Page 1

EE650

The EE650 air velocity transmitter is dedicated for accurate and reliable

measurement in building automation and ventilation applications.

The device employs an innovative air velocity sensing element, which

operates on the thermal anemometer principle and is manufactured by

E+E in state-of-the-art thin lm technology. Due to its innovative design,

the sensing element is very robust and highly insensitive to pollution,

which leads to outstanding long-term performance.

For the EE650 with analogue output, the measuring range 0-10/15/20 m/s

(0-2000/3000/4000 ft/min), the output signal 4-20 mA or 0-10 V as well as the

response time 1 or 4 seconds are selectable by jumpers.

The bus address, the termination resistor and the response time of the

Modbus RTU and BACnet MS/TP versions can also be easily set on the

electronics board.

The enclosure design and the mounting ange included in the scope of

supply allow for fast and easy installation.

With an optional adapter cable and the free EE-PCS product conguration

software, the user can adjust the EE650, set the output scale and select

the interface parameters.

Air Velocity Transmitter for

HVAC Applications

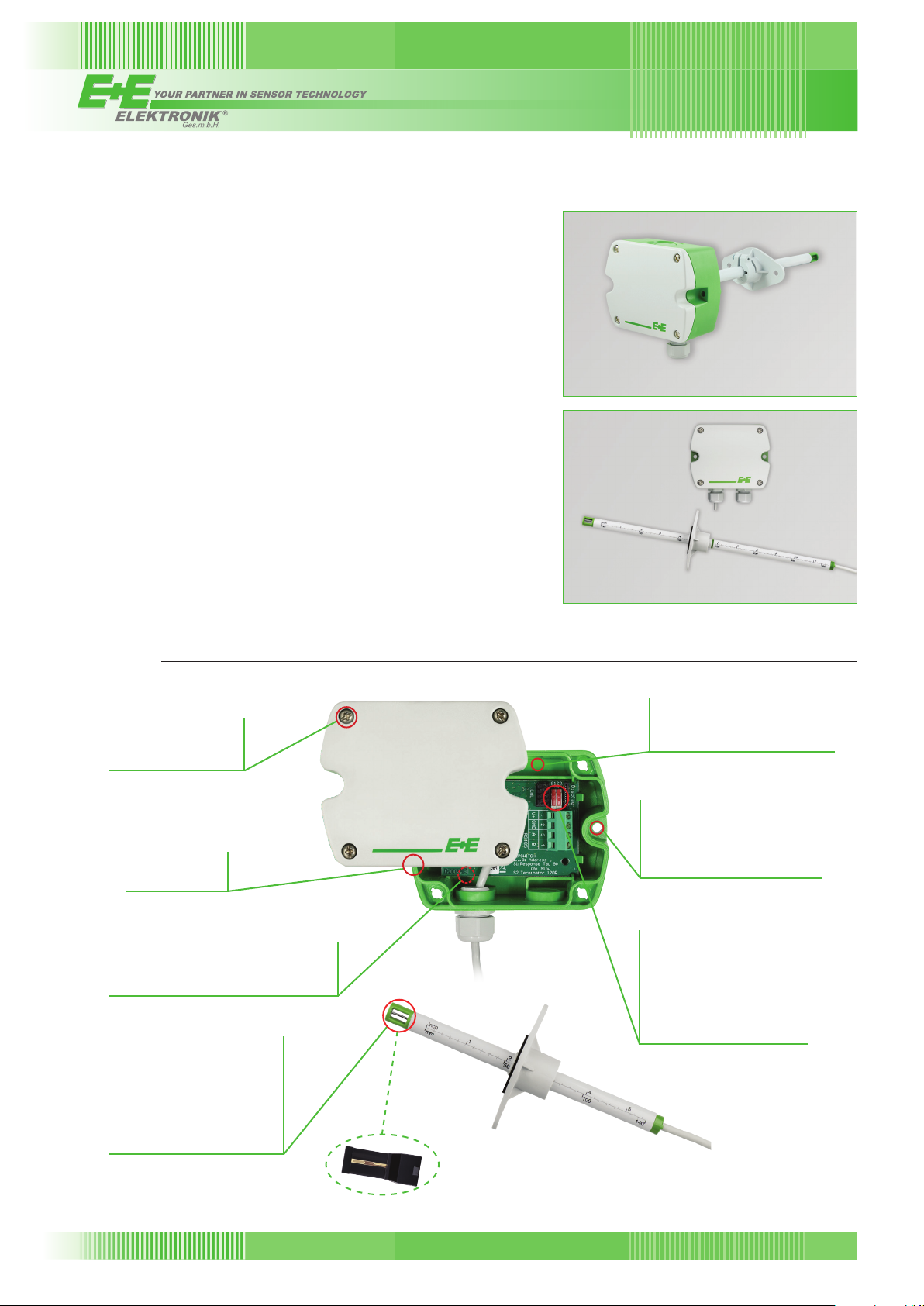

EE650 - Duct mounting

EE650 - Remote sensor probe

Features

Bayonet Screws

» Open/closed with a

¼ rotation

Enclosure

» IP65 / Nema 4

Electronics on the underside of the PCB

» Protection against mechanical

damage during installation

E+E Air velocity sensor VTQ

» Exceptional mechanical

stability thanks to transfer-

moulding technology

» High insensitivity to pollution

» Long-term stable

» Measurement down to 0.2 m/s

(40 ft/min)

Appropriate for US mounting

requirements

» Knock-out for ½” conduit tting

External mounting holes

» Fast and easy installation

with closed cover

» Electronics protected against

construction site pollution

Adjustment

Conguration

» Measuring range

» Output signal

» Response time

» Bus address

» Termination resistor

176

v2.0 / Modification rights reserved

EE650

EE650

Page 2

Technical data

V+

GND

AV

1

2

3

+

-

~

~

V/mA

M16x1,5

Measuring range

Working range 1) 0...10 m/s (0...2000 ft/min)

0...15 m/s (0...3000 ft/min)

0...20 m/s (0...4000 ft/min) (factory setting)

Accuracy at 20 °C 2) (68 °F), 0.2...10 m/s (40...2000 ft/min) ± (0.2 m/s (40 ft/min) + 3 % of m. v.)

45 % RH, 1013 hPa 0.2...15 m/s

0.2...20 m/s

Response time

Output

Analogue 1) 0 - 10 V -1 mA < IL < 1 mA

0...10 m/s / 0...15 m/s / 0...20 m/s 4 - 20 mA

Digital interface RS485 with max. 32 devices on one bus

Protocol Modbus RTU or BACnet MS/TP

General

Power supply (Class III) 24 V AC/DC ± 20 %

Current consumption

Electrical connection screw terminals max. 1.5 mm

Cable gland M16x1.5

Electromagnetic compatibility EN61326-1 EN61326-2-3

Industrial Environment

Enclosure material Polycarbonate, UL94V-0 approved

Protection class Enclosure IP65 / NEMA 4, remote probe IP20

Temperature range working temperature probe -25 ... 50 °C

working temperature electronic -10 ... 50 °C

storage temperature -30 ... 60 °C

Working range humidity 5...95 % RH (non-condensing)

1) Selectable by jumper, only for analogue output

2) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation).

The accuracy was calculated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

(40...3000 ft/min) ± (0.2 m/s (40 ft/min) + 3 % of m. v.)

1)

τ

typ. 4 sec. (factory setting) or typ. 1 sec. at constant temperature

90

(40...4000 ft/min) ± (0.2 m/s (40 ft/min) + 3 % of m. v.)

(factory setting) R

< 500 Ω (linear, 3-wires)

L

AC supply DC supply

Analogue ouput max. 170 mA max. 70 mA

RS485 max. 120 mA max. 50 mA

2

(AWG 16)

(-13...122 °F)

(14...122 °F)

(-22...140 °F)

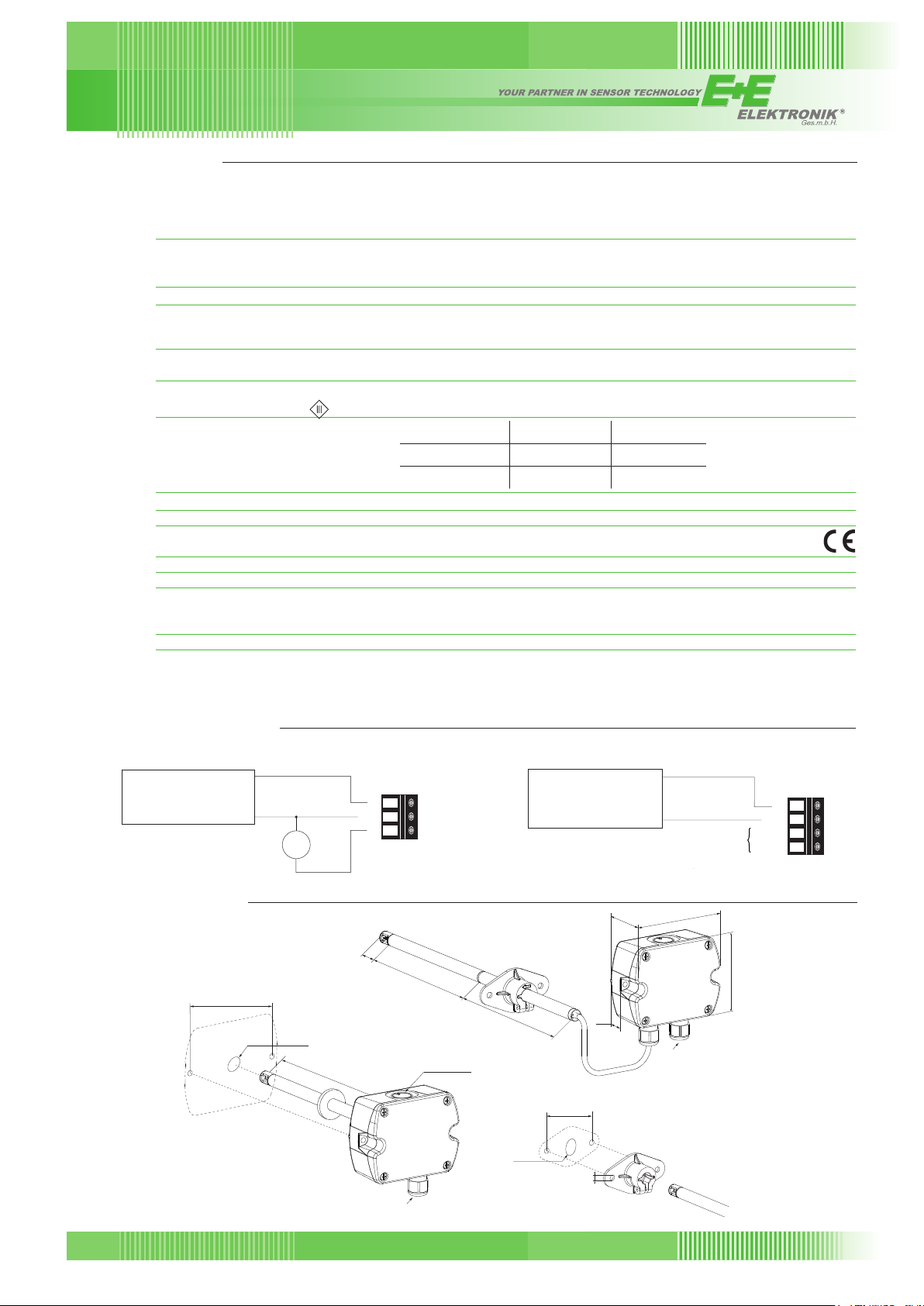

Connection Diagram

Analogue output

power supply

24 V AC/DC ±20 %

+

~

~

Dimensions (mm)

90

Duct mount

V/mA

Ø > 13

~110 or 210

GND

15

Digital interface

power supply

V+

AV

1

2

3

24 V AC/DC ±20 %

+

~

-

~

RS485

46

101

V+

GND

A (=D+)

B (=D-)

1

2

3

4

Remote sensor probe

155

FOR CONDUIT

INSTALLATION

155

19

Cable gland

M16x1,5

60

80,6

Mounting flange

Ø > 16

6

EE650

v2.0 / Modification rights reserved

Cable gland

177

Page 3

Ordering Guide

Type

Output

Probe length

Cable length

Hardware Configuration

Protocol

Baud rate

Setup RS485

1) Factory setting: Even Parity, Stopbits 1 Modbus Map see User Guide at www.epluse.com/ee650

2) Factory setting: No Parity, Stopbits 1 Product Implementation Conformance Statement (PICS) available at www.epluse.com/ee650

3) Only for BACnet MS/TP

Duct mounting T2

Remote sensor probe T3

4-20 mA (selectable by jumper to 0-10 V) A6 A6

RS485 J3 J3

100 mm L100

200 mm L200

300 mm (2 x 150 mm) L300

not applicable no code

1 m K1

2 m K2

5 m K5

10 m K10

Modbus RTU

BACnet MS/TP

9600 BD5

19200 BD6

38400 BD7

57600

76800

1)

P1

2)

3)

3)

EE650-

P3

BD8

BD9

Order Example

EE650-T2A6L200

Type: duct mounting

Output: 4-20 mA

Probe length: 200 mm

EE650-T3A6L300K2

Type: remote sensor probe

Output: 4-20 mA

Probe length: 300 mm

Cable length: 2 m

Scope of Supply

- EE650 Transmitter according to ordering guide

- Cable gland (two pieces at output RS485 for daisy chain wiring)

- Mounting flange

- Mounting materials

- Protection cap

- Quick guide

- Two self-adhesive labels for configuration changes (see user guide at www.epluse.com/relabeling)

- Test report according to DIN EN10204 - 2.2

Accessories

USB configuration adapter HA011066

Product configuration software EE-PCS (free download: www.epluse.com/EE650)

Power supply adapter V03 (see data sheet Accessories)

EE650-T2J3L200P1BD5

Type: duct mounting

Output: RS485

Probe length: 200 mm

Protocol: Modbus RTU

Baud rate: 9600

178

v2.0 / Modification rights reserved

EE650

Loading...

Loading...