806

Procedures for evaluation of conformity followed:

Annex V - 2000/14/CE

Measured sound power level: 110.0 dB (A) (DS 3500 S - BC

350 S) - 106.0 dB (A) (DS 3500 T - BC 350 T)

14. WARRANTY CERTIFICATE

This machine has been designed and manufactured using the

most modern techniques. The manufacturer guarantees its

products for 24 months from the date of purchase, for private

and hobby use. The warranty is limited to 12 months in case

of professional use.

Limited warranty

1) The warranty period starts on the date of purchase. The

manufacturer, acting through the sales and technic al

assistance network, shall replace free of charge any parts

p ro ve n de f ec ti v e i n m at er ia l, ma c hi ni n g o r

ma nuf act uri ng. The war ran ty d oes no t af fec t the

purcha ser’s ri ghts a s est abli shed un der legislati on

governing the consequences of defects in the machine.

2) Technical personnel will undertake the necessary repairs

in th e mi nimu m t ime po ssi ble , com pati ble wi th

organisational needs.

3) To make any claim under the warranty, this certificate

of warr anty, fully co mplete d, bearing th e d ealer’s

sta mp and accom panied by the invo ice or receipt

showing the date of purchase, must be displayed to

the personnel authorised to approve work.

4) The warranty shall be null and void if:

- the machine has evidently not been serviced correctly

Guaranteed sound power level: 112.0 dB (A) (DS 3500 S - BC

350 S) - 108.0 dB (A) (DS 3500 T - BC 350 T)

Technical Do cumentation deposit ed with Admin istrative

Headquarters: Technical Department

Signed in Bagnolo in Piano (RE) Italy - via Fermi, 4

Date: 31/01/2014

s.p.a.

Fausto Bellamico - President

- the machine has been used for improper purposes or has

been modified in any way,

- unsuitable lubricants and fuels have been used

- non-original spare parts and accessories have been fitted

- work ha s been done on the machine by unauthor ised

personnel

5) The war ranty does no t cover con sumab les or par ts

subject to normal wear.

6) The warranty does not cover work to update or improve

the machine.

7) T he wa rra nty does n ot co ver an y pre par ation or

servicing work required during the warranty period.

8) Damage incurred during transport must be immediately

brought to the attention of the carrier: failure to do so

shall render the warranty null and void.

9) Engi nes of other manu facture rs (Bri ggs & Stra tton,

Subaru, Honda, Lombardini, Kohler, etc.) fitted to our

machines are covered by the warranties of the engine

manufacturer.

10) The warranty does not cover injury or damage caused

directly or indirectly to persons or things by defects in

the machine or by periods of ex tended disuse of the

machine resulting from the said defects.

MODEL

SERIAL No

BOUGHT BY Mr.

Do not send! Only attach to requests for technical warranties.

40

DATE

DEALER

Page 25

15. TROUBLESHOOTING

WARNING: always stop the machine and remove the key before carrying out any of the

corrective checks recommended in the table below, except when they require the unit

to be in operation.

When all the possible causes have been checked and the problem is not resolved, consult an

Authorised Service Centre. If a problem occurs that is not listed in this table, consult an Authorised

Service Centre.

PROBLEM POSSIBLE CAUSES SOLUTION

Engine will not start or will

run only a few seconds

after starting.

Engine starts but will not

accelerate properly or will

not run properly at high

speed.

1. No spark

2. Flooded engine.

Ca rburetor re qui res

adjustment.

1. Watch for spark at spark plug

tip. If there is no spark, repeat

test with a new spark plug

(BPMR7A).

2. Follow procedure page 28. If

engine still fails to start, repeat

procedure with a new spark

plug.

Contact a Servicing Dealer for

carburetor adjustment.

GB

Engine does not reach full

speed and / or emits

excessive smoke

Engine starts, runs and

accelerates but will not

idle.

Engine starts and runs, but

cutting attachment is not

rotating

WARNING: Never

touch the cutting

attachment while the

engine is running.

WARNING: Do not attempt to carry out repairs without the necessary repairs and

technical expertise. Poorly executed repairs will automatically invalidate the warranty and

relieve the manufacturer of all liability.

1. Check oil fuel mixture.

2. Air filter dirty.

3. Carburetor requires

adjustment.

Ca rburetor re qui res

adjustment.

Clutch, bevel drive or

transmission shaft damaged

1. Use fresh fuel and the correct

2-cycle oil mix.

2. Clean per instruction in

Maintenance-Air Filter Section.

3. Contact a Servicing Dealer for

carburetor adjustment.

Turn idle speed screw

(Fig. 20) clockwise to increase idle

speed. See Operation-Carburetor

Adjustment.

Replace if necessary - contact a

Servicing Dealer.

“T”

41

Page 26

PREKLAD PÔVODNÝCH POKYNOV

ÚVOD

Aby ste strojové zariadenie používali správne a

aby ste predišli nehodám, nezačínajte prácu

bez toho, že by ste si veľmi pozorne prečítali

návod na používanie. V tomto návode nájdete

vysve tle nia čin nos ti rôznych častí, ako aj

pokyny pre nevyhnutné kontroly a údržbu.

Poz námka. Popisy a ilustrácie uvedené v

tomt o n ávod e n ie sú prísn e z áv äzn é.

V ý ro b c a si v y h r ad z u je p r áv o n a

vykonávanie zmien v tomto návode bez

predchádzajúceho upozornenia.

Okrem pok ynov na obsluhu obsahuje tento

ná vo d in fo rm áci e, k to ré si v yž ad uj ú

mimoriadnu pozornosť. Tieto informácie sú

o zn a če n é s ym b o lm i p o p í s an ý mi v

nasledujúcom texte:

POZOR: v prípade nebezpečenstva úrazov

alebo vážnych poranení osôb alebo vážneho

poškodenia majetku.

UPOZORNENIE: v prípade nebezpečenstva

poškodenia jednotky alebo jednotlivých častí

strojového zariadenia.

POZOR

RIZIKO POŠKODENIA SLUCHU

ZA NORMÁLNYCH PODMIENOK POUŽÍVANIA

SA OSOBA, KTORÁ STROJ POUŽÍVA, VYSTAVUJE

DENNEJ HLADINE HLUKU ROVNEJ ALEBO

VYŠŠEJ AKO

85 dB (A)

OBSAH

1. B E Z PE Č N O S TN É P RE D P I S Y

(obsahuje predpisy na používanie

stroja bezpečným spôsobom)

2. V YS V ET LE NI E S YM B OLO V A

BE ZPE ČNO STN É UPO ZORNENI A

(vysvetľuje, ako identifikovať strojové

zariadenie a význam symbolov)

3. HLAVNÉ KOMPONENTY (vysvetľuje

um ie st nen ie hl av ný ch pr vkov

tvoriacich strojové zariadenie)

4. MONTÁŽ (vysvetľuje ako odstrániť

obal a dokončiť montáž odpojených

prvkov)

105

107

107

107

5. ŠTARTOVANIE 109

6. ZASTAVENIE MOTORA 111

7. P O U ŽÍ V AN I E S T RO J O V ÉH O

ZARIADENIA

8. PREPRAVA 115

9. ÚDRŽBA (obsahuje všetky informácie

na zachovanie účinnosti strojového

zariadenia)

10. USKLADNENIE 119

11. O C H R A N A Ž I V O T N É H O

PROSTREDIA (Obsahuje niektoré

rady na použív anie strojové ho

zariaden ia v sú lade s o chranou

životného prostredia)

12. TECHNICKÉ ÚDAJE (Súhrn hlavných

charakteristík strojového zariadenia)

13. VYHLÁSENIE O ZHODE 123

14. ZÁRUCA A SERVIS (Súhrn záručných

podmienok)

15. PRÍRUČKA NA RIEŠENIE

PROBLÉMOV (Pomáha pri rýchlom

vyriešení prípadných problémov pri

používaní)

1. BEZPEČNOSTNÉ PREDPISY

POZOR

- Pokiaľ sa strojové zariadenie používa

správne, j e r ýc hlym p om oc níkom a

účinným nástrojom. Pokiaľ sa používa

nes pr ávn e al eb o be z do drž iava ni a

bezpečnostných predpisov, môže sa stať

nebezpečným nástrojom. Aby bola vaša

pr ác a v žd y pr íj emn á a bez peč ná,

dô sle dne do drži avajte be zpečn ost né

prav idlá, ktoré sú uvedené v tomto

návode na použitie.

- Vystavenie sa vibráciám vznikajúcich pri

dlh od ob om po už ív an í mo to ro vý ch

nástrojov s vnútorným spaľovaním môže

spôsobiť poškodenie ciev alebo nervov

prstov, rúk a zápästí u osôb, u ktorých sa

pr ejavujú prob lémy s obeho m kr vi a

anomálne opuchy. Dlhodobé používanie

za s tuden ého p oč asia m ôže v ies ť k

poškodeniu ciev aj ináč zdravých ľudí. Ak

sp ozor uje te symptó my ako tŕ pnut ie,

bo lesť , stratu cit livosti, zmeny farby

111

116

119

120

123

124

SK

105

Page 27

po kožk y aleb o jej vzhľa du, prípadn e

st ra tu c it liv os ti p rst ov, rú k a le bo

zápä stia, prest aňte stroj používať a

vyhľadajte lekára.

- Štartovací systém jednotky produkuje

el ektrom agnetické po le veľ mi nízkej

intenzity. Toto pole môže rušiť činnosť

niektorýc h pacemakerov. Na zníženie

ri zi ka vá žny ch al eb o sm rt eľ nýc h

poranení, by sa osoby s pacemakerom

mali p oradiť s o s vojím l ek árom a s

v ýr ob co m p ac em ak era e št e pr ed

používaním tohto stroja.

SK

POZOR: Vnútroštátne predpisy môžu

obmedz ovať p ouž ívanie strojového

zariadenia.

1 - Stroj nepoužívajte skôr, kým sa podrobne

neoboznámite s jeho obsluhou.

Začiatočníci by si mali pred prácou obsluhu

stroja vyskúšať.

2 - Stroj smú používať iba dospelé osoby, v

dobrom fyzickom stave, ktoré sú

oboznámené s jeho obsluhou v rozsahu

tohto návodu.

3 - Nepoužívajte krovinorez, keď ste unavení

alebo pod vplyvom alkoholu, drog, iných,

omamných látok alebo liekov.

4 - Noste vh odný o chzanný o dev a aj

iné ochranné prostriedky, ako čižmy,

hrubé nohavice, rukavice, slúchadlá a

protiúrazovú prilbu. Noste priliehavé, ale

pohodlné oblečenie.

5 - Nedovoľte používať krovinorez deťom.

6 - N ed ov oľ te in ým os ob ám , aby sa

zdrž iavali v ok ru hu 15 metrov od

krov inor ezu poč as je ho použ ívani a.

7 - Pred použitím krovinorezu skontrolujte,

či je upevňovacia skrutka kotúča dobre

utiahnutá.

8 - Krovinorez musí byť vybavený reznými

nástrojmi, ktoré sú odporúčané výrobcom

(pozri str. 121).

9 - Nepoužívajte krovinorez bez ochranného

štítu kotúča alebo hlavy.

10 - Pred naštartovaním motora sa ubezpečte,

či sa kotúč voľne točí a či nie je v kontakte

s cudzími predmetmi.

11 - Po čas práce kotúč často kontrolujte

zastavením motora. V prípade výskytu

trhlín alebo prasklín kotú č okam žite

vymeňte.

12 - Stroj používajte iba na dobre vetraných

miestach, nepoužívajte ho vo výbušnom

alebo horľavom prostredí ani v uzavretých

priestoroch.

13 - Ak je motor spustený, nerobte žiadnu

údržbu ani nechytajte kotúč.

14 - Na pohon stroja sa nesmie namontovať

žiadne zariadenie, ak ho neodporučil

výrobca.

15 - Nepracujte s poškodeným, zle opraveným,

ne spr ávne zm ontovaným alebo ináč

upraveným s trojom. Ne odstraňujte,

nepoškodzujte a nev yraďujte žiadne

bezpečnostné zariadenie. Používajte iba

rezacie zariadenia uvedené v tabuľke.

16 - Všetky štítky a nálepky s výstražnou

signalizáciou udržiavajte v dokonalom

stave . V prípa d e poškodenia alebo

opotrebovania ich treba včas vymeniť

(Obr. 24).

17 - Stroj nepoužívajte na iné účely ako sú

uvedené v návode (pozrite ods. 111).

18 - Stroj nenechávajte bez dozoru, ak je

zapnutý jeho motor.

19 - Motor neštartujte ak nie je krovinorez

kompletne zložený.

20 - Vž dy p re d k ažd ým z ač atí m p rác e

kontrolujte krovino rez, aby s te sa

ube zp eč il i, č i j e k až dá s úči as tk a,

bezpečnostné zariadenie úplne funkčné a

skrutkové spoje sú dotiahnuté.

21 - Nevykonávajte zása hy alebo opravy,

ktoré nie sú súčasťou normálnej údržby.

V takomto prípade sa radšej obráťte sa na

autorizovaný servis.

22 - V prípade, že stroj budete musieť vyradiť,

nevyhadzujte ho voľne, ale odovzdajte

ho v predajni, kde ste ho kúpili alebo v

zbernom stredisku.

23 - Vyžínač odovzdajte alebo požičiavajte len

skúseným osobám, ktoré sú oboznámené

s j eho obsluhou . S troj odovzdaj te

ďalším používateľom aj s návodom na

106

Page 28

používanie, aby si ho mohli pred použitím

prečítať.

24 - V prípade potreby akéhokoľvek ďalšieho

objasnenia alebo zásahu sa vždy sa

obráťte na vášho.

25 - Tento návod starostlivo uschovajte a pred

každým použitím píly ho konzultujte.

26 - Nezabudnite, že majiteľ alebo obsluhujúci

pracovník nesú zodpovednosť za úrazy

alebo riziká pre iné osoby, ako aj za ich

majetok.

POZOR

- J e dn o tk u n i kd y n e p ou ž ív a jt e s

p o š k o d e ný m i b e z p e č n o s t n ý mi

funk ciami. B ezpečnostné zari adenia

musíte kontro lovať a udržiav ať podľa

pokynov uvedených v tejto časti. Ak stroj

ne zo dp ov ed á p od mie nk am p od ľ a

pok ynov kont roly, zavolaj te servis a

dajte stroj opraviť.

- Akékoľvek používanie stroja, ktoré nie je

vyslovene uvedené v návode, sa musí

považovať za nevhodné používanie, teda

za zdroj rizika pre osoby a majetok.

3. HLAVNÉ KOMPONENTY (Obr.1)

1÷3 - Náradie

4 - Popruh

5 - Pár kužeľovitý

6 - Ochranný štít

7 - Kosiaca strunová hlavica

8 - Uzáver palivovej nádrže

9 - Vstrekovač paliva

10 - Skrutka nastavenia karburátora

11 - Kryt tlmiča výfuku

12 - Sviečka

13 - Vzduchový filter

14 - Štartovacia rukoväť

15 - Páčka sýtiča

16 - Bezpečnostná poistka plynu

17 - Tlačidlo stop

18 - Páčka plynu

19 - Pripojenie popruhu cez rameno

20 - Rukoväť

21 - Rúrka hriadeľa

22 - Tlačidlo polovičná plyn

4. MONTÁŽ

SK

2 . V Y S V E T L E N I E S Y M B O L O V A

BEZPEČNOSTNÉ UPOZORNENIA (Obr. 24)

1 - Pred prácou s týmto prístrojom si prečítajte

návod na použitie a údržbu.

2 - Používajte ochrannú prilbu, okuliare a

slúchadlá.

3 - Pri používaní kovových alebo plastových

kotúčov používajte ochrannú obuv a

rukavice.

4 - Pozor na odmrštené redmety.

5 - Udržiavajte min. vzdialenosť 15 m od

okolostojacich osôb a zvierat.

6 - POZOR! - Povrch môže byť horúci!

7 - Mimoriadnu pozornosť venujte spätnému

vrhu. Môže byť veľmi nebezpečný.

8 - Vstrekovač paliva.

9 - Druh stroja: VYŽÍVAČE.

10 - Zaručená hladina akustického výkonu

11 - Značka zhody CE

12 - Číslo série

13 - Rok výroby.

14 - Max. otáčky výstupného hriadeľa, OT./MIN.

MO NTÁ Ž O CHRANNÉHO ŠTÍT U (Obr. 7)

Pripevnite štít (A) k rúrke hriadeľa pomocou

skrutiek (B) v postoji, ktorý umožňuje bezpečnú

prácu.

POZNÁMKA: používajte nástavec štítu (C)

iba pri použití strunovej kosiacej hlavice.

Nást ave c štítu (C) m usí by ť up evnený

pomocou skrutky (D) ku krytu (A).

MONTÁŠ HLAVICE Z NYLONOVÝCH VLÁKIEN

(Obr. 8)

Nasaľte horný unášač (F). Vlošte čap hlavice (H)

do príslušného otvoru (L) a dotiahnite hlavicu

(N) rukou proti smeru hodinových ručičiek.

MONTÁŽ KOTÚČA (Obr. 9)

Povoľte lištu (A) v smere hodinových ručičiek;

odnímte spodný kryt (D) a spodný unášač (E).

Nasaľte kotúč (R) na horný unášač (F), dávajte

pozor na smer rotácie. Nasaľte spodný unášač

(E), spodný kryt (D) a dotiahnite skrutku (A) proti

smeru hodinových ručičiek. Do otvoru (L) vsuÀte

107

Page 29

čap a zablokujte kotúč a dotiahnite skrutku (A)

krútiacim momentom 2.5 kgm (25 Nm).

POZOR – Objímka (pozri šípk y C, Obr. 9)

musí zapadnúť do otvoru na namontovanie

kotúča.

- Spojte krovinorez s popruhom pomocou

karabínky (A, Obr. 10).

- Nastavte závesné oko (19A, Obr. 1), aby ste

dosiahli lepšie vyváženie krovinorezu.

- Nastavte dÍžku ramenného popruhu aby

mal krovinorez potrebnú výšku nad zemou.

MONTÁŽ RUKOVÄTE (Obr. 2)

Nasaľte rukoväť na trubicu hriadeľa a upevnite

ju pomocou skrutiek (A). Poloha rukoväte je

nastaviteľná podľa pošiadaviek obsluhy.

MONTÁŽ BEZPEČNOSTNEJ OPIERKY (Obr.

SK

9A)

Ak poušívate namiesto hlavice z nylonových

vlákien kotúč, je potrebné namontovať

“bezpečnostnú opierku”. Upevnite opierku (A)

pod úchytku rukoväte (C) (20B, Obr. 1), dávajte

pritom pozor, aby bola “bezpečnostná opierka”

pripevnená na ľavej strane krovinorezu.

UPEVNENIE DVOJRAMENNÉHO DRŽADLA

(Obr. 4)

- Pri upevnení rukoväte vsuňte pružinu (B) a

kruhovú podložku (C).

- Zarovnajte dvojramenné držadlo do pravého

uhla vzhľadom na rúrku prevodu.

- Nakoniec utiahnite svorku so skrutkou (D).

MONTÁŽ OVLÁDACÍCH RUKOVÄTÍ Obr.6)

- Uvoľnite skrutku (G). Matica (H) ostane v

ovládacej rukoväti (L).

- Nasuňte ovládaciu rukoväť (L) (akcelerátor M

musí byť otočený smerom k ozubenému

súkoliu) na držadlo (N) tak, aby boli zarovnané

otvory (P).

- Vsuňte skrutku (G) a pevne utiahnite.

UPOZORN ENIE: Ubezpe čte sa, či sú

vš et ky sú ča sti k ro vi nor ez u s práv ne

namontované a skrutky dobre utiahnuté.

PRÍPRAVNÉ PRÁCE

SPRÁVNE NASTAVENIE POPRUHU (4S, Obr. 1)

Správne nastavenie popruhu umožní náležité

vyváženie krovinorezu a vhodnú vzdialenosť od

zeme (Obr. 10).

- Používajte jednoduchý popruh.

SPRÁVNE NASTAVENIE POPRUHOV modely

DS 3500 T - BC 350 T

1. Navlečte si dvojité popruhy (4T, Obr. 1).

2. Pracku (A, Obr. 12) zasuňte do príslušného

úchytu a nastavte ju pomocou horného

popruhu (B).

3. Pracku (C) zasuňte do príslušného úchytu na

hrudníku.

4. Ramenné popruhy nastavte dvomi popruhmi

(D, Obr. 13). Týmito popruhmi je možné

rozložiť váhu nákladu predovšetkým na

ramená alebo do pásikov podľa priania

pracovníka.

5. Nastavte popruh (E, Obr. 12) v oblasti

hrudníka.

6. Pomocou karabínky pripevnite krovinorez k

popruhom (F, Obr.-1).

7. Výšku prístroja nad terénom nastavte dvoma

popruhmi (H-L, Obr. 14). Správnu vzdialenosť

medzi popruhmi a karabínkou je nutné

vymerať ako na obr. 10. Toto nastavenie

prispeje k ešte lepšiemu rozloženiu váhy a

správnemu vyváženiu krovinorezu.

UPOZORNENIE! - V prípade, že použijete

čepele na drevo (22-60-80 zubov), je povinné

použiť dvojitý popruh s možnosťou rýchleho

uvoľnenia.

SCHVÁLENÉ PRÍSLUŠENSTVO

Na zá kl ad ný st ro j mož no na mo nto vať

nasledujúce príslušenstvo značky Emak:

EH 25 Krovinorez (nastaviteľný) (1) (2)

EH 50 Krovinorez (nastaviteľný) (1) (2)

EP 100 Orezávač (2)

EP 120 Orezávač (2)

(1) Ochranná bariéra (A , Obr. 9A) musí byť

namontovaná pod kruhovou rukoväťou (loop).

(2) Nie je schválená na použitie s modelmi s

dvojramenným držadlom (DS 3500 T - BC 350

T).

108

Page 30

5. ŠTARTOVANIE

odev.

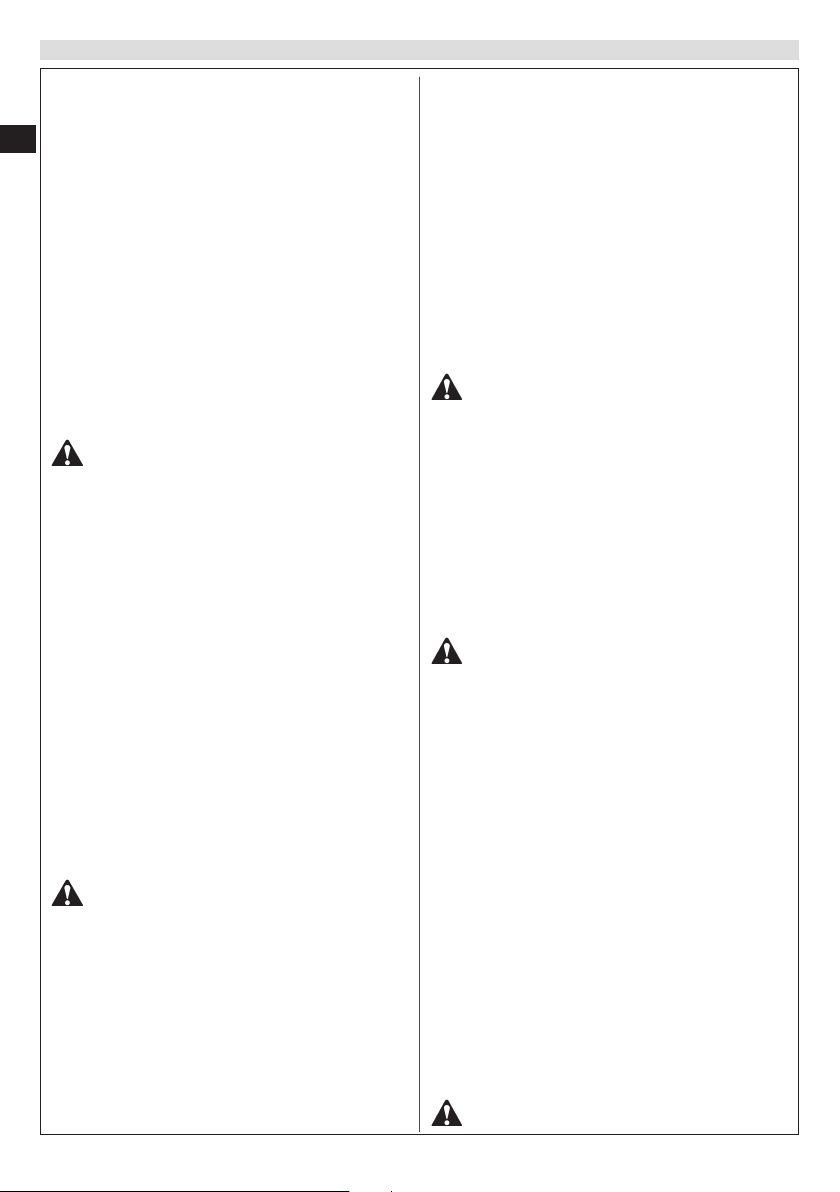

BENZINE

OLIE

A

PALIVO

POZOR: benzín je mimoriadne horľavé

palivo. Pri manipulácii s benzínom

alebo zmesou palív dávajte veľ ký

pozor. V blízkosti paliva ani vyžínača

nefajčte ani sa k nim nepribližujte s

otvoreným plameňom.

· Aby sa znížilo nebezpečenstvo požiaru a

popálenia sa, s palivom zaobchádzajte

opatrne. Je veľmi horľavé.

· Palivo premiešajte a naplňte ním nádobu

vhodnú na uchovávanie paliva.

· Palivo miešajte vonku, mimo dosahu iskier

alebo plameňov.

· Pred dopĺňaním paliva stroj položte na zem.

· Uzáver palivovej nádrže odskrutkujte pomaly,

aby sa uvoľnil tlak a zabránilo sa úniku paliva.

· Po doplnení paliva pevne uzatvorte uzáver.

Vibrácie by mohli spôsobiť jeho uvoľnenie a

únik paliva.

· Palivo uniknuté z jednotky osušte. Presuňte

stroj o približne 3 metre od miesta, kde ste

dopĺňali palivo, až potom naštartujte motor.

· Nikdy a za žiadnych okolností sa nepokúšajte

zapáliť uniknuté palivo.

· Počas manipulácie s palivom ani počas

prevádzky stroja nefajčte.

· Palivo skladujte na čerstvom, suchom a dobre

vetranom mieste.

· Neskladujte palivo na miestach, kde je suché

lístie, slama, papier a pod.

· Jednotku a palivo uchovávajte na miestach,

kde výpary paliva neprídu do kontaktu s

iskrami alebo otvoreným plameňom,

ohrievačmi vody a kotlami, elektrickými

motormi alebo spínačmi, sporákmi a pod.

· Pokiaľ je motor v chode, neotvárajte uzáver

palivovej nádrže.

· Palivo nepoužívajte na čistenie.

· Dávajte pozor, aby ste si palivom nezašpinili

l

1

5

10

15

20

25

2%-50 : 1

l (cm

0,02 (20)

0,10 (100)

0,20 (200)

0,30 (300)

0,40 (400)

0,50 (500)

4%-25 : 1

3

) l (cm3)

0,04 (40)

0,20 (200)

0,40 (400)

0,60 (600)

0,80 (800)

1,00 (1000)

Tento stroj je poháňaný dvojtaktným motorom a

vyžaduje prípravu zmesi benzínu a oleja pre

2-taktné motory. Pripravte zmes bezolovnatého

benzínu a oleja pre dvojtaktné motory v čistej

nádobe, ktorá je vhodná na uchovávanie

benzínu.

ODPORÚČANÉ PALIVO: TENTO MOTOR JE

SCHVÁLENÝ NA NAPÁJANIE BEZOLOVNATÝM 89

OKTÁNOVÝM BENZÍNOM PRE MOTOROVÉ

VOZIDLÁ ([R + M] / 2) ALEBO S VYŠŠÍM

OKTÁNOVÝM ČÍSLOM.

Zmiešajte olej pre dvojtaktné motory s benzínom

podľa pokynov na obale.

Odporúčame vám používať olej pre 2-taktné

motory Efco - Oleo-Mac v pomere 2% (1:50),

vyvinutý špeciálne pre všetky dvojtaktné

motory chladené vzduchom.

Správne pomery zmesi olej/palivo uvedené v

schéme (obr.A) sa vzťahujú na motorový olej

PROSINT 2 a EUROSINT 2 alebo na rovnocenný

kvalitný olej (špecifikácie JASO FD alebo ISO

L-EGD). Keď špecifikácie oleja NIE SÚ

rovnocenné alebo nie sú známe, použite zmes v

pomere 4% (1:25).

UPOZORNENIE: NEPOUŽÍVAJTE OLEJ

PRE MOTOROVÉ VOZIDLÁ ANI PRE 2-TAKTNÉ

LODNÉ MOTORY.

UPOZORNENIE:

- Kupujte iba také množstvo paliva, ktoré

spotrebujete; nekupujte viac, ako

spotrebujete počas jedného alebo dvoch

mesiacov;

- Benzín uchovávajte v hermeticky

uzavretej nádrži, na čerstvom a suchom

mieste.

109

SK

Page 31

UPOZORNENIE - Pri príprave zmesi

nikdy nepoužívajte palivo s obsahom etanolu

vyšším ako 10 %; môže sa použiť gasohol

(zmes benzínu a etanolu) s percentuálnym

obsahom etanolu do 10 % alebo palivo E10.

POZNÁMKA - Pripravujte vždy iba také

množstvo zmesi, ktoré potrebujete,

nenechávajte palivo dlho v nádrži alebo v

kanistri. Odporúča sa použitie stabilizačnej látky

Emak ADDITIX 2000 s kódom 001000972, ktorá

umožňuje uskladniť palivovú zmes na dobu 30

SK

dní.

Benzín s obsahom alkylov

UPOZORNENIE - Benzín s obsahom

alkylov nemá rovnakú hustotu ako normálny

benzín. Preto motory nastavené na normálny

benzín si môžu vyžadovať odlišné nastavenie

skrutky H. Pri tomto postupe sa musíte

obrátiť na autorizované servisné stredisko.

DOPĹŇANIE PALIVA

Pred dopĺňaním zmesi bandaskou potraste.

ŠTARTOVANIE

Pred naštartovaním motora sa

ubezpečte, či sa kotúč voľne točí a či nie je v

kontakte s cudzími predmetmi.

Pri minimálnych otáčkach sa rezacie

zariadenie nesmie otáčať. V opačnom

prípade kontaktujte Autorizovaného

Servisného Strediska, aby v ykonala

kontrolu a odstránenie problému.

POZOR: Krovinorez držte pevne

oboma rukami. Vždy stojte tak, aby bolo

vaše telo vľavo od stroja. Nikdy stroj nedržte

prekríženými rukami. Tieto pokyny musia

dodržiavať aj ľaváci.

Udržiavajte správny pracovný postoj.

Vystavenie sa vibráciám môže

spôsobiť poranenia osôb, ktoré trpia

problémami s obehom krvi alebo majú

problémy nervového pôvodu. Ak

spozorujete príznaky ako stŕpnutie, strata

citlivosti, zníženie normálnej sily alebo

zmeny farby pokožky, obráťte sa na svojho

lekára. Tieto príznaky sa zvyčajne prejavujú

na prstoch, rukách a zápästiach.

Pred naštartovaním motora skontrolujte, či

sa plynová páčka voľne pohybuje.

POZOR: dodržiavajte bezpečnostné

predpisy o manipulácii s palivom. Pred

dopĺňaním paliva vždy vypnite motor.

Palivo nikdy nedopĺňajte, keď je stroj alebo

motor v činnosti a kým sú horúce. Pred