Page 1

DS 2200 - DS 2400

(1.32 cu.in)

en

fr

es

OPERATOR’S INSTRUCTION MANUAL

MANUEL D’UTILISATION ET D’ENTRETIEN

MANUAL DE INSTRUCCIONES

Page 2

1

(T)

1 2 3

18

21

20A

20B

16

17

19B

19A

17

10

9

4

5

6

7

16

8

12

14

13

15

12

14

11

21

18

2 3

13

15

Page 3

4

D

A

5

B2

B1

90°

B

A

C

C

B

L

H

C

C

A

B

M

G

P

N

A

G

F

F

E

C

E

D

6

P

C

F

C

D

B

A

8

7

A

B

L

F

C

9

A

D

E

B

Page 4

FAT TO

FAT TO

T L H

C

A

B

0,5 mm

CMR7H

A

B

123

=

=

=

=

1

2

3

4

C

I

A

CLOSE

B

OPEN

12

14

15 16

17

19

13

18

Page 5

=

=

=

=

20

FAT TO

1

2

3

4

C

A

B

B

A

T L H

23

24

CMR7H

25

21

0,5 mm

FAT TO

22

26

27

123

Page 6

INTRODUCTION

To correctly use the brush cutter and prevent

accidents, do not start work without having

fi rst carefully read this manual. You will fi nd

explanations concerning the operation of the

various parts plus instructions for necessary

checks and relative maintenance.

Note: Illustrations and specifi cations

in this manual may vary according to

Country requirements and are subject to

change without notice by the

manufacturer.

THE OPERATOR’S MANUAL

Your operator’s manual is for your protection.

READ IT. Keep it in a safe place for reference.

Know what you are doing before you begin

assembly of the unit. Proper preparation and

upkeep go hand-in-hand with satisfactory

performance of the brush cutter and safety.

Contact your dealer or the distributor for your

area if you do not understand any of the

instructions in this manual.

In addition to the operating instructions, this

manual contain paragraphs that require your

special attention.

Such paragraphs are marked with the

symbols described below:

Warning: where there is a risk of an accident

or personal injury or serious damage to

property.

Caution: where there is a risk of damaging

the machine or its individual components.

WARNING - To ensure safe and

correct operation of the brush

cutter, this operator’s manual

should always be kept with or

near the machine. Do not lend or

rent your brush cutter without the

operator’s instruction manual.

WARNING: Allow only persons

who understand this manual to

operate your brush cutter.

en

3

Page 7

TABLE OF CONTENTS

PRODUCT IDENTIFICATION

Brush Cutter Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY

Understanding Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

en

State and Local Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SAFETY RULES

Basic Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fuel Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Precautions Against Kickout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintain Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recommended Cutting Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety equipment checking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Precautions to Reduce Vibration Risk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ASSEMBLY

Loop handle (DS 2200 TR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Assembling the bike handle (DS 2200 T - DS 2400 T). . . . . . . . . . . . . . . . . . . . . . 13

Assembling the cutting attachment guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Assembling the cutting attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Approved power tool attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

OPERATION

Fueling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Preparation for Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Starting the Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Breaking-in the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stopping the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Working Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

MAINTENANCE

Maintenance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cutting Attachment Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Carburetor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Starter Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Muffl er. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Spark Arresting Muffl er. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Bevel Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TROUBLESHOOTING

Using Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

STORAGE

Storing Brush cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TECHNICAL DATA

DS 2200 - DS 2400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4

Page 8

PRODUCT IDENTIFICATION

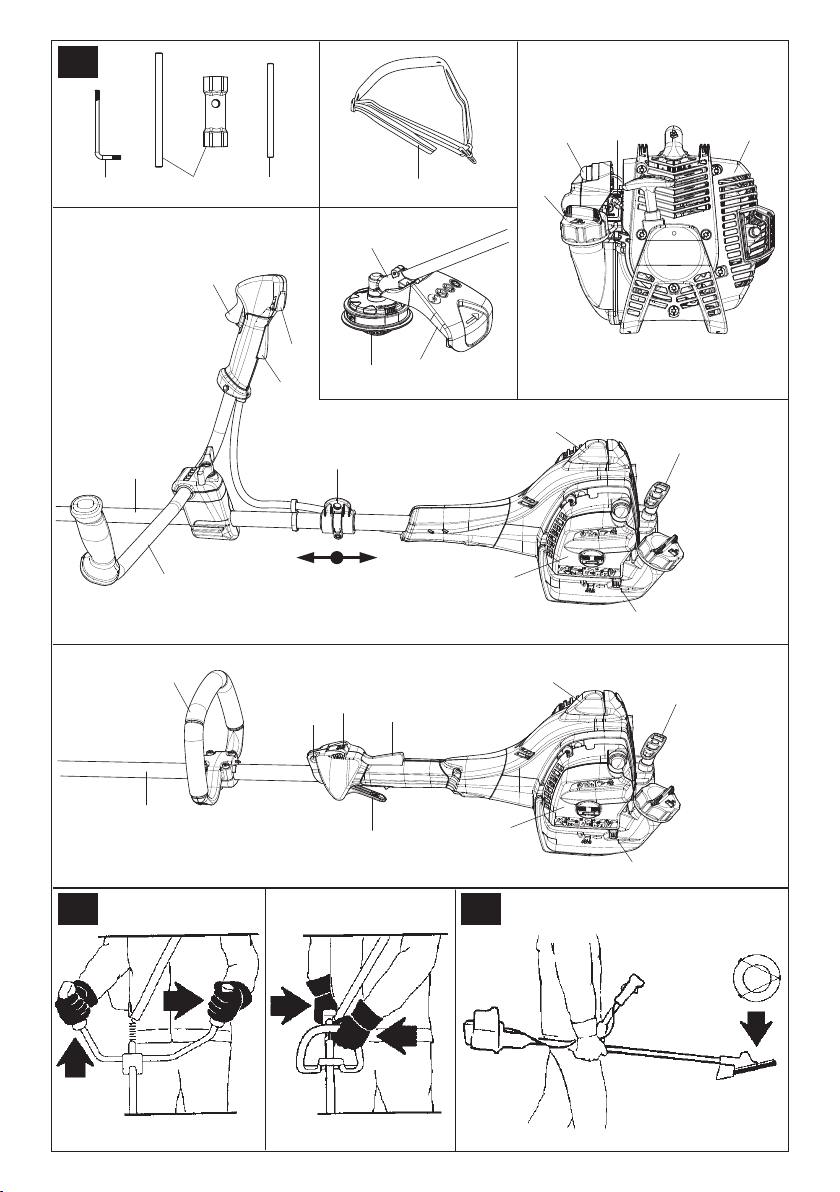

Brush Cutter Components (Fig. 1)

1 - Allen key

2 - Combination Wrench

3 - Locking Pin

4 - Simple Harness (only T model)

5 - Bevel Gear

6 - Cutting Attachment Guard

7 - Trimmer Head

8 - Fuel Tank Cap

9 - Purge Bulb

10 - Carburetor Adjustment Screw

11 - Muffl er Cover

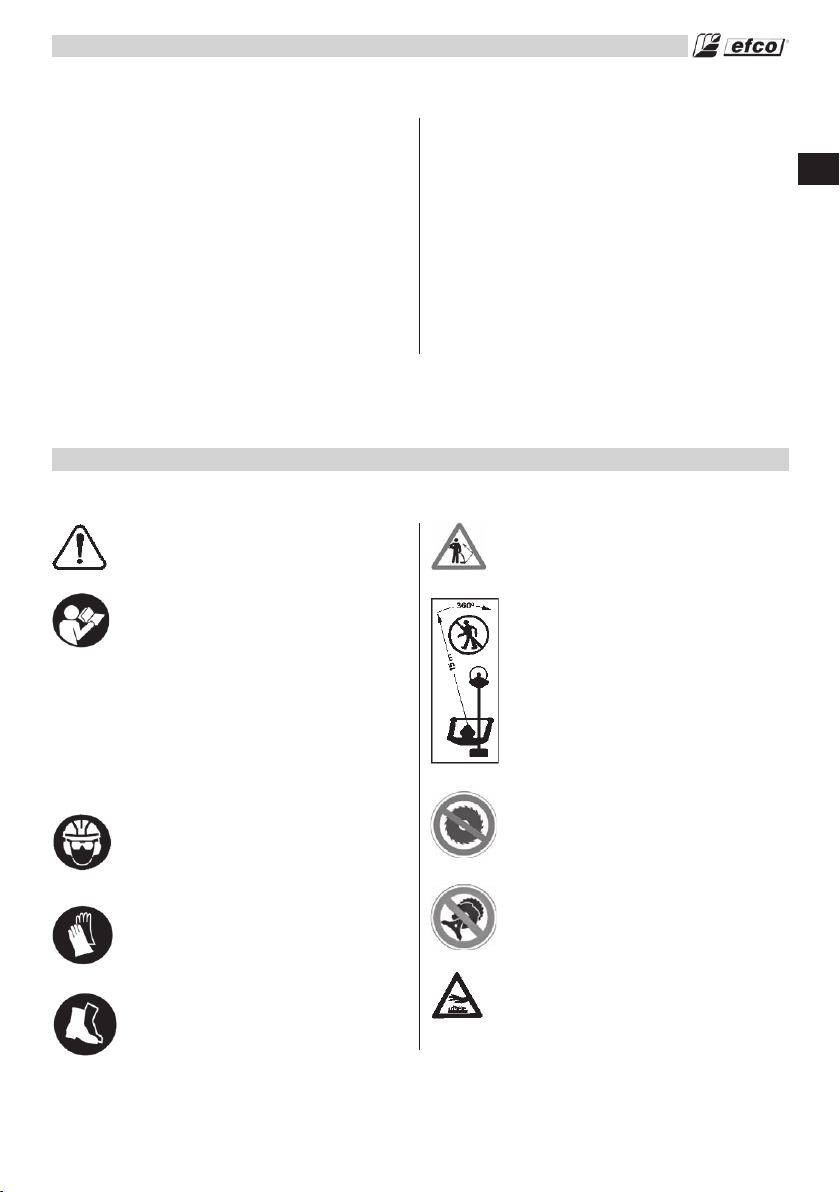

Understanding Safety Symbols

- This symbol indicates Warning,

and Caution.

- Your manual contains special

messages to bring attention

to potential safety concerns,

machine damage as well as

helpful operating and servicing

information. PLEASE READ

ALL THE INFORMATION

CAREFULLY TO AVOID INJURY

AND MACHINE DAMAGE.

- Wear eye, hearing and head

protection when operating this

equipment.

- Wear non-slip, heavy-duty

protective gloves when handling

the brush cutter and blades.

- Wear safety strong shoes or

boots having skid-proof sole and

anti-piercing insert.

12 - Spark Plug

13 - Air Filter Cover

14 - Starter Handle

15 - Choke Lever

16 - Throttle Trigger Lockout

17 - Switch

18 - Throttle Trigger

19 - Harness Attachment Point

20 - Loop handle (TR)-(S) / Bike handle (T)

21 - Shaft

SAFETY

- Be aware that objects can be

thrown.

- Keep bystanders away 50 ft (15

m).

- Do not use the brushcutter with

the wood cutting blade.

- On machines with a bent drive

shaft (TR) it is not possible to fi t

blades, only line heads.

- WARNING – The surface can be

hot.

en

5

Page 9

SAFETY

State and Local Requirements

The engine is NOT equipped with a

Spark Arrester System complying with

the requirements of SAE Recommended

en

Practice J335 and California Codes 4442

and 4443. All national forest land and

land managed by the states of California,

Maine, Washington, Idaho, Minnesota,

New Jersey and Oregon require internal

combustion engines to be equipped with

a spark arrester screen by law. Other

states and federal agencies are enacting

similar regulations.

Operating this engine in a state or locale

where such regulations apply, could result in

a violation of the law.

Note: When using a brush cutter for

logging purposes, refer to Code of Federal

Regulations, Parts 1910 and 1928.

WARNING: The ignition system

of your unit produces an

electromagnetic fi eld of a very low

intensity. This fi eld may interfere

with some pacemakers. To reduce

the risk of serious or fatal injury,

persons with pacemaker should

consult their physician and the

pacemaker manufacturer before

operating this tool.

damage in otherwise healthy

people. If symptoms occur such as

numbness, pain, loss of strength,

change in skin colour or texture,

or loss of feeling in the fi ngers,

hands, or wrists, discontinue the

use of this tool and seek medical

attention.

WARNING: The engine exhaust

from this product contains

chemicals known to the State of

California to cause cancer, birth

defects or other reproductive

harm.

Operate your brush cutter outdoors

only in a well ventilated area.

WARNING: Under no

circumstances may the design of

the machine be modifi ed. Always

use genuine accessories. Nonauthorized modifi cations and/or

accessories can result in serious

personal injury or the death

of the operator or others. Your

warranty may not cover damage

or liability caused by the use of

non-authorized accessories or

replacement parts.

WARNING: Muffl er surfaces

are very hot during and after

operation of the brush cutter,

keep all body parts away from the

muffl er. Serious burns may occur

if contact is made with the muffl er.

WARNING: Exposure to vibrations

through prolonged use of gasoline

powered hand tools could cause

blood vessel or nerve damage

in the fi ngers, hands, and wrists

of people prone to circulation

disorders or abnormal swellings.

Prolonged use in cold weather

has been linked to blood vessel

6

WARNING: A brush cutter or

trimmer can be dangerous if used

incorrectly or carelessly, and can

cause serious or fatal injury to the

operator or others. It is extremely

important that you read and

understand the contents of this

operator’s manual.

Page 10

SAFETY RULES

Basic Safety Precautions

• Read this manual carefully until you

completely understand and can follow all

safety rules, precautions, and operating

instructions before attempting to use the

unit.

• Restrict the use of your brush cutter to

adult users who understand and can follow

safety rules, precautions, and operating

instructions found in this manual. Minors

should never be allowed to use a brush

cutter.

• Do not handle or operate a brush cutter

when you are fatigued, ill, or upset, or if you

have taken alcohol, drugs, or medication.

You must be in good physical condition

and mentally alert. Brush cutter work is

strenuous. If you have any condition that

might be aggravated by strenuous work,

check with your doctor before operating a

brush cutter. Be more cautious before rest

periods and towards the end of your shift.

• Keep children, bystanders, and animals a

minimum of 50 feet (15 meters) away from

the work area. Do not allow other people

or animals to be near the brush cutter when

starting or operating the brush cutter.

• Major cases of brush cutter accidents

happen when the blade or thrown objects

hits the operator. While working with the

brush cutter, always use safety protective

approved clothing. The use of protective

clothing does not eliminate injury risks,

but reduces the injury effects in case of

accident. Consult your trusted supplier

to choose equipment in compliance

with legislation. The clothing must be

proper and not an obstacle. Wear adherent

protective clothing. Protective jackets and

dungarees leggings are ideal. Do not

wear clothes, scarves, ties or bracelets that

may get stuck into twigs. Tie up and protect

long hair (example with foulards, cap,

helmets, etc.). Safety boots having skid-

proof sole and anti-piercing insert. Wear

protective goggles or face screens. Use

protections against noises: for example,

noise reduction ear guards or earplugs.

The use of protections for the ear requires

much more attention and caution, because

the perception of audible warning signals

(screaming, alarms, etc.) is limited. Always

remove your hearing protection as soon as

the engine stops. Wear gloves that permit

the maximum absorption of vibrations.

• Only allow others to use this brush cutter

who have read this Operator’s Manual or

received adeguate instructions for the safe

and proper use of this brush cutter.

• Check the brush cutter each day to ensure

that each device, whether for safety or

otherwise, is functional.

• Never use a damaged, modifi ed, or

improperly repaired or assembled

brush cutter. Do not remove, damage or

deactivate any of the safety devices. Only

use cutting tools indicated in the table

(page 10). Always replace cutting tools or

safety devices immediately if it becomes

damaged, broken or is otherwise removed.

• Carefully plan your operation in advance.

Do not start cutting until you have a clear

work area, secure footing, and a planned

retreat path.

• All brush cutter service, other than the

operations shown in the present manual,

have to be performed by competent

personnel.

• The brush cutter must only be used for

trimming grass, grass clearing and / or

forestry clearing. It is unadvisable to cut

other types of material.

• It is unadvisable to hitch tools or applications

to the P.t.o. that are not specifi ed by the

manufacturer.

en

7

Page 11

SAFETY RULES

Fuel Handling

en

WARNING: Gasoline is an

extremely fl ammable fuel. Use

extreme caution when handling

gasoline or fuel mix. Do not smoke

or bring any fi re or fl ame near the

fuel or the brush cutter.

WARNING: Fuel and fuel fumes

can cause serious injury when

inhaled or allowed to come in

contact with the skin. For this

reason observe caution when

handling fuel and make sure there

is adequate ventilation.

WARNING: Beware of carbon

monoxide poisoning.

WARNING! – Muffl ers fi tted with

catalytic converters get very hot

during use and remain so for

some time after stopping. This

also applies at idle speed. Contact

can result in burns to the skin.

Remember the risk of fi re!

• Tighten fuel cap securely after refuelling.

Unit vibration can cause an improperly

tightened fuel cap to loosen or come off

and spill quantities of fuel.

• Wipe spilled fuel from the unit and allow

remaining fuel to evaporate. Move 10 feet

(3 m) away from refuelling site before

starting engine.

• Never attempt to burn off spilled fuel under

any circumstances.

• Do not smoke while handling fuel or while

operating the brush cutter.

• Store fuel in a cool, dry, well ventilated

place.

• Never place the brush cutter in a

combustible area such as dry leaves, straw,

paper, etc.

• Store the unit and fuel in an area where

fuel vapors cannot reach sparks or open

fl ames from water heaters, electric motors

or switches, furnaces, etc.

• Never take the cap off the tank when the

engine is running.

• Never use fuel for cleaning operations.

• Take care not to get fuel on your clothing.

If you have spilt fuel on yourself or your

clothes, change your clothes. Wash any

part of your body that has come in contact

with fuel. Use soap and water.

• Don’t expose fuel tank to direct sunlight.

• Keep fuel out of reach of children.

Operation and Safety

• To reduce the risk of fi re and burn

injury, handle fuel with care. It is highly

fl ammable.

• Mix, store and transport fuel in a container

approved for gasoline.

• Mix fuel outdoors where there are no

sparks or fl ames.

• Select bare ground, stop engine, and allow

to cool before

refuelling.

• Loosen fuel cap slowly to release pressure

and to keep fuel from escaping around the

cap.

8

WARNING: Always hold the brush

cutter with both hands when the

engine is running. Use a fi rm grip

with thumbs and fi ngers encircling

the brush cutter handles (Fig. 2).

• Keep all parts of your body away from the

cutting attachment when the engine is

running.

• Always carry the brush cutter with the

engine stopped and the muffl er away

from your body. When transporting your

Page 12

SAFETY RULES

brush cutter, use the appropriate blade

guard (Fig. 3). When transporting in a

vehicle, keep blade covered with the

guard. Properly secure your brush cutter to

prevent turnover, fuel

spillage and damage.

• Do not operate a brush cutter with

one hand! Serious injury to the operator,

helpers, bystanders, or any combination of

these persons may result from one-handed

operation. A brush cutter is intended for

two-handed use.

• Before you start the engine, make sure the

cutting attachment is not contacting any

object.

• Shut off the engine before setting down

the brush cutter. Do not leave the engine

running unattended.

• Only use the brush cutter in well-ventilated

places, do not operate the brush cutter

in explosive or fl ammable atmospheres or

in closed environments. Beware of carbon

monoxide poisoning.

• Do not operate brush cutter from a ladder

or in a tree. Always cut from a fi rm-footed

and safe position.

WARNING: Take great care when

working on sloping ground.

• Do not cut near electric cables.

• Keep the handles dry, clean, and free of oil

or fuel mixture.

• Never cut with the brush cutter above

shoulder height.

• Never use the brush cutter without blade

guard or the head guard.

• Do not start the engine with the arm not

mounted.

Precautions Against Kickout

WARNING: Avoid kickout which

can result in serious injury.

Kickout is the sideward, or

sudden forward motion of the

machine occurring when the

blade contacts any object such

as a log or stone, or when the

wood closes in and pinches the

saw blade in the cut. Contacting

a foreign object can also result in

loss of brush cutter control.

Reduce the Risk of Kickout

WARNING: Recognize that

kickout can happen. With a basic

understanding of kickout, you can

reduce the element of surprise

which contributes to accidents.

• Never let the moving blade contact any

object.

• Keep the working area free from

obstructions such as other trees, branches,

rocks, fences, stumps, etc. Eliminate or

avoid any obstruction that your blade could

hit while you are cutting.

• Keep your blade sharp. Follow

manufacturer’s blade sharpening and

maintenance instructions.

• Begin and continue cutting at full speed.

If the blade is moving at a slower speed,

there is greater chance of kickout

occurring.

Maintain Control

• Keep a good, fi rm grip on the brush cutter

with both hands when the engine is running

and don’t let go (Fig. 2). A fi rm grip will help

you reduce kickout and maintain control of

the brush cutter.

Keep the fi ngers encircling the handle.

• Stand with your weight evenly balanced on

both feet.

• Do not overreach. You could be drawn or

thrown off balance and lose control of the

brush cutter.

en

9

Page 13

SAFETY RULES

Safety Features

WARNING: As a brush cutter user,

en

do not solely rely on the product’s

safety features. You must follow all

safety precautions, instructions,

and maintenance in this manual

to help avoid serious injury.

Recommended cutting attachments

Cutting attachments Guards

p.n. Descriptions p.n. Descriptions

63110001

1

63102001

2

63122001

3

63019019

4

63019008A

5

4095567AR

6

4095673AR

7

4095638AR

8

4095681R

9

4095563AR

10

4095565AR

11

4095065AR

12

*protection p.n. 61372033 not needed

“Universal” head Ø 3” with 2

nylon lines, with Ø .08” line

“Load&Go” head Ø 4.3” with 2

nylon lines, with Ø .09” line

“Load&Go” head Ø 5.1” with 2

nylon lines, with Ø .09” line

“Tap’n go” head Ø 5.1” with 2

nylon lines, with Ø .09” line

“Tap’n go” head Ø 5.1” with 2

nylon lines, with Ø .09” line

Steel blade with 2 teeth, Ø

10”, thickness .063”

Steel blade with 3 teeth, Ø

10”, thickness .07”

Steel blade with 3 teeth, Ø

10”, thickness .055”

Steel blade with 3 teeth, Ø

10”, thickness .055”

Steel blade with 4 teeth, Ø

10”, thickness .055”

Steel blade with 8 teeth, Ø

8”, thickness .055”

Steel blade with 8 teeth, Ø

10”, thickness .055”

WARNING: Even with proper

maintenance, the correct

operation of the safety features

under fi eld conditions can not be

certifi ed.

• Position of handlebars, designed with

correct distance with each other. The

spread and position of the hands provided

by this design work together to give balance

and resistance in controlling the machine.

Models

61370122

61370051 DS 2200 S - T

61370155 DS 2400 S - T

61370051 DS 2200 S - T

61370155 DS 2400 S - T

61370051 DS 2200 S - T

61370155 DS 2400 S - T

61370051 DS 2200 S - T

61370155 DS 2400 S - T

61370155

61370155

61370155

61370155

61370155

61370155

61370155

Plastic guard

Plastic guard

Plastic guard

Plastic guard

Plastic guard

Plastic guard *

Plastic guard *

Plastic guard *

Plastic guard *

Plastic guard *

Plastic guard *

Plastic guard *

DS 2200 TR

DS 2200 S - T

DS 2400 S - T

DS 2200 S - T

DS 2400 S - T

DS 2200 S - T

DS 2400 S - T

DS 2200 S - T

DS 2400 S - T

DS 2200 S - T

DS 2400 S - T

DS 2200 S - T

DS 2400 S - T

DS 2200 S - T

DS 2400 S - T

WARNING: The use of cutting

devices not authorized by the

manufacturer can generate

safety risks.

10

WARNING: To use the blades with

the brush cutters DS 2200 S and

DS 2400 S must be purchased the

kit p.n. 61370224.

Page 14

SAFETY RULES

Safety equipment checking

WARNING: Never use a machine

with faulty safety equipment. The

machine’s safety equipment must

be checked and maintained as

described in this section. If your

machine fails any of these checks

contact your service agent to get

it repaired.

Throttle lock

The throttle lock is designed to prevent

accidental operation of the throttle control.

This arrangement means that the throttle

control is automatically locked at the idle

setting.

Make sure the throttle control is locked at the

idle setting when the throttle lock is released.

Press the throttle lock and make sure it returns

to its original position when you release it.

Check that the throttle control and throttle

lock move freely and that the return springs

work properly.

Stop switch

Use the stop switch to switch off the engine.

Start the engine and make sure the engine

stops when you move the stop switch to the

stop setting.

Cutting attachment guard

This guard is intended to prevent loose

objects from being thrown towards the

operator. The guard also protects the

operator from accidental contact with the

cutting attachment.

Check that the guard is undamaged and not

cracked. Replace the guard if it has been

exposed to impact or is cracked.

Always use the recommended guard for

the cutting attachment you are using. See

chapter on Technical data.

WARNING: Never use a cutting

attachment without an approved

guard. See the section on

Technical Data. Use of an

incorrect or faulty guard may lead

to serious personal injury.

Precautions to Reduce Vibration Risk

• The brush cutter is provided with antivibration (AV) system; never alter or modify

it.

• Wear gloves and keep your hands warm.

• Keep the blade sharp and the brush cutter,

including the AV system, well maintained.

A dull blade will increase the vibrations

transmitted to your hands.

• When using a string cord attachment

check that the cord is correctly wound; an

unbalanced attachment will highly increase

the vibration level.

• Maintain a fi rm grip at all times, but do

not squeeze the handles with constant,

excessive pressures, take frequent breaks.

All the above mentioned precautions do

not guarantee that you will not sustain

whitefi nger disease or carpal tunnel

syndrome. Therefore, continual and regular

users should monitor closely the condition

of their hands and fi ngers. If any of the

above symptoms appear, seek medical

advice immediately.

Maintenance Precaution

WARNING: Never operate a brush

cutter that is damaged, improperly

adjusted, or is not completely

and securely assembled.

• Be sure that the cutting attachment stops

moving when the throttle control trigger is

released. If the cutting attachment moves

en

11

Page 15

at idle speed, the carburetor may need

adjusting, see Operation-Carburetor

Adjusting Section. If the cutting attachment

still moves at idle speed after adjustment

en

has been made, contact a Servicing

Dealer for adjustment and discontinue use

until the repair is made.

WARNING: All brush cutter

service, other than items in the

Operator’s Manual maintenance

instructions, must be performed

by competent brush cutter service

personnel. (If improper tools are

used to remove the fl ywheel or

clutch, or if an improper tool is

used to hold the fl ywheel in order

to remove the clutch, structural

damage to the fl ywheel could

occur which could cause the

fl ywheel to burst and serious

injury could result.)

• Never modify your brush cutter in any way.

• Keep the handles dry, clean, and free of oil

or fuel mixture.

SAFETY RULES

WARNING: Use only recommended

accessories and replacement parts.

• Never touch the cutting attachment or

attempt to service the brush cutter while

the engine is running.

• Never use fuel for cleaning operations.

• Keep the brush cutter in a dry place, off

the ground with the blade guard on and the

tanks empty.

• If your brush cutter is no longer usable,

dispose of it properly without damaging the

environment by

handing it in to your local Dealer who will

arrange for its correct disposal.

• Replace immediately any safety device

when damaged or broken.

WARNING: The muffl er and other

parts of the engine (e.g. fi ns of

the cylinder, spark plug) become

hot during operation and remain

hot for a while after stopping the

engine.

To reduce risk of burns do not

touch the muffl er and other parts

while they are hot.

12

Page 16

ASSEMBLY

WARNING: The muffl er and other

parts of the engine (e.g. fi ns of

the cylinder, spark plug) become

hot during operation and remain

hot for a while after stopping the

engine. To reduce risk of burns do

not touch the muffl er and other

parts while they are hot.

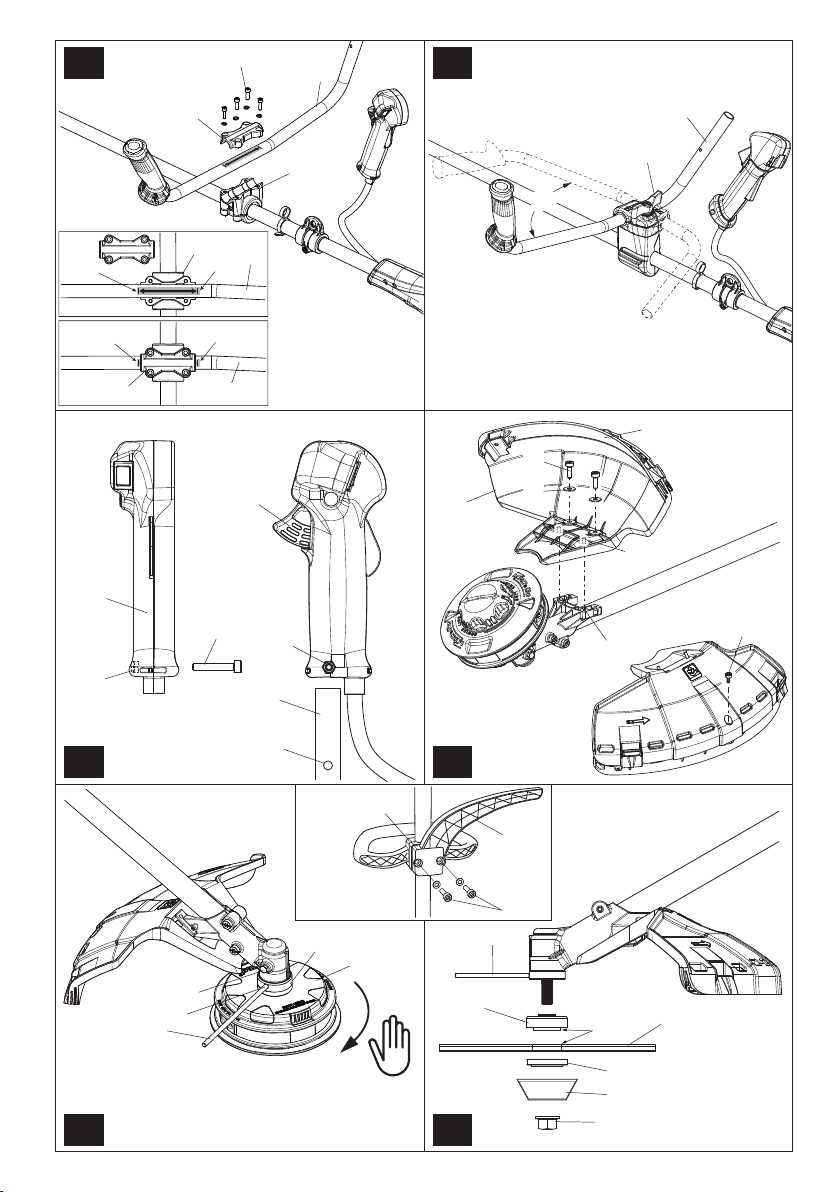

Loop handle (DS 2200 TR) (Fig.26)

Loosen the wing nut (A) and rotate the loop

handle (B) of 180°.

Assembling the bike handle

DS 2200 T

- Place the bike handle (A, Fig.4) in the lower

hub (B1).

CAUTION: The bike handle (A) must

be fi xed onto the hub (B) inside the

two notches (C) indicated on the

bike handle.

- Place the upper hub (B2) in position and

tighten the 4 screws (D), without fi nally

tighten yet.

- Line up the handlebar at a right angle to the

drive tube.

- Tighten down the screws (D) fi rmly.

DS 2400 T (swivelling bike handle)

- Release the wing screw (E, Fig.5) and

unscrew it until the bike handle (F) can be

turned anti-clockwise.

- Turn the handlebar 90° and then swing the

handles up.

- Tighten down the wing screw (E) fi rmly.

M must point toward the gearbox) onto the

bike handle (N) so that the holes (P) line up.

- Insert screw (G) and tighten down fi rmly.

WARNING: In mounting the

handlebar be careful to avoid the

cables getting twisted.

Assembling the cutting attachment

guard (Fig. 7) (DS 2200T - DS 2400 T)

- Insert the two pins (E) of the cutting

attachment guard, in the holes (F).

- Assemble the guard (A) to the gearbox with

screws (B) and washers (G) in a position

allowing the operator to work safely.

NOTE: assemble the skirt (C) only when

using the nylon heads. Secure the skirt

(C) to the protection (A) by means of the

screw (D).

WARNING: Never use a

cutting attachment without an

approved guard. See the section

on Recommended cutting

attachments (Page 10). An

incorrect or faulty guard may lead

to serious personal injury.

WARNING: The defl ector provided

with your brush cutter may not

protect the operator from all

foreign objects (gravel, glass, wire,

etc) thrown by the rotating cutting

attachment. Thrown objects

may also ricochet and strike the

operator.

WARNING: Immediately replace a

broken or damaged guard; never

try to mount the guard in incorrect

position.

en

Storage or transportation positions

- Reverse the sequence described above

to swing the handles up and turn the bike

handle clockwise.

Mounting the control handles (DS 2200 T –

DS 2400 T)

- Loosen the screw (G, Fig.6). The nut (H)

remains in the control handle (L).

- Push the control handle (L) (throttle trigger

Assembling the cutting attachment

WARNING: When fi tting the

cutting attachment it is extremely

important that the drive fl ange

engages correctly in the centre

hole of the cutting attachment. If

the cutting attachment is fi tted

incorrectly it can result in serious

and/or fatal personal injury.

13

Page 17

ASSEMBLY

en

WARNING: Only use cutting

attachments with the guards we

recommend! See the chapter on

Recommended cutting attachments

(Page 10). Refer to the instructions for

the cutting attachment to check the

correct way to load the cord and the

correct cord diameter. Keep the teeth

of the blade correctly sharpened!

Follow our recommendations. Also

refer to the instructions on the blade

packaging. Maintain the correct blade

setting! Follow our instructions.

WARNING: Always stop the engine

before doing any work on the

cutting attachment. The attachment

continues to rotate even after the

throttle has been released. Ensure

that the cutting attachment has

stopped completely and disconnect

the HT lead from the spark plug

before you start to work on it.

WARNING: Using an incorrect

cutting attachment or an incorrectly

sharpened blade increases the risk of

kickout.

WARNING: Always discard a blade

that is bent, twisted, cracked, broken

or damaged in any other way. Never

attempt to straighten a twisted blade

so that it can be reused. Only use

original blades of the specifi ed type.

Assembling the blade (excluding

machines with bent drive shaft-TR) (Fig. 9)

WARNING - To use the blades with the brush

cutters DS 2200 S and DS 2400 S must be

purchased the kit p.n. 61370224 which comprises:

1) cutting attachment guard (to fi t in place of that

supplied)

2) safety boom (to be mounted under the loop

handle)

3) blade

4) lower fl ange

5) cup

6) nut

Remove the skirt (C, Fig.7) from the cutting

attachment guard (A) before assembling the blade.

Fix the blade (R) onto the upper fl ange (F) making

sure that the rotation direction is correct.

WARNING: Collar (see arrows C, Fig.9)

must locate in blade’s mounting hole.

Fix the lower fl ange (E), the cup (B) and tighten

nut (A) anti-clockwise.

Put the pin provided in the appropriate hole (L)

to block the blade and allow the nut (A) to be

tightened to 18 ft lb (25 Nm).

Assembling the safety boom (DS 2200 S - DS

2400 S) (Fig. 9A)

When using the disc instead of nylon line head,

it is necessary to set up the “safety boom”. Fix

the boom (A) under the attachment (C) of handle

(20B, Fig. 1) by means of the screws (B). Taking

care to verify the “safety boom” being on the left

side of the brushcutter.

WARNING: To reduce the risk of

serious injury, never use wire or

metal-reinforced line or other material

in place of the nylon cutting lines.

Pieces of wire could break off and

be thrown at high speed toward the

operator or bystanders.

Assembling trimmer head (Fig.8)

For dismantling the trimmer head (C), put the

head fi xing pin (A) in the appropriate hole (B) and

loosen the head clockwise by hand.

For assembling the head (C), reverse the

sequence described after put the upper fl ange (F)

in place.

14

WARNING: Arrows on the cutting

attachment guard show the correct

direction of rotation of the cutting

tool.

WARNING! This machine is not

suitable for use with disc for wood

(22-60-80 teeth) and relevant metal

guard.

WARNING! – On machines with a

bent drive shaft (TR) it is not possible

to fi t disks, only line heads.

Page 18

ASSEMBLY

WARNING: Fit the blade protection

(M) p.n. 4196086 as shown (Fig.3)

before transporting or storing the

brush cutter.

CAUTION: Never use the brush cutter

without the cup (B, Fig.9) to avoid

damages to the thread.

WARNING: Never touch or adjust

the blade while the motor is running.

The blade is very sharp, always wear

protective gloves when performing

maintenance.

WARNING: After use the bevel

gear may be very hot, always wear

protective gloves when performing

maintenance.

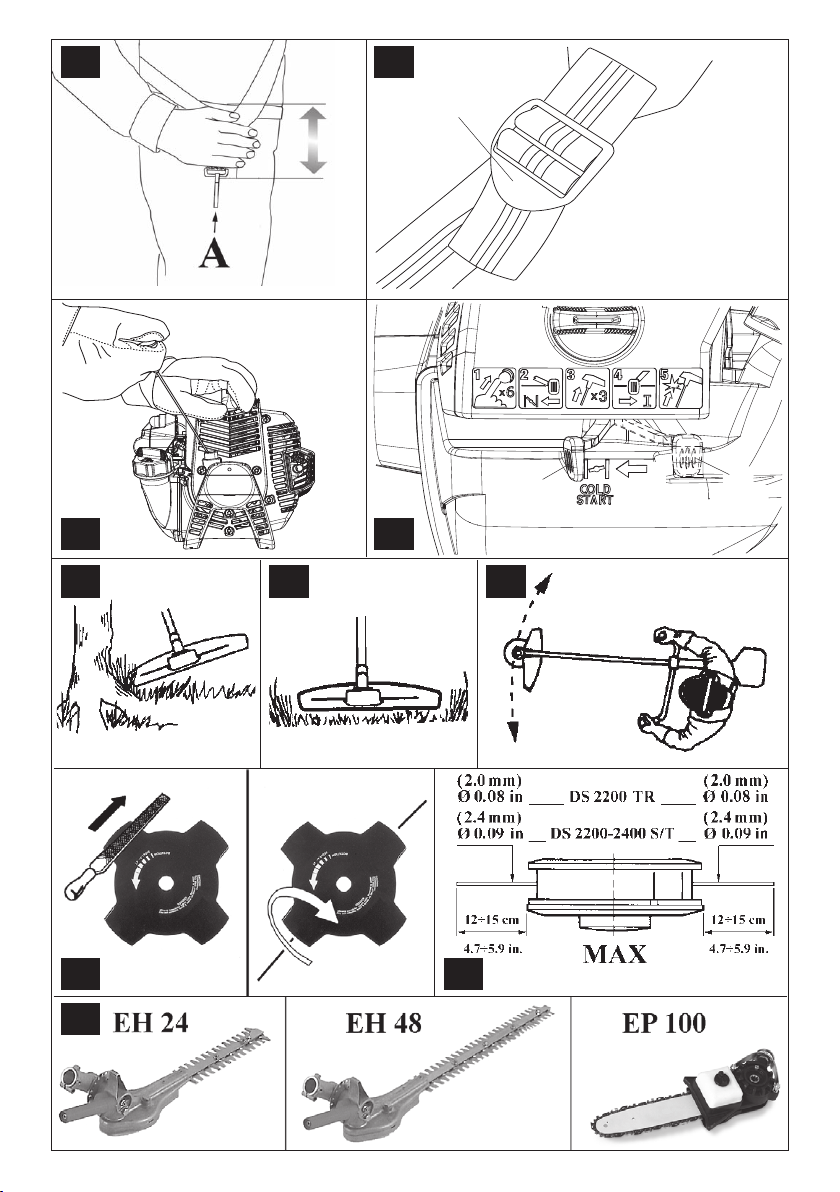

Approved power tool attachments (Fig.19)

The following Emak attachments may be mounted

to the basic power tool:

EH 24 Hedge trimmer (adjustable) (1) (2)

EH 48 Hedge trimmer (adjustable) (1) (2)

EP 100 Pole pruner (2)

(1) Safety boom (A, Fig.9A) must be assembled

under the loop handle.

(2) Not approved for use with bike handle units

(DS 2200 T – DS 2400 T).

en

15

Page 19

OPERATION

Fueling

en

Do Not Smoke!

This product is powered by a 2-cycle engine

and requires pre-mixing gasoline and 2-cycle

oil. Pre-mix unleaded gasoline and 2-cycle

engine oil in a clean container approved for

gasoline.

RECOMMENDED FUEL: THIS ENGINE IS

CERTIFIED TO OPERATE ON UNLEADED

GASOLINE INTENDED FOR AUTOMOTIVE

USE WITH AN OCTANE RATING OF 89 ([R +

M] / 2) OR HIGHER.

Mix 2-Cycle Engine Oil with gasoline according

to the instructions on the package. We strongly

recommend the use of 2% (50:1) Efco

Two Cycle Engine Oil, which is specifi cally

formulated for all Efco air-cooled two-stroke

engines.

The correct oil / fuel proportions shown in the

table below are suitable when using the Efco

Two Cycle Engine Oil or an equivalent highquality engine oil (JASO specifi cation FD or

ISO specifi cation L-EGD).

When oil specifi cations are NOT equivalent or

unknown use 4% (25:1) fuel / oil mixing ratio.

CAUTION - For the mixture,

never use a fuel with an ethanol

percentage higher than 10%;

gasohol (mixture of gasoline and

ethanol) up to 10% ethanol or E10

fuel are acceptable.

When using an oxygenated gasoline a good

practice of fuel management is necessary.

Gasoline oxygenated with alcohol readily

takes up water when it is present; the water

may be condensed out of humid air or be a

contaminant in the fuel system, including tank.

The use of oxygenated gasoline may cause

the occurrence of vapor-lock easier.

NOTE - Prepare only the quantity of mixture

required for immediate use; do not leave

fuel in the tank or a container for a long

time. Were commend the use of the additive

Emak ADDITIX 2000 code 001000972 if the

mixture is to be stored for 30 days.

Alkylate gasoline

CAUTION: DO NOT USE

AUTOMOTIVE OIL OR

2-CYCLE OUTBOARD OIL.

CAUTION:

- Match your fuel purchases to

your consumption; don’t buy

more than you will use in one

or two months;

- Store gasoline in a tightlyclosed validate container in a

cool, dry place.

16

CAUTIONS – Alkylate fuels have

different density than normal fuel.

Therefore engines, set with normal

fuel, need different H jet regulation

to avoid critical issues. For this

operation it’s necessary turned at

a Licensed Service Dealer.

Page 20

Fuel Mixture

OPERATION

Preparation for Cutting

2-Cycle Engine Oil (25:1) 4%

Gasoline . . . . . . . . . . . . . . Oil

1 Gallon (US) . . . . . . . . . . 5.2 oz.

1 Liter . . . . . . . . . . . . . . . . 40 cc (40 ml)

2-Cycle Engine Oil (50:1) 2%

Gasoline . . . . . . . . . . . . . . Oil

1 Gallon (US) . . . . . . . . . . 2.6 oz.

1 Liter . . . . . . . . . . . . . . . . 20 cc (20 ml)

Filling the Tank

WARNING: Follow safety

instruction for fuel handling.

Always shut off engine before

fuelling. Never add fuel to a

machine with a running or hot

engine. Move at least 10 feet (3 m)

from refuelling site before starting

engine. DO NOT SMOKE!

1. Clean surface around fuel cap to prevent

contamination.

2. Loosen fuel cap slowly.

3. Carefully pour fuel mixture into the tank.

Avoid spillage.

4. Prior to replacing the fuel cap, clean and

inspect the gasket.

5. Immediately replace fuel cap and hand

tighten. Wipe up any fuel spillage.

WARNING: Check for fuel leaks,

if any are found, correct before

use. Contact a Servicing Dealer if

necessary.

WARNING: To use the blades with

the brush cutters DS 2200 S and

DS 2400 S must be purchased the

kit p.n. 61370224.

WARNING: When using rigid

blades (only S and T models),

avoid cutting close to fences,

sides of buildings, tree trunks,

stones or other such objects that

could cause the brush cutter to

kick out or could cause damage

to the blade. We recommends use

of the nylon line heads for such

jobs. In addition, be alert to an

increased possibility of ricochets

in such situations.

WARNING: The brush cutter is

normally to be used at ground

level with the cutting attachment

parallel to the ground. Use of a

brush cutter above ground level

or with the cutting attachment

perpendicular to the ground may

increase the risk of injury, since

the cutting attachment is more

fully exposed and the brush cutter

may be more diffi cult to control.

Never use your brush cutter as a

hedge trimmer.

WARNING: If the blade loosens

after being properly tightened,

stop work immediately. The

retaining nut may be worn or

damaged and should be replaced.

Never use unauthorized parts

to secure the blade. If the blade

continues to loosen, see your

dealer. Never use a brush cutter

with a loose blade.

Basic Cutting Procedure

1. Wear non-slip gloves for maximum grip and

protection.

en

17

Page 21

WARNING: Hold the brush cutter

fi rmly with both hands (Fig. 2).

Always keep your body to the

en

left of tube. Never use a crosshanded grip. Left-handers should

follow these instructions too.

Keep a proper cutting stance.

2. Maintain a proper grip (Fig. 2) on the brush

cutter whenever the engine is running. The

fi ngers should encircle the handlebar and

the thumb is wrapped under the handlebar.

Fitting the harness

DS 2200 T – DS 2400 T models

Into S models, the harness is optional (not

included but available separately). On these

models the harness attachment point is not

adjustable (19B, Fig.1).

Correct adjustment of the harness permits

the brush cutter to be properly balanced

and at an appropriate height from the ground

(Fig. 10).

- Put on the single harness.

- Hook the brush cutter to the harness using

the hook (A, Fig. 10).

- Position the hook (19B, Fig. 1) to obtain the

best brush cutter balance (only T model).

- Position the buckle (C, Fig. 11) to obtain

the correct brush cutter height.

Correct balance

1 Forestry clearing

The machine is balanced by moving the

support ring on the machine forwards

or backwards. The machine is correctly

balanced when it freely hangs horizontally

from the support hook. In this way the risk

of hitting stones is reduced if you need to

release the handlebar.

2 Grass clearing

Let the blade balance at a comfortable cutting

OPERATION

height, i.e. close to the ground.

Work Area Precautions

WARNING: Cut only grass or

weed. Do not cut metal, plastics,

masonry, or non-wood building

materials.

• Never allow children to operate your brush

cutter. Only allow others to use this brush

cutter who have read this Operator’s

Manual or received adequate instructions

for the safe and proper use of this brush

cutter.

• Keep everyone - helpers, bystanders,

children, and animals at a safe distance

from the cutting area. During operations,

keep a minimum distance of 50 feet (15 m)

between workers.

• Always cut with both feet on solid ground to

prevent being pulled off balance.

• Make sure you can move and stand safely.

Check the area around you for possible

obstacles (roots, rocks, branches, ditches,

etc.) in case you have to move suddenly.

Take great care when working on sloping

ground.

• Do not cut above chest height, as a brush

cutter held higher is diffi cult to control

against kickout forces.

• Do not work near electrical wires. Leave

this operation for professionals.

• Cut only when visibility and light are

adequate for you to see clearly.

• Do not cut from a ladder, this is extremely

dangerous.

• Stop the brush cutter if the blade strikes a

foreign object. Inspect the brush cutter and

repair parts as necessary.

• Keep the blade out of dirt and sand. Even a

small amount of dirt will quickly dull a blade

and increase the possibility of kickout.

• Stop the engine before setting the brush

cutter down.

18

Page 22

OPERATION

• Be particularly cautious and alert while

wearing hearing protection because such

equipment may restrict your ability to hear

sounds indicating danger (calls, signals,

warnings, etc).

• Be extremely cautious when working on

slopes or uneven ground.

WARNING: Never use rigid blades

when cutting in stony areas.

Thrown objects or damaged

blades may result in serious or

fatal injury to the operator or

bystanders. Watch out for thrown

objects. Always wear approved

eye protection. Never lean over the

cutting attachment guard. Stones,

rubbish, etc. can be thrown up

into the eyes causing blindness or

serious injury. Keep unauthorised

persons at a distance. Children,

animals, onlookers and helpers

should be kept outside the safety

zone of 50 ft (15 m). Stop the

machine immediately if anyone

approaches. Never swing the

machine around without fi rst

checking behind you to make sure

no-one is within the safety zone.

WARNING: Never cut when

visibility is poor or in very high

or low temperatures or in freezing

weather.

Starting The Engine

WARNING: When the engine is

started with the choke in either the

choke or start throttle positions

the cutting attachment will start

to rotate immediately.

• Place the brush cutter on level ground and

ensure that no objects or obstructions are

in immediate vicinity which could come in

contact with the cutting attachment. Hold

the body of the machine on the ground

using your left hand (CAUTION! Not with

your foot!), see Fig. 12.

Start-up procedure

1) Slowly push the purge bulb 6 times (9,

Fig.1).

2) Pull the choke lever (15, Fig.1) in the

CLOSE position (A, Fig.13). In so

doing, it also activates automatically halfthrottle.

3) Place the brush cutter on the ground in a

stable position. Check that the blade is free.

Holding the brush cutter down (Fig.12), pull

the starter rope until the fi rst kick over of

the engine is heard (no more than 3 pulls).

A new unit may require additional pulls.

4) Push the choke lever (15, Fig.1) in OPEN

(I) position (B, Fig.13).

5) Pull the starter cord to start the engine.

Once the machine is started, warm up the

machine for about few seconds, without

touch the throttle lever. The machine could

need more seconds to warm up with cold

weather or at high altitudes. Finally, put the

choke lever (18, Fig.1) for deactivate the

automatic half-throttle.

CAUTION:

- Never wrap the starter cord

around your hand.

- When pulling the starter rope,

do not use the full extent of the

rope as this can cause the rope

to break.

- Do not let starter rope snap

back. Hold the starter handle

(14, Fig.1) and let the rope

rewind slowly.

en

19

Page 23

WARNING: Do not cut material

with the choke lever at the CLOSE

en

position. Do not operate your

brush cutter with the starting

throttle lock engaged. Cutting with

the starting throttle lock engaged

does not permit the operator

proper control of the brush cutter.

NOTE - STARTING WARM ENGINE:

Follow above starting instructions, but do

not use the CLOSE position for start up

again.

WARNING: Weather conditions

and altitude may affect carburetion.

Do not allow bystanders close to

the brush cutter while adjusting

the carburetor.

Keep the engine at full throttle the entire time

you are cutting.

NOTE: It is normal for smoke to be emitted

from a new engine during and after fi rst

use.

Breaking-in the Engine

OPERATION

Diffi cult Starting (or starting a fl ooded

engine)

The engine may be fl ooded with too much

fuel if it has not started after 10 pulls. Flooded

engines can be cleared of excess fuel by

following the warm engine starting procedure

listed above. Ensure the ON/STOP switch

is in the ON position. Starting could require

pulling the starter rope handle many times

depending on how badly the unit is fl ooded. If

engine fails to start refer to the

TROUBLESHOOTING TABLE (page 31).

Engine is Flooded

• Set the on/off switch to STOP.

• Engage a suitable tool in the spark plug

boot.

• Pry off the spark plug boot.

• Unscrew and dry off the spark plug.

• Open the throttle wide.

• Pull the starter rope several times to clear

the combustion chamber.

• Refi t the spark plug and connect the

spark plug boot, press it down fi rmly –

reassemble the other parts.

• Set the on/off switch to I, the starting

position.

• Set the choke lever to OPEN position –

even if engine is cold.

• Now start the engine.

The engine reaches the maximum power

after 5-8 hours of activity.

During this period of breaking-in do not make

the machine function idly at full throttle, to

avoid excessive functioning stress.

CAUTION! – During the breakingin period do not vary the

carburetion to obtain a presumed

power increment; the engine can

be damaged.

20

Stopping The Engine

Release the throttle trigger (18, Fig. 1) and let

the engine return to idle.

To stop the engine, push the switch (17). Do

not put the brush cutter on the ground when

the cutting attachment is still moving.

In the event that of the switch will not

function, pull the choke lever in the CLOSE

position (A, Fig. 13) to stop the engine.

Page 24

OPERATION

Pre-operation checking

WARNING: THE CUTTING

ATTACHMENT SHOULD NEVER

TURN AT IDLE. Turn the idle speed

screw “T” counter-clockwise to

reduce the idle RPM, or contact

a Servicing Dealer for adjustment

and discontinue use until the

repair is made.

Serious personal injury may

result from the cutting attachment

turning at idle.

A damaged clutch may cause a cutting

attachment to rotate at idle speed and

increase the risk of personal injury from loss

of control and from contact with the cutting

tool.

Working Techniques

General working instructions

WARNING: This section describes

the basic safety precautions for

working with brush cutter and

trimmers. If you encounter a

situation where you are uncertain

how to proceed you should ask

an expert. Contact your dealer

or your service workshop. Avoid

all usage which you consider to

be beyond your capability. You

must understand the difference

between forestry clearing, grass

clearing and grass trimming

before use.

Basic safety rules

1. Look around you:

• To ensure that people, animals or other

things cannot affect your control of the

machine.

• To ensure that people, animals, etc., do

not come into contact with the cutting

attachment or loose objects that are

thrown out by the cutting attachment.

WARNING: Do not use the machine

unless you are able to call for help

in the event of an accident.

2. Do not use the machine in bad weather,

such as dense fog, heavy rain, strong wind,

intense cold, etc. Working in bad weather is

tiring and often brings added risks, such as

icy ground, unpredictable felling direction,

etc.

3. Make sure you can move and stand safely.

Check the area around you for possible

obstacles (roots, rocks, branches, ditches,

etc.) in case you have to move suddenly.

Take great care when working on sloping

ground.

4. Switch off the engine before moving to

another area.

5. Never put the machine down with the

engine running.

• Always use the correct equipment.

• Make sure the equipment is well adjusted.

• Follow the safety precautions.

• Organise your work carefully.

• Always use full throttle when starting to

cut with the blade.

• Always use sharp blades.

• Avoid stones.

WARNING: Neither the operator of

the machine nor anyone else may

attempt to remove the cut material

while the engine is running or the

cutting equipment is rotating, as

this can result in serious injury.

Stop the engine and cutting

equipment before you remove

material that has wound around

en

21

Page 25

en

OPERATION

the blade shaft as otherwise there

is a risk of injury. The bevel gear

can get hot during use and may

remain so for a while afterwards.

You could get burnt if you touch it.

WARNING: Watch out for thrown

objects. Always wear approved

eye protection. Never lean over the

cutting attachment guard. Stones,

rubbish, etc. can be thrown up

into the eyes causing blindness or

serious injury. Keep unauthorised

persons at a distance. Children,

animals, onlookers and helpers

should be kept outside the safety

zone of 50 ft (15 m). Stop the

machine immediately if anyone

approaches. Never swing the

machine around without fi rst

checking behind you to make sure

no-one is within the safety zone.

or cracked. Replace the blade guard if it is

cracked.

• Check that the trimmer head and trimmer

guard are not damaged or cracked.

Replace the trimmer head or trimmer guard

if they have been cracked.

WARNING: Never use the machine

without a guard or with a defective

guard.

WARNING: The complete clutch

cover and shaft must be fi tted

before the machine is started,

otherwise the clutch can come

loose and cause personal injury.

Ensure the cutting attachment

cannot come into contact

with any object. Make sure no

unauthorised persons are in the

working area, otherwise there is

a risk of serious personal injury.

The safety distance is 50 ft (15

metres).

WARNING: Sometimes branches

or grass get caught between the

guard and cutting attachment.

Always stop the engine before

cleaning.

Check before starting

• Check the blade to ensure that no cracks

have formed at the bottom of the teeth or

by the centre hole. Discard a blade if cracks

are found.

• Check that the support fl ange is not cracked

due to fatigue or due to being tightened too

much. Discard the support fl ange if it is

cracked.

• Ensure the locking nut has not lost its

captive force. The tightening torque of the

locking screw should be 18 ftlb (25 Nm).

• Check that the blade guard is not damaged

22

Working methods

WARNING: Avoid cutting with the

area of the blade between the 12

o’clock and 3 o’clock positions.

Because of the speed of rotation

of the blade kickout can occur if

you attempt to cut thick stems

with this area of the blade.

Forestry clearing

• Before you start clearing, check the

clearing area, the type of terrain, the slope

of the ground, whether there are stones,

hollows etc.

• Start at whichever end of the area is

easiest, and clear an open space from

Page 26

OPERATION

which to work.

• Work systematically to and fro across the

area, clearing a width of around 13-16 ft

(4-5 m) on each pass. This exploits the full

reach of the machine in both directions and

gives the operator a convenient and varied

working area to work in.

• Clear a strip around 250 ft (75 m) long.

Move your fuel can as work progresses.

• On sloping ground you should work along

the slope. It is much easier to work along a

slope than it is to work up and down it.

• You should plan the strip so that you avoid

going over ditches or other obstacles on

the ground. You should also orient the strip

to take advantage of wind conditions, so

that cleared stems fall in the cleared area

of the stand.

Grass clearing using a grass blade

• Grass blades and grass cutters must not be

used on woody stems.

• A grass blade is used for all types of tall or

coarse grass.

• The grass is cut down with a sideways,

swinging movement, where the movement

from right-to-left is the clearing stroke and

the movement from left-to-right is the return

stroke. Let the left-hand side of the blade

(between 8 and 12 o’clock) do the cutting.

• If the blade is angled to the left when

clearing grass, the grass will collect in a

line, which makes it easier to collect, e.g.

by raking.

• Try to work rhythmically. Stand fi rmly with

your feet apart. Move forward after the

return stroke and stand fi rmly again.

• Let the support cup rest lightly against the

ground. It is used to protect the blade from

hitting the ground.

• Reduce the risk of material wrapping

around the blade by following these

instructions:

1. Always work at full throttle.

2. Avoid the previously cut material during

the return stroke.

• Stop the engine, unclip the harness and

place the machine on the ground before

you start to collect the cut material.

Grass trimming with a trimmer head

en

CAUTION: Do not work with

mowing line longer than the

intended diameter. With a properly

mounted guard, the built-in cutter

will automatically adjust the line

to its proper length. Overly long

lines can overload the engine,

resulting in damage to the clutch

mechanism and nearby parts.

Trimming

• Hold the trimmer head just above the

ground at an angle. It is the end of the cord

that does the work. Let the cord work at its

own pace. Never press the cord into the

area to be cut.

• The cord can easily remove grass and

weeds up against walls, fences, trees

and borders, however it can also damage

sensitive bark on trees and bushes, and

damage fence posts.

• Reduce the risk of damaging plants by

shortening the cord to 4 - 4.7 in (10-12 cm)

and reducing the engine speed.

Clearing

• The clearing technique removes all

unwanted vegetation. Keep the trimmer

head just above the ground and tilt it. Let

the end of the cord strike the ground around

trees, posts, statues and the like. (Fig. 14)

CAUTION: This technique

increases the wear on the cord.

• The cord wears quicker and must be fed

forward more often when working against

stones, brick, concrete, metal fences, etc.,

than when coming into contact with trees

and wooden fences.

23

Page 27

• When trimming and clearing you should

use less than full throttle so that the cord

lasts longer and to reduce the wear on the

trimmer head.

en

Cutting

• The trimmer is ideal for cutting grass that

is diffi cult to reach using a normal lawn

mower. Keep the cord parallel to the ground

when cutting. Avoid pressing the trimmer

head against the ground as this can ruin

the lawn and damage the tool. (Fig. 15)

• Do not allow the trimmer head to constantly

come into contact with the ground during

normal cutting. Constant contact of this

type can cause damage and wear to the

trimmer head.

Sweeping

• The fan effect of the rotating cord can be

used for quick and easy clearing up. Hold

OPERATION

the cord parallel to and above the area to

be swept and move the tool to and fro. (Fig.

16)

• When cutting and sweeping you should use

full throttle to obtain the best results.

WARNING: Never cut when

visibility is poor or in very high

or low temperatures or in freezing

weather.

WARNING: If the cutting tool or

defl ector becomes clogged or

stuck, always turn off the engine

and make sure the cutting tool

has stopped before cleaning.

Grass, weeds, etc. should be

cleaned off the cutting tool at

regular intervals.

24

Page 28

MAINTENANCE

Maintenance Chart

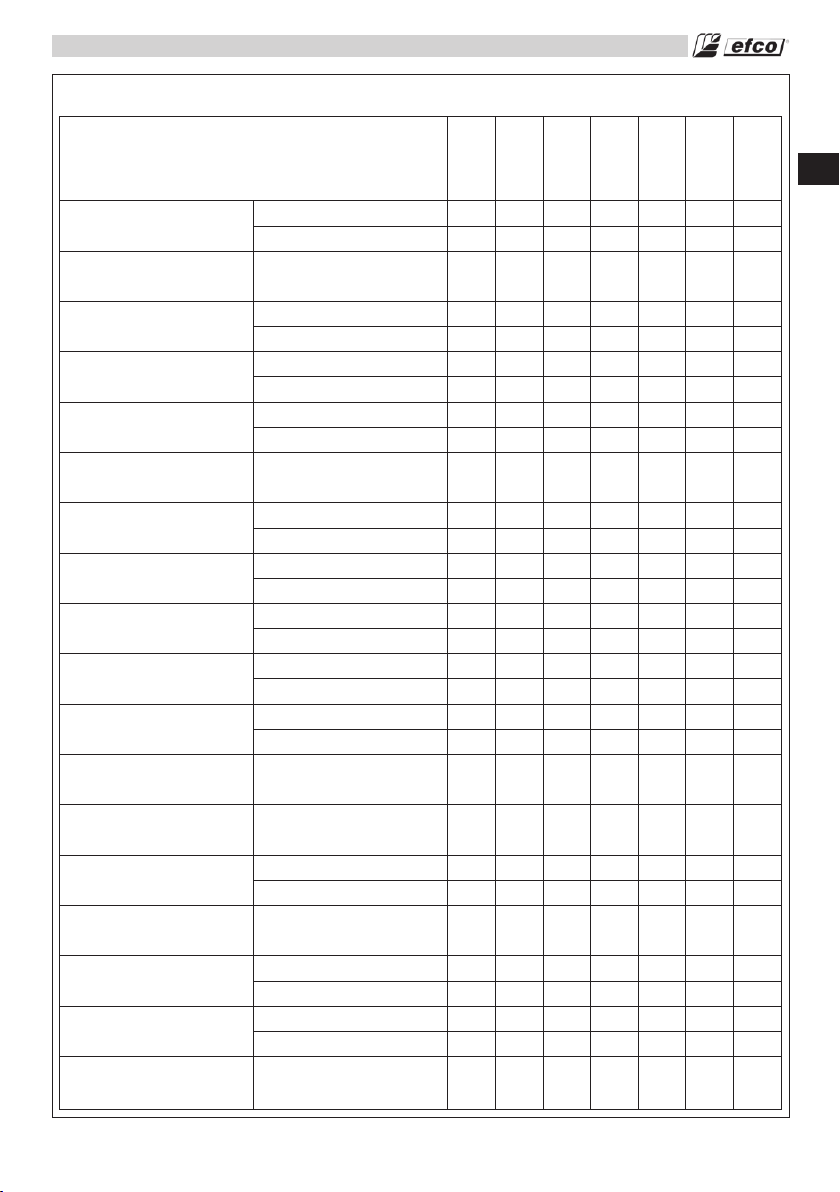

Please note that the following maintenance intervals apply for normal

operating conditions only. If your daily work requires longer than normal

or harsh cutting conditions are present the suggested intervals should

be shortened accordingly.

Complete Machine

Controls (Ignition Switch, Choke

Lever, Throttle Trigger, Trigger

Interlock)

Fuel Tank and Fuel Line

Fuel Filter

Cutting Attachments

Bevel Cear

Clutch Drum

Cutting Attachments Guard

Spark Arrestor Screen

(in Muffl er)

All Accessible Screws and Nuts

(Not Adjusting Screws)

Air Filter

Cylinder Fins

Inspect (Leaks, Cracks, and Wear)

Clean

Check Operation

Inspect (Leaks, Cracks, and Wear)

Clean

Inspect

Clean, Replace FIlter Element

(Damage, Sharpness, and Wear)

Inspect

Sharpen

Inspect

(Damage and Grease Level)

Inspect (Damage and Wear)

Replace

Inspect (Damage and Wear)

Replace

Inspect (Damage and Wear)

Clean or Replace

Inspect

Retighten

Clean

Replace

Clean

Use

After Each

Before Each

XX

XX

XX

XX

XX

X

Refueling Stop

Weekly

Daily Work

After Finishing

X

X

X

X

X

X

Monthly

X

X

Faulty

As Reguired

If Damaged or

Every 6

X

Months

XX

X

XX

XX

XX

Every 6

X

Months

en

Starter System Vents

Starter Rope

Carburetor

Spark Plug

Vibration Mounts

Cutting Attachments

nuts and screws

Clean

Inspect (Damage and Wear)

Replace

Check idle (Cutting Attachments

must not rotate at idle)

Check Eletrode Gap

Replace

Inspect (Damage, and Wear)

Replace by Dealer

Check that the locking nut of

the cutting equipment is tighten

correctly

XX

X

X

X

X

X

Every 6

X

X

Months

XX

25

Page 29

Cutting Attachment Maintenance

en

WARNING: It is absolutely

essential to comply with the

angles and dimensions specifi ed

below. If the blade is incorrectly

sharpened there is a risk of

increased kickout of the brush

cutter and increase risk of thrown

object, with resulting risk of injury.

Failure to replace or repair

damaged cutting attachment

can cause serious injury.

The blades are very sharp, always

wear protective gloves when

performing maintenance to the

blades.

General rules

• Only use cutting attachments with

the guards we recommend! See

Recommended cutting attachments

(Page 10).

• Keep the teeth of the blade correctly

sharpened! Follow our instructions and

use the recommended fi le gauge. An

incorrectly sharpened or damaged blade

increases the risk of accidents. (Fig. 17)

• Check the cutting attachment for damage

or cracks. A damaged cutting attachment

should always be replaced.

• Resharpen frequently, take away as little

material as possible – two or three strokes

of the fi le are usually enough.

MAINTENANCE

WARNING: Never repair damaged

cutting attachments by welding,

straightening or modifying the

shape. This may cause parts of

the cutting tool to come off and

result in serious or fatal injuries.

Sharpening grass cutters and grass blades

• See the cutting attachment packaging for

correct sharpening instructions. Sharpen

blades and cutters using a single-cut fl at

fi le.

• Sharpen all edges equally to maintain the

balance of the blade. (Fig. 17)

WARNING: Always discard a blade

that is bent, twisted, cracked,

broken or damaged in any other

way. Never attempt to straighten

a twisted blade so that it can be

reused. Only use original blades

of the specifi ed type.

Trimmer head

CAUTION: Always ensure the

trimmer cord is wound tightly and

evenly around the drum, otherwise

the machine will generate harmful

vibration.

To avoid out-of-balance:

• Resharpen the cutters uniformly – do not

alter the contour of the parent blade in any

way.

• After resharpening about 5 times, have

blade checked by your dealer.

26

• Only use the recommended trimmer heads

and trimmer cords. These have been tested

by the manufacturer to suit a particular

engine size. This is especially important

when a fully automatic trimmer head is

used. Only use the recommended cutting

attachment. See Recommended cutting

attachments (Page 10).

Page 30

MAINTENANCE

• Smaller machines generally require small

trimmer heads and vice versa. This is

because when clearing using a cord the

engine must throw out the cord radially

from the trimmer head and overcome the

resistance of the grass being cleared.

• The length of the cord is also important.

A longer cord requires greater engine

power than a shorter cord of the same

diameter.

• Make sure that the cutter on the trimmer

guard is intact. This is used to cut the cord

to the correct length.

• To increase the life of the cord it can be

soaked in water for a couple of days. This

will make the line tougher so that it lasts

longer.

• Only use line of the same diameter as the

original to avoid overloading the engine

(Fig.18).

• In order to get more line out of the cutting

head, tap it lightly on the ground while

working. NOTE: never hit the nylon head

against hard spots such as concrete or

stones, it could be dangerous.

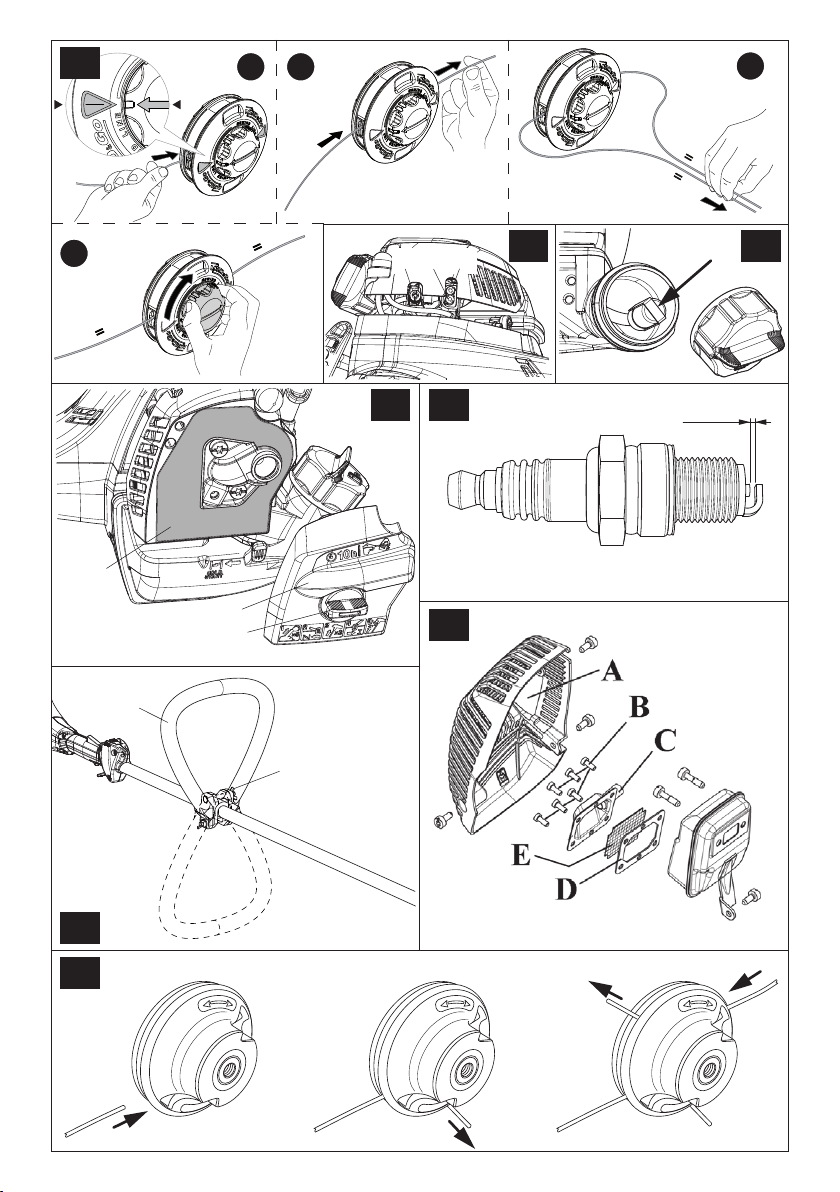

Replacing the nylon line on the

UNIVERSAL trimmer head (Fig.27)

DS 2200 TR: cut two pieces long 8 in (200

mm) of nylon line Ø 0.08 in (2.0 mm).

1. Inserting a line into the hole indicated with

LINE (1) until it is released about 0.4 in (10

mm) from the opposite side (2).

2. Repeat operation with the other line (3).

from the opposite side (Fig.20.2).

2. Divide the line into two equal parts (Fig.

20.3) and then load the trimmer head by

turning the knob (Fig. 20.4).

en

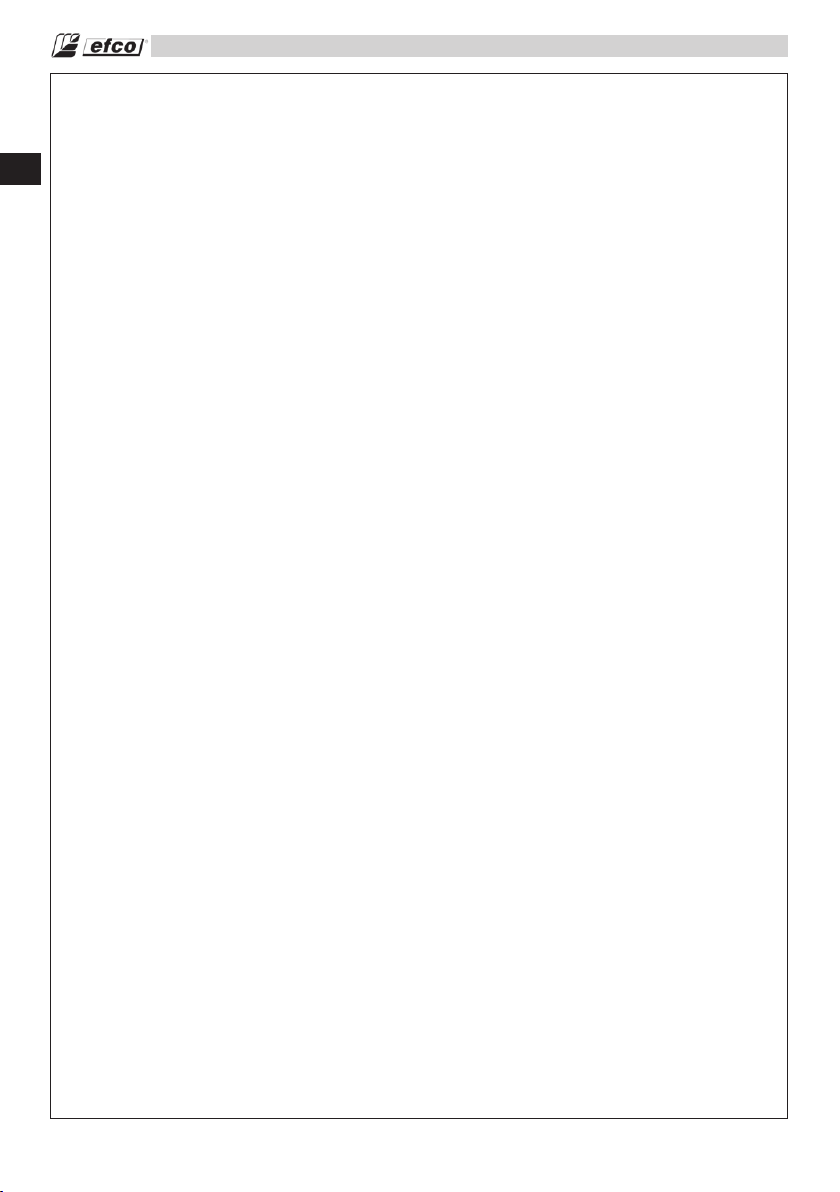

Carburetor Adjustment

Before adjusting the carburetor, clean

the cover vents and air fi lter as shown in

Illustration Fig. 23, refer to Operation-Starting

Unit and Maintenance-Air Filter Sections for

details. Allow the engine to warm up prior to

carburetor adjustment.

This engine is designed and manufactured

in order to comply with EPA (Environmental

Protection Agency) Phase 3 regulations.

The carburetor (Fig. 21) is designed to

permit only the adjustement of L and H

screws in a range of 1/4 round; the ± 1/8

round the hall range admissible for L and H

screws is determined by the manufacturer

and you can not modify it.

WARNING: Don’t try to force the

screws outside the range!

WARNING: Don’t modify the

carburetor in any way in such

case the engine will not run

in compliance with emissions

regulations.

Replacing the nylon line on the LOAD&GO

trimmer head (Fig.20)

DS 2200 S - DS 2200 T (Ø 4.3 in / 110 mm):

cut 13 ft (4 m) of nylon line Ø 0.09 in (2.4

mm).

DS 2400 S - DS 2400 T (Ø 5.1 in / 130 mm):

cut 28 ft (8.5 m) of nylon line Ø 0.09 in (2.4

mm).

1. Align the arrows and insert the line into the

trimmer head (Fig. 20.1) until it is released

Idle Speed Adjustment

• If the engine starts, runs, and accelerates

but will not idle; turn the idle speed screw

“T” clockwise to increase idle speed (Fig.

21).

• If the cutting attachment turns at idle, turn

the idle speed screw “T” counter-clockwise

to reduce the idle RPM and stop the

cutting attachment movement. If the cutting

attachment still moves at idle speed, contact

27

Page 31

a Servicing Dealer for adjustment and

discontinue use until the repair is made.

• Screw L must be adjusted so that the engine

promptly responds to sharp accelerations

en

and gives good idle operation.

• Screw H must be adjusted so that the

engine gives maximum power during the

cutting phase.

Fuel Filter

Check the fuel fi lter (Fig. 22) periodically.

Replace it if contaminated or damaged.

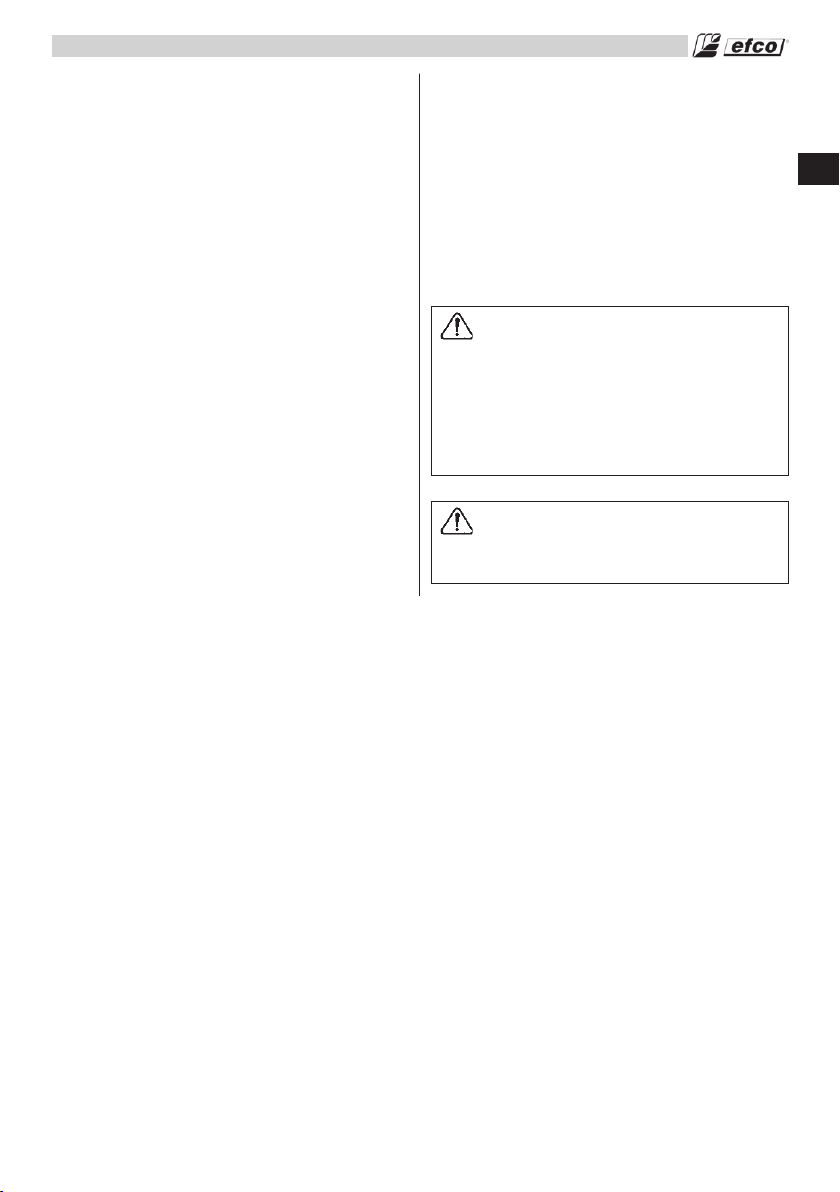

Air Filter

WARNING: Do not clean fi lter

in gasoline or other fl ammable

solvent to avoid creating a fi re

hazard or producing harmful

evaporative emissions.

If a power drop is noticed, check the air fi lter.

Open the air fi lter cover (A) and check the air

fi lter (C, Fig. 23) each day, change the fi lter if

heavily clogged or damaged.

DS 2200: Clean with Emak degreaser p/n

001101009A, rinse with water and blast dry

with compressed air.

DS 2400: Clean with Emak degreaser p/n

001101009A, rinse with water and blast dry

with compressed air, not too close, blowing

from the inside outwards.

Reinstall the air fi lter into cover. Place the air

fi lter cover onto the brush cutter. Tighten the

air fi lter cover screw (B) securely.

A used air fi lter can never be completely

cleaned. It is advisable to replace your air fi lter

with a new one after six month of operation.

Make sure the cover and the support are

clean before fi tting the new fi lter.

MAINTENANCE

CAUTION: Never run the engine

without the air fi lter, serious

damage could result.

Make sure the air fi lter is correctly

placed in the air fi lter cover before

reassembly.

Always replace damaged fi lters.

Do not clean a fi lter with a brush.

Starter Unit

WARNING: The coil spring is

under tension and could fl y apart

causing serious injuries. Never try

to disassemble or modify it.

Engine

Clean the cylinder fi ns with compressed air or

a brush periodically. Dangerous overheating

of engine may occur due to impurities on the

cylinder.

WARNING: Never run the machine

without all the parts, including

the starting housing, securely in

place.

Because parts can fracture and

pose a danger of thrown objects,

leave repairs to the fl ywheel and

clutch to trained Servicing Dealers.

Spark Plug

This engine uses a NGK CMR7H with .02”

(0.5 mm) electrode gap (Fig. 24). Use an

exact replacement and replace every six

months or more frequently, if necessary.

28

Page 32

MAINTENANCE

WARNING: Never test the

ignition system with ignition wire

connector removed from spark

plug or with unseated spark plug,

since uncontained sparking may

cause a fi re. A loose connection

between spark plug terminal and

ignition wire connector in the

boot may create arcing that could

ignite combustible fumes and

cause a fi re.

Use only resistor type spark plugs of the

approved range.

Factors such as:

- too much oil in fuel mix;

- dirty air fi lter;

- unfavourable running conditions, e.g.

operating at part load;

may result in rapid deterioration of the spark

plug.

Muffl er

WARNING! – This muffl er is fi tted

with a catalytic converter needed

for the engine to be in compliance

with the emissions requirements.

Never modify or remove the

catalytic converter: failure to do

so is a violation of law.

WARNING! – Muffl ers fi tted with

catalytic converters get very hot

during use and remain so for

some time after stopping. This

also applies at idle speed. Contact

can result in burns to the skin.

Remember the risk of fi re!

CAUTION! – If the catalytic

converter is damaged it should

be replaced. If the muffl er is

frequently blocked, this can be a

sign that the performance of the

catalytic converter is impaired.

Spark Arresting Muffl er (Fig. 25)

WARNING: A faulty or altered

spark arrester system screen can

create a fi re hazard.

Through normal use the screen can become

dirty and should be inspected weekly and

cleaned as required.

To clean:

• Allow the muffl er to cool.

• Remove the muffl er cover (A).

• Remove the six (6) defl ector screws (B).

• Remove the defl ector (C), the gasket (D)

and spark arrester (E).

• Clean and inspect the spark arrester

screen. If the spark arrester screen is

damaged, faulty or deteriorated, replace

the screen.

• Reassemble components in reversed order

of removal and torque the screw to 40 in/

lbs (4.5 Nm).

WARNING: If the spark arrester

screen is damaged, faulty or

deteriorated, replace the screen