Eemax Pro Series XTP MAINTENANCE MANUAL

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL FOR TANKLESS ELECTRIC WATER HEATERS

PROSERIES XTP™

i

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING

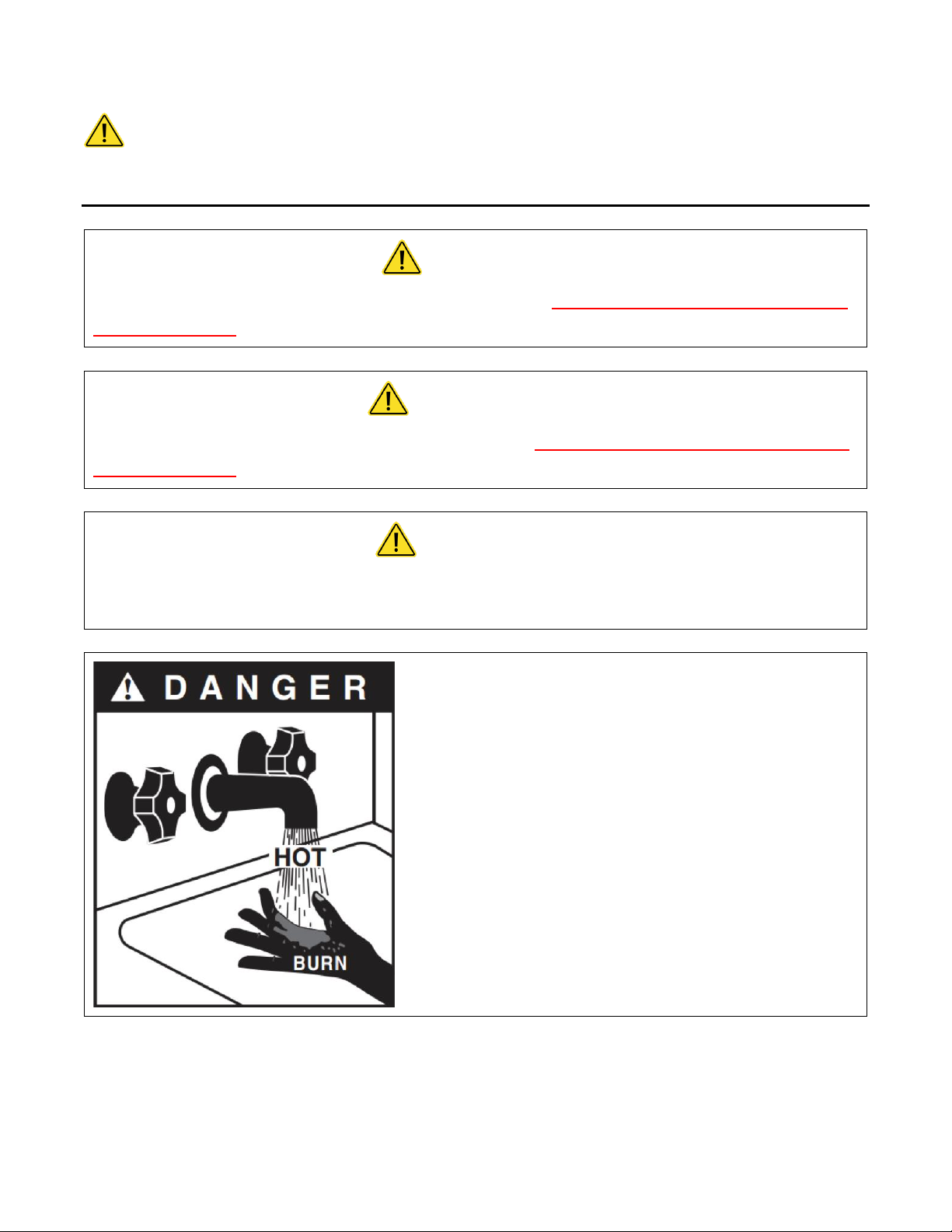

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury.

Hot water can be dangerous. There is a high scald

potential if the thermostat is set too high.

Water temperatures over 125 °F (51 °C) can cause

severe burns or scalding resulting in death.

Hot water can cause first degree burns with

exposure for as little as:

3 seconds at 140 °F (60 °C)

20 seconds at 130 °F (54 °C)

8 minutes at 120 °F (48 °C)

ii

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING

1. You must read and follow all

instructions. Serious bodily injury or

death could occur if you ignore this

warning.

2. All circuit breakers and/or disconnect

switches servicing the heater must be

turned off when installing, uninstalling,

or repairing this water heater.

3. The unit must be installed by a

licensed electrician and plumber.

4. The unit must be wired in accordance

with the current version of the

National Electrical Code (US) or

Canadian Electric Code (Canada).

5. This installation must comply with all

national, state, and local plumbing and

electrical codes.

6. When the heater is not within sight of

the electrical circuit breakers, an

additional local means of

disconnection of all ungrounded

conductors must be provided that is

within sight of the appliance or a

circuit breaker lockout must be used.

(Ref. NEC 422.31)

7. Per UL 499, this water heater is not

required to be installed with a

Temperature and Pressure relief valve

(T&P). However, local codes may vary.

In case a T&P relief valve is required, it

must be installed on the outlet hot

water line between the heater and the

isolation valve.

8. If the Eemax Tankless Water Heater is

installed in a location where water

damage could occur in the event of a

leak, it is recommended that a drip

pan be installed and connected to a

suitable drain. Alternatively, an active

water leak detector and shut off valve

can be installed to turn off your water

supply in the event a leak is detected.

9. If water supply has a high mineral

content, a water softening system is

recommended. Damage to the water

heater resulting from scale or hard

minerals will not be covered under

warranty.

iii

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING

10. When the heater is installed in a well

water system or if the plumbing

system is prone to introducing air into

the heater, it is highly recommended

that an air separator be installed in the

cold water feed to the heater to avoid

possible failure of the heating element

and/or heating chamber.

11. In accordance with NEC guideline, this

water heater is designed for a

maximum continuous duty cycle of 3

hours at 100% power output. . After

three hours heater should be powered

down for long enough to return heater

and electrical infrastructure to

ambient temperature. Exceeding this

rating, without proper pause, could

damage the heater and void the

warranty.

12. Provide an uninterrupted supply of

potable water to the heater at a

constant minimum pressure of 35PSI

(based on model) and maximum

pressure of 150 PSI.

13. Use of Water Hammer Arrestors in

applications with excess pipe lengths

or fast acting valves is strongly

recommended. Neglecting to do so will

damage the heater and void the

warranty.

14. This heater must be installed in a

location where it is not subject to

freezing temperatures unless supplied

with factory installed freeze

protection.

15. Properly purge air out of system

before power is applied. Purge water

through the system for a minimum 2

minutes at the maximum flow

available. During this process, close

and open the drain valve 3 times to

dislodge any air before power is

applied. Utilizing the recommended

boiler drain on the outside of the

heater is an acceptable means to

purge the system.

16. Applications located above the point

of use, i.e. in a drop ceiling must take

additional precautions for continuous

air elimination to prevent

interruptions to the hot water service.

Use of an air separator/scrubber is

required for this type of installation.

Recommended installation schematics

can be found in the APPLICATION

SCHEMATICS section of this manual.

iv

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING

17. Applications with the use of a circulating pump recirculation circulator must be

installed according schematics.

18. Should applications call for the use of antifreeze. A mixture of Propylene Glycol is the

only recommended antifreeze. The use of Ethylene glycol antifreeze is strictly

prohibited.

TABLE OF CONTENTS

TABLE OF CONTENTS ...................................................................................................................... IV

ABOUT YOUR PROSERIES XTP ............................................................................................................ 5

BEFORE INSTALLATION ...................................................................................................................... 6

MOUNTING THE HEATER TO THE WALL ............................................................................................. 6

ELECTRICAL HOOKUP ........................................................................................................................ 8

PLUMBING HOOKUP ....................................................................................................................... 10

COMMISSIONING THE WATER HEATER ............................................................................................ 13

SOFTWARE FEATURES ..................................................................................................................... 15

START-UP PROCESS ......................................................................................................................... 17

MONITORING & PREVENTIVE MAINTENANCE .................................................................................. 20

TECHNICAL SUPPORT ...................................................................................................................... 21

APPLICATIONS SCHEMATICS ............................................................................................................ 23

REPAIRS AND OPTIONS ................................................................................................................... 37

WIRING SCHEMATICS ...................................................................................................................... 39

5

ABOUT YOUR PROSERIES XTP

Congratulations on the purchase of ProSeries XTP! Read all set-up procedures and operating instructions carefully to

ensure maximum performance and energy savings from the water heater. It is important that the heater be installed

in accordance with stated instructions and the electrical and plumbing codes applicable to your area. Read this

manual thoroughly for important operating instructions and tips.

Tankless water heaters do not store hot water like conventional tank-type water heaters. ProSeries XTP tankless

electric models contain high powered sheathed technology heating elements that heat water instantly on-demand.

When there is a hot water demand, the flow meter within the heater recognizes the demand and initiates the

heating process. The flow meter measures the water flow rate while two thermistor sensors measure the incoming

and outgoing water temperature. The microprocessor controller receives this information and determines the

amount of power to send to the heating elements to heat the water to the desired temperature. Eemax tankless

electric water heaters only use as much power as needed by modulating the heating elements from 0 to 100%.

All electric tankless water heaters have a maximum flow rate. If this flow rate is exceeded, the heater will not be

capable of fully heating water. The amount of water that can be heated depends on the model and the incoming

water temperature. See diagram below to determine the maximum flow rates.

Dimensions:

All Models: Height=18.4” Width=20.5” Depth=5.5”

Temperature Rise at Specified Flow Rate (°F)

MODEL

TURN-

ON

GPM

0.5

GPM

1.0

GPM

2.0

GPM

3.0

GPM

4.0

GPM

6.0

GPM

8.0

GPM

10.0

GPM

XTP016480

0.5

-

109

55

36

27

22

18

14

XTP020480

0.5 - 137

68

46

34

27

23

17

XTP024480

0.5 - -

82

55

41

33

27

20

XTP027480

0.5 - -

92

61

46

37

31

23

XTP036480

0.5 - -

123

82

61

49

41

31

XTP048480

0.5 - - - 109

82

66

55

41

XTP054480

0.5 - - - 123

92

74

61

46

XTP018208

0.5 - 123

61

41

31

25

20

15

XTP024208

0.5 - -

82

55

41

33

27

20

XTP032208

0.5 - -

107

71

53

43

36

27

If you have questions at any time, please contact us directly at:

Manufacturer’s National Service Department

400 Captain Neville Dr. Waterbury, CT 06705

Phone: 1-(800)- 543-6163

6

BEFORE INSTALLATION

READ THESE INSTRUCTIONS THOROUGHLY AND COMPLETELY PRIOR TO INSTALLATION & USE. FAILURE TO

FOLLOW INSTRUCTIONS COULD CAUSE PROPERTY DAMAGE, SERIOUS PERSONAL INJURY, OR DEATH.

By installing this product, you acknowledge the terms of the manufacturer’s warranty. Once the heater is installed, do not return

product to the place of purchase. If you have any questions regarding the warranty or product return policies, please contact

Manufacturer’s national service department at 1-(800) 543-6163.

Before installation, inspect all components. The package includes:

ProSeries XTP unit

Mounting bracket with locking screw

Warranty card

Registration card

Recommended equipment for installation:

Electric drill for pre-drilling holes

Phillips Head screwdriver

Flat Head screwdriver

Tape measure/ruler

¾” Dielectric Unions

¾” shut off valves

¾” check valve

Air Eliminator/ Magnet Dirt Remover

Pressure Reducing Regulator

Boiler drains (may be beneficial)

Adjustable wrench

Pipe cutter (may be beneficial)

Pencil (used to mark measurements)

Level

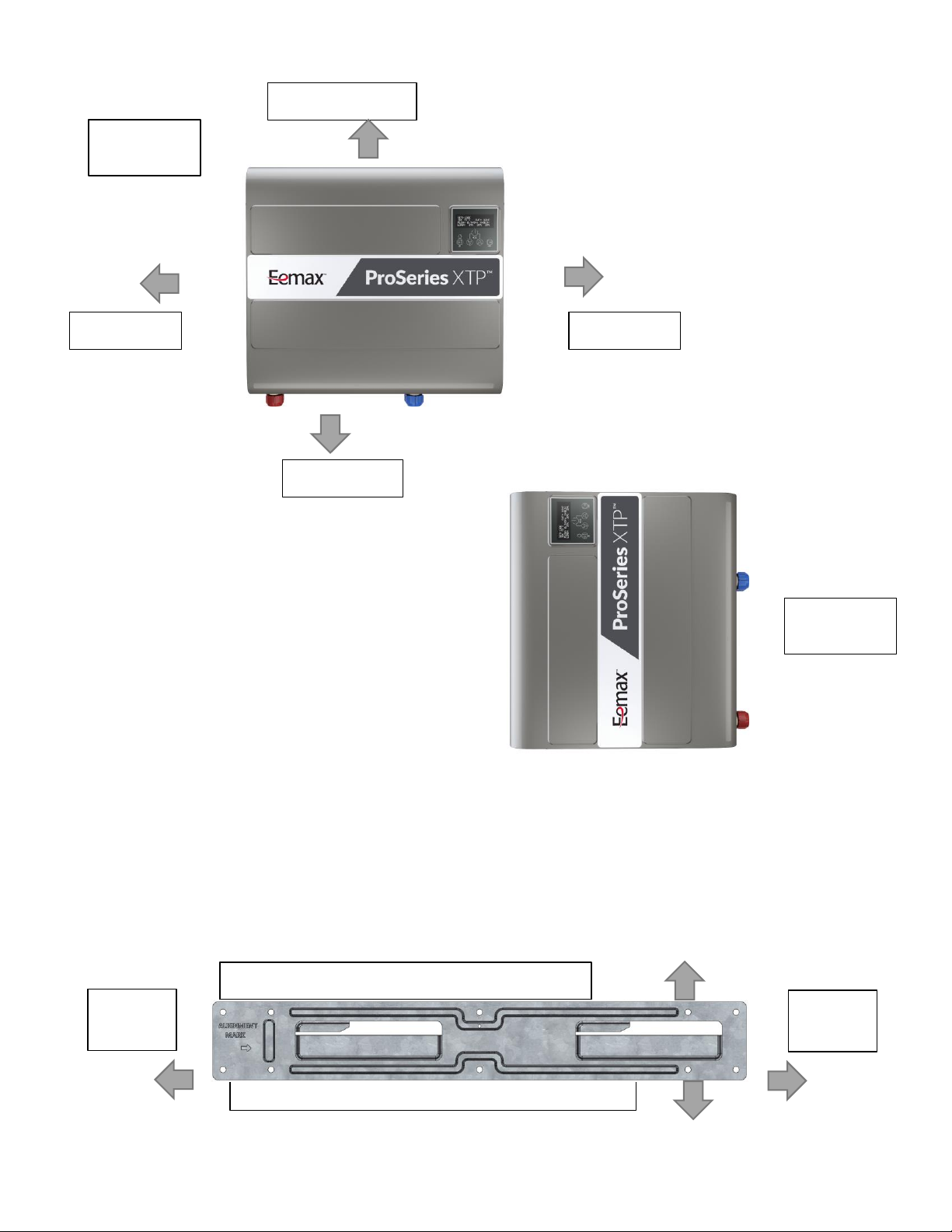

MOUNTING THE HEATER TO THE WALL

Follow the mounting instructions below as appropriate to your installation. Eemax recommends the heater be installed close to the

point-of-use.

CAUTION

This heater must be installed in a location where it is not subject to freezing

temperatures, unless supplied with factory installed freeze protection.

Install the product upright with the water connections facing downward for best performance. Mounting the heater in an alternate

(horizontal) orientation is acceptable. When mounting the unit in a horizontal orientation do not use the included bracket and

ensure the fittings are facing to the right as shown below. Note that the display readout and buttons will not rotate to accommodate

for this alternate orientation. The orientation of the display and buttons are not rotatable. Refer to the specified orientations below

for proper installation.

7

\

ProSeries XTP models are approved for zero clearance to combustible surfaces such as plywood.

Above clearances are recommended for service and installation.

1. Locate the best position to mount the unit. Check clearances around the unit according to the diagram below. Measure from

the top, bottom, left & right sides of the bracket to ensure proper clearances.

Hang the slide lock wall mounting bracket utilizing the appropriate anchors for the wall in at least 4 hole locations.

10" Top Clearance

8" Clearance

8" Clearance

18" Clearance

Upright

Installation

8"

Clearance

Measure 13" from top edge for 10" Top Clearance

Measure 30.5" from bottom edge for 18" of clearance

8"

Clearance

Alternate

Installation

8

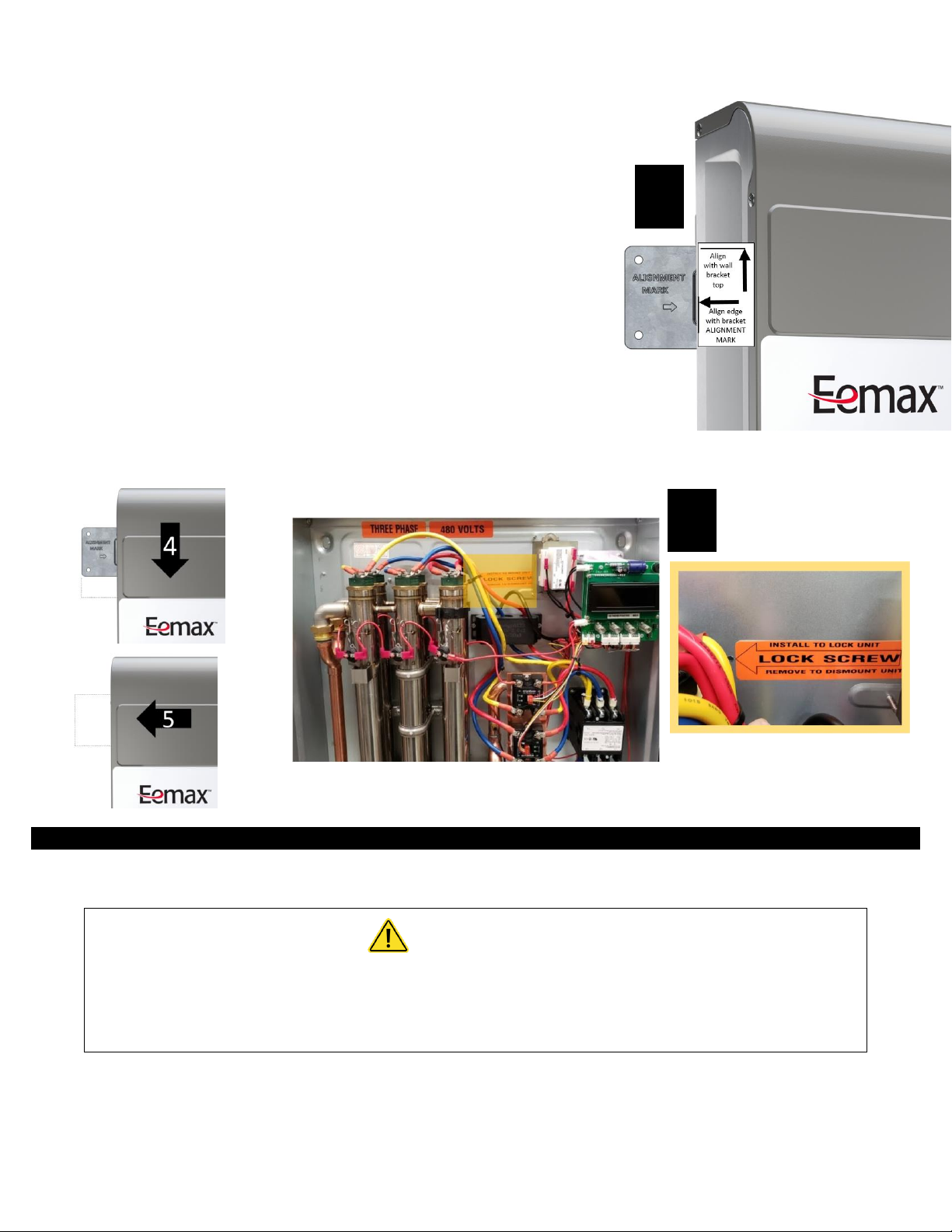

2. Remove the locking screw from the center of the slide lock bracket (to be

used in step 8)

3. Hang the unit on the bracket by aligning the left edge of the enclosure with

the alignment mark on the wall bracket and the top edge of the wall

bracket with the top edge of the alignment label on the front cover.

4. Slide the unit down onto the bracket until it stops, indicating that the wall

bracket is holding the weight of the unit.

5. Slide the unit to the left to until it stops. The stop is aligned such that the

unit will hide the wall mount bracket.

6. Test the bracket by lifting the unit upwards – it should not come free

7. Remove the cover

8. (Optional) Insert the locking screw through the center of the back plate and lightly hand tighten. This will prevent unwanted

sliding of the unit, i.e. tampering or accidental.

ELECTRICAL HOOKUP

Eemax recommends that the heater is installed and serviced by a licensed plumber and electrician.

WARNING

Before beginning any work on this installation, be sure that the electrical breaker is

"off" and that all mounting and plumbing work has been completed per these

instructions.

This heater must have its own independent circuit using insulated, UL listed, wire conductors (3 conductors plus ground) of the

appropriate size suitable for up to 90° C and protected by the correctly rated circuit breaker. For recommended conductor, ground

and breaker ratings refer to the chart below:

See chart on next page.

3

8

9

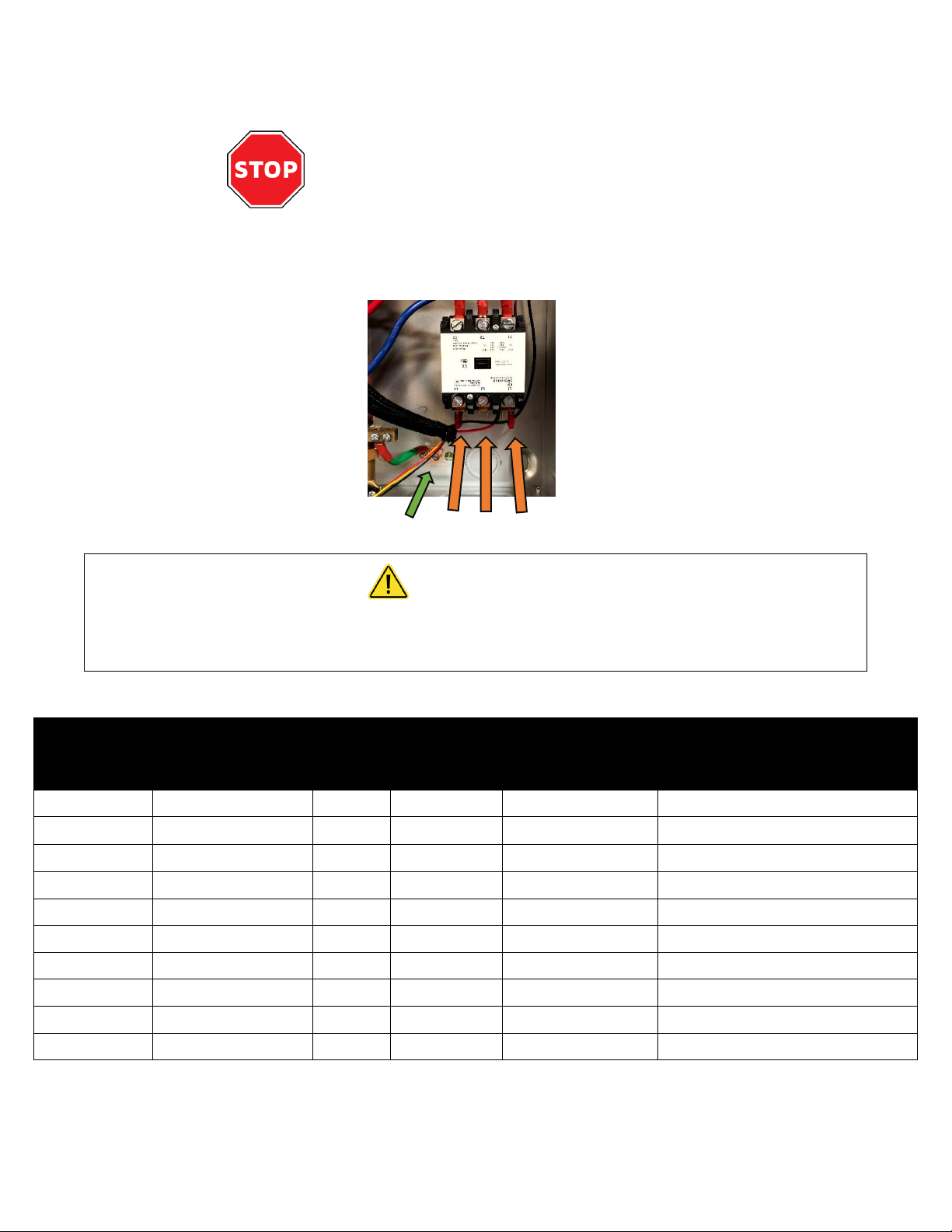

Before starting any electrical work: VERIFY there is

no power at the heater

The field wiring power conductors are to be secured to the L1, L2 and L3 connectors on the contactor(Fig. 1) .The

ground is to be secured to the GND connector to the left of the contactor.

Fig. 1

WARNING

Failure to ground the system may result in death, serious injury, and/or property

damage.

Electrical specifications

MODEL

VOLTS

THREE PHASE

DELTA

KW

TOTAL

AMPS

RECOMMENDED

WIRE SIZE (CU)

90° C

RECOMMENDED MINIMUM

BREAKER SIZE (PER NEC –

INTERMITTENT DUTY)

XTP016480

480

16

20

14

20

XTP020480

480

20

25

12

25

XTP024480

480

24

29

10

35

XTP027480

480

27

33

10

35

XTP036480

480

36

44

8

50

XTP048480

480

48

58

6

60

XTP054480

480

54

65.0

4

70

XTP018208

208

18

50.0

8

50

XTP024208

208

24

67

4

80

XTP032208

208

31.2

87

3

100

A ground terminal (or a wire connector marked "G", "GR”, "Ground", or "GROUNDING") is provided within the

enclosure. To reduce the risk of electric shock, connect this terminal or connector to the grounding terminal of the

electric service or supply panel with a continuous copper wire in accordance with your local electrical code.

GND L1 L2 L3

10

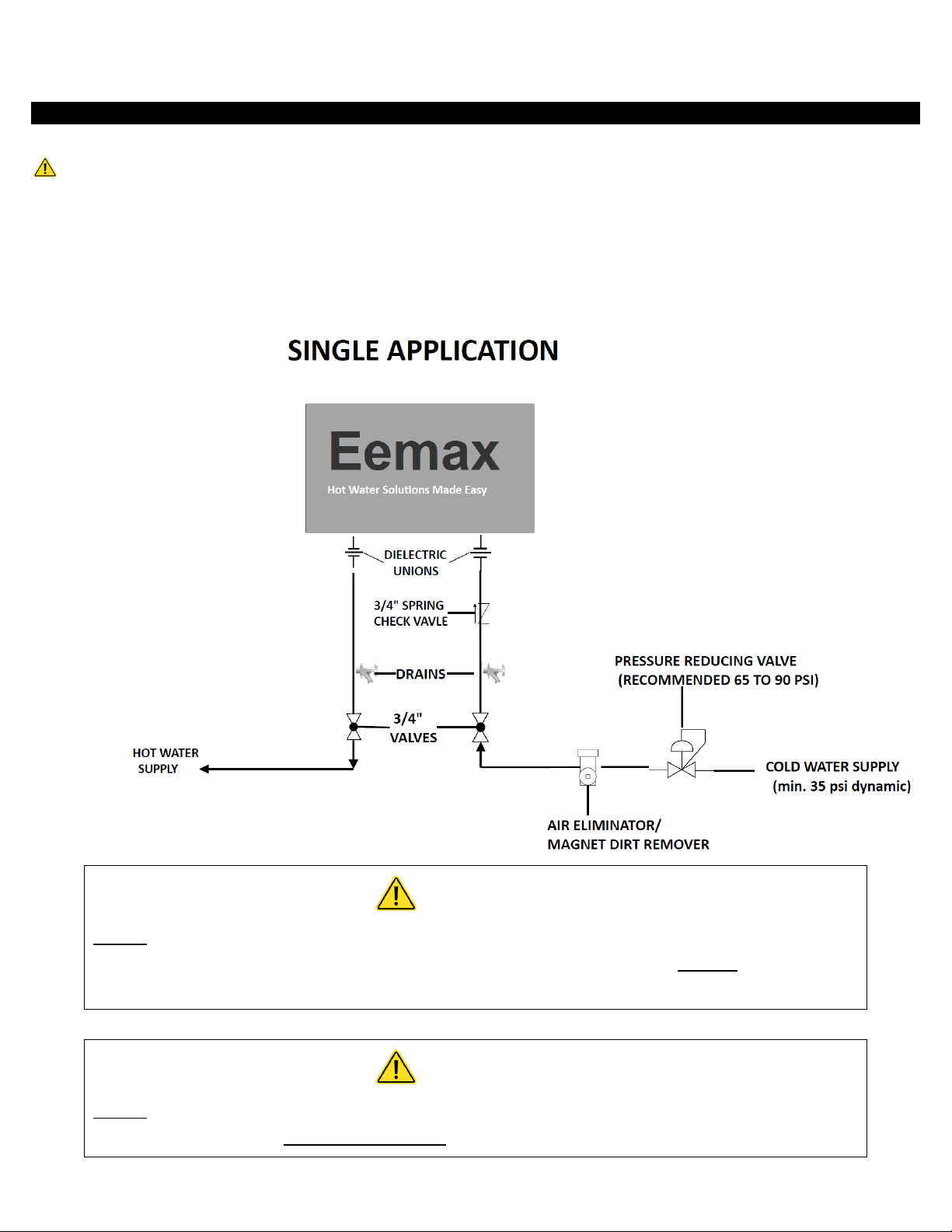

PLUMBING HOOKUP

Must flush line a minimum 2 minutes, at a maximum flow on initial start-up.

Reference the recommended installation diagram below. Additional installation diagrams for recirculation loops, multiple ProSeries

XTP units plumbed in series or parallel configurations, can be found in the APPLICATION SCHEMATICS section of this manual.

The heater is equipped with brass ¾” NPT fittings.

Make sure ONLY NPT fittings are used for connection to this heater.

Connect the cold water line with the inlet connection

(RIGHT fitting)

Connect the outlet pipe with

the outlet fitting

(LEFT fitting)

Do not reverse connections.

CAUTION

Never use pipe dope when making plumbing connections to this heater. Follow

standard industry practice with careful application of Teflon tape. Do not allow Teflon

tape to get into the heater.

CAUTION

Never solder any pipe connections attached to this heater – damage to the heater will

result. Doing this will void the warranty.

11

WARNING

Must flush out water heater for minimum 2 minutes at maximum flow on initial

start-up or after any service work has been performed. Close and open drain valve 3

times to remove any lodged air bubbles. Failure to do so may damage the heater.

Minimum inlet water pressure 35 psi dynamic.

Maximum water pressure not to exceed 150 psi. Recommended operating

pressure is 35 psi.

Use of a pressure regulator recommended.

Water supply inlet piping must be a minimum ¾” pipe diameter and it must be a

dedicated supply line. 1 ¼” minimum pipe diameter on trunk main when part of a

branch system.

The use of di-electric unions must be used on the inlet and outlet ports of the

water heater.

Recommended 40 mesh (1/64” or smaller) Y-strainer be installed in cold water

inlet to prevent debris from entering the water chambers. Blockage caused by

debris may cause element failure. Isolation valves recommended for servicing.

In applications where a long duty cycle is needed (more than 3 hours continuous

run time), or a short duty cycle (less than 30 sec. on time with less than minute off

time) please contact applications department. 1-800-543-6163

Hammer Arrestor: Systems with a large water volume, or long lengths of piping can

be susceptible to water hammer. The use of slow acting valves along with the

installation of a water hammer arrestor is highly recommended on all units. Failure to

install a water hammer arrestor can cause damage to water heater and void

warranty- refer to manufacturer’s installation manual for proper size and installation

location.

12

Proper water conditions must be maintained to prevent damage to the water heater.

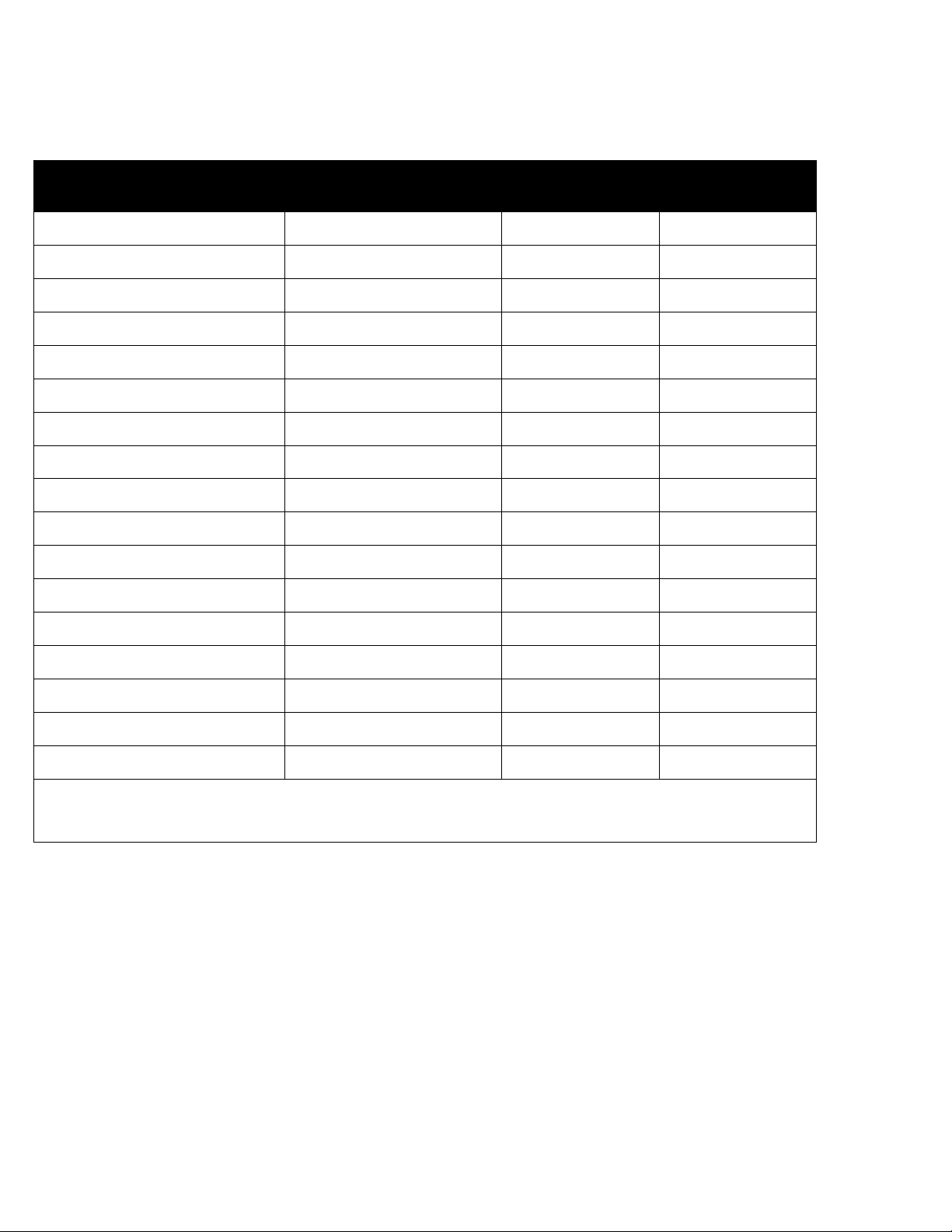

CONSTITUENT (MG/L)

MAXIMUM ALLOWABLE

CONCENTRATION

BETTER

BEST

Alkalinity

50

25

10

Calcium

25

5

0.5

Carbon Dioxide

0

0

0

Chlorine

100

15

1

Free Chlorine 1 1

0.05

Iron

0.2

0.1

0.01

Magnesium as Mg

0.5

0.1

0.1

Magnesium as Mn

0.1

0.1

0.1

Nitrate

25

25

10

Oxygen 2 1

0.1

Silica

15

10

1

Sodium

50

10

1

Sulfate

25

25

1

Total Dissolved Solids (TDS)*

200

100

5**

Total Hardness

25

10

1

pH

6.5 – 8.5

6.5 – 8.5

6.5 – 8.5

Turbidity (NTU)

5

5

1

* NOTE: Total dissolved solids

** NOTE: Do not reduce the TDS beyond this amount or the water will be too aggressive

Loading...

Loading...