Page 1

DS 2400 H (1.32 cu.in)

en

fr

es

OPERATOR’S INSTRUCTION MANUAL

MANUEL D’UTILISATION ET D’ENTRETIEN

MANUAL DE INSTRUCCIONES

Page 2

en

INTRODUCTION

To correctly use the hedge trimmer and prevent accidents, do not start work without having

first carefully read this manual. You will find explanations concerning the operation of the

various parts plus instructions for necessary checks and relative maintenance.

Note: Illustrations and specifications in this manual may vary according to Country

requirements and are subject to change without notice by the manufacturer.

THE OPERATOR’S MANUAL

Your operator’s manual is for your protection. READ IT. Keep it in a safe place for

reference. Know what you are doing before you begin assembly of the unit. Proper

preparation and upkeep go hand-in-hand with satisfactory performance of the hedge

trimmer and safety.

Contact your dealer or the distributor for your area if you do not understand any of the

instructions in this manual.

In addition to the operating instructions, this manual contains paragraphs that require your

special attention.

Such paragraphs are marked with the symbols described below:

Warning: where there is a risk of an accident or personal injury or serious damage to property.

Caution: where there is a risk of damaging the machine or its individual components.

WARNING - To ensure safe and correct operation of the hedge

trimmer this operator's manual should always be kept with or near

the machine. Do not lend or rent your hedge trimmer without the

operator's instruction manual.

WARNING: Allow only persons who understand this manual to

operate your hedge trimmer.

2

Page 3

TABLE OF CONTENTS

PRODUCT IDENTIFICATION

Hedge Trimmer Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY

Understanding Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

State and Local Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY RULES

Basic Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fuel Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Precautions to Reduce Vibration Risk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ASSEMBLY

Cutting implement assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fitting the handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

en

OPERATION

Fueling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preparation for Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Breaking-in the Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Stopping the Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Working Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

MAINTENANCE

Maintenance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Blade Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Carburetor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fuel Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Starter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Spark Plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Spark arresting muffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Blade gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Angle drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

TROUBLESHOOTING

Using Troubleshooting Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

STORAGE

Storing Hedge Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TECHNICAL DATA

DS 2400 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3

Page 4

en

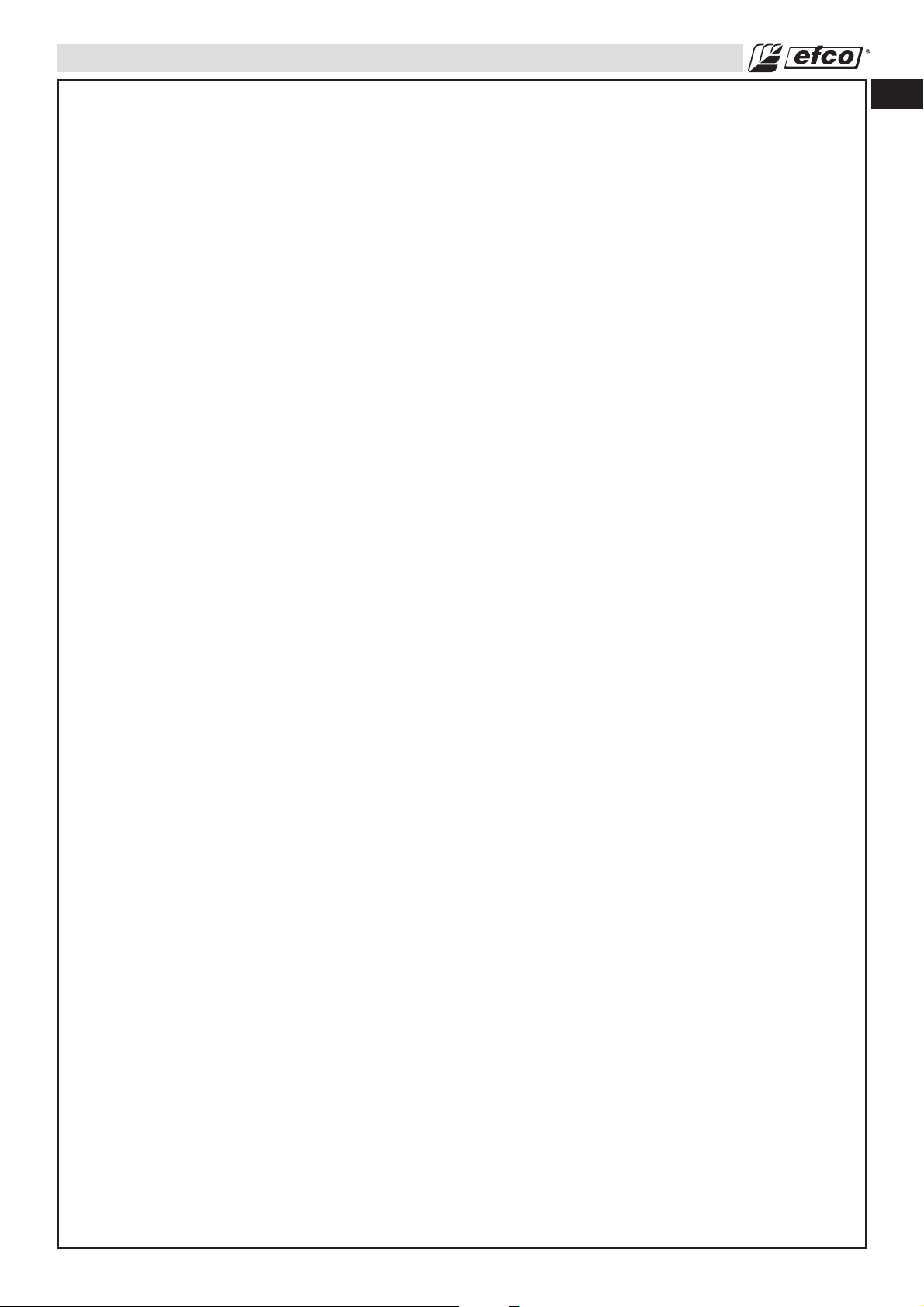

PRODUCT IDENTIFICATION

Hedge Trimmer Components

1. Harness attachment

2. On/o switch

3. Mu er guard

4. Spark plug

5. Air lter

6. Fuel tank cap

7. Fuel tank

8. Throttle lever

9. Primer bulb

10. Starter handle

11. Choke lever

12. Shaft arm

13. Rear handle

14. Front handle

4

15. Cutting implement

16. Blades

17. Blade gearbox

18. Angle drive grease nipple

19. Angle adjustment handgrip

20. Clamp screws

21. Angle drive

22. Selector disc

23. Blade gearbox grease nipple

24. Blade cover

25. Harness

26. Allen Key

27. Combination wrench

Page 5

SAFETY

Understanding Safety Labels

- This symbol indicates Warning, and

Caution.

- Your manual contains special

messages to bring attention to

potential safety concerns, machine

damage as well as helpful operating

and servicing information. PLEASE

READ ALL THE INFORMATION

CAREFULLY TO AVOID INJURY AND

MACHINE DAMAGE.

- Wear eye, hearing and head

protection when operating this

equipment.

en

- Wear non-slip, heavy-duty protective

gloves when handling hedge trimmer

and blade.

- WARNING! The surface can be hot!

State and Local Requirements

This engine is NOT equipped with a Spark Arrester System complying with the requirements of SAE Recommended

Practice J335 and California Codes 4442 and 4443. All national forest land and land managed by the states of

California, Maine, Washington, Idaho, Minnesota, New Jersey and Oregon require internal combustion

engines to be equipped with a spark arrester screen by law. Other states and federal agencies are enacting

similar regulations.

Operating this engine in a state or locale where such regulations apply, could result in a violation of the law.

Note: When using this machine for logging purposes, refer to Code of Federal Regulations, Parts 1910 and

1928.

WARNING: The ignition system of your unit produces an electromagnetic field of a very low

intensity. This field may interfere with some pacemakers. To reduce the risk of serious or fatal

injury, persons with pacemaker should consult their physician and the pacemaker manufacturer

before operating this tool.

WARNING: Muffler surfaces are very hot during and after operation of the hedge trimmer,

keep all body parts away from the muffler. Serious burns may occur if contact is made with

the muffler.

5

Page 6

en

SAFETY

WARNING: Exposure to vibrations through prolonged use of gasoline powered hand tools could

cause blood vessel or nerve damage in the fingers, hands, and wrists of people prone to

circulation disorders or abnormal swellings. Prolonged use in cold weather has been linked to

blood vessel damage in otherwise healthy people. If symptoms occur such as numbness, pain,

loss of strength, change in skin color or texture, or loss of feeling in the fingers, hands, or wrists,

discontinue the use of this tool and seek medical attention.

WARNING: The engine exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm. Operate your hedge trimmer

outdoors only in a well ventilated area.

6

Page 7

SAFETY RULES

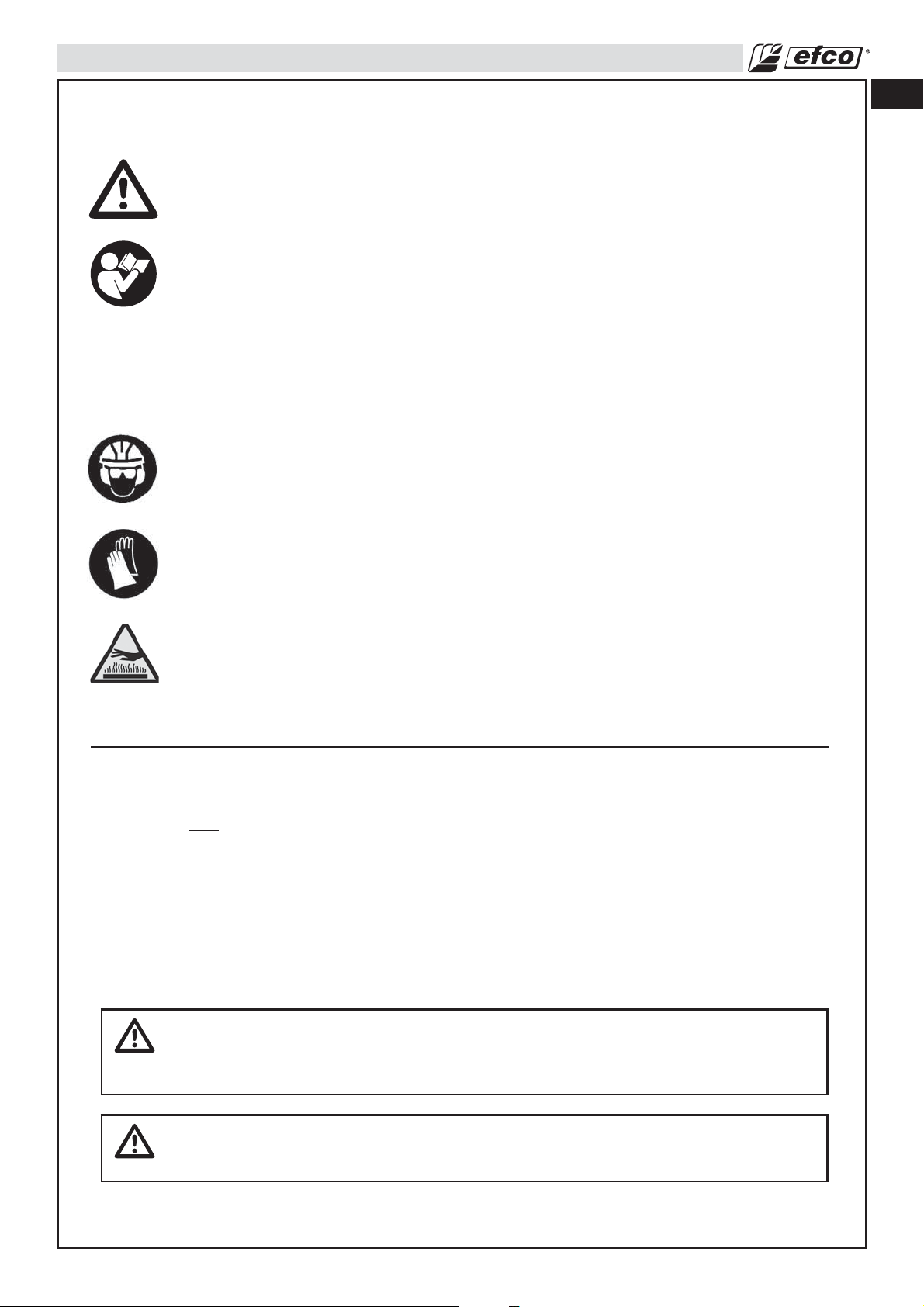

Basic Safety Precautions

• Read this manual carefully until you completely understand and

can follow all safety rules, precautions, and operating instructions

before attempting to use the unit.

• Restrict the use of your hedge trimmer to adult users who

understand and can follow safety rules, precautions, and operating

instructions found in this manual. Minors should never be allowed

to use a hedge trimmer.

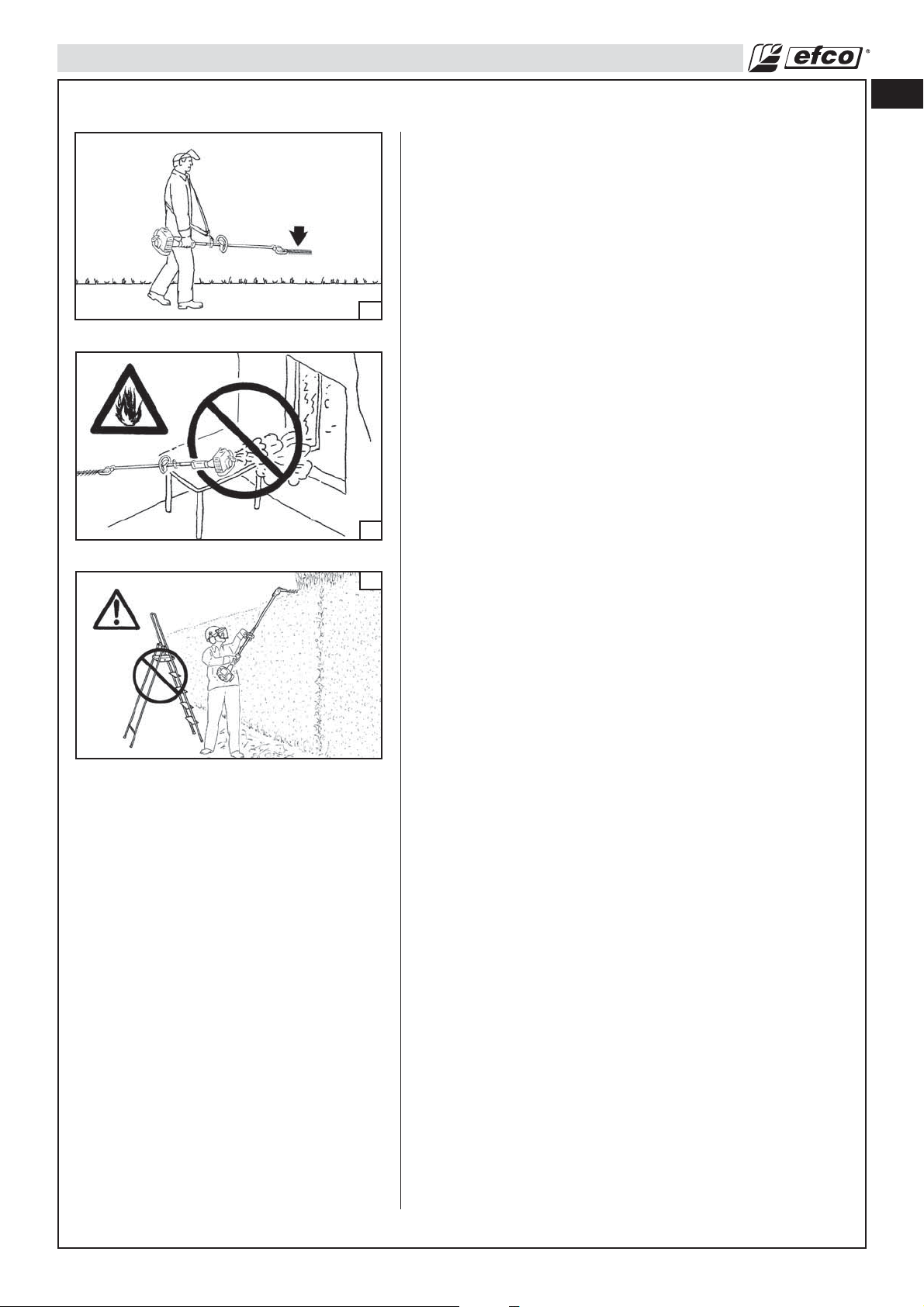

• Do not handle or operate a hedge trimmer when you are fatigued,

1

2

3

4

5

ill, or upset, or if you have taken alcohol, drugs, or medication. You

must be in good physical condition and mentally alert. Hedge

trimmer work is strenuous. If you have any condition that might be

aggravated by strenuous work, check with your doctor before

operating a hedge trimmer (Fig. 1). Be more cautious before rest

periods and towards the end of your shift.

• Keep children, bystanders, and animals a minimum of 35 feet (10

meters) away from the work area. Do not allow other people or

animals to be near the hedge trimmer when starting or operating

the hedge trimmer (Fig. 2).

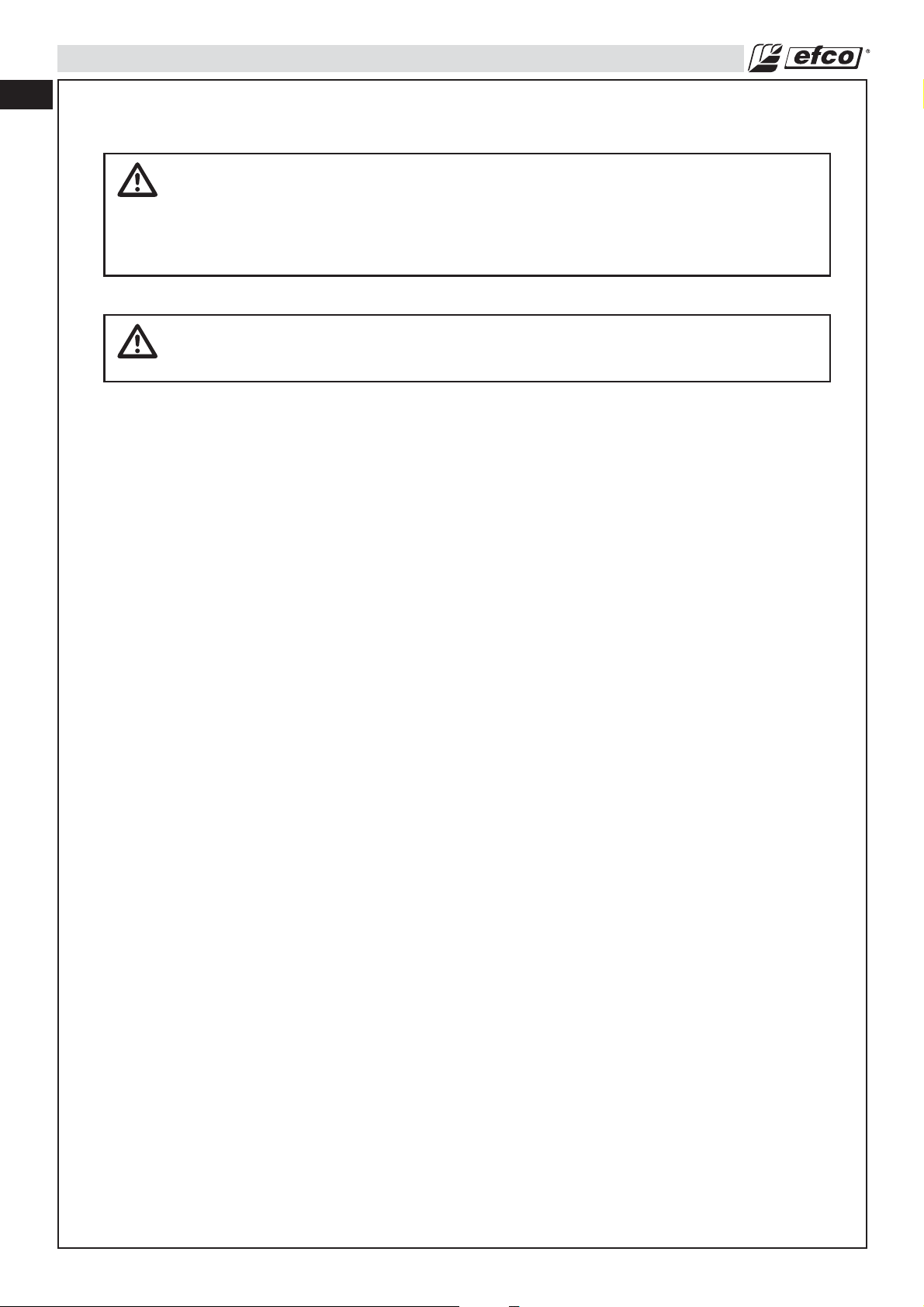

• While working with the hedge trimmer, always use safety protective

approved clothing. The use of protective clothing does not

eliminate injury risks, but reduces the injury effects in case of

accident. Consult your trusted supplier to choose equipment in

compliance with legislation. The clothing must be proper and not

an obstacle. Wear adherent anti-cut clothing. Protective jackets

(Fig.3) and dungarees (Fig.3) are ideal. Do not wear clothes,

scarves, ties or bracelets that can stuck in to twigs. Tie up and

protect long hair (example with foulards, cap, helmets, etc.). Safety

boots having skid-proof sole and anti-piercing insert (Fig.4).

Wear protective goggles or face screens (Fig.5)!. Use protections

against noises: for example noise reduction ear guards (Fig.4)

or earplugs. The use of protections for the ear requests much more

attention and caution, because the perception of danger audio

signals (screaming, alarms, etc.) is limited. Wear gloves (Fig.6,

page 8).

• Only loan your hedge trimmer to expert users who are completely

familiar with hedge trimmer operation and correct use. Give other

users the manual with operating instructions, which they have to

read before using the hedge trimmer.

• Check the hedge trimmer each day to ensure that each device,

whether for safety or otherwise, is functional.

• Never use a damaged, modified, or improperly repaired or

assembled hedge trimmer. Do not remove, damage or deactivate

any of the safety devices. Always replace blade, hand guard

immediately if it becomes damaged, broken or is otherwise

removed.

• Carefully plan your working operation in advance. Do not start

cutting until you have a clear work area, secure footing.

• All hedge trimmer service, other than the operations shown in the

present manual, have to be performed by competent personnel.

• The hedge trimmer must only be used to trim hedges or small

bushes. It is forbidden to cut other types of material. Do not use the

hedge trimmer as a lever to lift, move or break objects, nor lock it

on fixed supports. It is forbidden to apply tools or applications that

are not the ones indicated by the manufacturer onto the hedge

trimmer’s power take-off. Do not use it for pruning trees or cutting

grass. It is unadvisable to cut other types of material.

• It is unadvisable to hitch tools or applications to the P.t.o. that are

not specified by the manufacturer.

en

7

Page 8

en

SAFETY RULES

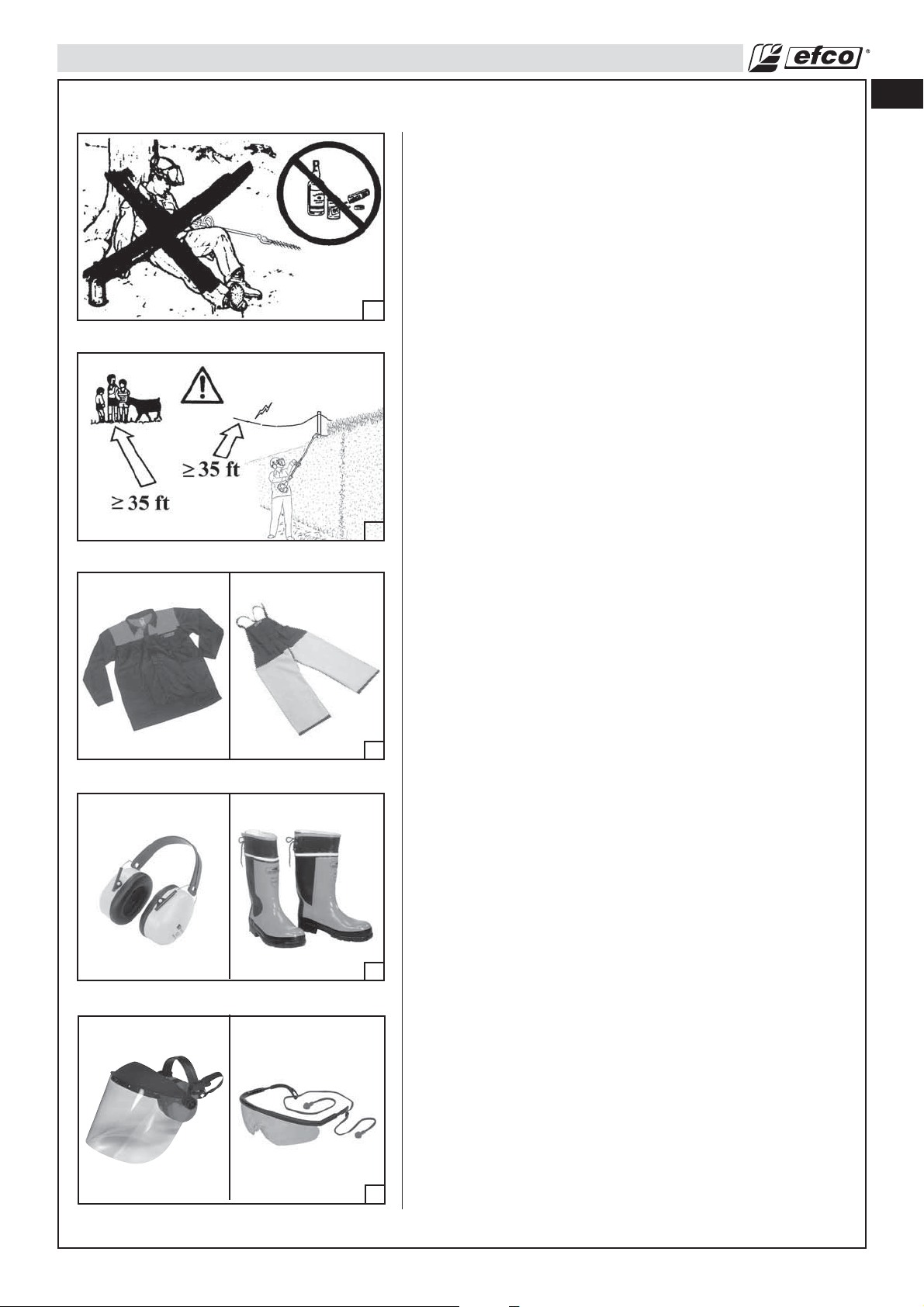

Fuel Handling

• To reduce the risk of fire and burn injury, handle fuel with care.

It is highly flammable.

6

7

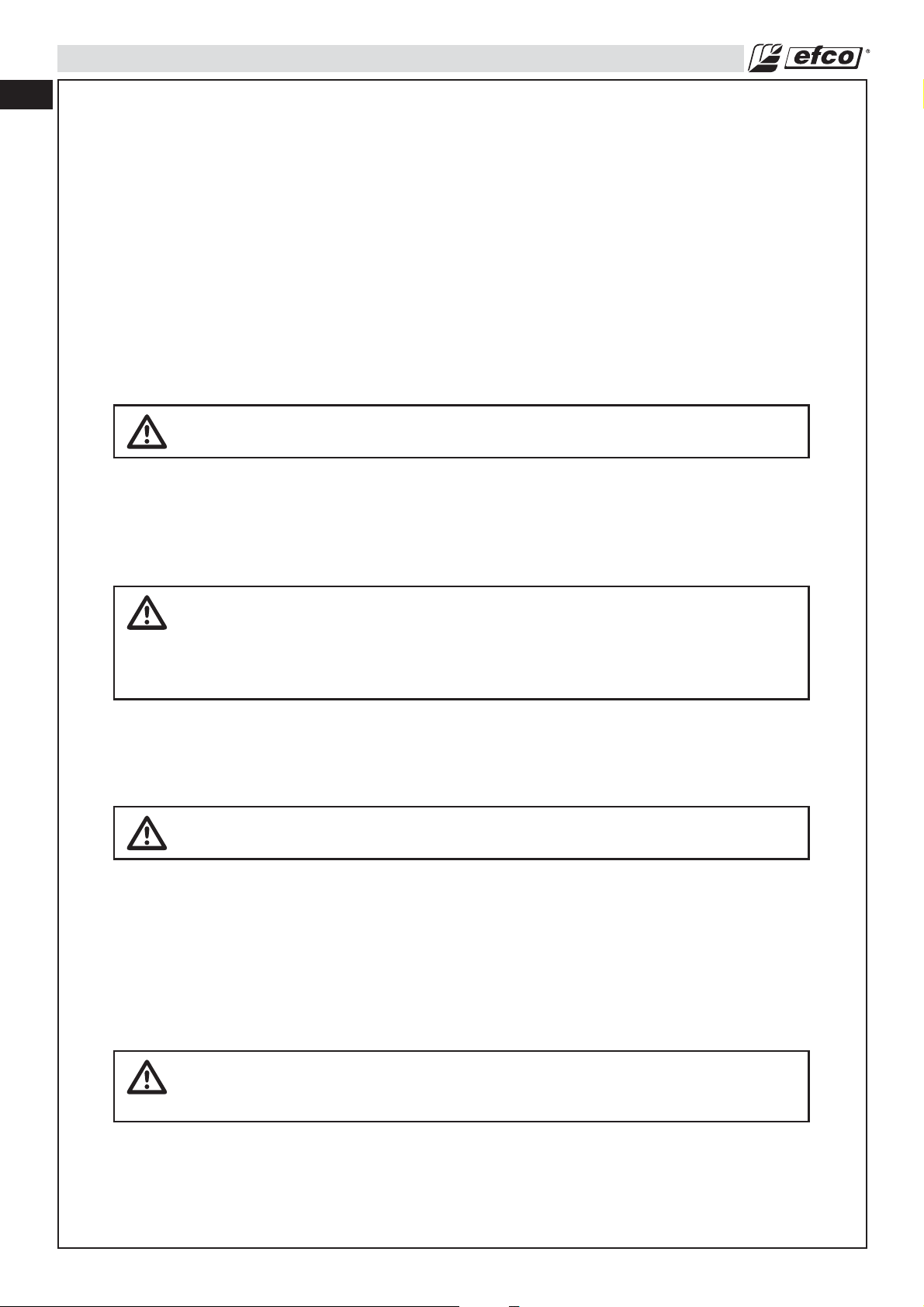

• Mix and store fuel in a container approved for gasoline (Fig. 8).

• Mix fuel outdoors where there are no sparks or flames.

• Select bare ground, stop engine, and allow to cool before

refueling.

• Loosen fuel cap slowly to release pressure and to keep fuel from

escaping around the cap.

• Tighten fuel cap securely after refueling. Unit vibration can cause

an improperly tightened fuel cap to loosen or come off and spill

quantities of fuel.

• Wipe spilled fuel from the unit. Move 10 feet (3m) away from

refueling site before starting engine (Fig. 9).

• Never attempt to burn off spilled fuel under any circumstances.

• Do not smoke while handling fuel or while operating the hedge

trimmer.

• Store fuel in a cool, dry, well ventilated place.

• Never place the hedge trimmer in a combustible area such as dry

leaves, straw, paper, etc.

• Store the unit and fuel in an area where fuel vapors cannot reach

sparks or open flames from water heaters, electric motors or

switches, furnaces, etc.

• Never take the cap off the tank when the engine is running.

• Never use fuel for cleaning operations.

• Take care not to get fuel on your clothing.

WARNING: Gasoline is an extremely flammable fuel. Use

extreme caution when handling gasoline or fuel mix. Do

not smoke or bring any fire or flame near the fuel or the

hedge trimmer (Fig. 7).

10

8

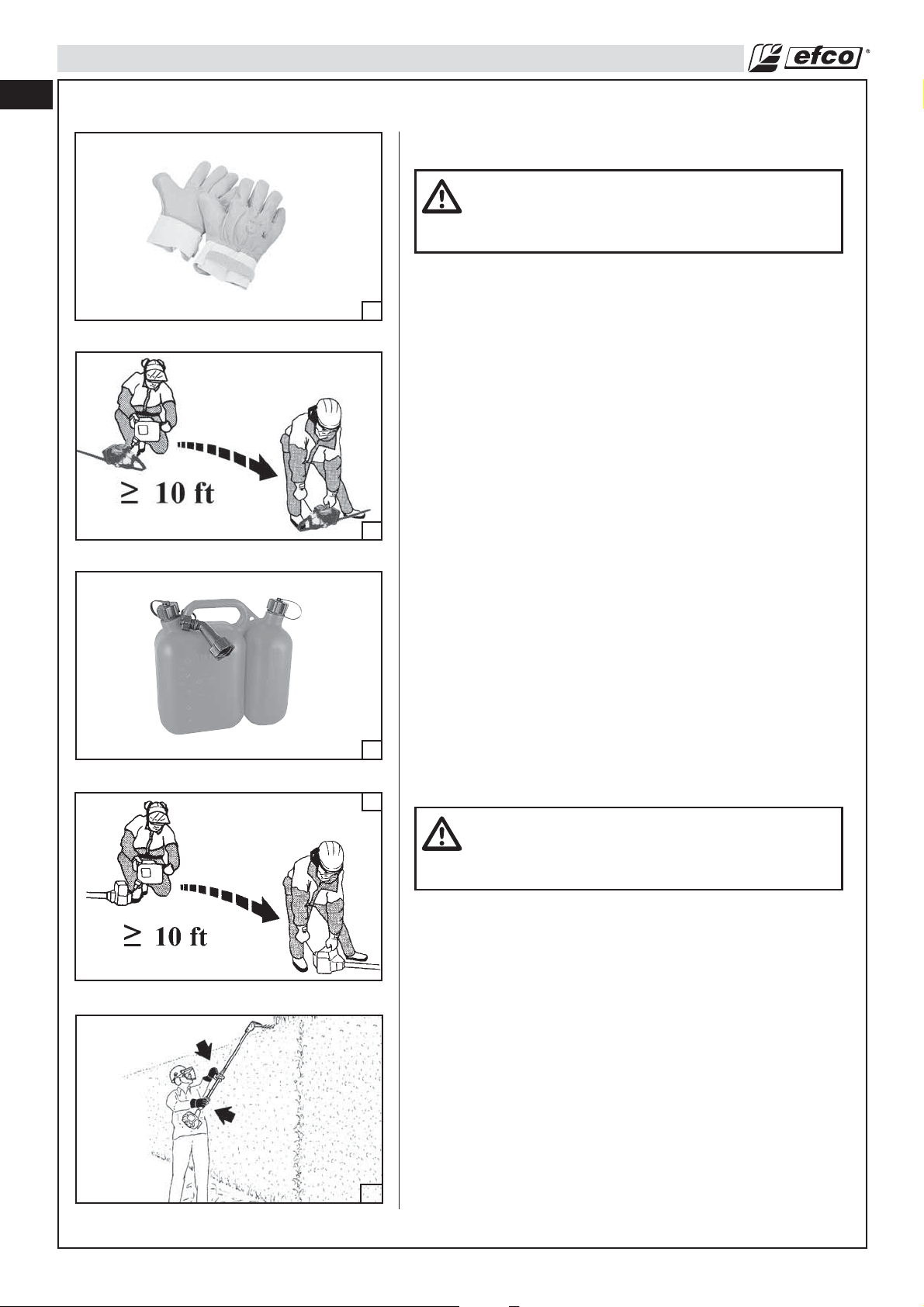

Operation and Safety

9

WARNING: Always hold the hedge trimmer with both

hands when the engine is running. Use a firm grip with

thumbs and fingers encircling the hedge trimmer

handles (Fig. 10).

• Keep all parts of your body away from the hedge trimmer when the

engine is running.

• Always carry the hedge trimmer with the engine stopped the blade

to the rear, and the muffler away from your body. When transporting

your hedge trimmer, use the appropriate blade cover (Fig. 11).

When transporting in a vehicle, keep blade covered with the blade

cover. Properly secure your hedge trimmer to prevent turnover, fuel

spillage and damage to the hedge trimmer.

• Do not operate a hedge trimmer with one hand! Serious injury

to the operator, helpers, bystanders, or any combination of these

persons may result from one-handed operation.

A hedge trimmer is intended for two-handed use.

• Before you start the engine, make sure the hedge trimmer is not

contacting any object.

• Shut off the engine before setting down the hedge trimmer.

Do not leave the engine running unattended.

• Only use the hedge trimmer in well-ventilated places, do not

8

Page 9

SAFETY RULES

operate the hedge trimmer in explosive or flammable atmospheres

or in closed environments (Fig. 12). Beware of carbon monoxide

poisoning.

• Do not operate hedge trimmer from a ladder or in a tree. Always cut

from a firm-footed and safe position.

• Do not cut near electric cables.

• Keep the handles dry, clean, and free of oil or fuel mixture.

• When the motor is running, grip the front handle firmly with your

left hand and the back handle with your right hand (Fig. 10). Check

11

that all parts of the body are kept away from the blades and muffler.

Never use a cross-handed grip. Left-handers should follow these

instructions too. Keep a proper cutting stance.

• Always cut from a firm-footed and safe position, particularly when

using steps and stools (Fig. 13).

en

12

13

9

Page 10

en

SAFETY RULES

Precautions to Reduce Vibration Risk

• The hedge trimmer is provided with anti-vibration (AV) system; never alter or modify it.

• Wear gloves and keep your hands warm.

• Keep the blade sharp and the hedge trimmer, including the AV system, well maintained. A dull blade will increase

cutting time, will increase the vibrations transmitted to your hands.

• Maintain a firm grip at all times, but do not squeeze the handles with constant, excessive pressures, take

frequent breaks. All the above mentioned precautions do not guarantee that you will not sustain whitefinger

disease or carpal tunnel syndrome. Therefore, continual and regular users should monitor closely the condition

of their hands and fingers. If any of the above symptoms appear, seek medical advice immediately.

Maintenance Precaution

WARNING: Never operate a hedge trimmer that is damaged, improperly adjusted, or is not

completely and securely assembled.

• Be sure that the blade stops moving when the throttle control trigger is released. If the blade moves at idle

speed, the carburetor may need adjusting, see Operation-Carburetor Adjusting Section. If the blade moves at

idle speed after adjustment has been made, contact a Servicing Dealer for adjustment and discontinue use until

the repair is made.

WARNING: All hedge trimmer service, other than items in the Operator's Manual maintenance

instructions, have to be performed by competent hedge trimmer service personnel. (If improper

tools are used to remove the flywheel or clutch, or if an improper tool is used to hold the

flywheel in order to remove the clutch, structural damage to the flywheel could occur which

could subsequently cause the flywheel to burst and serious injury could result.)

• Never modify your hedge trimmer in any way.

• Keep the handles dry, clean, and free of oil or fuel mixture.

WARNING: Use only accessories and replacement parts recommended.

• Never touch the blade or attempt to service the hedge trimmer while the engine is running.

• Never use fuel for cleaning operations.

• Keep the hedge trimmer in a dry place, off the ground with the blade cover on and the tanks empty.

• If your hedge trimmer is no longer usable, dispose of it properly without damaging the environment by

handing it in to your local Dealer who will arrange for its correct disposal.

• Replace immediately any safety device when damaged or broken.

10

WARNING: The muffler and other parts of the engine (e.g. fins of the cylinder, spark plug)

become hot during operation and remain hot for a while after stopping the engine. To reduce

risk of burns do not touch the muffler and other parts while they are hot.

Page 11

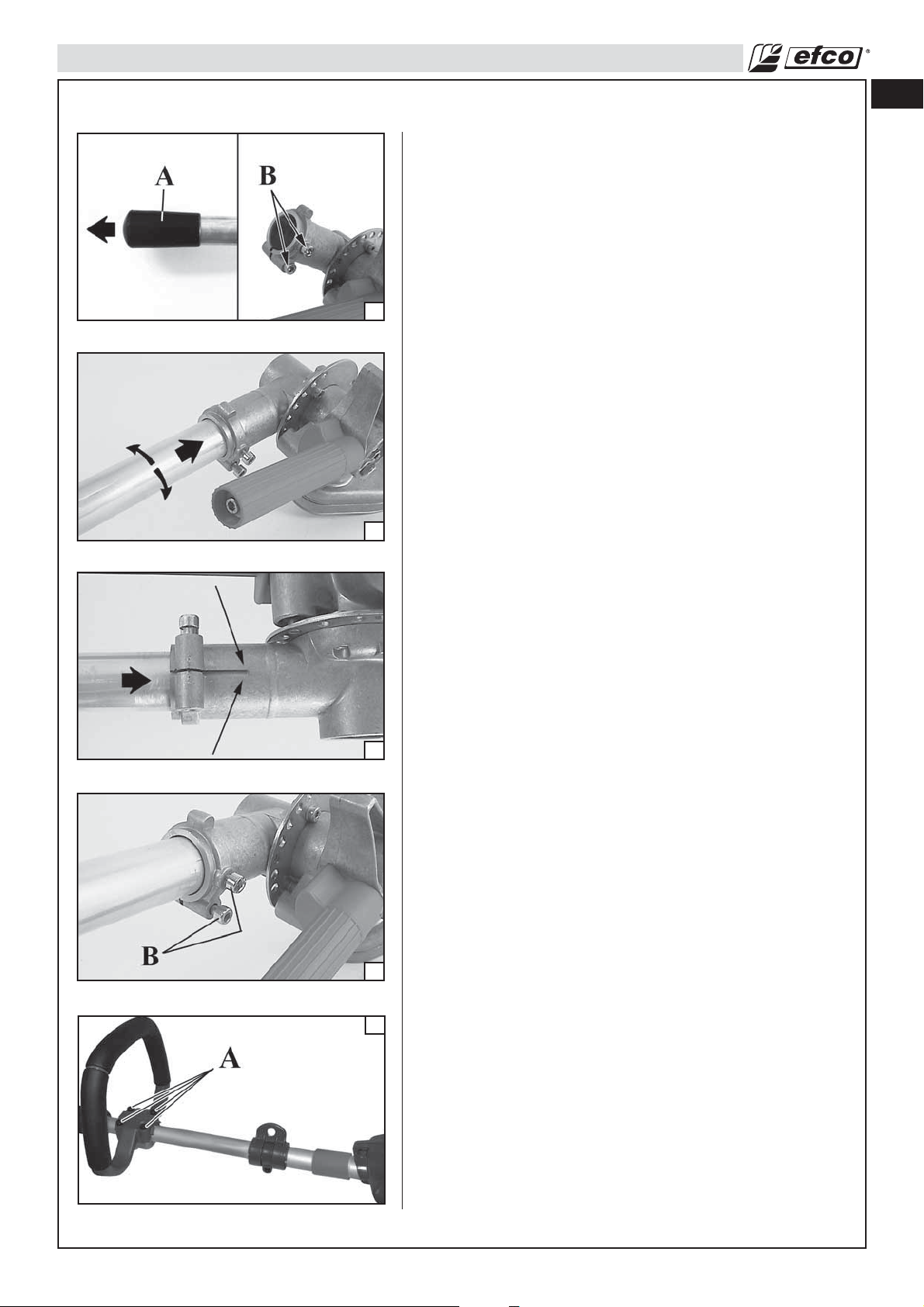

ASSEMBLY

14

en

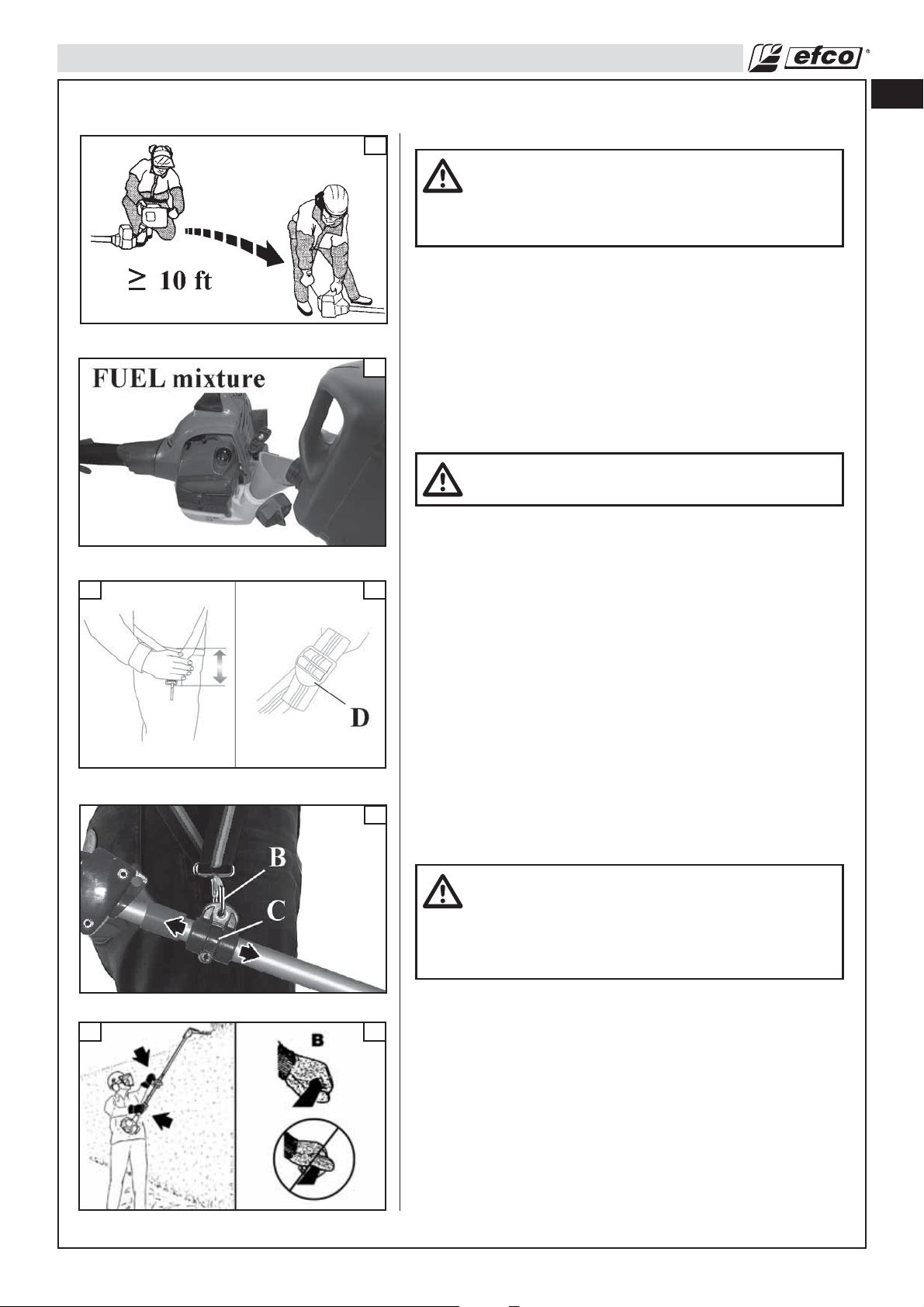

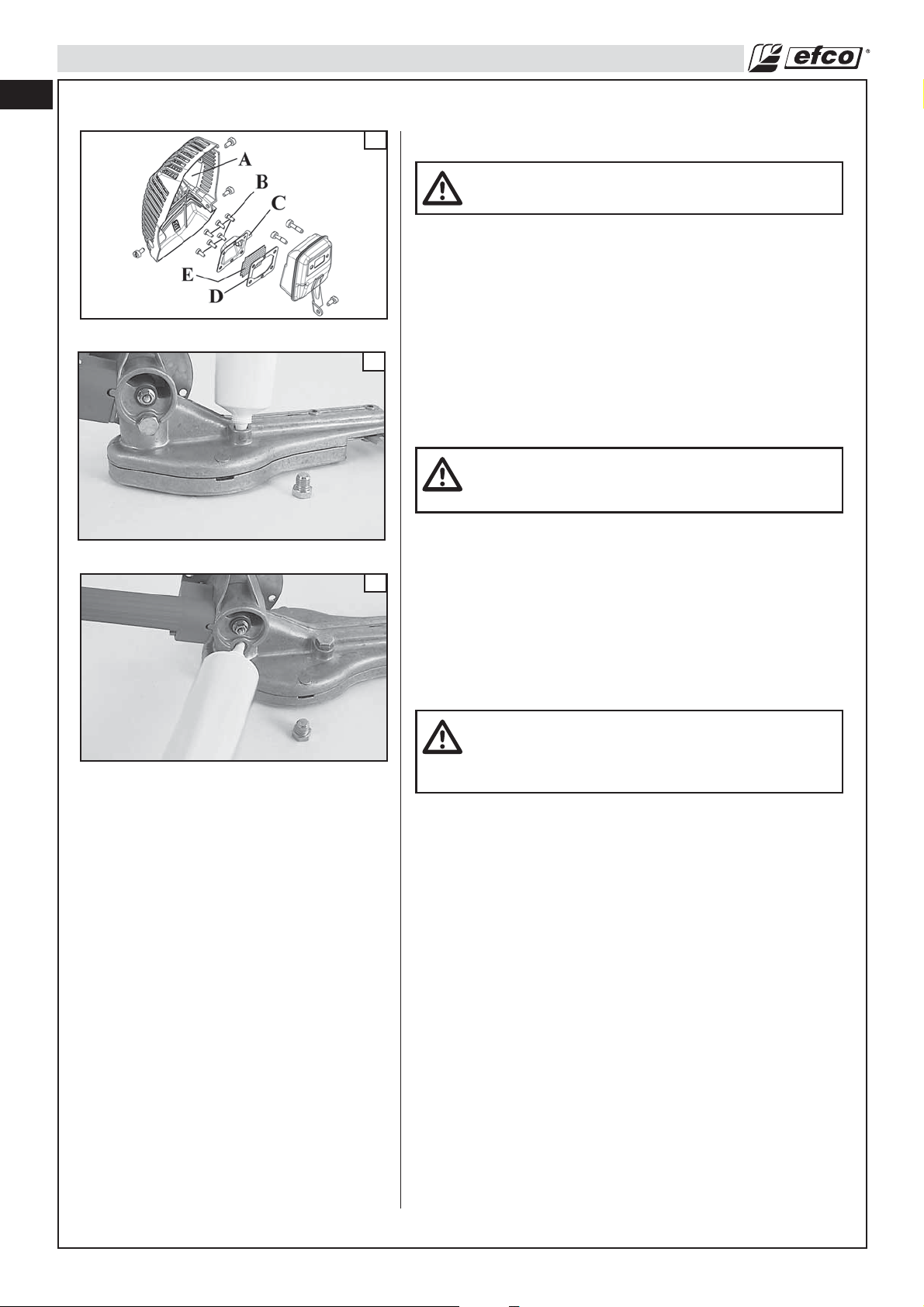

Cutting implement assembly

1. Remove the plug (A, Fig. 14)

2. Loosen the clamp screws (B, Fig.14) of the hedgetrimmer angle

drive and couple to the end of the shaft arm, twisting slightly

one way and the other (Fig.15). When the end of the arm can no

longer be seen through the clamp slit (Fig.16), push home until it

will go no further.

3. Tighten the clamp screws fully (B, Fig.17) to secure the

attachment.

Fitting the handle (Fig.18)

Fit the handle onto the shaft arm and secure it using screws (A),

washers, and nuts. The handle position is calculated depending on

the requirements of the operator.

15

16

17

18

11

Page 12

en

OPERATION

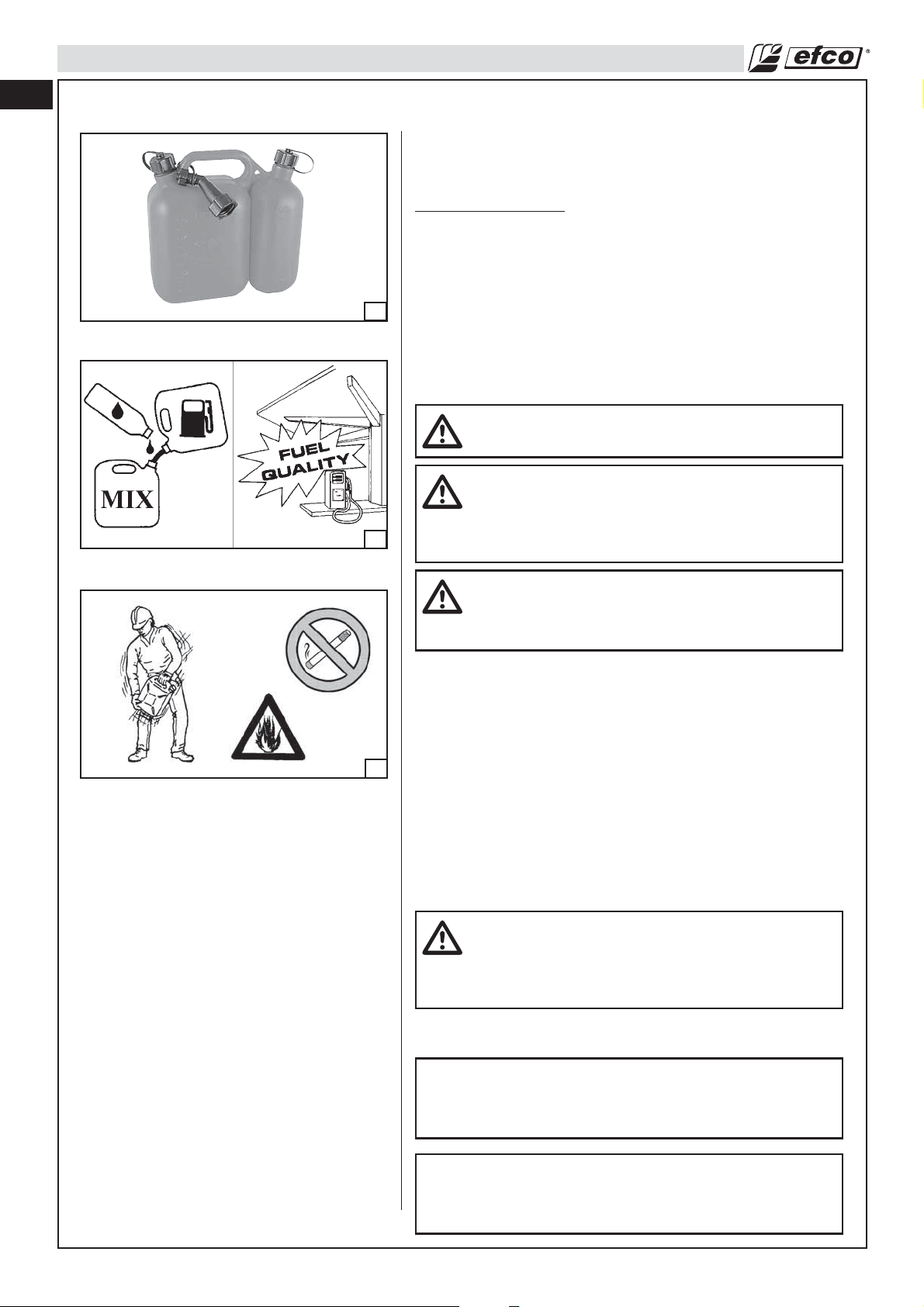

Fueling (Do Not Smoke!) (Fig. 21)

This product is powered by a 2-cycle engine and requires pre-mixing

gasoline and 2-cycle oil. Pre-mix unleaded gasoline and 2-cycle

engine oil in a clean container approved for gasoline (Fig. 19).

RECOMMENDED FUEL: THIS ENGINE IS CERTIFIED TO OPERATE ON

UNLEADED GASOLINE INTENDED FOR AUTOMOTIVE USE WITH AN

OCTANE RATING OF 89 ([R + M] / 2) OR HIGHER (Fig. 20).

Mix 2-Cycle Engine Oil with gasoline according to the instructions on

the package. We strongly recommend the use of 2% (50:1) Efco Two

Cycle Engine Oil, which is specifically formulated for all Efco air-

19

20

cooled two-stroke engines.

The correct oil / fuel proportions shown in the table below are

suitable when using the Efco Two Cycle Engine Oil or an equivalent

high-quality engine oil (JASO specification FD or ISO specification

L-EGD). When oil specifications are NOT equivalent or unknown use

4% (25:1) fuel / oil mixing ratio.

CAUTION: DO NOT USE AUTOMOTIVE OIL OR 2-CYCLE

OUTBOARD OIL.

CAUTION:

- Match your fuel purchases to your consumption; don’t

buy more than you will use in one or two months;

- Store gasoline in a tightly-closed container in a cool,

dry place.

21

CAUTION - For the mixture, never use a fuel with an

ethanol percentage higher than 10%; gasohol (mixture

of gasoline and ethanol) up to 10% ethanol or E10 fuel

are acceptable.

When using an Oxygenated Gasoline a good practice of Fuel

Management is necessary.

Gasoline Oxygenated with alcohol readily takes/up water when it is

present; the water may be condensed out of humid air or be a

contaminant in the fuel system, including tank.

The use of Oxygenated Gasoline may cause the occurrence of vaporlock easier.

NOTE - Prepare only the quantity of mixture required for immediate

use; do not leave fuel in the tank or a container for a long time. Were

commend the use of the additive Emak ADDITIX 2000 code

001000972 if the mixture is to be stored for 30 days.

Alkylate gasoline

CAUTIONS – Alkylate fuels have different density than

normal fuel. Therefore engines, set with normal fuel,

need different H jet regulation to avoid critical issues.

For this operation it’s necessary turned at a Licensed

Service Dealer.

Fuel Mixture

12

2-Cycle Engine Oil (25:1) 4%

Gasoline Oil

1 Gallon (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2 oz.

1 Liter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 cc (40 ml)

High Quality 2-Cycle Engine Oil (50:1) 2%

Gasoline Oil

1 Gallon (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6 oz.

1 Liter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 cc (20 ml)

Page 13

OPERATION

en

22

23

Filling the Tank (Fig. 23)

WARNING: Follow safety instruction for fuel handling.

Always shut off engine before fueling. Never add fuel to

a machine with a running or hot engine. Move at least 10

feet (3m) from refueling site before starting engine

(Fig. 22). DO NOT SMOKE!

1. Clean surface around fuel cap to prevent contamination.

2. Loosen fuel cap slowly.

3. Carefully pour fuel mixture into the tank. Avoid spillage.

4. Prior to replacing the fuel cap, clean and inspect the gasket.

5. Immediately replace fuel cap and hand tighten. Wipe up any fuel

spillage.

NOTE: It is normal for smoke to be emitted from a new engine

during and after first use.

WARNING: Check for fuel leaks, if any are found, correct

before use. Contact a Servicing Dealer if necessary.

24

27

25

26

28

Preparation for Cutting

Harness

Correct adjustment of the harness makes it possible to balance the

tool correctly and set an appropriate height from the ground (Fig.24).

- Put on the harness.

- Attach the hedgetrimmer to the harness by means of the snap hook

(B, Fig.26).

- Position the hook (C, Fig.26) to obtain the best hedgetrimmer balance.

- Position the buckle (D, Fig.25) to obtain the correct height of the

hedgetrimmer.

Proper Grip on Handles.

Refer to Safety Section for appropriate Safety Equipment.

1. Wear non-slip gloves for maximum grip and protection.

When the motor is running, grip the front handle firmly

with your left hand and the back handle with your right

hand (Fig. 27). Check that all parts of the body are kept

away from the blades and muffler. Never use a crosshanded grip. Left-handers should follow these

instructions too. Keep a proper cutting stance.

2. Maintain a proper grip (B, Fig. 28) on the hedge trimmer whenever

the engine is running. The fingers should encircle the handlebar

and the thumb is wrapped under the handlebar.

13

Page 14

en

OPERATION

Oil blades each gas tank filling (Fig. 29). Correct lubrication of the

blades during cutting minimises wear, ensuring longer blade life.

Always use a good quality oil.

Work Area Precautions

29

• Never allow children to operate your hedge trimmer. Only allow

• Keep everyone - helpers, bystanders, children, and animals a safe

• Always cut with both feet on solid ground to prevent being

pulled off balance.

• Do not cut above chest height.

• Do not cut near electrical wires or buildings. Leave this operation

30

• Cut only when visibility and light are adequate for you to see

• Do not cut from a ladder, this is extremely dangerous. Leave this

• Stop the engine if the blade strikes a foreign object. Inspect the

• Keep the blade out of dirt and sand. Even a small amount of dirt will

• Stop the engine before setting the hedge trimmer down.

• Be particularly cautious and alert while wearing hearing

protection because such equipment may restrict your ability to

• Be extremely cautious when working on slopes or uneven ground.

WARNING: Cut only hedges or materials made from

wood. Do not cut metal, plastics, masonry, or non-wood

building materials.

others to use this hedge trimmer who have read this Operator's

Manual or received adequate instructions for the safe and proper

use of this hedge trimmer.

distance from the cutting area (Fig. 30).

for professionals.

clearly.

operation for professionals.

blade and repair parts as necessary.

quickly dull a blade.

hear sounds indicating danger (calls, signals, warnings, etc).

31

32

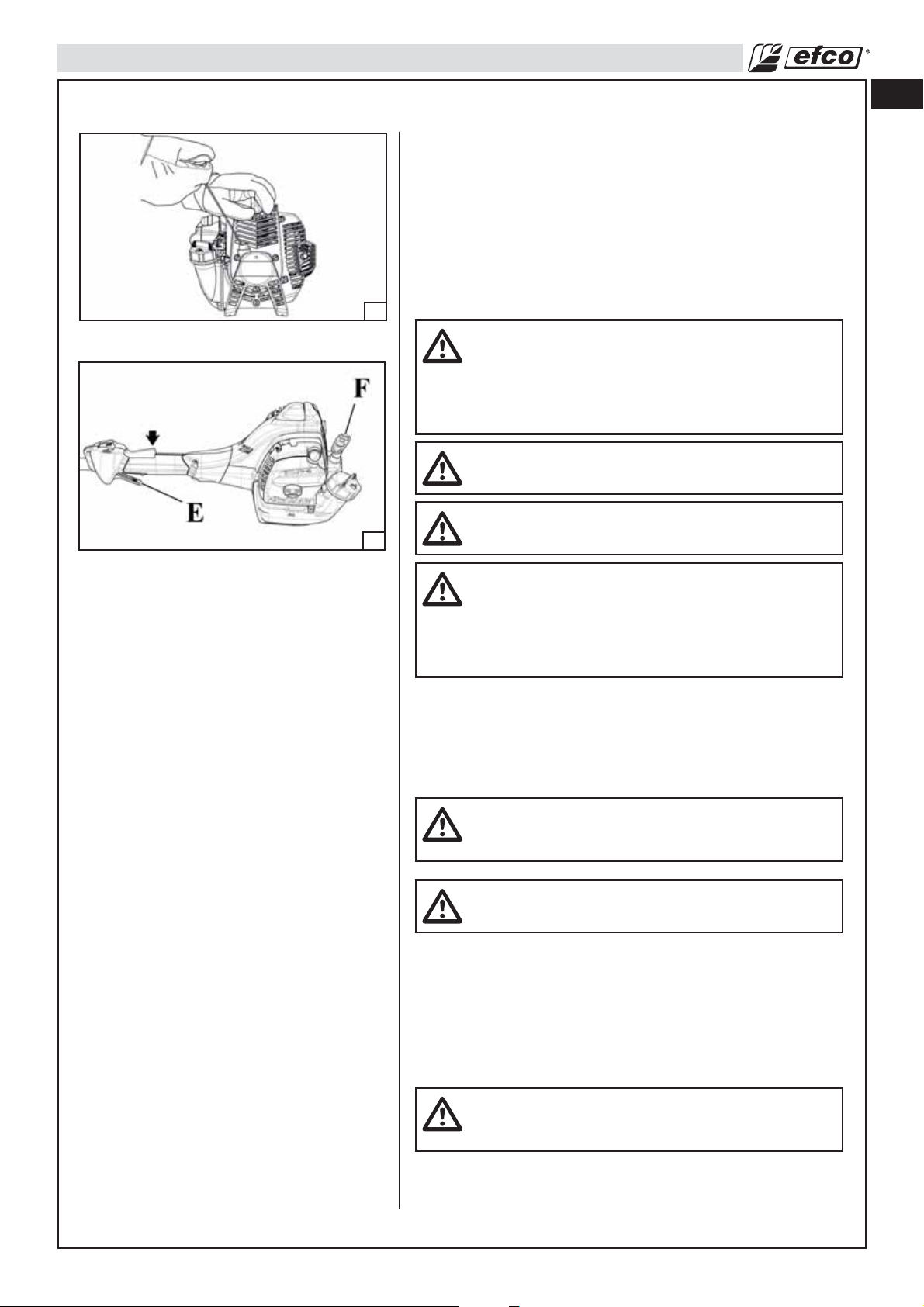

Starting The Engine

Start-up procedure

1) Slowly push the purge bulb 6 times (A, Fig.31).

2) Pull the choke lever (B, Fig.31) in the CLOSE position [0] (C, Fig.32).

In so doing, it also activates automatically half-throttle.

14

Page 15

OPERATION

3) Place the machine on the ground in a stable position. Check that

4) Push the choke lever (B, Fig.31) in OPEN (I) position (D, Fig.32).

5) Pull the starter cord to start the engine. Once the machine is

33

en

the blade is free. Holding the machine down (Fig.33), pull the

starter rope until the first kick over of the engine is heard (no more

than 3 pulls). A new unit may require additional pulls.

started, warm up the machine for about few seconds, without

touch the throttle lever. The machine could need more seconds to

warm up with cold weather or at high altitudes. Finally, push the

throttle lever (E, Fig.34) for deactivate the automatic half-throttle.

CAUTION:

- Never wrap the starter cord around your hand.

- When pulling the starter rope, do not use the full

extent of the rope as this can cause the rope to break.

- Do not let starter rope snap back. Hold the starter

handle (F, Fig.34) and let the rope rewind slowly.

WARNING: Once the engine is warmed up do not use the

choke to start up again.

34

WARNING! - Use the semi-acceleration device only in the

phase of starting the engine to cold.

WARNING: Do not cut material with the choke/fast idle

lever at the FULL CHOKE position. Do not operate your

hedge trimmer with the starting throttle lock engaged.

Cutting with the starting throttle lock engaged does not

permit the operator proper control of the hedge trimmer

speed.

NOTE - STARTING WARM ENGINE:

Follow above starting instructions, but do not use the open

Choke position for start up again. To set fast idle for warm engine

starting, pull choke out completely and push back in to the

original Close Position.

WARNING: Weather conditions and altitude may affect

carburetion. Do not allow bystanders close to the hedge

trimmer while adjusting the carburetor.

WARNING: Never attempt to start the hedge trimmer

when the blade is in a cut or kerf.

Breaking-In the Engine

The engine reaches maximum power after the first 5-8 hours of

activity. During this period of breaking-in do not use the engine at

wide open throttle without load, to avoid excessive functioning stress.

WARNING! - During the breaking-in period do not vary

the carburetion to obtain a presumed power increment;

the engine can be damaged.

NOTE: It is normal for smoke to be emitted from a new engine

during and after first use.

15

Page 16

en

OPERATION

Difficult Starting (or starting a flooded engine)

The engine may be flooded with too much fuel if it has not started

after 10 pulls. Flooded engines can be cleared of excess fuel by

following the warm engine starting procedure listed above. Ensure

the ON/STOP switch is in the ON position. Starting could require

pulling the starter rope handle many times depending on how badly

the unit is flooded. If engine fails to start refer to the

TROUBLESHOOTING TABLE (page 25).

35

Engine is Flooded

If you did not move the choke lever to warm start, quickly enough

after the engine began to fire, the combustion chamber is flooded.

- Set the on/off switch to STOP.

- Pry off the spark plug boot (1, Fig. 35).

- Unscrew and dry off the spark plug.

- Open the throttle wide.

- Pull the starter rope several times to clear the combustion chamber.

- Refit the spark plug and connect the spark plug boot, press it down

firmly.

- Set the choke lever to OPEN position – even if engine is cold.

- Now start the engine.

Stopping The Engine

Release the throttle trigger (B, Fig. 36) and let the engine return to

idle.

To stop the engine, push the switch (A). Do not put the hedge trimmer

on the ground when the blade is still moving.

In the event that the switch will not function, pull the choke lever in

CLOSE position (refer to Fig. 32) to stop the engine.

36

Pre-operation checking

WARNING: THE HEDGE TRIMMER SHOULD NEVER MOVE

AT IDLE. Turn the idle speed screw “T” counterclockwise

to reduce the idle RPM and stop the blade, or contact a

Servicing Dealer for adjustment and discontinue use

until the repair is made.

Serious personal injury may result from the blade

moving at idle.

16

Page 17

OPERATION

Working Techniques

General Working Instructions

WARNING: Do not cut during periods of high wind or

heavy precipitation.

WARNING: Never cut, when visibility is poor or in very

high or low temperatures or in freezing weather.

WARNING - Always wear the harness. Be careful not to

touch the gearbox housing after operation; THESE ARE

HOT ENOUGH TO CAUSE BURNS.

WARNING: Long-term exposure to noise can result in

permanent hearing impairment. So always use approved

hearing protection.

en

33

34

34

WARNING: Faulty blades can increase the risk of

accidents.

WARNING - If correctly used, the hedge trimmer is a

quick, easy to handle and efficient tool; if used

improperly or without the due precautions it could

become a dangerous tool. THE MACHINE CAN CAUSE

SERIOUS INJURY. For pleasant and safe work, always

strictly comply with the safety rules that follow and

throughout this manual.

• Check the cutting attachment. Never use blades that are dull,

cracked or damaged.

• Check that the machine is in perfect working order. Check that all

nuts and screws are tight.

WARNING: The complete clutch cover and gear housing

must be fitted before the machine is started, otherwise

the clutch may come loose and cause personal injury.

WARNING: If you encounter a situation where you are

uncertain how to proceed you should ask an expert.

Contact your dealer or your service workshop.

Avoid all usage which you consider to be beyond your

capability.

• When the engine is switched off, keep your hands and feet away

from the cutting attachment until it has stopped completely.

• Watch out for stumps of branches that can be thrown out during

cutting.

• Do not cut too close to the ground. Stones and other objects can be

thrown out.

• Check the working area for foreign objects such as electricity

cables, insects and animals, etc, or other objects that could damage

the cutting attachment, such as metal items.

• If any foreign object is hit or if high vibrations occur stop the

machine immediately. Disconnect the HT lead from the spark plug.

Check that the machine is not damaged. Repair any damage.

17

Page 18

en

OPERATION

• If anything jams in the blades while you are working, switch off the

• Always wear heavy-duty gloves when repairing the cutting

• Release the throttle trigger as soon as the cut is completed,

• If the cutter blades become jammed by thick branches or any other

36

Note: The hedgetrimmer can also be used without the handgrip.

In this case, remove the handgrip and hold the front sheath area

(C, Fig. 34) with your left hand during operation.

engine and wait until it has stopped completely before cleaning

the blades. Disconnect the HT lead from the spark plug.

attachment (Fig.33). This is extremely sharp and can easily cause cuts.

allowing the engine to idle. If you run the hedge trimmer at full

throttle without a cutting load, unnecessary wear or damage

can occur to the blade and engine.

obstruction, switch off the engine immediately before attempting

to free the blades.

CAUTION! - Always set the machine on the ground with

the engine switched off and as shown in Fig. 35.

37

38

39

Cutting season

Observe all country-specific and local regulations and ordinances

regarding hedge trimming.

Preparations

Before starting work, scare away small animals so that they cannot be

injured.

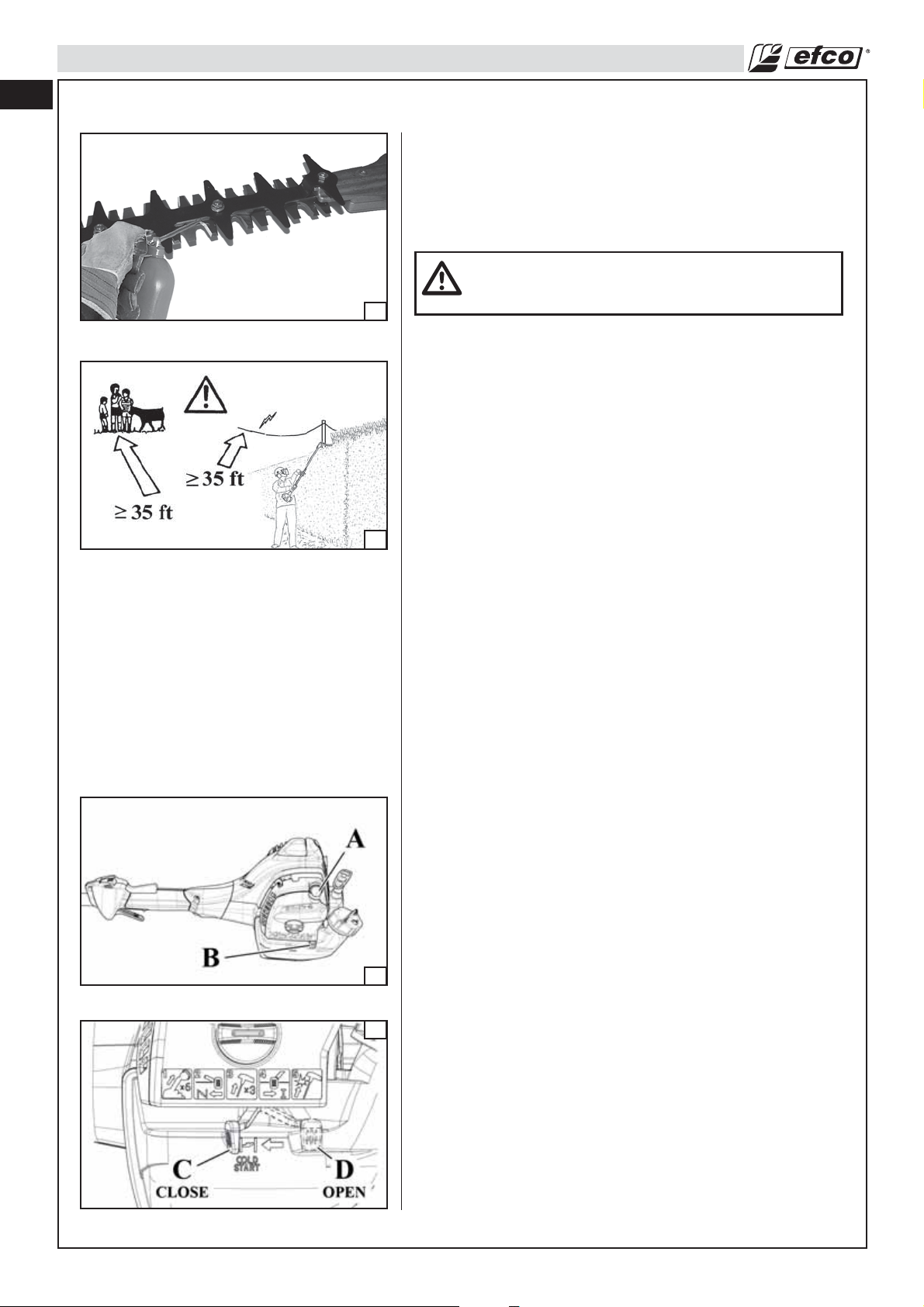

Adjusting the hedgetrimmer (Fig.36)

The angle between the hedgetrimmer and the shaft arm is adjustable

through 12 positions from 0° (fully extended) to 90° (right angle) both

up and down (full range of movement 180°) (Fig.37).

Adjustment procedure:

1. Switch o the engine.

2. Pull the angle adjustment handgrip (A, Fig.38) and twist

anticlockwise to disengage the mechanism.

3. Rotate the attachment to the position desired, selecting the

appropriate hole in the disc.

4. Release the handgrip and ensure the catch pin engages the hole

(Fig.39).

WARNING – With the pin engaged (having made the

adjustment) the handgrip should come to rest on the

housing as before (Fig.40).

18

40

Page 19

OPERATION

Cutting techniques

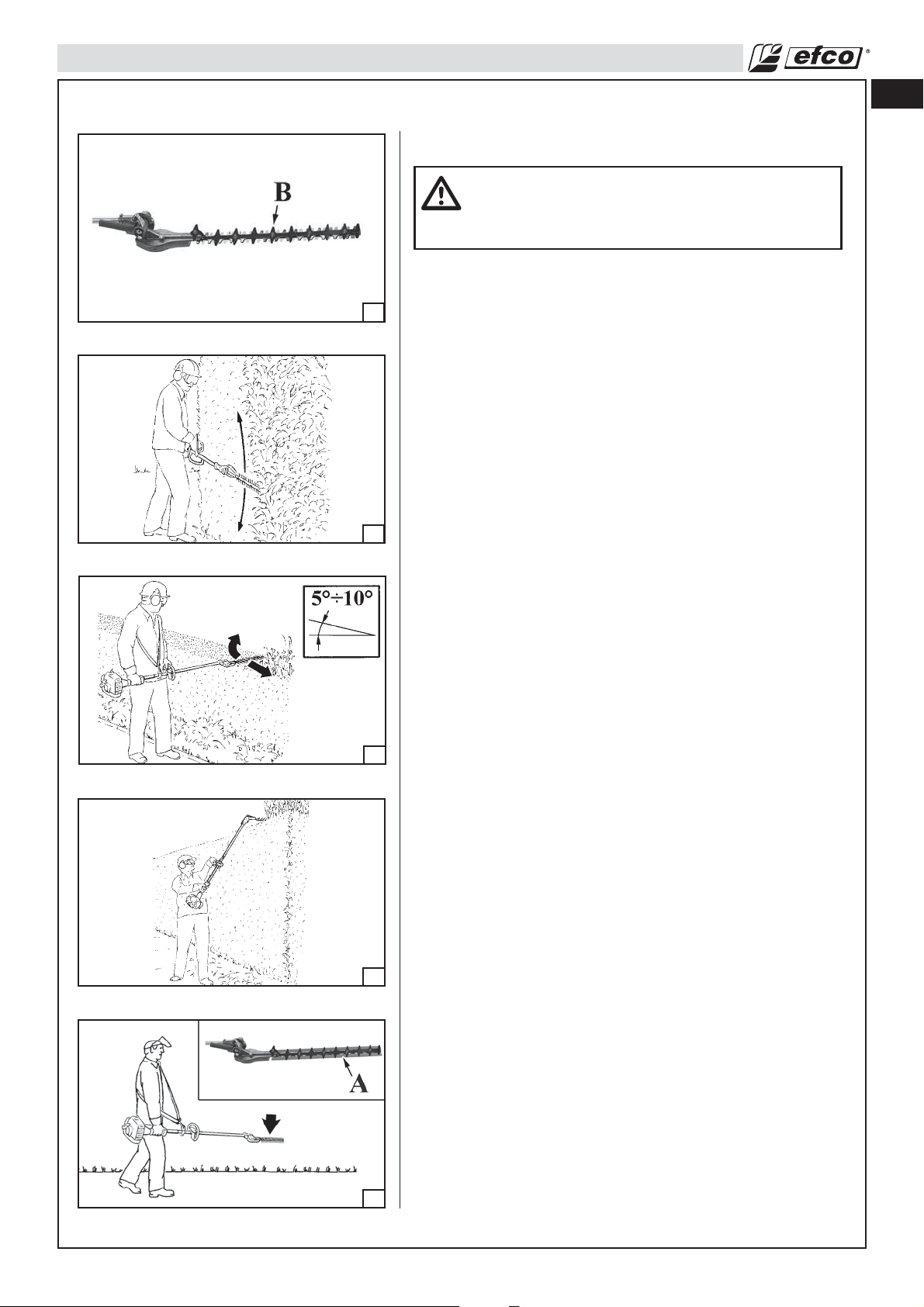

Trim sides of a hedge fi rst, and then the top. Cut slowly, specially

41

with thick hedges. If the hedge needs trimming back hard,

proceed gradually, making a succession of shallow cuts rather than

attempting a single deep cut.

Vertical cut: Use an arcing cut from the bottom upwards, then

downwards, to use both sides of the blades (Fig. 42).

Horizontal cut: In order to get the best cutting results, slightly tilt the

blade (5÷10°) towards the cutting direction (Fig. 43).

Overhead cut: using the attachment hedgetrimmer (Fig.44), elevate

the blade to the required height and cut as appropriate, sweeping left

and right in a wide arc.

en

WARNING! - Do not start the hedge trimmer without the

blade-guard (B, Fig.41). Do not use damaged or

excessively worn blades. If the blade gets jammed, turn

off engine before removing the obstruction.

42

43

Transportation

When you walk with your hedge trimmer, turn off the engine and put

on the blade cover (A, Fig.45). Grip the front handle and keep the

cutter blades behind you (Fig.45).

44

45

19

Page 20

en

MAINTENANCE

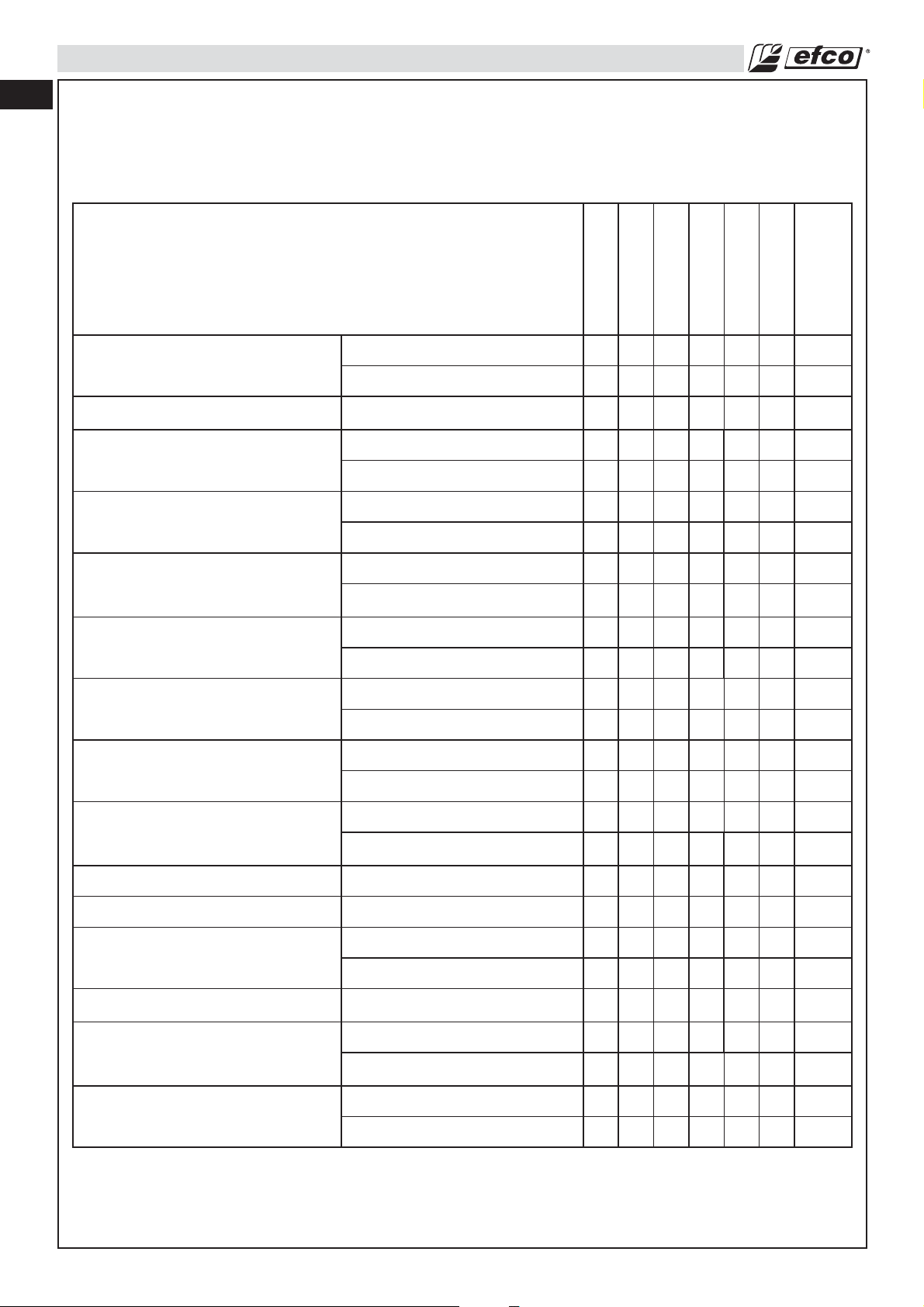

Maintenance Chart

Please note that the following maintenance intervals apply for normal operating

conditions only. If your daily work requires longer than normal or harsh cutting

conditions are present the suggested intervals should be shortened accordingly.

Complete Machine Inspect (Leaks, Cracks, and Wear)

Clean

Controls (Ignition Switch, Choke Lever,

Throttle Trigger, Trigger Interlock

Fuel Tank Inspect (Leaks, Cracks, and Wear)

Fuel Filter Inspect (Leaks, Cracks, and Wear)

Blade Inspect

Drum Inspect (Damage, Sharpness, and Wear)

Clutch Inspect (Damage, and Wear)

All Accessible Screws and Nuts (Not

Adjusting Screws

Air Filter Clean

Cylinder Fins Clean

Starter System Vents Clean

Starter Rope Inspect (Damage and Wear)

Carburetor Check ldle (Chain must not rotate at

Spark Plug Check Electrode Gap

Vibration Mounts Inspect (Damage, and Wear)

Check Operation

Clean

Clean

Clean, Replace Filter Element

Sharpen (Check Gauge Depth)

Replace

Inspect

Retighten

Replace

Replace

ldle)

Replace

Replace by Dealer

Weekly

Monthly

As Required

If Damaged or Faulty

Before Each Use

After Each

Refueling Stop

Daily Work

After Finishing

XX

X

XX

XX

X

XX

X

X

Every 6

X

Months

XX

XX

X

X

X

X

XX

Every 6

X

Months

X

X

X

X

XX

X

Every 6

X

Months

X

XX

20

Page 21

MAINTENANCE

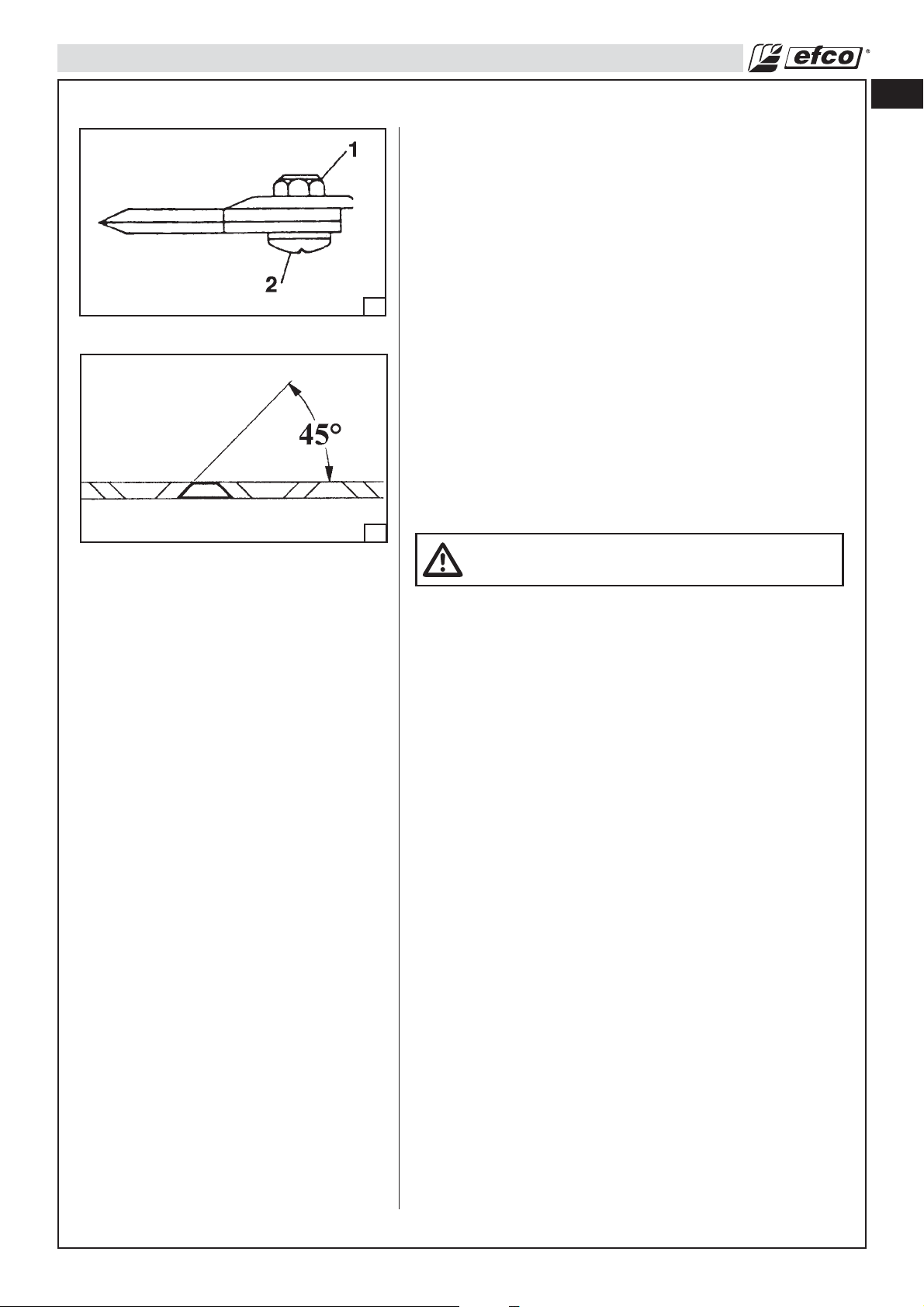

Blade Maintenance

Clean (don’t use grease solvent) any resin and plant residue from the

blades before and after using the machine.

With new blades: after the first working hour you need to inspect the

blades and if necessary adjust the gap between them for a correct

play.

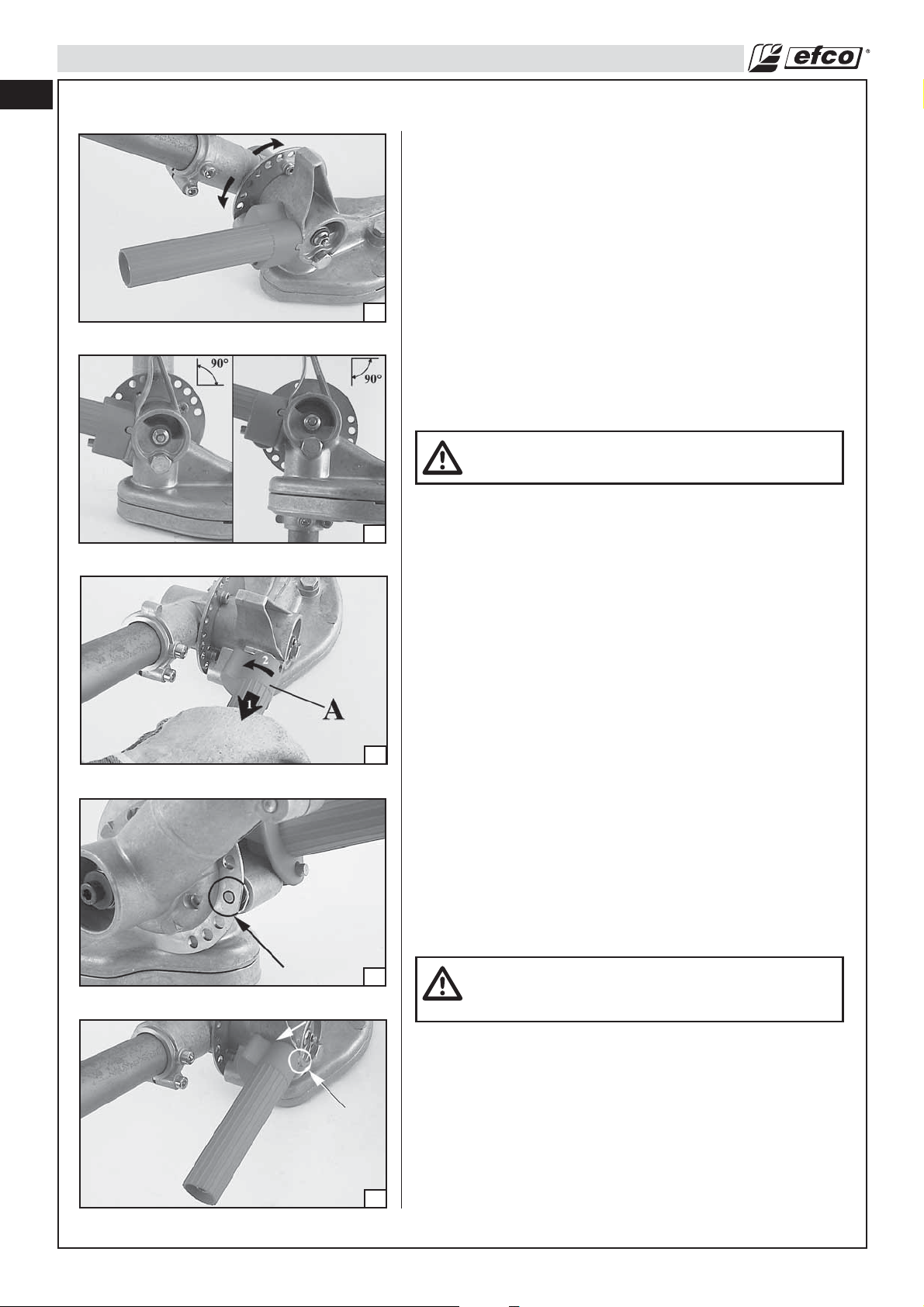

Adjustments (Fig.46): loosen nut (1): slightly tighten screw (2), then

46

unscrew it 1/4 of a turn. Tighten nut (1). Occasionally disassemble and

clean screw and nut (1 and 2).

Sharpening (Fig.47): always keep the file or sharpener at an angle of

45° to the blade, and:

• Always grind in the direction of the cutting edge;

• Files cut only in one direction; lift the file from the blade when

returning to start a new pass;

• Remove all burr from the edge of the blade with a slip stone;

• Remove as little material as possible;

• Before refitting the sharpened blades, remove filings and then

apply grease.

en

47

WARNING: Do not try to sharpen a damaged blade:

change it or take it to a Service Dealer.

• Check that the blade guard is not damaged or distorted. Replace

the blade guard if it is bent or damaged.

• Never repair damaged cutting attachments by welding,

straightening or modifying the shape.

21

Page 22

en

MAINTENANCE

48

49

50

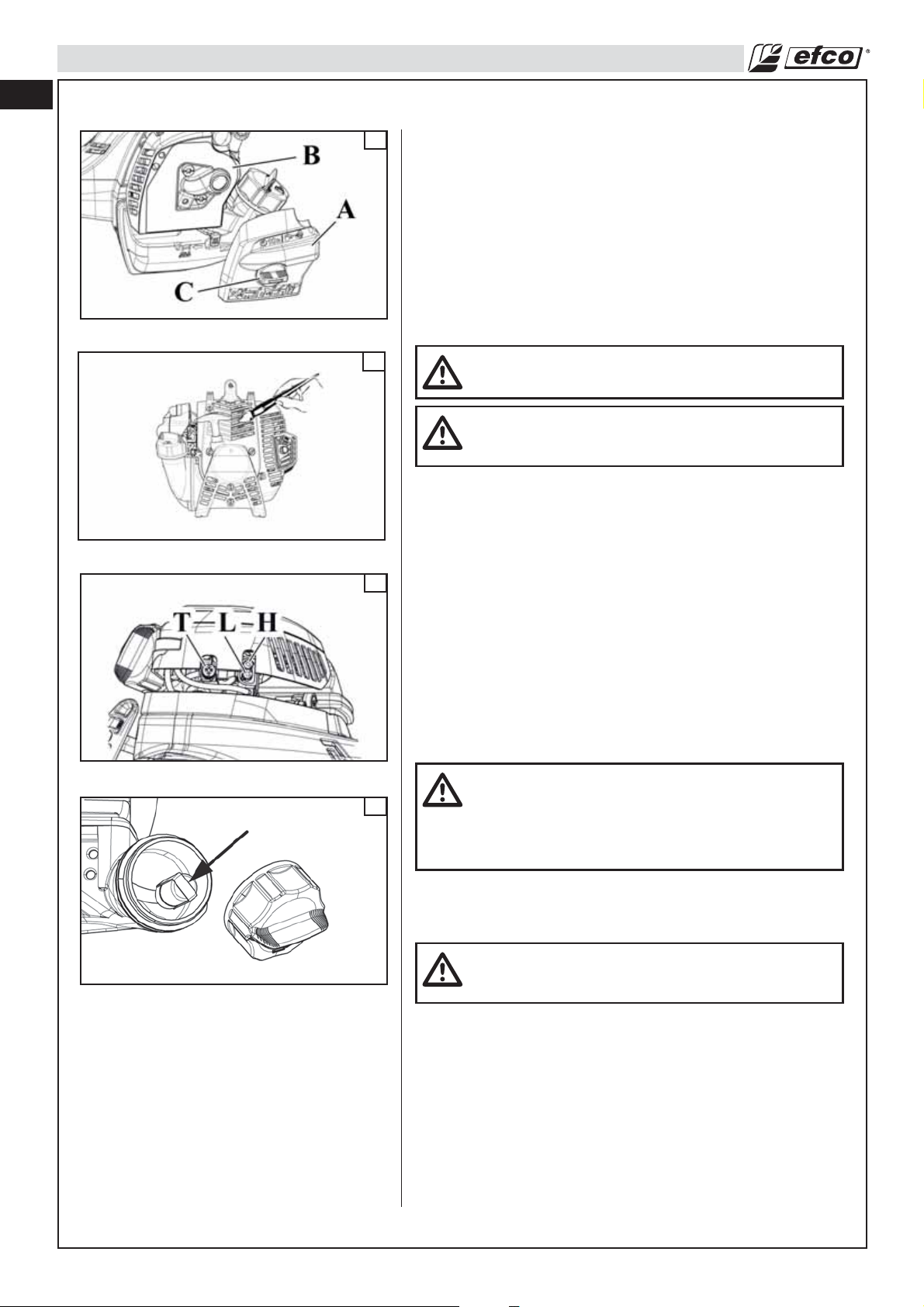

Carburetor Adjustment

Before adjusting the carburetor, clean the cover vents (Fig. 49) and air

filter (B, Fig. 48), refer to Operation-Starting Unit and Maintenance-Air

Filter Sections for details. Allow the engine to warm up prior to

carburetor adjustment.

This engine is designed and manufactured in order to comply with

EPA (Environmental Protection Agency) Phase 3 regulations.

The carburetor (Fig. 50) is designed to permit only the adjustement

of L and H screws in a range of 1/4 round; the ± 1/8 round the hall

range admissible for L and H screws is determined by the

manufacturer and you can not modify it.

WARNING: Don’t try to force the screws outside the

range!

WARNING: Don’t modify the carburetor in any way in

such case the engine will not run in compliance with

emissions regulations.

Idle Speed Adjustment

• If the engine starts, runs, and accelerates but will not idle; turn the

idle speed screw “T” clockwise to increase idle speed (Fig. 50).

• If the hedge trimmer turns at idle, turn the idle speed screw “T”

counterclockwise to reduce the idle RPM and stop the blade

movement. If the blade still moves at idle speed, contact a Servicing

Dealer for adjustment and discontinue use until the repair is made.

• Screw “L” must be adjusted so that the engine promptly responds

to sharp accelerations and gives good idle operation.

• Screw “H” must be adjusted so that the engine gives maximum

power during the cutting phase.

51

Fuel Filter

Check the fuel filter (Fig. 51) periodically. Replace it if contaminated or

damaged.

CAUTION: Never run the engine without the air filter,

serious damage could result.

Make sure the air fi lter is correctly placed in the air

filter cover before reassembly.

Always replace damaged filters.

Do not clean a filter with a brush.

Air Filter

WARNING: Do not clean filter in gasoline or other

flammable solvent to avoid creating a fire hazard or

producing harmful evaporative emissions.

If a power drop is noticed, check the air filter. Open the air fi lter cover

(A) and check the air filter (B, Fig. 48) each day, change the filter if

heavily clogged or damaged.

Clean with Emak degreaser p/n 001101009A, rinse with water and

blast dry with compressed air, not too close, blowing from the inside

outwards.

Reinstall the air filter into cover. Place the air filter cover onto the

brush cutter. Tighten the air filter cover screw (C) securely.

A used air filter can never be completely cleaned. It is advisable to

replace your air filter with a new one after six month of operation.

Make sure the cover and the support are clean before fitting the new

filter.

22

Page 23

CMR7H

MAINTENANCE

Starter Unit

Engine

Clean the cylinder fins with compressed air or a brush periodically.

Dangerous overheating of engine may occur due to impurities on the

52

cylinder.

Spark Plug

en

WARNING: The coil spring is under tension and could fly

apart causing serious injuries. Never try to disassemble

or modify it.

WARNING: Never run the machine without all the parts,

including the starting housing, securely in place.

Because parts can fracture and pose a danger of thrown

objects, leave repairs to the flywheel and clutch to

trained Servicing Dealers.

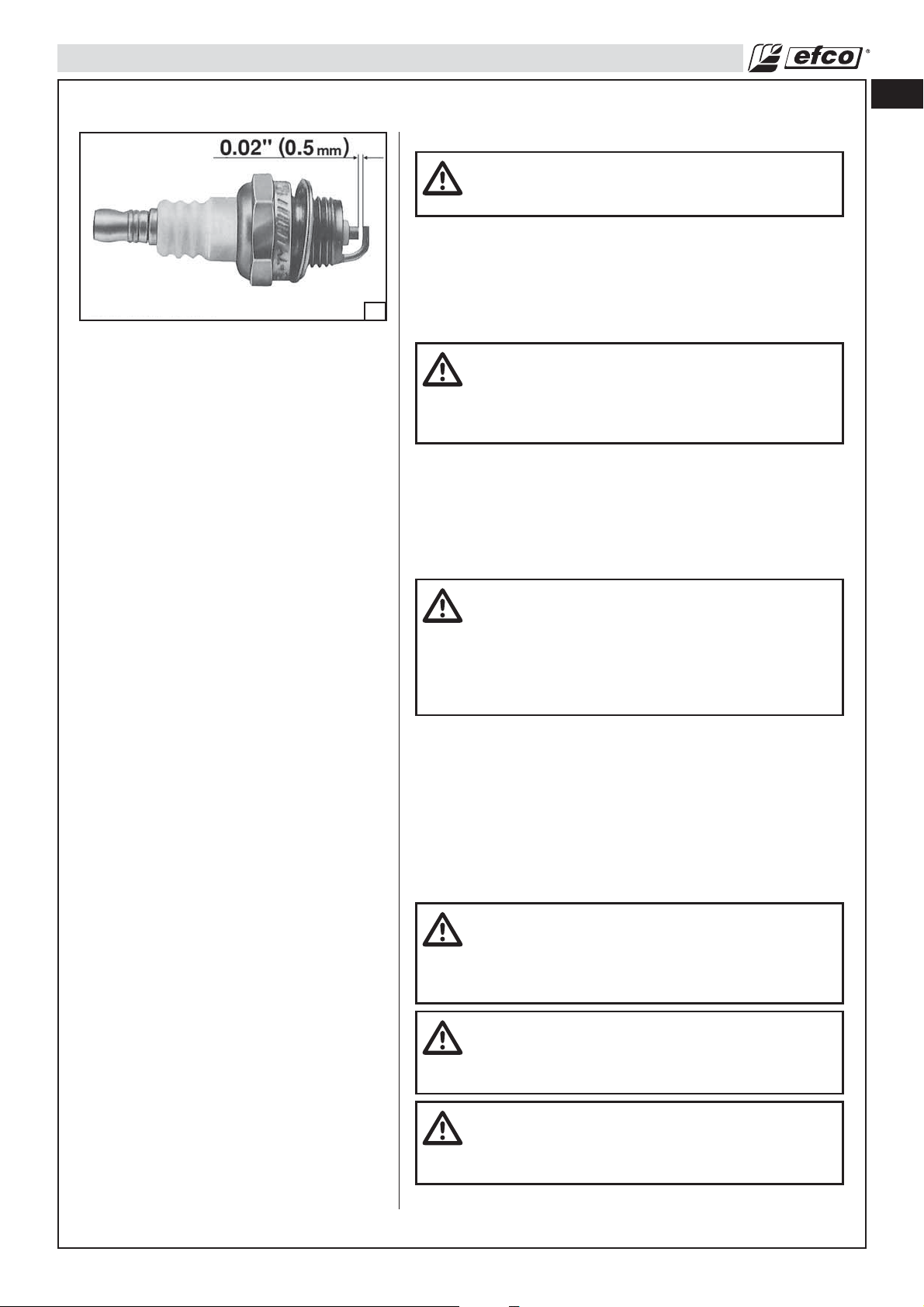

This engine uses a NGK CMR7H with .02” (0.5 mm) electrode gap

(Fig. 52). Use an exact replacement and replace every six months or

more frequently, if necessary.

WARNING: Never test the ignition system with ignition

wire connector removed from spark plug or with

unseated spark plug, since uncontained sparking may

cause a fire. A loose connection between spark plug

terminal and ignition wire connector in the boot may

create arcing that could ignite combustible fumes and

cause a fire.

Use only resistor type spark plugs of the approved range.

Factors such as:

- too much oil in fuel mix;

- dirty air filter;

- unfavourable running conditions, e.g. operating at part load;

may result in rapid deterioration of the spark plug.

Muffler

WARNING! – This muffler is fitted with a catalytic

converter needed for the engine to be in compliance

with the emissions requirements. Never modify or

remove the catalytic converter: failure to do so is a

violation of law.

WARNING! – Mufflers fitted with catalytic converters get

very hot during use and remain so for some time after

stopping. This also applies at idle speed. Contact can

result in burns to the skin. Remember the risk of fire!

CAUTION! – If the catalytic converter is damaged it

should be replaced. If the muffler is frequently blocked,

this can be a sign that the performance of the catalytic

converter is impaired.

23

Page 24

en

MAINTENANCE

53

54

55

Spark Arresting Muffler (Fig. 53)

WARNING: A faulty or altered spark arrester system

screen can create a fire hazard.

Through normal use the screen can become dirty and should be

inspected weekly and cleaned as required.

To clean:

• Allow the muffl er to cool.

• Remove the muffl er cover (A).

• Remove the six (6) defl ector screws (B).

• Remove the defl ector (C), the gasket (D) and spark arrester (E).

• Clean and inspect the spark arrester screen. If the spark arrester

screen is damaged, faulty or deteriorated, replace the screen.

• Reassemble components in reversed order of removal and torque

the screw to 40 in/lbs (4.5 Nm).

WARNING: If the spark arrester screen is damaged,

faulty or deteriorated, replace the screen or entire

muffler assembly.

The Spark Arrester System needs a periodic and accurate maintenance

and cleaning, in particular:

- check periodically the spark arrester screen and substitute it when

holes, bends or deformations appear;

- check carefully if dust, debris or organic material is in contact with

parts of the Spark Arrester System; clean it often with tools or shop

air.

If the screen needs to be replaced, please order the whole inner part p.n.

61370017R (E) and 58070144R (D).

WARNING: Do not operate your hedge trimmer if the

muffler is damaged, missing or modified. An improperly

maintained muffler will increase the risk of fire and

hearing loss.

Blade Gearbox

Refill gear housing every 20 working hours (Fig. 54). If necessary, add

15÷20 g grease with molybdenum bisulphide.

Angle Drive

Refill gear housing every 50 working hours (Fig. 55). If necessary, add

5÷10 g grease with molybdenum bisulphide.

24

Page 25

TROUBLESHOOTING

Using Troubleshooting Chart

WARNING: Always stop unit and disconnect spark plug before performing all of the recommended

remedies below except remedies that require operation of the unit.

When you have checked all the possible causes listed and you are still experiencing the problem, see your Servicing Dealer.

If you are experiencing a problem that is not listed in this chart, see your Servicing Dealer for service.

PROBLEM POSSIBLE CAUSE SOLUTION

en

Engine will not start or will run

only a few seconds after

starting.

Engine starts but will not

accelerate properly:

Engine starts but will not run

properly at high speed.

1. No spark

2. Flooded engine.

Carburetor requires “L” (Low jet)

adjustment.

Carburetor requires “H” (High jet)

adjustment.

1. Check Spark. Remove spark plug from cylinder.

Reattach the spark plug wire and lay spark plug

on top of cylinder. Pull the starter rope and

watch for spark at spark plug tip. If there is no

spark, repeat test with a new spark plug

(CMR7H).

2. With the ignition switch off, remove spark plug.

Move choke lever to Run position and pull

starter cord 15 to 20 times. This will clear excess

fuel from engine. Clean and reinstall spark

plug. Pull the choke lever all out and then

insert it completely in order to activate the

semi-acceleration device. Pull starter three

times with choke lever at run. If engine does

not start, move choke lever to choke and

repeat normal starting procedure. If engine still

fails to start, repeat procedure with a new

spark plug.

* Contact a Servicing Dealer for carburetor

adjustment.

* Contact a Servicing Dealer for carburetor

adjustment.

Engine does not reach full

speed and / or emits excessive

smoke

Engine starts, runs, and

accelerates but will not idle.

Engine starts and runs, but

the blade doesn't move

WARNING: Never

touch the blade

while the engine is

running.

*Note: This engine complies with EPA (Environmental Protection Agency) and CARB (California Air Resource Board)

regulations which require exhaust emission control. If your unit exhibits specific performance problems that can not be

corrected by the Trouble Shooting Section, the unit should be taken to a Servicing Dealer for repair.

1. Check oil fuel mixture.

2. Air filter dirty.

3. Spark arrester screen dirty.

4. Carburetor requires “H” (High jet)

adjustment.

Carburetor requires adjustment. Turn idle speed screw “T” clockwise to increase

1. Blade incorrectly fitted

2. Blade damaged

3. Clutch or transmission shaft

damaged

1. Use fresh fuel and the correct 2-cycle oil mix.

2. Clean per instruction in Maintenance-Air Filter

Section.

3. Clean per instructions in Maintenance-Spark

Arresting Muffler Section.

4. * Contact a Servicing Dealer for carburetor

adjustment.

idle speed. (If chain turns at idle, turn idle speed

screw “T” counterclockwise to decrease speed);

see Operation-Carburetor Adjustment.

1. Contact an Authorised Service Centre

2. Contact an Authorised Service Centre

3. Contact an Authorised Service Centre

25

Page 26

en

STORAGE

Storing Hedge Trimmer

WARNING: Stop engine and allow to cool, and secure the unit before storing or transporting in a

vehicle. Store unit and fuel in an area where fuel vapors cannot reach sparks or open flames from

water heaters, electric motors or switches, furnaces, etc. Store unit with all guards in place. Position

so that any sharp object cannot accidentally cause injury to a passersby. Store the unit out of reach

of children and other unauthorized persons.

1. Drain and clean the fuel tank in a well ventilated area.

2. Drain all fuel from tank into a container approved for gasoline. Run engine until it stops. This will remove all fuel-oil

mix which could become stale and leave varnish and gum in the fuel system.

3. Clean all foreign material from the hedge trimmer. Keep away from corrosive agents such as garden chemicals and

de-icing salts.

4. Abide by all Federal and local regulations for the safe storage and handling of gasoline. Excess fuel should be used

in other 2-cycle engine powered equipment.

5. Lubricate the blade bars with special grease before long periods of storage.

CAUTION: It is important to prevent gum deposits from forming in essential fuel system parts such

as the carburetor, fuel filter, fuel hose, or fuel tank during storage. Alcohol blended fuels (called

gasohol or E10 or using ethanol, methanol) can attract moisture which leads to fuel mixture

separation and formation of acids during storage. Acidic gas can damage the engine.

TECHNICAL DATA

DS 2400 H

ENGINE:

Displacement: 1.32 cu. in (21.7 cc)

Bore: 1.36 in (32 mm)

Stroke: 1.10 in (27 mm)

PERFORMANCE:

Idle Speed: 3,000 RPM

WOT (With Bar & Chain): 10,500 RPM

Power: 1.2 HP/0.9kW (8,500 RPM)

FUEL SYSTEMS:

Carburetor: Multi Position Diaphragm

Fuel Tank Capacity: 13.5 oz. (400 ml)

Fuel Mix: See Operation-Fueling Section

IGNITION SYSTEM:

Spark Plug: NGK CMR7H

Spark Plug Gap: 0.02 in. (0.5 mm)

CUTTING SYSTEM:

Blade pitch: 1.38 in. (35 mm)

Blade lenght: 19.7 in. (500 mm)

MUFFLER:

Catalytic Converters: present

Spark Arrester System: present

26

Page 27

INTRODUCTION

Pour un emploi correct de la taille-haies et pour éviter tout accident, ne commencez pas le

travail sans avoir préalablement lu ce manuel avec attention. Vous trouverez les descriptions

du fonctionnement des différents composants, ainsi que les instructions relatives aux

contrôles et aux procédures d'entretien requis.

Remarque: les illustrations et instructions présents dans ce manuel peuvent varier en

fonction des normes de chaque pays et sont sujettes à modifications sans préavis par le

fabricant.

MANUEL DE L'UTILISATEUR

Le manuel de l'utilisateur est destiné à votre propre protection. LISEZ-LE. Conservez-le dans

un endroit approprié de façon à pouvoir s'y référer au besoin. Ayez pris connaissance des

procédures avant de commencer le montage de l'unité. Une préparation et un entretien

fr

corrects vont de paire avec de bonnes performances de la machine et avec une sécurité

optimale.

Contactez votre concessionnaire ou votre distributeur local si vous ne comprenez pas

certaines des instructions délivrées par le présent manuel.

Outre les instructions relatives au fonctionnement, le présent manuel contient des paragraphes

requérant une attention particulière de votre part.

Ces paragraphes sont signalés par les symboles décrits ci-dessous :

Avertissement: présent en cas de risque d'accident, de blessure corporelle, ou de dégâts

matériels.

Mise en garde: présent en cas de risque d'endommagement de la machine ou de ses

composants.

AVERTISSEMENT : Afin de garantir un fonctionnement correct et en

toute sécurité de la taille-haies, il est recommandé de toujours

conserver le manuel de l'utilisateur à proximité de la machine. Ne

prêtez ou ne louez jamais votre taille-haies sans fournir le présent

manuel d'utilisation et d'entretien.

AVERTISSEMENT : Seules les personnes ayant intégralement

compris le présent manuel sont habilitées à utiliser votre taillehaies.

27

Page 28

fr

SOMMAIRE

IDENTIFICATION DU PRODUIT

Composants de la taille-haies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SÉCURITÉ

Comprendre les étiquettes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Réglementations nationales et locales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

RÈGLES DE SÉCURITÉ

Précautions de base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Manipulation du carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fonctionnement et sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Mesures de précaution pour réduire le risque de vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Précautions d'entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

MONTAGE

Montage de l'Outil de Coupe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Montage de la Poignée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

FONCTIONNEMENT

Alimentation en carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Préparation à la coupe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Démarrage du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Rodage du moteur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Arrêt du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Techniques de travail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

ENTRETIEN

Tableau d'entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Entretien de la lame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Réglage du carburateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Filtre à carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Filtre à air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Démarreur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Bougie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Silencieux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Silencieux pare-étincelles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Reducteur Lames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Reducteur Angulaire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DIAGNOSTIC DES PANNES

Utilisation du tableau de diagnostic des pannes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

REMISAGE

Remisage de la taille-haies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CARACTÉRISTIQUES TECHNIQUES

DS 2400 H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

28

Page 29

IDENTIFICATION DU PRODUIT

fr

Composants de la taille-haies

1. Sistème à courroie

2. Interrupteur d’arrêt du moteur

3. Protection du pot d’échappement

4. Bougie

5. Filtre à air

6. Bouchon du réservoir de carburant

7. Réservoir de carburant

8. Levier de l’accélérateur

9. Pompe primer

10. Poignée démarrage

11. Levier starter

12. Tuyau de transmission

13. Poignée arriére

14. Poignée avant

15. Outil de coupe

16. Lames

17. Réducteur lames

18. Graisseur réducteur angulaire

19. Poignée de réglage angulaire

20. Vis de fixation

21. Réducteur angulaire

22. Disque sélecteur

23. Graisseur réducteur lames

24. Fourreau protège-lames

25. Les courroies

26. Clè allen

27. Clè mixte

29

Page 30

SÉCURITÉ

fr

Comprendre les étiquettes de sécurité

- Ce symbole signale un Avertissement

et une Mise en garde.

- Votre manuel contient des messages

spéciaux attirant votre attention sur

les problèmes liés à la sécurité, les

dégâts éventuels de la machine, ainsi

que des informations utiles sur le fonctionnement et l'entretien. VEUILLEZ

LIRE TOUTES CES INFORMATIONS

AVEC ATTENTION AFIN D'ÉVITER DE

VOUS BLESSER OU D'ENDOMMAGER

LA MACHINE.

- Portez des lunettes de sécurité, des

protège-tympans ainsi qu'un masque

de protection lorsque vous utilisez

cette machine.

- ATTENTION: Les surfaces risquent

d'être très chaudes.

- Portez des gants de protection renforcés et antidérapants pour la manipulation de la taille-haies et de la lame.

Réglementations nationales et locales

Le moteur de l'appareil N'EST PAS n'est pas équipé d'un dispositif pare-étincelles conforme aux exigences des

'SAE Recommended practice J335' et 'California Codes 4442 et 4443'. La réglementation régissant tous les

terrains forestiers et territoires gérés par les États de Californie, Maine, Washington, Idaho, Minnesota,

New Jersey et Oregon exige que les moteurs à combustion interne soient équipés d'une protection pareétincelles. Les autres États et agences fédérales mettent en oeuvre des réglementations identiques.

L'utilisation de ce moteur dans un État ou un endroit régi par cette réglementation peut représenter une violation

de la loi.

Commentaire: Lorsque vous utilisez cet appareil à des fins d'exploitation forestière, veuillez consulter le

'Code of Federal Regulations', Parties 1910 et 1928.

AVERTISSEMENT: Le système d'allumage de votre machine génère un champ électromagnétique

de très faible intensité. Il est possible de ce champ crée des interférences sur le fonctionnement

d'un stimulateur cardiaque. Afin de réduire le risque de blessures graves, voire de mort, les

personnes équipées d'un stimulateur cardiaque sont vivement invitées à consulter leur

médecin ainsi que le fabricant du stimulateur avant d'utiliser la machine.

30

AVERTISSEMENT: les surfaces du silencieux deviennent très chaudes en cours de fonctionnement

et après arrêt de la taille-haies; tenez-vous à distance du silencieux. Tout contact avec le

silencieux peut entraîner de graves brûlures.

Page 31

SÉCURITÉ

AVERTISSEMENT: L'exposition aux vibrations générées lors de l'utilisation d'outils à moteurs

thermiques peut entraîner des lésions vasculaires ou nerveuses au niveau des doigts, des mains

et des poignets chez les personnes sujettes à des troubles de la circulation ou à des phénomènes

de tuméfactions anormaux. En outre, il a été démontré que l'utilisation prolongée par temps

froid entraînait des lésions des vaisseaux sanguins chez les personnes saines. En cas d'apparitions

de symptômes tels que des engourdissements douleurs, pertes de force, changements de la

couleur ou de la texture de la peau ou pertes de sensation au niveau des doigts, des mains ou

des poignets, interrompez immédiatement l'utilisation de la machine et consultez un médecin.

AVERTISSEMENT: Les vapeurs d'échappement du moteur de ce produit contiennent des substances

chimiques que l'état de Californie a reconnues à l'origine de cancers, d'anomalies congénitales ou

d'autres troubles de la reproduction. Utilisez votre taille-haies en extérieur, exclusivement dans

une zone bien ventilée.

fr

31

Page 32

RÈGLES DE SÉCURITÉ

fr

Précautions de base

• Lisez attentivement le présent manuel jusqu'à ce que vous ayez

intégralement compris les règles de sécurité, les mesures de

précaution et les instructions relatives au fonctionnement, et que

soyez en mesure de les appliquer avant toute utilisation de la

machine.

• Limitez l'utilisation de la taille-haies à des utilisateurs adultes

capables de comprendre et d'appliquer les règles de sécurité, les

mesures de précaution et les instructions relatives au

fonctionnement indiquées par le présent manuel. L'utilisation de la

1

2

3

4

5

machine par des mineurs est fortement déconseillée.

• Ne manipulez et n'utilisez pas la machine lorsque vous êtes

fatigué, malade ou perturbé, ou sous l'emprise de l'alcool, de

drogues ou de médicaments. Vous devez être en bonne forme

physique et en pleine possession de vos capacités mentales.

L'utilisation d'une taille-haies est relativement ardue et pénible. Si

vous présentez un état susceptible d'être aggravé par une tâche

physiquement exigeante, consultez préalablement votre médecin

(Fig. 1). Soyez plus vigilant avant les périodes de repos et en en

proximité de la fin de votre tour de travail.

• Maintenez les enfants, passants et animaux à une distance

minimale de 10 mètres (35 pieds) de la zone de travail. Ne tolérez

la présence d'aucune personne ou animal à proximité immédiate

de la taille-haies lors du démarrage ou en utilisation (Fig. 2).

• Portez en permanence des équipements de sécurité homologués

lorsque vous utilisez la taille-haies. Toutefois, le port de vêtements

de sécurité n'élimine pas les risques de blessures, mais il peut en

réduire les effets en cas d'accident. Demandez conseil à votre

distributeur habituel pour le choix des équipements conformes à

la réglementation. Les vêtements utilisés ne doivent en aucun cas

entraver les mouvements. Portez un vêtement anti-coupe près du

corps. La veste (Fig. 3) et la salopette (Fig. 3) sont des

équipements idéaux. Ne portez pas de vêtements, écharpes,

cravates ou bijoux susceptibles de s'accrocher aux buissons. Nouez

les cheveux longs et protégez-les (par exemple, à l'aide d'un

foulard, d'une casquette, d'un casque, etc.). Bottes de sécurité

coquées et équipées de semelles antidérapantes (Fig. 4).

Portez des lunettes de sécurité ou une visière de protection

(Fig. 5)! Utilisez des protections anti-bruit, notamment un

casque anti-bruit (Fig. 4) ou des protège-tympans. L'utilisation

de protections anti-bruit requiert une attention supplémentaire

en ce sens que la perception des signaux sonores d'avertissement

en cas de danger (tels que cris, alarmes, etc.) est réduite. Portez

des gants (Fig. 6).

• Ne prêtez votre taille-haies qu'à des utilisateurs expérimentés

rompus au fonctionnement et à l'utilisation corrects des taillehaies. Fournissez-leur le manuel contenant le mode d'emploi qu'ils

devront lire avant d'utiliser la taille-haies.

• Contrôlez quotidiennement votre taille-haies afin de garantir que

chaque dispositif de sécurité ou autre fonctionne correctement.

• Ne travaillez jamais avec une taille-haies endommagée, modifiée

ou mal réparée ou mal montée. Ne démontez, endommagez ou

neutralisez jamais l'un des dispositifs de sécurité. Remplacez

immédiatement un lame ou, une protection de main endommagés,

cassés ou démontés pour toute autre raison.

• Élaborez toujours votre plan de découpe à l'avance. Ne débutez

aucun tâche avant d'avoir une zone de travail dégagée, une assise

stable.

• Adressez-vous à un professionnel qualifié pour toute autre

intervention ne figurant pas dans le présent manuel.

• Le taille-haie doit exclusivement être utilisé pour la taille de haies

ou de petits buissons. Il est interdit de couper d'autres types de

matériaux. N'utilisez pas le taille-haie comme levier pour soulever,

déplacer ou briser des objets et ne le bloquez pas sur des supports

fixes. L'utilisation d'outils ou d'applications non indiqué(e)s par le

fabricant sur la prise de force est interdite. N'utilisez pas la machine

pour élaguer des arbres ou couper l'herbe. Il est fortement

déconseillé de couper un autre type de matériau.

• Il est fortement déconseillé de raccorder à la prise de force de la

taille-haies tout outil ou accessoire non spécifié par le fabricant.

32

Page 33

RÈGLES DE SÉCURITÉ

Manipulation du carburant

fr

AVERTISSEMENT: L'essence est un carburant hautement

inflammable. Manipulez l'essence ou le mélange de

carburant avec une extrême précaution. Ne fumez pas

ou ne produisez pas de source de flamme à proximité du

carburant ou de la taille-haies (Fig.7).

• Manipulez le carburant avec une extrême précaution afin

6

7

8

9

d'éviter tout risque d'incendie ou de brûlure. Le carburant est

hautement inflammable.

• Faites le mélange et conservez le carburant dans un conteneur

approuvé pour l'entreposage d'essence (Fig. 8).

• Faites le mélange de carburant en extérieur, en l'absence de toute

source d'étincelles ou de flammes.

• Choisissez une surface dégagée, coupez le moteur et laissez

refroidir avant de faire le plein.

• Devissez lentement le bouchon de carburant afin de libérer la

pression et d'empêcher le carburant de s'écouler par le bouchon.

• Resserrez fermement le bouchon de carburant après remplissage.

Sous l'effet des vibrations de la machine, un bouchon mal refermé

peut se desserrer, voire s'ouvrir, entraînant un déversement du

carburant.

• Essuyez toute trace de carburant sur la tronçonneuse. Déplacezvous à 3 mètres (10 pieds) de la zone de remplissage avant de

démarrer le moteur (Fig. 9).

• Ne tentez en aucun cas de brûler le carburant déversé.

• Ne fumez pas en manipulant le carburant ou en utilisant la taillehaies.

• Entreposez le carburant dans un endroit sec, frais et suffisamment

ventilé.

• Ne placez jamais la taille-haies sur un matériau facilement

inflammable, notamment sur des feuilles mortes, de la paille, du

papier, etc.

• Entreposez la machine et le carburant dans un endroit exempt de

sources d'étincelles ou de flammes nues, de moteurs électriques,

d'interrupteurs, de fours, etc., susceptibles d'enflammer les vapeurs

de carburant.

• Ne retirez jamais le bouchon du réservoir de carburant lorsque le

moteur tourne.

• N'utilisez jamais le carburant pour le nettoyage.

• Veillez à ne pas souiller vos vêtements de carburant.

10

Fonctionnement et sécurité

AVERTISSEMENT: Tenez toujours la taille-haies à deux

mains lorsque le moteur tourne. Enserrer fermement les

poignées de la taille-haiese entre les doigts et le pouce

(Fig.10).

• Tenez toutes les parties du corps à distance de la lame lorsque le

moteur tourne.

• Transportez toujours la taille-haies moteur coupé le lame et la

chaîne vers l'arrière, et le silencieux d'échappement à distance de

votre corps. Transportez toujours la taille-haies avec son couvercle

de la lame monté (Fig.11, page 44). Pour le transport à bord d'un

véhicule, montez toujours le couvercle de la lame. Fixez

correctement la taille-haies afin d'éviter qu'elle ne se renverse, que

le carburant ne s'écoule ou que la taille-haies ne soit endommagée.

33

Page 34

RÈGLES DE SÉCURITÉ

fr

11

12

13

• N'utilisez jamais la taille-haies d'une seule main! Une telle

manipulation peut blesser gravement l'utilisateur ou les personnes

se tenant dans la zone de travail. Une taille-haies s'utilise à deux

mains.

• Avant de démarrer le moteur, vérifiez que la chaîne n'est en contact

avec aucun objet.

• Coupez le moteur avant de poser la taille-haies. Ne laissez pas le

moteur tourner sans surveillance.

• Utilisez exclusivement la taille-haies dans une zone suffisamment

ventilée, ne l'utilisez pas dans un environnement explosif ou

inflammable ou dans des zones confinées (Fig.12). Faites attention

à la possibilité d’empoisonnement par monoxyde de carbone.

• N'utilisez pas la taille-haies sur une échelle ou directement sur un

arbre. Ayez toujours une assise stable et une position appropriée.

• N'effectuez aucune opération de coupe à proximité de câbles

électriques.

• Tenez vos mains au sec, propres et exemptes d'huile ou de

carburant.

• Quand le moteur tourne, saississez toujours fermement la poignée

avant de la main gauche et la poignée arrière de la main droite

(Fig. 10). Ne vous approchez pas de le lames ni du pot d’échappement.

Vous devez maintenir la machine à deux mains, sans jamais les

croiser. Ces directives s’appliquent également aux gauchers.

Conservez la position de coupe correcte.

• Coupez toujours en position stable et sûre, surtout si l’on opère sur

une échelle ou sur un escabeau (Fig. 13).

34

Page 35

RÈGLES DE SÉCURITÉ

Mesures de précaution pour réduire les risques liés aux vibrations

• La taille-haies est équipée d'un système anti-vibrations (AV); ne le modifiez jamais.

• Portez des gants et tenez vos mains au chaud.

• Tenez toujours la lame affûtée et effectuez correctement l'entretien de la taille-haies, notamment le système AV.

Une lame émoussée rallonge le temps de coupe, augmente les vibrations transmises directement aux mains.