Page 1

FlowCo

™

Non-Thermostatic Heater Ideal for Handwashing And Other Fixed-Flow Applications

Applications

•

Handwashing

•

Kitchen, bar, utility sink

•

Point-of-use & xed-ow xture

•

One (1) lavatory faucet, sensor faucet or metering faucet

Performance Features

•

Self-diagnostics with intelligent controls actively protect heater in

installed environment

•

InfoCue™ visible LED indicator communicates system status

and heater operation feedback

•

SafeStart™ technology engages upon start-up to help avoid

dry-re occurrence

•

Low activation ow starting at 0.25 GPM turn on

(model dependent)

•

Mounts in any orientation for a exible installation

•

Compact size ts almost anywhere; suitable for ADA compliant

facilities

•

Only one cold water line needed for an easy installation

•

No T&P relief valve needed (check local codes); Ready to go,

right out-of-the-box

•

Save water and time by installing unit at the point-of-use

•

Integral 3/8" compression ttings; no soldering or sweat

connections required

•

Control system activates heater only on demand

•

High temperature limit switch enables safe operation

•

5-year limited warranty on leaks, 1-year on parts

Product Specications

Dimensions: 10.75" H x 5.25" W x 3" D

Product Weight: (model dependent) 2.75 lb/3 lb

Cover: ABS-UL 94 5VA

Color: White

Min. Dynamic Operating Pressure: 30 PSI

Max. Dynamic Operating Pressure: 150 PSI

Element: Replaceable nichrome cartridge insert

Fittings: 3/8" compression ttings

UL listed le number: E86887

U.S. Patent Pending Technology

Note: For optimum performance, mounting location should be within 2 feet of xture.

Suggested Specication

Tankless water heater shall be an Eemax model number

SPEX________.

Unit shall have ABS-UL 94 5VA rated cover. Unit shall allow

mounting in any orientation. Element shall be replaceable cartridge

insert. Element shall be iron-free, nickel-chrome material. Unit

shall have replaceable lter in the inlet connector. Unit shall include

an integrated ow meter to ensure accurate turn-on / turn-o

ow rate. Heater shall be tted with 3/8" compression ttings to

eliminate the need for soldering. Maximum operating pressure of

150 PSI. Diagnostic features to include LED error/fault indicator.

Heater shall employ technology that engages upon start-up to

avoid dry-re occurrence. Hot water storage tanks prohibited. Unit

shall be Eemax or approved equal.

NOTE: Refer to rating chart for product information.

Specication options to be included with SPEX models:

_____ N4 NEMA 4 steel cabinet with powder coat nish

_____ N4X NEMA 4 stainless steel, corrosion-resistant cabinet

Tested and certied by the

Water Quality Association

against NSF/ANSI 372 for

lead free compliance.

Specications

Tankless Electric Water Heater

Special Design Service

Inquiries for units for unique applications are welcome. Call our

Technical Service department at 1-800-543-6163.

Information and product specications contained in this document are subject to change without notice. REV 2020-01

35

Page 2

FlowCo

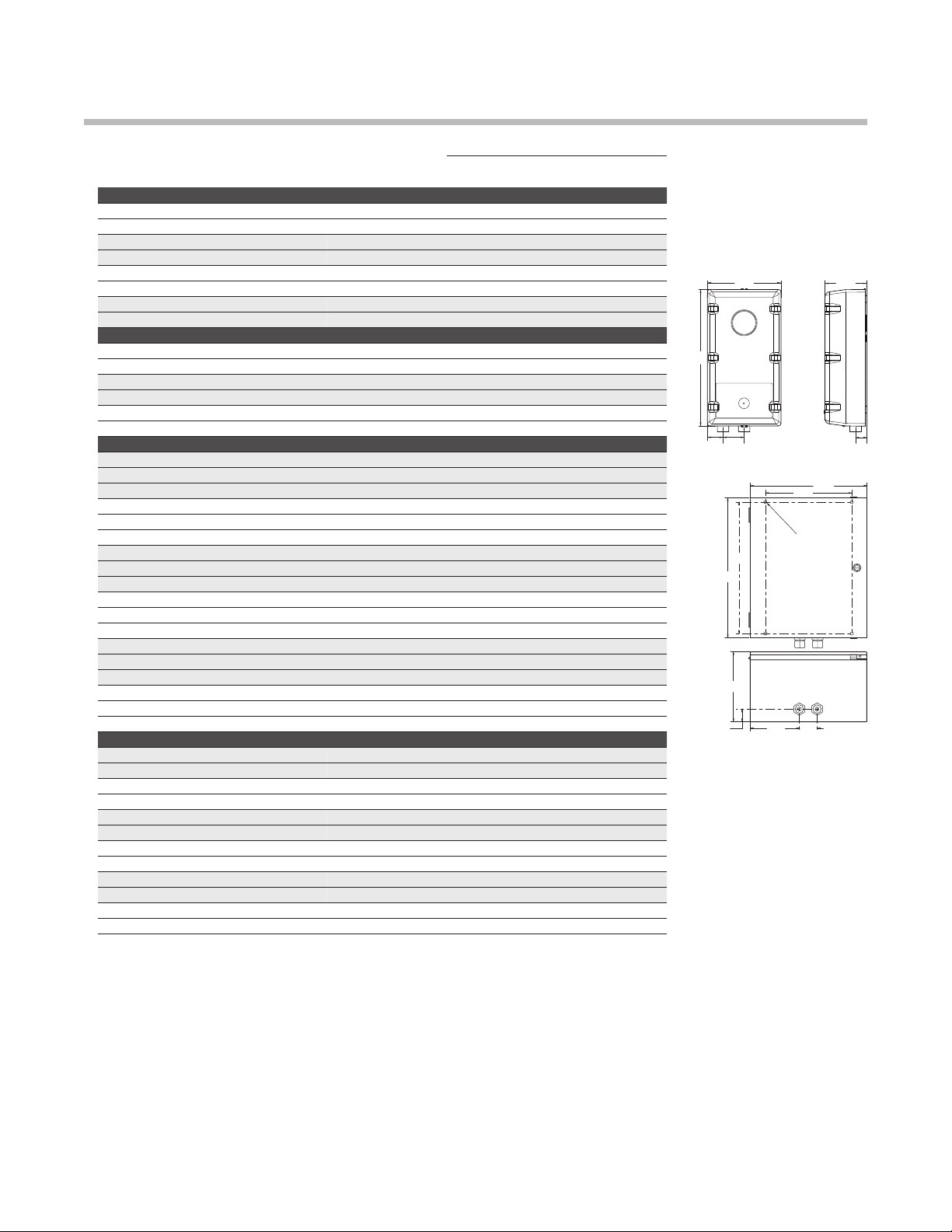

3.00

1.12

INLET

OUTLET

5.25

9.84

1.07 4.17 1.50

NEMA

4/4X

Non-Thermostatic Heater Ideal for Handwashing And Other Fixed-Flow Applications

Specications

Tankless Electric Water Heater

MODEL NUMBER

VOLTS 120

SPEX1812

C

SPEX1812CA (Canadian model)

SPEX2412

C

SPEX2412CA (Canadian model)

SPEX3012

C

SPEX3012CA (Canadian model)

SPEX3512

C

SPEX3512CA (Canadian model)

VOLTS 208 Single Phase

SPEX3208

C

SPEX3208CA (Canadian model)

SPEX4208

C

SPEX4208CA (Canadian model)

SPEX8208

C

SPEX8208CA (Canadian model)

VOLTS 240*

SPEX35

SPEX35 (derated 208V performance)

C

SPEX35CA (Canadian model)

SPEX48

SPEX48 (derated 208V performance)

C

SPEX48CA (Canadian model)

SPEX55

SPEX55 (derated 208V performance)

C

SPEX55CA (Canadian model)

SPEX65

SPEX65 (derated 208V performance)

C

SPEX65CA (Canadian model)

SPEX75

SPEX75 (derated 208V performance)

C

SPEX75CA (Canadian model)

SPEX95

SPEX95 (derated 208V performance)

C

SPEX95CA (Canadian model)

VOLTS 277 Single Phase

SPEX3277

C

SPEX3277CA (Canadian model)

SPEX4277

C

SPEX4277CA (Canadian model)

SPEX60

C

SPEX60CA (Canadian model)

SPEX80

C

SPEX80CA (Canadian model)

SPEX90

C

SPEX90CA (Canadian model)

SPEX100

C

SPEX100CA (Canadian model)

kW AMPS

1.8 15 14 AWG 0.2 41° 25° 16° 12° 8° 6°

1.8 15 14 AWG 0.2 41° 25° 16° 12° 8° 6°

2.4 20 14 AWG 0.25 55° 33° 22° 16° 11° 8°

2.4 20 14 AWG 0.25 55° 33° 22° 16° 11° 8°

3.0 25 12 AWG 0.25 68° 41° 27° 20° 14° 10°

3.0 25 12 AWG 0.25 68° 41° 27° 20° 14° 10°

3.5 29 10 AWG 0.3 80° 48° 32° 24° 16° 12°

3.5 29 10 AWG 0.3 80° 48° 32° 24° 16° 12°

3.0 15 14 AWG 0.25 68° 41° 27° 20° 14° 10°

3.0 15 14 AWG 0.25 68° 41° 27° 20° 14° 10°

4.1 20 14 AWG 0.4 – 56° 37° 28° 19° 14°

4.1 20 14 AWG 0.4 – 56° 37° 28° 19° 14°

8.3 40 8 AWG 0.7 – – 76° 57° 38° 28°

8.3 40 8 AWG 0.7 – – 76° 57° 38° 28°

3.5 15 14 AWG 0.3 80° 48° 32° 24° 16° 12°

2.6 13 14 AWG 0.3 59° 36° 24° 18° 12° 9°

3.5 15 14 AWG 0.3 80° 48° 32° 24° 16° 12°

4.8 20 14 AWG 0.4 – 66° 44° 33° 22° 16°

3.6 17 14 AWG 0.4 – 49° 33° 25° 16° 12°

4.8 20 14 AWG 0.4 – 66° 44° 33° 22° 16°

5.5 23 12 AWG 0.5 – 75° 50° 38° 25° 19°

4.1 20 12 AWG 0.5 – 56° 37° 28° 19° 14°

5.5 23 12 AWG 0.5 – 75° 50° 38° 25° 19°

6.5 27 10 AWG 0.7 – – 59° 44° 30° 22°

4.8 23 10 AWG 0.7 – – 44° 33° 22° 16°

6.5 27 10 AWG 0.7 – – 59° 44° 30° 22°

7.5 32 10 AWG 0.7 – – 68° 51° 34° 26°

5.6 27 10 AWG 0.7 – – 51° 38° 25° 19°

7.5 32 10 AWG 0.7 – – 68° 51° 34° 26°

9.5 40 8 AWG 0.8 – – – 65° 43° 32°

5.6 34 8 AWG 0.8 – – – 38° 25° 19°

9.5 40 8 AWG 0.8 – – – 65° 43° 32°

3.0 11 14 AWG 0.25 68° 41° 27° 20° 14° 10°

3.0 11 14 AWG 0.25 68° 41° 27° 20° 14° 10°

4.1 15 14 AWG 0.4 – 56° 37° 28° 19° 14°

4.1 15 14 AWG 0.4 – 56° 37° 28° 19° 14°

6.0 22 12 AWG 0.7 – – 55° 41° 27° 20°

6.0 22 12 AWG 0.7 – – 55° 41° 27° 20°

8.0 29 10 AWG 0.7 – – 73° 55° 36° 27°

8.0 29 10 AWG 0.7 – – 73° 55° 36° 27°

9.0 33 10 AWG 0.7 – – 82° 61° 41° 31°

9.0 33 10 AWG 0.7 – – 82° 61° 41° 31°

10.0 36 8 AWG 0.8 – – – 68° 46° 34°

10.0 36 8 AWG 0.8 – – – 68° 46° 34°

RECOMMENDED

WIRE SIZE

(75° C/CU)

TURN ON

(GPM)

0.3

GPM

TEMPERATURE RISE °F

0.5

0.75

GPM

GPM

1.0

GPM

1.5

GPM

GPM

* 240V units can be used on 208V single phase with

2.0

25% reduced temperature output. Please note per UL

standards the rating plate and installation instructions

will all be according to a 240V applied voltage. Check

with local ofcials prior to derating the electrical

infrastructure.

"C "indicates evaluation and compliance to either

Underwriters Laboratories (UL) or Intertek (ETL) under

CAN/CSA-C22.2 No. 64/No. 88.

9.73

1.50

11.08

11.81

5.91

7.30

4X Ø.25

MOUNTING

HOLES

INLETOUTLET

.81

36

Information and product specications contained in this document are subject to change without notice. REV 2020-01

Loading...

Loading...