efacec EFAPOWER EV-QC45 Installation And User Manual

Copyright and trademarks

©2014 EFACEC. All rights reserved. This material is protected by the copyright laws of Portugal and other

countries. It may not be modified, reproduced or distributed without the prior, express written consent of

EFACEC. All other products or services mentioned are the trademarks, service marks, registered trademarks or

registered service marks of their respective owners.

ii

TABLE OF CONTENTS

1 GENERAL PRODUCT DESCRIPTION ............................................................................... 2

2 GENERAL CHARACTERISTICS ........................................................................................ 3

2.1 TECHNICAL CHARACTERISTICS ...........................................................................................................3

2.2 STANDARDS ...................................................................................................................................4

3 PRODUCT PARTS PRESENTATION ................................................................................. 5

4 IMPORTANT SAFETY INSTRUCTIONS ............................................................................ 6

5 INSTALLATION ............................................................................................................. 7

5.1 ENVIRONMENTAL REQUIREMENTS .....................................................................................................7

5.1.1 Local Conditions .................................................................................................................................................... 7

5.1.2 Site Verification and Inspection ............................................................................................................................. 8

5.2 SITE PREPARATION ..........................................................................................................................9

5.2.1 Upstream Wiring Information ............................................................................................................................... 9

5.2.2 Surface Preparation ............................................................................................................................................ 10

5.2.3 Resources for Installation .................................................................................................................................... 10

5.2.4 Site Verification and Inspection ........................................................................................................................... 10

5.3 HANDLING AND PLACING .............................................................................................................. 11

5.3.1 Packaging ............................................................................................................................................................ 11

5.3.2 Visual Inspection ................................................................................................................................................. 11

5.3.3 Handling .............................................................................................................................................................. 12

5.3.4 Placing ................................................................................................................................................................. 12

6 START-UP .................................................................................................................. 16

6.1 VERIFICATION AND INSPECTION ...................................................................................................... 16

6.2 SWITCH ON ................................................................................................................................ 16

7 USER MANUAL .......................................................................................................... 20

7.1 OUTPUT CONNECTORS AND OUTLETS ............................................................................................. 20

7.1.1 CHAdeMO connector ........................................................................................................................................... 20

7.1.2 CCS connector...................................................................................................................................................... 20

7.1.3 AC connector ....................................................................................................................................................... 21

7.1.4 AC outlet.............................................................................................................................................................. 21

7.2 OPERATION ................................................................................................................................ 22

7.2.1 Options Interfaces ............................................................................................................................................... 23

7.2.2 CHAdeMO Charging System Interfaces ............................................................................................................... 24

7.2.3 Combined Charging System (CCS) Interfaces....................................................................................................... 25

7.2.4 AC43 Charging System Interfaces ....................................................................................................................... 26

7.2.5 AC22 Charging System Interfaces ....................................................................................................................... 27

8 MAINTENANCE MANUAL ........................................................................................... 28

8.1 POWER UP ERRORS ...................................................................................................................... 28

8.2 PREVENTIVE MAINTENANCE .......................................................................................................... 29

8.3 CHARGER / VEHICLE PROBLEMS ..................................................................................................... 29

iii

The information presented in this guide is subject to change without previous notice.

The technical specifications indicated here do not constitute a contractual obligation.

No part of this document may be photocopied, reproduced or translated to other language without the written

consent from EFACEC.

In case of any doubt regarding a subject described in this manual, please contact us at:

Electronic Power Systems Unit

Rua Eng.º Frederico Ulrich - Apartado 3078

4471-907 MOREIRA MAIA - PORTUGAL

Tel: (+351) 229432248 - Fax: (+351) 229403209

apv-sa@efacec.com

www.efacec.com

Electronic Power Systems Unit

2725 Northwoods Parkway, Ste. B

Norcross, Georgia 30071 USA

Tel: (1) 470 395-3648 - Fax: (1) 770 446 8920

support.eem.usa@efacec.com

www.efacecusa.com

1/32

1 GENERAL PRODUCT DESCRIPTION

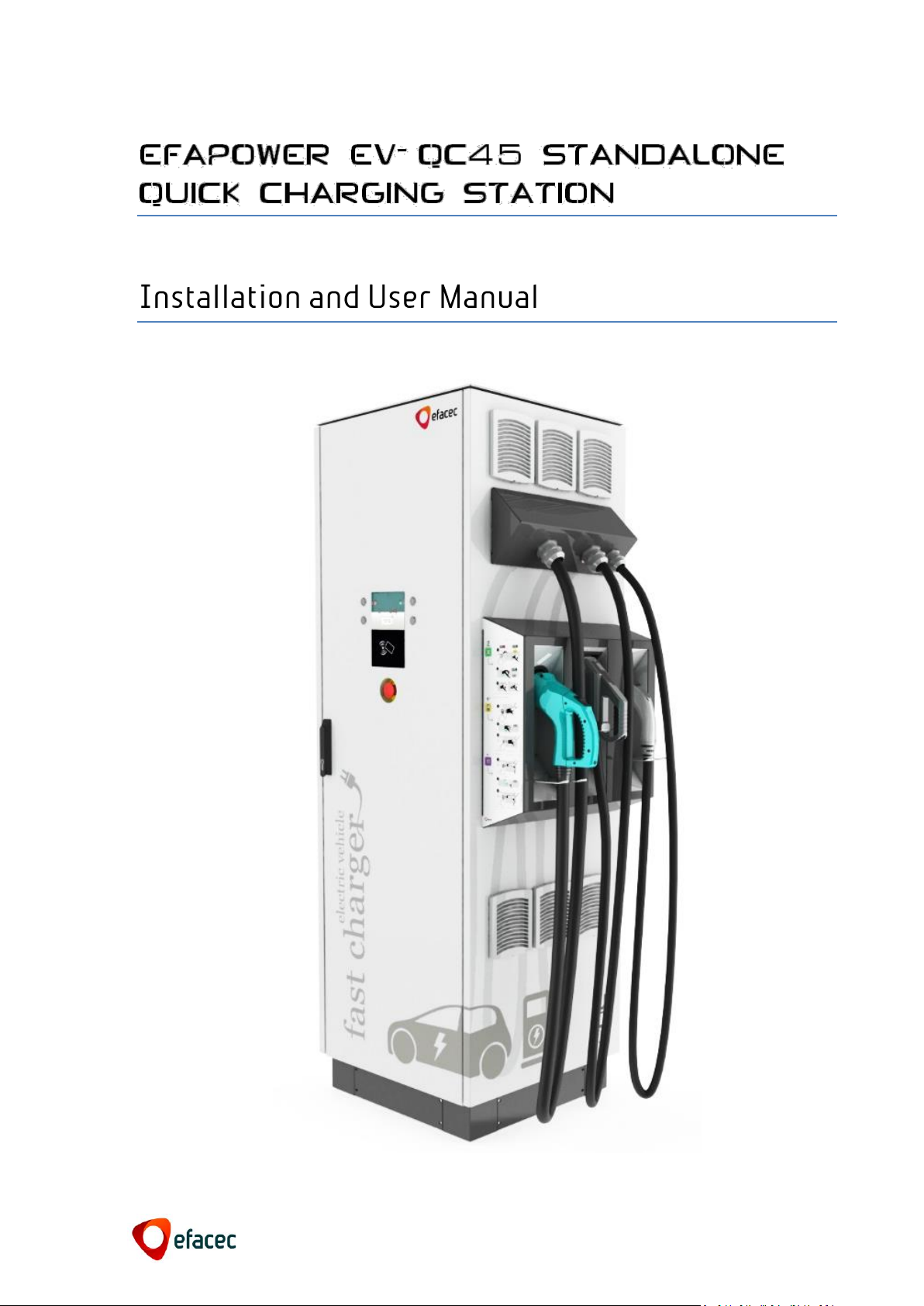

Figure 2 - EFAPOWER Kiosk

Figure 1 - EFAPOWER EV-QC45 STANDALONE

EFAPOWER EV-QC45 charging station is able to charge all electric vehicles compliant with CHAdeMO charging

system and Combined Charging System (CCS) standards.

Depending on the battery capacity, EFAPOWER EV-QC45 can charge properly equipped electric vehicles from

0% to 80% in roughly 30 minutes.

The battery charging state is displayed on the HMI and the

charging cycle finishes by itself or can be interrupted by user

command.

Optional AC outputs are available:

43kVA, 22kVA, 7kVA and 3kVA (Not in USA market).

EFAPOWER EV-QC45 is user friendly and safe. After user

identification, it only requires coupling the charger’s output plug

in the EV for automatic starting if all safety features are

accomplished.

Different configurations are available such as:

Power Cabinet Standalone - which is represented in this

installation and user manual - or

Kiosk with Power Cabinet – for a more personalized and

attractive user experience (for more information please contact

our commercial department).

EFAPOWER EV-QC45 has a means of measuring the output

energy that can be used for information and monitoring

purposes. It uses remote IP communication via GPRS, ADSL,

WIFI or any other to communicate business management

data and technical data.

The Quick Charger power electronics unique design results in top tier specifications for conductive DC fast

charging, such as high power output with an industry best power factor, THD and efficiency.

The Quick Charger is highly recommended for EV fleet bases, service stations, EV service workshops and public

EV infrastructure for fast charging.

EFAPOWER EV-QC45 codification and configurations are presented in chapter 3.

2/32

2 GENERAL CHARACTERISTICS

1

Technical Data CE

ETL

Nominal Input

Phases/Lines

3 phases + neutral + PE

Voltage

(400 ± 10%) V a.c.

(480 ± 10%) V a.c.

Current

73 A

64 A

Power

53kVA (@50kW peak power); 48kVA (@45kW)

Frequency

(50 ± 10%) Hz

(60 ± 10%) Hz

Efficiency

> 93%

Power Factor

0,98

THD Input Current

12,3

DC Output:

CHAdeMO

Voltage

(50 to 500) V d.c.

Current

120 A d.c.

Nominal Power

50kW at peak; 45kW at continuous

Communications with EV

JEVS G104 - CHAdeMO

Plug

JEVS G105 - CHAdeMO

DC Output:

CCS

Voltage

(50 to 500) V d.c.

Current

120 A d.c.

Nominal Power

50kW at peak; 45kW at continuous

Communications with EV

PLC

Plug

CCS – Type 2

SAE – Type 1

AC Output:

AC43 (or AC22)

Voltage

(400 ± 10%) V a.c.

Current

63 A a.c. (or 32 A a.c.)

Nominal Power

43kVA (or 22kVA)

Not Available

Plug (or Socket)

IEC62196 Type 2

Insulation

Input / Output / Ground

1500 V a.c.

1500 V a.c.

Control Circuit / Ground

500 Vac

Cabinet

Dimensions(WxDxH)

600 x 600 x 1800 mm

24” x 24” x 74.5” high

Weight

600 kg

1,323 lbs.

Protection Degree

IP54, IK10

IP54, IK10, NEMA 3R

HMI and Command

Unit

Contactless card specification

Mifare Classic 1K&4K | Mifare DesFire EV1

(Others under request)

Local interface

TFT Color display 6.4”

Buttons

Communication

Protocol (others under request)

Web Services over IP; Router 3G (GSM or CDMA)

OCPP; Efacec; others

Emergency STOP

Yes

Environment

Conditions

Temperature

Cold option (under request)

-25ᵒ to +50ᵒC

-35ᵒ to +50ᵒC

-13ᵒ to +122ᵒF

-31ᵒ to +122ᵒF

Humidity

5% to 95%

Place of installation

Indoor / Outdoor

Altitude

Up to 1000m

Up to 3280 feet

Sound Noise

<55 dB in all directions

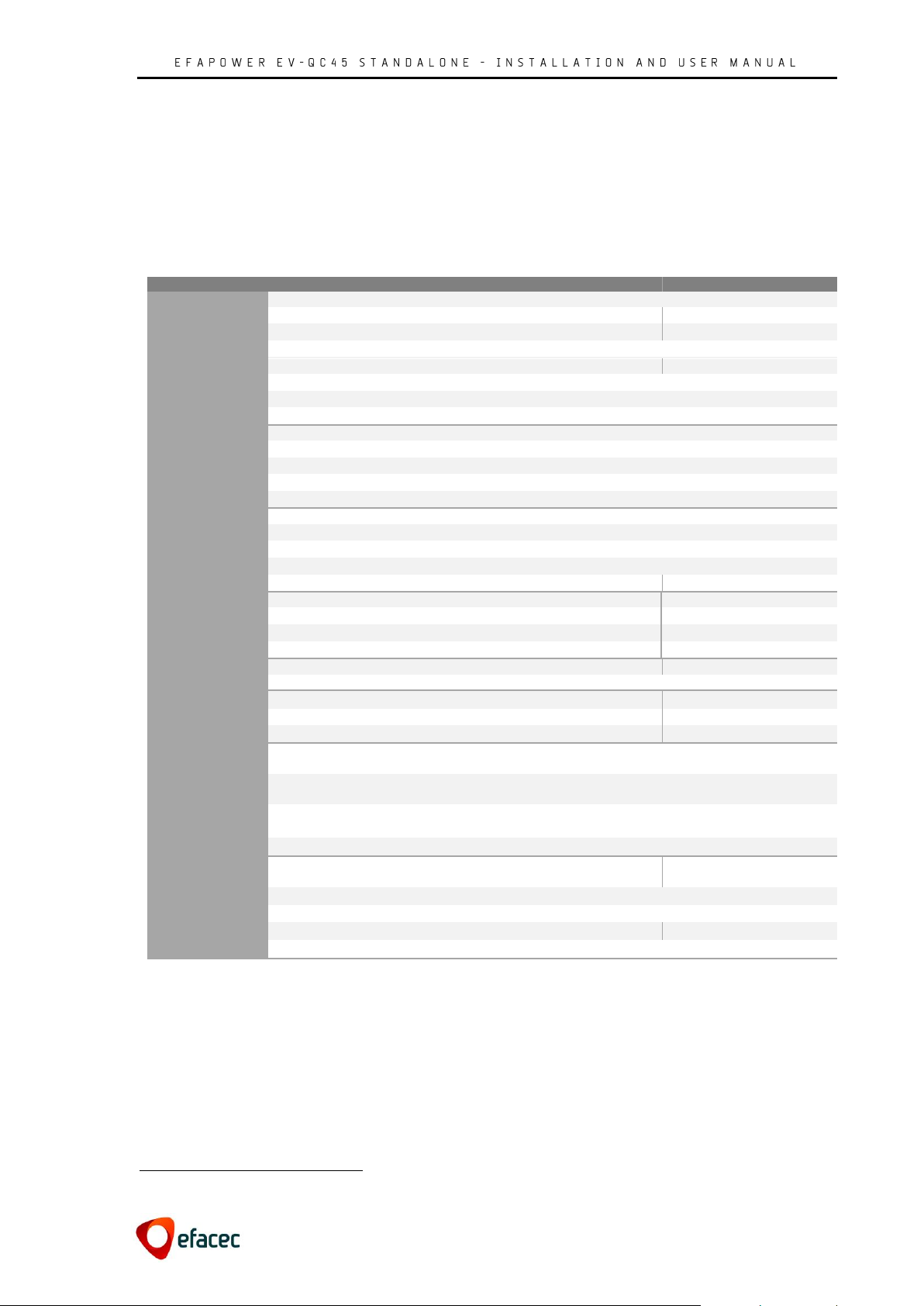

2.1 TECHNICAL CHARACTERISTICS

EFAPOWER EV-QC45 technical characteristics are indicated in the Table 1.

This unit is intended to have at least one DC output connection (CHAdeMO and/or CCS) and in addition can

have one of the two AC output1 connections (AC43 or AC22).

Table 1 – EFAPOWER EV-QC45 Technical Characteristics

Specifications are subject to change, without prior notice.

In case of an AC output connection one of the following scenarios can be supplied:

AC output not available for US market

AC and DC output connections can only charge one at a time:

In this case only the nominal current input referred above in Table 1 is needed.

AC and one DC output connections can charge simultaneous:

- For AC43: the total nominal current input needed is 136 A.

- For AC22: the total nominal current input needed is 105 A.

3/32

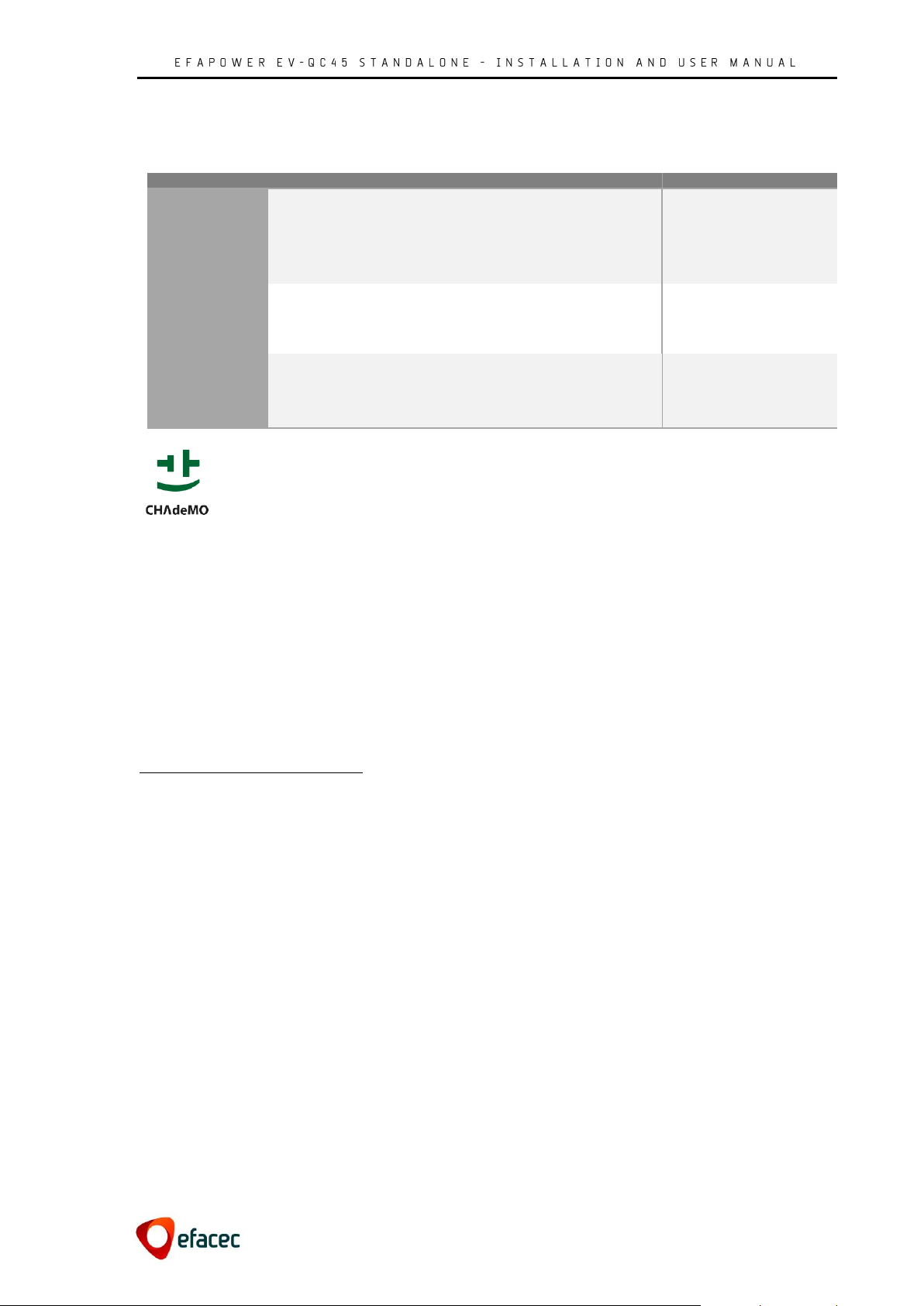

2.2 STANDARDS

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Technical Data CE

ETL

Applicable

Standards

Universal:

2006/95/CE2

2004/108/CE

3

EN/IEC 61851-14

IEC 621965

UL 2231-1

6

UL 2231-27

UL 2202

8

SAE J17729

ADA10

DC Charging System:

EN/IEC 61851-2311

EN/IEC 61851-2412

EN/IEC 61000-6-213

EN/IEC 61000-6-414

---

AC Charging System:

EN/IEC 61851-2215

EN/IEC 61000-6-116

EN/IEC 61000-6-317

EV-READY

----

(not available)

The EFAPOWER EV-QC45 Quick Charging Station complies with the following standards:

Table 2 – EFAPOWER EV-QC45 Applicable Standards

Efacec is an official member of the CHAdeMO Association

2006/95/CE: Low Voltage Directive

2004/108/CE: EMC directive

EN/IEC 61851-1: Electric vehicle conductive charging system. Part 1: General Requirements

IEC 62196: Plugs, socket-outlets, vehicle connectors and vehicle inlets - Conductive charging of electric vehicles

UL 2231-1: Personnel Protection Systems for Electric Vehicle (EV) Supply Circuits: General Requirements

UL 2231-2: Personnel Protection Systems for Electric Vehicle (EV) Supply Circuits: Particular Requirements for

Protection devices for Use in Charging Systems

UL 2202: Electric Vehicle (EV) Charging System Equipment

SAEJ1772: SAE Surface Vehicle Recommended Practice J1772, SAE Electric Vehicle Conductive Charge Coupler

ADA: American with Disabilities Act

EN/IEC 61851-23: Electric vehicle conductive charging system - Part 23: DC electric vehicle charging station

EN/IEC 61851-24: Electric vehicle conductive charging system - Part 24: Digital communication between a d.c.

EV charging station and an electric vehicle for control of d.c. charging

EN/IEC 61000-6-2: Electromagnetic compatibility (EMC). Part 6-2: Generic standards – Immunity for industrial

environments

EN/IEC 61000-6-4: Electromagnetic compatibility (EMC). Part 6-4: Generic standards –Emission standard for

industrial environments

EN/IEC 61851-22: Electric vehicle conductive charging system. Part 22: AC Electric Vehicle Charging Station

EN/IEC 61000-6-1: Electromagnetic compatibility (EMC). Part 6-1: Generic standards - Immunity for

residential, commercial and light-industrial environments

EN/IEC 61000-6-3: Electromagnetic compatibility (EMC). Part 6-3: Generic standards - Emission standard for

residential, commercial and light-industrial environments

4/32

3 PRODUCT PARTS PRESENTATION

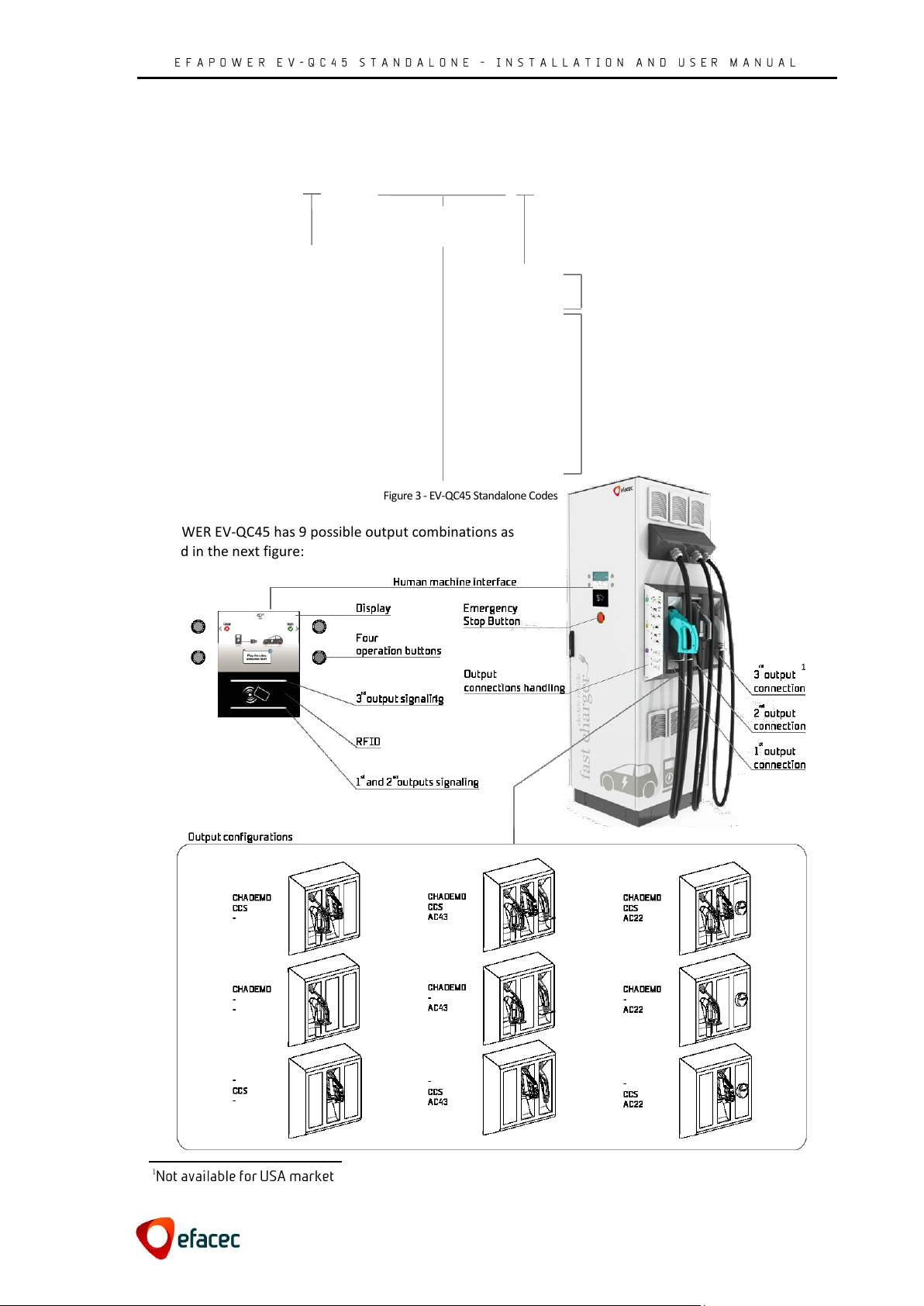

Figure 3 - EV-QC45 Standalone Codes

EV-QC45 YY GCCB ZZZZ ZZZZ ZZZZ Y

- – without extras

L – CHAdeMO Lock

DCA – CHAdeMO

At least one

One at most

CE – European markets

UL – USA & Canada markets

EFAPOWER EV-QC45 has 9 possible output combinations as

showed in the next figure:

1

1

1

The mechanical structure is composed by a standalone Power Cabinet. Its codification is presented below.

C – Cold option

DCC – CCS

AC43

AC22P

AC22S

AC11P

AC11S

AC7P

AC7S

AC3P

AC3S

Figure 4 - EFAPOWER EV-QC45 Parts

5/32

4 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that must be followed during installation of the EFAPOWER EV

QC45 Quick Charging Station.

Grounding instructions

The EFAPOWER EV QC45 Quick Charging Station must be connected to a grounded, metal, permanent wiring

system; or an equipment-grounding conductor is to be run with circuit conductors and connected to the

equipment grounding terminal or lead on the Electric Vehicle Supply Equipment (EVSE). Connections to the

EVSE shall comply with all local codes and ordinances.

Safety and compliance

This document provides instructions to install the EFAPOWER EV QC45 Quick Charging Station and should not

be used for any other product. Before installing the EFAPOWER EV QC45 Charging Station, you should review

this manual carefully and consult with a licensed contractor, licensed electrician and trained installation expert

to ensure compliance with local building practices, climate conditions, safety standards, and state and local

codes. The EFAPOWER EV QC45 Quick Charging Station should be installed only by a licensed contractor and a

licensed electrician and in accordance with all local and national codes and standards. The EFAPOWER EV QC45

Quick Charging Station should be inspected by a qualified installer prior to the initial use. Under no

circumstances will compliance with the information in this manual relieve the user of his/her responsibility to

comply with all applicable codes or safety standards. This document describes the most commonly-used

installation and mounting scenarios. If situations arise in which it is not possible to perform an installation

following the procedures provided in this document, contact EFACEC. EFACEC is not responsible for any

damages that may occur resulting from custom installations that are not described in this document.

No accuracy guarantee

Reasonable effort was made to ensure that the specifications and other information in this manual are accurate

and complete at the time of its publication. However, the specifications and other information in this manual

are subject to change at any time without prior notice.

Warranty information and disclaimer

Your use of, or modification to, the EFAPOWER EV QC45 Quick Charging Station in a manner in which the

EFAPOWER EV QC45 Quick Charging Station is not intended to be used or modified will void the limited

warranty. Other than any such limited warranty, the EFACEC products are provided “AS IS,” and EFACEC and its

distributors expressly disclaim all implied warranties, including any warranty of design, merchantability, fitness

for a particular purposes and non-infringement, to the maximum extent permitted by law.

Limitation of liability

IN NO EVENT SHALL EFACEC OR ITS AUTHORIZED DISTRIBUTORS BE LIABLE FOR ANY INDIRECT, INCIDENTAL,

SPECIAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION, LOST PROFITS, LOST

DATA, LOSS OF USE, COST OF COVER, OR LOSS OR DAMAGE TO THE EFAPOWER EV QC45 CHARGING STATION,

ARISING OUT OF OR RELATING TO THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF EFACEC OR ITS

AUTHORIZED DISTRIBUTORS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

6/32

5 INSTALLATION

All matters for installing the EFAPOWER EV-QC45 are described in this chapter.

5.1 ENVIRONMENTAL REQUIREMENTS

EFAPOWER EV-QC45 reliability is dependent upon compliance of environmental specifications. The design of

the environmental control system for your EFAPOWER EV-QC45, in case of extreme environmental conditions,

must ensure that the Unit can operate reliably while remaining within the range of its operating specifications.

5.1.1 LOCAL CONDITIONS

The installation of EFAPOWER EV-QC45 shall not be made in a commercial garage (repair facility)

or closer than 508mm (20 feet) of an outdoor motor fuel dispensing device.

EFAPOWER EV-QC45 is in an IP54, IK10 (NEMA 3R) enclosure. This Unit is intended to work below 50ᵒC (122ᵒF)

ambient temperature.

Clearance around the cabinet

The air must circulate freely throughout the ventilation grids in order for the charger’s cooling system to be

effective. The ventilation areas on the sides and back must not be blocked, assuring that the Quick Charger

cooling system can be effective. Efacec recommends clearance of at least 1meter (40’’) in the front (HMI

interface) and on right side (output cables) and 500mm (20’’) of clearance in the remaining sides of the cabinet.

Input Power Cables

AC input cables must be copper with appropriate power rating.

EFAPOWER EV-QC45 can be placed in 3 alternative positions as showed in Figure 5.

Figure 5 - EFAPOWER EV-QC45 alternative orientations

7/32

Even though, non-conductive dust does not influence the system’s operation, it may however, with excessive

accumulation, not allow proper cooling, therefore limiting the equipment’s thermal capabilities. Consequently,

dust accumulation must be avoided in order to guarantee a better thermal performance.

Conductive dust and acid vapors must be kept away from the Quick Charger.

On locations with harsh weather conditions (high temperatures, heavy dust, snow and/or very low

temperatures) it’s recommended to provide additional protection, either inside a building or a shelter, or

providing a protection roof for the Unit. See example in Figure 6.

Figure 6 - EFAPOWER EV-QC45 with shelter

5.1.2 SITE VERIFICATION AND INSPECTION

Check if the installation of the Quick Charger is not planned to be made in a commercial garage (repair

facility) or closer than 508mm (20 feet) of an outdoor motor fuel dispensing device;

Check if the access passages to the Quick Charger Station layout site are not blocked in order to allow its

transportation;

Check if Quick Charger Station layout site is compliant with the specified clearance around the cabinet.

8/32

Loading...

Loading...