Eelectron PD00D01KNX Product Handbook

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

1/42

PRESENCE DETECTOR, CONSTANT LIGHT CONTROLLER

PD00D01KNX

Product Handbook

Product:

PD00D01KNX

Description:

PRESENCE DETECTOR, CONSTANT CONTROLLER

Document

Version: 1.3

Date:

03/10/2017

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

2/42

INDEX

General Introduction .............................................................................................................. 5

Product and functional overview ............................................................................................ 5

Presence / Motion detector ................................................................................................ 5

Presence detector (HVAC) ................................................................................................ 6

Functionality of the Presence detector / Motion detector / HVAC-detector ......................... 7

Operating Sequence ..................................................................................................... 7

Use as single device or as main detector, respectively secondary detector .................. 7

Brightness measuring – adjustable via KNX ................................................................. 8

Integrated 2-level light control (switching) ..................................................................... 8

Integrated constant light level control (dimming) ........................................................... 9

Application program ........................................................................................................ 11

Commissioning / Factory default settings ........................................................................ 11

Parameter and Communication objects ............................................................................... 12

General ........................................................................................................................... 12

Parameter General ..................................................................................................... 12

Parameter Functional blocks ....................................................................................... 13

Brightness measuring ...................................................................................................... 14

Parameter ................................ ................................................................ ................... 14

Communication objects ............................................................................................... 15

Motion detector / Presence detector ................................................................................ 16

Parameter ................................ ................................................................ ................... 16

Begin of Motion ........................................................................................................... 18

Overshoot time ........................................................................................................... 19

End of Motion.............................................................................................................. 20

Communication objects motion detector ..................................................................... 21

Communication objects presence detector ................................................................. 22

HVAC-Presence detector ................................................................................................ 24

Parameter ................................ ................................................................ ................... 24

Begin of HVAC Presence ............................................................................................ 24

Overshoot time ........................................................................................................... 26

End of HVAC Presence .............................................................................................. 26

Communication objects ............................................................................................... 28

2-level light controller (on-off) .......................................................................................... 29

Parameter ................................ ................................................................ ................... 29

Switch-On ................................................................................................................... 29

Switch-Off ................................................................................................................... 30

Communication objects ............................................................................................... 30

Constant light level control continuous ............................................................................ 31

Parameter ................................ ................................................................ ................... 31

Actual value ................................................................................................................ 31

Setpoint ...................................................................................................................... 31

Controller .................................................................................................................... 32

Controller Output ........................................................................................................ 32

Slaves ......................................................................................................................... 33

Slave offset data ......................................................................................................... 33

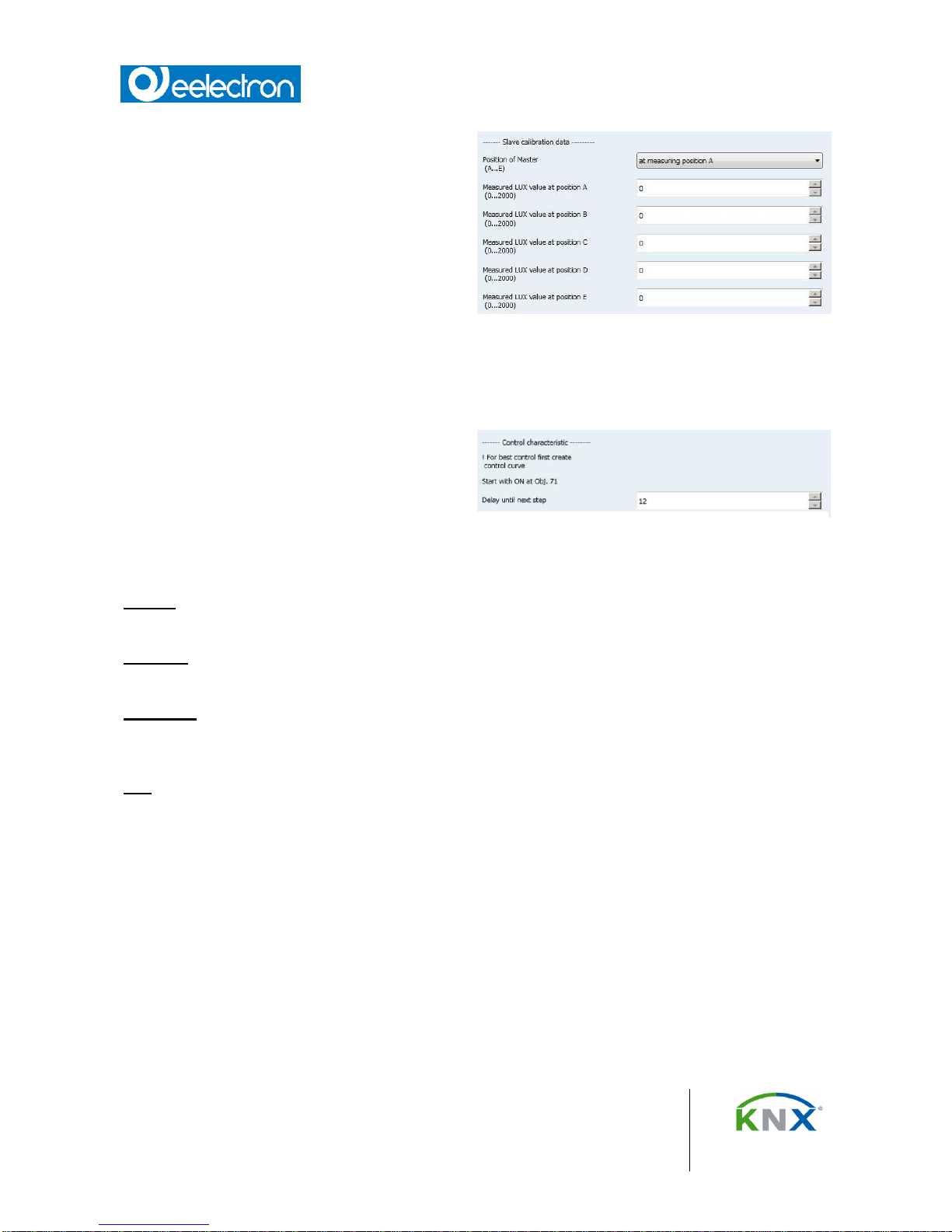

Slave calibration data .................................................................................................. 34

Control characteristic .................................................................................................. 34

Communication objects ............................................................................................... 34

IR–Decoder ..................................................................................................................... 36

Parameter ................................ ................................................................ ................... 36

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

3/42

Button mode A ............................................................................................................ 37

Button Pair B [C, D, E, F] ............................................................................................ 39

Communication objects ............................................................................................... 39

Appendix .............................................................................................................................. 40

Determination of the correction factor of the brightness sensor (calibration) .................... 40

Determination of the control characteristic ....................................................................... 41

Determination of characteristic of used lights in the room ................................................ 41

Example of configuration ................................................................................................. 42

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

4/42

Any information inside this manual can be changed without advice.

This handbook can be download freely from the website: www.eelectron.com

Exclusion of liability:

Despite checking that the contents of this document match the hardware and software, deviations

cannot be completely excluded. We therefore cannot accept any liability for this.

Any necessary corrections will be incorporated into newer versions of this manual.

Symbol for relevant information

Symbol for warning

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

5/42

General Introduction

This manual is intended to be used by installers and describes functions and parameters of the

device PD00D01KNX and how is possible to change settings and configurations using ETS

software tool.

Product and functional overview

The device is a presence/motion detector with integrated constant light level control. The device

communicates via KNX with actuators or other KNX devices. It is designed for mounting on the

ceiling. Owing to its tilting sensor head, the device can be aligned with the required capture area.

The main application for the device is automatic control of the lighting on an office workplace.

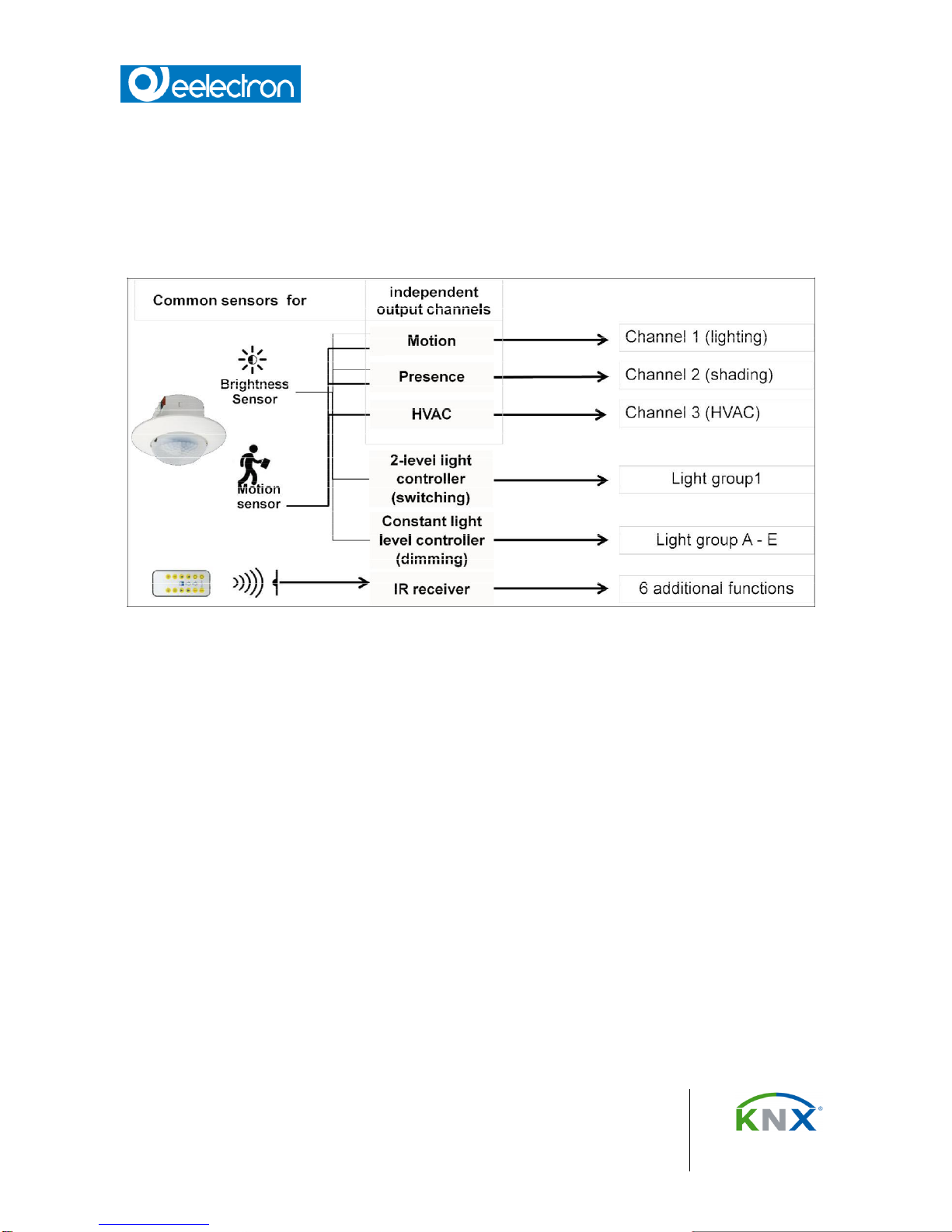

Presence / Motion detector

The detector senses the presence of a person or that there is no longer anyone in its detection

area. The detector signal can be analyzed via two separate communication channels, termed

motion detector and presence detector. The detection range is identical for all channels. Each

channel can be locked individually via communication objects.

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

6/42

Presence detector (HVAC)

The detector has an additional control output for HVAC applications.

For example, this function can switch systems that are used for heating, ventilating and climate

control (HVAC) of the room from “Energy saving mode” in an unused room to “Comfort mode” in an

occupied room and back to “Energy saving mode”, when the room is again unoccupied.

Fig. 1 Three independent configuration detector channels for different applications

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

7/42

Functionality of the Presence detector / Motion detector /

HVAC-detector

For each detector channel, 4 communication objects are available, overall 12 different

communication objects. It is possible to send one or two KNX telegrams at the beginning and at

the end of a detected presence, according to configuration. The values of the communication

objects are configured for each functional block (motion detector, presence detector, HVACdetector) via corresponding parameters.

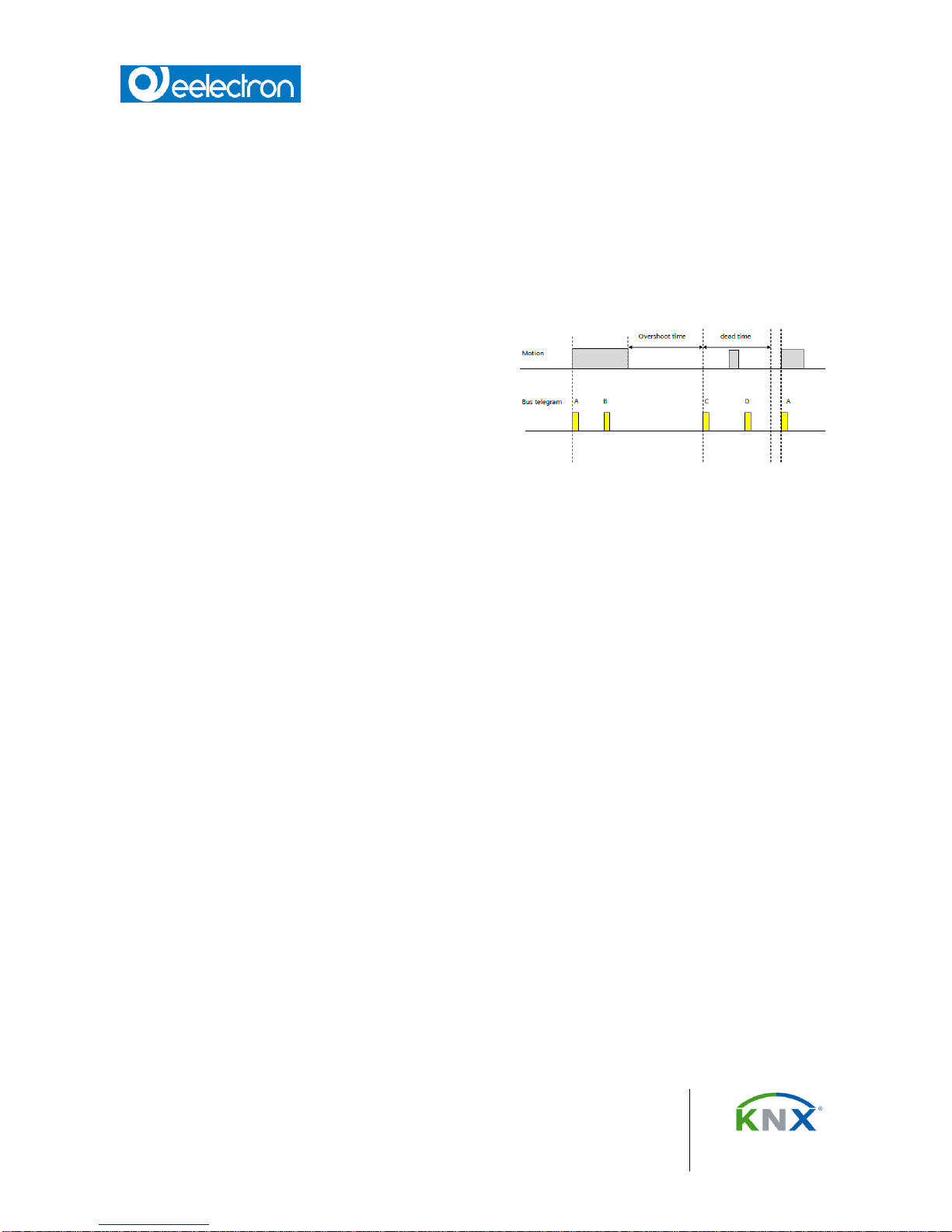

Each time a presence is detected, the overshoot

time is started. Its duration is configurable for each

functional block separately. The end of presence is

determined by the end of the overshoot time.

The duration of the dead time is also configurable

per functional block. It is used to protect the

actuators that are connected to the detector. If a

presence is detected during the dead time, neither

telegrams are sent nor the overshoot time is started.

In the following the telegrams, which are send at the beginning of a presence, are called A and B,

the telegrams, which are sent at the end of a presence, are called C and D.

Operating Sequence

After the device has detected a presence, telegram A is sent immediately. If it has been configured

to send also a tele-gram B, then telegram B is sent after the configured time (optionally also

cyclically).

If there are no motions any more, at the end of the overshoot time telegram C and (if configured)

telegram D are sent. Telegram D can also be sent cyclically.

If there are motions during the overshoot time is running, the overshoot time is restarted.

Use as single device or as main detector, respectively secondary detector

The detector can be operated as an independent device, as the main or secondary detector.

According to the requirement, additional presence detectors can be connected with the “main

detector” via KNX as “secondary detectors” to extend the presence detection zone. “Secondary

detectors” supply motion information only to the main detector.

Fig. 2 Flowchart

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

8/42

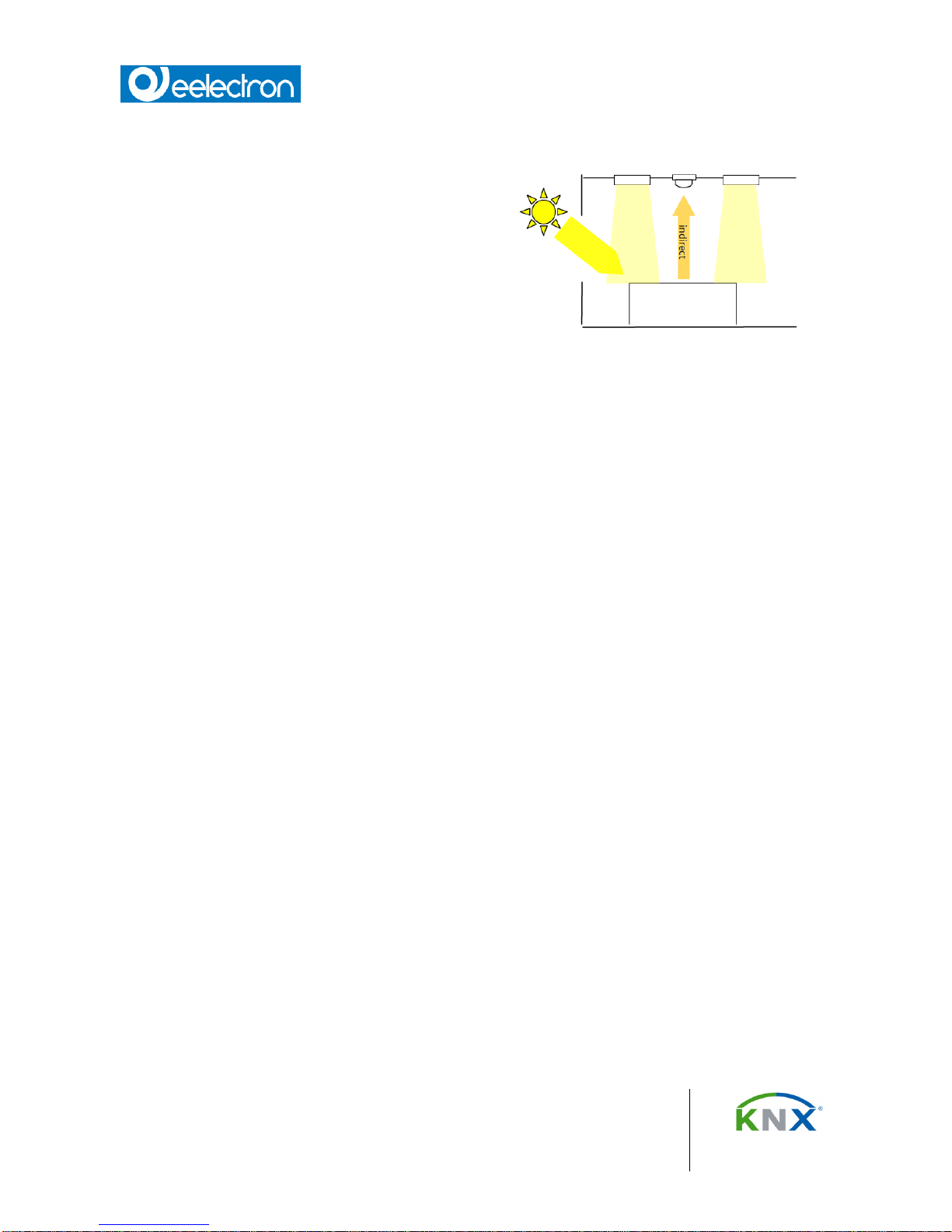

Brightness measuring – adjustable via KNX

The device contains an independent light sensor.

The signal measured there is available both at the

KNX and internally.

Because the light sensor measures directly, it must

be possible to calibrate it for indirect measurement,

so that it can be adapted to the different installation

sites. Rapid brightness fluctuations are filtered out.

The measurement range of the internal light sensor

is between 20 and 1000 Lux.

The settings determine whether the brightness value computed by the device or a brightness value

received from outside is used for the detector's remaining functional blocks.

For indirect brightness measuring a maximal distance of 2,8 m is recommended. In case of larger

distances the measuring can be realized via a reference area with 2,8 m distance.

Integrated 2-level light control (switching)

If the brightness controller is enabled (automatic mode) the lighting is switched on as soon as the

brightness falls below a set lower threshold. The lighting is switched off if the set upper brightness

threshold is exceeded. The brightness thresh-olds are variable either via parameters or via

communication objects.

The controller can also be operated semi-automatically by separating into two individual switching

objects for exceeding or falling below the threshold. In this way, it can be switched to “Only on” or

“Only off.”

If the controller receives a switching or dimming command via the associated communication

object over KNX, then this is deemed an external override and the controller switches automatic

mode off. This change of status is sent simultaneously on the bus via the “Automatic Status”

object.

Fig. 3 Indirect brightness measuring

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

9/42

Integrated constant light level control (dimming)

The luminance of the day light falling through a window into a room decreases in the room with the

distance from the window.

Depending on lamp type, the lighting is controlled to

the preset brightness value via dimming actuators or

switching/dimming actuators. The brightness setpoint

may be configured via a parameter or set via a

communication object.

For optimum use of the day light penetrating the room

the presence detector with constant light level control

offers the option to control a main lighting group

directly and up to four additional lighting control groups

each via their own characteristic curve and their own

controller (master/slave operation).

All lighting groups are dimmed to the same set point value. This allows controlling the light level in

a room with only one presence detector with constant light level control. Depending on the relative

distance of the additional lighting groups to the window compared to the main lighting group, each

of these additional lighting groups has to be dimmed brighter or darker than the main lighting

group.

Firstly, this requires determining the installation position

of the presence detector. The presence detector can be

installed on the ceiling at any of the positions A –E. The

position of the presence detector determining the main

lighting group is in principle freely selectable. Yet, it

should be close to the window allowing the best

measurement of the daylight contribution.

For master/slave operation the day light curve under

lighting groups A – E has to be captured. For this

purpose the artificial lighting has to be completely turned

off, such that just the natural day light is illuminating the

room. Ideally, the day light is evenly falling into the room

(no sharp shade / sunlight edges), bright, and diffused,

e.g. at noon on a bright day with overcast sky. Under each lighting group the luminance (Lux) has

to be measured manually and these values have to be entered into ETS.

Fig. 5 Position of lighting groups A-E

Fig. 4 Principal of constant light level control with

five luminaries

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

10/42

The control characteristic curve for the

additional lighting groups has to be determined

without day light. For that purpose the room

has to be completely darkened or the

characteristic curve has to be determined at

night. Sending a start signal to communication

object 71 starts the determination of the

characteristic curves. The presence detector

automatically generates 15 discrete control

values in the range 0%...100% for each

constant light level controller of the main and

additional lighting groups. The controllers send

dimming values to the corresponding lighting groups and the presence detector measures the

resulting luminance level. The period for the measurement can be configured between 10 and 60

seconds to allow for optimal pre-heating of the lamps.

After successful completion or interruption of

the calibration run the controller is in the state

„inactive“.

In case of successful completion the lighting

groups are set to 50%, in case of a failure to

minimum value ~ 6%.

During operation the constant light level controller can take up to four different states:

Active: In this state the constant lighting control is active. In a configurable period the controller

compares set point and actual values and sends a control value.

Inactive: In the state the controller is passive. The controller does not compare set point value and

actual value and does not send control values.

Stand-by: In this state the controller is passive. Different from the state “inactive” it still compares

the set point value with the actual value. On a corresponding difference between set point value

and actual value the controller automatically switches to the active state.

Off: The controller function is stopped and actuators for main and additional lighting groups are

first dimmed to a minimum and then completely turned off a second later.

Behavior on bus voltage failure / recovery

On bus voltage failure the current setpoint value is saved.

On bus voltage recovery the setpoint value is restored. The controller is in the state OFF.

Fig. 6 Parameters for measured brightness values

Fig. 7 Parameters for control characteristics

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

11/42

Application program

You need the KNX Engineering Tool Software (ETS) version 3.0 f and higher to load the

application program.

Commissioning / Factory default settings

After programming the device starts up with a warm-up phase of about 40 seconds.

Factory default settings

In the factory default state, the parameter Operating Mode is set to Setting Mode.

While the device is in "Setting Mode", the integrated programming LED displays the PIR sensor

state. (illuminates briefly with motion)

Programming mode

A short press of the learning button (< 2 s) enables the programming mode. This is indicated by

the programming key (LED). An additional press disables the programming mode.

Factory settings

A very long press of the learning button (> 20 s) sets the device to factory default. This will be

indicated by a continuous flashing of the programming LED for ~ 8 s.

Note

A long press of the learning button (> 5 s to 20 s) enables the connection test for commissioning

with Desigo. This mode will be disabled by an additional short press of the learning button.

Behaviour after programming

The behavior of the device after programming with the ETS is dependent on the configuration.

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

12/42

Parameter and Communication objects

The communication objects listed in the following paragraphs are available. Which of them are

visible and can be linked with group addresses will be determined by setting the parameters.

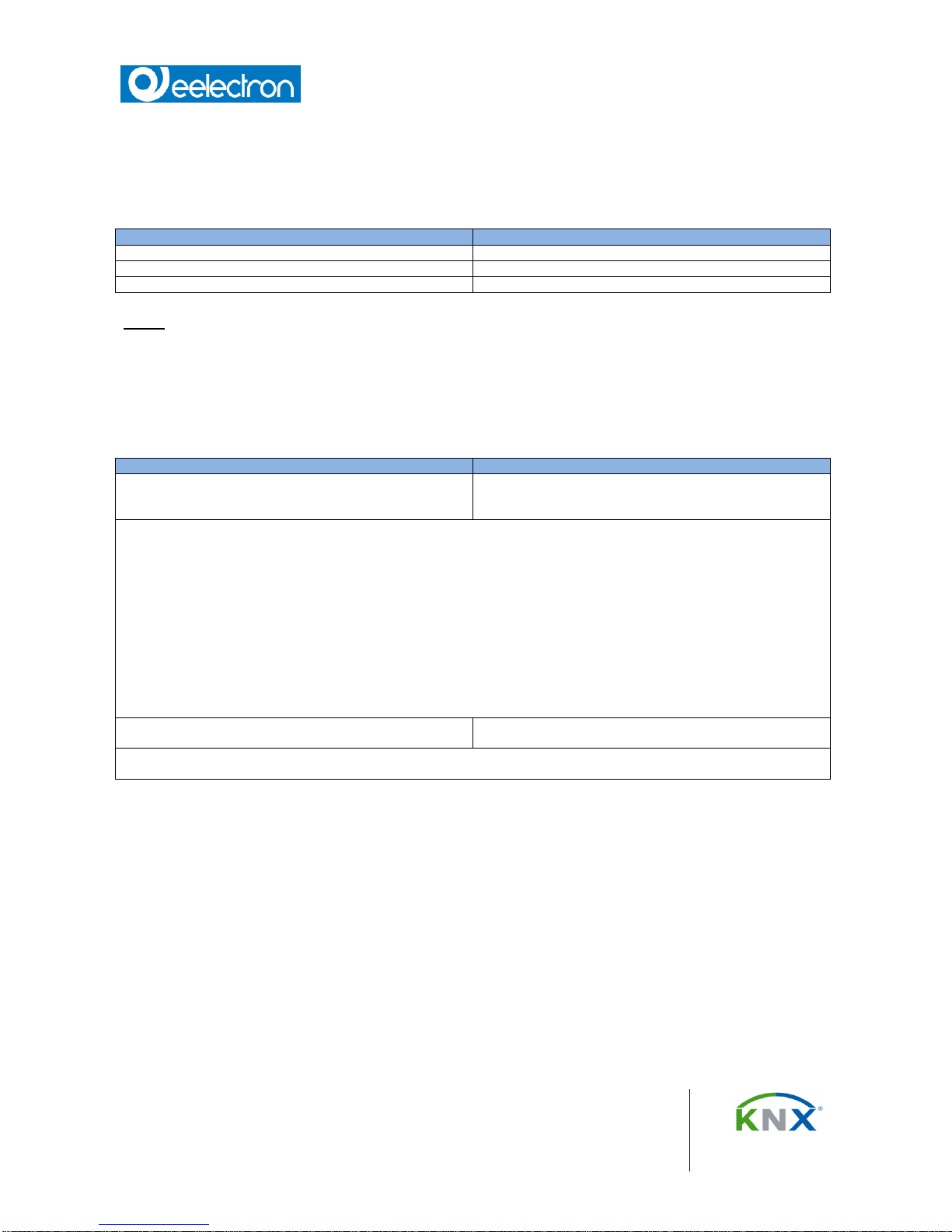

Description

Presence detector, constant light

Application

25 CO Presence detector, constant light

Maximum number of group addresses

160

Maximum number of assignments

200

Note: The number and type of visible objects can vary dependent on the parameter settings.

General

Parameter General

Parameter

Settings

Operating mode

normal (40s start up time)

test mode (5s ramp up without LED)

test mode (5s ramp up with LED)

Use these parameters to determine the mode.

During the test phase the test mode with or without LED can be selected. If “test mode (5s ramp up without LED)” is

selected, the LED of the detector does not flash. So it is possible to test the brightness threshold and the delay time.

In “test mode (5s ramp up with LED)”, the integrated programming LED shows the status of the motion detector. So it is

possible to test the detection range of the PIR sensor independent of the brightness value:

LED stays on:

Programming mode

LED flashes (clocking

sequence):

Device running up

LED comes on for a short time:

Motion has been detected

After the test phase has been finished, the operating mode “normal” should be selected. Afterwards the software has to

be downloaded again to the device.

Evaluate status object [sec.]

(0 = no evaluation)

0-255

4

When switching lights on and off in a detector's detection area, the change of temperature of the lighting may lead to

motion being detected incorrectly. To prevent this, the sensor is disabled for a certain time (0 - 255 seconds).

PD00D01KNX– Product Handbook

Eelectron Spa

Via Claudio Monteverdi 6, I-20025 Legnano (MI), Italia

Tel +39 0331.500802 - Fax +39 0331.564826

info@eelectron.com www.eelectron.com

C.F. e P.IVA 11666760159 - Capitale sociale: 800.000,00 interamente versato

Tribunale di Milano 359157-8760-07 - CCIAA Milano 1486549

PD00D01KNXFI00030103.DOCX

13/42

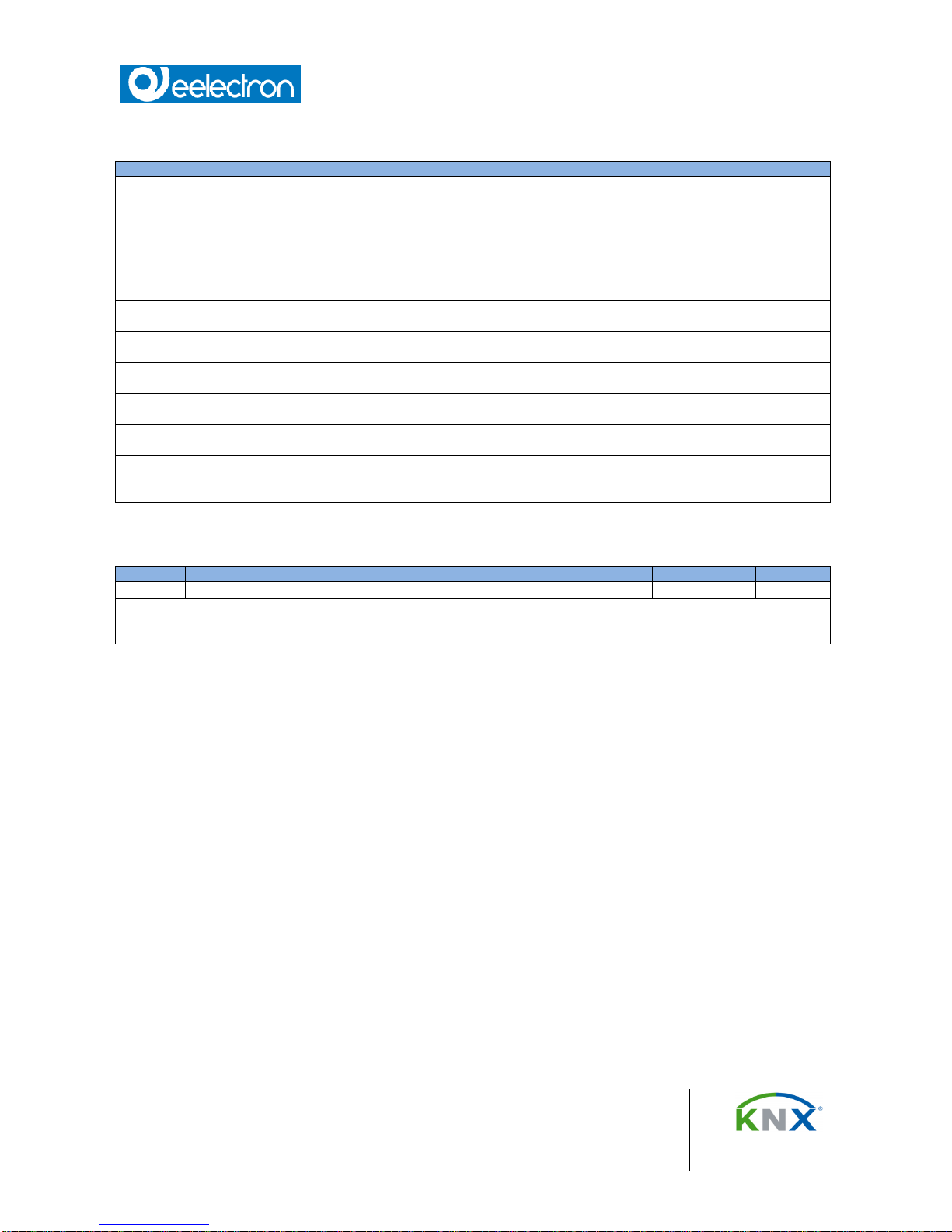

Parameter Functional blocks

Parameter

Settings

Motion detector

deactivated

active

This parameter determines whether an analysis has to be carried out according to the motion detector criteria. If it is

set to “inactive” all relevant additional parameters and objects are invisible.

Presence detector

deactivated

active

This parameter determines whether an analysis has to be carried out according to the presence detector criteria. If

it is set to “inactive” all relevant additional parameters and objects are invisible.

Presence detector (HVAC) (Heating, Ventilating, Air

Conditioning)

deactivated

active

This parameter determines whether an analysis has to be carried out according to the criteria for HVAC control. If

it is set to “inactive” all relevant additional parameters and objects are invisible.

Light control (on-off)

active

deactived

This parameter determines whether an analysis has to be carried out according to the criteria for light control. If it is

set to “inactive” all relevant additional parameters and objects are invisible.

Constant light level control continuous

deactivated

active

This parameter determines whether an analysis has to be carried out according to the criteria for constant light level

control. If it is set to “inactive” all relevant additional parameters and objects are invisible.

General Object

Obj.-no.

Object name

Function

Type

Flags 0 Status of switching actuator

On/Off

1bit

CRWT

This object notifies the detector whether the actuator controlled by the device has switched. If a change of status (1->0

or 0->1) has occurred, then the sensor is not analyzed for a configurable time. This prevents the detector sensing the

fall in temperature of an incandescent lamp that has just been switched off as motion.

Loading...

Loading...