Page 1

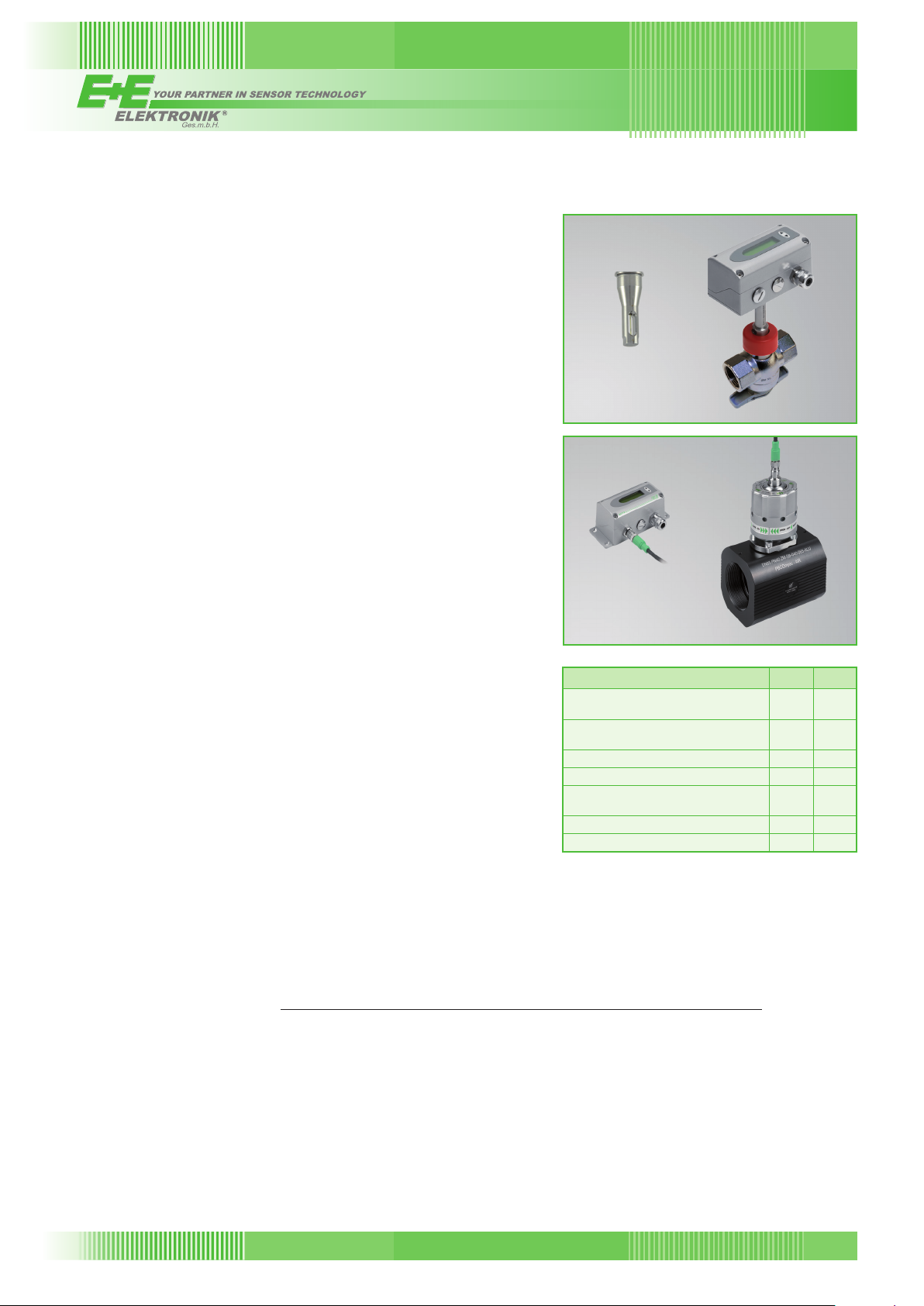

EE771/EE772

Inline Flow meter for compressed air and gases

The inline flow meter EE771/EE772, based on the measurement

principle of thermal mass flow, is ideally suited for the measurement of flow in pipelines DN15 (1/2”) up to DN80 (3”). Measurement of for instance the usage of compressed air, nitrogen, CO

O2, argon or other non-corrosive, non-flammable gasses.

The flow meters are setting new standards in terms of measurement accuracy and reproducibility thanks to their applicationspecific adjustment during production. As such, the EE771/

EE772 is adjusted under a pressure of 7 bar.

The unique mounting concept with a measurement valve with

shut-off function permits rapid installation and removal of the

device for periodical calibration. It simultaneously ensures high

measurement accuracy through exact and reproducible positioning in the pipe.

The core design of the flow meter is based on the E+E hot film

sensor element, which is produced using the most modern thin

film technology. This flow sensor features excellent long-term

stability, a fast response time and an extremely high degree of

reliability.

flow sensor

,

2

EE771 Compact

DN15 (1/2“) - DN80 (3“)

detail

Two outputs are available, for further processing of the measure-

EE772 remote probe

ment data. Depending on the application, these outputs can be

configured as analogue (current or voltage), switch output or as

pulse output for the measurement of the consumption.

Bus interface for Modbus RTU or M-Bus

Optionally, the ow meter is available with an additional bus

interface for Modbus RTU or M-BUS (Meter-Bus).

Configuration software

The ow meter can be congured conveniently, to meet the requirements of the application with the standard conguration soft-

ware and the integrated USB interface.

Attribute

Sensor exchange under pressure

with short ow interruption

Sensor exchange under pressure

without ow interruption

pipeline DN15...DN50 (1/2“...2“)

pipeline DN40...DN80 (1 1/2“...3“)

Additional assembly of dew point-

and pressure sensors

max. working pressure 16 bar 232 PSI

max. working pressure 40 bar 580 PSI

EE771 EE772

Functionality of the software:

• Conguration of the output (scale / set point)

• 2-point user calibration for ow and temperature

• Readout of the counter values

• Reset of min / max values and counter

• Indication of the measurement value

Typical Applications Features

Measurement of consumption of compressed air

Compressed air counter

Mass flow measurement of industrial gases

quick sensor exchange at line pressure

Bus interface for Modbus RTU or M-Bus

high accuracy ± 1.5 % of reading

factory adjustment under pressure

exceptional reproducibility

broad working range of 1:400

very service friendly

196

v4.6 / Modification rights reserved

EE771/EE772

EE771/EE772

Page 2

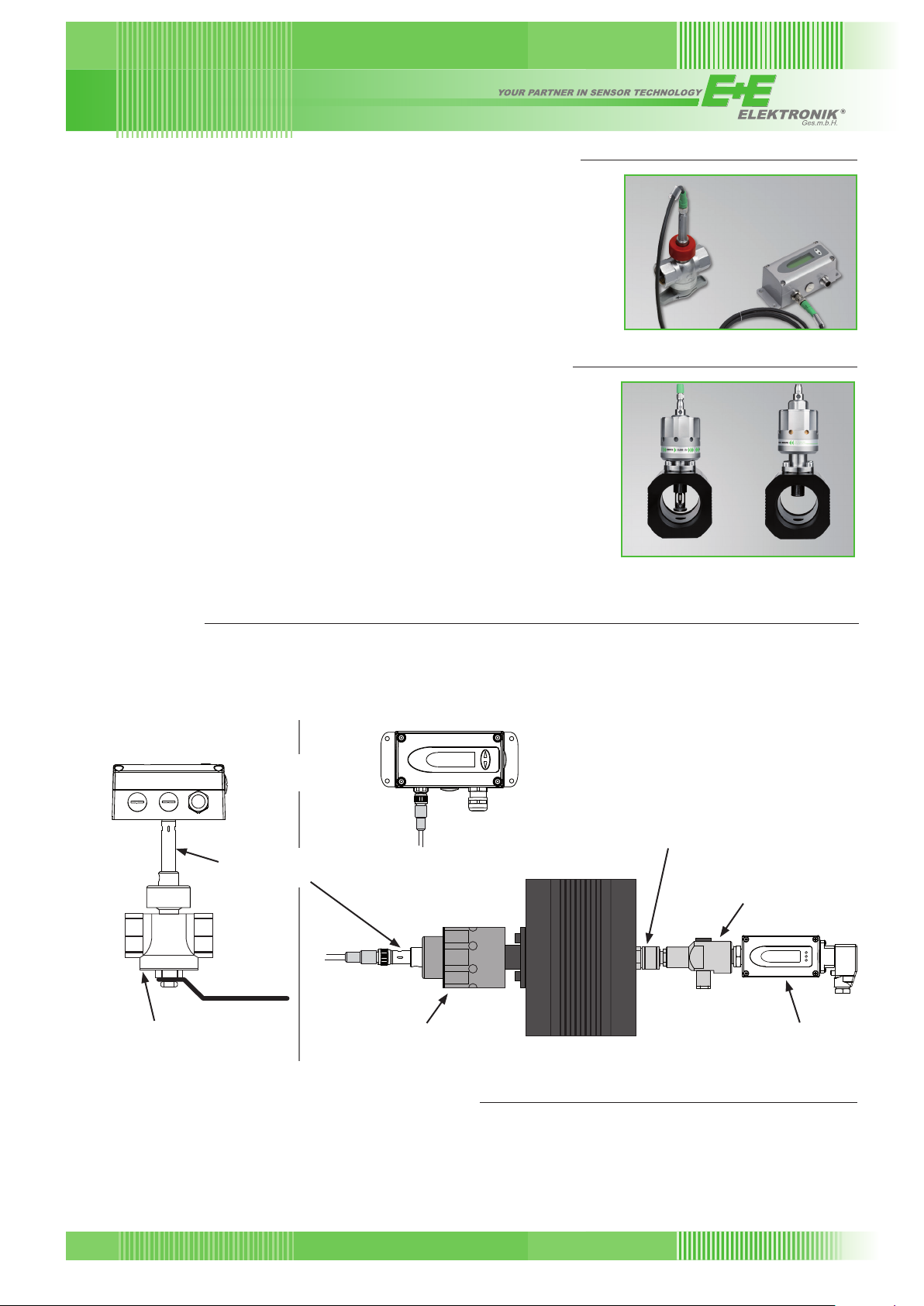

EE771 - Measurement valve with shut-off function

The measurement valve with shut-off function allows the exact alignment

of the sensing head within seconds during instalment and removal, with

only interrupting the process flow for a short moment.

The measurement valve is suitable for pressures up to 16 bar

(232 PSI) and

available for pipe diameters DN15 (1/2") to DN50 (2").

EE772 - Gauge mounting block with hot tap valve

The unique assembly concept with one mounting valve permits simple

installation and removal of the sensors for regular calibration, and also

ensures a high level of measurement accuracy via precise and reproduc-

ible positioning of the ow sensor in the pipeline.

The gauge mounting block with hot tap valve is used in applications where

ow interruption is not permissible. The ow meter can be removed for

calibration or maintenance with no ow interruption.

The gauge mounting block with hot tap valve assembly is suitable for applications up to 40 bar (PN40) and is available for line sizes of DN40 (1 1/2“)

to DN80 (3“).

The additional option of integrating dewpoint or pressure sensors saves

on installation costs. The gauge mounting block with hot tap valve makes it easy to set up a comprehensive

compressed air monitoring system.

measuring remove

Construction

The ow meter consist of the transmitter and the mounting valve. The transmitter is modular and consist of the

probe and the evaluation electronics. The measurement probe contains the sensor element and the measurement electronics, in which the data of the factory calibration is stored. The enclosure with the signal conditioning

is mounted either on the measurement probe (compact) or is remote with a sensor cable up to 10 meter

evaluation electronics

with optional display

quick coupling (accessory)

probe with sensor and

measurement electronics

Measurement valve with

shut-off function

EE771

hot tap valve

EE772

Gauge mounting

block

sampling cell for dew point

sensor (accessory)

dew point sensor

EE371 or EE355

(accessory)

(33 feet).

Measurement of consumption (totalizer)

The EE771/EE772 holds an integrated counter for the usage. The amount is indicated in the display and

stored; the data will not be lost due to a power outage. The availability of the consumption amount as a free

congurable pulse output is another helpful feature.

EE771/EE772

v4.6 / Modification rights reserved

197

Page 3

Dimensions in mm (inch)

115 (4.53)

60 (2.36)

EE77x-A

56 (2.2)

v

: 5.43 m/s

0

T: 23.75 °C

direction of ow is right to left

v

: 5.43 m/s

0

T: 23.75 °C

145 (5.71)

60 (2.36)

EE77x-A / EE77x-B

EE77x-B direction of ow is left to right

Compact

Only at DN15:

Reduction

173 (6.81)

3/4“-1/2“

A A B

173 (6.81)

HA075xxx

Measurement valve with shut-off function

152 (5.98)

female thread

183 (7.2)

(6.38)

162

EE77x-C

Remote probe

Measurement valve

DN15 R

DN20 Rp or NPT 3/4” 72 (2.83) 92 (3.62)

DN25 Rp or NPT 1” 83 (3.27) 124 (4.88)

DN32 Rp1 1/4" 100 (3.94) 124 (4.88)

DN40 Rp or NPT 1 1/2" 110 (4.33) 147 (5.79)

DN50 Rp or NPT 2” 131 (5.16) 147 (5.79)

dimensions in mm (inch)

Female thread:

BSP thread acc. EN 10226 (old DIN 2999) or NPT

200 (7.87)

Thread A B

1/2" 100±8 (3.94±0.32) 92 (3.62)

p

210 (8.27)

H

opening for additional

108.5 (4.27) 108.5 (4.27)L

sensors G1/2“

HA071xxx

Gauge mounting block

pipe diameter Thread L H

DN40 (1 1/2”) R

or NPT 1 1/2" 110 (4.33) 108.5 (4.27)

p

DN50 (2”) Rp or NPT 2" 131 (5.16) 108.5 (4.27)

DN65 (2 1/2”) Rp or NPT 2 1/2" 131 (5.16) 108.5 (4.27)

DN80 (3”) Rp or NPT 3" 131 (5.16) 118.5 (4.67)

dimensions in mm (inch)

female thread:

Whitworth-Thread acc. EN 10226 (old DIN 2999) or NPT

198

H

L

HA072xxx

Gauge mounting block with hot tap valve

v4.6 / Modification rights reserved

EE771/EE772

Page 4

Technical data

Measuring value

Flow

Measurand Volumetric flow at standard conditions acc. DIN 1343

P

Measuring range low (L1) high (H1)

DN32 (1 1/4”): 1.45...289 Nm3/h 0.85...170.0 SCFM 1.45...578 Nm3/h 0.85...340 SCFM

DN40 (1 1/2”): 2.26...452 Nm3/h 1.33...265.9 SCFM 2.26...904 Nm3/h 1.33...531.8 SCFM

DN50 (2”): 3.50...700 Nm3/h 2.06...411.8 SCFM 3.50...1400 Nm3/h 2.06...823.6 SCFM

DN65 (2 1/2”): 5.97...1400 Nm3/h 3.51...823.6 SCFM

DN80 (3”): 9.04...1400 Nm3/h 5.32...823.6 SCFM

standardized flow in air, CO2, ≤DN50 (2”): 0.5...100 Nm/s 100...19685 SFPM 0.5...200 Nm/s 100...39370 SFPM

nitrogen, argon DN65 (2 1/2”): 0.5...117 Nm/s 100...23031 SFPM

DN80 (3”): 0.5...77 Nm/s 100...15157 SFPM

O2 ≤DN25 (1”): 0.5...100 Nm/s 100...19685 SFPM 0.5...200 Nm/s 100...39370 SFPM

standardized volumetric flow in air DN15 (1/2”): 0.32...63 Nm3/h 0.19...37.1 SCFM 0.32...126 Nm3/h 0.19...74.1 SCFM

DN20 (3/4”): 0.57...113 Nm3/h 0.34...66.5 SCFM 0.57...226 Nm3/h 0.34...133 SCFM

DN25 (1”):

Accuracy in air at 7bar (101.5 Psi) (abs) and 23°C (73°F)1) ± (1.5 % of measuring value + 0.5% of full scale)

Temperature coefficient ± (0.1 % of measuring value/°C)

Pressure coefficient

Response time t

2)

0.5 % of measuring value / bar

90 < 1 sec.

Sample rate 0.1 sec.

Temperature

Measuring range

Accuracy at 20°C (68°F) ± 0.7 °C (1.26 °F)

Outputs

Output signal and display ranges are freely scalable

Analogue output voltage 0 - 10 V max. 1 mA

current (3-wire) 0 - 20 mA and 4 - 20 mA R

Switching output potential-free max. 44 VDC, 500 mA switching capacity

Pulse output Totalizer, pulse length: 0.02...2 sec.

Bus interface (optional) Modbus RTU or M-BUS (Meter-Bus)

Digital interface USB (for configuration)

Input

Optional pressure compensation 4 - 20 mA (2-wire; 15 V) for pressure sensor

General

Supply voltage 18 - 30 V AC/DC

Current consumption max. 200 mA (with display)

Temperature range ambient temperature: -20...60 °C

medium temperature: -20...80 °C (-4...176 °F)

storage temperature: -20...60 °C (-4...140 °F)

Nominal pressure EE771 up to 16 bar (232 Psi)

Humidity no condensation

Medium compressed air or none corrosive gases

Connection cable gland M16x1.5 (optional connector M12x1 8 pol.)

Electromagnetic compatibility EN61326-1 EN61326-2-3

Industrial Environment

Material housing metal (AlSi3Cu)

probe stainless steel

sensor head stainless steel / glass

measurement ball valve brass

gauge mouting block Aluminium

Housing protection class IP65 / Nema 4

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was

culated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

2) The flow meter is calibrated at 7 bar (abs) 101.5 Psi. If the working pressure is different from 7 bar (101.5 Psi) you can compensate the error by setting the actual

pressure with the configuration software.

0 = 1013.25 mbar (14.7 PSI); t0 = 0 °C (32 °F)

0.90...176 Nm3/h 0.53...103.5 SCFM 0.90...352 Nm3/h 0.53...207.1 SCFM

-20...80 °C (-4...176 °F)

L<500 Ohm

(-4...140 °F)

EE772 up to 40 bar (580 Psi)

EE771/EE772

v4.6 / Modification rights reserved

199

Page 5

Flow measuring range in dependence on operating pressure

EE771

EE772

Nm/s

Nm/s

working pressure [bar]

Formula for calculating the standardized volumetric ow:

V’n = vn * id2 * π/4 * 3600

V’n ... standardized volumetric ow [m3/h]

vn ... standardized ow [m/s]

id ... inner pipe diameter [m]

π ... 3,1415

Connection Diagram

Modbus data A (=D+) / M-Bus

Modbus data B (=D-) / M-Bus

P

4...20mA

I

mA_Input

V

OUT 1-2

1)

Analogue-

or switching output

Switching or pulse output

18...30V AC/DC

mA

OUT 1-1

OUT 2-1

OUT 2-2

≅

working pressure [bar]

+15V

Vcc

GND

5

Bus-interface

6

7

Pressure sensor input

8

9

10

Signal-Output

11

12

13

Supply voltage

14

air, nitrogen, O2, argon

CO

2

With analogue output OUT 1-1 is connected with GND.

Switching and pulse output are potential-free.

Ordering Guide Accessories

- Dew point sensor EE371 or EE355 see datasheet EE371 or EE355

- Sampling cell for dew point sensor HA050102

- Quick coupling G1/2“ for gauge mounting block HA070202

- Inlet and outlet pipe segment for measurement valve DN15*) HA070215

- Inlet and outlet pipe segment for measurement valve DN20

*)

HA070220

- Inlet and outlet pipe segment for measurement valve DN25*) HA070225

- Inlet and outlet pipe segment for measurement valve DN32*) HA070232

- Inlet and outlet pipe segment for measurement valve DN40*) HA070240

- Inlet and outlet pipe segment for measurement valve DN50

*) Inlet and outlet pipe segment is only available for measurement valve with BSP thread

*)

HA070250

Scope of supply

- EE771 respectively EE772 Transmitter

according Ordering Guide

- 1 x Cable gland

- 1 x Allen key

200

- 1 x USB cable

- User Guide (GERMAN / ENGLISH / FRENCH)

- Inspection certicate according to DIN EN10204 - 3.1

- Conguration software

v4.6 / Modification rights reserved

EE771/EE772

Page 6

Ordering Guide

The complete Flow meter consists of the Transmitter (pos. 1) and the measurement valve with shut-off function

(pos. 2). Both have to be ordered together! The probe cable (pos. 3) is only necessary for model C.

Position 1 - Transmitter EE771- EE772-

Model Compact ri-le

Working range low L1

Measurement valve for DN15 (1/2“) N015

pipe diameter DN20 (3/4“) N020

Display without display x x

Mounting measurement valve with shut-off function K

Hardware Configuration

Electric connection cable gland A A

Bus-Interface without bus-interface x x

Physical parameters of temperature T [°C] [°F] B B

ouput 1 standardized volumetric flow V‘

Physical parameters of temperature T [°C]

output 2 standardized volumetric flow V‘

Output 1

Output 2 switching ouput S S

Software Configuration

Measured value unit metric / SI M M

Medium air A A

Position 2 - measurement valve

DN15 - measurement valve HA075015 not available DN40 - Gauge mounting block HA071040 HA171040

DN20 - measurement valve HA075020 HA175020 DN50 - Gauge mounting block HA071050 HA171050

DN25 - measurement valve HA075025 HA175025 DN65 - Gauge mounting block HA071065 HA171065

DN32 - measurement valve HA075032 not available DN80 - Gauge mounting block HA071080 HA171080

DN40 - measurement valve HA075040 HA175040 DN40 DN50 - measurement valve HA075050 HA175050 DN50 DN15 - measurement valve for O

DN20 - measurement valve for O

DN25 - measurement valve for O

Compact le-ri

remote probe C C

high H1 H1

DN25 (1“) N025

DN32 (1 1/4“) N032

DN40 (1 1/2“) N040 N040

DN50 (2“) N050 N050

DN65 (2 1/2“) N065

DN80 (3“) N080

with display D D

gauge mounting block M

gauge mounting block with hot tap valve W

1 plug for power supply and outputs Q Q

Modbus RTU 1 1

M-Bus (Meter-Bus) 5 5

mass flow m‘ [kg/h] S S

standardized flow v

mass flow m‘ [kg/h] S S

standardized flow v

consumption

analogue output

switching output S S

pulse output

non metric US / GB N N

nitrogen B B

CO

2

2)

O

2

argon G G

BSP-Thread NPT-

2)

2

2)

2

2)

2

HA076015 not available DN65 - Gauge mounting block with hot tap valve HA072065 HA172065

HA076020 HA176020 DN80 - Gauge mounting block with hot tap valve HA072080 HA172080

HA076025 HA176025

direction od flow right to left

direction od flow left to right

1)

1)

Thread

3

n [Nm

/h] [SCFM] R R

n [Nm/s] [ft/min] T T

[°F] B B

3

n [Nm

/h] [SCFM] R R

n [Nm/s] [ft/min] T T

Qn [Nm3] [ft

0-5 V 2 2

0-10 V 3 3

0-20 mA 5 5

4-20 mA 6 6

3

] I I

Gauge mounting block with hot tap valve HA072040 HA172040

Gauge mounting block with hot tap valve HA072050 HA172050

A A

B B

I I

C C

D

BSP-Thread NPT-Thread

Position 3 - Probe cable (only model C)

cable length 2 m (6.56 ft) HA010816

1) consumption measuring is possible only with pulse output (output 2 = I)

2) Medium O

only for mounting valve DN15 up to DN25. The mounting valve and the sensor is oil and grease-free.

2

5 m (16.4 ft) HA010817

10 m (32.8 ft) HA010818

Order Example

Position 1 - Transmitter Position 2 - measurement valve

EE771-AL1N025xKAx/RI6IMA

Model: Compact ri-le

Working range: low 0.9 ... 176 Nm3/h

Measuring pipe-diameter: DN25 (1”)

Display: no

Mounting: measurement ball valve

El. connection: cable gland

Bus-Interface: without bus-interface

EE771/EE772

v4.6 / Modification rights reserved

Phys. parameter output 1: standardized volumetric flow

Phys. parameter output 2: consumption

Output 1: 4-20 mA

Output 2: pulse output

Measured value unit: metric SI

Medium: air

HA070025

DN25 - measurement valve with shut-off

function

201

Loading...

Loading...