User Manual

EE431

Duct and Immersion Temperature Sensor

User Manual EE431

Content

1 General Information ...................................................................................................................................... 3

1.1 Explanation of Warning Notices and Symbols ....................................................................................... 3

1.2 Safety Instructions ................................................................................................................................ 4

1.2.1. General Safety Instructions ......................................................................................................................... 4

1.2.2. Intended Use ............................................................................................................................................... 4

1.2.3. Mounting, Start-up and Operation ................................................................................................................ 4

1.3 Environmental Aspects.......................................................................................................................... 5

2 Scope of Supply ........................................................................................................................................... 5

3 Product Description ..................................................................................................................................... 5

3.1 General ................................................................................................................................................. 5

3.2 Dimensions ........................................................................................................................................... 6

3.2.1. EE431 Duct and Immersion Temperature Sensor ........................................................................................ 6

3.3 Electrical Connection ............................................................................................................................ 6

3.3.1. Wiring for Active Models .............................................................................................................................. 7

3.3.2. Wiring Diagram for Models with Passive T output ........................................................................................ 9

3.4 Display .................................................................................................................................................. 9

4 Mounting and Installation ............................................................................................................................ 9

4.1 Duct Mounting ..................................................................................................................................... 10

4.1.1. Mounting with flange.................................................................................................................................. 10

4.1.2. Minimum Immersion Depth ........................................................................................................................ 10

4.1.3. Mounting with Immersion Well ................................................................................................................... 10

4.1.4. Maximum Inflow Velocity on the Immersion Well ........................................................................................11

5 Setup and Configuration ............................................................................................................................ 12

5.1 Software ............................................................................................................................................. 12

5.1.1. EE-PCS Product Configuration Software ................................................................................................... 12

5.1.2. PCS10 Product Configuration Software ..................................................................................................... 13

5.2 EE431 analogue with HA011023 ......................................................................................................... 13

5.3 EE431 analogue with EE-PCA and HA011065 .................................................................................... 13

5.4 EE431 with RS485 Digital Interface .................................................................................................... 13

5.4.1. Hardware Bus Termination ........................................................................................................................ 13

5.4.2. Device Address ......................................................................................................................................... 14

5.4.3. BACnet MS/TP Setup ................................................................................................................................ 14

5.4.4. BACnet MS/TP Protocol Settings .............................................................................................................. 14

5.4.5. Modbus RTU Protocol Settings .................................................................................................................. 15

5.4.6. Modbus Register Map ............................................................................................................................... 16

5.4.7. Modbus RTU Example ............................................................................................................................... 17

6 Maintenance and Service ........................................................................................................................... 17

6.1 Calibration and Adjustment ................................................................................................................. 17

6.1.1. Definitions ................................................................................................................................................. 17

6.1.2. Temperature Calibration and Adjustment ................................................................................................... 18

6.1.3. Calibration and Adjustment at E+E Elektronik ............................................................................................ 18

6.1.4. Calibration and Adjustment by the User ..................................................................................................... 18

6.2 Repairs and Display Change............................................................................................................... 19

7 Accessories ................................................................................................................................................ 19

8 Technical Data ............................................................................................................................................ 20

9 Conformity .................................................................................................................................................. 22

9.1 Declarations of Conformity .................................................................................................................. 22

9.2 FCC Part 15 Compliance Statement ................................................................................................... 22

9.3 ICES-003 Compliance Statement ........................................................................................................ 22

Duct and Immersion Temperature Sensor | 2

1 General Information

This user manual serves for ensuring proper handling and optimal functioning of the device. The user manual

shall be read before commissioning the equipment and it shall be provided to all staff involved in transport,

installation, operation, maintenance and repair. E+E Elektronik Ges.m.b.H. does not accept warranty and liability

claims neither upon this publication nor in case of improper treatment of the described products.

This document may contain technical inaccuracies and typographical errors. The content will be revised on a

regular basis. These changes will be implemented in later versions. The described product(s) can be improved

and changed at any time without prior notice.

The user manual may not be used for the purposes of competition without the written consent of E+E Elektronik

Ges.m.b.H. and may not be forwarded to third parties. Copies may be made for internal purposes. All information,

technical data and diagrams included in these instructions are based on the information available at the time of

writing.

PLEASE NOTE

Find this document and further product information on our website at www.epluse.com/ee431.

User Manual EE431

1.1 Explanation of Warning Notices and Symbols

Safety precautions

Precautionary statements warn of hazards in handling the device and provide information on their prevention.

The safety instruction labeling is classified by hazard severity and is divided into the following groups:

DANGER

Danger indicates hazards for persons. If the safety instruction marked in this way is not followed, the hazard

will verly likely result in severe injury or death.

WARNING

Warning indicates hazards for persons. If the safety instruction marked in this way is not followed, there is a

risk of injury or death.

CAUTION

Caution indicates hazards for persons. If the safety instruction marked in this way is not followed, minor or

moderate injuries may occur.

NOTICE

Notice signals danger to objects or data. If the notice is not observed, damage to property or data may

occur.

Informational notes

Informational notes provide important information which stands out due to its relevance.

INFO

The information symbol indicates tips on handling the device or provides additional information on it. The

information is useful for reaching optimal performance of the device.

The title field can deviate from “INFO” depending on the context. For instance, it may also read “PLEASE

NOTE”.

Duct and Immersion Temperature Sensor | 3

1.2 Safety Instructions

1.2.1. General Safety Instructions

NOTICE

Improper handling of the device may result in its damage.

▪ Avoid any unnecessary mechanical stress and inappropriate use.

▪ Installation, electrical connection, maintenance and commissioning shall be performed by qualified

personnel only.

▪ Use the temperature sensors only as intended and observe all technical specifications.

▪ The device is designed for operation with class III supply (EU) and class 2 supply (NA).

▪ Do not apply the supply voltage to the RS485 data lines.

1.2.2. Intended Use

The EE431 duct and immersion temperature sensor is optimized for reliable and accurate temperature monitoring

in air and liquids within the specified temperature range (refer to datasheet www.epluse.com/ee431).Typical

applications for the sensor are building automation, HVAC and process control.

Apply the mounting and installation methods described in chapter 4 Mounting and Installation.

User Manual EE431

WARNING

The manufacturer cannot be held responsible for damages as a result of incorrect handling, installation, and

maintenance of the device.

▪ Do not use the temperature sensors in explosive atmosphere or for measurement of aggressive gases.

▪ This device is not appropriate for safety, emergency stop or other critical applications where device

malfunction or failure could cause injury to human beings.

▪ The device may not be manipulated with tools other than specifically described in this manual.

NOTICE

Failing to follow the instructions in this user manual may lead to measurement inaccuracy and device

failures.

▪ The EE431 may only be operated under the conditions described in this user manual and within the

specification included in chapter 8 Technical Data.

▪ Unauthorized product modification leads to loss of all warranty claims. Modification may be accomplished

only with an explicit permission of E+E Elektronik Ges.m.b.H.!

1.2.3. Mounting, Start-up and Operation

The EE431 has been produced under state of the art manufacturing conditions, has been thoroughly tested and

has left the factory after fulfilling all safety criteria. The manufacturer has taken all precautions to ensure safe

operation of the device. The user must ensure that the device is set up and installed in a way that does not impair

its safe use. The user is responsible for observing all applicable local and international safety guidelines for

safe installation and operation of the device. This user manual contains information and warnings that must be

observed by the user in order to ensure safe operation.

PLEASE NOTE

The manufacturer or his authorized agent can be only be held liable in case of willful or gross negligence.

In any case, the scope of liability is limited to the corresponding amount of the order issued to the

manufacturer. The manufacturer assumes no liability for damages incurred due to failure to comply with the

applicable regulations, operating instructions or the specified operating conditions. Consequential damages

are excluded from the liability.

Duct and Immersion Temperature Sensor | 4

WARNING

Non-compliance with the product documentation may cause safety risk for persons (accidents, personal

injury) or damage to property (measurement installation).

▪ Mounting, installation, commissioning, start-up, operation and maintenance of the device may be

performed by qualified staff only. Such staff must be authorized by the operator of the facility to carry out

the mentioned activities.

▪ The qualified staff must have read and understood this user manual and must follow the instructions

contained within.

▪ All process and electrical connections shall be thoroughly checked by authorized staff before putting the

device into operation.

▪ Do not install or start-up a device supposed to be faulty. Make sure that such devices are not accidentally

used by marking them clearly as faulty.

▪ A faulty device may only be investigated and possibly repaired by qualified, trained and authorized staff. A

faulty device shall be removed from the process.

▪ Service operations other than described in this user manual may only be performed by the manufacturer.

1.3 Environmental Aspects

PLEASE NOTE

Products from E+E Elektronik Ges.m.b.H. are developed and manufactured in compliance with all relevant

environmental protection requirements. Please observe local regulations for the disposal of the device.

User Manual EE431

For disposal, the individual components of the device must be separated according to local recycling

regulations. The electronics shall be disposed of correctly as electronics waste.

2 Scope of Supply

▪ Temperature sensor according to ordering code

▪ Test report according to DIN EN10204-2.2 (for active output only)

▪ Quick guide (digital interface only)

▪ Cable gland

3 Product Description

3.1 General

The EE431 duct and immersion sensor reliably measures the temperature (T) in air and liquids. It is optimized for

building automation, HVAC and process control. The measured data is available at the voltage or current output,

on the RS485 interface with Modbus RTU or BACnet MS/TP protocol and on the optional display. The analogue

output can be set to °C or °F. In addition, the EE431 features a wide choice of sensing elements for passive

temperature measurement.

Duct and Immersion Temperature Sensor | 5

3.2 Dimensions

3.2.1. EE431 Duct and Immersion Temperature Sensor

Values in mm (inch)

Temperature sensor

80.8 (3.18)

63 (2.48)

38 (1.5)

Ø4

(0.16)

Ø6 (0.24)

User Manual EE431

1)

L

39.5 (1.56)

42 (1.65)

55.3 (2.18)

Cable gland M12x1.5

(only for RS485)

Mounting accessories

Mounting flange

(not included in the scope of supply)

56 (2.2)

Ø > 9 (0.35)

20 (0.8)

Cable gland M16x1.5

Optional display

Ø 5

(0.2)

Length

1)

in mm

65 2.56

115 4.53

150 5.91

300 11.81

Length

in inch

Immersion well

(not included in the scope of supply)

Widthacrossats:22 (0.87)

14 (0.55)

Ø8

(0.31)

55.3 (2.18)

8

(0.31)

2)

L

Length

2)

in mm

50 1.97

100 3.94

135 5.31

285 11.22

Length

in inch

3.3 Electrical Connection

EE431 features screw terminals for connecting the power supply and the outputs. Insert the cables into the

enclosure through the M16 cable gland.

NOTICE

It is important to make sure that the cable glands are closed tightly. This is necessary for assuring the IP

rating of the enclosure according to EE431 specification, as well as for stress relief at the screw terminals on

the EE431 board.

Duct and Immersion Temperature Sensor | 6

WARNING

Incorrect installation, wiring or power supply may cause overheating and therefore personal injuries or

damage to property.

For correct cabling of the device, always observe the presented wiring diagram for the product version used.

The manufacturer cannot be held responsible for personal injuries or damage to property as a result of

incorrect handling, installation, wiring, power supply and maintenance of the device.

3.3.1. Wiring for Active Models

Models with analogue output (0...10V)

1

User Manual EE431

Power supply

15 - 35 V DC, 24 V AC ±20 %

5

1

5

Duct and Immersion Temperature Sensor | 7

Models with analogue output (4...20mA)

1

5

User Manual EE431

Power supply

10 V DC + RL x 20 mA < V+ < 35 V DC

1

5

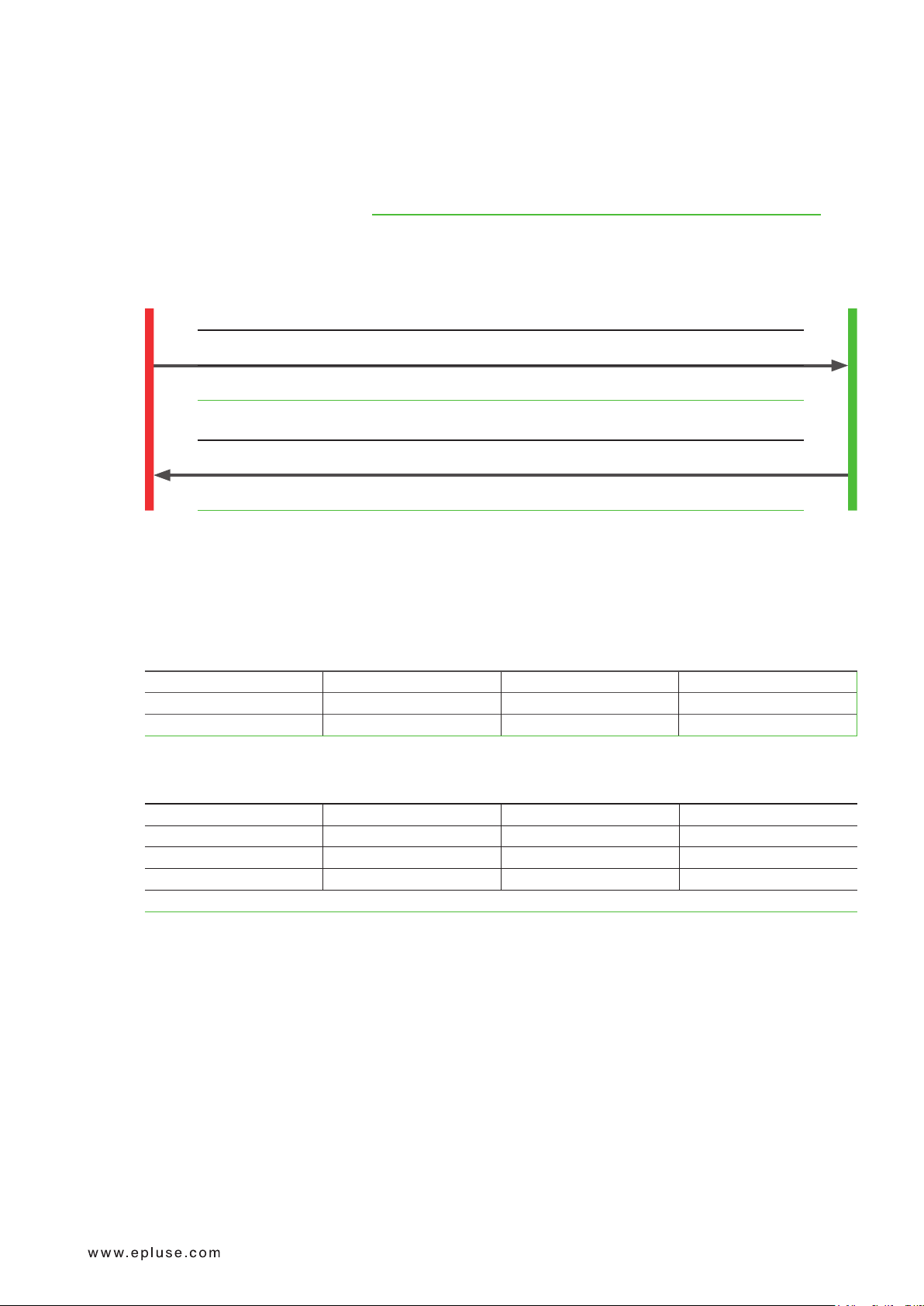

Models with digital interface

1

2

3

4

Power supply

15 - 35 V DC, 24 V AC ±20 %

RS485

GND

A (=D+)

B (=D-)

V+

1

2

3

4

Fig. 1 Temperature sensor connection options

No. Function

1

2

3

4

5

Tab. 1 Part of the digital temperature sensor electronics board types

Screw terminals for power supply and outputs

Address DIP switch for RS485 interface

Configuration connector (USB configuration adapter) for RS485 interface

Busterminationresistor120Ω(jumper)

Configuration connector for analogue version

Duct and Immersion Temperature Sensor | 8

3.3.2. Wiring Diagram for Models with Passive T output

The unit wiring diagram applies to all passive types. The connections can be interchanged.

2-wire connection

Fig. 2 Temperature sensor connection for passive models

3.4 Display

The single-line LC (Liquid Crystal) display is only available for the active models with analogue output (according

to ordering code see datasheet www.epluse.com/ee431).

Depending on the order code, the measured data is displayed in °C or °F. The displayed unit can be changed with

the free PCS10 Product Configuration Software, refer to chapter 5 Setup and Configuration for further details.

User Manual EE431

EE431 set for °F EE431 set for °C

4 Mounting and Installation

NOTICE

Improper handling of the device may result in its damage.

▪ Assembly and installation may only be carried out by qualified personnel.

NOTICE

Failing to follow the instructions in this user manual may lead to measurement inaccuracy and device

failures.

▪ For accurate measurement it is essential that the temperature of the sensor is the same as the

temperature of the air to measure.

▪ Mount the temperature sensor at representative locations of the space to be monitored (see Fig. 3 and

Fig. 5 ).

▪ The sensor may not be exposed to extreme mechanical stress.

For best accuracy please observe the following general mounting instructions and recommended mounting

positions.

Duct and Immersion Temperature Sensor | 9

4.1 Duct Mounting

Flow

Temperature sensor

4.1.1. Mounting with flange

▪ Mount the sensor about one meter from the inlet

▪ Mount the probe in a way, that the probe tip is placed in the middle of the duct

±0.3

60

±0.11

2.36

Ø > 16

Ø > 0.63

Fig. 3 Correct position of the probe in a flange

4.1.2. Minimum Immersion Depth

Placement options

6

0.24

Temperature sensor

User Manual EE431

Temperature sensor

Min. 50 mm (1,97")

Fig. 4 Correct position in a pipe

4.1.3. Mounting with Immersion Well

1. 2.

Fig. 5 Handling of the immersion well

Procedure:

1. The spring inside the well must be removed and replaced by a standard M12x1.5 cable gland

(not included in the scope of supply).

2. Insert the sensor and fix it by fastening the cable gland.

Flow

NOTICE

Observe the operating temperature range of the cable gland to match the process parameters.

Duct and Immersion Temperature Sensor | 10

PLEASE NOTE

Flow

▪ For installation avoid regions of high turbulences (e.g. after fittings)

▪ Mount the sensor in the opposite direction to flow (see the picture Correct Position below)

Correct Position Incorrect Position

User Manual EE431

Flow

Fig. 6 Position of the probe in the pipe with immersion well

4.1.4. Maximum Inflow Velocity on the Immersion Well

Immersion Well Length Brass Stainless Steel

50 mm (1.97") 26 m/s (5118 ft/min) 29 m/s (5708 ft/min)

100 mm (3.94”) 12 m/s (2362 ft/min) 15 m/s (2953 ft/min)

135 mm (5.31”) 6 m/s (1181 ft/min) 9 m/s (1771 ft/min)

285 mm (11.22”) 1 m/s (197 ft/min) 2 m/s (394 ft/min)

Tab. 2 Maximal inflow velocity

Flow

Duct and Immersion Temperature Sensor | 11

5 Setup and Configuration

The temperature sensor is ready to use and does not require any configuration by the user. The factory

setup corresponds to the type number ordered. For ordering guide please refer to the datasheet at

www.epluse.com/ee431. The user can change the factory setup with the free Product Configuration Software and

corresponding accessories (see Tab. 3 Configuration accessories).

Sensor Models EE-PCS PCS10

User Manual EE431

Configuration with

Analogue 0 - 10 V / 4 20 mA

Analogue 0 - 10 V / 4 20 mA

Digital version

Tab. 3 Configuration accessories

No. Description

1

2

Tab. 4 Positioning of the configuration adapter

5.1 Software

HA011023

1

2

EE-PCA with HA011065

EE431-M3J3 HA011066

Plug in the configuration adapter at the bottom

Plug in the configuration adapter on the top

5.1.1. EE-PCS Product Configuration Software

For sensor adjustment and for changing the settings, please proceed as follows:

1. Download the EE-PCS Product Configuration Software from www.epluse.com/configurator and install it on the

PC.

2. Connect the E+E device to the PC using the appropriate configuration adapter.

3. Start the EE-PCS software.

4. Follow the instructions on the EE-PCS opening page for scanning the ports and identifying the connected

device.

5. Click on the desired setup or adjustment mode from the main EE-PCS menu on the left and follow the online

instructions of the EE-PCS.

Duct and Immersion Temperature Sensor | 12

5.1.2. PCS10 Product Configuration Software

For sensor adjustment and for changing the settings, please proceed as follows:

1. Download the PCS10 Product Configuration Software from www.epluse.com/pcs10 and install it on the PC.

2. Connect the E+E device to the PC using the USB configuration adapter.

3. Start the PCS10 software.

4. Follow the instructions on the PCS10 opening page for scanning the ports and identifying the connected

device.

5. Click on the desired setup or adjustment mode from the main PCS10 menu on the left and follow the online

instructions of the PCS10.

5.2 EE431 analogue with HA011023

Use the PCS10 and the HA011023 USB Configuration Adapter for EE431 with analogue output. An external

power supply according to the technical data is required. The power supply adapter V03 is suitable. As soon as

the device is connected to the adapter, the display shows CAL.

With the PCS10, the output scaling, the output measuring unit and the displayed unit (°C or °F) can be changed.

Upper and lower thresholds can be set up for the measurands. The display flashes at one-second interval for

measured T beyond the range.

User Manual EE431

An offset (Fig. 11) and a 1- or 2-point adjustment (Fig. 12) can be performed, as well as a reset to the factory

adjustment and settings. Besides, the configuration settings can also be exported or imported.

Fig. 7 HA011023 USB Configuration Adapter for EE431 with analogue output

5.3 EE431 analogue with EE-PCA and HA011065

Use the EE-PCS and EE-PCA with the connection cable HA011065. For further details see datasheet EE-PCA

(available at www.epluse.com/ee431).

With the PCS10, the output scaling, the output measuring and the displayed unit (°C or °F) can be changed.

An offset (Fig. 11) and a 1- or 2-point adjustment (Fig. 12) can be performed, as well as a reset to the factory

adjustment and settings. Besides, the configuration settings can also be exported or imported.

5.4 EE431 with RS485 Digital Interface

Use the EE-PCS and the USB configuration adapter HA011066.

With the EE-PCS, an offset adjustment (Fig. 11) and 1- or 2-point adjustment (Fig. 12) can be performed.

The temperature adjustment can be reset to the factory settings. In addition, further digital configuration settings

can be made (see below).

5.4.1. Hardware Bus Termination

Thebusterminationcanberealizedwith120Ωresistor(slideswitchontheboard).

Duct and Immersion Temperature Sensor | 13

5.4.2. Device Address

Address Switch

0 0 0 0 0 0 0 0

Address Switch

1 1 0 1 0 0 0 0

User Manual EE431

0

1

0

1

Address setting via EE-PCS Product Configuration Software

All DIP switches at position 0 address has to be set via EE-PCS. (factory

setting)

Modbus (slave device):

Factory setting 66 (permitted values: 1…247).

BACnet (master device):

Factory setting 66 (permitted values: 0…127).

Example: 0000 0000 = Address is set via configuration software.

Address setting via DIP switch

Modbus (slave device): Setting the DIP switches to any other address than 0,

overrules the Modbus address set via EE-PCS (permitted values: 1…247).

BACnet (master device): Setting the DIP switches to any other address than 0,

overrules the BACnet address set via configuration software.

BACnet Note: permitted values are 0…127. The 8th bit of the DIP switches is

ignored (ID 127 = 0111 111). To set address 0 via DIP switches, the 8th bit shall

be set to 1 (ID 0 = 1000 0000).

Example: 0000 1011 binary = Address set to 11.

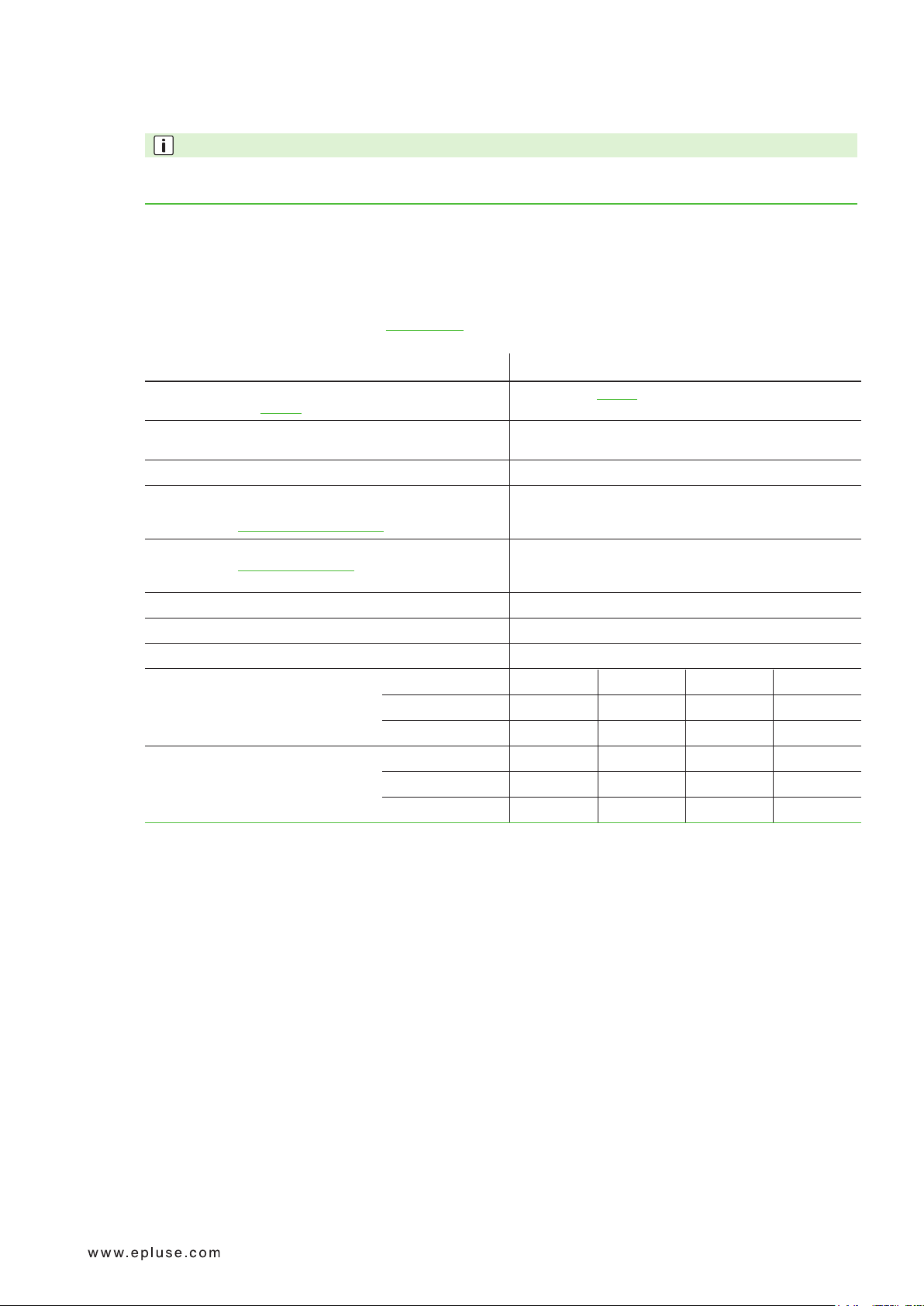

5.4.3. BACnet MS/TP Setup

Refer to PICS (Product Implementation Conformance Statement) - available on www.epluse.com/ee431.

5.4.4. BACnet MS/TP Protocol Settings

Factory settings

Baud rate As per type number ordered 9 600,19 200,38 400,57 600,76 800,115 200

Data bits 8 8

Parity None None

Stop bits 1 1

BACnet address 66 0…127

Tab. 5 BACnet protocol settings

PLEASE NOTE

TherecommendedsettingsformultipledevicesinaBACnetMS/TPnetworkare38 400,8,none,1.

User selectable values

(via EE-PCS / BACnet MS/TP protocol)

The EE4x1D PICS (Product Implementation Conformance Statement) are available on the E+E website at

www.epluse.com/ee431.

BACnet address and baud rate can be set via:

▪ EE-PCS Product Configuration Software and the USB configuration adapter HA011066.

▪ BACnet protocol, see the PICS.

Duct and Immersion Temperature Sensor | 14

5.4.5. Modbus RTU Protocol Settings

User Manual EE431

Factory settings

Baud rate As per type number ordered 9 600,19 200,38 400

Data bits 8 8

Parity Even None, odd, even

Stop bits 1 1, 2

Modbus address 66 1...247

Tab. 6 Modbus RTU protocol settings

User selectable values

(via EE-PCS / Modbus protocol)

PLEASE NOTE

TherecommendedsettingsformultipledevicesinaModbusRTUnetworkare9 600,8,even,1.

Device address, baud rate, parity and stop bits can be set via:

▪ EE-PCS Product Configuration Software and the USB configuration adapter HA011066.

The EE-PCS10 can be downloaded free of charge from www.epluse.com/configurator.

▪ Modbus protocol in the register 1 (0x00) and 2 (0x01).

See Application Note Modbus AN0103 (available at www.epluse.com/ee431).

The measured values are saved as 32 bit float value (FLOAT32) and 16 bit signed integer (INT16). The factory

setting for the Modbus address is 66 as an INT16 value. This address can be changed by the user in the register

1 (0x00), permitted values are 1...247.

The serial number as ASCII-code is located in read-only registers 1 - 8 (0x00 - 0x07, 16 bits per register).

The firmware version is located in register 9 (0x08) (bit 15...8 = major release; bit 7...0 = minor release). The

sensor name as ASCII-code is located in read-only registers 10 - 17 (0x09 - 0x11, 16 bits per register).

NOTICE

When reading the serial number or the sensor name, it is always necessary to read all 8 registers, even if the

desired information requires less.

NOTICE

For obtaining the correct floating point values, both registers have to be read within the same reading

cycle. The measured value can change between two Modbus requests, exponent and mantissa may get

inconsistent then.

Duct and Immersion Temperature Sensor | 15

User Manual EE431

Communication settings (INT16)

Parameter Register number1) [Dec] Register address2) [Hex]

Write register: function code 0x06

Modbus address

Modbus protocol settings

Device information (INT16)

Parameter Register number1) [Dec] Register address2) [Hex]

Read register: function code 0x03 / 0x04

Serial number (as ASCII) 1 0x00

Firmware version 9 0x08

Sensor name (as ASCII) 10 0x09

1) Register number starts from 1.

2) Protocol address starts from 0.

3) If the address is set via DIP switch, the response will be NAK.

4) For Modbus address and protocol settings see Application Note Modbus AN0103 (available at www.epluse.com/ee431).

Tab. 7 Digital sensors’ registers for device setup

3)

4)

1 0x00

2 0x01

5.4.6. Modbus Register Map

The measured data is saved as 32 bit floating point values (FLOAT32) and as 16 bit signed integer values (INT16).

FLOAT32

Measurand Unit

Read register: function code 0x03 / 0x04

Temperature °C 1003 0x3EA

Temperature °F 1005 0x3EC

Temperature °K 1009 0x3F0

INT16

Measurand Unit

Read register: function code 0x03 / 0x04

Temperature °C 100 4002 0xFA1

Temperature °F 50 4003 0xFA2

Temperature K 50 4005 0xFA4

1) The choice of measurement units (metric or non-metric) must be done according to the ordering guide, see EE431 datasheet.

Switching from metric to non-metric or vice versa by using the EE-PCS is not possible.

2) Register number starts from 1

3) Register address starts from 0

4) Examples: For scale 100, the reading of 2550 means a value of 25.5. For scale 50, the reading of 2550 means a value of 51.

Tab. 8 FLOAT32 and INT16 measured data registers

1)

1)

Register number2) [DEC] Register address3)[HEX]

Scale4)Register number2) [DEC] Register address

3)

[HEX]

Duct and Immersion Temperature Sensor | 16

5.4.7. Modbus RTU Example

Example of Modbus RTU command for reading the Temperature (float value) T = 26,953624 °C from the register

0x3EA.

Device EE431; Modbus address 66 [42 in HEX]

Reference document (chapter 6.3): http://www.modbus.org/docs/Modbus_Application_Protocol_V1_1b.pdf.

Read the temperature (FLOAT32) T from register address 0x3EA:

User Manual EE431

Master (e.g. PLC)

Temperature Sensor

Request [Hex]:

Modbus

address

42 03 03 EA 00 02 EB 48

Function

code

Starting

address Hi

Starting

address Lo

Qty. of

registers Hi

Qty. of

registers Lo

CRC

Response [Hex]:

Modbus

address

42 03 04 A1 06 41 D7 3B 04

Fig. 8 Example temperature query

Function

code

Byte

count

Register 1

value Hi

Register 1

value Lo

Register 2

value Hi

Register 2

value Lo

CRC

Decoding of floating point values:

Floating point values are stored according to IEEE754. The byte pairs 1, 2 and 3, 4 are transformed as follows

(numbers taken from T reading Modbus request/response example, Fig. 8):

Modbus response [Hex]

Register 1 Hi Register 1 Lo Register 2 Hi Register 2 Lo

A1 06 41 D7

MMMMMMMM MMMMMMMM SEEEEEEE EMMMMMMM

Fig. 9 Modbus response

IEEE754

Register 2 Hi Register 2 Lo Register 1 Hi Register 1 Lo

41 D7 A1 06

0100 0001 1101 0111 1010 0001 0000 0110

SEEE EEEE EMMM MMMM MMMM MMMM MMMM MMMM

Decimal value: 26.953624725341796875

Fig. 10 Data representation according to IEEE754

6 Maintenance and Service

6.1 Calibration and Adjustment

6.1.1. Definitions

Calibration: The specimen is compared with a reference and its deviation from the reference is documented.

Adjustment: The specimen is brought in line with the reference.

Duct and Immersion Temperature Sensor | 17

6.1.2. Temperature Calibration and Adjustment

Measured value

(or last calibration point LOW)

Depending on the application and the requirements of certain industries, there might arise the need for periodical

temperature calibration or adjustment.

6.1.3. Calibration and Adjustment at E+E Elektronik

Calibration and/or adjustment can be performed in the E+E Elektronik calibration laboratory. For information on

the E+E capabilities in ISO or accredited calibration please see www.eplusecal.com.

6.1.4. Calibration and Adjustment by the User

Depending on the level of accuracy required, the temperature reference can be:

▪ Liquid bath calibrator

▪ Dry block calibrator

▪ Climate chamber

▪ Handheld device (e.g. Omniport30), please see www.epluse.com/omniport30.

Perform offset and 1- or 2-point adjustment via the E+E Product Configuration Software (see below).

User Manual EE431

Measured value

OFFSET

Fig. 11 Offset adjustment

ADJUSTMENT POINT LOW

NEW CHARACTERISTICS

adjusted measured value

FACTORY (or current) CHARACTERISTICS

current measured value

Reference value

1/2 OUTPUT SCALE

ADJUSTMENT POINT HIGH

NEW CHARACTERISTICS

Adjustment point NEW

current measurement

lower limit output scale

Fig. 12 1- or 2-point adjustment

FACTORY (or current) CHARACTERISTICS

Reference value

upper limit output scale

(or last calibration point HIGH)

Duct and Immersion Temperature Sensor | 18

6.2 Repairs and Display Change

PLEASE NOTE

Repairs may be carried out by the manufacturer only. The attempt of unauthorized repair excludes any

warranty claims.

7 Accessories

For further information see datasheet Accessories.

User Manual EE431

Description

Product configuration adapter for 4 - 20 mA version without

display (Available at EE-PCA)

Configuration adapter for display and 0 - 10 V versions without

display

USB configuration adapter for digital output HA011066

E+E Product Configuration Software for digital output and

for 4 - 20 mA version without display

(Free download: www.epluse.com/configurator)

E+E Product Configuration Software

(Free download: www.epluse.com/pcs10) for display and 0 - 10 V

versions without display

Power supply adapter for digital output V03

Conduit Adapter, M16x1.5 auf 1/2" HA011110

Mounting flange HA401101

Immersion well - thread R ½" ISO

Immersion well - thread ½" NPT

Length in mm (inch) 50 (1.97") 100 (3.94") 135 (5.31") 285 (11.22")

Brass HA400101 HA400104 HA400102 HA400103

Stainless steel

Length in mm (inch) 50 (1.97") 100 (3.94") 135 (5.31") 285 (11.22")

Brass HA400111 HA400114 HA400112 HA400113

Stainless steel

Code

See datasheet EE-PCA

HA011023

EE-PCS

PCS10

HA400201 HA400204 HA400202 HA400203

HA400211 HA400214 HA400212 HA400213

Duct and Immersion Temperature Sensor | 19

8 Technical Data

Measurands

Temperature (T) - Active

Measuring range Duct sensor (probe tip)

With immersion well (probe tip)

Accuracy

@ 20 °C (68 °F)

Optional for analogue output

1) Uncertainty of factory calibration at 20 °C ±0.1 °C (68 °F ±0.18 °F).

Temperature (T) - Passive

Measuring range

Duct sensor

Immersion Sensor with Pt and Ni T sensor

Sensor type

Pt100 DIN B R0:100Ω TC: 3.850 x 10-3/°C DIN EN 60751

Pt1000 DIN B

NTC10k B3950 R25:10kΩ±0.5%

NTC20k B4286 R25:20kΩ±0.2°C

Ni1000 TK6180 DIN B R0:1000Ω TC: 6180 ppm/K DIN 43760

Ni1000 TK5000 DIN B R0:1000Ω TC: 5000 ppm/K DIN 43760

User Manual EE431

-40 °C…+110 °C (-40...+230 °F)

-40 °C…+130 °C (-40...+266 °F)

±0.25 °C (0.36 °F)

±0.1 °C (±0.18 °F)

-40 °C…+110 °C (-40...+230 °F)

-40 °C…+150 °C (-40...+302 °F)

Nominal resistance Sensitivity Standard

R0:1000Ω TC: 3.850 x 10-3/°C

1)

DIN EN 60751

B

: 3989 K

25/85

(B

: 3950 K ± 1.0 %)

25/50

B

: 4286 K

25/85

(B

: 4286 K ± 1.0 %)

25/85

-

-

Outputs

Analogue

Analogue output 0 - 10 V -1mA < IL < 1 mA IL = load current

Digital

Digital interface RS485 (EE431 = 1 Unit Load)

Protocol

Factory settings

Supported Baud rates

Measured data types

Protocol

Factory settings

Supported Baud rates

T Sensor Passive

Sensor connection 2-wire connection

Measuring current, typ. <1 mA (according to technical data of the specific T sensing element)

4 - 20 mA (2-wire) RL ≤500Ω RL = load resistance

Modbus RTU

Baud rate see order information, data bits 8, parity even, 1 stop bit, Modbus address 66

9 600,19 200und38 400

FLOAT32 and INT16

BACnet MS/TP

Baud rate see order information, data bits 8, parity none, 1 stop bit, BACnet address 66

9 600,19 200,38 400,57 600,76 800und115 200

Duct and Immersion Temperature Sensor | 20

User Manual EE431

General

Power supply class III

USA & Canada: Class 2 supply necessary,

max. voltage 30 V DC

for output RS485 and 0 - 10 V

for output

Current consumption,

4 - 20 mA

Voltage output DC supply max. 0.8mA

@ 24 V

Current output According to output current According to output current

Digital interface DC supply typ. 3.5 mA

Electrical connection Screw terminals max. 2.5 mm2 (AWG14)

Cable glands M16x1.5 / M12x1.5 / UL94 V-2

Insulation resistance (probe)

@20 °C (68 °F)

LC-display Available for output A3 and A6

Response time t

Duct sensor at 3 m/s (590 ft/min) air velocity

63

Immersion sensor in liquid water bath

Humidity working range 5…95 %RH, non-condensing

Temperature working range

Storage conditions

Without display

With display

Probe material Stainless steel (1.4571 / 316Ti)

Enclosure Material

Protection rating

Electromagnetic compatibility EN 61326-1 EN 61326-2-3 Industrial environment

Conformity

15 - 35 V DC or 24 V AC ±20 %

10 V DC + RL x 20 mA < V+ < 35 V DC RL = load resistance

with display max. 1.7 mA

AC supply max. 4.6 mA

AC supply typ. 12 mA

rms

rms

with display max. 7 mA

rms

>100MΩ

1 line, switchable between °C / °F or according to order code

Without backlight

Visible area 38 mm x 20 mm (1.5" x 0.8")

<1 min

<30 s

Duct sensor

(probe tip)

-40…+110 °C

(-40...+230 °F)

With immersion well (probe tip) Electronics

Active Passive

-40…+130 °C

(-40...+266 °F)

-40 °C…+150 °C

(-40...+302 °F)

without Display

-40…+70 °C

(-40...+158 °F)

-30…+70 °C (-22...+158 °F)

5…95 %RH, non-condensing

-20...+50 °C (-4...+122 °F)

5…95 %RH, non-condensing

Polycarbonate (PC), UL94 V-0 approved

IP65 / NEMA4X

FCC Part15 Class B ICES-003 Class B

Electronics

with Display

-20...+50 °C

(-4...+122 °F)

Configuration and adjustment

For display and 0 - 10 V

For digital and 4 - 20 mA version without display

PCS10 Product Configuration Software (free download: www.epluse.com/pcs10) and

configuration adapter.

EE-PCS Product Configuration Software (free download: www.epluse.com/configurator)

and configuration adapter.

Duct and Immersion Temperature Sensor | 21

9 Conformity

9.1 Declarations of Conformity

E+E Elektronik Ges.m.b.H. hereby declares that the product complies with the respective regulations listed below:

European directives and standards.

and

UK statutory instruments and designated standards.

Please refer to the product pages at www.epluse.com/ee431 for the Declarations of Conformity.

9.2 FCC Part 15 Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the installation manual, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

User Manual EE431

▪ Reorient or relocate the receiving antenna.

▪ Increase the separation between the equipment and receiver.

▪ Connect the equipment into an outlet on a circuit different from that to which thereceiver is connected.

▪ Consult the dealer or an experienced radio/TV technician for help.

9.3 ICES-003 Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Duct and Immersion Temperature Sensor | 22

Company Headquarters &

Production Site

E+E Elektronik Ges.m.b.H.

Langwiesen 7

4209 Engerwitzdorf | Austria

T +43 7235 605-0

F +43 7235 605-8

info@epluse.com

www.epluse.com

Subsidiaries

E+E Sensor Technology (Shanghai) Co., Ltd.

T +86 21 6117 6129

info@epluse.cn

E+E Elektronik France SARL

T +33 4 74 72 35 82

info.fr@epluse.com

E+E Elektronik Deutschland GmbH

T +49 6171 69411-0

info.de@epluse.com

E+E Elektronik India Private Limited

T +91 990 440 5400

info.in@epluse.com

E+E Elektronik Italia S.R.L.

T +39 02 2707 86 36

info.it@epluse.com

E+E Elektronik Korea Ltd.

T +82 31 732 6050

info.kr@epluse.com

E+E Elektronik Corporation

T +1 847 490 0520

info.us@epluse.com

Version v1.0 | 11-2023

© Copyright E+E Elektronik Ges.m.b.H. | All rights reserved.

Loading...

Loading...