Page 1

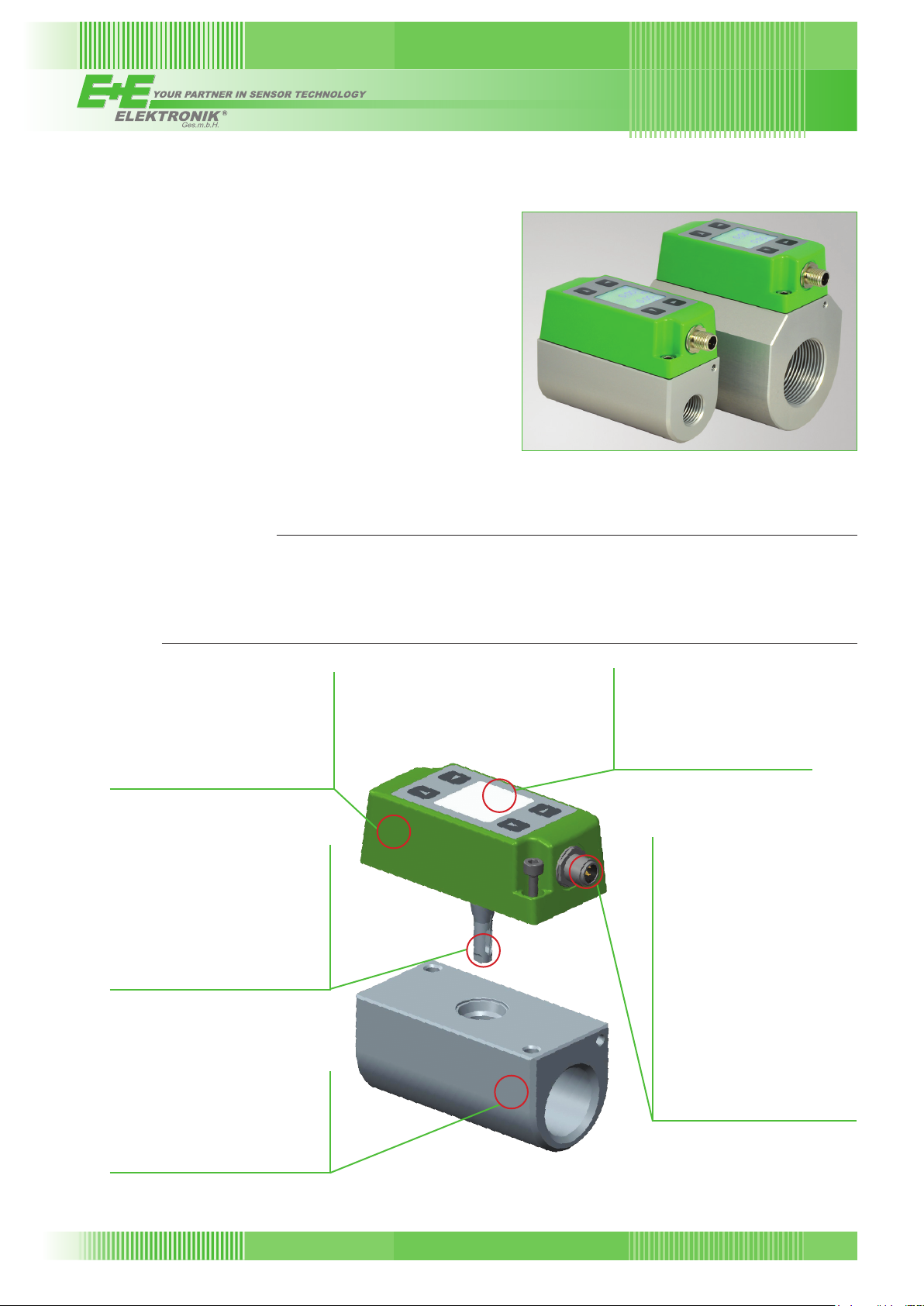

EE741

Modular, compact, inline ow meter

for compressed air and gases

The EE741 inline flow meter is dedicated for accurate metering

and monitoring of compressed air and technical gases in DN15

to DN50 pipes.

The thermal measuring principle and the well-proven E+E hot film

sensor element lead to best long-term stability and fast response

time.

Outstanding measuring accuracy, even in the lower measuring

range is achieved by an application-specific multi-point factory

adjustment performed at 7 bar (102 psi). This allows reliable leak

detection and corresponding energy savings.

The construction of the EE741 is optimized for easy installation

and maintenance.

The EE741 is user configurable and can be easily adapted to any measuring task. The setup can be set using either

display and push buttons or the free product configuration software EE-PCS.

Typical applications

EE741

• Compressed air consumption measurement

• Monitoring of technical gases O

Features

Transmitter

» For each three pipe diameters

» Installation and removal without dis-

assembling the pipework facilitatesregular calibration

» Application-specific adjustment

under pressure for best accuracy

Sensor head and thermal ow sensor

» Robust design in stainless steel

» Very short response time

» Wide measuring range

» Long-term stable and accurate

» Negligible pressure drop

» Highly insensitive to contamination

» No additional pressure and

temperature compensation required

Gauge mounting block

» Precise and reproducible positioning

of the transmitter for best accuracy

» Aluminum or stainless steel

» Can be operated with sealing plug

also without transmitter

, N2, Ar, CO2 and other

2

• Nitrogen generators

• Leak detection

Display

» Shows instantaneous values and

overall consumption

» Intuitive device setup with push-

buttons

» Can be rotated in 90° increments

Output

» User configurable via display or PC

» 0-20 / 4-20 mA output

» Two switch outputs

» Pulse output

» Modbus RTU

» M-Bus

Measurands

» Standard volume flow

» Mass flow

» Standard flow

» Temperature

» Integrated consumption meter

(totalisator) for cost-effective

consumption analysis without

additional datalogger

190

v2.3 / Modification rights reserved

EE741

EE741

Page 2

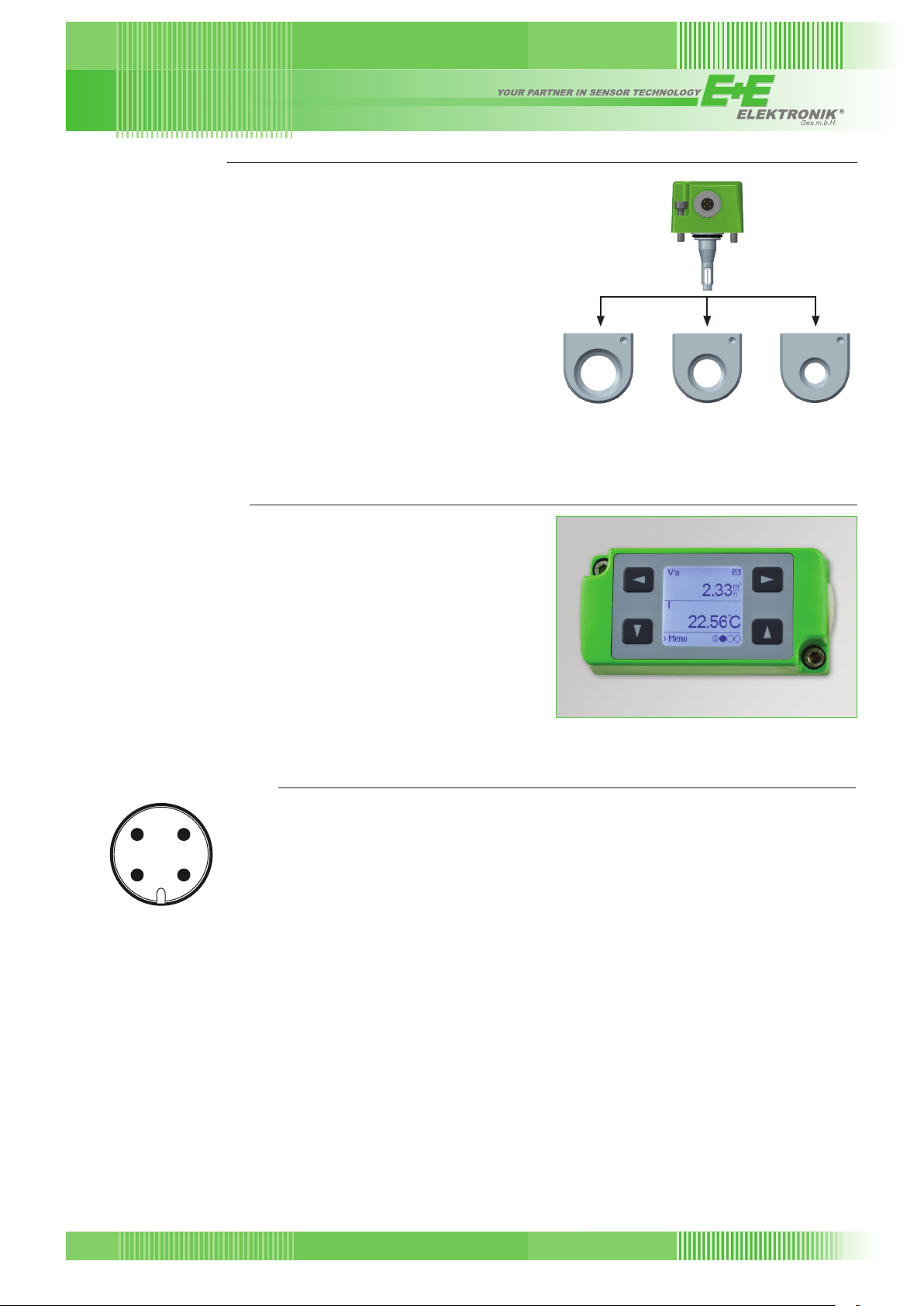

Modular design

One and the same transmitter can be used for each of three pipe

diameters:

EE741: DN15 (1/2“) / DN20 (3/4“) / DN25 (1“)

EE741-N50: DN32 (1-1/4“) / DN40 (1-1/2“) / DN50 (2“)

The pipe diameter is easily changed via the display menu or the

Configurator software.

Once the gauge mounting block is built into the pipeline, the transmitter

can be installed and removed without disassembling the pipework.

As a result, the EE741 is also ideal for temporary measurement at

serveral mounting blocks. The sealing plug included in the scope of

supply enable the normal operation of the compressed air system

when the transmitter is removed.

Display (optional)

The state-of-the-art LCD shows the current measured values and the

overall consumption. The user specific device setup can be easily

performed with the push buttons and intuitive menu guidance.

The display can be rotated in 90° increments with a push button for

convenient orientation in any mounting position of the flow meter.

The EE741 without display can be configured by the user via USB

interface with the free EE-PCS product configuration software.

Connection diagram

34

1 2

M12 plug on device

Output 1: Analogue [mA] or switch

Output 2: Pulse or switch

The output signal is freely selectable and configurable.

Analogue/switch/

pulse output

1...V+

2...Output 1

3...GND

4...Output 2

Modbus RTU

1...V+

2...RS485 A (=D+)

3...GND

4...RS485 B (=D-)

M-Bus / Meter-bus

1...V+

2...M-Bus

3...GND

4...M-Bus

EE741

v2.3 / Modification rights reserved

191

Page 3

Technical data

Measured values

Flow

Measurands m

Standard conditions (factory setting) 1013.25 mbar

Measuring range in air

DN20 (3/4”): 0.4...135.7 Nm3/h (0.24...79.77 SCFM)

DN25 (1”): 0.6...212 Nm3/h (0.36...124.71 SCFM)

DN32 (1-1/4“): 0.9...347.4 Nm3/h (0.52...202.06 SCFM)

DN40 (1-1/2“): 1.4...542.8 Nm

DN50 (2“): 2.2...848.2 Nm

Accuracy2) in air at 7 bar (102 psi) (abs) and 23 °C (73 °F) ± (3 % of measured value + 0.3 % of full scale)

Temperature coefficient ± 0.25 % of the measured value / °C deviating from 23 °C

Pressure coefficient3) + 0.5 % of the measured value / bar deviating from 7 bar (102 psi)

Response time t90 < 2 sec.

Measuring rate 0.1 sec.

Temperature

1)

DN15 (1/2”): 0.2...76.3 Nm3/h (0.12...44.88 SCFM)

Measuring range -20...60 °C (-4...140 °F)

Accuracy at 20 °C (68 °F) and flow >0.5 Nm/s ± 0.7 °C (1.26 °F)

Outputs

Analogue output (scalable) 0 - 20 mA / 4 - 20 mA RL<500 Ohm

Switch output DC PNP, max. 100 mA, V

Configurable: N/C or N/O, hysteresis, window

Pulse output Consumption meter, pulse length 0.02...2 sec.

Bus-interface Modbus RTU (max. 32 units in one bus) or

M-BUS (Meter-Bus)

Configuration interface USB

General

Supply voltage 18 - 30 V DC

Current consumption (max.)

with display I

without display I

Operating pressure (max.) 16 bar

Ambient temperature

with display 0...50 °C

without display -20...60 °C (-4...140 °F)

Medium and storage temperature -20...60 °C (-4...140 °F)

Humidity 0…100 % RH, non-condensing

Medium Compressed air or none corrosive gases

Electrical connection M12x1 4 pol. plug

Electromagnetic compatibility EN61326-1 EN61326-2-3

Industrial environment

Material

Enclosure Polycarbonate

Sensor head / sensor element Stainless steel 1.4404 / glass

Gauge mounting block Aluminium anodized or stainless steel 1.4404

Enclosure protection class IP65

1) Factory setting of the output see manual.

2) The tolerance specifications include the uncertainty of the factory calibration with a coverage factor k=2 (2 x standard deviation). The tolerance was calculated in accordance

with EA-4/02 following the GUM (Guide to the Expression of Uncertainty in Measurement).

3) The flow meter is factory adjusted at 7 bar (102 psi) (abs). At operating pressure other than 7 bar (102 psi) (abs), the error can be corrected by entering the actual system pressure via display menu or with EE-PCS configuration software.

3

/h, m3/min, l/min, l/s, kg/h, kg/min, m/s, SCFM, ft/min, °C, °F

≤120 mA (P

max

≤60 mA (P

max

(232 psi)/ PN16

(32...122 °F)

(14.7 psi), 0 °C (32 °F) (configurable)

3

/h (0.81...315.71 SCFM)

3

/h (1.22...493.35 SCFM)

<2.5 V, 10 kOhm Pull-down

drop

≤2,5 W)

max

≤1,6 W)

max

(73 °F)

192

v2.3 / Modification rights reserved

EE741

Page 4

Dimensions (mm/inch)

EE741:

M12 x 1M12 x 1

100 / 3.94

EE741-N50:

50 / 1.97

50 / 1.97

84.5 /3.33

Internal thread:

Whitworth thread

according to EN 10226

(old DIN 2999) or NPT

Mounting

block

DN15 1/2"

DN20 3/4"

DN25 1"

1)

DN32

DN40 1-1/2”

DN50 2”

Rp or NPT

1-1/4”

1) only Rp thread

Thread

123 /4.84

Internal thread:

Whitworth thread

according to EN 10226

(old DIN 2999) or NPT

Modbus Map

88.5 / 3.48

100 / 3.94

1)

80 / 3.15

The flow meter can be operated in a Modbus RTU network with max. 32 devices. Writing 0 into the

corresponding register will reset the MIN/MAX values and the consumption meter.

For Modbus protocol settings see Application Note Modbus AN0103 (www.epluse.com/EE741).

Read Registers (Function Code 0x03 / 0x04)

Register [DEC]

30501 1F4 Temperature °C 32-bit float

30503 1F6 Temperature °F 32-bit float

30507 1FA Standard flow Nm/s 32-bit float

30509 1FC Standard flow SFPM 32-bit float

30511 1FE Mass flow kg/h 32-bit float

30513 200 Mass flow kg/min 32-bit float

30517 204 Standard volume flow Nm³/h 32-bit float

30519 206 Standard volume flow Nm³/min 32-bit float

30521 208 Standard volume flow l/min 32-bit float

30523 20A Standard volume flow l/s 32-bit float

30525 20C Standard volume flow SCFM 32-bit float

30529 210 Consumption meter status m³ 64-bit-double

30533 214 Consumption meter status ft³ 64-bit-double

1) Complete Modbus Map see operating instructions.

Protocol address [HEX]

Muasured value Unit Type

Data transmission

Baud rate 9600 9600, 19200, 38400

Data bits 8 8

Parity EVEN None, Odd, Even

Stop bits 1 1 oder 2

Slave addresse 240 1...247

EE741

v2.3 / Modification rights reserved

Factory setting Adjustable values

193

Page 5

Ordering information

A complete flow meter consists of a transmitter (Item 1) and a gauge mounting block (Item 2).

Item 1 - Transmitter EE741-

Pipe diameter / Type

Output

Display Without display no code

Hardware

Cleaning

Factory setting

pipe diameter

(selectable)

2)

Output 1

2)

Output 2

Measurand output 1

2)

Software configuration

Measurand output 2

2)

Unit for process parameters

3)

Medium

Item 2 - Gauge mounting block

Aluminum gauge mounting block

Stainless steel gauge mounting block

Stainless steel gauge mounting block

for oxygen

1) The parts of the transmitter/mounting block in contact with the medium are oil and grease-free. Only for DN15, DN20 and DN25.

2) Only for analogue/switch and pulse output

3) Other gases upon request

1)

for DN15, DN20, DN25 no code

for DN32, DN40, DN50 N50

Analogue/switch/pulse output A6

RS485 Modbus RTU J3P1

M-Bus J5P4

With display D2

without no code

degreased for oxygen measurement

1)

DN15 (1/2“)

DN20 (3/4“)

DN25 (1“)

DN32 (1-1/4“) only for N50

DN40 (1-1/2“) only for N50

DN50 (2“) only for N50

Analogue output 4-20 mA

0-20 mA

Switch output

Pulse output (Only with Measurand output 2 = Consumption)

Switch output

Standard volume flow V‘n [Nm3/h]

V‘n [Nm

3

/min]

V‘n [l/min]

V‘n [l/s]

V‘n [SCFM]

Mass flow m‘ [kg/h]

m‘ [kg/min]

Standard flow vn [Nm/s]

vn [SFPM]

Temperature T [°C]

T [°F]

Consumption Qn [Nm3] (Only for output 2 = Pulse output)

Standard volume flow V‘n [Nm

V‘n [Nm

3

/h]

3

/min]

V‘n [l/min]

V‘n [l/s]

V‘n [SCFM]

Mass flow m‘ [kg/h]

m‘ [kg/min]

Standard flow vn [Nm/s]

vn [SFPM]

Temperature T [°C]

T [°F]

SI units [mbar, °C]

US units [psi, °F]

Air

Nitrogen

CO

2

Oxygen

Argon

BSP-thread NPT-thread

DN15 (1/2“) HA079015 HA179015

DN20 (3/4“) HA079020 HA179020

DN25 (1“) HA079025 HA179025

DN32 (1-1/4“) HA079032

DN40 (1-1/2“) HA079040 HA179040

DN50 (2“) HA079050 HA179050

DN15 (1/2“) HA078015 HA178015

DN20 (3/4“) HA078020 HA178020

DN25 (1“) HA078025 HA178025

DN15 (1/2“) HA081015 HA181015

DN20 (3/4“) HA081020 HA181020

DN25 (1“) HA081025 HA181025

AF2

DN15

DN20

DN25

DN32

DN40

DN50

no code

GA5

GA9

no code

GB9

no code

MA84

MA85

MA86

MA87

MA80

MA81

MA22

MA23

MA1

MA2

no code

MB83

MB84

MB85

MB86

MB87

MB80

MB81

MB22

MB23

MB1

MB2

no code

U2

no code

FU2

FU3

FU4

FU7

194

v2.3 / Modification rights reserved

EE741

Page 6

Order Example

Item 1 - Transmitter

EE741-A6D2DN15

Pipe diameter/type for DN15, DN20, DN25

Output: Analogue/switch/pulse output

Display: With display

Pipe diameter (selectable): DN15 (1/2”)

Unit for process parameters: SI units [mbar, °C]

Medium: Air

Item 2 - Gauge mounting block

HA079015

Aluminum gauge mounting block DN15 (1/2“)

Accessories

- Inlet and outlet path BSP thread, stainless steel, for mounting block DN15 (1/2“) HA070215

DN20 (3/4“) HA070220

DN25 (1“) HA070225

DN32 (1-1/4“) HA070232

DN40 (1-1/2“) HA070240

DN50 (2“) HA070250

Scope of supply

Item 1: EE741:

• EE741 according to ordering guide

• 1 x Allen key

• 1 x USB cable

• M12x1 straight socket, can be assembled

• Operating instructions

• Two self-adhesive labels for configuration changes

(see user guide at www.epluse.com/relabeling)

• Inspection certificate according to DIN EN10204 - 3.1

Item 2: Gauge mounting block:

• Gauge mounting block incl. sealing plug

EE741

v2.3 / Modification rights reserved

195

Loading...

Loading...