Page 1

ELECTRIC INSTANTANEOUS WATER HEATER

INSTALLATION GUIDE AND OWNER’S MANUAL

IF YOU REQUIRE ANY HELP OR HAVE ANY QUESTIONS RELATING TO THE

INSTALLATION OR PERFORMANCE OF THIS HEATER, PLEASE CALL OUR

TECHNICAL SERVICE DEPARTMENT TOLL FREE : 1-800-543-6163.

HAVE THE INFORMATION LISTED BELOW WHEN CALLING :

S/N __________ MODEL # ___________________ INSTALL DATE ___________

EEMAX

ProAdvantage Series 1

PA004120T 1Φ 120V PA010240T 1Φ 240V

PA008208T 1Φ 208V PA012240T 1Φ 240V

PA005240T 1Φ 240V PA008277T 1Φ 277V

PA007240T 1Φ 240V PA010277T 1Φ 277V

READ THE GENERAL SAFETY SECTION AND THE ENTIRE MANUAL BEFORE

INSTALLING OR OPERATING THIS WATER HEATER. FAILURE TO FOLLOW

THE SAFETY RULES MAY CAUSE THE UNIT TO OPERATE IMPROPERLY,

WHICH COULD LEAD TO DEATH, SERIOUS BODILY INJURY AND/OR

PROPERTY DAMAGE. READ THE ENCLOSED WARRANTY CARD. WARRANTY

OF THIS WATER HEATER WILL DEPEND ON PROPER INSTALLATION AND

OPERATION. THE WARRANTY SHALL BE VOID IF THE DESIGN HAS BEEN

ALTERED. THE MANUFACTURER OF THIS HEATER WILL NOT BE LIABLE FOR

ANY DAMAGES BECAUSE OF FAILURE TO COMPLY WITH THE INSTALLATION

AND OPERATING INSTRUCTIONS OUTLINED ON THE FOLLOWING PAGES.

THE INSTALLATION MUST CONFORM TO THE INSTRUCTIONS IN

THIS MANUAL; ELECTRIC COMPANY RULES; AND LOCAL CODES, OR IN

THE ABSENCE OF LOCAL CODES, WITH THE LATEST EDITION OF THE

NATIONAL ELECTRICAL CODE. THESE PUBLICATIONS ARE AVAILABLE FROM

YOUR LOCAL GOVERNMENT, PUBLIC LIBRARY, OR ELECTRIC COMPANY.

WARNING

1

DISCONNECT THE POWER CIRCUIT BEFORE SERVICING.

MODELS

COVERED:

Page 2

GENERAL SAFETY

The “Eemax ProAdvantage” heater is specifically designed to take in cold or hot water and

heat it up to a maximum of 140F (60C). To obtain optimum performance and energy savings,

the unit should be located as near as possible to the point of use. The unit is supplied with

1/2” compression fittings.

THIS UNIT HAS ONE DEDICATED INDEPENDENT 120V, 208V,240V OR 277V

CIRCUIT. USE CORRECTLY RATED WIRES AND CIRCUIT BREAKERS.

U.L. 499, 18.4. THE RATING OF THE BRANCH-CIRCUIT OVERCURRENT

PROTECTIVE DEVICE SHALL BE 150% OF THE RATING OF THE PRODUCT.

DO NOT USE SPACE SAVING BREAKERS.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR MAINTENANCE,

MAY CAUSE DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAMAGE. REFER TO

THIS MANUAL FOR ASSISTANCE OR CONSULT THE LOCAL ELECTRIC UTILITY FOR

FURTHER INFORMATION.

FAILURE TO GROUND THE SYSTEM MAY RESULT IN DEATH OR SERIOUS INJURY.

WARNING

WARNING

WATER HEATERS ARE EQUIPPED FOR ONE VOLTAGE ONLY: THIS WATER HEATER IS

EQUIPPED FOR THE VOLTAGE DISPLAYED ON THE MODEL RATING PLATE. DO NOT

USE THIS WATER HEATER WITH ANY OTHER VOLTAGE OTHER THAN THE ONE

SHOWN ON THE MODEL RATING PLATE. FAILURE TO COMPLY WITH THIS MAY RESULT

IN DEATH, SERIOUS BODILY INJURY, AND/OR PROPERTY DAMAGE. IF YOU HAVE ANY

QUESTIONS OR DOUBTS CONSULT EEMAX OR YOUR LOCAL ELECTRIC COMPANY.

WARNING

HAZARD OF ELECTRICAL SHOCK! BEFORE REMOVING THE COVER OR SERVICING THE

WATER HEATER, MAKE SURE ALL ELECTRICAL SOURCES TO THE WATER HEATER ARE

TURNED “OFF”. FAILURE TO DO THIS MAY RESULT IN DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE.

NOTE: THIS UNIT HAS ONE DEDICATED INDEPENDENT ELECTRICAL POWER

CIRCUIT CONNECTION.

2

DISCONNECT THE POWER CIRCUIT BEFORE SERVICING.

DO NOT SOLDER PIPES WHILE THE UNIT IS INSTALLED

(serious damage to the electronic flow switch will result).

Page 3

I. MOUNTING THE UNIT

1) The unit should be mounted as close to the point of use as possible.

Do not install the heater above a faucet or “point of use” because the siphoning effect may

drain the heater which can cause premature element burn out. If the unit must be installed at

a higher elevation, you must install spring loaded check valves on both the inlet and outlet of

the water heater.

2) This unit must only be mounted in a vertical position with the water fittings positioned at

the bottom of the unit. Mounting other than in the vertical position will cause element burn

out and permanent damage to the water heater.

3) The cold water inlet is on the right hand side and the hot water outlet is on the left hand side

as marked by the fittings of the unit. Under NO circumstances can these be reversed.

4) Leave a minimum of 8” above the unit for easy replacement of the element.

5) The heater should be fixed to the wall using all four mounting holes of the backplate. (Fig.1)

Use an appropriate fastener for the weight. For the unit to be mounted against hollow walls,

we suggest using steel wall anchors with the correct grip range, and #10-32 screws at a

minimum.

NOTE: The heater should be installed below the level of all hot water outlets serviced by this

heater. Otherwise install spring loaded check valves on both the inlet and outlet.

NOTE: PRESSURE AND TEMPERATURE RELIEF VALVE

These units are not required by UL to have a Pressure and Temperature Relief

Valve (PTRV). You should check with local codes to find out if one is required in your

area. If local codes require the use of a temperature and pressure relief valve it

should be installed on the outlet hot water pipe before the outlet ball valve.

3

Requirements:

Max Output: 3.5 kW @ 120 volts

8.3 KW @ 208 volts

11.5 kW @ 240 volts

10.0 kW @ 277 volts

About 0.7 - 2.5 GPM at showering temperature.

MODELS:

1Φ 120V: PA004120T

1Φ 208V: PA008208T

1Φ 240V: PA005240T, PA007240T,

PA010240T, PA012240T

1Φ 277V: PA008277T, PA010277T

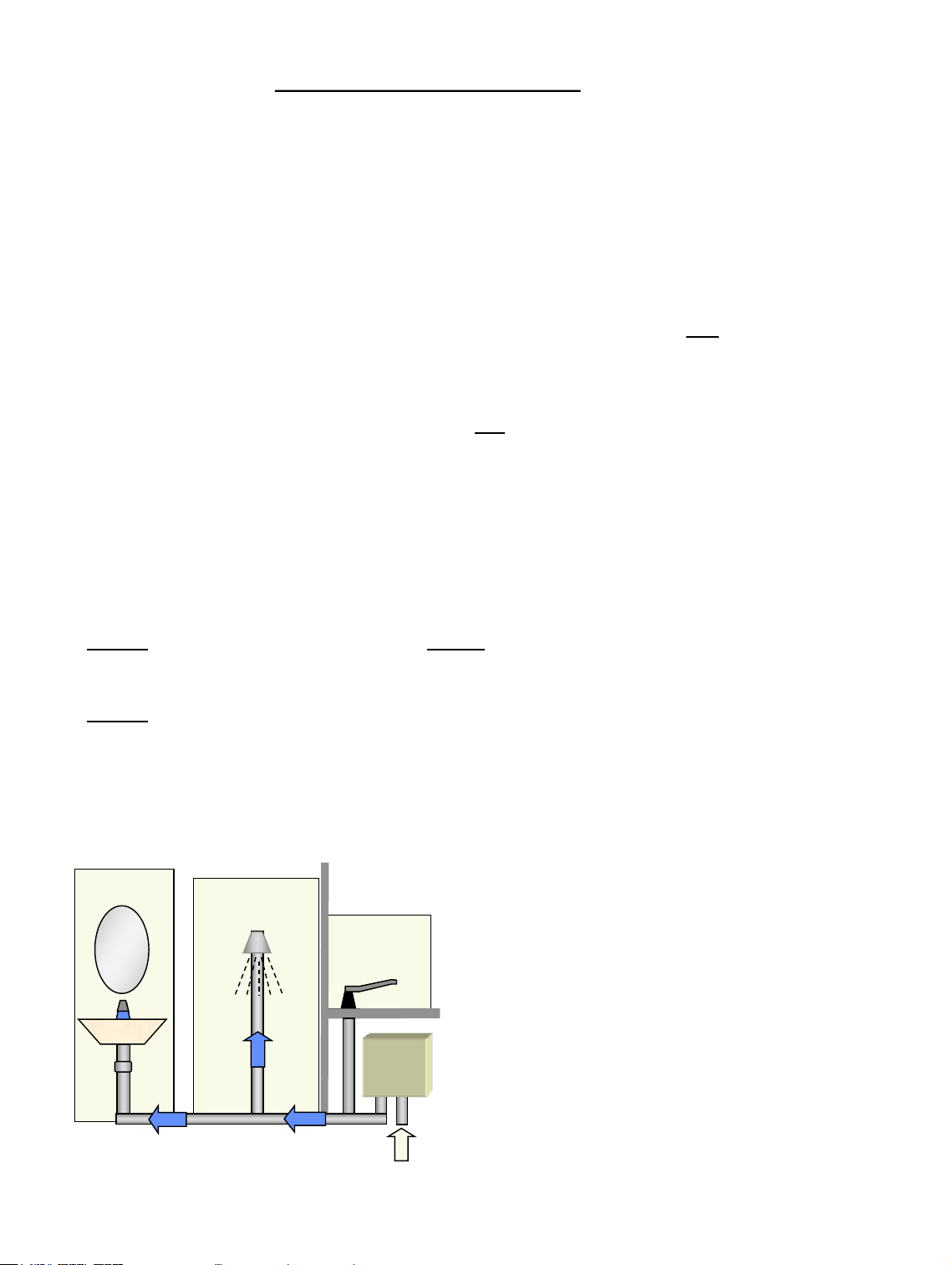

Eemax

Lavatory

Shower

Kitchen

Hot outlet

Cold inlet

Page 4

Mounting Layout for Series 1 Systems

4

Fig 1

Page 5

II. PLUMBING HOOK-UP

1) The unit is supplied with ½” compression fittings (Figure 2a ).

2) DO NOT USE PIPE DOPE AND DO NOT SOLDER TO THE INLET OR OUTLET.

3) Take care to ensure that the pipes are correctly aligned with the inlet and outlet bosses

in order to avoid excessive stress on the heater body molding.

NOTE: When soldering pipe joints remove heater from the wall. Serious damage can occur

if any soldering is done while pipes are connected to the heater.

Run water through the supply pipe to remove all debris from the pipe before

connecting the heater. Failure to do so could cause damage to the flow switch.

4) Install isolating valves (full flow ball valve type) on both inlet and outlet pipes. This allows unit

to be isolated for maintenance purposes. (Fig. 2b)

5) When all plumbing is complete, fully check the system for water leaks at all the plumbing

connections. If any leaks are present take corrective action. Then fully open both inlet and

outlet BALL VALVES, run the hot water outlet fed by this heater for a minute or two, until the

water flow is continuous, free from “gulping” and from all visible air pockets.

NOTE:

ALL MOUNTING AND PLUMBING MUST BE COMPLETE BEFORE YOU

PROCEED WITH ELECTRICAL HOOK-UP.

TEST THE INSTALLATION FOR LEAKS BEFORE CONNECTING THE

ELECTRICAL SUPPLY.

5

Figure 2a

Hot outlet

½” Compression Fitting

DO NOT

SOLDER

Cold inlet

½” Compression Fitting

DO NOT SOLDER

Inlet filter

1 1/2 “

Page 6

MINIMUM - 8” CLEARANCE ABOVE UNIT

NOTE: When soldering pipe joints remove heater from the wall. Serious

damage can occur if any soldering is done while pipes are connected to the

heater.

Take care to ensure that the pipes are correctly aligned with the inlet and

outlet bosses in order to avoid excessive stress on the heater body

molding.

6

Inlet Isolating

Ball Valve. (Always

leave fully open when

unit is in service.)

Outlet Isolating

Ball Valve

(throttle open

just enough to

obtain adequate

flow of hot water)

Union

Threaded type

Teflon tape only

No pipe dope

NPT

Elbow(s)

Pipe support

Figure 2b

Pipe

support

L1

GND

N

L2

or

Contactor

Wire nut

(GND)

Page 7

III. ELECTRICAL HOOK-UP

WARNING

BEFORE DOING ANY WORK ON THE UNIT BE SURE THE

BREAKER IS “OFF” TO AVOID ANY DANGER OF SHOCK.

“Eemax ProAdvantage” heaters are manufactured to the following specifications:

The L1, L2, or N should be connected to the slots in the contactor marked L1 and L2.

(see Fig 2b). The ground lead must be connected to the stud marked GND.

GROUND MUST BE BROUGHT TO THE “GROUND” AT THE CIRCUIT BREAKER PANEL.

Use a dedicated circuit with appropriate wiring and circuit breaker configuration which is

dictated by the power requirements of the unit. (see Table 1 and Fig 3)

DANGER

FAILURE TO GROUND THE SYSTEM MAY RESULT IN DEATH OR SERIOUS INJURY.

MODEL TYPE Voltage kW output AMPERAGE

PA004120T 1f 120 V 3.5 29

PA008208T 1f 208 V 8.3 40

PA005240T 1f 240 V 4.8 20

PA007240T 1f 240 V 6.5 27

PA010240T 1f 240 V 9.5 40

PA012240T 1f 240 V 11.5 48

PA008277T 1f 277 V 8.0 29

PA010277T 1f 277 V 10.0 36

Table 1

7

Figure 3

Dedicated

Single Pole (120/277 Volts)

or

Double Pole (208/240 Volts)

Circuit

ON

OFF

or

Circuit Breaker Panel

ON

ON

OFF

OFF

Page 8

IMPORTANT

BEFORE SWITCHING “ON” THE POWER AT THE MAIN CIRCUIT BREAKER PANEL

MAKE SURE THAT THE HOT WATER CIRCUIT IS FREE OF AIR POCKETS OR ELSE

PREMATURE FAILURE OF THE ELEMENT WILL OCCUR. TO DO THIS OPEN ALL HOT

WATER OUTLETS ONE AT A TIME FOR A MINUTE OR TWO UNTIL THE WATER FLOW

IS CONTINUOUS AND FREE FROM “GULPING” AND FREE FROM VISIBLE AIR POCKETS.

1) Open fully both inlet and outlet valves at the heater. (see Fig 2b)

2) Open any hot water outlet in the system. If the outlet is a “single lever” mixer type turn to the

hottest position. Run for one minute to clear all the air from the system.

3) Slowly close OUTLET ball valve until the water flow from the faucet just starts to reduce.

NOTE: This process has two effects. One, any air in the system will be purged out. Two, the

heater unit will be pressurized up to the supply pressure. This will prevent the elements from

having air pockets when energized.

4) At this point you may energize the hot water heater. Once energized the Thermostatic control

touch pad display on the front cover will illuminate. This is where and when you will program

your desired temperature.(see Fig 4)

NOTE: Unit will display the programmed temperature, not the actual outlet temperature

IV COMMISSIONING YOUR HEATER

8

To trouble shoot the display board, shut off power to the unit. Press and hold all three buttons,

and re-energize the unit. If display board is working properly, the word “Yes” will display. If the

board has a fault it will display “No” and you should call technical support for a replacement.

F/C

140 F

Increase temperature

Decrease

temperature

Fahrenheit / Celsius

Figure 4

Touch Pad Display

Page 9

TROUBLESHOOTING

SYMPTOM “A”: NO HEAT, INDICATOR LIGHT – OFF

1) ELECTRIC SUPPLY IS OFF

Ensure the breaker is properly connected to the contactor. (see Fig 2b)

Check the main circuit breaker and reset it to “on”. (see Fig 3)

2) NO OR LOW WATER FLOW

Ensure that the minimum flow rate to switch on your heater is met.

Minimum flow rate = 0.70 gallons per minute. Check that the inlet filter screen is clear from

any debris. This is located in the brass inlet boss. (see Fig 2a)

3) WATER CONNECTIONS ARE REVERSED

Cold water inlet = right side, hot water outlet = left side.

4) ELEMENT BURNED OUT

TURN OFF THE MAIN CIRCUIT BREAKER!

Using an ohmmeter test the resistance of the heating element

across the two threaded termination rods on top of the element.

The resistance reading should be 4-15 ohms. If the resistance

is much greater than this value, call Eemax for a replacement element.

SYMPTOM “B”: LOW OR NO HEAT, INDICATOR LIGHT - ON

1) WATER FLOW TOO HIGH

Reduce the water flow by adjusting the outlet ball valve.

2) INCORRECT POWER SUPPLY

Make sure that the unit is connected to the voltage supply specified on the rating label on

the front cover of the unit.

3) ELEMENT BURNED OUT

TURN OFF THE MAIN CIRCUIT BREAKER!

Repeat the steps from paragraph 4 above.

9

Figure 5

Page 10

L1 L2

ECO

CONTROL

BOARD

HEATER

CORE

TRIAC

CONTACTOR

Figure 6

Figure 7

10

RELAY (ORG) TO RELAY COIL

T/C (BLU) 2 PIN CONNECTOR

6 – Wire + T/C

EX 284

EL/L (BLK) ELEMENT RING

TRIAC (BLK)

RELAY (ORG) TO ECO

L1 POWER (BLK) FROM RELAY LINE SIDE

L2-N POWER (RE FROM RELAY LINE SIDE

Figure 8

Loading...

Loading...