Portable Ultrasonic Flowmeter

Portalok 7S

User Manual

PORTALOK_7SV4-5-1EN

Portable Ultrasonic Flowmeter Portalok 7S

2 PORTALOK_7SV4-5-1EN, 2014-09-01

Table of Contents Portalok 7S

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Regarding this User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 First Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 General Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Measurement System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Measurement Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Measurement Arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Description of the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Selection of the Measuring Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Acoustic Penetration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Undisturbed Flow Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Selection of the Measurement Arrangement Taking onto Account the Measuring Range

and the Measuring Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4 Selection of the Sound Plane Near an Elbow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Installation of the Transmitter Portalok 7S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Connection of the Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4 Connection of the Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.5 Connection of the Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Installation of the Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Preparation of the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 Orientation of the Transducers and Transducer Distance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 Start-up of the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.4 HotCodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.5 Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9 Basic Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.1 Input of the Pipe Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.2 Input of the Medium Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.3 Other Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.4 Defining the Measuring Point Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.5 Defining the Number of Sound Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.6 Transducer Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.7 Start of the Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.8 Detection of the Flow Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.9 Interruption of the Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

PORTALOK_7SV4-5-1EN, 2014-09-01 3

Portalok 7S Table of Contents

10 Displaying the Measured Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.1 Selection of the Physical Quantity and of the Unit of Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

10.2 Adjustment of the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

10.3 Status Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

10.4 Transducer Distance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

11 Advanced Measuring Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.1 Command Execution during Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

11.2 Damping Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

11.3 Totalizers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

11.4 Upper Limit of the Flow Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

11.5 Cut-off Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

11.6 Uncorrected Flow Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

11.7 Change of the Limit for the Inner Pipe Diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11.8 Program Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

12 Data Logger and Transmission of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12.1 Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

12.2 Transmission of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

13 Libraries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13.1 Partitioning of the Coefficient Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

13.2 Input of Material/Medium Parameters Without the Extended Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

13.3 Extended Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

13.4 Deleting a User Defined Material/Medium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

13.5 Arrangement of the Material/Medium Scroll List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

14 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

14.1 Time and Date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

14.2 Dialogs and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

14.3 Measurement Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

14.4 Setting the Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

14.5 Instrument Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

15 SuperUser Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

15.1 Activation/Deactivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

15.2 Defining the Flow Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

15.3 Limit of the Signal Amplification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

15.4 Upper Limit of the Sound Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

15.5 Detection of Long Measurement Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

15.6 Number of Decimal Places of the Totalizers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

15.7 Manual Reset of the Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

15.8 Display of the Sum of the Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

15.9 Display of the Last Valid Measured Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

15.10 Display During the Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

16 Outputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

16.1 Installation of an Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

16.2 Error Value Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

16.3 Activation of the Current Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

16.4 Activation of a Binary Output as a Pulse Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

16.5 Activation of a Binary Output as an Alarm Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

16.6 Behavior of the Alarm Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

4 PORTALOK_7SV4-5-1EN, 2014-09-01

Table of Contents Portalok 7S

17 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

17.1 Problems with the Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

17.2 Selection of the Measuring Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

17.3 Maximum Acoustic Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

17.4 Application Specific Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

17.5 Large Deviations of the Measured Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

17.6 Problems with the Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

17.7 Data Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

A Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

B Units of Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

C Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

PORTALOK_7SV4-5-1EN, 2014-09-01 5

Portalok 7S Table of Contents

6 PORTALOK_7SV4-5-1EN, 2014-09-01

1 Introduction Portalok 7S

1 Introduction

1.1 Regarding this User Manual

This user manual has been written for the personnel operating the ultrasonic flowmeter Portalok 7S. It contains important

information about the measuring instrument, how to handle it correctly, and how to avoid damages.

Read the safety instructions carefully. Make sure you have read and understood this user manual before using the measuring instrument.

All reasonable effort has been made to ensure the correctness of the content of this user manual. However, If you find any

erroneous information, please inform us. We will be grateful for any suggestions and comments regarding the concept and

your experience working with the measuring instrument.

This will ensure that we can further develop our products for the benefit of our customers and in the interest of technological progress. If you have any suggestions about improving the documentation and particularly this user manual, please let

us know so that we can consider your comments for future reprints.

The contents of this user manual are subject to changes without prior notice. All rights reserved. No part of this user manual may be reproduced in any form without EESiFlo's written permission.

1.2 Safety Instructions

The user manual contains instructions that are marked as follows:

Note! This text contains important information about the use of the measuring instrument.

Attention! This text contains important instructions which should be observed to avoid damage or destruction of

the measuring instrument. Proceed with special caution!

Observe these safety instructions!

1.3 Warranty

The Portalok 7S measuring instrument is guaranteed for the term and to the conditions specified in the sales contract provided the equipment has been used for the purpose for which it has been designed and operated according to the instructions given in this User Manual. Misuse of the flowmeter will immediately revoke any warranty given or implied.

This includes:

• replacement of a component of Portalok 7S with a component that was not approved by EESiFlo

• unsuitable or insufficient maintenance

• repair of Portalok 7S by unauthorized personnel

EESiFlo assumes no responsibility for injury to the customer or third persons proximately caused by the material owing to

defects in the product which were not predictable or for any indirect damages.

Portalok 7S is a very reliable instrument. It is manufactured under strict quality control using modern production techniques. If installed as recommended in an appropriate location, used cautiously and taken care of conscientiously, no troubles should appear.

In case of a problem which cannot be solved with the help of this user manual (see chapter 17), contact our sales office

giving a precise description of the problem. Specify the type, serial number and firmware version of the measuring instrument.

PORTALOK_7SV4-5-1EN, 2014-09-01 7

Portalok 7S 2 Handling

2 Handling

2.1 First Inspection

The measuring instrument has already been tested thoroughly at EESiFlo. At delivery, ensure that no damage has occurred during transportation.

Check that the specifications of the measuring instrument delivered correspond to the specifications given on the purchase order.

The type and the serial number of the transmitter are shown on the nameplate. The transducer type is printed on the transducers.

2.2 General Precautions

Portalok 7S is a precise measuring instrument and has to be handled with care. To obtain good measurement results and

not damage the measuring instrument, it is important that great attention is paid to the instructions given in this user manual, particularly to the following points:

• Protect the transmitter from shocks.

• Keep the transducers clean. Manipulate the transducer cables with caution. Avoid excessive cable bend.

• Make sure to work under correct ambient and operating temperatures. The ambient temperature has to be within the

operating temperature range of the transmitter and the transducers.

• Observe the degree of protection.

2.3 Cleaning

• Clean the transmitter with a soft cloth. Do not use detergents.

• Remove traces of the coupling compound from the transducers with a soft paper towel.

8 PORTALOK_7SV4-5-1EN, 2014-09-01

3 General Principles Portalok 7S

transducers

transmitter

pipe

3 General Principles

For the ultrasonic measurement of the flow rate, the flow velocity of the medium flowing in a pipe is determined. Further

physical quantities (e.g., volumetric flow rate, mass flow rate) are derived from the flow velocity and from additional physical quantities, if necessary.

3.1 Measurement System

The measurement system consists of a transmitter, the ultrasonic transducers with the transducer cables and the pipe on

which the measurement is conducted.

The ultrasonic transducers are mounted on the outside of the pipe. Ultrasonic signals are sent through the medium and received by the transducers. The transmitter controls the measuring cycle, eliminates the disturbance signals and analyzes

the useful signals. The measured values can be displayed, used for calculations and transmitted.

Fig. 3.1: Example of a measurement setup

3.2 Measurement Principle

The flow velocity of the medium is measured using the transit time difference correlation principle (see section 3.2.2).

3.2.1 Terms

Flow profile

Distribution of the flow velocities over the cross-sectional pipe area. For an optimal measurement, the flow profile has to

be fully developed and axisymmetrical. The shape of the flow profile depends on whether the flow is laminar or turbulent

and is influenced by the conditions in the supply line of the measuring point (see chapter 5).

Reynolds number Re

Coefficient describing the turbulence behavior of a medium in the pipe. The Reynolds number Re is calculated from the

flow velocity, the kinematic viscosity of the medium and the inner pipe diameter.

If the Reynolds number exceeds a critical value (usually approx. 2 300), a transition from a laminar flow to a turbulent flow

takes place.

Laminar flow

A flow without any turbulence. There is no disruption between the parallel flowing layers of the medium.

Turbulent flow

A flow in which turbulence (swirling of the medium) occurs. In technical applications, the flow in the pipe is mostly turbulent.

Transition range

The flow is partly laminar and partly turbulent.

Transit time difference ∆t

Difference of the transit times of the signals in and against the flow direction. The flow velocity of the medium in the pipe is

determined from the transit time difference (see Fig. 3.2 and Fig. 3.3).

Sound speed c

Speed of the propagating sound. The sound speed depends on the mechanical properties of the medium and the pipe material. In pipe materials and other solid materials, a distinction is made between the longitudinal and transversal sound

speed. For the sound speed of some media and materials see annex C.1.

PORTALOK_7SV4-5-1EN, 2014-09-01 9

Portalok 7S 3 General Principles

V·V

·

m

·

m

·

V·V

·

Flow velocity v

The average value of the flow velocities over the cross-sectional pipe area.

Acoustic calibration factor k

a

ka = cα/sin α

The acoustic calibration factor ka is a parameter of the transducer which results from the sound speed c within the transducer and the angle of incidence (see Fig. 3.2). According to Snell's law of refraction, the angle of propagation in the adjoining medium or pipe material is:

= cα/sin α = cβ/sin β = cγ/sin γ

k

a

Volumetric Flow Rate

= v . A

The volume of the medium that passes through the pipe per unit time. The volumetric flow rate is calculated from the product of the flow velocity v and the cross-sectional pipe area A.

Fluid mechanics correction factor k

Re

With the fluid mechanics correction factor kRe, the measured value of the flow velocity in the area of the sound beam is

converted into the value of the flow velocity across the whole cross-sectional pipe area. In case of a fully developed flow

profile, the fluid mechanics correction factor only depends on the Reynolds number and the roughness of the inner pipe

wall. The fluid mechanics correction factor is recalculated by the transmitter for each new measurement.

Mass flow rate

.

ρ

=

The mass of the medium that passes through the pipe per unit time. The mass flow rate is calculated from the product of

the volumetric flow rate and the density ρ.

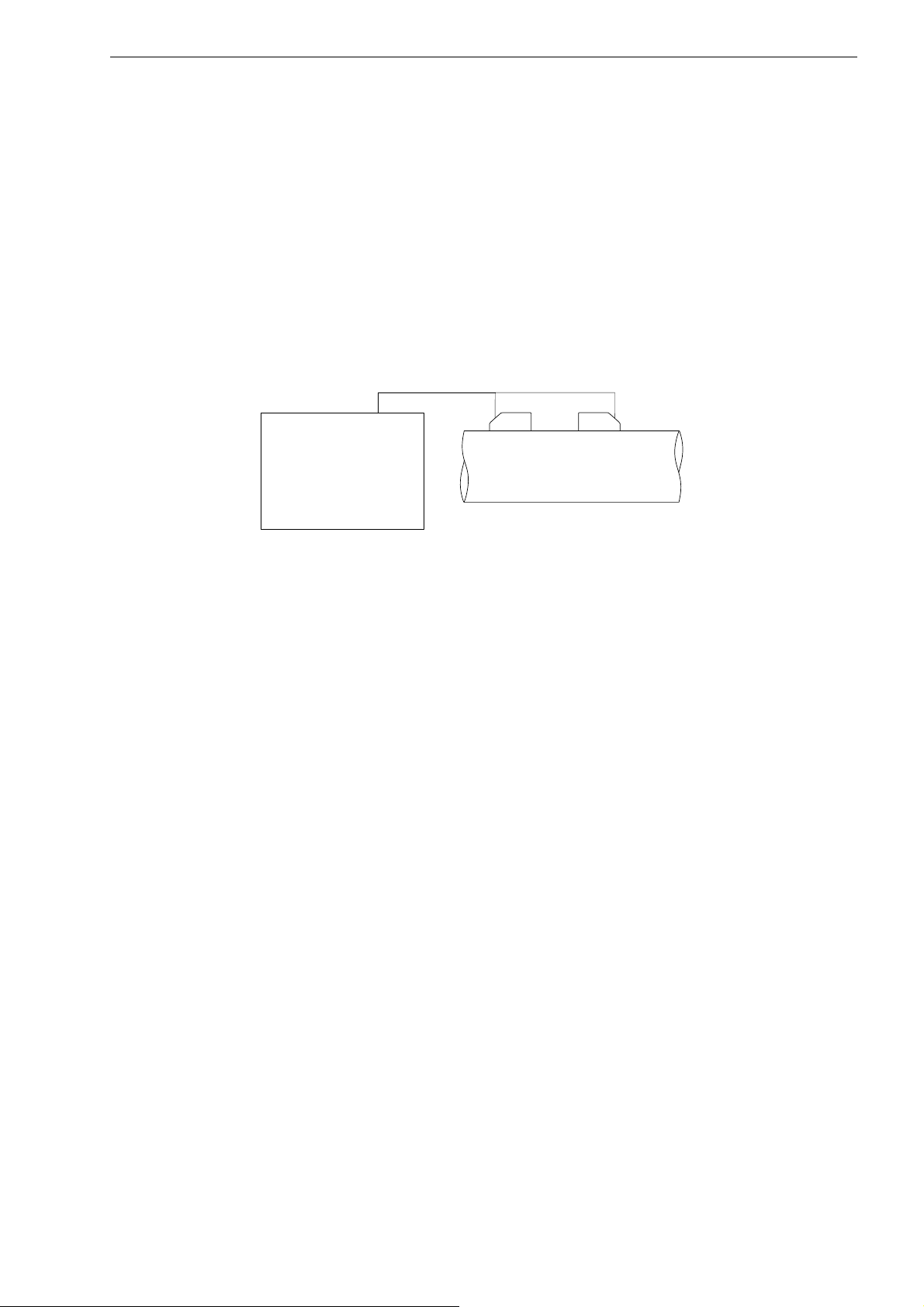

3.2.2 Measurement of the Flow Velocity

The signals are emitted and received by two transducers alternatively in and against the flow direction. If the medium

moves, the signals propagating in the medium are displaced with the flow. This displacement causes a reduction in distance for the signal in the flow direction and an increase in distance for the signal against the flow direction in the wedge of

the receiving transducer (see Fig. 3.2 and Fig. 3.3). This causes a change in the transit times. The transit time of the signal

in the flow direction is shorter than the transit time against the flow direction. This transit time difference is proportional to

the average flow velocity.

The flow velocity of the medium is calculated as follows:

. ka . ∆t/(2 . tfl)

v = k

Re

with

v - flow velocity of the medium

k

- fluid mechanics correction factor

Re

k

- acoustic calibration factor

a

∆t - transit time difference

t

- transit time in the medium

fl

10 PORTALOK_7SV4-5-1EN, 2014-09-01

3 General Principles Portalok 7S

transducer (emitter)

flow direction

of the medium

sound path without flow

sound path with flow

pipe wall

α

β

γ

c

α

c

α

c

γ

c

β

transducer (receiver)

reduction in distance

in the transducer

flow direction

of the medium

sound path without flow

sound path with flow

α

β

γ

c

α

c

α

c

γ

c

β

increase in distance

in the transducer

pipe wall

transducer (receiver)

transducer (emitter)

∆t

signal in the

flow direction

signal against

the flow direction

Fig. 3.2: Sound path of the signal in the flow direction

PORTALOK_7SV4-5-1EN, 2014-09-01 11

Fig. 3.3: Sound path of the signal against the flow direction

Fig. 3.4: Transit time difference ∆t

Portalok 7S 3 General Principles

transducer distance

transducer distance

transducer distance

2 sound paths

in 1 sound plane

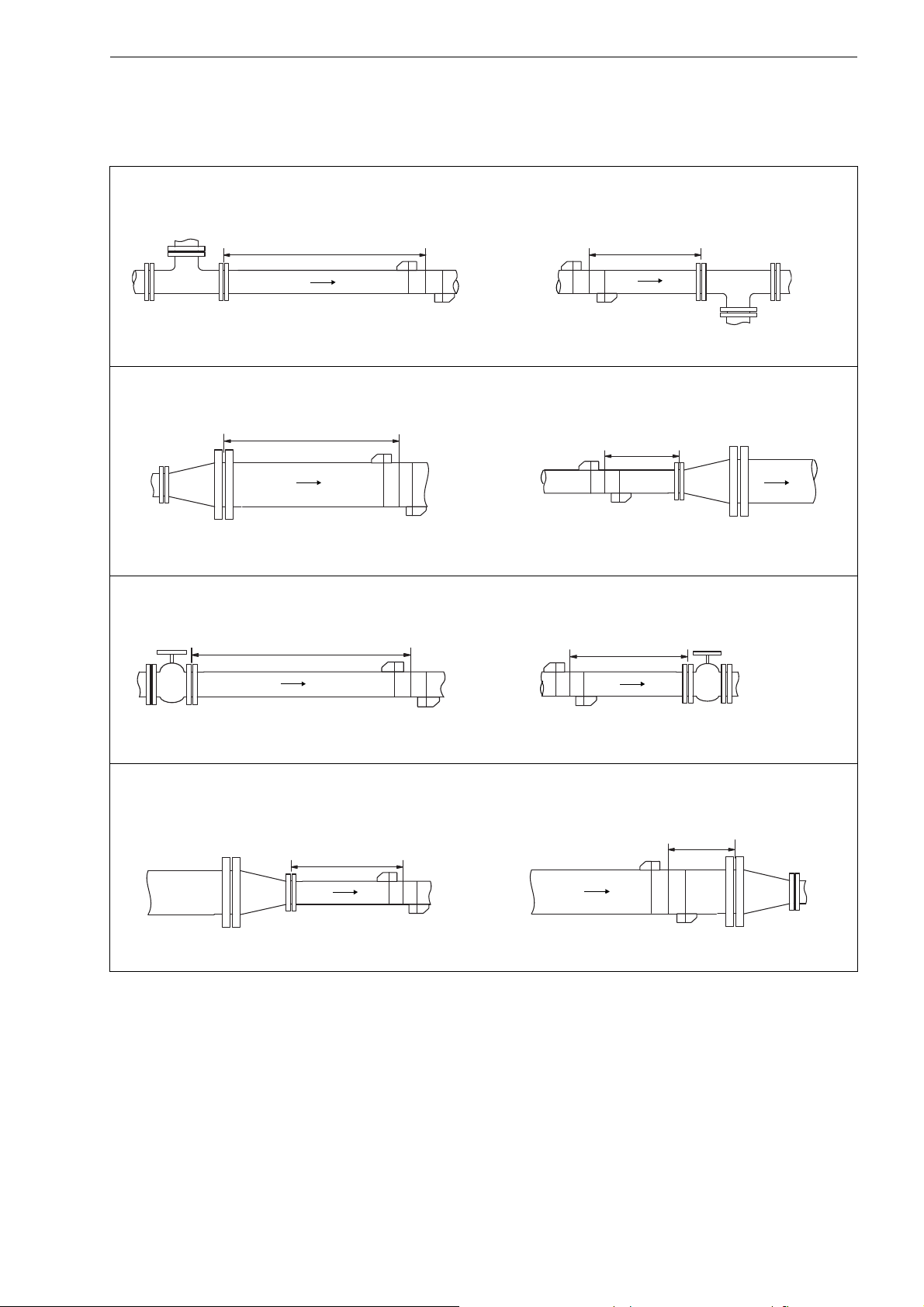

3.3 Measurement Arrangements

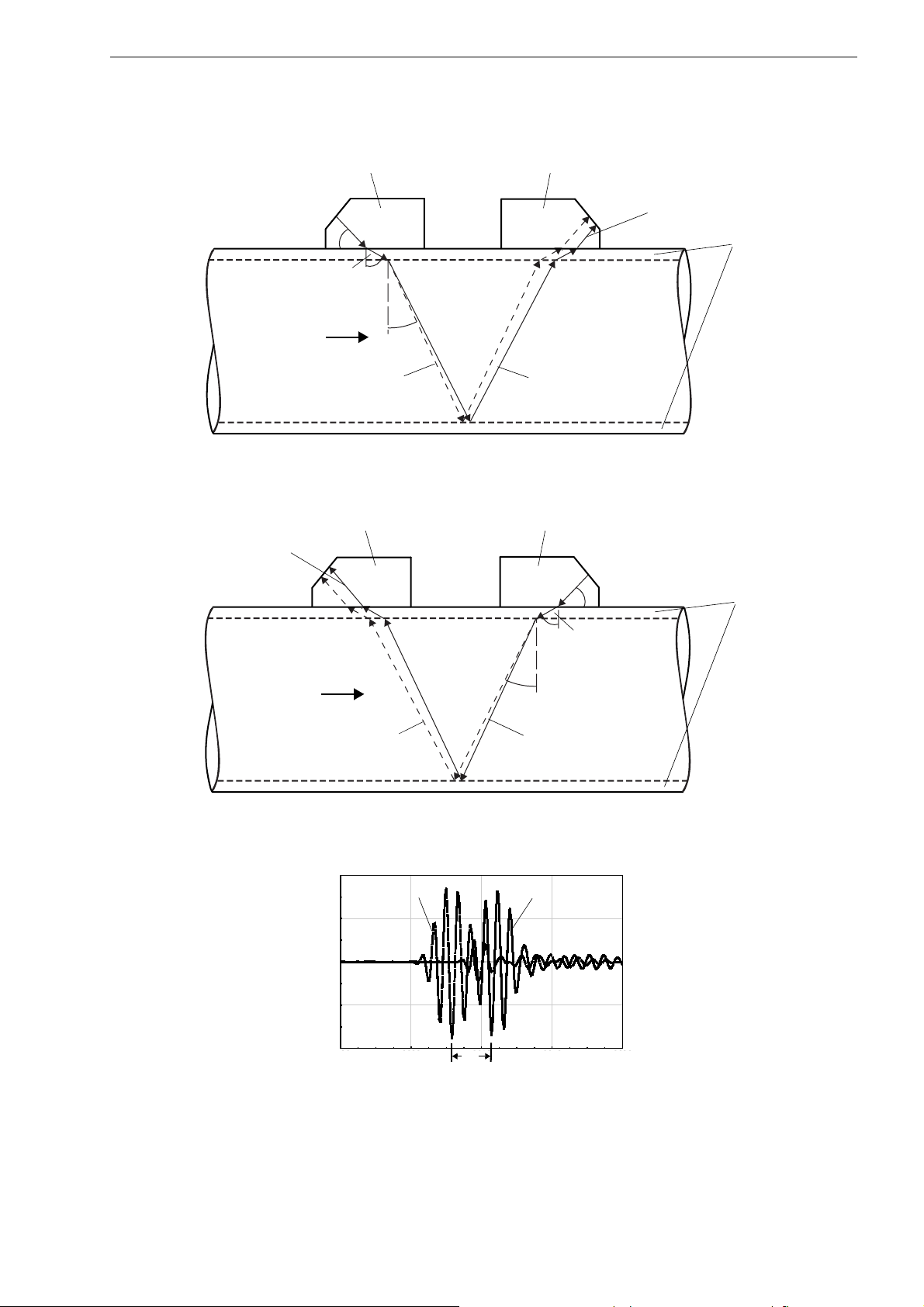

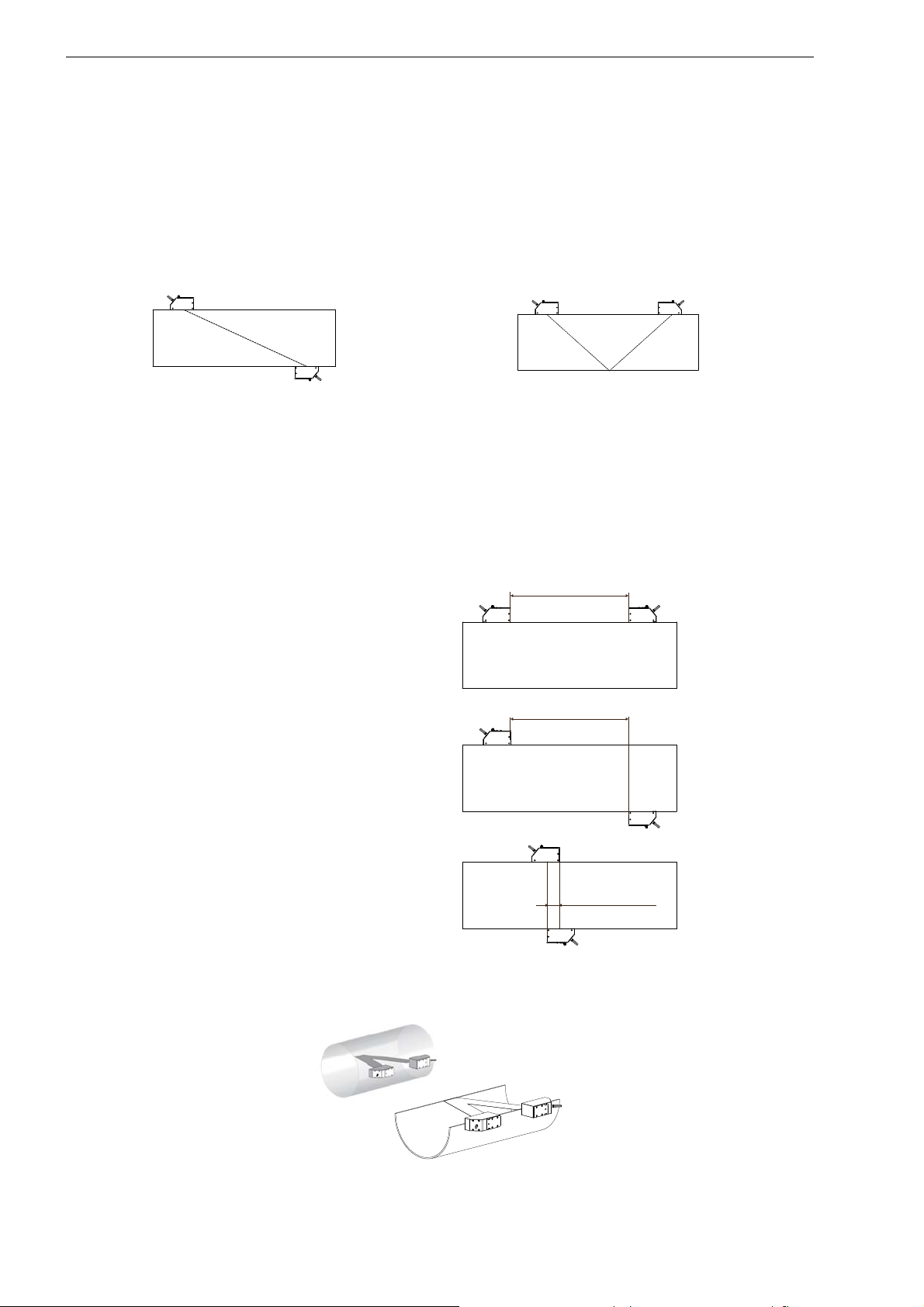

3.3.1 Terms and Definitions

Diagonal arrangement

The transducers are mounted on the opposite sides of the pipe (see Fig. 3.5).

Reflection arrangement

The transducers are mounted on the same side of the pipe (see Fig. 3.6).

Fig. 3.5: Diagonal arrangement Fig. 3.6: Reflection arrangement

Number of sound paths

The number of times the ultrasonic signal traverses the liquid before arriving at the receiving transducer. The number of

sound paths is:

• odd if the measurement is conducted in the diagonal arrangement (see Fig. 3.5)

• even if the measurement is conducted in the reflection arrangement (see Fig. 3.6).

Transducer distance

Distance between the transducers. It is measured between the inner edges of the transducers.

reflection arrangement

diagonal arrangement

(positive transducer distance)

diagonal arrangement

(negative transducer distance)

Sound plane

The plane containing the sound paths (see Fig. 3.7).

12 PORTALOK_7SV4-5-1EN, 2014-09-01

Fig. 3.7: Sound paths in a sound plane

3 General Principles Portalok 7S

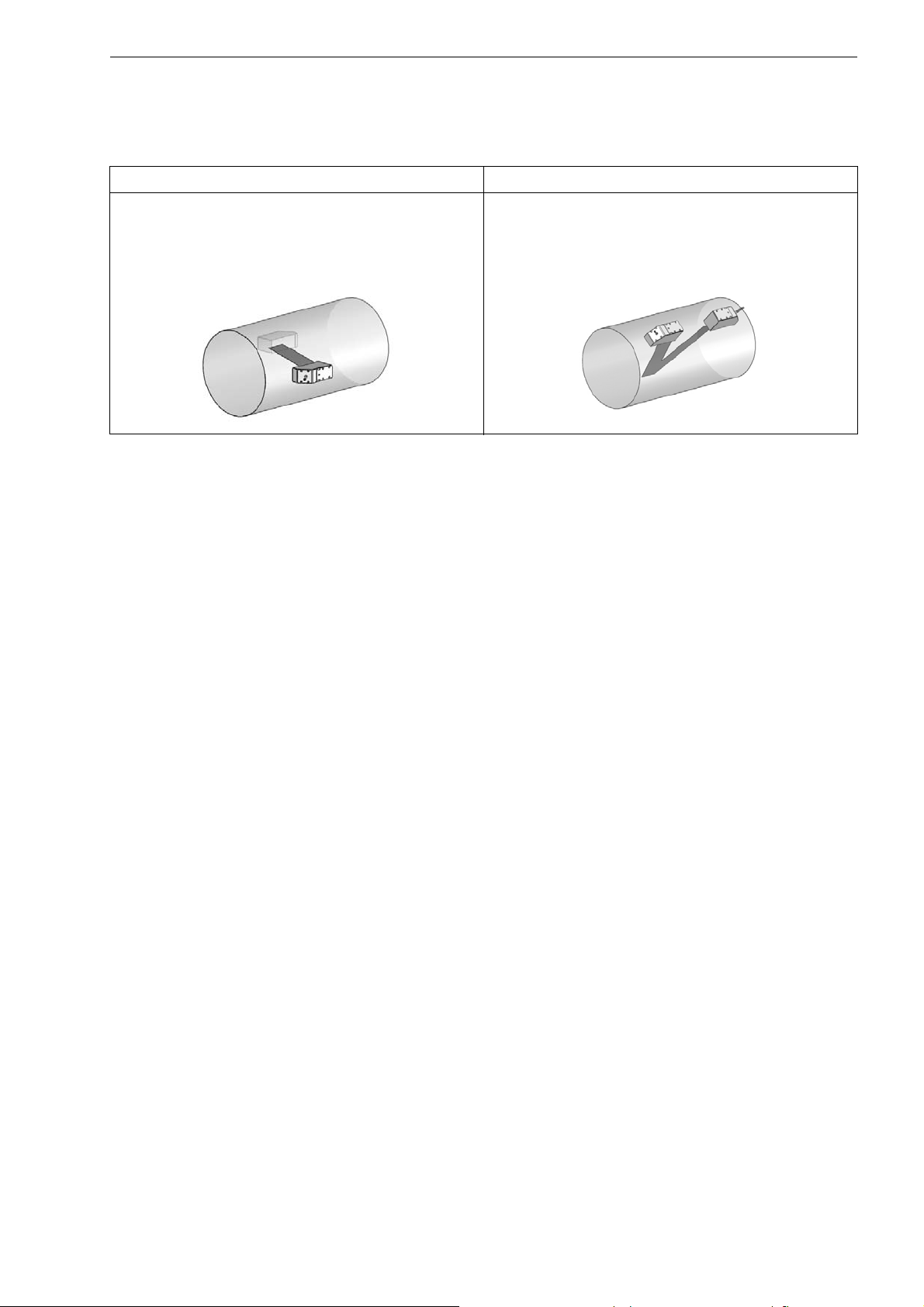

3.3.2 Examples

Diagonal arrangement Reflection arrangement

1 transducer pair

1 sound path

1 transducer pair

2 sound paths

PORTALOK_7SV4-5-1EN, 2014-09-01 13

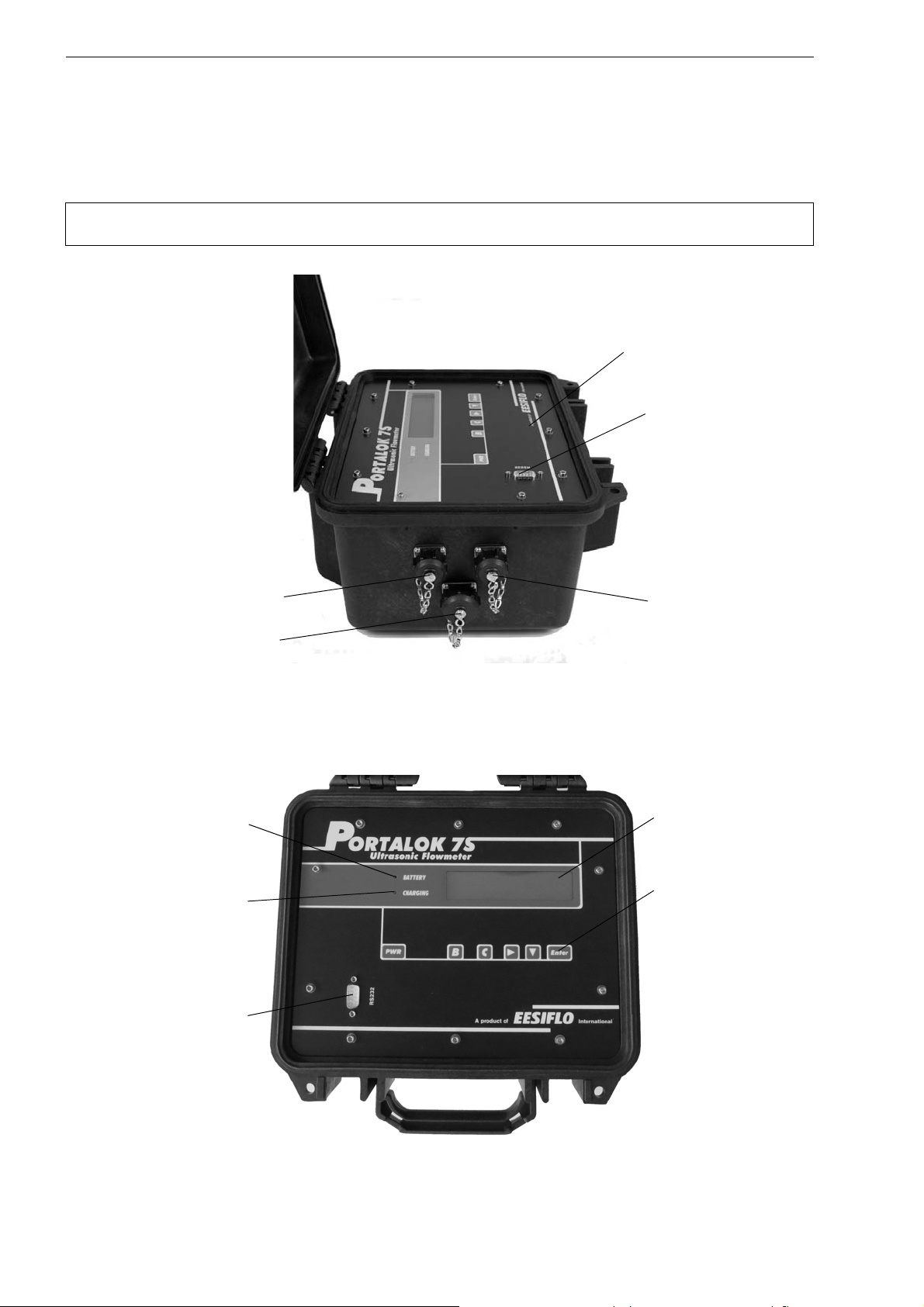

Portalok 7S 4 Description of the Transmitter

RS232 interface

command panel

output

transducer

power supply

2x 16-digit LCD display,

backlit

keyboard

RS232 interface

state indicator

"BATTERY"

state indicator

"CHARGING"

4 Description of the Transmitter

The transmitter Portalok 7S has 1 measuring channel.

The cover has to be opened to access the command panel.

Attention! The degree of protection of the transmitter is only ensured if the cable glands are firmly tightened,

the housing is tightly screwed and the cover is closed and latched.

Fig. 4.1: Connections and command panel of the transmitter Portalok 7S

Fig. 4.2: Command panel of the transmitter Portalok 7S

14 PORTALOK_7SV4-5-1EN, 2014-09-01

4 Description of the Transmitter Portalok 7S

4 Description of the Transmitter

4.1 Keyboard

The keyboard consists of 5 keys.

Tab. 4.1: General functions

PWR switching the transmitter on/off, switching the backlight on/off

Press key PWR briefly to switch on the transmitter or to switch on/off the backlight when the

transmitter is on. Press key PWR for 3 seconds to switch off the transmitter.

ENTER confirmation of selection or entered value

B + C INIT: Press these two keys while switching on the transmitter to perform an initialization (see

section 8.2).

B + C + ENTER RESET: Press these three keys simultaneously to correct a malfunction. The reset has the

same effect as restarting the transmitter. Stored data are not affected.

B interruption of the measurement and selection of the main menu

Be careful not to stop a current measurement by inadvertently pressing key B!

Tab. 4.2: Navigation

scrolling to the right or up through a scroll list

scrolling to the left or down through a scroll list

Tab. 4.3: Input of digits

moving the cursor to the right

scrolling through the digits above the cursor

C Moving the cursor to the left. If the cursor is on the left margin:

• an already edited value will be reset to the value which was stored previously

• an unedited value will be deleted.

If the entered value is not valid, an error message will be displayed. Press ENTER and enter a

correct value.

Tab. 4.4: Input of text

moving the cursor to the right

scrolling through the characters above the cursor

C resetting all characters to the last stored entry

PORTALOK_7SV4-5-1EN, 2014-09-01 15

Portalok 7S 5 Selection of the Measuring Point

5 Selection of the Measuring Point

Attention! Portalok 7S is must not be used in explosive atmospheres. If the measuring point is within a poten-

tially explosive atmosphere, the danger zone and gases that may be present have to be determined.

The transducers and the transmitter have to be appropriate for these conditions.

The correct selection of the measuring point is crucial for achieving reliable measurement results and a high measurement

accuracy.

A measurement on a pipe is possible if

• the ultrasound propagates with a sufficiently high amplitude (see section 5.1)

• the flow profile is fully developed (see section 5.2)

The correct selection of the measuring point and thus, the correct transducer positioning guarantees that the sound signal

will be received under optimum conditions and evaluated correctly.

Due to the variety of applications and the different factors that influence the measurement, there is no standard solution for

the transducer positioning. The correct position of the transducers is influenced by the following factors:

• diameter, material, lining, wall thickness and shape of the pipe

• medium

• gas bubbles in the medium

Avoid measuring points in the vicinity of deformations and defects of the pipe and in the vicinity of welds.

Avoid locations with deposit formation in the pipe.

The ambient temperature at the measuring point has to be within the operating temperature range of the transducers.

Select the location of the transmitter within cable reach of the measuring point.

The ambient temperature at the location has to be within the operating temperature range of the transmitter.

5.1 Acoustic Penetration

The pipe has to be acoustically penetrable at the measuring point. The acoustic penetration is reached when pipe and medium do not attenuate the sound signal so strongly that it is completely absorbed before reaching the second transducer.

The attenuation in the pipe and in the medium depends on:

• kinematic viscosity of the medium

• proportion of gas bubbles and solids in the medium

• deposits on the inner pipe wall

• pipe material

The following requirements have to be met at the measuring point:

• the pipe is always filled completely

• no material deposits in the pipe

• no bubbles accumulate

Note! Even bubble-free media can form gas bubbles when the medium expands, e.g., before pumps and

after large increases of the pipe diameter.

Observe the notes in the following table.

16 PORTALOK_7SV4-5-1EN, 2014-09-01

5 Selection of the Measuring Point Portalok 7S

Tab. 5.1: Recommended transducer position

Horizontal pipe

Select a measuring point where the transducers can be mounted on the side of the pipe, allowing the sound waves to

propagate in the pipe horizontally. Thus, solid at the bottom or gas bubbles at the top of the pipe will not influence the

propagation of the signal.

correct: disadvantageous:

Vertical pipe

Select the measuring point at a pipe location where the medium flows upward. The pipe has to be completely filled.

correct: disadvantageous:

Free inlet or outlet pipe section:

Select the measuring point at a pipe location where the pipe cannot run empty.

correct: disadvantageous:

correct: disadvantageous:

PORTALOK_7SV4-5-1EN, 2014-09-01 17

Portalok 7S 5 Selection of the Measuring Point

l

l

l

l

l

l

5.2 Undisturbed Flow Profile

Some flow elements (elbows, slide valves, valves, control valves, pumps, reducers, diffusers, etc.) distort the flow profile

in their vicinity. The axisymmetrical flow profile needed for correct measurement is no longer given. A careful selection of

the measuring point helps to reduce the impact of disturbance sources.

It is most important that the measuring point is chosen at a sufficient distance from any disturbance sources. Only then it

can be assumed that the flow profile in the pipe is fully developed. However, measuring results can be obtained even if the

recommended distance to disturbance sources cannot be observed for practical reasons.

Recommended straight inlet and outlet pipe lengths for different types of flow disturbance sources are shown in the examples in Tab. 5.2.

Tab. 5.2: Recommended distance from disturbance sources

D = nominal pipe diameter at the measuring point, l = recommended distance

disturbance source: 90° elbow

supply line: l ≥ 10 D return line: l ≥ 5 D

disturbance source: 2x 90° elbows in same plane

supply line: l ≥ 25 D return line: l ≥ 5 D

disturbance source: 2x 90° elbows in different planes

supply line: l ≥ 40 D return line: l ≥ 5 D

18 PORTALOK_7SV4-5-1EN, 2014-09-01

5 Selection of the Measuring Point Portalok 7S

l

l

l

l

l

l

l

l

Tab. 5.2: Recommended distance from disturbance sources

D = nominal pipe diameter at the measuring point, l = recommended distance

disturbance source: T piece

supply line: l ≥ 50 D return line: l ≥ 10 D

disturbance source: diffuser

supply line: l ≥ 30 D return line: l ≥ 5 D

disturbance source: valve

supply line: l ≥ 40 D return line: l ≥ 10 D

disturbance source: reducer

supply line: l ≥ 10 D return line: l ≥ 5 D

PORTALOK_7SV4-5-1EN, 2014-09-01 19

Portalok 7S 5 Selection of the Measuring Point

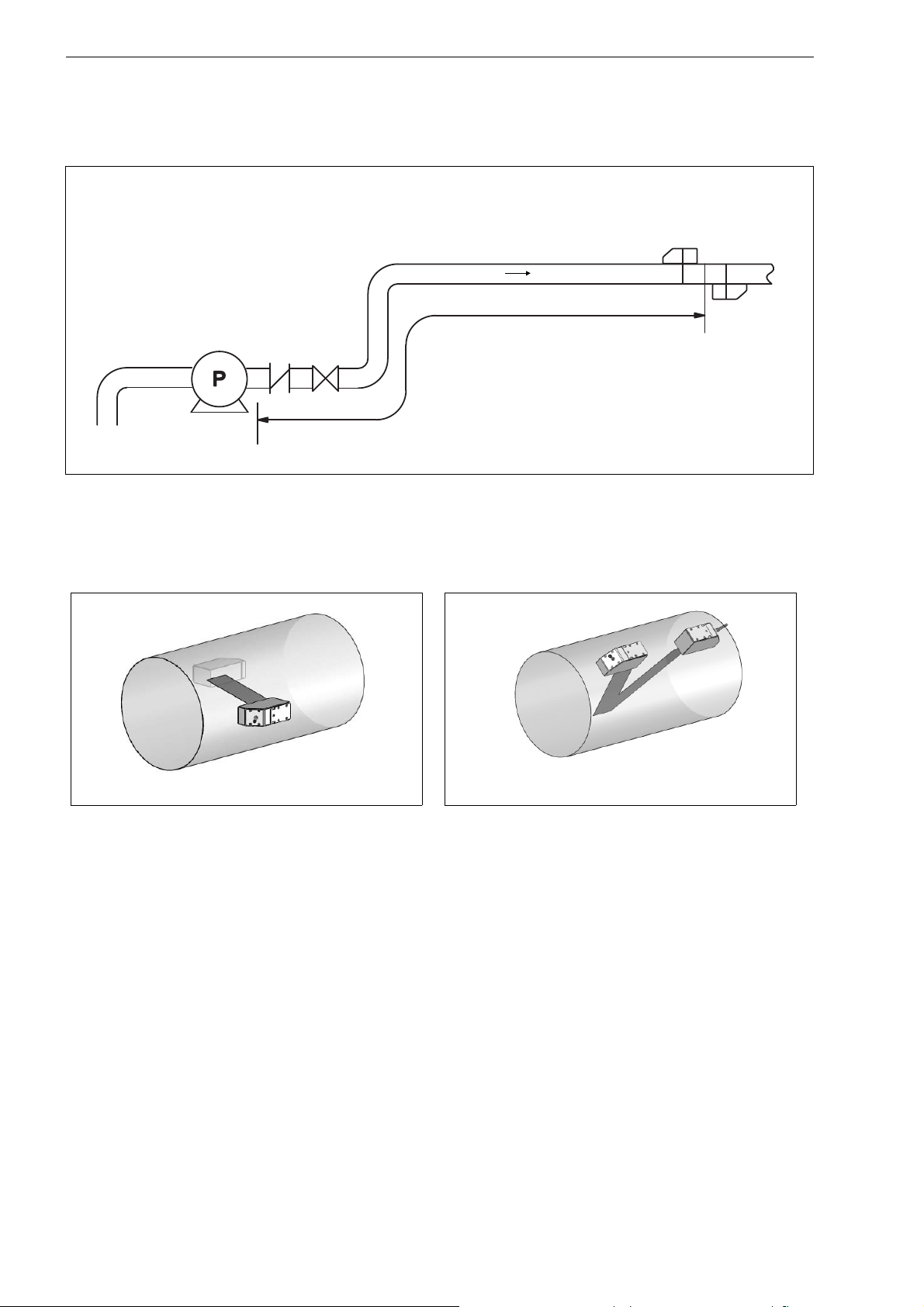

l

Tab. 5.2: Recommended distance from disturbance sources

D = nominal pipe diameter at the measuring point, l = recommended distance

disturbance source: pump

supply line: l ≥ 50 D

5.3 Selection of the Measurement Arrangement Taking onto Account the Measuring

Range and the Measuring Conditions

Diagonal arrangement Reflection arrangement

• wider flow velocity and sound speed range compared to

the reflection arrangement

• use in the presence of deposits on the inner pipe wall or

with strongly attenuating media (only 1 sound path)

• smaller flow velocity and sound speed range compared

to the diagonal arrangement

• transverse flow effects are compensated for because the

beam crosses the pipe in 2 directions

• higher accuracy of measurement because the accuracy

increases with the number of sound paths

20 PORTALOK_7SV4-5-1EN, 2014-09-01

5 Selection of the Measuring Point Portalok 7S

elbow plane

flow direction

elbow plane

flow direction

flow direction

5.4 Selection of the Sound Plane Near an Elbow

On vertical pipes On horizontal pipes

• The sound beam plane (see section 3.3) has an angle

of 90° to the elbow plane. The elbow is upstream of the

measuring point.

With measurements in both directions

• The sound beam plane (see section 3.3) is selected according to the nearest elbow (horizontal or vertical, depending on the pipe orientation - see above).

• The sound beam plane (see section 3.3) has an angle

of 90° ±45° to the elbow plane. The elbow is upstream

of the measuring point.

PORTALOK_7SV4-5-1EN, 2014-09-01 21

Portalok 7S 6 Installation of the Transmitter Portalok 7S

LOW BATTERY !

6 Installation of the Transmitter Portalok 7S

6.1 Location

Select the measuring point according to the recommendations in chapter 5. The ambient temperature has to be within the

operating temperature range of the transducers.

Select the location of the flowmeter within cable reach of the measuring point. The ambient temperature has to be within

the operating temperature range of the transmitter.

6.2 Connection of the Transducer

It is recommended to run the cables from the measuring point to the transmitter before connecting the transducers to

avoid load on the connectors.

Connect the transducer to the transmitter (see Fig. 4.1).

6.3 Power Supply

The transmitter can be operated with the battery (see section 6.3.1) or with the power supply unit (see section 6.3.2).

6.3.1 Power Supply with the Battery

The transmitter has a Li-Ion battery and can be operated independently of the power supply unit.

At delivery, the battery is charged approx. 30 %. The battery does not need to be fully charged before it is used for the first

time.

This message will be displayed if the battery is almost empty:

The capacity is sufficient for the display and storing of the current parameter record. A

measurement is no longer possible.

Charging the battery

Connect the power supply unit to the transmitter (see Fig. 4.1). Switch on the transmitter. Charging starts automatically.

The max. charging time is approx. 8 h.

During the charging process, the ambient temperature should be in the range 0...45 °C (32...113 °F).

A measurement can be made during the charging process. Charging will be stopped automatically when the battery is fully

charged.

Storage of the battery

The battery remains in the transmitter. After storage, the transmitter can immediately be operated with the battery.

• charge state: > 30 %

• storing temperature: 12...25 °C (54...77 °F)

State of the battery

The transmitter Portalok 7S has 2 LEDs which indicate the state of the battery.

The state indicator "BATTERY"

• is off when the battery is charged to > 50 %

• is on when the battery is charged to 20...50 %

• blinks when the battery is charged to < 20 %.

The state indicator "CHARGING"

• is off when the transmitter is not connected to the power supply

• is on when the transmitter is connected to the power supply and the battery is fully charged

• blinks when the transmitter is connected to the power supply and the battery is being charged.

6.3.2 Power Supply with the Power Supply Unit

Attention! • Use only the power supply unit supplied by EESiFlo.

• Connect the power supply unit to the transmitter (see Fig. 4.1).

22 PORTALOK_7SV4-5-1EN, 2014-09-01

• The power supply unit is not protected against moisture. Use it only in dry rooms.

• The voltage indicated on the power supply unit must not be exceeded.

• Do not connect a defective power supply unit to the transmitter.

6 Installation of the Transmitter Portalok 7S Portalok 7S

+

-

+

-

mA

a

b

A

B

C

D

6.4 Connection of the Output

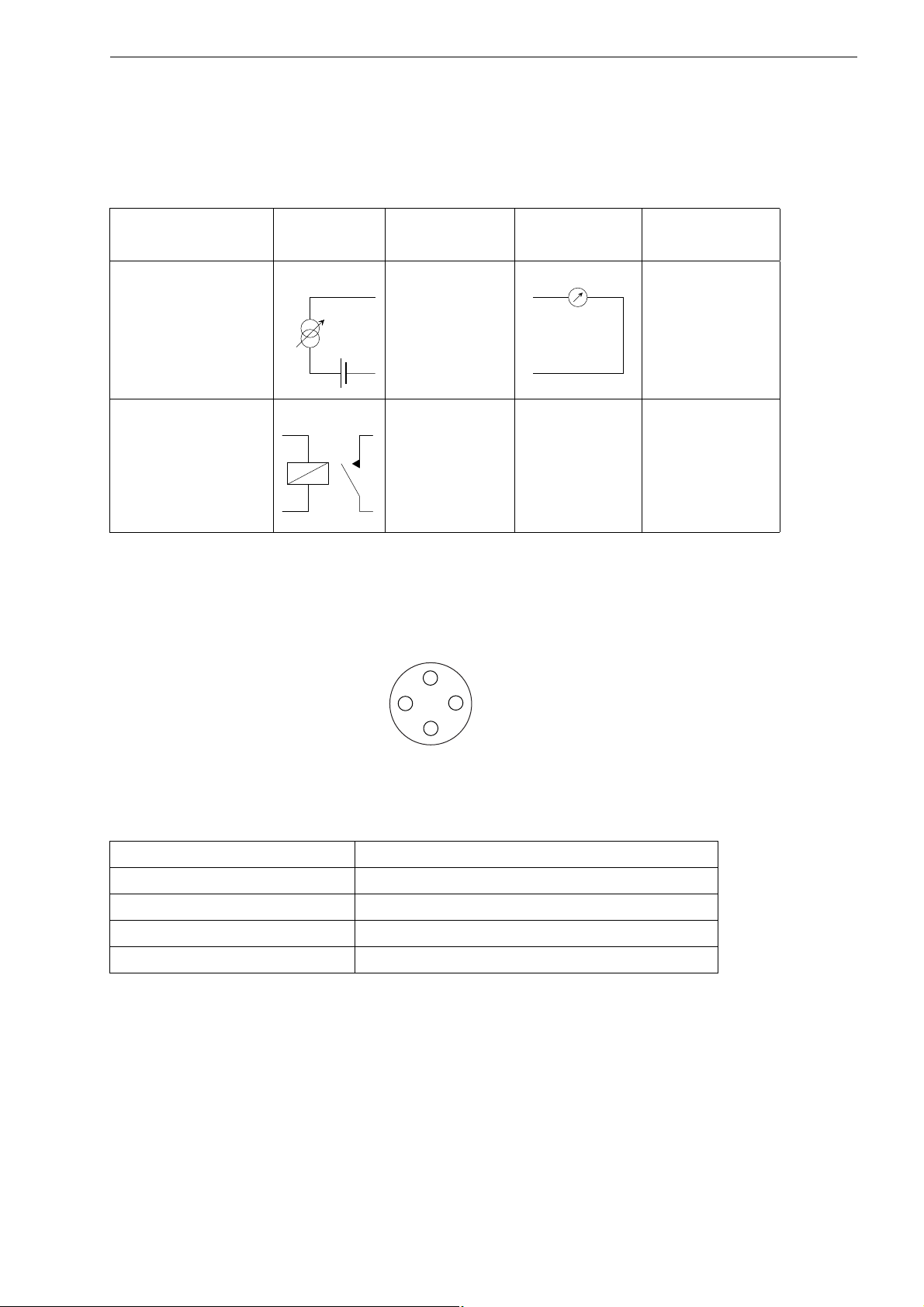

For the connection of the output see Fig. 4.1, Fig. 6.1, Tab. 6.1 and Tab. 6.2.

Tab. 6.1: Circuits of the outputs

output transmitter external circuit remark

internal circuit connection

active current loop

binary output

(Reed relay)

see Fig. 6.1

see Fig. 6.1

R

< 500 Ω

ext

U

max

I

= 250 mA

max

= 48 V

The number, type and connections of the outputs are customized.

R

is the sum of all ohmic resistances in the circuit (e.g,. resistance of the conductors, resistance of the amperemeter/

ext

voltmeter).

Fig. 6.1: Pin assignment for the connection of the output

Tab. 6.2: Pin assignment for the connection of the output

pin connection

A (+) binary output B1 (Reed relay)

B (-) binary output B1 (Reed relay)

C (+) current output I1

D (-) current output I1

6.5 Connection of the Serial Interface

Connect the RS232 cable to the transmitter (see Fig. 4.1 and Fig. 4.2) and the serial interface of the PC. If the RS232 cable cannot be connected to the PC, use an RS232/USB adapter.

PORTALOK_7SV4-5-1EN, 2014-09-01 23

Portalok 7S 7 Installation of the Transducers

transducer distance

7 Installation of the Transducers

7.1 Preparation of the Pipe

• The pipe has to be stable. It has to be able to withstand the pressure exerted by the transducer mounting fixture.

Rust, paint or other deposits on the pipe absorb the sound signal. A good acoustic contact between the pipe and the transducers is obtained as follows:

• Clean the pipe at the selected measuring point:

- If present, the paint layer has to be smoothed by sanding. The paint does not need to be removed completely.

- Remove any rust or loose paint.

• Use coupling foil or apply a bead of acoustic coupling compound along the center line of the contact surface of the

transducers.

• Observe that there must be no air pockets between the transducer contact surface and the pipe wall.

7.2 Orientation of the Transducers and Transducer Distance

Mount the transducers onto the pipe in such way that the engravings on the transducers form an arrow (see Fig. 7.1). The

transducer cables show in opposite directions.

The transducer distance is the distance between the inner edges of the transducers (see section 3.3 and Fig. 7.1)

For the determination of the flow direction see section 9.8.

Fig. 7.1: Correct orientation of the transducers and transducer distance

7.3 Installation

Fix the transducers onto the pipe using the supplied mounting hardware.

24 PORTALOK_7SV4-5-1EN, 2014-09-01

8 Start-up of the Transmitter Portalok 7S

EESIFLO

EESXXXX-XXXXXXX

>PAR<mea opt sf

Parameter

INITIALISATION

----DONE----

FACTORY DEFAULT?

no >YES<

Delete Meas.Val.

no >YES<

>PAR<mea opt sf

Parameter

8 Start-up of the Transmitter

8.1 Switching on

Press key PWR to switch on the transmitter. The serial number of the transmitter is displayed for a short time.

Data cannot be entered while the serial number is displayed.

After the transmitter is switched on, the main menu is displayed in the default language.

The language of the display can be set (see section 8.5).

8.2 Initialization

During an initialization (INIT) of the transmitter, the settings in the program branches Parameter and Output Options

and some of the settings in the program branch Special Funct. are reset to the default settings of EESiFlo.

For INIT-resistant settings, see annex A.

Proceed as follows to execute an initialization:

• While switching on the transmitter: keep keys B and C pressed.

• During the operation of the transmitter: press keys B, C and ENTER at the same time. A RESET is executed. Release

key ENTER only. Keep keys B and C pressed.

After the initialization has been executed, the message INITIALISATION DONE is displayed.

After the initialization, the remaining settings of the transmitter can be reset to the default settings and/or the stored measured values can be deleted.

Select yes to reset the remaining settings to the default settings or no to keep them at the

current settings.

Press ENTER.

If yes is selected, the message FACTORY DEFAULT DONE will be displayed.

Select yes to delete the stored measured values or no to keep them stored.

Press ENTER.

This display will only be indicated if measured values are stored in the data logger.

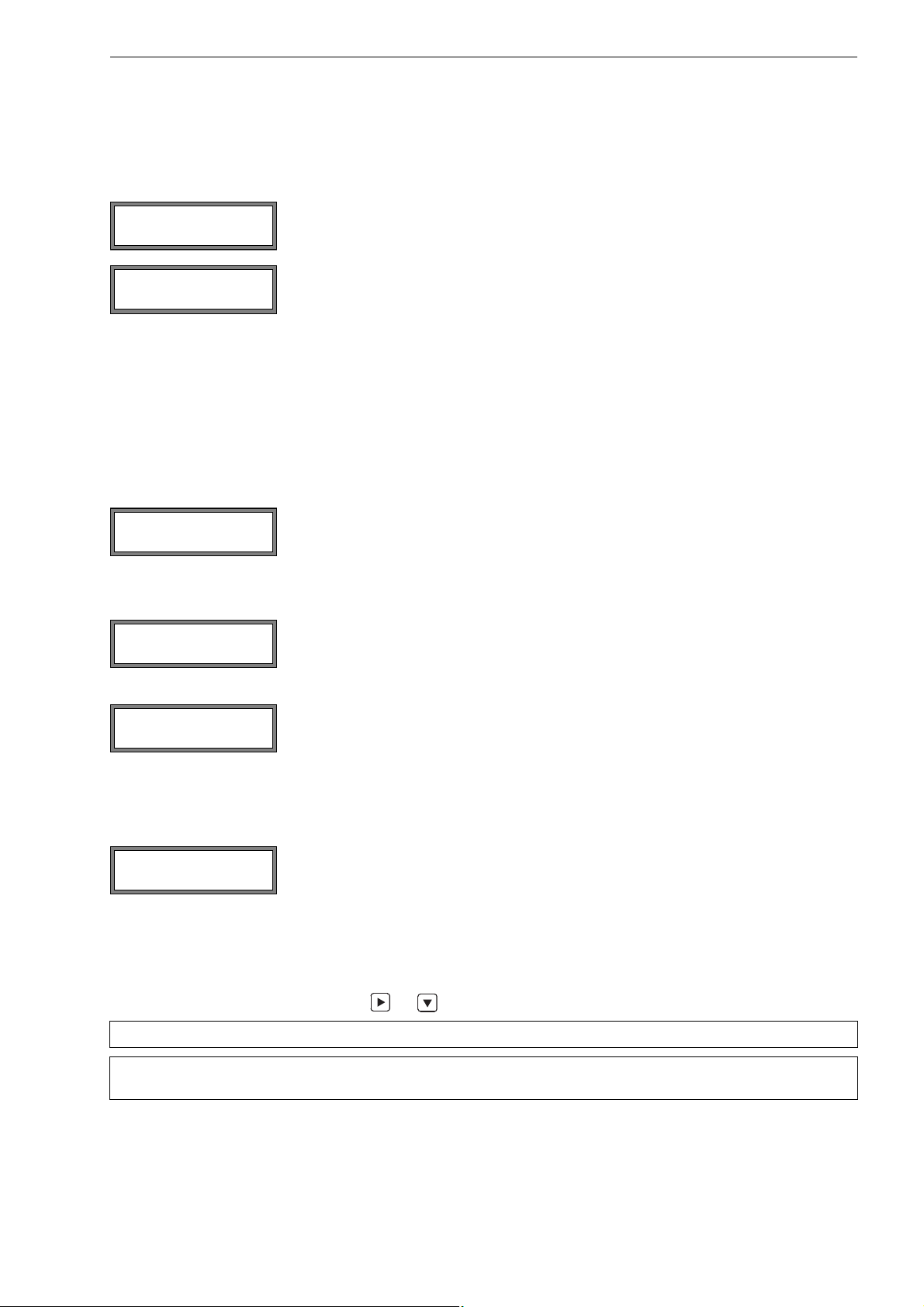

8.3 Display

8.3.1 Main Menu

The main menu contains the following program branches:

• par (Parameter)

• mea (Measuring)

• opt (Output Options)

• sf (Special Function)

The selected program branch is displayed in capital letters and in angle brackets. The complete designation of the selected program branch is displayed in the lower line.

Select a program branch by pressing key or . Press ENTER.

Note! By pressing key B, the measurement will be stopped and the main menu is selected.

Note! In this user manual, all program entries and keys are indicated with typewriter characters (Parame-

PORTALOK_7SV4-5-1EN, 2014-09-01 25

ter). The menu items are separated from the main menu by a backslash "\".

Portalok 7S 8 Start-up of the Transmitter

Parameter

>par<

↓

pipe parameters

↓

medium

parameters

↓

transducer type

↓

extension cable

Measuring

>mea<

↓

measuring

point number

↓

sound path

↓

transducer

positioning

↓

measurement

↓

consistency check

Output Options

>opt<

↓

physical quantity

↓

unit of

measurement

↓

damping

↓

measured value

transmission

Special Funct.

>sf<

↓

system settings¹

↓

instrument

information

↓

print measured

values

↓

delete measured

values

↓

program code

↓

install material

↓

install medium

8.3.2 Program Branches

• Program branch Parameter

input of the pipe and medium parameters

• Program branch Measuring

processing of the steps for the measurement

• Program branch Output Options

setting of the physical quantity, the unit of measurement and the parameters for the measured value transmission

• Program branch Special Funct.

contains all functions that are not directly related to the measurement

For an overview of the program branches see figure below. For a detailed overview of the menu structure see annex A.

¹ SYSTEM settings contains the following menu items:

• dialogs and menus

• measuring

• outputs

•storing

• serial transmission

• miscellaneous

• set clock

• libraries

26 PORTALOK_7SV4-5-1EN, 2014-09-01

8 Start-up of the Transmitter Portalok 7S

SYSTEM settings↕

Dialogs/Menus

Lining

no >YES<

R1=FUNC<typ mode

Function: MAX

SYSTEM settings↕

Miscellaneous

Input a HOTCODE

no >YES<

Please input a

HOTCODE: 000000

INVALID HOTCODE

hotcode: 000000

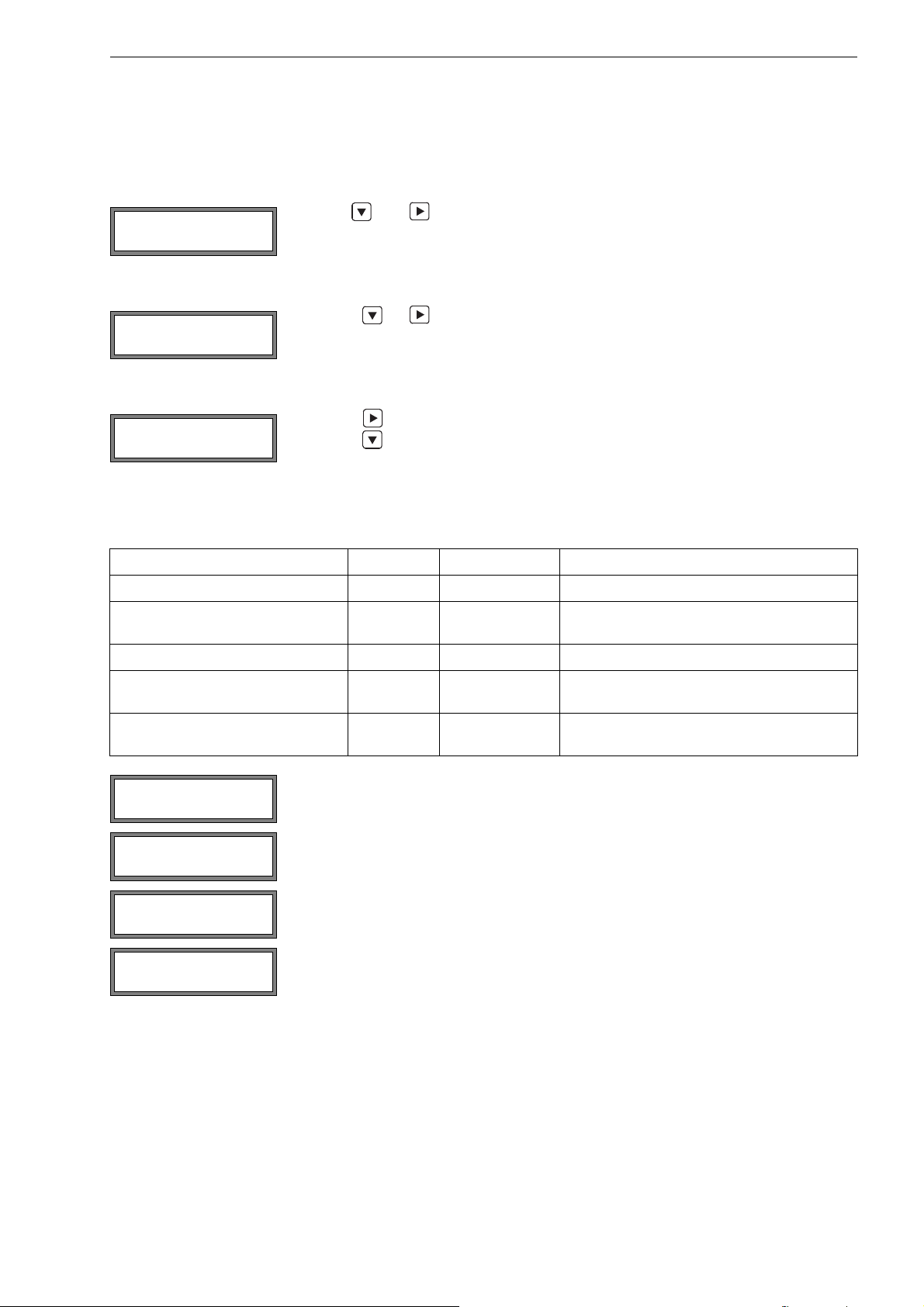

8.3.3 Navigation

A vertical arrow ↕ will be displayed if the menu item contains a scroll list. The current list item will be displayed in the lower

line.

Use key and to select a list item in the lower line. Press ENTER.

Some menu items contain a horizontal scroll list in the lower line. The selected list item is displayed in capital letters and

in angle brackets.

Press key or to scroll through the lower line and select a list item. Press ENTER.

Some menu items contain a horizontal scroll list in the upper line. The selected list item is displayed in capital letters and

in angle brackets. The current value of the list item is displayed in the lower line.

Press key to scroll through the upper line and select a list item.

Press key to scroll through the lower line and select a value for the selected list item.

Press ENTER.

8.4 HotCodes

A HotCode is a key sequence that activates certain functions and settings:

function HotCode see section deactivation

language selection 9090xx 8.5

manual input of the lower limit for

the inner pipe diameter

activation of the SuperUser mode 071049 15.1 HotCode 071049

change of the transmission parameters of the RS232 interface

resetting the contrast of the display

to medium

Select Special Funct.\SYSTEM settings\Miscellaneous.

Select yes to enter a HotCode.

Enter the HotCode. Press ENTER.

071001 11.7

232-0- 12.2.4

555000 14.4

PORTALOK_7SV4-5-1EN, 2014-09-01 27

An error message will be displayed if an invalid HotCode has been entered. Press ENTER.

Portalok 7S 8 Start-up of the Transmitter

8.5 Language Selection

The transmitter can be operated in the languages listed below. The language can be selected with the following HotCodes:

Tab. 8.1: HotCodes for language selection

909031 Dutch

909033 French

909034 Spanish

909044 English

909049 German

Depending on the technical data of the transmitter, some of the languages might not be implemented.

When the last digit has been entered, the main menu will be displayed in the selected language.

The selected language remains activated when the transmitter is switched off and on again. After an initialization, the default language set by EESIFLo is activated.

28 PORTALOK_7SV4-5-1EN, 2014-09-01

9 Basic Measurement Portalok 7S

>PAR<mea opt sf

Parameter

Outer Diameter

100.0 mm

Outer Diameter

1100.0 MAXIMAL

Wall Thickness

3.0 mm

Pipe Material ↕

Carbon Steel

c-Material

3230.0 m/s

9 Basic Measurement

The pipe and medium parameters are entered for the selected measuring point (see chapter 5). The parameter ranges are

limited by the technical characteristics of the transducers and of the transmitter.

Note! During the parameter input, the transducers should be connected to the transmitter.

Note! The parameters will only be stored when the program branch Parameter has been edited in its en-

tirety.

9.1 Input of the Pipe Parameters

Select the program branch Parameter. Press ENTER.

9.1.1 Outer Pipe Diameter/Pipe Circumference

Enter the outer pipe diameter. Enter the actual pipe diameter, not the nominal pipe diameter. Press ENTER.

An error message will be displayed if the entered parameter is outside of the range. The

limit will be displayed.

Example: upper limit 1100 mm for the connected transducers and for a pipe wall thickness

of 50 mm.

It is possible to enter the pipe circumference instead of the outer pipe diameter (see section 14.2.1).

If the input of the pipe circumference has been activated and 0 (zero) is entered for the Outer Diameter, the menu item

Pipe Circumfer. will be displayed. If the pipe circumference is not to be entered, press key B to return to the main

menu and start the parameter input again.

9.1.2 Pipe Wall Thickness

Enter the pipe wall thickness. Press ENTER.

Note! The inner pipe diameter (= outer pipe diameter - 2x pipe wall thickness) is calculated internally. If the

value is not within the inner pipe diameter range of the connected transducers, an error message will

be displayed.

It is possible to change the lower limit of the inner pipe diameter for a given transducer type (see section 11.7).

9.1.3 Pipe Material

The pipe material has to be selected to be able to determine the sound speed. The sound speed for the materials in the

scroll list are stored in the transmitter.

Select the pipe material.

If the medium is not in the scroll list, select Other Material. Press ENTER.

It can be specified which materials will be displayed in the scroll list (see section 13.5).

When the pipe material has been selected, the corresponding sound speed is set automatically. If Other Material has

been selected, the sound speed has to be entered.

Note! Enter the sound speed of the material (i.e. longitudinal or transversal speed) which is nearer to 2500

For the sound speed of some materials see annex C.1.

PORTALOK_7SV4-5-1EN, 2014-09-01 29

Enter the sound speed of the pipe material. Press ENTER.

m/s.

Portalok 7S 9 Basic Measurement

Lining

no >YES<

Lining ↕

Bitumen

c-Material

3200.0 m/s

Liner Thickness

3.0 mm

Roughness

0.4 mm

Medium ↕

Water

9.1.4 Pipe Lining

If the pipe has an inner lining, select yes. Press ENTER.

If no is selected, the next parameter will be displayed (see section 9.1.5).

Select the lining material.

If the material is not in the scroll list, select Other Material. Press ENTER.

It can be specified which materials will be displayed in the scroll list (see section 13.5).

If Other Material is selected, the sound speed has to be entered.

Enter the sound speed of the lining material. Press ENTER.

For the sound speed of some materials see annex C.1.

Enter the thickness of the liner. Press ENTER.

Note! The inner pipe diameter (= outer pipe diameter - 2x pipe wall thickness - 2x liner thickness) is calcu-

lated internally. If the value is not within the inner pipe diameter range of the connected transducers,

an error message will be displayed.

It is possible to change the lower limit of the inner pipe diameter for a given transducer type (see section 11.7).

9.1.5 Pipe Roughness

The flow profile of the medium is influenced by the roughness of the inner pipe wall. The roughness is used for the calculation of the profile correction factor. As, in most cases, the pipe roughness cannot be determined exactly, it has to be estimated.

For the roughness of some materials see annex C.2.

Enter the roughness of the selected pipe or liner material.

Change the value according to the condition of the inner pipe wall. Press ENTER.

9.2 Input of the Medium Parameters

Select the medium from the scroll list.

If the medium is not in the scroll list, select Other Medium. Press ENTER.

It is possible to specify which media will be displayed in the scroll list (see section 13.5).

For the programmed parameters of common media see annex C.3.

If a medium is selected from the scroll list, the menu item for the input of the medium temperature is displayed directly (see

section 9.2.4).

If Other Medium is selected, the medium parameters have to be entered first:

• average sound speed of the medium

• range around the average sound speed of the medium

• kinematic viscosity

• density

30 PORTALOK_7SV4-5-1EN, 2014-09-01

9 Basic Measurement Portalok 7S

c-Medium

1500.0 m/s

c-Medium range

auto >USER<

c-Medium=1500m/s

range +-150m/s

Kinem.Viscosity

1.00 mm2/s

Density

1.00 g/cm3

Medium Temperat.

20.0 C

Transducer Type↕

Standard

Additional cable

65.0 m

9.2.1 Sound Speed

The sound speed of the medium is used for the calculation of the transducer distance at the beginning of the measurement. However, the sound speed does affect the measuring result directly. Often, the exact value of the sound speed for a

medium is unknown. Therefore, a range of possible values for the sound speed has to be entered.

Enter the average sound speed of the medium. Press ENTER.

This display will only be indicated if Other Medium is selected.

Select auto or user. Press ENTER.

auto: The area around the average sound speed is defined by the transmitter.

user: The area around the average sound speed has to be entered.

Enter the area around the average sound speed of the medium. Press ENTER.

This display will only be indicated if user is selected.

9.2.2 Kinematic Viscosity

The kinematic viscosity has an effect on the flow profile of the medium. The entered value and other parameters are used

for the profile correction.

Enter the kinematic viscosity of the medium. Press ENTER.

This display will only be indicated if

Other Medium is selected.

9.2.3 Density

The density is used to calculate the mass flow (product of the volumetric flow rate and the density).

Note! If the mass flow is not measured, press ENTER. The other measuring results will not be affected.

Enter the operating density of the medium. Press ENTER.

This display will only be indicated if Other Medium is selected.

9.2.4 Medium Temperature

At the beginning of the measurement, the medium temperature is used for the interpolation of the sound speed and thus,

for the calculation of the recommended transducer distance.

During the measurement, the medium temperature is used for the interpolation of the density and the viscosity of the medium.

Enter the medium temperature. The value has to be within the operating temperature range

of the transducers. Press ENTER.

9.3 Other Parameters

9.3.1 Transducer Parameters

Select Standard to use the standard transducer parameters stored in the transmitter.

Press ENTER.

This display will only be indicated if no transducers are connected to the transmitter.

9.3.2 Extension Cable

PORTALOK_7SV4-5-1EN, 2014-09-01 31

If the transducer cable has to be extended, enter the additional cable length (e.g., between

the junction box and the transmitter). Press ENTER.

Portalok 7S 9 Basic Measurement

par>MEA<opt sf

Measuring

par>MEA<opt sf

NO DATA!

Meas.Point No.:

xxx (↑↓← →)

A:

2 NUM

Sound Path

2NUM

Transd. Distance

54 mm Reflec

9.4 Defining the Measuring Point Number

Select program branch Measuring. Press ENTER.

If this error message is displayed, the parameters are not complete. Enter the missing parameters in the program branch Parameter.

Optional: If the data logger or the serial interface is activated, the measuring point number has to be entered:

Enter the measuring point number. Press ENTER.

If arrows are displayed in the lower line on the right, ASCII text can be entered. If no arrows

are displayed, only digits, point and hyphen can be entered.

9.5 Defining the Number of Sound Paths

A number of sound paths is recommended according to the connected transducers and the

entered parameters. Change the value, if necessary.

Press ENTER.

For defining the number of sound paths, see section 3.3.

9.6 Transducer Distance

A value for the transducer distance is recommended. Fix the transducers (see chapter 7).

Adjust the transducer distance.

Press ENTER.

Reflec - reflection arrangement

Diagon - diagonal arrangement

The transducer distance is the distance between the inner edges of the transducers (see section 3.3 and Fig. 7.1)

In case of a measurement in diagonal arrangement on very small pipes, a negative transducer distance is possible.

Note! The accuracy of the recommended transducer distance depends on the accuracy of the entered pipe

and medium parameters.

32 PORTALOK_7SV4-5-1EN, 2014-09-01

9 Basic Measurement Portalok 7S

Transd. Distance

54 mm !

S=

<>=54 mm!

S=■■■■■■

Q=■■■■■■■■■■■■

time= 94.0 μs

Q=■■■■■■■■■■■

Transd. Distance?

53.9 mm

L=(50.0) 54.0 mm

54.5 m3/h

→Adjust transd.

54.5 m3/h

Transd. Distance?

50.0 mm

L=(51.1) 50.0 mm

54.5 m3/h

9 Basic Measurement

9.6.1 Fine Adjustment of the Transducer Distance

If the displayed transducer distance is adjusted, press ENTER.

The measuring for the positioning of the transducers is started.

The amplitude of the received signal is displayed by the bar graph S=.

• Shift a transducer slightly within the range of the recommended transducer distance until

the bar graph reaches its max. length.

The following quantities can be displayed in the upper line by pressing key and in the

lower line by pressing key :

• ■<>■ =: transducer distance

• time: Transit time of the measuring signal in μs

• S=: signal amplitude

• Q=: signal quality, bar graph has to have max. length

If the signal is not sufficient for measurement, Q= UNDEF will be displayed.

In case of large deviations, check if the entered parameters are correct or repeat the measurement at a different point on

the pipe.

After the precise positioning of the transducers, the recommended transducer distance is

displayed again.

Enter the actual (precise) transducer distance. Press ENTER.

9.6.2 Consistency Check

If a wide range for the sound speed has been entered in the program branch Parameter or the exact parameters of the

medium are not known, a consistency check is recommended.

The transducer distance can be displayed during measurement by scrolling with key .

The optimum transducer distance (here: 50.0 mm) is displayed in the upper line in parentheses, followed by the entered transducer distance (here: 54.0 mm). The latter value has

to correspond to the adjusted transducer distance.

If necessary, scroll in the upper line until →Adjust transd. is displayed. Press ENTER.

The amplitude of the received signal S= is displayed again. Press ENTER to adjust the

transducer distance.

The optimum transducer distance is calculated on the basis of the measured sound speed. It is therefore a better approximation than the first recommended value which had been calculated on the basis of the sound speed range entered in the

program branch Parameter.

If the difference between the optimum and the entered transducer distance is less than specified in Tab. 9.1, the measurement is consistent and the measured values are valid. The measurement can be continued.

If the difference is greater, adjust the transducer distance to the displayed optimum value. Afterwards, check the signal

quality and the signal amplitude bar graph (see section 9.6.1). Press ENTER.

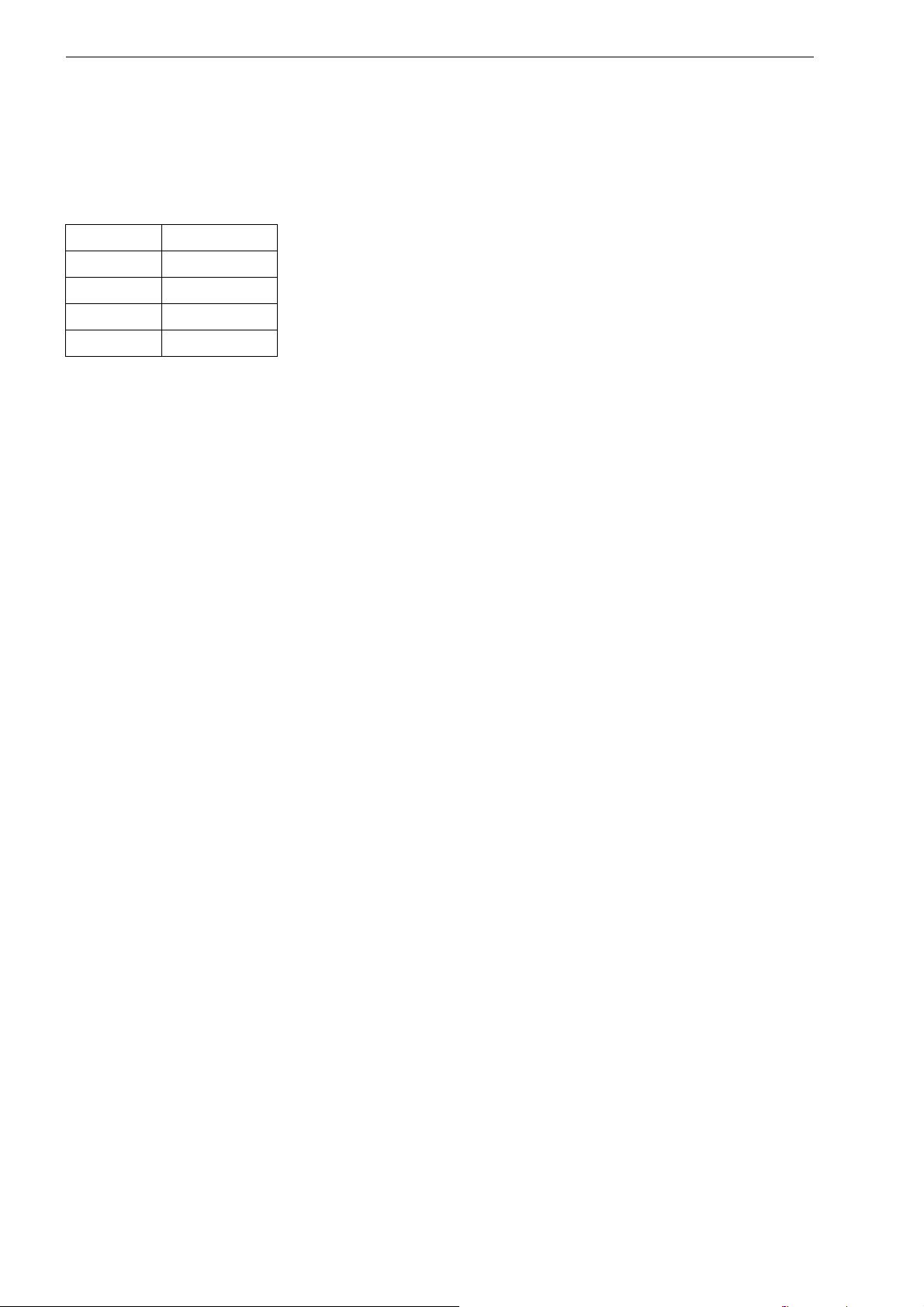

Tab. 9.1: Standard values for signal optimization

transducer frequency difference between the optimum and the entered transducer distance [mm]

M10

P10

Note! If the transducer distance is changed during the measurement, the consistency check will have to be

PORTALOK_7SV4-5-1EN, 2014-09-01 33

Enter the new adjusted transducer distance. Press ENTER.

Press key again to scroll until the transducer distance is displayed and check the difference between the optimum and the entered transducer distance. Repeat the steps if

necessary.

repeated.

Portalok 7S 9 Basic Measurement

Volume flow

31.82 m3/h

9.6.3 Value of the Sound Speed

The sound speed of the medium can be displayed during the measurement by pressing key .

If an approximate range for the sound speed has been entered in the program branch Parameter and the transducer distance has been optimized afterwards as described in section 9.6.2, it is recommended to write down the sound speed for

the next measurement. By doing this, it will not be necessary to repeat the fine adjustment.

Also write down the medium temperature because the sound speed depends on the temperature. The value can be entered in the program branch Parameter or a user defined medium can be created for this sound speed (see section 13.2

and 13.3).

9.7 Start of the Measurement

The measured values are displayed in the lower line.

If necessary, scroll in the upper line until →Adjust transd. is displayed and press EN-

TER to return to the fine adjustment of the transducer distance (see section 9.6.1).

The outputs and the serial interface continuously receive the measured values of the measuring channel. The results are

displayed according to the currently selected output options. The default unit of measurement of the volumetric flow rate is

m³/h. For the selection of the values to be displayed and for the setting of the output options see chapter 10. For further

measuring functions see chapter 11.

9.8 Detection of the Flow Direction

The flow direction in the pipe can be detected with the help of the displayed volumetric flow rate in conjunction with the arrow on the transducers:

• The medium flows in the direction of the arrow if the displayed volumetric flow rate is positive (e.g., 54.5 m³/h).

• The medium flows against the direction of the arrow if the displayed volumetric flow rate is negative (e.g., -54.5 m³/h).

9.9 Interruption of the Measurement

The measurement is interrupted by pressing key B if it is not protected by a program code (see section 11.8).

Note! Be careful not to stop a current measurement by inadvertently pressing key B!

34 PORTALOK_7SV4-5-1EN, 2014-09-01

10 Displaying the Measured Values Portalok 7S

par mea >OPT< sf

Output Options

Physic. Quant. ↕

Volume flow

Volume in: ↕

m3/h

10 Displaying the Measured Values

The physical quantity is set in the program branch Output Options (see section 10.1).

During the measurement, the designation of the physical quantity is displayed in the upper line, the measured value in the

lower line. The display can be adapted (see section 10.2).

10.1 Selection of the Physical Quantity and of the Unit of Measurement

The following physical quantities can be measured:

• sound speed

• flow velocity: calculated on the basis of the measured transit time difference

• volumetric flow rate: calculated by multiplying the flow velocity by the cross-section of the pipe

• mass flow rate: calculated by multiplying the volumetric flow rate by the operating density of the medium

The physical quantity is selected as follows:

Select the program branch Output Options. Press ENTER.

Select the physical quantity in the scroll list. Press ENTER.

For the selected physical quantity (except for the sound speed), a scroll list with the available units of measurement is displayed. The unit of measurement which was selected previously is displayed first.

Select the unit of measurement of the selected physical quantity. Press ENTER.

Press B to return to the main menu. The further menu items of the program branch Output Options are for the activation of the measured value transmission.

Note! If the physical quantity or the unit of measurement is changed, the settings of the outputs will have to

be checked (see chapter 16).

10.2 Adjustment of the Display

During the measurement, the display can be adapted as to display two measured values simultaneously (one in each line

of the display). This does not affect totalizing, transmission of the measured values, etc.

The following information can be displayed in the upper line:

display explanation

Mass Flow= designation of the physical quantity

+8.879 m3 values of the totalizers

full= date and time at which the data logger will be full, if activated

Mode= measuring mode

L= transducer distance

Rx= alarm state indication if it is activated (see section 16.6.5) and if alarm outputs are activated (see

section 16.6).

status line (see section 10.3)

The measured values of the physical quantity selected in the program branch Output Options can be displayed in the

lower line:

display explanation

12.3 m/s flow velocity

1423 m/s sound speed

124 kg/h mass flow rate

15 m3/h volumetric flow rate

PORTALOK_7SV4-5-1EN, 2014-09-01 35

Portalok 7S 10 Displaying the Measured Values

Flow Velocity

* 2.47 m/s

S3 Q9 c RT F

Press key during the measurement to change the display in the upper line, press key to change the display in

the lower line.

The character * indicates that the displayed value (here: flow velocity) is not the selected

physical quantity.

10.3 Status Line

Important data on the ongoing measurement are displayed in the status line. The quality and precision of the ongoing

measurement can be estimated.

Press key during the measurement to scroll through the upper line to the status line.

value explanation

S signal amplitude

0

…

9

< 5 %

…

90 %

Q signal quality

0

…

9

< 5 %

…

90 %

c sound speed

comparison of the measured and the expected sound speed of the medium. The expected sound

speed is calculated on the basis of the medium parameters (medium selected in the program branch

Parameter, temperature dependence).

√ ok, is equal to the expected value

↑ > 20 % of the expected value

↓ < 20 % of the expected value

? unknown, cannot be measured

R flow profile

information about the flow profile based on the Reynolds number

T fully turbulent flow profile

L fully laminar flow profile

↕ the flow is in the transition range between laminar and turbulent flow

? unknown, cannot be calculated

F flow velocity

comparison of the measured flow velocity with the flow limits of the system

√ ok, the flow velocity is not in the critical range

↑ the flow velocity is higher than the current limit

↓ the flow velocity is lower than the current cut-off flow (even if it is not set to zero)

0 the flow velocity is in the offset range of the measuring method

? unknown, cannot be measured

36 PORTALOK_7SV4-5-1EN, 2014-09-01

10 Displaying the Measured Values Portalok 7S

L=(51.2) 50.8 mm

54.5 m3/h

10.4 Transducer Distance

By pressing key during the measurement, it is possible to scroll to the display of the

transducer distance.

The optimum transducer distance (here: 51.2 mm) is displayed in parentheses in the upper line, followed by the entered

transducer distance (here: 50.8 mm).

The optimum transducer distance might change during the measurement (e.g., due to temperature fluctuations).

A deviation from the optimum transducer distance (here: -0.4 mm) is compensated internally.

Note! Never change the transducer distance during the measurement!

PORTALOK_7SV4-5-1EN, 2014-09-01 37

Portalok 7S 11 Advanced Measuring Functions

S=

<>=54 mm!

32.5 m3

54.5 m3/h

Damping

10 s

Volume flow

54.5 m3/h

32.5 m3

54.5 m3/h

NO COUNTING !

3.5 m/s

11 Advanced Measuring Functions

11.1 Command Execution during Measurement

Commands that can be executed during a measurement are displayed in the upper line. A command begins with the arrow →. If programmed, a program code has to be entered first (see section 11.8).

Press until the command is displayed. Press ENTER. The following commands are available:

Tab. 11.1: Commands that can be executed during the measurement

command explanation

→Adjust transd.

Select transducer positioning.

If a program code is active, the measurement will be continued 8 s after the last keyboard entry.

→Clear totalizer

All totalizers will be reset to zero.

→Break measure Stop the measurement and return to the main menu.

11.2 Damping Factor

Each displayed measured value is a floating average of all measured values of the last x seconds, with x being the damping factor. A damping factor of 1 s means that the measured values are not averaged because the measuring rate is approx 1/s. The default value of 10 s is appropriate for normal flow conditions.

Strongly fluctuating values caused by high flow dynamics require a higher damping factor.

Select the program branch Output Options. Press ENTER until the menu item Damping is displayed.

Enter the damping factor. Press ENTER.

Press B to return to the main menu.

11.3 Totalizers

Total volume or total mass of the medium at the measuring point can be determined.

There are two totalizers, one for the positive flow direction, one for the negative flow direction.

The unit of measurement used for totalizing corresponds to the volume or mass unit selected for the physical quantity.

The values of the totalizers can be displayed with up to 11 places, e.g., 74890046.03. For the definition of the number of

decimal .

Press key to scroll through the upper line to the display of the totalizers.

Select the command →Clear totalizer in the upper line to reset the totalizers to zero. Press ENTER.

38 PORTALOK_7SV4-5-1EN, 2014-09-01

The value of the totalizer will be displayed in the upper line (here: the volume which has

passed through the pipe at the measuring point in the positive flow direction after the activation of the totalizers).

This error message will be displayed if the totalizers are to be activated. The flow velocity

cannot be totalized.

11 Advanced Measuring Functions Portalok 7S

Quantity Storage

one >BOTH<

Quantity recall

off >ON<

Quant. wrapping

off >ON<

Velocity limit

0.0 m/s

Selection of the totalizers for storing

It is possible to store the totalizer for one flow direction or the totalizers for both flow directions. Select Special

Funct.\SYSTEM settings\Storing\Quantity Storage.

If one is selected, only the totalizer whose value is changing will be stored. This can apply

to the totalizer for the positive or the negative flow direction.

If both is selected, the values of the totalizers for both flow directions will be stored.

Press ENTER.

When the measurement is stopped

The behavior of the totalizers when the measurement is stopped or after a RESET of the transmitter is set in Special

Funct.\SYSTEM settings\Measuring\Quantity recall.

If on is selected, the values of the totalizers will be stored and used for the next measurement.

If off is selected, the totalizers will be reset to zero.

11.3.1 Overflow of the Totalizers

The overflow behavior of the totalizers can be set:

Without overflow:

• The value of the totalizer increases to the internal limit of 1038.

• if necessary, the values will be displayed as exponential numbers (±1.00000E10). The totalizer can only be reset to

zero manually.

With overflow:

• The totalizer will be reset to zero automatically when ±9999999999 is reached.

Select Special Funct.\SYSTEM settings\Measuring\Quant. wrapping.

Select on to work with overflow. Select off to work without overflow. Press ENTER.

Independently of the setting, the totalizers can be reset to zero manually.

Note!

The overflow of a totalizer influences all output channels, e.g., data logger, online transmission of data.

The transmission of the sum of both totalizers (the throughput Q) via an output will not be valid after

the first overflow (wrapping) of one of the corresponding totalizers.

To signalize the overflow of a totalizer, an alarm output with the switching condition QUANT. and the

type HOLD have to be activated.

11.4 Upper Limit of the Flow Velocity