Page 1

EE771 Series

FLOW METER for

COMPRESSED AIR and GASES

BA_EE771_e // V4.1 // technical data are subject to change // 193296

Manual

Hardware and Software

Page 2

E+E Elektronik® Ges.m.b.H. doesn't accept warranty and liability

claims neither upon this publication nor in case of improper treatment

of the described products.

The document may contain technical inaccuracies and typographical

errors. The content will be revised on a regular basis. These changes

will be implemented in later versions. The described products can be

improved and changed at any time without prior notice.

© Copyright E+E Elektronik

®

Ges.m.b.H.

All rights reserved.

USA

FCC notice:

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the installation manual, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Caution:

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate this device.

CANADIAN

ICES-003 notification:

This Device B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

Canada.

2

Page 3

Table of contents - HARDWARE

1. GENERAL

1.1. Safety Instructions .................................................................................................. 4

1.1.1. Intended Use ................................................................................................... 4

1.1.2. Installation, start up and control

1.2. Environmental aspects .............................................................................................. 5

............................................................................................................. 4

.................................................................................. 5

2. PRODUCT DESCRIPTION ....................................................................................... 6

3. INSTALLATION ...................................................................................................... 7

3.1. Mounting dimensions ............................................................................................... 7

3.1.1. Model Compact (EE771-A and EE771-B) ......................................................................... 7

3.1.2. Model remote sensing probe (EE771-C)

3.2. Determining installation site ......................................................................................... 8

3.2.1. Process pressure ............................................................................................... 8

3.3. Installation position .................................................................................................. 9

3.4. Required length of straight pipe..................................................................................... 10

3.5. Assembly of the measurement ball valve ........................................................................... 11

3.5.1. Assembly without flow meter, but with screw cap instead (blind cap) ................................................ 11

3.5.2. Shut off the measurement ball valve

3.6. Installation of the flow meter sensing probe ........................................................................ 12

3.6.1. Flow direction................................................................................................... 12

3.6.2. Installation of the sensing probe

.......................................................................... 7

.............................................................................. 11

.................................................................................. 12

4. ELECTRICAL CONNECTIONS .................................................................................13

4.1. Connection diagram ................................................................................................. 13

4.1.1. Relay and pulse output, internal switching ........................................................................ 13

4.1.2. Connection with optional plug for power supply and outputs (order code Q)

4.2. Bus Output (optional) ............................................................................................... 14

4.2.1. M-Bus (Meter-Bus) .............................................................................................. 14

4.2.2. Modbus RTU

4.2.3. Data Transmission

4.2.4. Addressing

................................................................................................... 15

.............................................................................................. 15

..................................................................................................... 15

.......................................... 13

5. CONTROL COMPONENTS ...................................................................................... 16

5.1. Jumper J1 and J2 ................................................................................................... 16

5.2. Digital interface USB ( for configuration)............................................................................ 16

5.3. Display / Indicator with keypad (optional) ........................................................................... 16

5.3.1. Indication of the analogue and pulse output ....................................................................... 17

5.3.2. Indication of the switch output

5.3.3. Indication of the MIN / MAX values

5.3.4. Reset of the consumption counter or the MIN / MAX value

5.3.5. Maximum consumption counter

.................................................................................... 17

............................................................................... 17

......................................................... 18

.................................................................................. 18

6. ERROR MESSAGES .............................................................................................. 18

7. MAINTENANCE ..................................................................................................... 19

7.1. Removal of the sensing probe of the flow meter ................................................................... 19

7.2. Cleaning of the sensor of the flow meter ........................................................................... 19

8. REPLACEMENT PARTS / ACCESSORIES .................................................................19

8.1. Order Code Replacement Sensor .................................................................................. 19

8.2. Order Code Miscellaneous .......................................................................................... 20

9. TECHNICAL DATA .................................................................................................20

9.1. Factory setting of outputs ........................................................................................... 21

Table of contents - SOFTWARE

1. General ................................................................................................................ 22

2. Installation ........................................................................................................... 23

2.1. Configuration of the USB Interface (VirtualCOM) ................................................................... 23

3. User Interface ....................................................................................................... 24

4. Menu toolbar ........................................................................................................ 25

4.1. File .................................................................................................................. 25

4.2. Transmitter .......................................................................................................... 25

4.3. Extras ............................................................................................................... 25

5. Input Screen ......................................................................................................... 25

5.1. Output 1, Output 2 .................................................................................................. 25

5.1.1. Output mode ................................................................................................... 25

5.1.2. Measurand

5.1.3. Units

5.1.4. Output mode – analogue

5.1.5. Output mode – switch (relay)

5.1.6. Output mode – pulse

5.2. Minimum flow shutdown ............................................................................................ 27

5.3. Display .............................................................................................................. 28

5.4. Adjustment .......................................................................................................... 28

5.4.1. 1-point adjustment .............................................................................................. 28

5.4.2. 2-point adjustment

5.4.3. Reset to factory settings

5.5. Measuring values overview ......................................................................................... 30

5.5.1. Reset of the MIN / MAX values .................................................................................. 30

5.5.2. Reset of the consumption counter (totalizer)

5.6. Setting up Process Parameters ..................................................................................... 30

5.6.1. Change the Process Gas ........................................................................................ 30

5.6.2. Changing the standard conditions

5.6.3. Pressure compensation

5.7. External pressure transmitter for pressure compensation .......................................................... 31

5.8. Bus configuration.................................................................................................... 31

..................................................................................................... 25

........................................................................................................... 25

........................................................................................ 26

.................................................................................... 26

............................................................................................ 27

.............................................................................................. 29

......................................................................................... 29

....................................................................... 30

................................................................................ 31

......................................................................................... 31

3

Page 4

1. GENERAL

This manual is a part of the scope of supply and serves to ensure optimal operation and functioning of the

equipment.

For this reason, the manual must be read before start-up.

Therefore, it is necessary that this manual is read and understood by those responsible for the handling,

installation, and maintenance of the equipment.

This manual may not be used for competitive purposes or passed on to third parties

without the written consent of E+E Elektronik® Ges.m.b.H.

It is permitted to make copies for personal use.

All information, technical data and illustrations contained in these instructions are based on

information available at the time of publication.

Symbol Clarification

This symbol indicates safety instructions.

The safety instructions have to be carried out unconditionally. If disregarded loss, injury, or damage may be

inflicted to people and property. In any case E+E Elektronik® Ges.m.b.H. cannot be hold responsible.

This symbol indicates attention.

The note should be observed to achieve an optimal functioning of the equipment.

1.1. Safety Instructions

1.1.1. Intended Use

The flow meter is intended to be used for the measurement of air and other non-corrosive gases in pipelines

only. Consult the factory first before the measurement of wet or filthy gases.

The design of the flow meter allows for the EE771 to be installed in a pressurized system up to PN16 – is

16 bar (230 psi).

Prior to the start of the installation, the system has to be depressurized. Before the installation or

removal of the sensing probe or the screw cap, the measurement ball valve should be closed.

Mounting, electrical installation, putting in operation and maintenance should only be done by qualified

personnel.

The use of the flow meter EE771 in any other way than described in this manual bears a safety risk for people and the entire measurement installation and is therefore not allowed.

The manufacturer cannot be hold responsible for damages as a result of incorrect handling, installation, and

maintenance of the equipment.

To avoid health risks or damage to the equipment, the installation should not be operated on with tools, which

are not specifically mentioned or described in this manual.

Excessive mechanical stress and inappropriate handling must be avoided.

A short interruption of the flow using the measurement ball valve cannot be avoided when exchanging the

sensing probe.

The flow meter can only be utilized in accordance with the conditions defined in the technical data. Otherwise,

inaccuracies of the measurement will occur and equipment failures cannot be ruled out.

For the safety of the user and for the functionality of the equipment the recommended steps by the

manufacturer to put into operation, to test and to maintain should be taken and completed.

4

Page 5

1.1.2. Installation, start up and control

The flow meter is designed and built in accordance with the latest state in technology, tested adequately and

has been shipped from the factory in good order and condition.

As the user, you are responsible to comply with all applicable safety regulations amongst others:

• Instruction for the installation

• Local standards and codes

The manufacturer has taken all measures to assure safe operation. The user has to make sure that the

equipment is positioned and installed in such a way that safe operation is not impaired.

The equipment is tested in the factory and shipped in good order and condition.

This manual contains information and notes of caution, which have to be adhered to by the user to assure a

safe operation.

• Mounting, electrical installation, putting into operation and maintenance should only be done by

qualified personnel. The plant operator should authorize qualified personnel to operate on the

installation.

• It is necessary that this manual is read and understood by these professionals and that they follow

the instructions as detailed in this manual.

• Check all connections of the entire installation thoroughly, before putting the system into operation.

• Disconnect the device from power supply before opening or closing to avoid damages.

• Do not put a damaged product into operation and make sure that that does not happen

inadvertently.

• A malfunction of the equipment should only be handled and fixed by authorized and qualified

personnel

• If it is not possible to repair the malfunction, put the equipment out of operation and make sure that

it cannot be put back into operation again.

• Repairs not described in this manual may only be carried out by the manufacturer or by the

respective service organization.

Disclaimer of Liability

The manufacturer or their delegated representative is only liable in case of intend or gross negligence. The

accountability is limited to the value of the order issued at the time to the manufacturer.

The manufacturer is not liable for damages, originated from disregarding the safety instructions or violating

the instructions of the manual or operating conditions.

Consequential damages are excluded from the any liability.

1.2. Environmental aspects

The products from E+E Elektronik® are developed and designed in due consideration to the importance of the

protection of the environment. Therefore, disposal of the product also should not lead to pollution of the

environment.

The single-variety components must be separated before the transmitter is disposed of. The electronic

components must be collected and as electronic scrap properly be disposed of.

5

Page 6

2. PRODUCT DESCRIPTION

The flow meter of the series EE771, based on the measurement principle of thermal mass flow, is suited for

the measurement of flow of air and gases in pipelines. Measurement of for instance the consumption of compressed air, nitrogen, helium, argon, CO2 or other non-corrosive and non-flammable gases.

The EE771 measures the volume flow at standard conditions according to DIN 1343 (P0 = 1023.25 mbar;

t0 = 273.15 K or 0 °C (32 °F). In addition to the standard volume flow, the measurand mass flow, norm flow

and temperature are available.

The EE771 has an integrated consumption counter. The consumption quantity is indicated in the display and

is not lost after a power failure. Two signal outputs are available. Depending on the application, the outputs

can be configured as analogue (current or voltage), switch output or as pulse output for the measurement of

the consumption.

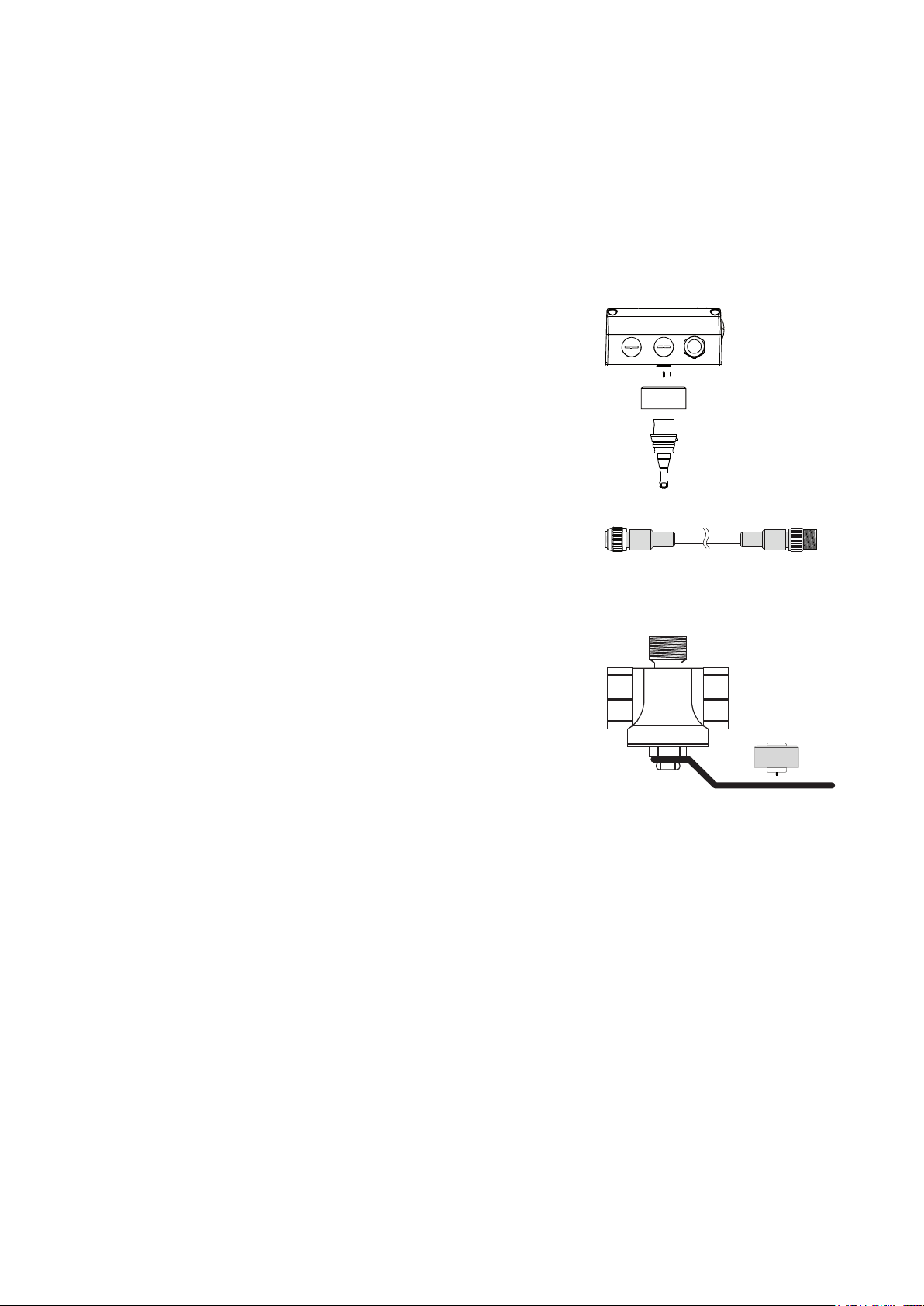

Signal conditioning with optional display

1

The enclosure with the signal conditioning is mounted either on the

measurement probe (model A or B compact) or is remote with a

plugable sensor cable up to 10 meter (33 feet) (model C with remote

probe).

Sensing probe with measurement electronics

2

The interchangeable sensing probe contains the sensor element and

the measurement electronics, in which the data of the factory

calibration is stored. The sensing probe is easy and quickly inter-

changeableintheeld,independentoftheelectronics for the signal

conditioning.After the exchange, the conguration of the outputs is

unchanged.

1

2

3

Sensor cable (only by model C with remote sensing probe)

3

The sensor cable allows for the remote installation, up to 10 meter

(33 feet), of the sensing probe from the housing with the signal conditioning.

Measurment valve with shut-off function

4

The measurement ball valve assembly allows for the easy and reliable

installation within the pipeline. During installation in the pipeline,

observe the required inlet and outlet paths (see page 10). The

nominal size of the measurement ball valve assembly must match the

nominal size of the pipe.

The measurment valve with shut-off function allows for the instalment

and removal of the sensing probe with only interrupting the process

flow for a short moment. The measurement ball valve assembly is

suitable for pressures up to 16 bar (PN16) and available for pipe diameters DN15 (1/2”) to DN50 (2”).

Screw cap

5

The screw cap, with female thread, is screwed in place if the flow

meter is not installed and the pipeline has to be used.

4

5

6

Page 7

3. INSTALLATION

3.1. Mounting dimensions

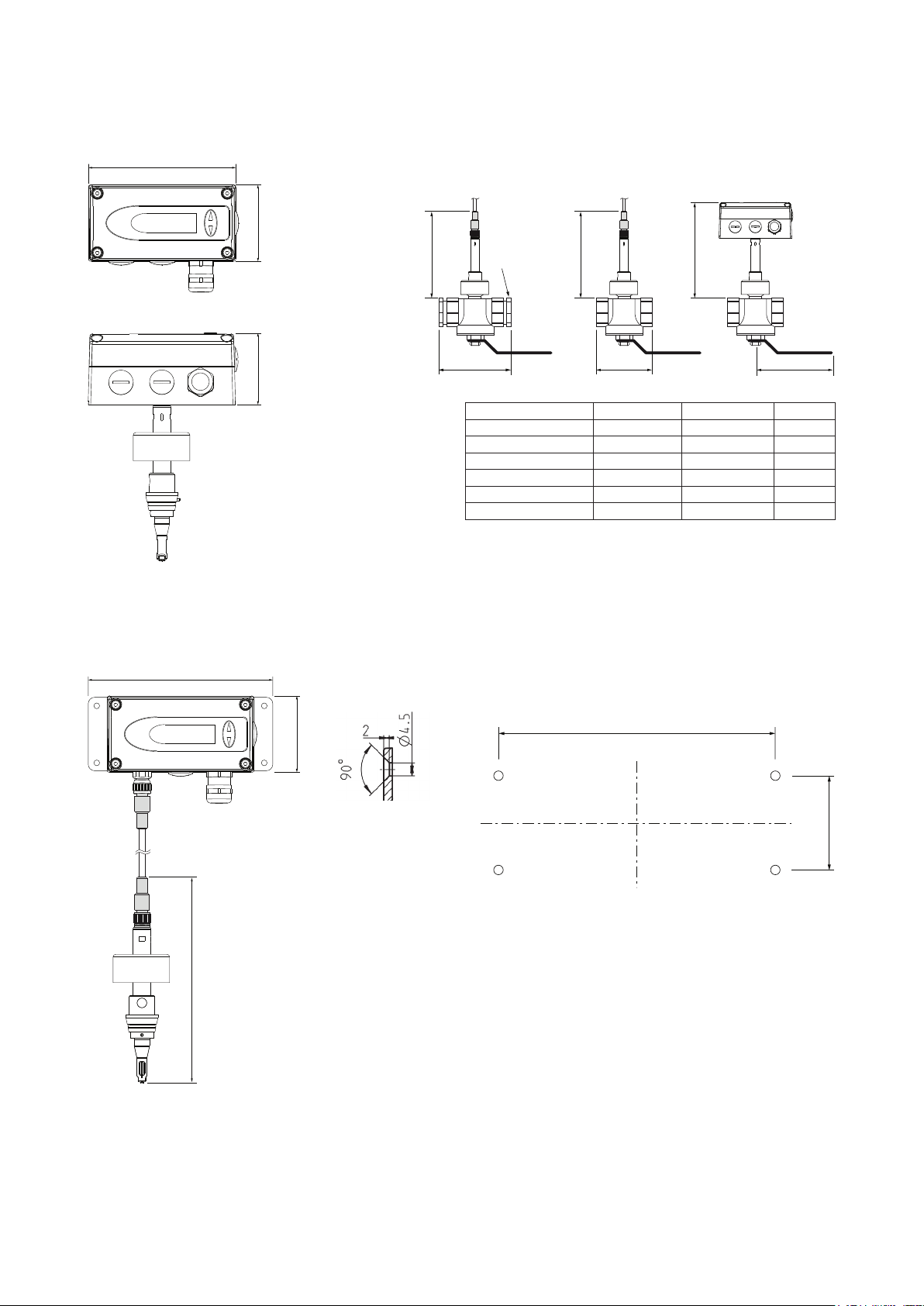

3.1.1. Model Compact (EE771-A and EE771-B)

115 (4.53)

cable gland

M16x1.5

60 (2.36)

56 (2.2)

Measurement ball valve

Only at DN15:

Reduction

173 (6.81)

Dimensions in mm (inch)

3/4“-1/2“

A A B

Measurment ball valve Thread A B

DN15 R

DN20 Rp or NPT 3/4” 72 (2.83) 92 (3.62)

DN25 Rp or NPT 1” 83 (3.27) 124 (4.88)

DN32 Rp1 1/4" 100 (3.94) 124 (4.88)

DN40 Rp or NPT 1 1/2" 110 (4.33) 147 (5.79)

DN50 Rp or NPT 2” 131 (5.16) 147 (5.79)

dimensions in mm (inch)

Female thread: BSP thread acc. EN 10226 (old DIN 2999) or NPT

173 (6.81)

1/2" 100±8 (3.94±0.32) 92 (3.62)

p

183 (7.2)

3.1.2. Model remote sensing probe (EE771-C)

145 (5.71)

Cross-section

bore hole:

60 (2.36)

cable gland

M16x1.5

207

Drilling Plan:

129 (5.08)

40 (1.57)

The bottom part of the housing is mounted with

4 screws (not in the scope of supply)

Max. screw diameter: 4.5 mm (0.17 inch).

e.g. 4.2 x 38 mm DIN 7938H Screws

7

Page 8

3.2. Determining installation site

•

The installation site should be easy accessible and free of vibrations and shocks

• Observe at least 120 mm (5 inch) clearance above the housing with the signal conditioning, in

order to be able to remove the sensing probe if necessary.

• The ambient temperature should not exceed the value as stated in the specifications (see page 20)

– consider heating by radiation.

• Air purity on the installation site according to ISO 8573-1:2010: at least class 3.4.4

• The fluid should not condense at the installation site. Condensation on the tip of the sensing probe

must be avoided.

• In compressed air systems, the installation must be downstream of the dryer. If there is no dryer, at

least steam trap and suitable filter must be present.

• Observe the direction of the flow by the installation (see page 11).

• Observe the recommended straight pipe lengths up and downstream, in order to warrant the speci-

fied measurement accuracy.

• The flow meter should be installed as far as possible from any flow disturbance. Valves or check-

valves should be installed in a respective distance from the flow meter.

3.2.1. Process pressure

Because of the measuring principle the thermal mass flow meter EE771 is largely independent of the process

pressure and is factory calibrated at a pressure of 7 bar (100 psi).

In order to achieve the highest measurement accuracy, the slight dependence on process pressure can be

compensated for in two ways:

• if the process pressure is stable, by programming the pressure value in the configuration software

(see page 30).

• in case of strong fluctuations of the process pressure (e.g. 3 to 10 bar (40 to 150 psi)) an external

pressure transmitter can be installed and connected to the pressure-compensation input

(see page 31).

In order to install or remove the measurement section the pipeline system should

be depressurized.

8

Page 9

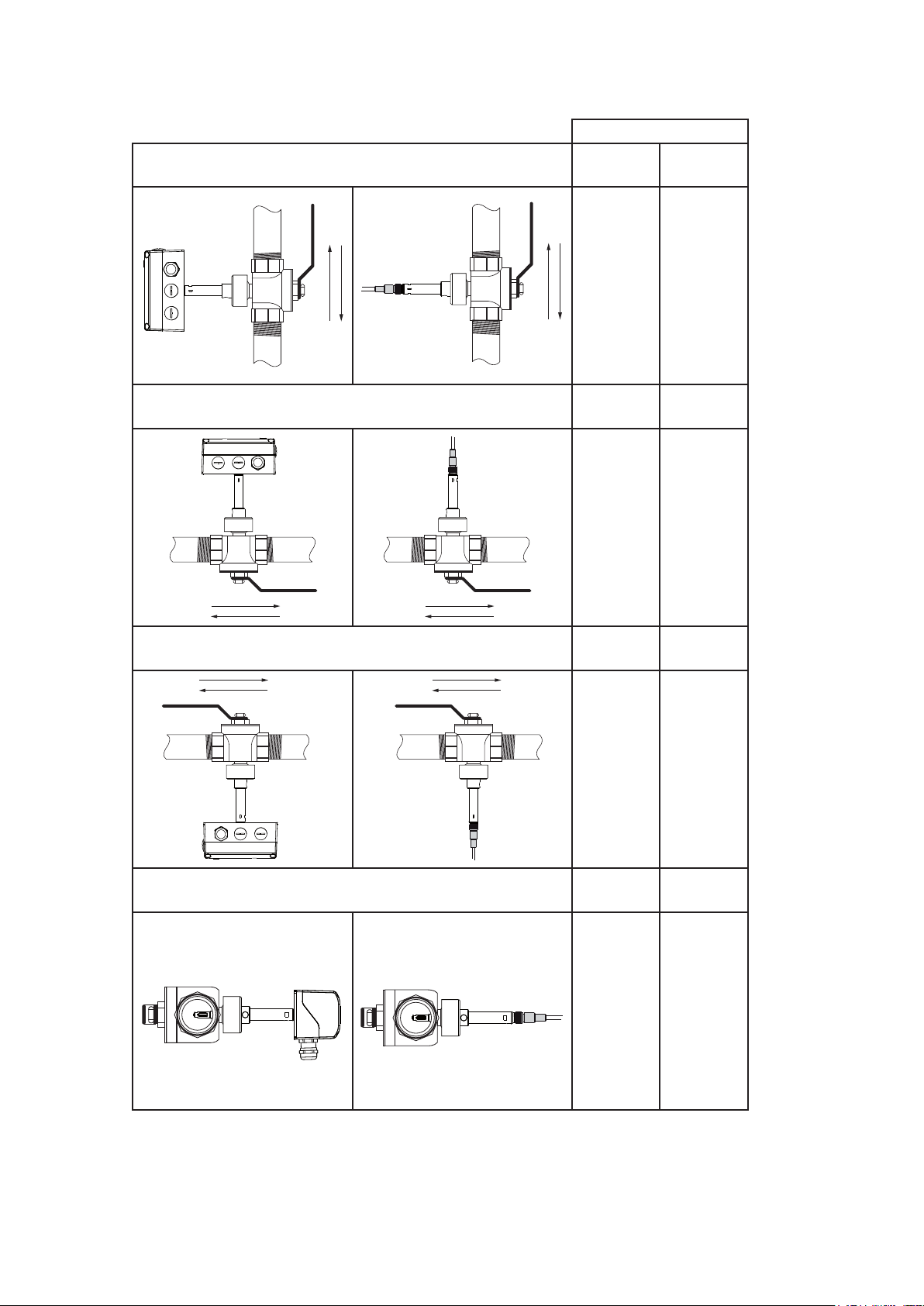

3.3. Installation position

Make sure that the arrow on the tip of the sensing probe is pointing in the direction of the flow.

Model

Vertical Mounting Compact Remote

+ ++

Horizontal Mounting, sensor upwards

Horizontal Mounting, sensor downwards

Horizontal Mounting, sensor across

++ ++

- -

++ ... recommended installation position

+ ..... not recommended if there is vibration on the pipeline

- ...... not recommended

9

+ ++

Page 10

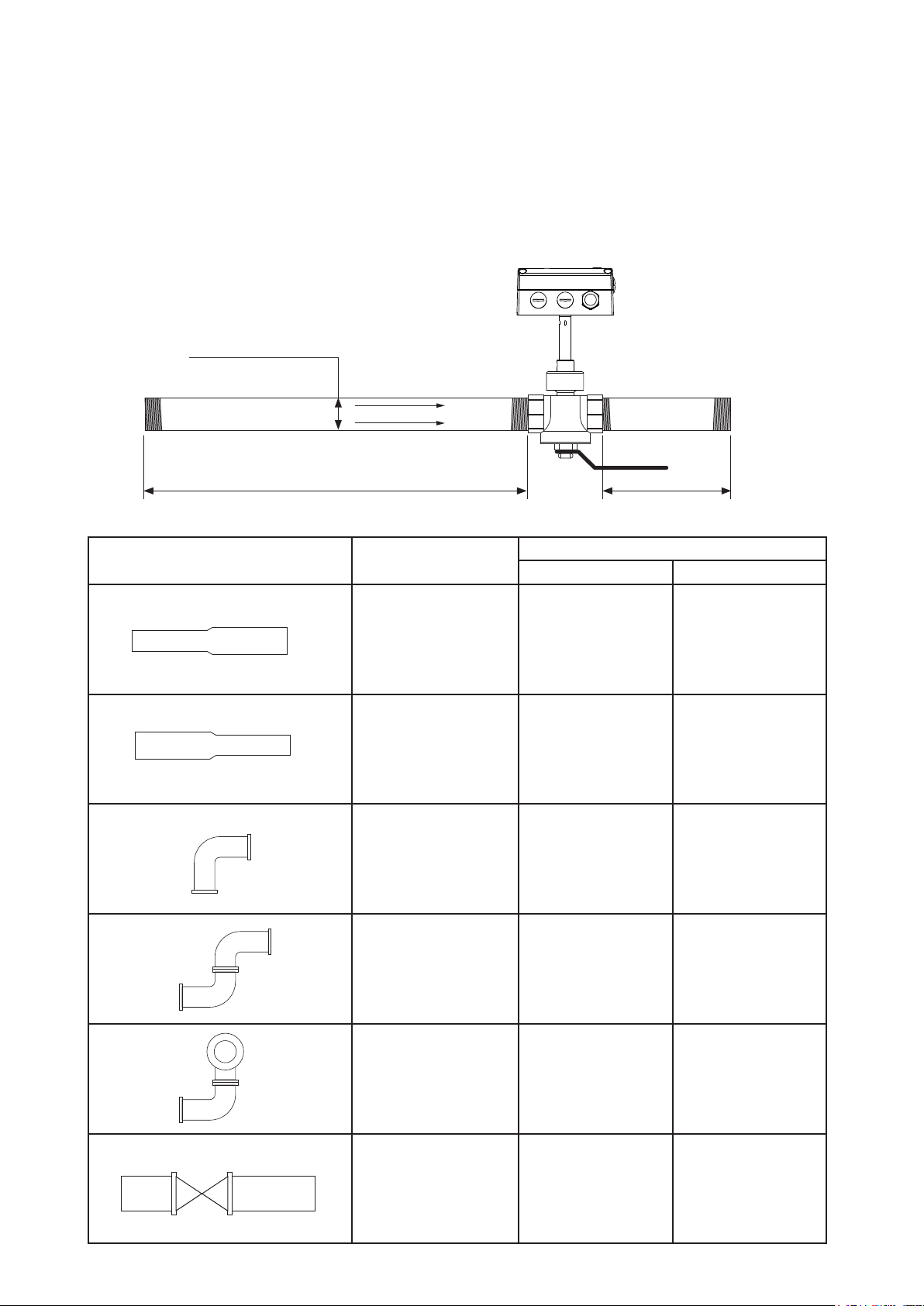

3.4. Required length of straight pipe

The flow meter should be installed as far as possible from disturbances of the flow. The causes for disturbance

of the flow are for instance, reducers, elbows, T-pieces, valves, gate valves, etc. The specified measurement

accuracy can be achieved only when the following straight inlet and outlet pipe lengths are installed:

• The wall thickness of the inlet and outlet pipe should be 2,6 mm.

• The stated values are as a minimum. If possible, allow for greater distances.

• Valves or gate valves should be installed downstream of the flow meter.

• With lighter gases the inlet straight pipe should be longer.

nominal pipe size (DN)

owdirection

straight inlet pipe

Type

Extension 15 x DN 5 x DN

Reduction 15 x DN 5 x DN

90° - elbow 20 x DN 5 x DN

straight outlet pipe

(DN = Nominal Pipe Size)

Straight inlet pipe Straight outlet pipe

Two 90° - elbows,

in one level

Two 90° - elbows,

in two levels, T-piece

Valve, gate valve 50 x DN 5 x DN

10

25 x DN 5 x DN

30 x DN 5 x DN

Page 11

3.5. Assembly of the measurement ball valve

•

All connections to be made with appropriated sealing material on the threads.

• The sealing material should not change the area of the inner cross section of the pipe. It must be

warranted that the connections after installation are free of leaks.

• All fittings must be tested on seal tightness.

• Make sure during the assembly of the measurement section that the arrows on the pipe section

and the measurement ball valve are pointing in the same direction as the flow.

• The recess for the alignment pin must be at the side of the outlet.

recess for

alignment pin

Flow Direction

3.5.1. Assembly without flow meter, but with screw cap instead (blind cap)

In order to use the measurement section without the flow meter, the blind screw cap (in

the scope of supply) must be screwed tight onto the opening of the measurment ball

valve. If not needed the screw cap can be screwed and stored on the handle of the

measurment valve with shut-off function.

3.5.2. Shut off the measurement ball valve

The measurment ball valve assembly allows for the installation and removal of the flow meter within seconds,

with only a very short interruption of the flow.

Never remove the flow meter

or the blind screw cap while

the measurement ball valve

is open.

That is extremely danger-

OPEN

CLOSED

ous!

11

Page 12

3.6. Installation of the flow meter sensing probe

3.6.1. Flow direction

The flow direction is indicated with an arrow on the tip of the probe. Due to the alignment pin is the installation

of the sensing probe in the measurment ball valve only possible in the direction of the flow. After a removal,

the sensing probe will be re-installed in the measurement section in exactly the same position as done at the

factory. Hence, the highest reproducibility is guaranteed.

Flow Direction

3.6.2. Installation of the sensing probe

Make sure that the measurment ball valve is shut off.

Remove transport protection cap of the head of the sensing probe.

•

• Mount the sensing probe in the measurment valve with shut-off function in such a way that the

alignment pin fits in the recess on the measurement ball valve.

• Screw the retainer nut by hand so far that a certain resistance is noticeable.

• Check the correct installation position of the flow meter. The alignment pin must fit in the recess on

the measurment ball valve.

• Tighten the red coloured retainer nut by hand. Tightening by hand should be sufficient. However, if

the seal is not leak tight carefully tighten the nut with an appropriate tool a bit further

• The mechanical installation of the flow meter is therewith completed.

12

Page 13

4. ELECTRICAL CONNECTIONS

Before electrical connections are made turn off the power supply first. If not observed the electronics can be

damaged as a result.

Only a qualified electrotechnical engineer may install the device.

• Unscrew the four screws and remove the cover of the housing.

• The screw terminals are located in the bottom part of the housing.

• For the electrical connection of the flow meter a six-wire cable is needed (e.g. 6 x 1 mm

17))

4.1. Connection diagram

measuring probe

2

(AWG

Modbus data A (=D+) / M-Bus

Modbus data B (=D-) / M-Bus

+

p

4...20mA

I

-

V

or

or

18...30V AC/DC

Screw terminal OUT 1-1 for the analogue output is internally connected with GND.

•

mA

≅

+15V

mA_Input

OUT 1-2

OUT 1-1

OUT 2-1

OUT 2-2

Vcc

GND

optional bus output

Modbus RTU or M-Bus

optional

pressure sensor

signal output 1

analogue- or switching output

signal output 2

switching- or pulse output

supply

• The housing should be grounded to achieve optimal electromagnetic compliance.

4.1.1. Relay and pulse output, internal switching

OUT x-1

OUT x-2

The relay switch and pulse outputs are both potential free.

4.1.2. Connection with optional plug for power supply and outputs (order code Q)

Pin Assignment

1 OUT 2-2

2 OUT 1-2

3 OUT 1-1

4 GND

Connection plug for the

power supply and analogue outputs (rear view of

the terminals)

5 OUT 2-1

6 n.c.

7 Vcc

8 n.c.

13

Page 14

4.2. Bus Output (optional)

4.2.1. M-Bus (Meter-Bus)

The M-Bus (Meter Bus) is a field bus for recording consumption data. Transmission is carried out serially on

a reverse polarity protected two-wire line. The flow meter as M-Bus slave requires a separate supply voltage.

No specific topology (line or star) is prescribed for the cabling. Normal telephone cable of type J-Y(St)Y

Nx2x0.8 mm can be used. A maximum of 250 meters is permitted per segment (primary addressed).

Read-out of the current measurement/consumption data

The following measurement/consumption values are transmitted during a standard query:

• Standard volumetric flow (32 Bit Real)

• Temperature (32 Bit Real)

• Mass flow (32 Bit Real)

• Consumption meter status (32 Bit Real)

• Flow velocity (32 Bit Real)

• Standard volumetric flow (32 Bit Integer)

• Temperature (32 Bit Integer)

• Mass flow (32 Bit Integer)

• Consumption meter status (64 Bit Integer)

• Flow velocity (32 Bit Integer)

The table below shows the package structure of the measurement/consumption data sent by the EE77x transmitter:

Header

68 Start of telegram

4F 4F L-eld(length)

68 Second starting signal

08 C-eld(RSP_UD)

XX A-eld(Adresse)

Start User data

72 CI-eld(variabledatastructure)

XX XX XX XX Identicationnumber

A5 16 Producer (0x16A5 … EUE)

01 Version

09 Medium (9 … compressed air)

XX Access number (continuous)

00 Status

00 00 Signature

Data record 1: Volumenstrom

05 DIF (32 Bit Real)

3E VIF(Volumeowmesseinm³/h)

XX XX XX XX Act. measuring value

Data record 2: Temperature

05 DIF (32 Bit Real)

5B VIF (Temperature in °C)

XX XX XX XX Act. measuring value

Data record 3: Mass ow

05 DIF (32 Bit Real)

53 VIF(Massowinkg/h)

XX XX XX XX Act. measuring value

Data record 4: Consumption meter reading

05 DIF (32 Bit Real)

16 VIF(Volumeinm³)

XX XX XX XX Act. measuring value

Data record 5: Flow rate

05 DIF (32 Bit Real)

7F VIF(manufacturerspecicinm/s)

XX XX XX XX Act. measuring value

Data record 6: Pressure

05 DIF (32 Bit Real)

6B VIF (Pressure in bar)

XX XX XX XX Act. measuring value

Data record 7: Volume ow

04 DIF (32 Bit Integer)

-3

-2

m³)

-3

-3

m³/h)

-2

kg/h)

bar)

°C)

3B VIF(Volumeowin10

XX XX XX XX Act. measuring value

Data record 8: Temperatur

04 DIF (32 Bit Integer)

59 VIF (Temperature in 10

XX XX XX XX Act. measuring value

Datenrecord 9: Mass ow

04 DIF (32 Bit Integer)

51 VIF(Massowin10

XX XX XX XX Act. measuring value

Datenrecord 10: Consumption meter reading

07 DIF (64 Bit Integer)

13 VIF (Volume in 10

XX XX XX XX

XX XX XX XX

Datenrecord 11: Flow rate

04 DIF (32 Bit Integer)

7F VIF(manufacturerspecicin10

XX XX XX XX Act. measuring value

Data record 12: Pressure

04 DIF (32 Bit Real)

68 VIF (Pressure in 10

XX XX XX XX Act. measuring value

End of user data

XX Check sum

16 End of telegram

Akt. consumption data

-2

m/s)

14

Page 15

Secondary addressing

1 2 3 4 5 6 7 8

1 - ON

0 - OFF

1 2 3 4 5 6 7 8

1 - ON

0 - OFF

1 2 3 4 5 6 7 8

1 - ON

0 - OFF

In addition to primary addressing, the EE77x transmitter provides the option of secondary addressing. The

fields of identification number, manufacturer, version and medium are used together as the secondary

address. The exact sequence of the secondary addressing is described in detail in the M-Bus Standard: http://

www.m-bus.com/files/MBDOC48.PDF.

4.2.2. Modbus RTU

The measured values are stored as a 32 Bit float value. Depending on the measurement unit selected, the

measurements are saved in SI or US/GB units. The measurement unit can be changed using the configuration

software.

For resetting the MIN/MAX-Values write 0 to the corresponding write register.

For Modbus protocol setting please see Application Note AN0103 (www.epluse.com/EE771).

Modbus Map:

Register Protocol-

Address

Read Registers (Function Code 0x03 / 0x04) / 32Bit float Value

30026 19 Standardized Flow Nm/s SFPM

30028 1B Standardized Volumetric Flow Nm

30030 1D Temperature °C °F

30032 1F Massflow kg/h kg/h

30034 21 Consumption reading m

30036 23 Pressure bar psi

30261 104 MIN-Value Standardized Flow Nm/s SFPM

30263 106 MAX-Value Standardized Flow Nm/s SFPM

30265 108 MIN-Value Standardized Volumetric Flow Nm

30267 10A MAX-Value Standardized Volumetric Flow Nm

30269 10C MIN-Value Temperature °C °F

30271 10E MAX-Value Temperature °C °F

30273 110 MIN-Value Massflow kg/h kg/h

30275 112 MAX-Value Massflow kg/h kg/h

30277 114 MIN-Value Pressure bar psi

30279 116 MAX-Value Pressure bar psi

Write Registers (Function Code 0x06) / 16Bit integer Value

60261 104 Reset MIN/MAX-Value Standardized Flow

60262 105 Reset MIN/MAX-Value Standardized Volumetric Flow

60263 106 Reset MIN/MAX-Value Temperature

60264 107 Reset MIN/MAX-Value Massflow

60265 108 Reset MIN/MAX-Value Pressure

Measuring Value SI-Unit US/GB-Unit

3

/h SCFPM

3

3

/h SCFPM

3

/h SCFPM

3

ft

4.2.3. Data Transmission

Factory Setting

M-Bus

Baud Rate 2400 9600 600...9600 9600...57600

Data Bits 8 8 8 8

Parity EVEN EVEN None, Odd, Even None, Odd, Even

Stop Bits 1 1 1 or 2 1 or 2

Slave-Address 1 1 0...254 1...247

Factory Setting

Modbus

Adjustable Values

M-Bus Modbus RTU

4.2.4. Addressing

The flow meters are factory-set to address 1. The slave address can be set via switches on the PCB.

Factory Setting:

1 - ON

0 - OFF

1 2 3 4 5 6 7 8

Slave-Address = 1

Slave-Address = 255

1 - ON

0 - OFF

1 2 3 4 5 6 7 8

The address set using

the configurator software

is used.

Dip-Switch for address setting

15

Page 16

5. CONTROL COMPONENTS

V

0

: 323.8 m3/h

Maximal

5.1. Jumper J1 and J2

If the signal output is altered from relay to analogue output or vice versa, Jumper Output 1 has to be relocated.

If the analogue output is altered from a current to a voltage output or vice versa, Jumper Out-1 has to be

relocated.

signal output 1 =

switching output

signal output 1 =

analogue output

Jumper Output 1

Jumper Out-1

analogue output = current signal (e.g. 4-20 mA)

analogue output = voltage signal (e.g 0-10 V)

Modbus RTU only

Line Termination = OFF

Line Termination = ON

150 Ohm parallel to

bus output A and B

Jumper Line Termination

5.2. Digital interface USB (for configuration)

The USB connector is behind the blind screw cap, at the side of the housing.

• remove the blind screw cap with a screwdriver

• plug in the USB connector

Install the configuration software, which is in the scope of supply. The configuration software is

available for downloading as well from our website at www.epluse.com

blind screw cap

USB-cable

5.3. Display / Indicator with keypad (optional)

An optional two-line display is available for the flow meter EE771. The display is an integral part of the cover

of the housing and has two soft-keys for the control of the indicator.

line 1

V

: 1.3 m3/h

0

T : 27.97 °C

pushbutton - UP

pushbutton - DOWN

line 2

16

Page 17

Depending on the configuration of the outputs either the measured values, the status of the relay or the consumption

V

0

: 323.8 m3/h

Maximal

T : 27.97 °C

V

0

: 1.3 m3/h

V

0

: 45.0 m3/h

Rel : 1

V

0

: 323.8 m3/h

Maximal

V

0

: 323.8 m3/h

Maximal

V

0

: 323.8 m3/h

Maximal

is indicated.

measurand

measuring value

unit

V

: 1.3 m3/h

0

T : 27.97 °C

Measurand SI Unit US Unit

v

0 Standardized Flow m/s SFPM

T Temperature °C °F

V

0 Standardized Volumetric

m3/h; m3/min; l/min SCFM; SLPM

Flow

m Massflow kg/h; kg/min; kg/s kg/h; kg/min; kg/s

Q Consumption m

3

3

ft

p Pressure bar psi

5.3.1. Indication of the analogue and pulse output

Line 1 indicates always the configured measurand at output 1. In line 2 the desired measurement value can be

indicated using the UP and DOWN keys.

5.3.2. Indication of the switch output

Line 1 indicates the status of the switch output. In line 2 the desired measurement value can be indicated using the

UP and DOWN keys.

The display shows an inverse image if the relay output is active (relay has switched).

Rel : 1

V0: 1.5 m3/h

Rel : 1

V

: 45.0 m3/h

0

Switch output inactive (relay has not switched) Switch output active (relay has switched)

5.3.3. Indication of the MIN / MAX values

Keep the DOWN key pressed for > 3 sec to indicate the MIN value.

Keep the UP key pressed for > 3 sec to indicate the MAX value.

V

: 1.3 m3/h

0

T : 27.97 °C

MAX value press pushbutton UP >3s

MIN value press pushbutton DOWN >3s

17

Page 18

After that the several different measurement values can be indicated using the UP or DOWN keys.

Keep the DOWN or UP key pressed for > 3 sec to exit the MIN / MAX mode.

Maximal

: 323.8 m3/h

V

0

5.3.4. Reset of the consumption counter or the MIN / MAX value

Keep both the UP and DOWN key pressed for > 3 sec to enter the menu for resetting the consumption counter or the MIN / MAX value. Select the desired menu item by pressing the UP or DOWN key briefly.

Maximal

: 323.8 m3/h

V

0

Press pushbutton UP and DOWN at the same time for >3s

To confirm the selected choice of the menu keep the DOWN or UP key pressed for > 3 sec.

Select menu item “NO” or “EXIT” to cancel without resetting.

> Clear Consumption

Clear Min/Max

Exit

5.3.5. Maximum consumption counter

The maximum consumption counter readout on the display is 999,999,999.0 m

3

or 99,999,999.0 ft3. Then it

shows “LCD maximum”. The internal memory continues counting. The maximum counter reading is 3.4 * 1038

m3. It is possible to read-out the counter reading with the configuration software.

6. ERROR MESSAGES

In case the flow meter is equipped with the optional display, the following error message can be indicated.

ERROR 01: sensing probe is not detected

Cause: the sensing probe is not connect or is defect

Effect: the display indicates “0” for all measurand. The analogue output defaults to the lowest

configured value.

Action: check the head of the sensing probe for visual damage.

check the sensor cable from the sensing probe to the electronics of the signal conditioning.

ERROR 02: the EEprom is defect

Cause: the EEPROM for the storing of the consumption counter and MIN /MAX value is defect.

Effect: the consumption counter and MIN / MAX values are no longer available. All measure-

ment values though are still indicated. The analogue, relay and pulse output are still

functional.

Action: return the flow meter to the manufacturer.

18

Page 19

7. MAINTENANCE

Regular cleaning of the sensor is necessary is used in applications with wet or filthy gases. Cleaning of the sensor

is necessary prior to calibration or evaluation.

7.1. Removal of the sensing probe of the flow meter

•

Shut off the measurement valve with shut-off function

(see page 11).

• Turn off the power supply, remove the cover and disconnect the

power wires on the screw terminal.

• Loose the retainer nut and pull the sensor probe from the meas-

urement section.

Never remove the flowmeter while the measurement ball valve is open.

That is extremely dangerous!

• Operation without the flow meter installed page 11.

7.2. Cleaning of the sensor of the flow meter

Do not use an abrasive cleaning agent, an organic solvent containing halogen or acetone.

• Clean the head of the sensor probe by carefully swirling in warm water of isopropyl alcohol. It is recom-

mended to use isopropyl alcohol if the pollution is crease or oil.

The sensor should not be touch by fingers or solid objects like screwdrivers or brushes!

• Leave the sensor to dry in ambient air.

8. REPLACEMENT PARTS / ACCESSORIES

8.1. Order Code Replacement Sensor

EE771-R-

Hardware Configuration

Model compact ri-le direction od flow right to left A

compact le-ri

remote probe C

Working range low

high

Measuring pipe - DN15 N015

diameter DN20 N020

DN25 N025

DN32 N032

DN40 N040

DN50 N050

Mounting Measurment ball valve K

1)

Plug

cable gland A

1 plug for power supply and outputs Q

1)

only for model A and B

direction od flow left to right B

(0,5...100 Nm/s) or (100...19685 ft/min) L1

(0,5...200 Nm/s) or (100...39370 ft/min) H1

19

Page 20

Order Example Order Example

EE771-R-AL1N025KC12

Model: Compact ri-le

Working range: low

Measuring pipe - diameter: DN25

Mounting: Measurment ball valve

Plug: 1 plug for power supply and outputs

EE771-R-CL1N025K

Model: remote probe

Working range: low

Measuring pipe - diameter: DN25

Mounting: Measurement ball valve

8.2. Order Code Miscellaneous

Measurement ball valve DN15 - Measurement ball valve HA075015

DN20 - Measurement ball valve HA075020

DN25 - Measurement ball valve HA075025

DN32 - Measurement ball valve HA075032

DN40 - Measurement ball valve HA075040

DN50 - Measurement ball valve HA075050

Probe cable (for model C)

cable length 2 m HA010816

5 m HA010817

10 m HA010818

screw cap (blind cap) HA070201

9. TECHNICAL DATA

Measuring value

Flow

Measurand Volumetric flow at standard conditions acc. DIN 1343

P

Measuring range low (L1) high (H1)

DN32: 1,45...289 Nm3/h 0.85...170.0 SCFM 1,45...578 Nm3/h 0.85...340 SCFM

DN40 2,26...452 Nm3/h 1.33...265.9 SCFM 2,26...904 Nm3/h 1.33...531.8 SCFM

DN50: 3,50...700 Nm3/h 2.06...411.8 SCFM 3,50...1400 Nm3/h 2.06...823.6 SCFM

standardizedflow ≤DN50: 0,5...100Nm/s 100...19685 SFPM 0,5...200 Nm/s 100...39370 SFPM

standardized

volumetric flow

Accuracy in air at 7bar (abs) and 23°C (73°F)1) ± (1,5 % of measuring value + 0,5 % of full scale)

Accuracy of temperature compensation ± (0,1 % of measuring value/°C)

Response time t90 typ. 1 sec.

Sample rate 0,1 sec.

Temperature

Measuring range

DN15: 0,32...63 Nm3/h 0.19...37.1 SCFM 0,32...126 Nm3/h 0.19...74.1 SCFM

DN20: 0,57...113 Nm3/h 0.34...66.5 SCFM 0,57...226 Nm3/h 0.34...133 SCFM

DN25:

Accuracy at 20 °C (68 °F) ± 0,7 °C (1.26 °F)

Outputs

Output signal and display ranges are freely scalable

Analogue output voltage 0 - 10 V max. 1 mA

current (3-wire) 0 - 20 mA and 4 - 20 mA R

Switching output potential-free max. 44 VDC, 500 mA switching capacity

Pulse output Totalizator, pulse length: 0,02...2 sec.

Bus output (optional) Modbus RTU or M-BUS (Meter-Bus)

Digital interface USB (for configuration)

Input

Optional pressure compensation 4 - 20 mA (2-wire; 12 V) for pressure sensor

0 = 1013,25 mbar; t0 = 0 °C (273,15 K)

0,90...176 Nm3/h 0.53...103.5 SCFM 0,90...352 Nm3/h 0.53...207.1 SCFM

-20...80 °C (-4...176 °F)

L<500 Ohm

20

Page 21

General

Supply voltage 18 - 30 V AC/DC

Current consumption max. 200 mA (with display)

Temperature range ambient temperature: -20...60 °C

medium temperature: -20...80 °C (-4...176 °F)

storage temperature: -20...60 °C (-4...140 °F)

Nominal pressure up to 16 bar (232 psi)

Humidity no condensation

Medium compressed air or none corrosive gases

Connection cable gland M16x1,5 (optional connector M12x1 8pol.)

Electromagnetic compatibility EN61326-1 EN61326-2-3

Industrial Environment

Material housing metal (AlSi3Cu)

probe stainless steel

sensor head stainless steel / glass

measurement ball valve brass

Housing protection class IP65 / Nema 4

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was

culated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

9.1. Factory setting of outputs

SI-Unit

Analogue output

[0...10 V / 0(4)...20 mA] from to unit

low (L1) high (H1)

standardized DN15: 0 60 120 Nm

volumetric flow DN20: 0 110 220 Nm

DN25: 0 175 350 Nm3/h

DN32: 0 285 570 Nm3/h

DN40: 0 450 900 Nm3/h

DN50: 0 700 1400 Nm

mass flow DN15: 0 75 150 kg/h

DN20: 0 140 280 kg/h

DN25: 0 220 440 kg/h

DN32 0 360 720 kg/h

DN40: 0 570 1140 kg/h

DN50: 0 890 1780 kg/h

standardized flow

temperature all Ø -20 80 80 °C

≤DN50 0 100 200 Nm/s

(-4...140 °F)

3

/h

3

/h

3

/h

Switching output [switching point/hysteresis]

volumetric flow DN20 90/9 180/18 Nm3/h

DN25: 150/15 300/30 Nm3/h

DN32: 230/23 460/46 Nm3/h

DN40: 360/36 720/72 Nm

DN50: 560/56 1120/112 Nm3/h

mass flow DN15: 60/6 120/12 kg/h

DN20: 110/11 220/22 kg/h

DN25: 200/20 400/40 kg/h

DN32: 290/29 580/58 kg/h

DN40: 460/46 920/92 kg/h

DN50: 700/70 1400/140 kg/h

standardized flow

temperature

Pulse output pulse-value = 1 m

standardized DN15 50/5 100/10 Nm3/h

3

≤DN50 80/8 180/18 Nm/s

all Ø 30/3 70/7 °C

3

pulse-duration = 0,1 sec.

/h

21

Page 22

US-Unit

Analogue output [0...10 V / 0(4)...20 mA] from to unit

low (L1) high (H1)

standardized DN15: 0 35 70 SCFM

volumetric flow DN20: 0 60 120 SCFM

DN25: 0 100 200 SCFM

DN32: 0 165 330 SCFM

DN40: 0 260 520 SCFM

DN50: 0 410 820 SCFM

mass flow DN15: 0 75 150 kg/h

DN20: 0 140 280 kg/h

DN25: 0 220 440 kg/h

DN32 0 360 720 kg/h

DN40: 0 570 1140 kg/h

DN50: 0 890 1780 kg/h

standardized flow

Temperatur alle Ø -4 176 176 °F

Switching output [switching point/hysteresis]

volumetric flow DN20 50/5 100/10 SCFM

DN25: 80/8 160/16 SCFM

DN32: 130/13 260/26 SCFM

DN40: 210/21 420/42 SCFM

DN50: 330/33 660/66 SCFM

mass flow DN15: 60/6 120/12 kg/h

DN20: 110/11 220/22 kg/h

DN25: 200/20 400/40 kg/h

DN32: 290/29 580/58 kg/h

DN40: 460/46 920/92 kg/h

DN50: 700/70 1400/140 kg/h

standardized flow

temperature

standardized DN15 30/3 60/6 SCFM

≤DN50 0 20000 40000 SFPM

≤DN50 15000/1500 30000/3000 SFPM

all Ø 90/9 150/15 °F

Pulse output pulse-value = 1CF pulse-duration = 0.1 sec.

CONFIGURATION SOFTWARE

LIMITED LIABILITY

E+E Elektronik shall not be held liable for any damages or consequential damages (for example, but not

restricted to, loss of earnings, interruption of business, loss of information and data or any other financial

losses) resulting from the installation, use or impossibility of use of an E+E Elektronik software product and

any associated support services or non-performance of support services.

1. General

The configuration software can be downloaded free of charge at www.epluse.com/ee771

The configuration software, allows for a user-friendly adaptation of the flow meter to the application. In addition, the measurement values for flow and temperature can be calibrated / adjusted.

The system requirements for the installation and execution of the software are:

• Windows XP with SP3, Windows Vista or Windows 7

• .NET framework 3.5 with SP1

• USB 2.0 interface

During setup there will be no installation of .NET Framework 3.5 SP1 – if the required version is not already

installed on the computer the following error message will appear at the start of the configuration software.

.NET Framework 3.5 SP1 can be installed using Windows Update.

22

Page 23

2. Installation

In order to set up a smooth installation of the configuration software of the EE771, admin authorization for the

personal computer is required.

• During installation of the software the EE771 should NOT be connected with the USB cable to the

computer.

• Wit Setup.exe the InstallShield-Wizard for the EE771 configurator will be started.

• Follow the instructions on the screen to install the software.

At first, the configuration software will be installed and then the installation of the USB driver activated – except

if the user has defined that USB setup is disabled.

The USB driver will be automatically installed the moment the first connection is made with the EE771.

The appearing dialog boxes can be dealt with the settings “No. do not download driver from the internet” and

“Install the hardware automatically”.

If the EE771 configuration software and the USB driver are installed correctly, and the EE771 is connected

via the USB interface with the personal computer, a connection “Silicon Labs C210x USB to UART Bridge”

should have been created in the device manager.

See: Start => Settings => Control Panel => System => Hardware => Device

Manager

2.1. Configuration of the USB Interface (VirtualCOM)

After the startup of the software, the correct VirtualCOM interface for the

USB driver must be configured

The number for the used USB interface can be found under:

Start => Settings => Control Panel => System => Hardware => Device

Manager

The setting is done under menu “Extras” and menu item “Optional extras

...”

23

Page 24

Select the COM-port number as shown in the device manager.

These settings are done only once and at the first start of the configuration software. The settings are stored

for future use.

3. User Interface

4

1

2

3

1

3

2

Basic information:

After retrieving the data from the transmitter, the basic information of the device is shown here.

Status message:

Here are the messages shown about the status and other information.

Input screen:

Input screen for the configuration or adjustment of the flow meter.

4

Menu tool bar:

Selection of menu items.

24

Page 25

4. Menu toolbar

4.1. File

Delete status message deletes the status messages.

Exit closes the configuration software.

4.2. Transmitter

Read reads the actual configuration of the transmitter.

Send uploads the ‘new’ configuration to the transmitter.

The following settings are uploaded to the transmitter

• Units

• Output 1

• Output 2

• Display mode

• Pressure transmitter

Prior to uploading the ‘new’ configuration to the transmitter, a dialog box will show a summary of the

changes. Click on the button ‘OK’ and the configuration will be uploaded to the transmitter; click

‘Cancel’ to cancel the operation.

4.3. Extras

Configurations of the VirtualCOM- interface (see page 23).

5. Input Screen

5.1. Output 1, Output 2

In this screen the actual settings of the transmitter for the output 1 and 2, resp. relay 1 and 2 are shown. The

user can alter and upload these settings to the transmitter, together with other changes of the configuration.

5.1.1. Output mode

Here the mode of signal output can be determined.

Output 1: analogue or switch (relay) output

Output 2: switch (relay) or pulse output

NOTE:

In case the mode of output 1 is changed, the Jumper J1 on the board of the signal conditioning electronics has to

be relocated as well (see page 25)

5.1.2. Measurand

Here is determined which measurand will be represented at the particular output.

5.1.3. Units

Choice of the engineering units of the selected measurand in either SI- (m/s; °C; m3/h) or US-units

(SFPM; °F; SCFM).

25

Page 26

NOTE:

The setting “Units” on the tabs for Output 1 and Output 2 are in sync with each other. If the units are changed

on one of the output tabs, automatically the units on the other output tab are changed accordingly.

5.1.4. Output mode – analogue

Within the limits of measurement range and the scaling of the output, the analogue output can be freely configured and scaled. Either a standard output signal (0 – 5 V, 0 – 10 V, 0 – 20 mA, 4 – 20 mA) can be selected

or a user defined range for the current / voltage output (e.g. 1 – 9 V).

NOTE:

In case the analogue output is changed (from current to voltage or vice versa), the Jumper J2 on the board

of the signal conditioning electronics has to be relocated as well (see page 25).

5.1.5. Output mode – switch (relay)

In the field for the “Switch-mode”, one can select “Hysteresis” or “Window”.

The field for “Type” is to determine the switch action of the relay, NO = Normally Open (activate to close), NC

= Normally Close (activate to open).

Under “Measuring range” in the field “From” the low value of the measuring range can be entered and in the

field “To” the high value.

The hysteresis of the set point is entered as a percentage of the

measuring range.

[measuring range] = high measuring value – low measuring value

e.g. hysteresis

set point = 500 Nm3/h and reset point is 450 Nm3/h

Hysteresis = 50 Nm3/h = 0.5 % of measuring range

Hysteresis

Nm3/h

When the measurement value reaches set point 1, the relay will

be activated. The value at the reset point is the value at set point 1

minus the hysteresis.

set point 1

e.g. set point 1 = 100 Nm3/h and the hysteresis 5 Nm3/h.

the relay switches at 100 Nm3/h. The reset point is at 96 Nm3/h.

NO (activate to close)

NC (activate to open)

Hysteresis

1

0

1

0

t

Hysteresis = 5 Nm3/h = 5% of the measuring range

26

Page 27

Window

Nm3/h

The relay is activated as long as the measuring value is

between the values of set point 1 and set point 2.

The hysteresis of each set point is fixed at 0.2% of the meas-

set point 1

set point 2

uring range.

e.g.: set point 1 = 100 Nm3/h; set point 2 = 80 Nm3/h;

hysteresis of each set point is 1 Nm3/h (0.2% of 500 Nm3/h)

t

NO (activate to close)

NC (activate to open)

1

0

1

0

3

80 Nm

/h = set point 2

100 Nm3/h = set point 1

99 Nm3/h = set point 1 - hysteresis

79 Nm3/h = set point 2 - hysteresis

5.1.6. Output mode – pulse

If output 2 is configured for pulse, the measurand can be consumption only. Under “Pulse”, the duration of the

pulse and the pulse value (Significance level of pulse) can be freely configured.

Volume Flow [m3/h] Number of Pulses

3

/Pulse]

=

HourPulse Value [m

The duration of the pulse can be set between 0.02 and 2 seconds.

3

e.g. Duration of pulse = 100ms; one pulse for each Nm

consumed

The pulse – interval – ratio must be at least 1 : 2, meaning that the duration of the pulse interval must be at

least twice the duration of the pulse itself.

OUT 2

≥ 2 s

1/3 min. 2/3

t

Calculation of the minimum “pulse value” or the maximum “pulse duration”.

IMPW_MIN = NORMV_MAX [m3/h] * IMPL [s] / 1200

IMPL_MAX = IMPW [m3] * 1200 / NORMV_MAX [m3/h]

IMPW pulse value [m

IMPL pulse length (duration) [s]

IMPW_MIN minimum pulse value [m3]

IMPL_MAX maximum pulse length (duration)

NORMV_MAX expected maximum volume flow (Nm3/h)

3

]

5.2. Minimum flow shutdown

The minimum flow shutdown is switched on and off using the “active” checkbox.

Iftheoutputsignalis≤thantheset“Shutdownvalue”,theflowmeterissues0ontheanalogueoutput.

27

Page 28

5.3. Display

If an optional display is installed, at the tab Display the following items can be entered:

Drop-down input field “Display-Mode”

• Single spaced

• Double spaced (default)

Checkbox “Backlight”

• Checked = ON

• Unchecked = OFF

In the input field

“Description (free text), a

user specific name (max.

16 characters) for the

transmitter can be

entered.

e.g.: HALL 1

With the button “send” only the description will be uploaded to the transmitter.

5.4. Adjustment

The user can perform an adjustment for the measurands normflow and temperature in air.

The configuration software distinguishes between a 1-point and a 2-point adjustment automatically, depending

on how many reference points for adjustments are entered.

The values entered for the customer’s adjustment are stored in the electronics of the sensing probe and are

therefore not lost if the electronics of the signal conditioning are replaced (see page 6)

If the checkbox “Performing customer-adjustment” is checked, the adjustment mode will be activated and the

actual measuring value in the set interval automatically retrieved from the flow meter (transmitter).

NOTE: At first change to “Calibration gas” in the tab “Process parameters”.

While the customer-adjustment is active all other pages, functions and commands are deactivated.

In the field “Adjustment” the measurand to be adjusted is selected.

In the field “Measuring value” the actual measurement value of the transmitter is indicated.

The update-interval can be set.

In the field “Reference value” the measurement value of the standard is entered.

After clicking the button “send” a control dialog box appears in which the values can be corrected if needed.

Then the reference value will be uploaded to the flow meter (transmitter) and is the adjustment procedure

complete.

The reference point of the customer-adjustment must be within the determined measuring range.

The customer-adjustment results in a slight rotation of the characteristic line, in such a way that the measurement deviation at the upper and lower adjustment points equals zero.

The configuration software determines, depending on its position, if it is an upper or lower adjustment point.

5.4.1. 1-point adjustment

lower adjustment point upper adjustment point

possibility 1 0 - 50% of measuring range 100% of measuring range

possibility 2 0% of measuring range >50 - 100% of m.r.

28

m.r. ... measuring range

Page 29

upper adjustment point at 80% of measuring range

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

lower adjustment point automatically at 0% of m.r.

lower adjustment point at 20% of measuring range

upper adjustment point automatically at 100% of m.r.

100%

90%

80%

70%

60%

50%

40%

output signal

30%

20%

10%

characteristic line before adjustment

characteristic line after adjustment

selected adjustment point

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

measuring range

100%

90%

80%

70%

60%

50%

40%

output signal

30%

20%

10%

characteristic line before adjustment

characteristic line after adjustment

selected adjustment point

measuring range

5.4.2. 2-point adjustment

With a 2-point adjustment procedure the lower adjustment point must be between 0 and 40% of the measuring

range, and the upper adjustment point between 60 and 100% of the measuring range. If the adjustment point is

between 40 and 60% of the measuring range, automatically a 1-point adjustment procedure will be executed instead.

lower adjustment point upper adjustment point

possibility 1 0 - <40% of m.r. 60 - 100% of m.r.

possibility 2 40 - <50% of m.r. 100% of m.r.

possibility 3 0% of m.r. 50 - <60% of m.r.

lower adjustment point at 10% of measuring range

upper adjustment point at 90% of measuring range

100%

90%

80%

70%

60%

50%

40%

output signal

30%

20%

10%

characteristic line before adjustment

characteristic line atfer adjustment

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

measuring range

29

Page 30

5.4.3. Reset to factory settings

Customer-adjustment can be reset to the factory settings by checking the appropriate checkbox and subsequently clicking the “reset” button.

5.5. Measuring values overview

The tab measuring values provides an overview of the retrieved actual measurement values of the flow

meter (transmitter). Clicking on “Fetch values” will retrieve the actual measurement and MIN / MAX values for

flow, volume flow, temperature, mass flow and pressure (only if a pressure transmitter is connected) from the

transmitter – additional the reading of the consumption meter is retrieved as well.

Checking the “Polling” checkbox will retrieve the measuring data from the transmitter at the selected interval.

5.5.1. Reset of the MIN / MAX values

The MIN/ MAX values of each measurand, as stored in the flow meter (transmitter), can be reset by checking

the appropriate checkbox and subsequently clicking the “Clear MIN / MAX” button.

5.5.2. Reset of the consumption counter (totalizer)

The reading of the consumption meter can be reset by clicking the “Reset meter” button.

5.6. Setting up Process Parameters

In the tab Process Parameters you can change the Process gas (medium) and set the pressure compensation

5.6.1. Change the Process Gas

NOTE: This function is only active if the flow meter for a medium different from air has been ordered (see

order code Medium in the data sheet)

Calibration-Gas: Is the gas (medium) in which the flow meter was calibrated in the factory. Unless otherwise

specified, the flow meter is calibrated at the factory always in air.

Process-Gas: Is the gas (medium) in the measured process. The adjustable process gases are set at the

factory and can be selected from a list.

The flow meter is factory set to the ordered gas (medium).

If the setting for the process-gas modified or changed between calibration- and process gas, the changed

setting has to be sent to the transmitter. Use “send data to the transmitter and read ...” button.

The “active gas” to which the flow meter is set, you can see in the field basic information.

30

Page 31

5.6.2. Changing the standard conditions

The flow meter is factory-set to standard conditions conforming to DIN 1343.

Factory setting: P

The corrected volume flow measured value is calculated in line with the standard conditions set.

5.6.3. Pressure compensation

The flow meter is factory-adjusted to 7 bar (abs). At an operating pressure other than 7 bar (abs), the error

can be corrected via the pressure coefficient of +0.5% of the measured value per bar by entering the actual

system pressure.

The “Send” button is used only to send the process pressure to the transmitter.

= 1013.25 mbar, t0 = 0°C (273.15 K)

0

5.7. External pressure transmitter for pressure compensation

In order to achieve the highest accuracy, the input from an external pressure transmitter will be very useful if

the pressure fluctuates strongly (e.g. 3 to 10 bar (45 to 150 psi)). An absolute pressure transmitter with a

2-wire loop powered 4 – 20 mA output should be used.

On the tab “Pressure transmitter” the measuring range can be entered.

5.8. Bus configuration

If the flow meter is equipped with an optional bus module, the data transfer rate and the network address can

be set on the “Bus configuration” tab.

The network address set is only used when the dip switches on the flow meter PCB are set to 255 (see page 14).

31

Page 32

HEAD OFFICE:

E+E ELEKTRONIK Ges.m.b.H.

Langwiesen 7

A-4209 Engerwitzdorf

Austria

Tel: +43 7235 605 0

Fax: +43 7235 605 8

info@epluse.com

www.epluse.com

SALES OFFICES:

E+E CHINA / BEIJING

Tel: +86 10 84992361

info@epluse.cn www.epluse.cn

E+E CHINA / SHANGHAI

Tel: +86 21 61176129

info@epluse.cn www.epluse.cn

E+E GERMANY

Tel: +49 6172 13881 0

info@epluse.de www.epluse.de

E+E FRANCE

Tel: +33 4 7472 35 82

info@epluse.fr www.epluse.fr

E+E ITALY

Tel: +39 02 2707 8636

info@epluse.it www.epluse.it

E+E KOREA

Tel: +82 31 732 6050

info@epluse.co.kr www.epluse.co.kr

E+E USA

Tel: +1 508 530 3068

office@epluse.com www.epluse.com

Loading...

Loading...