Page 1

Mod. DS 2400 T

Mod. DS 2400 S

Mod. DS 240 T

Mod. DS 240 S

Product Information

Language

Nr. 199

Date 3/2012

Subject DS 240 S-T (EURO 1)

INGLESE

NEW BRUSHCUTTERS / TRIMMERS –

DS 240 S AND DS 240 T – EURO 1

Emak presents its new range of the word’s most lightweight brushcutters, establishing a new benchmark in their

class.

The DS 240 S and DS 240 T range was developed for demanding private users who need to use a brushcutter

regularly and are looking for a tool that is:

- lightweight: easy to handle and guaranteeing lasting eciency,

- simple: easy starting, operation and maintenance

- compatible with fatigue-free operation

To meet these requirements, these new brushcutters use a series of technical solutions that are normally standard features only on professional models. Special attention was devoted to compliance with the most stringent

anti-pollution regulations (Euro 1) and compatibility with alkylate petrol.

Thanks to the new super economy engines, these brushcutters will provide more than 50 minutes of continuous

operation before refuelling.

Page 2

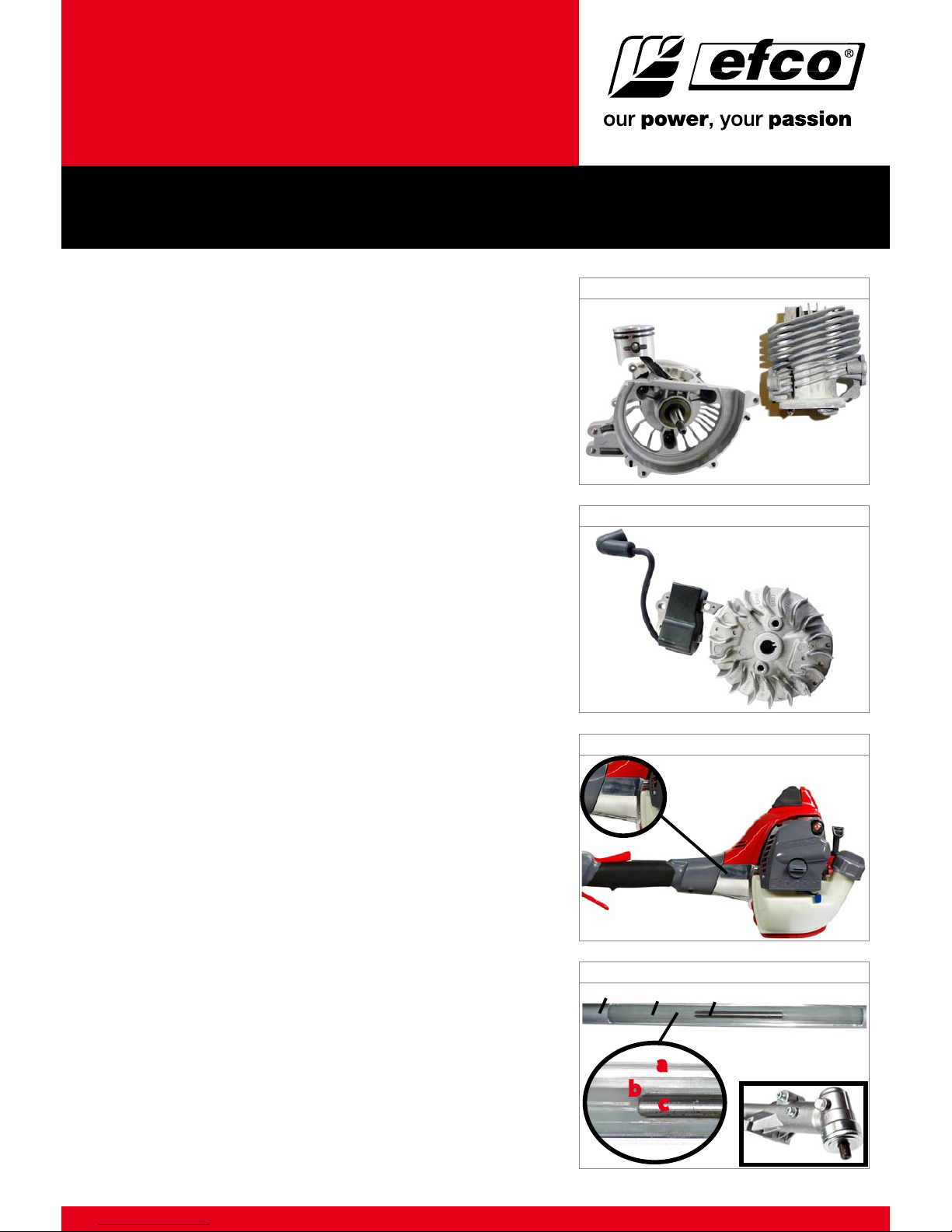

Fig. 3

Fig. 4

Fig. 2

Fig. 1

a

b

c

d

b

ca

PERFORMANCE AND ENGINEERING

• 21.7 cm³ 1.2 HP (0.9 kW) 2-stroke engines, in compliance with

regulations (Euro 1), compatible with alkyl petrol and featuring

a high linear torque curve even at low revs.

• Piston with 2 rings, diecast cylinder with Nickel plating, forged

con rod and crankshaft (Fig. 1): guaranteeing an extremely rugged and durable engine.

• Digital coil with electronic control (Fig. 2) and revs limiter: for

easier starting, improved performance thanks to uniform combustion, and reduced fuel consumption.

• Aluminium cover and clutch support (Fig. 3): optimised and

reduced weight of the tool while imparting high strength and

lasting reliability.

• Ø 24 mm aluminium tube (Fig. 4a), nylon sheath (Fig. 4b), 7 mm

internal rigid shaft (Fig. 4c) and aluminium bevel gear pair with

M 10 male drive pin (Fig. 4d), for unimpeded power transmis-

sion.

Page 3

Fig. 8

Fig. 7

Fig. 6

Fig. 5

a

b

c

b

a

c

OPERATOR DESIGN FEATURES

• A graphic representation of starting operations facilitates engi-

ne starting even for less expert users (Fig. 5a).

• Air purge primer (Fig. 5b) visible on the engine cover ensures

easier access and operation.

• The on/o switch (Fig. 5c) returns automatically to the “on” position after each stop (always on).

• Choke lever integral with half-throttle setting for fast and easy

starting.

• “Easy on” device (Fig. 6) composed of a double spring in the

starter cover combined with driver with two ratchets means

reduced force with each pull and fast starting with fewer rope

pulls.

• Filler cap with two grips (Fig. 7a) (side and top) and tank ller

neck (Fig. 7b) in vertical position for easier refuelling.

• Transparent fuel tank (Fig. 7c) for instant view of the quantity of

fuel remaining.

• Innovative 130 mm Ø “LOAD & GO” line head (Fig. 8): for strai-

ghtforward line replacement - just 20 seconds to rewind the line

and resume work.

Page 4

Fig. 11

Fig. 12

Fig. 10

Fig. 9

a

b

c

a

b

b

c

c

OPERATING BENEFITS

• Built-in antivibration system: greatly reduced vibrations felt by

the operator during use of the tool (Fig. 9).

• Ergonomic loop and handles: clad in soft rubber (Fig. 10a-b) offer an anatomic and comfortable grip of the tool in all operating

conditions.

• The twin version with ergonomic aluminium handlebar features an easy-to-use adjuster knob (Fig. 10c).

• 150 mm drive tube: the operator is always able to maintain an

erect posture.

• New stone guards for ecient protection against projected de-

bris.

In addition, simply removing the skirt with line cutter knife (Fig.

11c) makes the line head suitable for use with a metal blade.

• Harness, supplied as standard (Fig. 12a S version), (Fig.12b T

version) is easy to adjust and imparts greater freedom of movement allowing improved weight distribution in accordance with

the operator’s stature.

Page 5

Fig. 15

Fig. 16

Fig. 14

Fig. 13

a

a

a

b

SERVICE FRIENDLY

• Generously sized cloth air lter: guarantees high ltration eciency and easy maintenance (Fig. 13a).

• Filter support (Emak patent) with anti-backow element (Fig.

13b), (prevents the lter from becoming fouled by fuel) for longer operation between lter maintenance procedures.

• Filter cover accessible without tools by means of specic knob

(Fig. 14a): facilitates air lter inspection and cleaning.

• Silencer protection (Fig. 15a) separate from the engine cover,

removable by means of 3 screws: provides rapid access in the

case of maintenance.

• All screws are of the TORX head type, to allow the use of a sin-

gle tool for most maintenance procedures (Fig. 16) .

Page 6

TECHNICAL SPECIFICATIONS

MODEL1.

DS 240 S DS 240 T

ENGINE

TYPE Emak 2-stroke / EURO 1

DISPLACEMENT cm

3

21,7

BORE x STROKE mm x mm 32 x 27

MAXIMUM POWER OUTPUT HP/kW (rpm) 1,2 / 0,9 (8500)

MAXIMUM TORQUE Nm (rpm) 1,2 (6500)

IDLING SPEED rpm 2800-3100

MAXIMUM NO LOAD SPEED rpm 10300

HOURLY FUEL CONSUMPTION (at max power output) g/h (rpm) 410 - 450 (8500)

IGNITION SYSTEM

TYPE Digital with variable ignition advance and speed limitetor

COIL WALBRO MBU53

SPARK PLUG NGK CMR7H

EASY START Yes

FUEL & LUBRICATION SYSTEM

CARBURETTOR WALBRO WT-1041

FUEL Compatibility with alkylate mix

FUEL TANK CAPACITY l 0,4

AIR FILTER Generously sized cloth

PRIMER Si

TRANSMISSION SYSTEM

DRIVE SHAFT ( Ø ) “Outer / Inner” mm Ø24 (Ø7internal rigid shaft)

BEVEL GEAR PAIR Pin male M10x1,25 sx

CLUTCH COVER Aluminium

CLUTCH (DIMENSION) mm Yes

ERGONOMICS

HARNESS Single harness Simple with cushion

FRONT HANDLE Ergonomic loop and handles clad in soft rubber ergonomic aluminium handlebar adjuster knob

REAR HANDLE Ergonomic with moulded rubber grips

ON / OFF SWITCH A button (always on)

ANTI-VIBRATION SYSTEM

Nylon sheath + antivibration rubber on the

clutch cover

Nylon sheath + antivibration rubber on the

clutch cover + 2 on handlebar support

CUTTING SYSTEM

STANDARD CUTTING DISC Steel disc cutter with 3 teeth Ø 10” / 255 mm, thickness1,8 mm

STANDARD NYLON STRINGHEAD Load &Go Ø130mm line 2,4 mm

CUTTING GUARD - CUTTING WIDTH (with stringhead) Ø mm 370

IN COMPLIANCE WITH

WEIGHT (Without cutting tools) kg 4,5 5,25

POWER-TO-WEIGHT RATIO kg / Kw 5,0 5,8

Page 7

It's an Emak S.p.A. trademark Member of the Yama Group

Via E. Fermi, 4 • 42011 Bagnolo in Piano (Reggio Emilia) Italy

Tel. +39 0522 956611 • Fax +39 0522 951555

venditeitalia@efco.it • www.efco.it

Loading...

Loading...