Page 1

LavAdvantage

™

Thermostatic Heater Ideal for Handwashing and Other Fixed or Variable Flow Applications

Applications

•

Handwashing

•

Kitchen, bar, utility sinks

•

Fixed or variable ow

•

Ideal for multiple sensor or metering faucets

•

Eyewash fountains (EE models - 90°F max)

•

Sanitation (S models - 180°F)

Performance Features

•

Self-diagnostics with intelligent controls actively protect heater in

installed environment

•

SafeStart™ technology engages upon start-up to help avoid

dry-re occurrence

•

Industry's lowest activation with 0.2 GPM turn on ow

•

Digital LED display with accessible user interface communicates

system status and heater operation feedback

•

Silent operation on all models except for SPEX012240T

•

Mounts in any orientation for a exible installation

•

Compact size ts almost anywhere; suitable for ADA compliant

facilities

•

Only one input line, hot or cold, needed for an easy installation

•

Designed to deliver hot water to a single pipe faucet, mixing

valves or mixing faucets

•

Integral 3/8" compression ttings; no soldering or sweat

connections required

•

No T&P relief valve needed (check local codes); Ready to go,

right out-of-the-box

•

Save water and time by installing unit at the point-of-use

•

Control system activates heater only on demand

•

High temperature limit switch enables safe operation

•

Active energy management with power modulation allows for

thermostatic accuracy

•

5-year limited warranty on leaks, 1-year on parts

Product Specications

Dimensions: 10.75" x 5.25" x 3"

Weight: 4 lb

Cover: ABS-UL rated 94 5VA

Color: White

Adj. Temperature Range: 70°F-140°F*

Min. Dynamic Operating Pressure: 30 PSI

Max. Dynamic Operating Pressure: 150 PSI

Element: Replaceable Nichrome cartridge insert

Fittings: 3/8" compression ttings

UL listed le number: E86887

U.S. Patent #'s: 4,762,980 and 4,960,976

Special Design Service

Inquiries for units for unique applications are welcome.

Call our Technical Service department at 1-800-543-6163.

Note: For optimum performance, mounting location should be located within 2 feet of xture.

Suggested Specication

Tankless water heater shall be an Eemax LavAdvantage model

number SPEX___________.

Unit shall have ABS-UL 94 5VA rated cover. Unit shall have

0.2 GPM turn on. Unit shall allow mounting in any direction.

Element shall be replaceable cartridge insert. Unit shall have

replaceable lter in the inlet connector. Element shall be iron free,

Nickel Chrome material. Tankless water heater to utilize complex

algorithm, actively managing power application to real time

system demand. Integrated ow meter, along with inlet and outlet

temperature sensors provide data which allows the unit to instantly

adapt to variations in input parameters. Heater shall be tted with

3/8" compression ttings to eliminate need for soldering. Maximum

operating pressure of 150 PSI. Accessible diagnostic features to

include error/fault display. Hot water storage tanks prohibited. Unit

shall be Eemax or approved equal.

Tankless water heater user interface must have the following

capabilities:

•

Selectable display including Celsius /Fahrenheit, setpoint, ow

rate, inlet temperature outlet temperature, power factor

•

Capable of displaying ow rate in gallons per minute & liters per

minute

•

Diagnostic features to include error/fault display

•

Control board must maintain error/fault history of 5 events

Specication options to be included with SPEX models:

_____ EE Emergency Eyewash. Meets ANSI tepid water

_____ ML Multiple Lavatory. Factory set to 110°F. Max

_____ S Sanitation. Factory set to 120°F. Max temp. 180°F.

_____ N4 NEMA 4 steel cabinet with powder coat nish

_____ N4X NEMA 4 stainless steel, corrosion-resistant cabinet

Tested and certied by the

Water Quality Association

against NSF/ANSI 372 for

lead free compliance.

requirements. Factory set to 90°F. Max temp. 90°F.

temp. 110°F

Specications

Tankless Electric Water Heater

*Special settings available, see specication options

Information and product specications contained in this document are subject to change without notice. REV 2020-01

37

Page 2

LavAdvantage

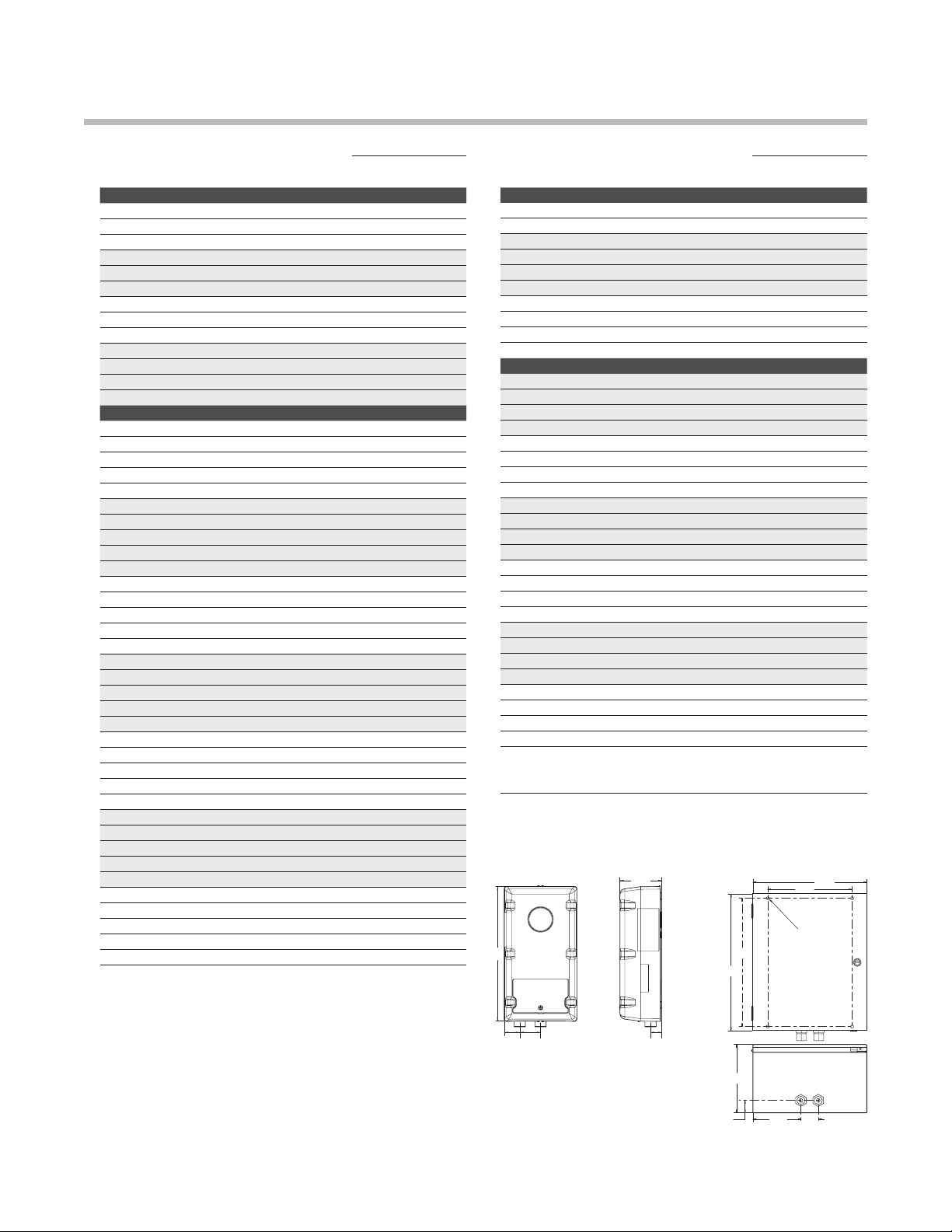

1.12

5.25

3.00

INLET

OUTLET

9.84

1.07 4.17 1.50

NEMA

4/4X

Thermostatic Heater Ideal for Handwashing and Other Fixed or Variable Flow Applications

Specications

Tankless Electric Water Heater

TURN

ON

(GPM)

TEMPERATURE RISE °F

0.35

0.5

GPM

GPM

1.0

GPM

RECOM'D

MODEL NUMBER kW AMPS

VOLTS 120

C

SPEX1812T

C

SPEX1812T EE

C

SPEX1812T S

C

SPEX2412T

C

SPEX2412T EE

C

SPEX2412T S

C

SPEX3012T

C

SPEX3012T EE

C

SPEX3012T S

C

SPEX3512T

C

SPEX3512T EE

C

SPEX3512T ML

C

SPEX3512T S

VOLTS 240*

C

SPEX35T

C

SPEX35T (derated 208V perf.)

C

SPEX35T EE

C

SPEX35T ML

C

SPEX35T S

C

SPEX48T

C

SPEX48T (derated 208V perf.)

C

SPEX48T EE

C

SPEX48T ML

C

SPEX48T S

C

SPEX55T

C

SPEX55T (derated 208V perf.)

C

SPEX55T EE

C

SPEX55T ML

C

SPEX55T S

C

SPEX65T

C

SPEX65T (derated 208V perf.)

C

SPEX65T EE

C

SPEX65T ML

C

SPEX65T S

C

SPEX75T

C

SPEX75T (derated 208V perf.)

C

SPEX75T EE

C

SPEX75T ML

C

SPEX75T S

C

SPEX95T

C

SPEX95T (derated 208V perf.)

C

SPEX95T EE

C

SPEX95T ML

C

SPEX95T S

C

SPEX012240T

C

SPEX012240T (derated 208V perf.)

C

SPEX012240T EE

C

SPEX012240T ML

C

SPEX012240T S

* 240V units can be used on 208V single phase with 25% reduced temperature output. Please note per UL standards

the rating plate and installation instructions will all be according to a 240V applied voltage. Check with local ofcials

prior to derating the electrical infrastructure.

† Temperature electronically limited to factory preset not to exceed temperature.

" C" indicates evaluation and compliance to either Underwriters Laboratories (UL) or Intertek (ETL) under CAN/

CSA-C22.2 No. 64/No. 88.

1.8 15 14 AWG 0.2 35° 25° 12° 6°

1.8 15 14 AWG 0.2 35° 25° 12° 6°

1.8 15 14 AWG 0.2 35° 25° 12° 6°

2.4 20 14 AWG 0.2 47° 33° 16° 8°

2.4 20 14 AWG 0.2 47° 33° 16° 8°

2.4 20 14 AWG 0.2 47° 33° 16° 8°

3.0 25 12 AWG 0.2 59° 41° 20° 10°

3.0 25 12 AWG 0.2 59° 41° 20° 10°

3.0 25 12 AWG 0.2 59° 41° 20° 10°

3.5 29 10 AWG 0.2 68° 48° 24° 12°

3.5 29 10 AWG 0.2 † 48° 24° 12°

3.5 29 10 AWG 0.2 68° 48° 24° 12°

3.5 29 10 AWG 0.2 68° 48° 24° 12°

3.5 15 14 AWG 0.2 68° 48° 24° 12°

2.7 13 14 AWG 0.2 53° 37° 18° 9°

3.5 15 14 AWG 0.2 † 48° 24° 12°

3.5 15 14 AWG 0.2 68° 48° 24° 12°

3.5 15 14 AWG 0.2 68° 48° 24° 12°

4.8 20 14 AWG 0.2 94° 66° 33° 16°

3.6 17 14 AWG 0.2 70° 49° 25° 12°

4.8 20 14 AWG 0.2 † † 33° 16°

4.8 20 14 AWG 0.2 94° 66° 33° 16°

4.8 20 14 AWG 0.2 94° 66° 33° 16°

5.5 23 12 AWG 0.2 107° 75° 38° 19°

4.1 20 12 AWG 0.2 80° 56° 28° 14°

5.5 23 12 AWG 0.2 † † 38° 19°

5.5 23 12 AWG 0.2 107° 75° 38° 19°

5.5 23 12 AWG 0.2 107° 75° 38° 19°

6.5 27 10 AWG 0.2 † 89° 44° 22°

4.9 24 10 AWG 0.2 96° 67° 33° 17°

6.5 27 10 AWG 0.2 † † 44° 22°

6.5 27 10 AWG 0.2 † 89° 44° 22°

6.5 27 10 AWG 0.2 127° 89° 44° 22°

7.5 32 10 AWG 0.2 † 102° 51° 26°

5.6 27 10 AWG 0.2 109° 76° 38° 19°

7.5 32 10 AWG 0.2 † † 51° 26°

7.5 32 10 AWG 0.2 † 102° 51° 26°

7.5 32 10 AWG 0.2 146° 102° 51° 26°

9.5 40 8 AWG 0.2 † † 65° 32°

7.0 34 8 AWG 0.2 † 96° 48° 24°

9.5 40 8 AWG 0.2 † † † 32°

9.5 40 8 AWG 0.2 † † 65° 32°

9.5 40 8 AWG 0.2 † 130° 65° 32°

11.5 48 8 AWG 0.2 † † 79° 39°

8.7 42 8 AWG 0.2 † † 59° 30°

11.5 48 8 AWG 0.2 † † † 39°

11.5 48 8 AWG 0.2 † † 79° 39°

11.5 48 8 AWG 0.2 † † 79° 39°

WIRE SIZE

(75° C/CU)

2.0

GPM

RECOM'D

TURN

MODEL NUMBER kW AMPS

VOLTS 208 Single Phase

C

SPEX3208T

C

SPEX3208T ML

C

SPEX4208T

C

SPEX4208T EE

C

SPEX4208T ML

C

SPEX4208T S

C

SPEX8208T

C

SPEX8208T EE

C

SPEX8208T ML

C

SPEX8208T S

VOLTS 277 Single Phase

SPEX3277T

SPEX3277T EE

SPEX3277T ML

SPEX3277T S

SPEX4277T

SPEX4277T EE

SPEX4277T ML

SPEX4277T S

SPEX60T

SPEX60T EE

SPEX60T ML

SPEX60T S

SPEX80T

SPEX80T EE

SPEX80T ML

SPEX80T S

SPEX90T

SPEX90T EE

SPEX90T ML

SPEX90T S

SPEX100T

SPEX100T EE

SPEX100T ML

SPEX100T S

3.0 15 14 AWG 0.2 59° 41° 20° 10°

3.0 15 14 AWG 0.2 59° 41° 20° 10°

4.1 20 14 AWG 0.2 80° 56° 28° 14°

4.1 20 14 AWG 0.2 † 56° 28° 14°

4.1 20 14 AWG 0.2 80° 56° 28° 14°

4.1 20 14 AWG 0.2 80° 56° 28° 14°

8.3 40 8 AWG 0.2 † † 57° 28°

8.3 40 8 AWG 0.2 † † 57° 28°

8.3 40 8 AWG 0.2 † † 57° 28°

8.3 40 8 AWG 0.2 † 113° 57° 28°

3.0 11 14 AWG 0.2 59° 41° 20° 10°

3.0 11 14 AWG 0.2 59° 41° 20° 10°

3.0 11 14 AWG 0.2 59° 41° 20° 10°

3.0 11 14 AWG 0.2 59° 41° 20° 10°

4.1 15 14 AWG 0.2 80° 56° 28° 14°

4.1 15 14 AWG 0.2 † 56° 28° 14°

4.1 15 14 AWG 0.2 80° 56° 28° 14°

4.1 15 14 AWG 0.2 80° 56° 28° 14°

6.0 22 12 AWG 0.2 † 82° 41° 20°

6.0 22 12 AWG 0.2 † † 41° 20°

6.0 22 12 AWG 0.2 † 82° 41° 20°

6.0 22 12 AWG 0.2 117° 82° 41° 20°

8.0 29 10 AWG 0.2 † 109° 55° 27°

8.0 29 10 AWG 0.2 † † 55° 27°

8.0 29 10 AWG 0.2 † 109° 55° 27°

8.0 29 10 AWG 0.2 † 109° 55° 27°

9.0 33 10 AWG 0.2 † † 61° 31°

9.0 33 10 AWG 0.2 † † † 31°

9.0 33 10 AWG 0.2 † † 61° 31°

9.0 33 10 AWG 0.2 † 123° 61° 31°

10.0 36 8 AWG 0.2 † † 68° 34°

10.0 36 8 AWG 0.2 † † † 34°

10.0 36 8 AWG 0.2 † † 68° 34°

10.0 36 8 AWG 0.2 † 137° 68° 34°

WIRE SIZE

(75° C/CU)

ON

(GPM)

0.35

GPM

Sux Denitions

EE Meets ANSI Z358.1 tepid water requirements. Max. temperature 90°F

ML Multi lavs 0.2 turn on with 110° temp setting

S Sanitation not to exceed 180°

9.73

1.50

.81

11.08

11.81

TEMPERATURE RISE °F

0.5

1.0

GPM

GPM

7.30

4X Ø.25

MOUNTING

HOLES

2.0

GPM

38

Information and product specications contained in this document are subject to change without notice. REV 2020-01

5.91

INLETOUTLET

Loading...

Loading...