Page 1

EE75 Series

Air / Gas Velocity

Transmitter

BA_EE75_e_12// technical data subject to change // 192310

Manual

Hardware and Software

Page 2

E+E Elektronik® Ges.m.b.H. doesn't accept warranty and liability claims neither

upon this publication nor in case of improper treatment of the described products.

The document may contain technical inaccuracies and typographical errors. The

content will be revised on a regular basis. These changes will be implemented in

later versions. The described products can be improved and changed at any time

without prior notice.

© Copyright E+E Elektronik

®

Ges.m.b.H.

All rights reserved.

USA

FCC notice:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the installation manual, may

cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct theinterference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Caution:

Any changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate this device.

CANADIAN

ICES-003 notification:

This Device B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

1

Page 3

HARDWARE

CONFIGURATION

SOFTWARE

TABLE OF CONTENTS

1. GENERAL 3

1.1 Symbol assertion 3

1.2 Safety instructions 3

1.3 Environmental information 3

2. PRODUCT DESCRIPTION 3

3. INSTALLATION 4

3.1 Installing the housing 4

3.2 Mounting Model A (wall mounting) 4

3.3 Mounting Model B (duct mounting) 4

3.3.1 Mounting with brackets 4

3.3.2 Mounting with a flange 4

3.4 Mounting Model C (remote probe) 5

3.4.1 Installing the housing 5

3.4.2 Installing the probe 5

3.5 Mounting Model E (remote probe, pressure-tight to 10 bar / 145psi) 5

3.5.1 Installing the housing 5

3.5.2 Installing the probe 5

4. ELECTRICAL CONNECTIONS 7

4.1 Connection diagram 7

4.2 Connection diagram with plug connections (optional) 7

4.3 Assignment USB - interface cable 7

5. OPERATING COMPONENTS 8

5.1 Circuit board 8

5.2 Jumpers for setting the output signal 8

5.3 Jumpers for setting the velocity response time 8

5.4 Display module with buttons (optional) 9

6. VELOCITY/TEMPERATURE CALIBRATION 10

6.1 Selecting the appropriate calibration method (1-point or 2-point calibration) 10

6.1.1 General information on 1-point v/T calibration 10

6.1.2 General information on 2-point v/T calibration 11

6.2 Velocity calibration 11

6.2.1 Calibration procedure using configuration software 11

6.2.2 Calibration procedure using buttons on the display module (optional) 11

6.3 Temperature calibration 11

6.3.1 Calibration procedure using configuration software 11

6.3.2 Calibration procedure using buttons on the display module (optional) 11

6.4 Resetting to factory calibration 12

6.4.1 Resetting v/T to factory calibration 12

6.4.2 Resetting v to factory calibration 12

6.4.3 Resetting T to factory calibration 12

7. SELF-HELP / MAINTENANCE 13

8. REPLACEMENT PARTS / ACCESSORIES 13

9. TECHNICAL DATA 13

1. GENERAL INFORMATION 14

2. INSTALLATION 14

2.1 Installing the USB-interface 14

3. MENU ITEMS 16

3.1 File 16

3.2 Help 16

4. EE75 CONFIGURATOR 16

4.1 Start 16

4.2 Analog 17

4.3 Display 17

4.4 Response Time 17

4.5 Cross Section 18

4.6 Probe Cable 18

4.7 Switching Off 19

4.8 Media Correction 19

4.9 Calibration 19

4.9.1 Information on 1-point v/T calibration 20

4.9.2 Information on 2-point v/T calibration 20

4.9.3 v calibration procedure using the configuration software 20

4.9.4 T calibration procedure using the configuration software 20

4.9.5 Activating factory calibration 20

4.10 Measuring Values 21

4.11 Information 21

2

Page 4

1. GENERAL

This manual forms part of the scope of supply and serves to ensure proper handling and optimum functioning of the instrument.

Consequently, it is essential to read the manual before commissioning.

The manual is also to be brought to the attention of any person involved in transport, setup,

operation, maintenance or repair.

This manual must not be used for competition purposes without the written consent of

E+E Elektronik® and must not be forwarded to third parties.

Copies for personal use are permitted.

All information, technical data and illustrations contained in this manual are based on the information available at the time of publication.

1.1 Symbol assertion

This symbol indicates a safety instruction.

Safety instructions must always be followed. Failure to do so can result in injuries or

damage, for which E+E Elektronik® accepts no liability.

This symbol indicates a note.

These notes should be observed to achieve optimum functioning of the equipment.

1.2 Safety instructions

•

Excessive mechanical stress and improper use must be avoided.

• As the sensor element is sensitive to electrostatic discharge (ESD), appropriate

protective measures should be taken when touching it.

• Installation, electrical connection, maintenance and commissioning must only be

carried out by qualified personnel.

1.3 Environmental information

E+E Elektronik® products are developed with due consideration to all major environmental issues. Bearing this in mind, care should also be taken to avoid polluting the environment when

disposing of equipment. When disposing of the transmitter, the individual

components must be sorted according to type.

Electronic components must be kept together and disposed of in the proper manner for electronic scrap.

Hardware

2. PRODUCT DESCRIPTION

The EE75 series velocity transmitters were developed to obtain accurate measuring results over

a wide range of velocities and temperatures.

They have a robust metal housing to protect them against possible damage in rough

industrial environments and come in four different models, providing a comprehensive range of

mounting options:

• Model A for wall mounting

• Model B for duct mounting

• Model C with remote probe

• Model E with remote probe, pressure-tight to 10 bar (145psi)

3

Page 5

all dimensions in mm

3. INSTALLATION

Before starting the installation please make sure that the upper and lower

modules of the housings are not mixed up! Only with identical serial

numbers the function of the transmitter can be guaranteed within the

specifications (see chapter 9. “Technical Data”).

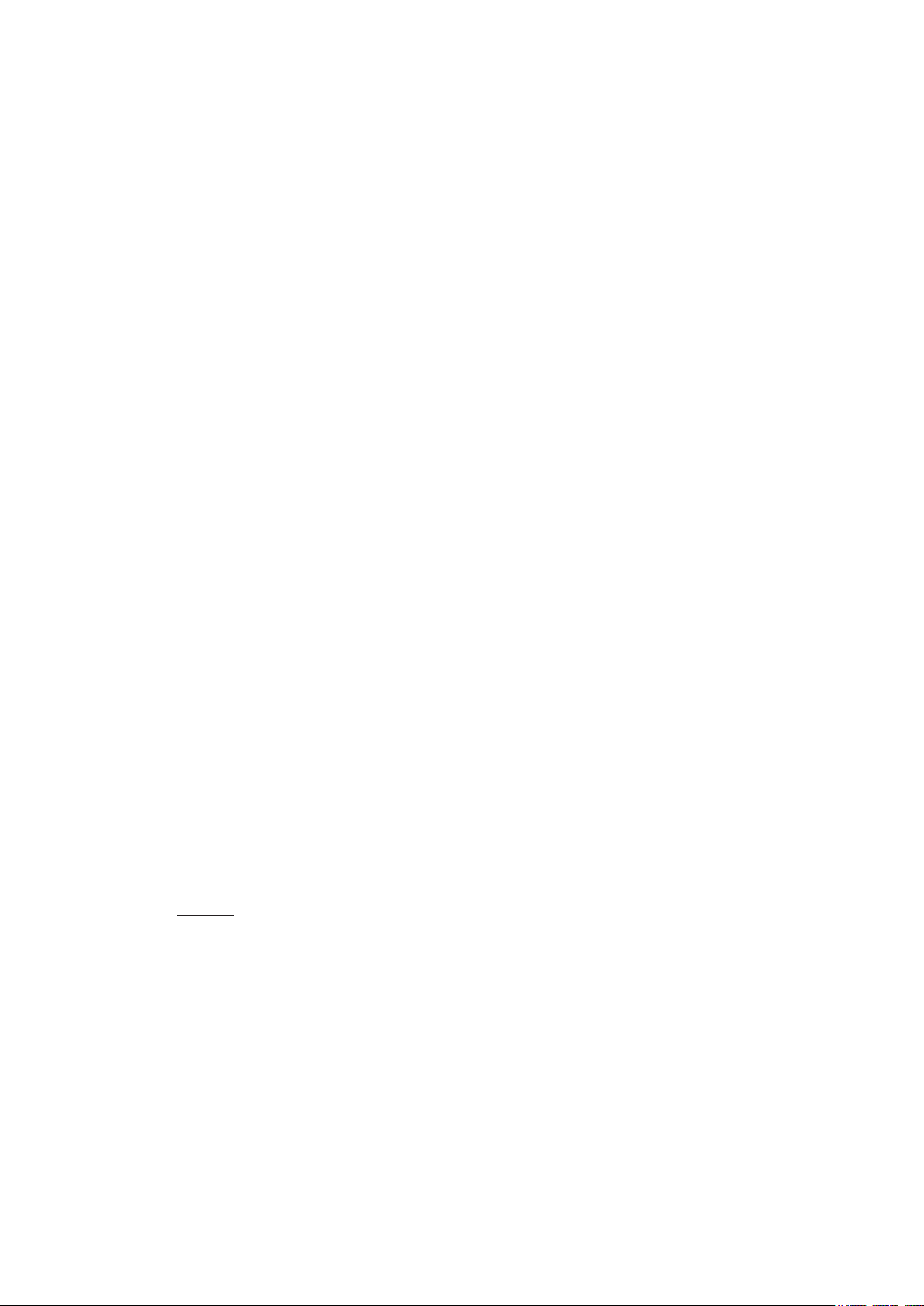

3.1 Installing the housing

145 (5.7”)

115 (4.5”)

40 (1.6”)

129 (5.1”)

cross-section of bore:

2 (0.1”)

90°

∅4.5

(0.2”)

60 (2.4”)

1. On delivery, the two mounting brackets (on the left and right of the

housing base plate) are attached to the lower part of the housing with

two screws each, facing inwards. For installation, the brackets can be

swung out and screwed down (see drawing).

2. The dimensions of the mounting holes are as shown in the adjacent

drawing.

3. The bottom part of the housing is fitted using 4 screws (not included).

Max. screw diameter 4.5 mm

(0.18”), for example 4.2 x 38mm (0.17 x 1.5”)

- DIN 7983H screws.

4. Connecting the transmitter (see Section 4 - Electrical Connections)

5. Lift the upper part of the housing into position and screw it into place

using the four Allen screws included (Allen key provided).

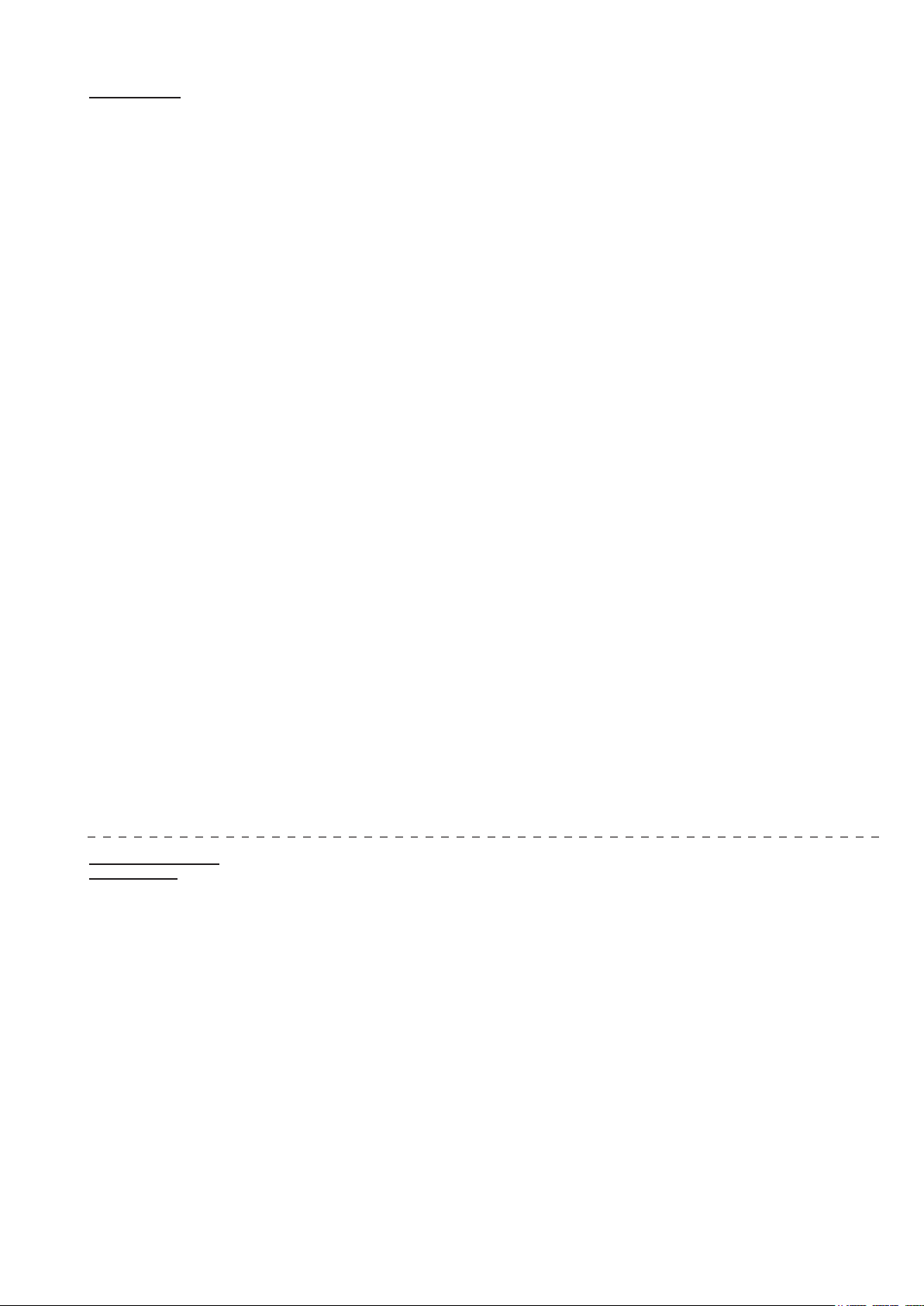

3.2 Mounting Model A (wall mounting)

selected probe length

∅8

(0.3”)

selected probe length

∅8

(0.3”)

12 (0.5”)

bore diameter: 5.1 (0.2”)

12 (0.5”)

2 (0.1”)

sealing

rubber

See Section 3.1 - Installation of the housing

3.3 Mounting Model B (duct mounting)

There are two types of duct mounting:

3.3.1 Mounting with brackets

See Section 3.1 - Installation of the housing

OR:

3.3.2 Mounting with a flange

The stainless steel mounting flange allows for the transmitter to

be mounted on the outside wall of the duct in which the

measurement takes place and adjusted to any insertion depth.

80

(3.1”)

Hardware

4

Page 6

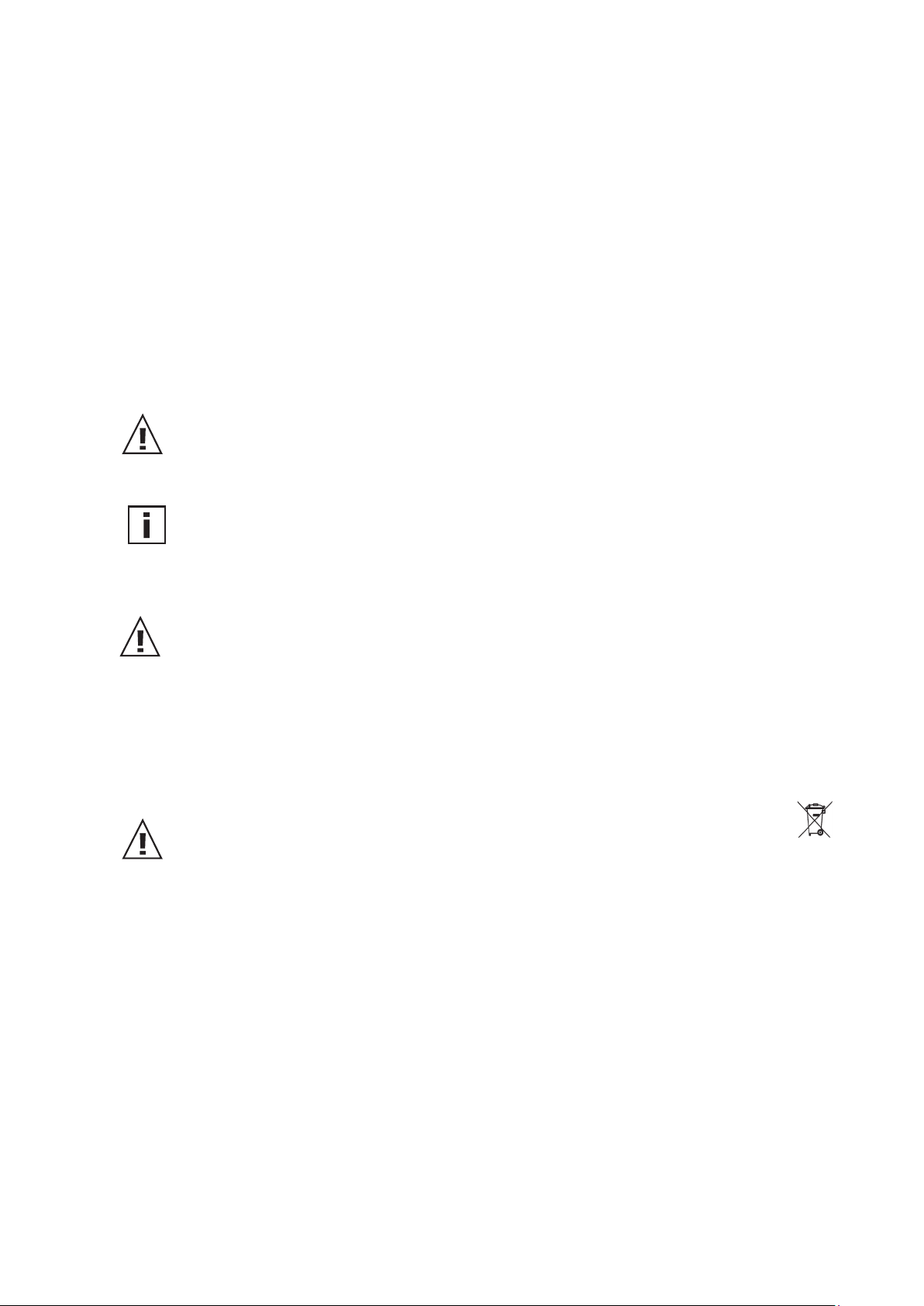

selected probe length

3.4 Mounting Model C (remote probe)

∅8

(0.3”)

12

(0.5”)

selected probe length

∅8

(0.3”)

12

(0.5”)

3.4.1 Installing the housing

See Section 3.1 - Installing the housing

3.4.2 Installing the probe

See Section 3.3.2 - Mounting with a flange

3.5 Mounting Model E (remote probe,

pressure-tight to 10 bar

/ 145psi)

3.5.1 Installing the housing

See Section 3.1 - Installing the housing

3.5.2 Installing the probe

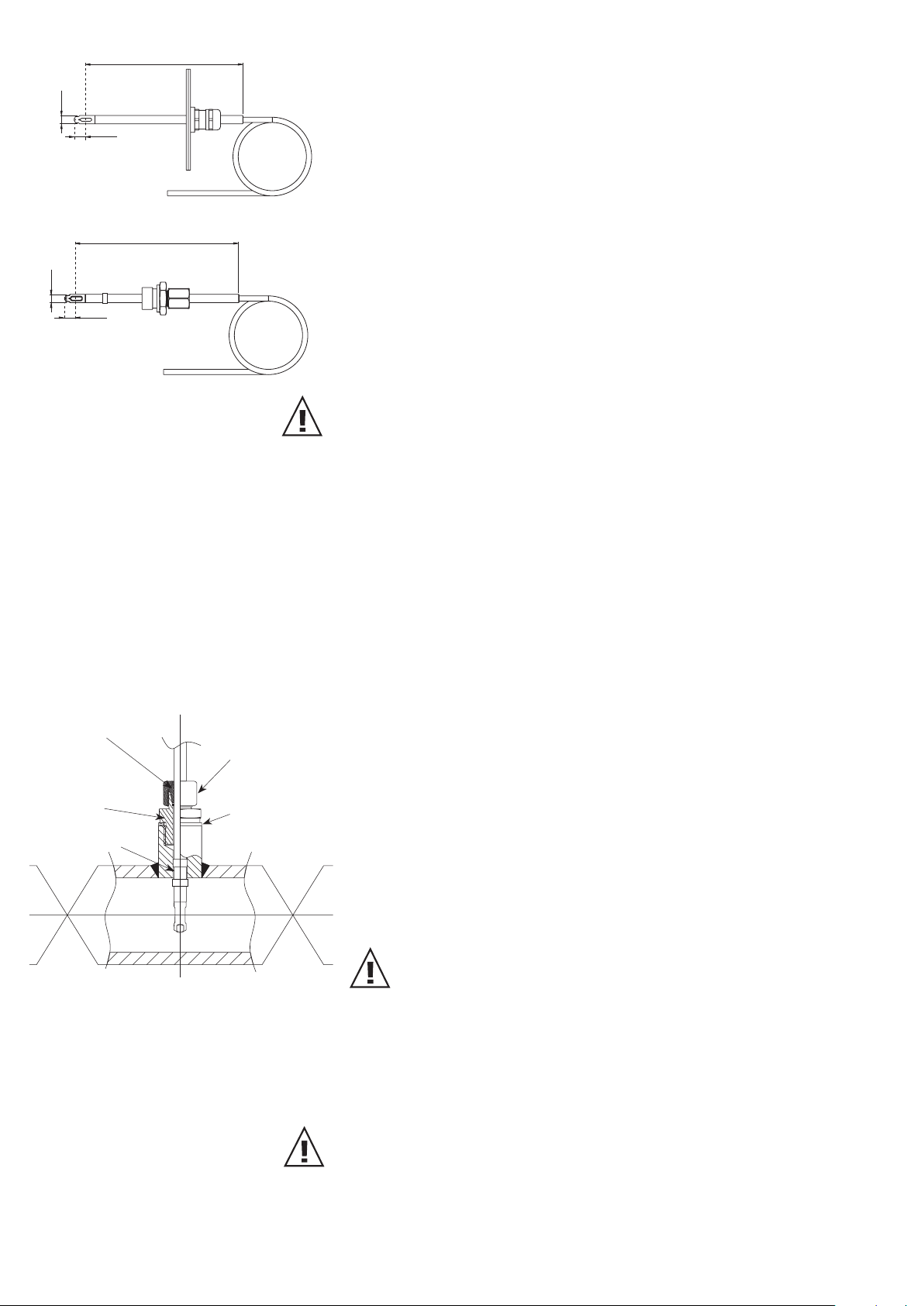

General safety instructions for installation using pressuretight movable screw connections

As the sensing probe can be exposed to very high pressures in the

measuring environment, there is a risk of sudden, unintentional expulsion of the probe during or after improper installation. Special care

should therefore be taken when working on or in the vicinity of the

sensing probe. Do not, under any circumstances, bend directly over the

probe.

When installing the sensor probe, be careful not to damage the surface

of the sensing probe.

This could damage the seals (resulting in leakage and pressure loss)

or cause problems when removing the probe (may get stuck).

Before installing the sensing probe, make sure it is free from any impurities such as grease or dirt.

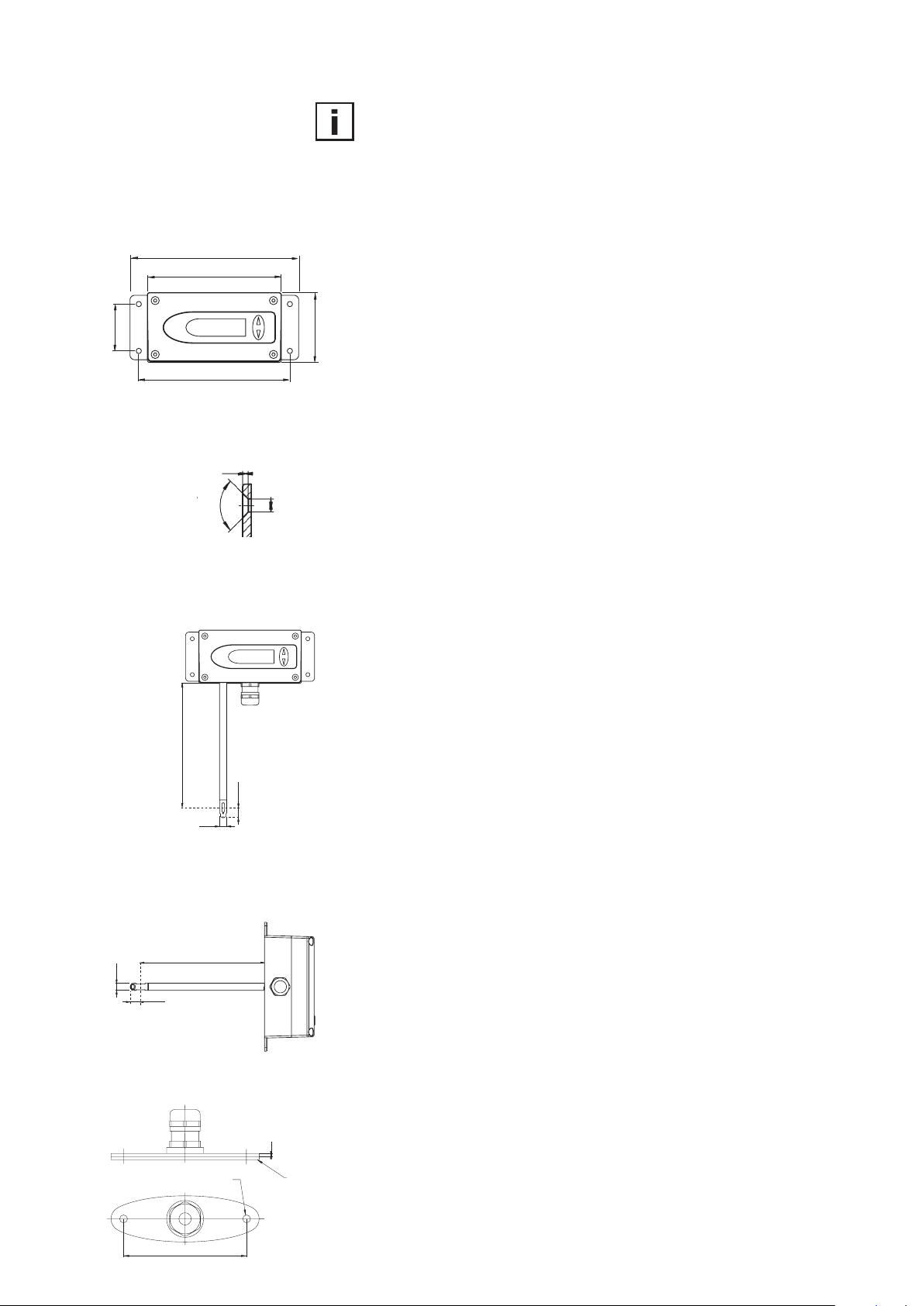

clamping

ring

1/2” ISO

or NPT

bore ∅

> 9.2mm (0.4”)

shut-off

valve

Hardware

lock nut

sealing ring

shut-off

valve

Installing the probe

There should be a shut-off valve on both sides of the probe insert when

installing the probe. This makes it easy to remove the transmitter for

maintenance and calibration.

1. Install the probe with the shut-off valves closed.

2. Insert the sensor probe into the process.

3. To ensure the probe is installed securely, the lock nut must be

tightened to a specified torque of 10 Nm.

If no torque spanner is available, tighten the lock nut by hand as far

as possible and then turn it a further ~ 90° with an appropriate

open-ended spanner.

An inadequate torque results in a low tension force (fixing

force) on the clamping sleeve. This brings with it a risk of injury

due to sudden expulsion of the sensing probe. An excessive

torque can lead to permanent deformation of the clamping

sleeve and sensing probe, making removal and re-installation

more difficult or even impossible.

Removing the probe

1. If the sensor probe is installed in a pressure chamber, make sure

that the pressure in the chamber and the ambient pressure are

in equilibrium before removing the probe.

2. Hold the sensing probe/housing firmly. (Attention: Do not bend the

connection cable)

3. Slowly loosen the lock nut using a spanner (spanner width 24).

4. The entire probe can now be removed.

5

Page 7

General installation instructions:

Scaling the insertion depth on the probe

The insertion depth can be read off directly on the probe. The depth is

measured from the centre of the velocity measuring slot (= middle of

x

scale

the sensor). The scaling on the probe has an offset of 30mm (1.2”). This

allows for the insertion depth "X" (= distance between middle of sensor

and mounting plate) to be read off directly above the screwed cable

gland (see sketch).

Flow direction

Flow direction:

The arrow on the sensor probe should be pointing exactly in the

direction of flow!

indicates the orientation of the tip of the arrow.

indicates the orientation of the tail of the arrow.

Model A (wall mounting):

indicates the orientation of the tip of the arrow.

Models B (duct mounting):

Models C and E (remote probe):

To be able to read off the orientation of the remote sensor head beyond

the measuring line, a mark has been punched at the end of the

sensing probe. This corresponds with:

flow

corresponds to the tip of the arrow

6

Hardware

Page 8

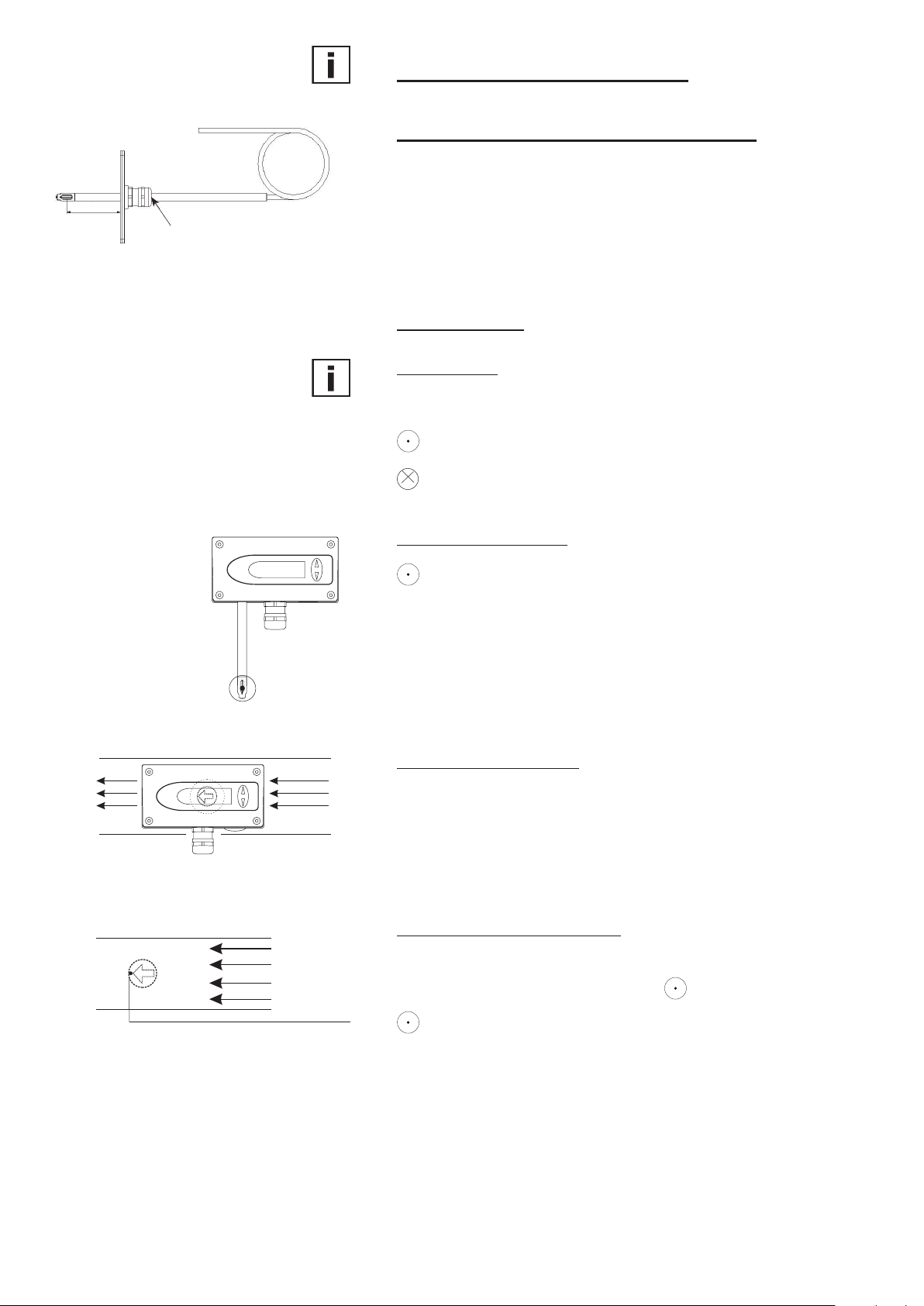

4. ELECTRICAL CONNECTIONS

4.1 Connection diagram

brown

black

red

orange

shield

green

white

red

black

shielding

measuring probe

analogue outputs

supply

USB-interface

Coupling for supply

and analogue outputs

(front view)

Plug for USB interface

(front view)

4.2 Connection diagram with plug connections

(optional)

Description: Connection assignment:

VCC 5

GND 4

GND 3

OUT2 2

Euro-Standard

OUT1 1

Description: Connection assignment:

D+ 3

D- 1

V-bus 2

GND 4

Euro-Standard

Cable connection to the plugs should be as indicated by the numbers above.

4.3 Assignment USB - interface cable

colour of wire: signal: terminal no.:

green D+ 11

white D- 12

red Vbus 13

black

shielding

USB-GND 14

Hardware

7

Page 9

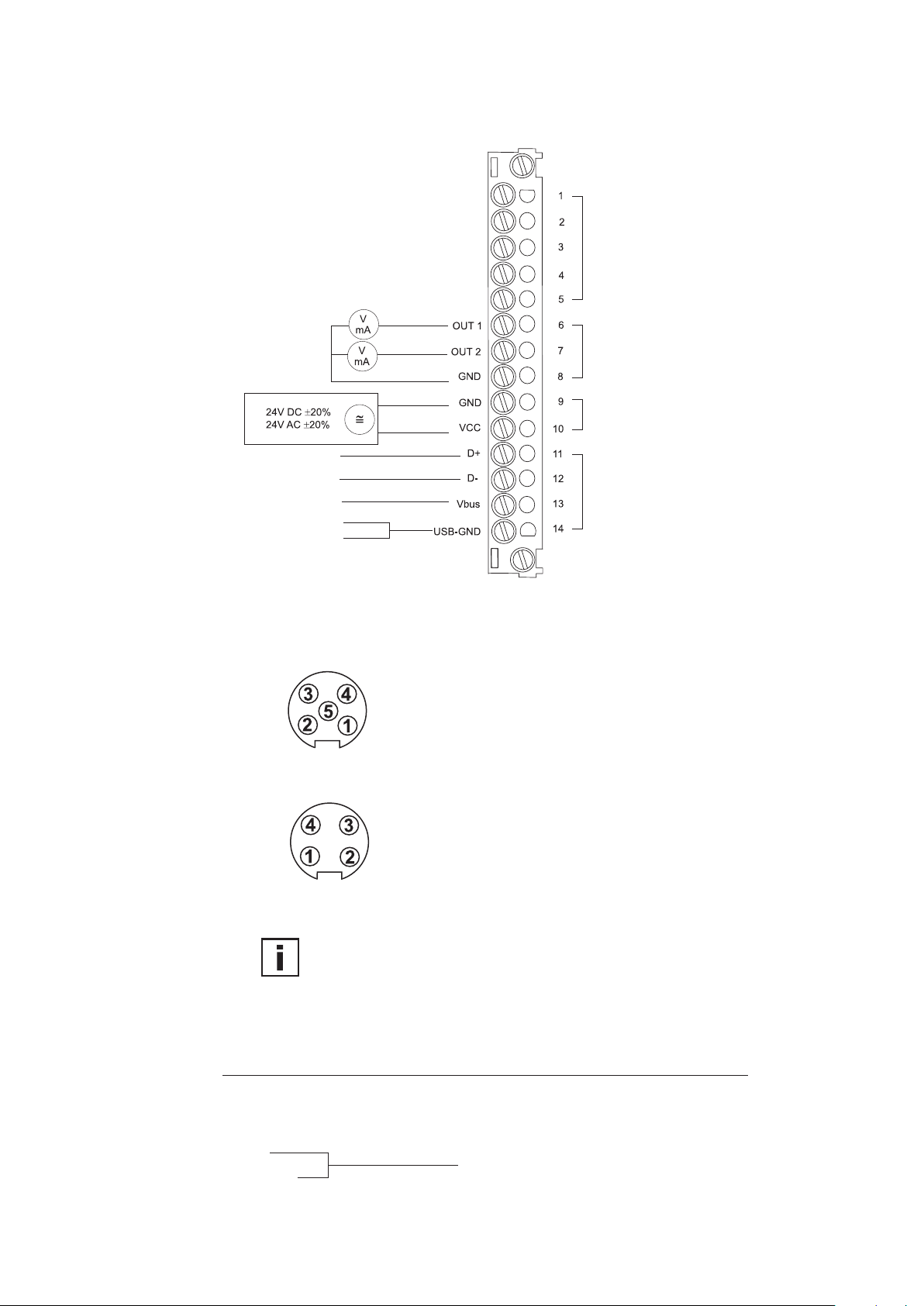

5. OPERATING COMPONENTS

5.1 Circuit board

plug connection

blue

iumper

(detail A)

detail A:

Jumper# Function

I current output signal

S signal

U voltage output signal

1 (arrow) τ

2 τ

3 τ

4 free

-velocity (2s)

90-1

-velocity (4s)

90-2

-velocity (10s)

90-3

5 free

5.2 Jumpers for setting the output signal

If the transmitter output signal is set from current to voltage by use of the configuration

software, additionally 2 jumpers must be set on the circuit board as follows:

EE75-VTx6

(for current output, e.g. 4-20mA)

I S U

EE75-VTx3

(for voltage output, e.g. 0-10V)

I S U

5.3 Jumpers for setting the velocity response time

The EE75 series allows users to set the velocity response time:

a) Setting the velocity response time using jumpers:

Jumper position (Also see Section 5.1 - Circuit board): Response time:

no jumper 1.5sec

jumper at pos. 1 2sec (factory setting)

jumper at pos. 2 4sec (factory setting)

jumper at pos. 3 10sec (factory setting)

b) Setting the velocity response time using configuration software:

The response time (τ90) can also be set to any value between 1.5 and 40 s using the

configuration software, without changing the jumpers on the circuit board.

See Configuration Software, Section 4.4 - Response Time

Hardware

8

Page 10

RH: 63.0%

MAX

RH: 63.0%

MIN

5.4 Display module with buttons (optional)

1. Measurand

2. Unit

3. Measurand selection and

4. Min/Max function

5. Measured value

6. Status line

v: 5.43 m/s

v: 5.43 m/s

1. MEASURAND:

2. UNIT:

SI SI US

v Velocity m/s ft/min

T Temperature °C °F

v Volume m³/min ft³/min

4. MIN / MAX FUNCTION:

The MIN/MAX function can be used to record the lowest and highest values measured

for each measurand since the last reset or the last interruption of the power supply.

Highest measured value: MAX

1. Select the required measurand (UP / DOWN button)

2. To display the maximum value, press the UP button and hold it for approx. 5 s.

3. To return to the normal operating mode, press the UP button again and hold it

for approx. 5 s.

Lowest measured value: MIN

1. Select the required measurand (UP / DOWN button)

2. To display the minimum value, press the DOWN button and hold it for approx. 5 s.

3. To return to the normal operating mode, press the DOWN button again and hold

it for approx. 5 s.

By pressing the UP and DOWN buttons simultaneously in normal operating mode the

stored MIN/MAX values for all measurands can be reset by selecting "CLEAR MIN/MAX

BUFFER"; recording can then be restarted (for details see Section 5.3 - Display module with buttons, point 7 - Menu navigation).

3. MEASURAND SELECTION:

Pressing the ∆ or ∇ button

switches between the various

physical quantities (measurands).

Hardware

5. MEASURED VALUE:

The measured value of the respective measurand is indicated.

6. STATUS LINE:

The status line indicates the transmitter's current operating status:

- no indication: normal operating mode / measurement in progress

- MIN or MAX: see point 4 - MIN/MAX function

- CAL LOW: V or T calibration routine for the low adjustment point selected.

- CAL HIGH: V or T calibration routine for the high adjustment point selected.

7. MENU NAVIGATION:

Pressing the UP and DOWN buttons simultaneously for approx. 5 s during a measurement

(in normal operating mode) a 4-line menu is displayed with the following options:

- CALIBRATION: (Calibration)

- FACTORY SETTINGS: (Factory settings)

- CLEAR MIN/MAX BUFFER: (Clear Min/Max buffer)

- EXIT: (returns to normal operating mode without executing any

of the menu items)

Pressing the UP and DOWN buttons moves the cursor “>” on the left-hand side of the

display up and down to select one of the adjacent menu items.

Pressing the UP and DOWN buttons simultaneously for approx. 5 s confirms the selection

and executes the selected menu item.

9

Page 11

6. VELOCITY/TEMPERATURE CALIBRATION

The EE75 can be calibrated / adjusted using either the buttons on the optional display

module or the USB interface and configuration software provided.

Instructions for calibration:

To achieve comparable results to the E+E factory setting, please note following:

a) The adjustment should be done in a wind tunnel with homogeneous, low turbulent

owprole.

b)Inserttheprobe10cmdeepintotheowchannel.

c)Thexturesshouldbemountedoutsidetheowchannelandshouldnotriseintothe

air stream (see drawing):

OK

not OK

6.1 Selecting the appropriate calibration method

(1-point or 2-point calibration)

The EE75 transmitter series can be calibrated in 2 different ways:

- 1-point v/T calibration:

Quick and easy option for obtaining precise measuring results at a specific working

point. 1-point calibration should only be used for very limited working ranges.

- 2-point v/T calibration:

With 2-point calibration, precise measuring results can be obtained over the entire

v/T measuring range. The more complicated 2-point calibration procedure is preferable

to 1-point calibration, if higher precision or a wider working range is required.

6.1.1 General information on 1-point v/T calibration:

If possible the selected calibration point should be similair to the working point (of the

limited working range) of the transmitter.

Example: Working range v 8 - 12m/s (1600 - 2400ft/min) > calibration point at 10m/s (2000ft/min); working

range T 18 - 22°C (64.4 - 71.6°F) - > calibration point at 20°C (68°F).

- If the selected calibration point is < 50% of the max. measuring range, V/T-CAL LOW

should be selected for calibration / adjustment.

- If the selected calibration point is > 50% of the max. measuring range, V/T-CAL HIGH

should be selected for calibration / adjustment.

Example: v measuring range 0 - 10m/s (0 - 2000ft/min); actual working range 6 - 8m/s (1200 - 1600ft/min);

selected calibration point 7m/s (1400ft/min); perform 1-point calibration, selecting V-CAL HIGH.

Hardware

10

Page 12

6.1.2 General information on 2-point v/T calibration:

With 2-point calibration, v/T calibration / adjustment is performed at 2 different calibration points.

To ensure the smallest possible deviation in measuring results over the entire measuring range,

the two calibration points should be selected as follows:

- The low calibration point should be in the lower third of the measuring range.

Calibration / adjustment must be performed using the V/T-CAL LOW function.

- The high calibration point should be in the upper third of the measuring range.

Calibration / adjustment must be performed using the V/T-CAL HIGH function.

Example: EE75 vT**1 - measuring range = 0 - 2m/s (0 - 400ft/min).

Low calibration point (V-CAL LOW) should be around 0.4 m/s (0...0.7).

High calibration point (V-CAL HIGH) should be around 1.8 m/s (1.4...2).

6.2 Velocity calibration

6.2.1 Calibration procedure using configuration software

See Configuration Software, Section 4.9.3 - v calibration process using a configurator

6.2.2 Calibration procedure using buttons on the display module (optional)

1. Position the sensor head in the middle of the reference system (wind tunnel).

2. Stabilise the probe at the reference velocity (for at least 1 minute). The temperature of

the measuring probe and the reference system must be approximately the same.

3. Press both buttons for approx. 5 s to display the menu window.

4. Use the buttons and cursor so select the menu item "CALIBRATION" and confirm the

selection.

5. Select "V-Cal" and confirm the selection.

6.1 "1-point calibration":

- Select the calibration point as described in Section 6.1.1.

- If calibration point > 50% of measuring range, select "V-CAL HIGH" and

confirm the selection.

- If calibration point < 50% of measuring range, select "V-CAL LOW" and

confirm the selection.

6.2 "2-point calibration":

- Select the low (high) calibration point as described in Section 6.1.2.

- Approach the low (high) calibration point in the reference system, select

"V-CAL LOW" ("V-CAL HIGH”) on the transmitter and confirm the selection.

7. The status line should display either CAL LOW (CAL HIGH).

8. The measuring value can now be adjusted with the reference value in 0.1m/s (20ft/min)

increments by pressing the UP or DOWN button. The updated value is displayed

immediately and present at the analogue output.

9. To save the adjusted measuring value in the instrument, press both buttons

simultaneously for approx. 5 s, then select "YES" in the "SAVE" menu and confirm the

selection. This exits the calibration routine and the transmitter returns to normal

operating mode.

Selecting "NO" in the "SAVE" menu exits the calibration routine without saving the

adjusted measuring value.

10. In the case of 1-point v calibration, the procedure is now complete.

11. For 2-point v calibration, repeat steps 6.2-9 with the (high) calibration point.

Hardware

6.3 Temperature calibration

6.3.1 Calibration procedure using configuration software

See Configuration Software, Section 4.9.4 - T calibration procedure using a configurator

6.3.2 Calibration procedure using buttons on the display module (optional)

1. Insert the sensor head in the temperature reference system.

2. Allow it to stabilise (min. 15 minutes). The greater the difference in temperature

between the measuring probe and the reference system, the longer the required

stabilisation time.

11

Page 13

3. Press both buttons for approx. 5 s to display the menu window.

4. Use the buttons and cursor to select the menu item "CALIBRATION" and confirm the

selection.

5. Select "T-Cal" and confirm the selection.

6.1 "1-point calibration":

Select the calibration point as described in Section 6.1.1.

- If calibration point > 50% of measuring range, select "T-CAL HIGH" and confirm the

selection.

- If calibration point < 50% of measuring range, select "T-CAL LOW" and confirm the

selection.

6.2 "2-point calibration":

Select the low (high) calibration point as described in Section 6.1.2.

- Approach the low (high) calibration point in the reference system, select

"T-CAL LOW" ("T-CAL HIGH") on the transmitter and confirm the selection.

7. The status line should display either CAL LOW (CAL HIGH).

8. The measuring value can now be adjusted with the reference value in 0.1°C (32.18°F)

increments by pressing the UP or DOWN button. The updated value is displayed

immediately and present at the analogue output.

9. To save the adjusted measuring value in the instrument, press both buttons

simultaneously for approx. 5 s, then select "YES" in the "SAVE" menu and confirm the

selection. This exits the calibration routine and the transmitter returns to normal

operating mode.

Selecting "NO" in the "SAVE" menu exits the calibration routine without saving the

adjusted measuring value.

10. In the case of 1-point T calibration, the procedure is now complete.

11. For 2-point T calibration, repeat steps 6.2-9 with the (high) calibration point.

6.4 Resetting to factory calibration

If necessary the transmitter can be reset to the factory settings (factory calibration data),

after a v or T customer calibration has been performed.

6.4.1 Resetting v/T to factory calibration:

1. Press both buttons for approx. 5 s to display the menu window.

2. Select "Factory settings" and confirm the selection.

3. Select "Restore Settings" and confirm the selection.

4. The customer calibration data (v, T) has now been reset to the factory calibration data.

6.4.2 Resetting v to factory calibration:

1. Press both buttons for approx. 5 s to display the menu window.

2. Select "Calibration" and confirm the selection.

3. Select "V-CAL" and confirm the selection.

4. Select "V-FACTORY SETTINGS" and confirm the selection.

5. Select "Restore Settings" and confirm the selection.

6. The customer calibration data (v) has now been reset to the factory calibration data.

6.4.3 Resetting T to factory calibration:

1. Press both buttons for approx. 5 s to display the menu window.

2. Select "Calibration" and confirm the selection.

3. Select "T-CAL" and confirm the selection.

4. Select "T-FACTORY SETTINGS" and confirm the selection.

5. Select "Restore Settings" and confirm the selection.

6. The customer calibration data (T) has now been reset to the factory calibration data.

12

Hardware

Page 14

7. SELF-HELP / MAINTENANCE

- If the measuring values are unrealistic, the first thing to check is the angle of inflow.

- Also check the sensor element for soiling. If dust has collected on the element, blow it off

carefully with oil-free compressed air. If there is anything else on the sensor, clean it

carefully using isopropyl alcohol and allow it to dry. Do not touch the velocity sensor with

your fingers!

- If there is no output and indication, check the power supply.

8. REPLACEMENT PARTS / ACCESSORIES

- Stainless steel mounting plate HA010207

- USB interface cable HA010310

9. TECHNICAL DATA

Measuring value

Air velocity

Working range 0... 2m/s

0... 10m/s

0... 40m/s

Accuracy 1) in air at 25°C (77°F) 2) 0.06... 2m/s (12...400ft/min) ± 0.03m/s / 6ft/min

at 45% RH and 1013hPa 0.15...10m/s

0.2... 40m/s

Uncertainty of factory calibration

1)

± (1% of measuring value, min. 0.015m/s

Temperature dependence electronics typ. -0.0 05 % of measur ing value / °C

Temperature dependence probe ± (0 .1% of measur ing value/°C )

Dependence of angle of inflow: < 3% for α < 20°

of direction of inflow: < 3%

3)

τ

Response time

< 1.5...40s (configurable)

90

Temperature

Working range probe: -40...120°C (-40...248°F)

probe cable: -40...105°C (-40...221°F)

electronic: -40...60°C (-40...140°F)

electronic with display: -30...60°C

Accuracy at 20°C (68°F) ±0.5°C (±0.9°F)

Temperature dependence electronics typ. -0.01°C / °C

Response time

3)

τ

90

10s

Outputs

output signals and display ranges are freely scaleable (see ranges below)

voltage 0-10V (e.g: 0-5V, 1-5V etc.) -1mA < I

current (3-wire) 0-20mA (e.g: 4-20mA etc.) R

v-scaling 0...2 / 10 / 40m/s

T-scaling -40...120°C (-40...248°F)

Vol-scaling 0...10000m³/min (0...353147ft³/min)

General

Supply voltage 24V DC/AC ± 20%

Current consumption max. 100mA; max. 160mA (with display)

Connection screw terminals max. 1.5mm

Electromagnetic compatibility EN61326-1 EN61326-2-3 ICES-003 ClassB

Industrial Environment FCC Part15 ClassB

Pressure range Model E pressure tight up to 10bar

Material housing / protection class: metal (AlSi3Cu) / IP65; Nema 4

measuring probe: stainless steel

measuring head: PBT (polybuthylenterephthalat)

System requirements

for configuration software Windows 2000 or Windows XP

Interface USB 1.1

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation).

The accuracy was calculated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

2) Accuracy refers to measurement in air

3) Response time τ

is measured from the beginning of a step change to the moment of reaching 90% of the step.

90

(0...400ft/min)

(0...2000ft/min)

(0...8000ft/min)

(30...2000ft/min) ± (0.10m/s / 20ft/min + 1 % of measuring value)

(40...8000ft/min) ± (0.20m/s / 40ft/min + 1 % of measuring value)

(3ft/min))

(-22...140°F)

< 1mA

L

< 350 Ohm

(0...400 / 2000 / 8000ft/min)

2

(AWG 16)

L

(145psi)

Hardware

13

Page 15

CONFIGURATION SOFTWARE

LIMITED LIABILITY

E+E Elektronik® shall not be held liable for any damages or consequential damages (for

example, but not restricted to, loss of earnings, interruption of business, loss of

information and data or any other financial losses) resulting from the installation, use or impossibility of use of an E+E Elektronik® software product and any associated support services or

non-performance of support services.

1. GENERAL INFORMATION

The configuration software included in the scope of supply provides a user-friendly

alternative to the use of the buttons on the optional display module for adjusting the transmitter

to suit the relevant application or to calibrate / adjust the velocity and temperature settings.

System requirements: Windows XP or higher, interface USB 1.1 or higher.

NOTE:

Any use beyond these purposes is not permitted.

The permanent connection between EE75 and PC via the USB interface in normal operation

may cause a malfunction and does not meet the CE-criteria.

2. INSTALLATION

NOTE:

Administrator authorisations may be required for problem-free installation of the EE75 configuration software.

1. Insert the CD-ROM supplied in the appropriate drive on your PC.

2. Do NOT yet connect the EE75 to the PC using the USB Port.

3. Run "Setup.exe" to install the EE75 configuration software.

4. The InstallShield Wizard for the EE75 configurator is launched.

5. Follow the instructions to install the software.

6. Clicking the "Finish" button completes configuration software installation.

2.1 Installing the USB-interface

NOTE:

The USB interface software must also be installled to allow your PC and the EE75

velocity transmitter to communicate properly.

1. Connect terminals and USB-interface located in the back module of the

EE75 housing under zero-potential conditions

2. Replace and secure the upper module of the housing

3. Connect EE75 to the supply voltage (VCC)

4. You can now connect the EE75 to your chosen USB Port on your PC

(max. transmission distance 3 m).

5. The driver software will be installed automatically

Configurations Software

14

Page 16

If the EE75 configuration software and the associated USB interface have been set up

correctly, a connection has been assigned to the EE75 USB to UART Bridge Controller on

your PC's Control Panel.

See Start/Settings/Control Panel/System/Hardware/Device Manager

6. The configuration software can now be opened by double-clicking the EE75 icon on

your desktop.

7. Specify the selected USB Port (for details, see Configuration Software, Section 3.1 - File)

8. Pressing the "Read" button will start the communication with the EE75 and downloads

its configuration.

Configurations Software

15

Page 17

3. MENU ITEMS

3.1 File

Load Settings:

Save Settings:

Select COM Port:

Exit:

Opens the saved transmitter configuration settings from an archive file on the PC.

Saves the displayed configuration settings in an archive file on the PC.

Selects the USB interface used on your PC.

If the "Remember next time" box is checked, the selected interface will always be used in

future.The number of the USB Port can be found under:

Start -> Settings -> Control Panel -> System -> Hardware -> Device Manager

Closes the configuration software.

Read:

Write:

3.2 Help

Provides general information on the configuration software.

4. EE75 CONFIGURATOR

4.1 Start

The "Start" tab is used to initiate communication with the connected transmitter.

This function downloads the current transmitter configuration and serial number.

The configuration changes made on the other tabs can be uploaded to the

transmitter using the "Write" command.

Note: Execute the "Read" function before making any new configuration change!

16

Configurations Software

Page 18

4.2 Analog

The "Analog" tab allows free configuration and

scaling of the twoanalogue outputs

Range:

Measurement value:

Upper / Lower Limit:

Physical quantity:

The drop-down input field is used either to select a

standardised output signal (0-5 V, 0-10 V, 0-20 mA,

4-20 mA) or to specify a user-defined current/

voltage output range (e.g. 1-9 V).

Specifies the physical quantities the outputs will

represent.

If the measurement value “volumetric flow rate” is

selected, the cross section has to be defined (see

chapter 4.5 cross section).

Specifies the required display range. The limits must

lie within the maximum span as indicated.

Allows a user to choose whether measuring results are displayed and output in

SI units (m/s; °C; m³/min) or US units (ft/min.; °F; ft³/min.).

4.3 Display

With an optional display, the following can be set on the Display tab:

"Display Mode" drop-down input field:

- Single-line display

- Two-line display (factory setting)

"Backlight on" check box

- Activated = ON

- Not activated = OFF

4.4 Response Time

As described under Hardware, Section 5.2 - Jumpers for setting the velocity response time, three

different response times can be set.

In the factory settings, the following response times are assigned to the 3 jumper positions:

Jumper at position 1: τ90 = 2 s

Jumper at position 2: τ90 = 4 s

Jumper at position 3: τ90 = 10 s

Users can also assign a response time of between 1.5 and 40 s to each jumper position using the

configuration software.

Example:

Jumper at position 1: changes from 2 s (factory setting) to 35 s.

The green pilot lamp next to the jumper position indicates which jumper position is

currently set and consequently active.

Note: If the response time of the jumper currently active is changed anduploaded using the

"Write" function, the transmitter's velocity response is switched without changing the hardware

(jumper position).

Configurations Software

17

Page 19

4.5 Cross Section

The EE75 allows volumetric flow to be displayed in [m³/min] or [ft³/min.] (see Hardware,

Section 5.3 - Display module with buttons - Measurands).

The volume is calculated based on the flow velocity measured and the cross section. Consequently,

the cross sectional area of the duct must be entered in [m²] or [ft²].

To make it easier to calculate the cross sectional area, the "Cross sect." tab provides input

assistance:

Circular:

Rectangular:

Measure and enter the duct diameter in [m] or [ft]

- Press "calculate"

- The cross section is calculated and entered in the "Cross sectional area" field

Measure and enter the duct length and width in [m] or [ft]

- Press "calculate"

- The cross section is calculated and entered in the "Cross sectional area" field

If the duct has a different shape or the cross-sectional area is already known, the value can, of

course, also be entered directly in the "Cross sectional area" field, in [m²] or [ft²].

4.6 Probe Cable

The length of the probe cable (transmitter with remote probe) should not normally be changed.

However, if it is necessary to do so, the new (modified) probe cable length must be entered on

the "Probe Cable" tab. This virtually rules out additional measuring errors due to the modified

cable length.

Example: You order an EE75 VTC***K500 (5m /

with 3m (9.8ft). The new cable length of 2m (6.6ft) should be entered and uploaded using the

"Write" function.

Notes:

- The cable length is measured from the centre of the sensor element in the sensor head to

the point where it enters the housing (PG / screw connection).

- To increase the length of the probe cable, the instrument must be returned to E+E Elektronik.

18

16.4ft cable length) and then cut the cable

Configurations Software

Page 20

Switching point OFF

and Hysteresis:

4.7 Switching Off

The low flow cut-off is intended to prevent the

display or output signal fluctuating if the flow is cut

off.

Small differences in temperature in the duct can

produce small flow fluctuations, which would be recorded by the transmitter without the low flow

cut-off.

(switching point OFF + hysteresis = switching point

ON) can be defined in the input fields of the "Switching

Off" tab.

active

switching point OFF

Note:

The EE75 comes with the low flow cut-off function activated, with a switching point OFF of 0.1m/s (20ft/min)and

hysteresis

switching point ON

a hysteresis of 0.05m/s (10ft/min).

Should you require smaller flow velocities to be

displayed, deactivate the low flow cut-off (switching

point OFF + hysteresis = 0m/s or ft/min.).

4.8 Media Correction

The EE75 measures air velocity [m/s] temperature-independent, but pressure-dependent and

is standardised to 45% relative humidity and air

pressure of 1013mbar at the factory.

If e.g. the media pressure is significantly different, the actual values can be defined in the input

field on the "Mediacorr." tab to obtain the best possible measuring results.

4.9

Calibration

Velocity and temperature calibration is not only possible using the buttons on the integrated display,

the EE75 can also easily be calibrated / adjusted using the configuration software.

Note:

The configuration software automatically distinguishes between the low and high calibration points.

- If the selected calibration point is BELOW the centre of the measuring range, it is automatically

recognised as the "low calibration point" (CAL LOW).

- If the selected calibration point is ABOVE the centre of the measuring range, it is automatically

recognised as the "high calibration point" (CAL HIGH).

Example:

EE75 VT**1: Measuring range = 0-2m/s (0-400ft/min) -> centre of measuring range = 1m/s (200ft/min)

- 0.5m/s (100ft/min) -> calibration point lies below 1m/s (200ft/min) -> CAL LOW

- 1.6m/s (300ft/min) -> calibration point lies above 1m/s (200ft/min) -> CAL HIGH

Configurations Software

19

Page 21

4.9.1 Information on 1-point v/T calibration

If possible the selected calibration point should be similair to the working point

(of the limited working range) of the transmitter.

Example:

Working range v 8 - 12m/s (1600 - 2400ft/min) > calibration point at 10m/s (2000ft/min);

working range T 18 - 22°C (64.4 - 71.6°F) > calibration point at 20°C (68°F).

4.9.2 Information on 2-point v/T calibration

v/T calibration / adjustment is performed at 2 different calibration points.

To ensure the smallest possible deviation in measuring results over the entire

measuring range, the two calibration points should be selected as follows:

- The low calibration point should be in the lower third of the measuring range.

- The high calibration point should be in the upper third of the measuring range.

Example:

EE75 vT**1 - measuring range = 0 - 2 m/s

- Low calibration point (V-CAL LOW) should be around 0.4 m/s (0...0.7).

- High calibration point (V-CAL HIGH) should be around 1.8 m/s (1.4...2).

(0 - 400ft/min)

4.9.3 v calibration procedure using the configuration software

1. Position the sensor head in the middle of the reference system (wind tunnel).

2. Set the required calibration point in the reference system (wind tunnel).

3. Stabilise the probe at the reference velocity (for at least 1 minute).

4. Clicking on the "Velocity calibration" button opens the menu window shown below.

5. Enter the velocity displayed by the reference system in the "Reference value"

input field.

6. Clicking "Save" adjusts the EE75 measuring value with the reference value.

7. In the case of 1-point calibration, the process is now complete.

8. For 2-point calibration, repeat steps 2-7.

4.9.4 T calibration procedure using the configuration software

Click on the "Temperature calibration" button. The 1 or 2-point temperature

calibration procedure is similar to the velocity calibration (see Section 4.9.3 -

v calibration process using a configurator).

4.9.5 Activating factory calibration

Clicking the "Activate factory calibration" button deletes the customer calibration

data set for velocity and temperature and restores the factory settings.

Configurations Software

20

Page 22

4.10 Measuring Values

The configuration software allows the EE75 measuring values to be queried periodically on the

"Measuring Values" index card.

If the "Activate automatic Query" function is activated, all measuring values are downloaded

according to the specified interval and displayed in the desingated fields.

This function is particularly useful for checking transmitters, which do not have the (optional) display

module.

Model:

Serial number:

Software version:

Production date:

Last customer V adjustment:

Last customer T adjustment:

4.11 Information

The "Information" tab contains general information on the transmitter. It also saves the date of

the last customer calibration done with the configuration software.

Type of transmitter.

Reference to the serial number of the connected transmitter.

Version of the firmware used.

Date of production.

Date of last velocity adjustment.

Date of last temperature adjustment.

Configurations Software

21

21

Page 23

22

Configurations Software

Page 24

HEAD OFFICE:

E+E ELEKTRONIK Ges.m.b.H.

Langwiesen 7

A-4209 Engerwitzdorf

Austria

Tel: +43 7235 605 0

Fax: +43 7235 605 8

info@epluse.com

www.epluse.com

TECHNICAL OFFICES:

E+E CHINA / BEIJING

Tel: +86 10 84992361

info@epluse.cn www.epluse.cn

E+E CHINA / SHANGHAI

Tel: +86 21 61176129

info@epluse.cn www.epluse.cn

E+E GERMANY

Tel: +49 6172 13881 0

info@epluse.de www.epluse.de

E+E FRANCE

Tel : +33 4 7472 35 82

info@epluse.fr www.epluse.fr

E+E ITALIEN

Tel: +39 02 2707 86 36

info@epluse.it www.epluse.it

E+E KOREA

Tel: +82 31 732 6050

info@epluse.co.kr www.epluse.co.kr

E+E USA

Tel: +1 508 530 3068

office@epluse.com www.epluse.com

Loading...

Loading...