Page 1

Operating manual

data logger

for external sensors

BA-OP20E-04-EN

v1.0 / Modification rights reserved

Page 2

This release replaces all previous releases. No part of this publication may be reproduced without written permission. The same applies for electronically processing, duplicating or spreading the publication. Subject to technical changes. All rights

reserved. Trademarks are used without guarantee that they may be used freely and primarily following the spelling of the manufacturer. The product names used are registered and should be treated appropriately. Changes to construction in the

interests of constant improvements to the product, as well as changes to the shape and colour are reserved. The delivered product may vary from product images. This document was produced with all due care. We accept no liability whatsoever

for mistakes or omissions.

Operating manual data logger for external sensors

2

EN

In order to use your data logger according to its intended use and utilise its com-

plete range of functions, carefully read all documentation about this device.

This operating manual describes the functions of the hardware.

A separate manual – the software manual – describes how to use the software

and configure the data logger with the software and can be opened after the

software has been installed by using the help function in the software.

Your new data logger was built according to current state-of-the-art technology

and fulfils valid European and national directives. This conformity has been

tested and the corresponding declarations and documents are kept on file by

the manufacturer.

To keep this condition and ensure safe operation, as a user, you must observe

the following safety instructions:

1. Safety

We accept no liability for damages caused by non-observance of this manual

or unprofessional handling. Any warranty claims are voided in such cases !

Before starting the measuring device for the first time, read this

manual from front to bac

k !

For reasons of safety and conformity (CE), any unauthorised change made to

the device construction or components which are to be used with the measuring

device are prohibited!

Before using the device, observe the following:

• Never measure live parts.

• Observe the storage and operating conditions.

• The only party responsible for determining measured results to be valid,

drawing conclusions and deriving actions is the user ! The correctness of

the results presented is excluded from any liability or guarantee.

Liability for damages which have been caused by utilising

the

pr

esented measured results is strictly excluded.

2. Intended use

The data logger is designed to detect and record a range of measured values

that are detected by the measuring device and the connected external sensors.

The measured data can be detected at variable selectable recording or request

intervals, then saved and transmitted to a connected PC.

The measuring device may only be used for this intended use while complying

with specified technical data for the measuring device and external sensors.

Any other use is considered misuse and contrary to the intended use.

The product must not be disposed of with household waste.

Dispose of this device in a manner according to the relevant

legal requirements.

Content Page

1. Safety 2

2. Intended use 2

3. Equipment 3

4. Scope of supply 4

5. Preparation before starting 4

5.1.

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5.1.1. Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5.1.2. Installation of the SmartGraph software . . . . . . . . . . . . . .4

5.1.3 Preparing data logger configuration . . . . . . . . . . . . . . . . .4

5.2. Note at initial startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

6. Operation 4

6.1.

Switching on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

6.2. Basic settings and operating modes . . . . . . . . . . . . . . . . . . . . . . .4

6.2.1. The four operating modes . . . . . . . . . . . . . . . . . . . . . . . .5

6.2.2. Network function (M51) . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.2.3. Factory settings (M52) . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.2.4. Acoustic function (M53) . . . . . . . . . . . . . . . . . . . . . . . . . .6

7. Connection and configuration of external sensors 6

7.1

BUS sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7.1.1 Connection of BUS sensors . . . . . . . . . . . . . . . . . . . . . . . .6

7.1.2 Configuration of BUS sensors (M6x) . . . . . . . . . . . . . . . . .6

7.1.3 Logging the BUS sensors (M7x) off . . . . . . . . . . . . . . . . . .7

7.2 Connection of analogue sensors . . . . . . . . . . . . . . . . . . . . . . . . . .7

7.2.1 Sensors for measuring voltage 0 - 1V . . . . . . . . . . . . . . .7

7.2.2 Sensors for measuring current, 2-cable 4 - 20 mA

and 3-cable 0 - 20 mA . . . . . . . . . . . . . . . . . . . . . . . . . . .7

7.2.3 Pt100 sensors in 3- and 4-cable switching . . . . . . . . . . .8

7.2.4 Thermal elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.3 Configuration of analogue sensors (M81) . . . . . . . . . . . . . . . . . . .8

8. Measured values display and data recording 9

8.1.

Channel groups and measuring channels . . . . . . . . . . . . . . . . . . .9

8.2 Processing channels for converting measured values . . . . . . . . . .9

8.3. Displaying measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

8.4. Data recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9. Alarm function 11

9.1.

Alarm configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

9.2. Alarm display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

9.3. Acoustic alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

9.4. Using the alarm hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

10. Notes on maintenance and operation 12

10.1. Battery change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

10.2. Deleting measured data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

10.3. Positioning for mobile use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

10.4. Mounting on a wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

10.5. Moving to another site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

11. Technical data 13

12. Status codes 14

Table of contents

Page 3

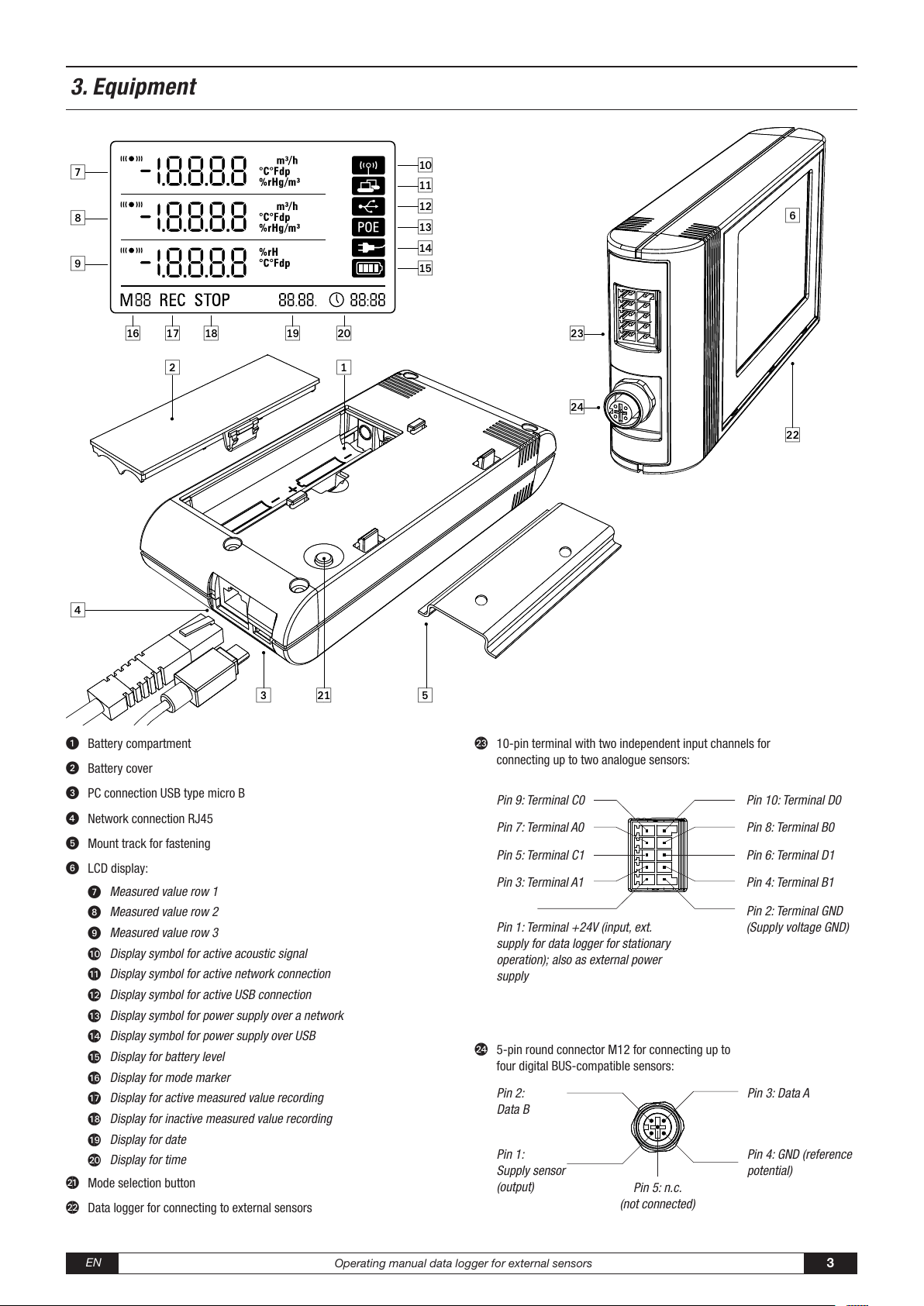

3. Equipment

Battery compartment

Battery cover

PC connection USB type micro B

Network connection RJ45

Mount track for fastening

LCD display:

Measured value row 1

Measured value row 2

Measured value row 3

Display symbol for active acoustic signal

Display symbol for active network connection

Display symbol for active USB connection

Display symbol for power supply over a network

Display symbol for power supply over USB

Display for battery level

Display for mode marker

Display for active measured value recording

Display for inactive measured value recording

Display for date

Display for time

Mode selection button

Data logger for connecting to external sensors

10-pin terminal with two independent input channels for

connecting up to two analogue sensors:

Pin 9: Terminal C0

Pin 7: Terminal A0

Pin 5: Terminal C1

Pin 3: Terminal A1

Pin 1: Terminal +24V (input, ext.

supply for data logger for stationary

operation); also as external power

supply

5-pin round connector M12 for connecting up to

four digital BUS-compatible sensors:

Pin 2:

Data B

Pin 1:

Supply sensor

(output)

Pin 5: n.c.

(not connected)

Pin 10: Terminal D0

Pin 8: Terminal B0

Pin 6: Terminal D1

Pin 4: Terminal B1

Pin 2: Terminal GND

(Supply voltage GND)

Pin 3: Data A

Pin 4: GND (reference

potential)

EN

Operating manual data logger for external sensors

3

Page 4

Operating manual data logger for external sensors

4

EN

5.2. Note at initial startup

b

After starting the device for the first time, the message “SET TIME”

appears on the display. However, no settings need to be made directly

on the device. The time synchronises itself with the PC time automatically when

connected to the SmartGraph software for the first time.

6. Operation

The PC software SmartGraph is the central configuration interface for your data

log

ger. All additional configuration and visualisation specifications can only be

set by software.

Basic settings can be directly configured with one-button operation by using

the mode selection button on your data logger.

You can restrict the one-button operation with the mode selection button from

your software if necessary (key lock). It is not possible to operate your data

logger with the mode selection button in this case.

6.1. S

witching on and off

When current is being supplied, the data logger cannot completely switch off,

but can only be set to an operating mode with minimal energy consumption

(M1). In this mode, measured value detection, measured value display and data

recording are inactive. An overview of the four various operating modes is pro-

vided in the next chapter.

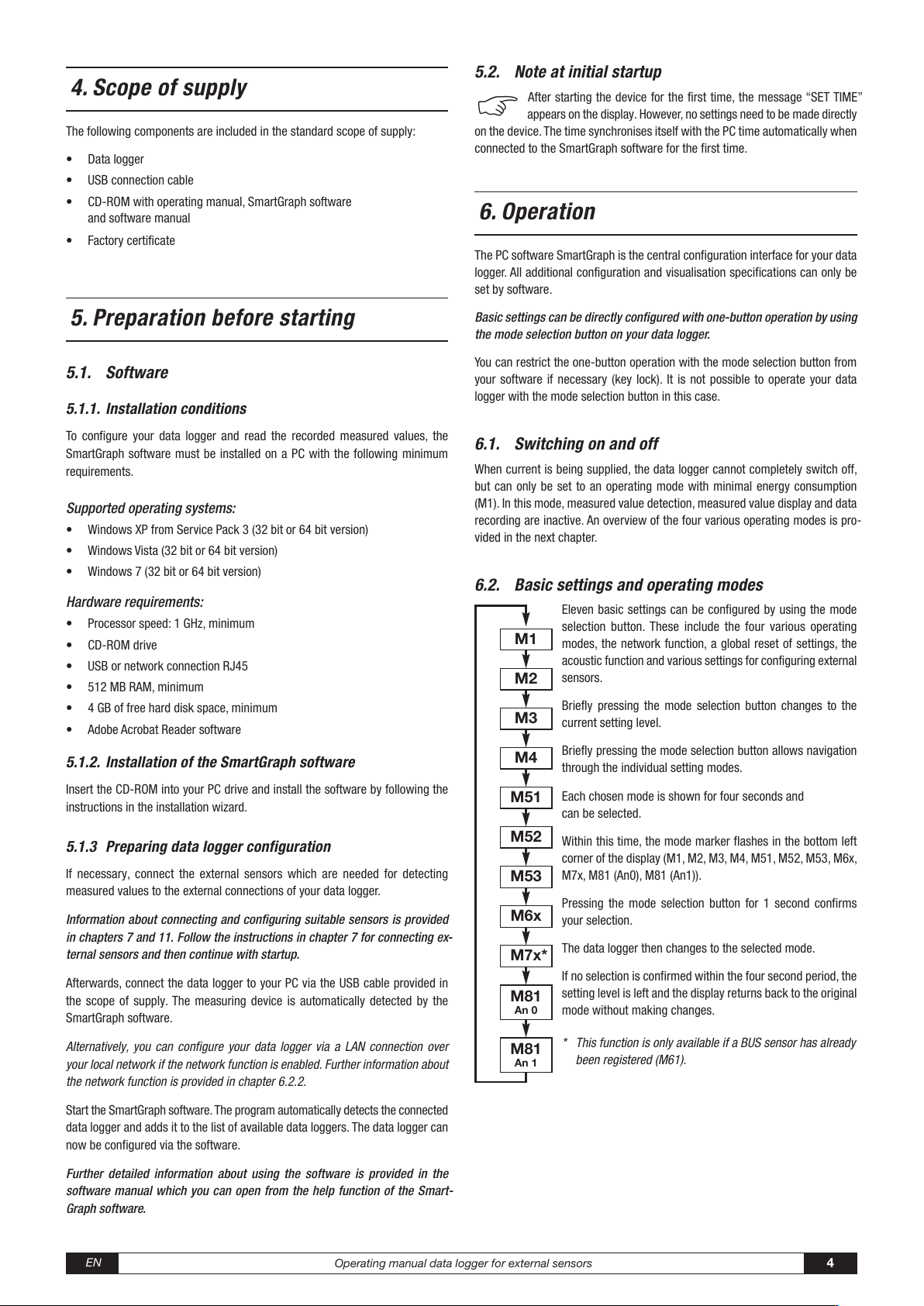

6.2. B

asic settings and operating modes

Eleven basic settings can be configured by using the mode

selection button. These include the four various operating

modes, the network function, a global reset of settings, the

acoustic function and various settings for configuring external

sensors.

Briefly pressing the mode selection button changes to the

current setting level.

Briefly pressing the mode selection button allows navigation

through the individual setting modes.

Each chosen mode is shown for four seconds and

can be selected.

Within this time, the mode marker flashes in the bottom left

corner of the display (M1, M2, M3, M4, M51, M52, M53, M6x,

M7x, M81 (An0), M81 (An1)).

Pressing the mode selection button for 1 second confirms

your selection.

The data logger then changes to the selected mode.

If no selection is confirmed within the four second period, the

setting level is left and the display returns back to the original

mode without making changes.

* This function is only available if a BUS sensor has already

been registered (M61).

M81

An 0

M1

M2

M3

M4

M51

M52

M53

M6x

M81

An 1

M7x*

4. Scope of supply

The following components are included in the standard scope of supply:

• Data logger

• USB connection cable

• CD-ROM with operating manual, SmartGraph software

and software manual

• Factory certificate

5. Preparation before starting

5.1. Software

5.1.1. Installation conditions

To configure your data logger and read the recorded measured values, the

SmartGraph software must be installed on a PC with the following minimum

requirements.

Supported operating systems:

• Windows XP from Service Pack 3 (32 bit or 64 bit version)

•

Windows Vista (32 bit or 64 bit version)

• Windows 7 (32 bit or 64 bit version)

Hardware requirements:

• Processor speed: 1 GHz, min

imum

•

CD-ROM drive

• USB or network connection RJ45

• 512 MB RAM, minimum

• 4 GB of free hard disk space, minimum

• Adobe Acrobat Reader software

5.1.2. Installation of the SmartGraph software

Insert the CD-ROM into your PC drive and install the software by following the

instructions in the installation wizard.

5.1.3 Preparing data logger configuration

If necessary, connect the external sensors which are needed for detecting

measured values to the external connections of your data logger.

Information about connecting and configuring suitable sensors is provided

in chapters 7 and 11. Follow the instructions in chapter 7 for connecting ex-

ternal sensors and then continue with startup.

Afterwards, connect the data logger to your PC via the USB cable provided in

the scope of supply. The measuring device is automatically detected by the

SmartGraph software.

Alternatively, you can configure your data logger via a LAN connection over

your local network if the network function is enabled. Further information about

the network function is provided in chapter 6.2.2.

Start the SmartGraph software. The program automatically detects the connected

data logger and adds it to the list of available data loggers. The data logger can

now be configured via the software.

Further detailed information about using the software is provided in the

software manual which you can open from the help function of the Smart-

Graph software.

Page 5

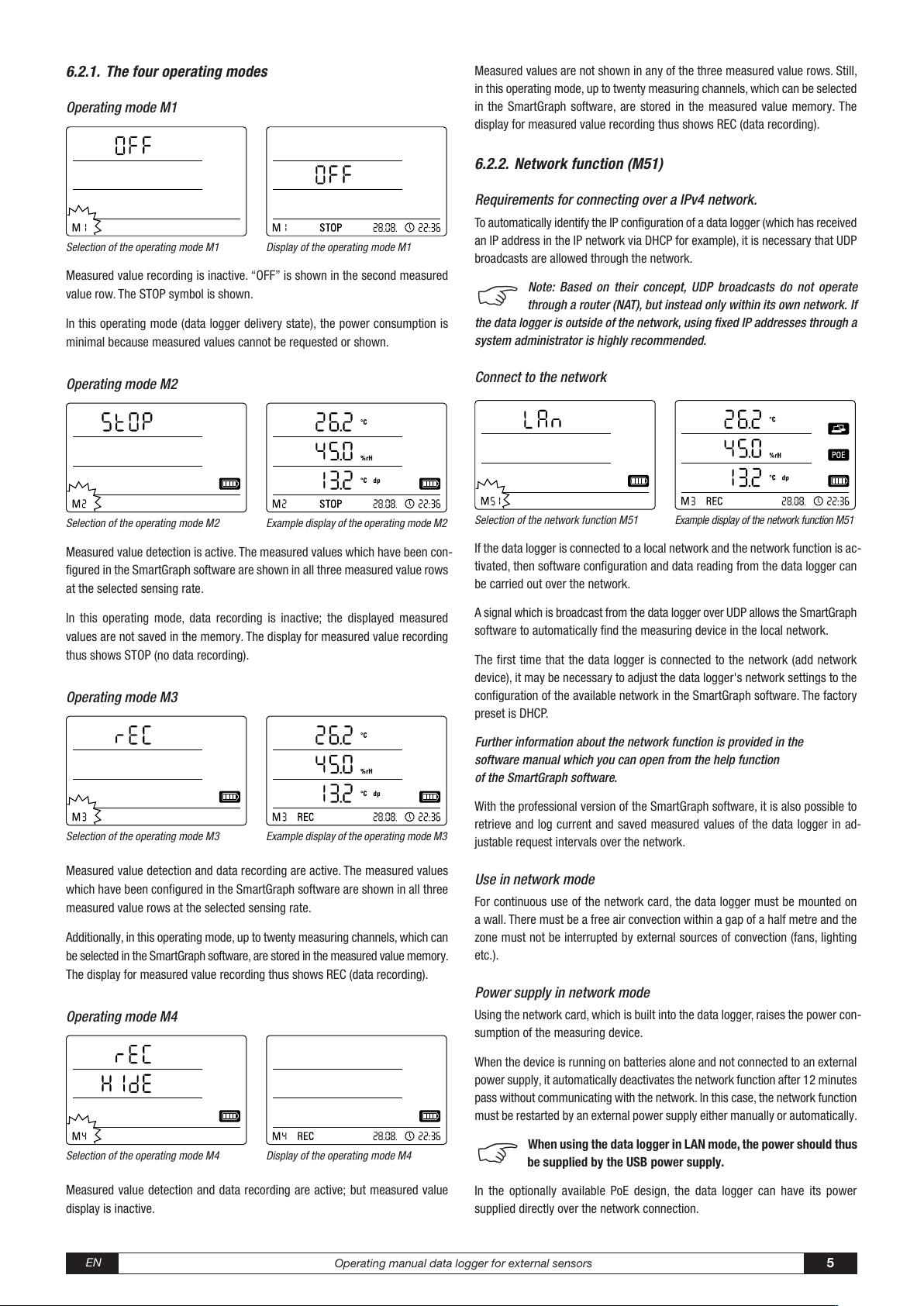

.2.1. The four operating modes

6

Operating mode M1

Selection of the operating mode M1 Display of the operating mode M1

Measured value recording is inactive. “OFF” is shown in the second measured

value row. The STOP symbol is shown.

In this operating mode (data logger delivery state), the power consumption is

minimal because measured values cannot be requested or shown.

Measured values are not shown in any of the three measured value rows. Still,

in this operating mode, up to twenty measuring channels, which can be selected

in the SmartGraph software, are stored in the measured value memory. The

display for measured value recording thus shows REC (data recording).

6.2.2. Network function (M51)

Requirements for connecting over a IPv4 network.

To automatically identify the IP configuration of a data logger (which has received

an IP address in the IP network via DHCP for example), it is necessary that UDP

broadcasts are allowed through the network.

Note: Based on their concept, UDP broadcasts do not operate

b

the data logger is outside of the network, using fixed IP addresses through a

system administrator is highly recommended.

through a router (NAT), but instead only within its own network. If

Operating mode M2

Selection of the operating mode M2 Example display of the operating mode M2

Measured value detection is active. The measured values which have been con-

figured in the SmartGraph software are shown in all three measured value rows

at the selected sensing rate.

In this operating mode, data recording is inactive; the displayed measured

values are not saved in the memory. The display for measured value recording

thus shows STOP (no data recording).

Operating mode M3

Selection of the operating mode M3 Example display of the operating mode M3

Connect to the network

Selection of the network function M51

If the data logger is connected to a local network and the network function is ac-

tivated, then software configuration and data reading from the data logger can

be carried out over the network.

A signal which is broadcast from the data logger over UDP allows the SmartGraph

software to automatically find the measuring device in the local network.

The first time that the data logger is connected to the network (add network

device), it may be necessary to adjust the data logger's network settings to the

configuration of the available network in the SmartGraph software. The factory

preset is DHCP.

Further information about the network function is provided in the

software manual which you can open from the help function

of the SmartGraph software.

With the professional version of the SmartGraph software, it is also possible to

retrieve and log current and saved measured values of the data logger in ad-

justable request intervals over the network.

Example display of the network function M51

Measured value detection and data recording are active. The measured values

which have been configured in the SmartGraph software are shown in all three

measured value rows at the selected sensing rate.

Additionally, in this operating mode, up to twenty measuring channels, which can

be selected in the SmartGraph software, are stored in the measured value memory.

The display for measured value recording thus shows REC (data recording).

Operating mode M4

Selection of the operating mode M4 Display of the operating mode M4

Measured value detection and data recording are active; but measured value

display is inactive.

EN

Operating manual data logger for external sensors

Use in network mode

For continuous use of the network card, the data logger must be mounted on

a wall. There must be a free air convection within a gap of a half metre and the

zone must not be interrupted by external sources of convection (fans, lighting

etc.).

Power supply in network mode

Using the network card, which is built into the data logger, raises the power con-

sumption of the measuring device.

When the device is running on batteries alone and not connected to an external

power supply, it automatically deactivates the network function after 12 minutes

pass without communicating with the network. In this case, the network function

must be restarted by an external power supply either manually or automatically.

When using the data logger in LAN mode, the power should thus

b

In the optionally available PoE design, the data logger can have its power

supplied directly over the network connection.

be supplied by the USB power supply.

5

Page 6

Information for system administrators

Broadcast over UDP:

PC sends to ....................................UDP:255.255.255.255:52010

(data logger receives at UDP port 52010*)

data logger replies to ......................UDP:255.255.255.255:52005

(PC receives at UDP port 52005*)

Data transmission over TCP:

data logger receives at TCP port 52015*

* The ports can be reconfigured, but this is not recommended.

Open or lost TCP connections are closed by the data logger after a TCP timeout

of 120 seconds.

.2.4. Acoustic function (M53)

6

Activating or deactivating the acoustic function switches the data logger's

acoustic signal either on or off. If the acoustic function is active, the function's

display symbol is shown on the display.

When the acoustic function is active, alarm results are indicated as a tone, pro-

vided an active alarm has been preset for one or more of the three display

measured values in the SmartGraph software.

Selection of the acoustic function M53 Example display of the acoustic function M53

6.2.3. Factory settings (M52)

This function resets the device settings

to factory settings.

Even when resetting the device to factory

settings or when there are no batteries

in the device, the measurement data re-

mains in the memory and is not deleted.

Selection of the reset function M52

Information about deleting the measured data is provided in chapter 9.2.

If the acoustic function is not active, then none of the navigations steps which

require the mode selection button on the data logger to be pressed are acknowl-

edged by a tone. The same applies for selecting a mode.

If no selection is made, and thus the setting level is exited, then a tone is also

emitted.

7. Connection and configuration of external sensors

The data logger has a 5-pin round connector M12 for connecting digital BUS-

compatible sensors (BUS-sensor) and also has a 10-pin terminal with two inde-

pendent input channels for connecting up to two analogue sensors.

7.1 BUS sensors

7.1.1 Connection of BUS sensors

Attach the BUS sensor to the 5-pin round connector of the data logger (see ,

chapter 3). The sensor is supplied with current via the plug.

By optionally using up to three Y-distributors, a maxi-

mum of four digital BUS sensors can be connected to

the data logger.

Further information about the currently available BUS

sensors is provided in the technical data in chapter 11.

7.1.2 Configuration of BUS sensors (M6x)

So that BUS sensors can be used with the data logger, each BUS sensor must

first be registered at the data logger individually.

It is only possible to configure if the data logger is not

in logging mode (M3 or M4)!

The BUS sensors can be configured at the data logger as described below or

otherwise, directly in the SmartGraph software. Further detailed information

about configuration of the BUS sensors in the software is provided in the

software manual which you can open by using the help function of the Smart-

Graph software.

To configure at the data logger, connect the first BUS sensor to be registered to

the 5-pin round connector of the data logger and then use the mode selec -

tion button to navigate to the configuration mode M6x – as described in chapter

6.2. The option for registering the BUS sensor is shown on the display (n1 for

the first sensor to n4 for the fourth sensor).

Briefly pressing the mode selection button starts registration of the BUS sensor.

The display then changes to the scan mode and the connected BUS sensor is

automatically detected and identified.

At identification, the sensor is assigned a four-digit BUS ID. The first two digits

of the ID represent the sensor type (e.g. 71 for TFF sensors). The last two digits

represent the sensor number and are automatically assigned according to the

order of registration – 01 for the first to 04 for the fourth registered sensor.

After sensor registration, a message is displayed with information about the

BUS ID – the message symbol in the bottom right corner of the display flashes.

Briefly pressing the mode selection button closes the message.

Tip: Note the BUS ID for measuring in the future

directly on the sensor.

R

EN

Operating manual data logger for external sensors

6

Page 7

.2.1 Sensors for measuring voltage 0 - 1V

Ri

+-

Sensor

B0 / B1

A0 / A1

GND

Sensor: 4 … 20 mA

External power supply

A0 / A1

+24V

Sensor

GND

Sensor: 0/ 4 … 20 mA

External power supply

A0 / A1

+24V

Sensor

7

The sources of voltage are connected with the positive pole at terminal B and

with the negative pole at terminal A, as shown in the diagram:

Example display: Registration function

61 selection for registering the first

M

BUS sensor (n1).

Important: If several sensors are used, each sensor must first

b

signed a BUS ID in this manner. The registration process cannot be carried

out if more than one sensor is connected to the BUS !

Thus, ensure that only the applicable sensor is connected

to the BUS for registration.

This restriction only applies for the registration process. After all sensors

have been individually registered, it is possible to use several BUS sensors

without difficulty, of course.

Otherwise, the BUS sensors can be configured directly

in the SmartGraph software.

Further detailed information about configuration of the BUS sensors in the

software is provided in the software manual which you can open by using

the help function of the SmartGraph software.

be individually connected to the data logger, registered and as-

Example display: Message specifying

he BUS ID (71.01) for the first registered

t

BUS sensor.

7.1.3 Logging the BUS sensors (M7x) off

Important: The voltage input is a real difference input.

If the sensor is connected to the data logger via cables which are

too long, it might be necessary to connect the sensor via shielded cabling.

The cable shield should be connected to the GND terminal.

To register and configure sensors for measuring voltage at the data logger,

follow the instructions in chapter 7.3.

7.2.2 Sensors for measuring current, 2-cable 4 - 20 mA

and 3-cable 0 - 20 mA

The switching supports current measurement in 2-cable and 3-cable operation.

For 2-cable operation, sensor supply and supply for the datalogger must have

identical reference potential. In 2-cable and 3-cable operation, the sensor

current is fed into the A0/A1 terminal.

Wiring diagram for measuring current in 2-cable operation:

Example display: Log off function M70

selection for logging off the first selected

sensor.

To log off a registered BUS sensor from the data logger again, use the mode

selection button to navigate to the configuration mode M7x. The option for re-

moving the first BUS sensor is shown on the display.

To log off, it is not necessary to connect the sensor to the device!

If several BUS sensors had already been connected and a BUS sensor which is

not the first is to be removed, press the mode selection button until the BUS ID

shows the sensor to be removed.

Briefly pressing the mode selection button now starts BUS sensor log off. After

sensor log off, a message is displayed with information about the BUS ID – the

message symbol in the bottom right corner of the display flashes. Briefly press -

ing the mode selection button closes the message.

Example display: Message specifying

the BUS ID (71.01) for the logged off

BUS sensor.

7.2 Connection of analogue sensors

The data logger has a 10-pin terminal with two independent input channels for

connecting up to two analogue sensors. Input channel 1 has pins 1, 3, 5, 7 and

9 while input channel 2 has pins 2, 4, 6, 8 and 10 (see , chapter 3).

Both of the input channels support the sensor configurations listed in

the following subchapters.

EN

Operating manual data logger for external sensors

The sensor current is converted into voltage in the data logger at a load. The

load has a resistance of <50 Ω. Both the sensor and the data logger can be sup-

plied via an external source of voltage.

Wiring diagram for measuring current in 3-cable operation:

This switching is used for sensors whose own current usage is over 4 mA, such

as gas sensors for example.

To register and configure sensors for measuring current at the data logger,

follow the instructions in chapter 7.3.

7

Page 8

.2.3 Pt100 sensors in 3- and 4-cable switching

D0 / D1

B0 / B1

A0 / A1

Pt100

D0 / D1

B0 / B1

A0 / A1

C0 / C1

Pt100

TC+

TC(-)

B0 / B1

A0 / A1

Sensor

7

For 3-cable switching, the PT100 is connected to the measurement switching

via 3 cables. The measuring current is fed into the sensor via the D0/D1 cable.

The resistance of the PT100 is determined from the terminal voltages B0/B1,

C0/C1 and D0/D1:

Important: The data logger is able to compensate cable

resistances up to 10 Ω. The compensation typically reduces

the influence of the cable resistance by a factor of 100.

For 4-cable switching, the PT100 is connected to the measurement switching

via 4 cables. The measuring current is fed into the sensor via the D0/D1 and

C0/C1 cable. The resistance of the PT100 is determined from the terminal

currents B0/B1, A0/A1:

At initial startup, there is no sensor assignment preset in the factory; at later

configurations, previous specifications are preset. Pressing and holding the

mode selection button makes it possible to now change to the configuration

menu for the analogue sensor specifications.

Press the mode selection button again until the desired sensor specification

appears on the screen. Then, press and hold the mode selection button to

confirm the desired sensor specification.

After sensor registration, a message is displayed with information

about the desired sensor configuration – the message symbol in the

bottom right corner of the display flashes. Briefly pressing the mode

selection button closes the message.

Example LCD displays of sensor specification for registering

an analogue sensor at the first input channel (AN0):

Selection for specifying no sensor assign-

ment at the first input channel.

Status indicating that no sensor is

registered at the first input channel.

For exact temperature measurements, 4-cable switching is recommended.

To register and configure PT100 sensors at the data logger,

follow the instructions in chapter 7.3.

7.2.4 Thermal elements

The data logger supports the connection of thermal elements of the types J, K

and S. The thermal element is connected with the positive pole at terminal B

and with the negative pole at terminal A:

Important: When connecting thermal elements,

observe the polarity.

To register and configure thermal elements at the data logger, follow the in -

structions in chapter 7.3.

7.3 Configuration of analogue sensors (M81)

So that analogue sensors can be used with the data logger, their specification

at the data logger must be configured correctly.

Selection of a sensor for measuring

voltage 0 - 1V.

Selection of a sensor for measuring

current in 2-cable operation.

Selection of a sensor for measuring

current in 3-cable operation.

Status indicating that a sensor is

registered for measuring voltage 0 - 1V

at the first input channel.

Status indicating that a sensor is regis-

tered for measuring current in 2-cable

operation at the first input channel.

Status indicating that a sensor is regis-

tered for measuring current in 3-cable

operation at the first input channel.

It is only possible to configure if the data logger is not in logging mode

(M3 or M4)!

To configure the sensors, use the mode selection button to navigate to the con-

figuration mode M81 (AN0) – as described in chapter 6.2 – in order to configure

the specification of a sensor for the first input channel. Alternatively, navigate to

the configuration mode M81 (AN1) to configure the specification of a sensor for

the second input channel. The option for configuring the first analogue sensor is

shown on the display.

EN

Operating manual data logger for external sensors

Selection of a PT100 sensor in 3-cable

operation.

Status indicating that a PT100 sensor is

registered in 3-cable operation at the first

input channel.

8

Page 9

election of a PT100 sensor in 4-cable

S

operation.

tatus indicating that a PT100 sensor is

S

registered in 4-cable operation at the first

nput channel.

i

election of a thermal element of the

S

J type at the first input channel.

tatus indicating that a thermal element

S

of the J type is registered at the first

nput channel.

i

election of a thermal element of the

S

K type.

tatus indicating that a thermal element

S

of the K type is registered at the first

input channel.

election of a thermal element of the

S

S type at the first input channel.

8. Measured values display and data recording

8.1. Channel groups and measuring channels

Each measured value in the specified measuring unit which is detected by a

connected sensor represents a channel group.

A temperature sensor with the specifiable measuring units °C or °F represents

for example two channel groups (temperature °C and temperature °F).

The amount of channel groups which can be detected by a BUS sensor depends

on the sensor design. The BUS sensor of the TFF type can detect seven different

channel groups for example.

Analogue sensors for measuring voltage and current can only detect one channel

group each; analogue sensors for measuring temperature can detect two channel

groups (°C and °F).

For each channel group, there are then four measuring channels for recording:

Current measured value (cur), minimum measured value (min), maximum meas-

ured value (max) and average measured value (mid).

When all sensors are assigned with a total of four connected BUS sensors of

the TFF type and two connected analogue PT100 sensors, the data logger can

detect a total of 32 channel groups and 128 measuring channels, as shown in

table 2.

Further detailed information about configuration of the processing channels

in the software is provided in the software manual which you can open by us-

ing the help function of the SmartGraph software.

8.3. Displaying measured values

One of the channel groups specified in table 1 for displaying measured values

can be configured to be displayed on each of the three measured value rows.

Here, the current measured value is always shown on the display.

8.4. Data recording

If either of the operating modes M3 or M4 are selected, then the data logger is

in logging mode (REC) and the measured values of the measuring channels se-

lected for recording are saved in the device.

Up to 20 of the measuring channels specified in table 2 can be simultaneously

recorded in the data memory of the measuring device.

Recording begins immediately from the moment that the operating mode M3 or

M4 is selected and is carried out in ring mode. This means that when the

memory limits are reached, the recording does not stop but continues to record.

The older values are simply overwritten by the newest measured values.

tatus indicating that a thermal element

S

of the S type is registered at the first

input channel.

8.2 Processing channels for converting

measured values

With the SmartGraph software, analogue sensors which supply a current or volt-

age value can be used as processing channels for converting measured values.

Processing channels make it possible to convert the input values of analogue

sensors which supply a current or voltage value into the actual measured value.

Measuring unit, conversion parameter and decimal points can be specified for

each processing channel and assigned to a sensor type (see table 1).

Table 1: Available processing channels for converting measured values

associable

units:

associable

sensor types:

EN

counts, logic, digits, °C, °F, K, °Cdp, °Fdp, %rH, g/kg, g/m³, µm, mm, cm, dm, m, km, in, mil, ft, mi, m/s, km/h, kts, ppm,

mV, V, mA, A, Hz, kHz, bar, mbar, Pa, mPa, hPa, kPa, m³, l, s, ms, µs, %, °, mm/h, m³/h, l/m², in/h, mil/h, g, kg

temperature, relative humidity, absolute humidity, dew point, battery voltage, voltage, current, absolute air pressure, relative

air pressure, building moisture, flow rate, mix ratio, CO2 concentration, particles 0.1 µm, particles 0.2 µm, particles 0.3 µm,

particles 0.5 µm, particles 1 µm, particles 5 µm, particles 10 µm, particles x µm, particles y µm, particles z µm, unknown, in-

active, wet-bulb temperature, global radiation, daylight, amount of rain, wind speed, wind direction, analogue/digital input,

ground moisture, leaf wetness

Operating manual data logger for external sensors

Tip: Current, minimum, maximum and average measured values

R

for a channel group each represent one measuring channel. If these

values should be available for later documentation and evaluation, each of

the measuring channels must already be selected during memory organi -

sation for recording, because it is not possible to calculate these values in

the software.

The specifications for type, duration and scope of data recording in the logging

mode can be individually set in the software. Detailed information is provided in

the software manual.

9

Page 10

Table 2: Overview of available channel groups (measured values) and measuring channels of the data logger

Sensor

assign-

Sensor type Channel group

(measured value)

Unit Available

ment

Temperature °C – cur min max mid

Temperature °F – cur min max mid

BUS

sensor 1

e.g. TFF sensor

BUS class 71

Dew point °C – cur min max mid

Dew point °F – cur min max mid

Relative humidity % – cur min max mid

Absolute humidity g/m³ – cur min max mid

Mix ratio g/kg – cur min max mid

Temperature °C – cur min max mid

Temperature °F – cur min max mid

BUS

sensor 2

(with Y

distributor)

e.g. TFF sensor

BUS class 71

Dew point °C – cur min max mid

Dew point °F – cur min max mid

Relative humidity % – cur min max mid

Absolute humidity g/m³ – cur min max mid

Mix ratio g/kg – cur min max mid

Temperature °C – cur min max mid

Temperature °F – cur min max mid

BUS

sensor 3

(with Y

distributor)

e.g. TFF sensor

BUS class 71

Dew point °C – cur min max mid

Dew point °F – cur min max mid

Relative humidity % – cur min max mid

Absolute humidity g/m³ – cur min max mid

Mix ratio g/kg – cur min max mid

Temperature °C – cur min max mid

Temperature °F – cur min max mid

BUS

sensor 4

(with Y

distributor)

e.g. TFF sensor

BUS class 71

Dew point °C – cur min max mid

Dew point °F – cur min max mid

Relative humidity % – cur min max mid

Absolute humidity g/m³ – cur min max mid

Mix ratio g/kg – cur min max mid

Measuring voltage 0 - 1 V Voltage V

Measuring current in 2-cable operation 4 - 20 mA Current mA cur min max mid

Measuring current in 3-cable operation 0 - 20 mA Current mA cur min max mid

PT100 temperature measurement in 3-cable operation Temperature °C – cur min max mid

Analogue

sensor 1

at input

channel 1

(An0)

PT100 temperature measurement in 3-cable operation Temperature °F – cur min max mid

PT100 temperature measurement in 4-cable operation Temperature °C – cur min max mid

PT100 temperature measurement in 4-cable operation Temperature °F – cur min max mid

Temperature measurement with thermal element K type Temperature °C – cur min max mid

Temperature measurement with thermal element K type Temperature °F – cur min max mid

Temperature measurement with thermal element J type Temperature °C – cur min max mid

Temperature measurement with thermal element J type Temperature °F – cur min max mid

Temperature measurement with thermal element S type Temperature °C – cur min max mid

Temperature measurement with thermal element S type Temperature °F – cur min max mid

Measuring voltage 0 - 1 V Voltage V

Measuring current in 2-cable operation 4 - 20 mA Current mA cur min max mid

Measuring current in 3-cable operation 0 - 20 mA Current mA cur min max mid

PT100 temperature measurement in 3-cable operation Temperature °C – cur min max mid

Analogue

sensor 2

at input

channel 2

(An1)

PT100 temperature measurement in 3-cable operation Temperature °F – cur min max mid

PT100 temperature measurement in 4-cable operation Temperature °C – cur min max mid

PT100 temperature measurement in 4-cable operation Temperature °F – cur min max mid

Temperature measurement with thermal element K type Temperature °C – cur min max mid

Temperature measurement with thermal element K type Temperature °F – cur min max mid

Temperature measurement with thermal element J type Temperature °C – cur min max mid

Temperature measurement with thermal element J type Temperature °F – cur min max mid

Temperature measurement with thermal element S type Temperature °C – cur min max mid

Temperature measurement with thermal element S type Temperature °F – cur min max mid

processing

channels for

converting

measured

yes,

see table 1

yes,

see table 1

values Available measuring

channels for data recording

(max. 20 channels available for

saving) and for displaying

(max. 3 channels for display)

cur min max mid

cur min max mid

EN

Operating manual data logger for external sensors

10

Page 11

9. Alarm function

9.1. Alarm configuration

An alarm function can be configured in the measuring device administration for

each of the measuring channels selected for display or recording.

By defining an upper and lower alarm limit value, a value corridor is specified.

This is the so-called good range and when the range is exited, an alarm sounds.

Note: The alarm function can only be represented on the display for the

channel groups of the three measuring channels selected for measured

value display, and only in the operating modes M2 and M3 !

However, saving alarm results of other selected measuring channels in logging

mode is independent of the selected display of the measured values. That

means that the alarm results of the measuring channels which are not for

display but for data recording are also recorded.

Even in the operating mode M4 when displaying measured values is deactivated,

all preselected alarm results are recorded !

9.2. Alarm display

The alarm display is only possible for

measured values which are preselected

for displaying and which have been con-

figured with an active alarm function.

9.3. Acoustic alarm

If an alarm goes off while the acoustic function is activated (see chapter 6.2.4.

Acoustic function), then and alarm tone sounds and only stops when the

measured value returns to the good range.

9.4. Using the alarm hysteresis

If you use the alarm function without alarm hysteresis, then an alarm sounds

and is recorded each time the preset limit values are exceeded.

If your limit values have been selected very close to each other, then this means

that an alarm situation occurs very often.

For example, if you set a room temperature of 24 °C as the upper alarm limit

and a room temperature of 10 °C as the lower alarm limit and the room temper-

ature continually deviates between 23.5 and 25 °C during the measuring period,

then there will be many individual alarm signals created and recorded.

To prevent this, you can define an alarm hysteresis. With this setting, you define

a value by which the measured value must have returned to the valid value

corridor, the good range, in order to switch off the alarm.

If an alarm hysteresis of 1 °C was set, the alarm in the previous example would

go off once as 24 °C was exceeded and then only stop as the temperature

drops below 23 °C again.

Upper alarm

limit value

If an alarm occurs at one of these meas-

uring channels, the alarm symbol

Example display for an alarm result of the

measuring channel shown in the first

measured value row.

flashes beside the measured value dis-

play for this channel while the good

range is exited.

If the measured value then reaches the

defined value corridor, that is, the good range, then the alarm symbol stops

flashing and is shown continually.

This indicates that an alarm result occurred. If the good range is exited during

the course of a measurement, the alarm symbol flashes again.

Reading the measured value memory deletes the alarm display.

Alarm display

Upper alarm

limit value

Valid value

corridor

“good range”

Lower alarm

limit value

flashing

static

Logging mode

Reading the measured value memory

Valid value

corridor

“good range”

Lower alarm

limit value

flashing

static

Upper alarm

limit value

Valid value

corridor

“good range”

Lower alarm

limit value

flashing

static

Alarm display without hysteresis

Logging mode

Alarm display with hysteresis

HYSTERESIS

Logging mode

Additionally, a hysteresis can be set by which the measured value must return

to the valid range to switch off the alarm.

EN

Operating manual data logger for external sensors

11

Page 12

10. Notes on maintenance and operation

10.1. Battery change

If “LO bAtt” appears in the upper row of the display, then the batteries need

to be changed.

No data can be recorded while batteries are being changed. If data

recording is running, pause it and ensure that the data logger is in

operating mode M1 or M2 before changing the batteries.

To replace the batteries, open the battery compartment, remove the used batter-

ies and then insert new batteries, while observing the correct poles.

The time is maintained for at least a minute during battery change,

even when batteries are not inserted.

Only use appropriate batteries which comply with the technical data. Other types

of batteries can cause operating errors. Do not use rechargeable batteries !

Do not dispose of used batteries in the household rubbish or throw them in the

fire; instead, dispose of them according to the relevant legal requirements.

10.2. Deleting measured data

The detected measured data are permanently saved in the internal Flash

memory. Even when resetting the device to factory settings or when there are

no batteries in the device, the measurement data remains in the memory and is

not deleted.

Saved data can only be deleted via the SmartGraph3 software as a whole and

not individually.

10.3. Positioning for mobile use

For mobile measured value recording, the data logger can be positioned at any

site. Observe the permissible ambient conditions for operation (see technical

data). Due to its compact dimensions, the data logger can be hidden for non-

intrusive applications.

10.4. Mounting on a wall

For stationary data detection, the data logger can also be mounted on a wall

or a similar holding device. A mount track is included in the scope of supply

for fastening.

For network operation, wall mounting is absolutely necessary.

Additional information about network operation is provided

in chapter 6.2.2.

10.5. Moving to another site

Especially when moving from cold to warm ambient conditions, e.g. when

moving into a heated room after storage in a car over night, depending on hu-

midity in the room, condensation may form on the printed circuit board.

This physical trait can lead to false measured values. Unfortunately, it is neces -

sary for the construction and cannot be prevented in any measuring devices.

In these cases, please wait approx. 5 minutes until the measuring device has

“acclimatised” before starting to measure.

The deletion process takes approx. 2

minutes. During this time, the following

messages appears on the display:

“FOMA FLSH xxx %”.

During the entire deleting period, access

to the device is not possible and it does

Display for deleting measured data.

In the display, 6 % of the data have been

deleted so far.

on the display. Afterwards, the display returns to normal operation.

Further detailed information about using the software is provided in the

software manual which you can open from the help function of the Smart-

Graph software.

not respond to requests from the Smart-

Graph3 software.

After memory has been completely

deleted, “FOMA FLSH 100 %” is shown

EN

Operating manual data logger for external sensors

12

Page 13

11. Technical data

Technical data of the data logger for external sensors

Measuring range 0 … 1 V

Voltage input

0 - 1 V

Accuracy ±200 µV ± 0.1 % of measured value

Resolution < 500 µV

Measuring range 2-cable operation: 4 … 20 mA, 3-cable operation: 0 … 20 mA

Voltage

measurement

Thermal element K

Thermal element J

Thermal element S

Pt100

Accuracy ± 4 µA ± 0.1 % of measured value

Resolution < 5 µA

Total load approx. 50 Ω

Measuring range -200 °C … 1,200 °C

Accuracy

Resolution < 0.2 °C

Measuring range -200 °C … 1,200 °C

Accuracy

Resolution < 0.2 °C

Measuring range -50 °C … 1,700 °C

Accuracy

Resolution < 0.2 °C

Measuring range -200 °C … 500 °C

Accuracy ± 0.2 °C ± 0.1 % of the measured value

Resolution < 0.02 °C

Sensing interval 10 / 30 s, 1 / 10 / 12 / 15 / 30 min, 1 / 3 / 6 / 12 / 24 h

± 1 °C ± 0.5 % of the measured value at -200 °C … 0 °C,

± 1 °C ± 0.2 % of the measured value at 0 °C … 1,200 °C

± 1 °C ± 0.5 % of the measured value at -200 °C … 0 °C,

± 1 °C ± 0.2 % of the measured value at 0 °C … 1,200 °C

± 1 °C ± 0.5 % of the measured value at -50 °C … 0 °C,

± 1 °C ± 0.2 % of the measured value at 0 °C … 1,700 °C

Memory

organisation

Configuration and

dimensions

Power supply

Permissible

operating ambient

conditions

Scope of supply

Saving interval 1 / 10 / 12 / 15 / 30 min, 1 / 3 / 6 / 12 / 24 h

Data storage 16 MB, approx. 3,200,000 measured values

Data recording up to 20 simultaneous measuring channels

LCD display W 90 x H 64 mm

Housing Plastic

Dimensions L 180 x W 32 x H 78 mm

Weight approx. 250 g

Interfaces USB, LAN, RS485 (Sensor BUS)

internal

external

Air temperature -20 °C to +50 °C

Relative humidity 0 to 95 % RH, < 20 g / m³ (non-condensing)

Height 10,000 m above sea level

Measuring device, CD-ROM with SmartGraph 3 PC software for representing the evaluation

Standard

of measured values graphically and numerically and operating manual,

4 x LR6 AA batteries, battery life > 1 year

(depending on connected sensor and configuration)

USB, LAN (PoE configuration),

terminals for external power supply to supply the sensor

USB connection cable, batteries

EN

Optional Measuring device in PoE configuration, TFF sensors

Operating manual data logger for external sensors

13

Page 14

12. Status codes

In the event of a sensor error, the following codes may appear on one of the three LCD rows instead of the measured value

E 2C.........Initialisation error at the sensor

E 27 .........Faulty calibration data

E 36 .........Channel disabled (e.g. channel configured in the LCD,

but sensor logged off or removed)

E 50 .........Value to be displayed too large to fit on display

Sensor Status Measuring range Code

Negative polarity approx. < -0.024 V 0x53 (CHANNEL_UNDERRANGE)

Limit range -0.024 V … 0.000 V Displayed: 0.000V

0 … 1 V

4 … 20 mA

Normal operation mode 0.000 V … 1.000 V

Limit range 1.000 V … 1.024 V Displayed: 1.000V

Overvoltage approx. > 1.024 V 0x52 (CHANNEL_OVERRANGE)

Special case: open Input floating, e.g. CHANNEL_OVERRANGE, so 0x52

Negative polarity approx. < -0.48 mA 0x53 (CHANNEL_UNDERRANGE)

Sensor breakage approx. -0.48 mA … 0.30 mA 0x55 (MEAS_UNABLE)

Fault current 0.30 mA … 3.00 mA 0x51 (VALUE_UNDERFLOW)

Limit range 3.00 mA … 4.00 mA Displayed: 04.00mA

E 51 .........Value to be displayed too small to fit on display

E 52 .........Channel value in the saturation (upper limit)

E 53 .........Channel value in the saturation (lower limit)

E 54 .........Data error. Received data are not plausible

E 55 .........Measurement not possible of sensor not reachable

0 … 20 mA

Normal operation mode 4.00 mA … 20.00 mA

Limit range 20.00 mA … 20.48 mA Displayed: 20.00mA

Overcurrent approx. > 20.48 mA 0x52 (CHANNEL_OVERRANGE)

Negative polarity approx. < -0.48 mA 0x53 (CHANNEL_UNDERRANGE)

Limit range -0.48 mA … 0.00 mA Displayed: 0.00mA

Normal operation mode 0.00 mA … 20.00 mA

Limit range 20.00 mA … 20.48 mA Displayed: 20.00mA

Overcurrent approx. > 20.48 mA 0x52 (CHANNEL_OVERRANGE)

EN

Operating manual data logger for external sensors

14

Loading...

Loading...