Original operating manual

EFA pneumatic circular saws

OM No.: 001 580 654

Version 26.06.2018

Original operating manual

Translation of the original operating manual

Pneumatic circular saws

EFA 17

EFA 19

EFA SK 08D

EFA SK 16D

EFA SK 16-8D

EFA SK 16-8DR

EFA SK 18-8D

This manual must be given to the user (worker)!

A copy of this manual must be given to all personnel working with this tool!

Schmid und Wezel GmbH

Maschinenfabrik

Maybachstraße 2

75433 Maulbronn, Germany

Telephone: +49 (0) 7043 / 102-0

Fax: +49 (0) 7043 / 102-78

E-mail: efa-verkauf@efa-germany.de

Website address: www.efa-germany.de

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

2 of 19

Version 26.06.2018

Table of contents

1. Verwendung, Lieferumfang, Zubehör ........................................................................................... 4

1.1 Symbole in dieser Anleitung ......................................................................................................... 4

1.2 Bestimmungsgemäße Verwendung .............................................................................................. 4

1.3 Unvorschriftsmäßiger Gebrauch ................................................................................................... 4

1.4 Restgefahren ................................................................................................................................. 5

1.5 Lieferumfang ................................................................................................................................. 5

2. Technische Daten ............................................................................................................................ 6

3. Sicherheitshinweise ........................................................................................................................ 6

3.1 Allgemeine Sicherheitshinweise ................................................................................................... 6

3.2 Verhalten am Arbeitsplatz ............................................................................................................. 7

4. Anschluss und Inbetriebnahme ..................................................................................................... 7

4.1 Arbeitsplatz ................................................................................................................................... 7

4.2 Installation ..................................................................................................................................... 7

4.2.1 Druckluft-Kreissäge anschließen ........................................................................................ 7

4.2.2 Filterdruckminderer ............................................................................................................. 8

4.2.3 Federzug ............................................................................................................................. 8

5. Handhabung..................................................................................................................................... 9

5.1 Schalterbetätigung ........................................................................................................................ 9

5.1.1 Einschalten .......................................................................................................................... 9

5.1.2 Ausschalten ....................................................................................................................... 10

5.2 Arbeiten mit der Druckluft-Kreissäge ..........................................................................................10

5.2.1 Vorbereitung ...................................................................................................................... 10

5.2.2 Tiefenanschlag einstellen ................................................................................................. 10

5.2.3 Arbeitsweise ...................................................................................................................... 10

5.2.4 Betriebssicherheit.............................................................................................................. 10

6. Montage ..........................................................................................................................................11

6.1 Sägeblattwechsel ........................................................................................................................11

6.1.1 Tiefenanschlag entfernen ................................................................................................. 11

6.1.2 Sägeblatt ausbauen .......................................................................................................... 11

6.1.3 Sägeblatt einbauen ........................................................................................................... 12

6.2 Einstellung des Federzugs ..........................................................................................................13

7. Reinigung und Schmierung während des Betriebs ...................................................................14

7.1 Tägliche Reinigung .....................................................................................................................14

7.1.1 Desinfektion ...................................................................................................................... 14

7.1.2 Reinigung der Druckluft-Kreissäge ................................................................................... 14

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

3 of 19

Version 26.06.2018

7.2 Tägliche Wartung ........................................................................................................................15

7.2.1 Werkzeuge und Zubehör .................................................................................................. 15

7.2.2 Schmierung ....................................................................................................................... 15

7.2.3 Sägeblatt ........................................................................................................................... 15

7.3 Erweiterte Wartung .....................................................................................................................15

7.3.1 Wartung der Säge ............................................................................................................. 15

7.3.2 Schärfen des Sägeblattes ................................................................................................. 16

7.3.3 Wartungseinheit ................................................................................................................ 16

8. Instandhaltung ...............................................................................................................................17

8.1.1 Reparatur durch den Kundendienst .................................................................................. 17

8.2 Reparaturen ................................................................................................................................18

9. Transport und Lagerung ...............................................................................................................18

10. Rücknahme ....................................................................................................................................18

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

4 of 19

Version 26.06.2018

1. Use, scope of supply,

accessories

General information concerning the proper

use of the equipment – please read this

section carefully!

This manual is intended for the machine

operator. Keep this manual accessible at all

times.

The pneumatic circular saw may only be

operated:

in a perfect technical state, in line with the

intended use, in consideration of all of the

safety- and hazard-relevant aspects,

with all the safety devices attached,

in compliance with the safety instructions,

after the operating personnel have read

and understood these instructions,

particularly Chapter 3 Safety Instructions

and Chapter 4 Connection and Startup.

It is assumed that the operating personnel

is sufficiently familiar with the use of

pneumatic circular saws. Instruction is

provided by our specialist personnel.

1.1 Symbols used in this manual

DANGER

Death, severe injury, or significant

property damage will occur if

proper precautions are not taken.

WARNING

Death, severe injury, or significant

property damage may occur if

proper precautions are not taken.

CAUTION

Minor Injury may occur if proper

precautions are not taken.

Mandatory sign

Danger to individuals who do not

follow the instructions given by the

corresponding symbol.

ATTENTION

Damage to property or the

environment may occur if the proper

precautions are not taken.

Text passages marked with this

symbol provide essential

information and useful tips.

1.2 Intended use

Depending on the design, the pneumatic

circular saw is designed for light and

demanding breaking, particularly for sawing

ribs in pigs and for cutting cattle, calves, and

game.

Pneumatic circular saws from Schmid & Wezel

(S & W) comply with the relevant safety

regulations.

1.3 Improper use

The machine is not equipped for a different

type of use. If the operator wishes to use the

device for other purposes, please consult

Schmid & Wezel GmbH (S&W) in advance.

We would like to point out that improper use

leads to greater risk of accidents and

increased wear. In the event of noncompliance, the liability shall be borne by the

user alone.

The pneumatic circular saw may pose a

hazard if untrained personnel use it

inappropriately or for improper purposes.

WARNING

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

5 of 19

Version 26.06.2018

Risk of immediate death or

death from bleeding due to

improper and incorrect

handling of the device!

Work carefully and according to

instructions.

Only trained, instructed, and authorized

individuals over the age of 16 may operate the

pneumatic circular saw. The responsibilities

and competences concerning the operation

must be clearly defined and complied with.

The pneumatic circular saw must not be

operated by individuals under the influence of

alcohol, medication or drugs.

Maintenance and repairs require special skills

and knowledge, which is why only specialized

persons who have been trained accordingly

are authorized to perform these tasks.

Conversions and modifications of the

pneumatic circular saw

Unauthorized modifications of the pneumatic

circular saw are not permitted for safety

reasons.

Spare parts and accessories have been

specially developed for the pneumatic circular

saw. We expressly point out that we only

accept spare parts and special designs

supplied by us.

The installation and/or use of such products

may have a negative effect on the active and

passive safety.

Schmid & Wezel GmbH accepts no liability for

damage caused using non-original spare parts

or special designs.

Modifications and alterations to the machine

are not permitted and exempt S&W from any

warranty and liability.

1.4 Residual risks

There is a risk of injury from the saw blades.

Pay attention to the correct use of the

machine.

Remain focused and act with caution when

working with the trimmer. Always wear

personal protective equipment.

A faulty compressed air connection and a high

proportion of water in the compressed air may

cause a jet of water escaping at the connection

point. Therefore, ensure that the hose

connection is correct and that the water

content in the compressed air is as low as

possible (drain the water separator regularly).

The water separator is not part of the machine

but must be connected upstream (see Chapter

4.2.1).

1.5 Delivery content

Delivery content EFA 17 & EFA 19

Pneumatic circular saw / rib saw

Threaded fitting

Screw-on nozzle

Single open-end wrench

Retention pin

Operating manual

Delivery content EFA SK 08 D

Pneumatic circular saw / rib saw

Single open-end wrench

Retention pin

Delivery content EFA SK 16 / 18 – 8 D / DR

Pneumatic circular saw / rib saw

Single open-end wrench

Retention pin

Accessories

For special accessories for the individual

machines

see spare parts list

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

6 of 19

Version 26.06.2018

3. Safety instructions

3.1 General safety instructions

It is essential to follow the safety precautions

when using the pneumatic circular saw:

WARNING

Cutting hazard: Limbs may be

severed!

Never reach into the area of the

saw blade.

CAUTION

Machine damage and danger to

third parties due to improper

use!

Use the machine correctly.

ATTENTION

Use only original EFA spare

parts!

This is the only way to ensure that

the machine functions properly

Wear personal protective

equipment!

Chain-mesh gloves

Eye protection

Select personal protection equipment

according to the regulations applicable on

the premises and to the accident

prevention regulations in force.

Carry out installations, maintenance, and

repair only with devices disconnected from

compressed air supply!

Read the operating instructions carefully,

comply with the instructions therein, and

store them in a place where they are

accessible to everyone at all times.

Only specialized persons are authorized to

perform any installation, maintenance, or

repair tasks.

Name

Unit

Performance characteristics

EFA 17

EFA 19

EFA

SK 8D

EFA

SK 16D

EFA SK 16-8D

EFA SK 16-8DR

EFA

SK 18-8D

Operating pressure

bar

6-8

6-8

6-8

6-8 7 7

Air consumption

at full load

m³ / min

1.2

1.2

0.6

0.75

0.9

0.9

Power

Watt

880

880

295

480

790

790

Speed (saw blade)

rpm

1800

1200

2800

2000

2000

2000

Saw blade Ø

mm

210

270

80

160

160

180

Cutting depth

mm

15-75

adjustab

le

100

20

15-75

adjustable

15-45 adjustable

60

Connections on the

maintenance unit

Inches ‚‘

R 3/8“

R 3/8“

R 3/8“

R 3/8“

R 3/8“

R 3/8“

Hose length

m 5 5 5 5 5 5

Weight

kg

8.4

9.0

1.1

2.5

2.7

3.1

Hand-arm vibration

m/s²

< 2.5

< 2.5

< 2.5

< 2.5

< 2.5

< 2.5

Sound pressure level

dB(A)

< 85

< 85

< 85

> 85

> 85

> 85

Cross-section

mm

d = 13

D = 18

d = 13

D = 18

d = 4

D = 11

d = 13

D = 18

d = 13

D = 18

d = 13

D = 18

2. Technical data

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

7 of 19

Version 26.06.2018

3.2 Conduct at the workplace

Keep your workplace tidy and in good

working condition. A cluttered or messy

workplace can lead to accidents.

Take into account environmental

influences. Ensure good lighting (min. 500

lux).

Keep other persons away from your

workplace. Remain focused and act with

caution during your work.

Do not use the pneumatic circular saw

when you are tired and/or unfocused.

Avoid wearing loose clothing and jewelry

that can be caught by moving parts. Wear

sturdy shoes during your work. Always

wear a hairnet!

Ensure that your workplace has a correct,

ergonomic set-up. Ensure safe footing and

keep your balance at all times.

Store the pneumatic circular saw in a safe

place. Store unused equipment in a dry

place.

Service your tools with care. Only use

sharp and undamaged saw blades to

ensure safe work.

Use only original EFA accessories. Use of

other accessories will void the warranty.

The use of other tool inserts or

accessories presents a risk of injury to you

and other persons.

Lay down the unused pneumatic circular

saw so that accidental contact with the

sharp saw blade is not possible

4. Connection and start-up

4.1 Place of work

The work space for the operator should be at

least 1.5 sqm.

No other place of work should extend into this

area as movements with the pneumatic circular

saw could result in the risk of injury.

The illumination at the place of work must be at

least 500 lux.

4.2 Installation

CAUTION

Danger due to automatic start!

Connect the pneumatic circular saw

to the power supply only when

switched off!

CAUTION

Tripping hazard!

Lay compressed air lines outside of

the working area.

CAUTION

Danger of malfunctions and

injuries!

Installation work may only be

carried out by authorized specialist

personnel.

4.2.1 Connecting the pneumatic circular

saw

The pneumatic circular saw is supplied ready

for operation.

ATTENTION

Device damage!

Operate the pneumatic circular saw

only with clean, anhydrous, oiled

air!

Attach the pneumatic circular saw (1) with

the threaded nipple of the compressed air

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

8 of 19

Version 26.06.2018

hose (2) to the maintenance unit (3) (with

filter pressure reducer). Make sure to

assemble the maintenance unit in the

following order: Water separator (4),

pressure gauge (5), oil mist blower (6).

To ensure lubrication of the pneumatics motor,

the maintenance unit must be set to 1-2 drops

of oil per minute (or one drop of oil for

approximately 15 cuts).

Pneumatic connection (schematic diagram)

Pneumatic connection (EFA 17 / 19)

Pneumatic connection (EFA SK 08D)

A faulty compressed air connection and a high

proportion of water in the compressed air may

cause water to escape at the connection point.

Therefore, ensure that the hose connection is

correct and that the water content in the

compressed air is low (drain the water

separator regularly).

If no dried air is available, the customer must

install a water absorber.

Before connection, remove impurities by

blowing air through the compressed air

hose using a compressed air gun.

4.2.2 Filter pressure reducer

The air from compressed-air systems is usually

contaminated and has accumulated moisture.

Therefore, a filter pressure reducer with water

separator should be installed between the

compressed air system and the tool. This not

only controls the operating pressure but cleans

and drains the compressed air. In addition, this

improves on the usefulness and increases the

service life of the pneumatic circular saw

significantly.

The filter pressure reducer should be installed

as close as possible to the pneumatic circular

saw.

Set the operating pressure on the filter

pressure reducer to max. 8 bar.

You can purchase a suitable filter pressure

reducer on request from our sales department

at Schmid & Wezel.

4.2.3 Spring balancer

The machine must always be operated in

combination with a weight relief system (spring

balancer). Install this with a sliding trolley

above the working area on an element

assembled higher or on the ceiling.

Information on fine adjustment of the spring

balancer is provided in Chapter 6.2.

Hang the pneumatic circular saw as top-heavy

as possible. The vertical position can be

adjusted if necessary.

Attaching or removing the weight relief may

result in a risk of the machine slipping or falling

due to weight (depending on the version

between 2.5 and 9 kg). Also make sure that

the machine is not jammed by the snap hook

3

2

1

5

6 4 3

2

1

5

6

4

1 1 2

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

9 of 19

Version 26.06.2018

or the hook of the air circular saw. Be careful!

CAUTION

Risk of injury when adjusting

the spring balancer with

pneumatic circular saw

attached!

Remove the pneumatic circular saw

before adjusting the spring

balancer!

5. Handling

5.1 Switch operation

ATTENTION

Read the operating manual and

connect the pneumatic circular saw

correctly before turning on!

CAUTION

Machine damage and danger to

third parties due to improper

use!

Use the machine correctly.

WARNING

Cutting hazard: Limbs may be

severed!

Never reach into the area of the

saw blade.

Wear eye protection or safety

goggles during work!

The pneumatic circular saw is equipped with a

valve lever (1) for connecting the compressed

air flow.

Operating the switch lever (here SK 18-8D)

Operating the switch lever (EFA 17 / 19)

5.1.1 Turning on

1. Make sure that the manual pneumatic

circular saw is connected to the local

compressed air supply (supply pressure: 7

bar).

2. Carry out a function test before starting

work.

3. Hold the unit firmly by the handle (1).

4. To turn on, actuate the switch lever with

your index and middle fingers.

ATTENTION

Improper handling will lead to

increased wear!

Hearing impairment!

Ear protection is recommended

when used in continuous operation!

1

1

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

10 of 19

Version 26.06.2018

5.1.2 Turning off

Release the switch lever

The switch automatically turns off by the return

spring.

After turning off, the pneumatic circular saw

comes to a standstill after a short follow-up.

The machine can be switched on and off at

any time.

5.2 Working with the pneumatic

circular saw

Wear eye protection or safety

goggles during work!

5.2.1 Preparation

Check before using the device whether

the operating data of the compressed air

supply and the device match.

the pneumatic circular saw is functional

the general safety instructions

(see Chapter 3.1) have been considered.

5.2.2 Setting the depth stop

EFA 17, SK 16D, SK 16-8D:

The pneumatic circular saws EFA 17, SK 16D

and SK 16-8D are equipped with an adjustable

depth stop (1). The stop must be set for the

respective application.

Adjust cutting depth with stop (if present),

loosen wing nut (2) and swivel stop (1)

over pivot point (3)

Tighten the wing nut (2) (see Abb 6).

Adjustment range: 15 - 65 mm

Adjusting the cutting depth (SK 16-8D)

5.2.3 Method of operation

EFA 17,19,SK08-D, SK16-8D, SK18-8D:

Hold pneumatic circular saw securely at

both handles and turn on (except SK168DR).

CAUTION

Blocking hazard!

Do not stop the saw during the

cutting process.

Insert into the meat while running.

Remove from the meat while running and

then turn off.

In case of work interruption, lay the

pneumatic circular saw flat on its side

without any load on the handle.

During prolonged stoppages in work,

disconnect the machine from the compressed

air network.

5.2.4 Operating safety

Work particularly carefully when the

machine is switched on.

Hold the machine firmly at both handles (if

present)

Never press the switch lever when the

machine is not in operation.

Do not tilt or jam the blade

Protective equipment on the saw must not

be removed to complete cutting

After turning off, the saw blade comes to a

1 2 3

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

11 of 19

Version 26.06.2018

standstill within 2 seconds. Only then may

the handles be released

To aid safe handling (guidance), the rib saw

should be hung on a spring balancer.

6. Assembly

WARNING

Cutting hazard!

Disconnect the saw from the

compressed air supply before

assembly operations!

6.1 Saw blade replacement

ATTENTION

Use only original EFA spare

parts!

This is the only way to ensure that

the machine functions properly

The following tools and accessories are

needed for disassembly / assembly:

Single open-end wrench (accessory)

Retention pin

6.1.1 Removing the depth stop

EFA 17, SK16D, SK16-8D:

1. Loosen the screw (1) at the pivot point

2. Unscrew the wing nut (2) and remove the

depth stop (3) (if installed).

Removing the depth stop (SK 16-8D) (1)

6.1.2 Removing the saw blade

3. Turn the saw blade manually until hole (1)

is congruent with hole (2).

Saw blade replacement (SK 16-8D) (2)

EFA 19, SK 16-8D, SK 18-8D:

Saw blade replacement (SK 18-8D) (3)

Wear cut-resistant protective gloves

when working!

4. Lock the saw blade (3) with a retaining pin

(4) (or a comparable tool) and unscrew the

clamping nut (5) with a single open-end

wrench (6) (right-hand thread) (Abb 10 and

Abb 11).

ATTENTION

SK16-8DR

Left-hand thread!

2 1 1 2 3 2 1

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

12 of 19

Version 26.06.2018

Saw blade replacement (SK 18-8D) (4)

Saw blade replacement (SK 16-8D) (5)

Saw blade replacement (SK 8-8D) (6)

5. The saw blade (3) can now be removed.

ATTENTION

The sealing washer (7) may adhere

to the saw blade (3) and may need

to be detached from the saw blade.

Do not remove the sealing washer

(7) with the saw blade (3)!

6.1.3 Installing the saw blade

Saw blade replacement (SK 18-8D) (3)

1. Place sealing washer (1) underneath and

new saw blade (2) on square (3) of drive

spindle.

3 7 4 4 6 5 3 5 2 1 3 5 4 3 6 7 1 1 2 3 4 5 6

EFA SK 08D

1. Insert retaining pin (1) into hole (2)

2. Hold drive arm (3) with retaining pin.

3. Loosen nut (4) with single open-end

wrench (5) and remove.

4. Remove spring washer (6) and saw blade

(7).

Saw blade replacement (EFA SK 08D)

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

13 of 19

Version 26.06.2018

ATTENTION

Note the movement direction of

the saw blade!

See the corresponding marking on

the saw blade (5).

Saw blade replacement (SK18-8D) (3)

2. Screw in clamping nut (4) with recess (see

detail) against the saw blade (2) and

tighten (right-hand thread).

ATTENTION

SK16-8DR

Left-hand thread!

EFA 17,19, SK 16, SK 16-8D:

3. Move the depth stop to the working

position. Tighten screw at pivot point and

wing nut.

EFA SK 08D

Installing the saw blade (EFA SK 08D)

1. Place saw blade (1) on lower spring

washer (2)

2. Slide the upper spring washer (3) over the

drive arm (4) onto the saw blade.

3. Secure the drive arm with the retaining pin

(5) and tighten the nut (6) with the single

open-end wrench (7).

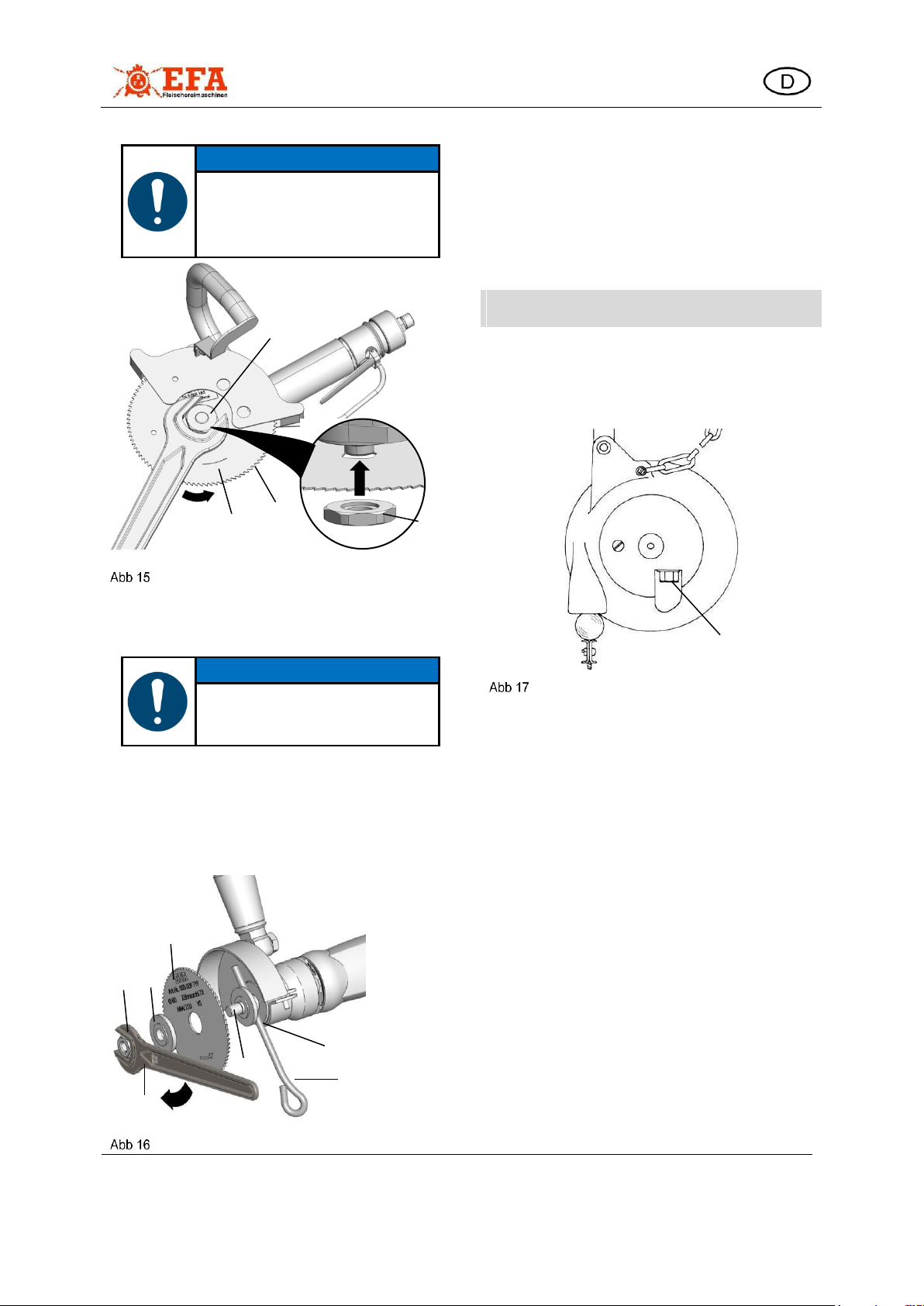

6.2 Adjusting the spring balancer

The spring balancers from Schmid & Wezel

differ according to the maximum permissible

load.

Adjusting spring balancer (1)

The fine tuning of the spring balancer is done

with the PLUS / MINUS screw (1) on the

housing.

Turn the screw in MINUS direction until the

saw is hanging freely in equilibrium (with

the spring balancer) at working height.

If pulling out is not possible, the spring

balancer is jammed, and a readjustment is

necessary:

Turn the screw in PLUS direction until the

saw can be pulled out and start again with

fine adjustment

4

2 4 5

1

+ -

6

1

4 7 2

5

3

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

14 of 19

Version 26.06.2018

Spring balancers for devices up to 14 kg:

Before adjusting the load capacity,

attach the load with the rope fully

retracted.

Adjustment in direction "Plus" (+)

increases the load capacity.

Adjustment in direction "Minus" (-)

reduces load capacity.

The correct setting is achieved

when the attached load can be

pulled easily into the desired

position and returns to its original

position after releasing.

Adjusting spring balancer (2)

Use an Allen key on the adjusting screw

(2) to make the desired setting within the

permissible adjustment range.

The adjusting screw (2) acts on the spring

catch (3) which is provided with a marking on

the outside. This marking indicates the

adjustment.

7. Cleaning and lubrication

during operation

WARNING

Cutting hazard!

Turn off and disconnect the saw

from the compressed air supply

before starting maintenance!

7.1 Daily cleaning

After completion of breaking, the pneumatic

circular saw must be cleaned.

Trouble-free continuous operation is only

guaranteed if the pneumatic circular saw is

always kept hygienically clean. The machine

should normally be disinfected before each

cleaning.

Observe the applicable safety and

hygiene requirements.

7.1.1 Disinfection

Disinfect the machine during operation after

every cut with hot water (approx. 82 °C).

Disinfectants must not be allowed to come into

direct or indirect contact with foodstuffs. Rinse

the machine with clear water after disinfection.

ATTENTION

Do not use any aggressive solvents!

Do not use a steam blaster or highpressure cleaner! Do not immerse

the device in water!

7.1.2 Cleaning the pneumatic circular

saw

Clean the device after use with cloth, brush,

and warm water (40 - 55 °C). Soak stubborn or

encrusted residues.

Use a cleaning agent, preferably foam, and

apply to the surface to be cleaned and leave

for 15 - 20 minutes. Subsequently wash off the

loosened dirt manually with warm water.

Recommended cleaning agents

Diversey Lever Tego 2000:

Surface-active disinfectant

Diversey Lever GmbH

Mallaufstr. 50-56, 68219

Mannheim/Germany

P3-topax 91: Surface-active disinfectant

Henkel-Ecolab Deutschland GmbH

Postfach 13 04 06, 40554 Düsseldorf

A cleaning plan and further details can be

obtained from the above addresses.

The above-mentioned cleaning agents are only

recommendations. When using other cleaning

agents, the customer must check material

compatibility and hygiene regulations.

3

2

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

15 of 19

Version 26.06.2018

7.2 Daily maintenance

7.2.1 Tools and accessories

Grease gun

Suitable for contact with food

7.2.2 Lubrication

Each time the saw blade is cleaned, apply

a little acid-free, EFA special oil.

Lubricants

The lubricating grease and oil are subject to

the regulations required in the food industry.

Use only lubricants that comply with German

food regulations and FDA guidelines.

This relates to unintentional contact with the

processed product (food) that cannot be ruled

out with certainty. Therefore, use only food

grade lubricants.

You can buy suitable lubricating grease and oil

for your machine from the sales department of

Schmid & Wezel.

7.2.3 Saw blade

Inspect the saw blade at regular intervals.

If the self-locking effect of the hex. nut is no

longer assured, it must be replaced without

delay.

7.3 Advanced Maintenance

After approx. 50 operating hours, extended

maintenance is required.

7.3.1 Maintenance of the saw

Disconnect the saw from the compressed

air supply

To maintain the lubrication of ball bearings

and gearbox, grease the machine at the

grease nipples with 1 - 2 strokes out of the

grease gun (see Abb 19 and Abb 20).

Grease nipples (SK 18-8D)

Grease nipples (EFA 17 / EFA 19)

In case of decreasing performance or after

approx. 400 operating hours, the rotor

slides of the pneumatics motor must be

checked for wear and replaced if

necessary (we recommend sending the

pneumatic circular saw in this case to our

service department).

A dirty silencer (1) must be cleaned or

replaced.

1

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

16 of 19

Version 26.06.2018

Silencer (here EFA SK 08 D)

7.3.2 Sharpening the saw blade

ATTENTION

Incorrectly sharpened saw blades

lead to production losses and

endanger the user.

For sharpening, please contact the

sharpening service of the nearest

authorized workshop or contact our

head office directly.

Sharpening can also be carried out on

commercially available automatic circular saw

blade sharpening machines.

More detailed information on sharpening the

saw blade relating to the different saw blade

geometries (tooth shapes) is available on

request from our service department.

ATTENTION

Do not use force as parts could be

damaged! Only use original EFA

spare parts!

7.3.3 Maintenance unit

For proper operation and to maintain the

adequate service life of the pneumatic circular

saw, the maintenance unit (filter pressure

reducer) must be checked at regular intervals.

Remove any condensation and, if

necessary, fill up with special oil (available

from S&W).

Check the operating pressure (max. 8 bar)

at regular intervals.

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

17 of 19

Version 26.06.2018

Malfunctions may occur during operation, but

these are generally relatively simple to

remedy.

ATTENTION

Only qualified, instructed specialist

personnel may carry out all

operations.

Table 1: "Faults and corrective measures"

describes these malfunctions together with

their possible causes and suggests corrective

measures

The machine does not start up when

actuating the switch lever

Air filter on maintenance unit is dirty

Replace air filter

Loose hose connection

Check the proper connection of the

hoses

Rotor slide defective

Return to manufacturer for service.

Handle is difficult or impossible to

press

Valve spring broken

Valve jammed due to soiling

Return to manufacturer for service.

Handle iced

Air pressure set too high

Adjust to 6 - 8 bar

Machine does not start

Parts of the motor or transmission are

defective

Return to manufacturer for service.

Machine parts corroded

Water in inlet line. Air conditioner

defective

If necessary, replace maintenance unit

or return to manufacturer for service.

8.1.1 Repair by After-Sales Service

Only specialized persons are authorized to

perform repairs. Our service department is at

your disposal for any repairs needed.

If your equipment needs to be repaired, please

contact the nearest authorized service center

or our head office.

Upon request, spare parts lists can be

provided to any authorized service center.

In the event of malfunctions that cannot be

clearly localized, the device should be returned

to S&W for repair. Please state the error

symptoms if you do so.

For other faults that the system operator can

rectify, the fault list may provide information

about the cause and rectification of the fault.

Do not repair defective devices on

site (in the immediate vicinity of

food)!

Provide all of the necessary tools

and ensure that the work

environment is clean.

WARNING

Cutting hazard!

Disconnect the device from the

compressed air supply before

starting any repairs!

WARNING

Cutting hazard!

Turn off and disconnect the saw

from the compressed air supply

before starting maintenance!

CAUTION

Malfunction

Possible cause

Remedy

8. Maintenance

Tab 1 Malfunctions and their rectification

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

18 of 19

Version 26.06.2018

Danger of malfunctions and

injuries!

Only qualified, instructed specialist

personnel may carry out

maintenance.

Maintenance unit

Check the maintenance unit at regular

intervals, but at least once a week, remove the

condensation and add special oil.

Special oil for maintenance system:

EFA special oil 0.5 l part no. 001 365 611

EFA special oil 5.0 l part no. 001 365 612

Special grease for gear box and ball

bearings:

Bearings/planetary gear 0,8 kg

part no.: 001 365 644

Gearbox 1kg part no.: 001 365 623

Gearbox 5kg part no.: 001 365 624

8.2 Repairs

CAUTION

Danger of malfunctions and

injuries!

Only authorized specialist personnel

may carry out repairs.

WARNING

Cutting hazard!

Turn off and disconnect the saw

from the compressed air supply

before starting any repairs!

ATTENTION

Use only original spare parts!

This is the only way to ensure that

the machine functions properly

Our service department is at your disposal for

any repairs needed.

EFA Service

Phone: +49-(0) 7043 102-82

Fax: +49(0)7043 / 102-78

In the event of a repair, please contact your

nearest contract workshop or our parent

company directly.

9. Transport and storage

The machine must be stored in a dry room.

Clean the machine and transport only in a dry

condition.

Ensure that the machine is not damaged

during transport.

Use the original packaging.

10. Return of waste electrical

equipment

Return your waste electrical equipment to our

head office.

Original operating manual

Pneumatic circular saws

OM No.: 001 580 654

19 of 19

Version 26.06.2018

Loading...

Loading...