Page 1

User Manual

EE600

Differential Pressure Sensor

BA_EE600_e // v1.5 // technical data are subject to change

Page 2

E+E Elektronik Ges.m.b.H. accept warranty and liability claims neither upon this publication nor in case of improper

treatment of the described products.

The document may contain technical inaccuracies and typographical errors. The content will be revised and

updated on aregular basis. The described products can be improved and changed at any time without prior notice.

© Copyright E+E Elektronik Ges.m.b.H.

All rights reserved.

EMC note USA (FCC):

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

EMC note Canada (ICES-003):

CAN ICES-3 (A) / NMB-3 (A)

Page 3

CONTENT

1 General ................................................................................................................................................. 4

1.1 Explanation of symbols .................................................................................................................................4

1.1.1 General safety instructions ..................................................................................................................................4

1.1.2 Mounting, start-up and operation .........................................................................................................................4

1.2 Environmental aspects ..................................................................................................................................5

2 Scope of Supply .................................................................................................................................5

3 Product Description ............................................................................................................................ 6

4 Setup ...................................................................................................................................................7

4.1 Analogue version ...........................................................................................................................................7

4.1.1 Select the measurement range with S1 and S2 ...................................................................................................7

4.1.2 Select the response time with S3 and S4 ............................................................................................................7

4.1.3 Select the display unit with S5 and S6 ................................................................................................................7

4.1.4 Select the backlight for the display with S7 ..........................................................................................................8

4.1.5 Select the output signal with S8 ...........................................................................................................................8

4.1.6 Outputs.................................................................................................................................................................8

4.2 Digital version ................................................................................................................................................8

4.2.1 EE-PCS Product Configuration Software .............................................................................................................9

4.2.2 RS485 Digital Interface settings ...........................................................................................................................9

4.2.3 BACnet Protocol Settings ....................................................................................................................................9

4.2.4 Modbus Protocol Settings ..................................................................................................................................10

4.2.5 Modbus Register Map ........................................................................................................................................10

4.2.6 Reading example ............................................................................................................................................... 11

4.2.7 Application settings ............................................................................................................................................ 11

5 Installation .........................................................................................................................................14

5.1 Pressure connection ....................................................................................................................................15

6 Maintenance and service .................................................................................................................. 16

6.1 Cleaning ......................................................................................................................................................16

6.2 Repairs ........................................................................................................................................................16

6.3 Readjustment of EE600 ..............................................................................................................................16

6.3.1 Zero Point Adjustment ........................................................................................................................................ 16

6.3.2 Span Point Adjustment ....................................................................................................................................... 17

6.3.3 Return to Factory Adjustment ............................................................................................................................ 17

7 User Interface ....................................................................................................................................18

7.1 LED indication ............................................................................................................................................18

7.2 Display .........................................................................................................................................................18

7.2.1 Analogue version ...............................................................................................................................................18

7.2.2 Digital version..................................................................................................................................................... 18

7.2.3 Out of range ....................................................................................................................................................... 19

8 Technical Data ..................................................................................................................................20

Page 4

1 General

This user manual serves for ensuring proper handling and optimal functioning of the device.

The user manual shall be read before commissioning the equipment and it shall be provided to all staff

involved in transport, installation, operation, maintenance and repair.

The user manual may not be used for the purposes of competition without the written consent of E+E

Elektronik® and may not be forwarded to third parties. Copies may be made for internal purposes. All

information, technical data and diagrams included in these instructions are based on the information

available at the time of writing.

1.1 Explanation of symbols

This symbol indicates safety information.

It is essential that all safety information is strictly observed. Failure to comply with this information can

lead to personal injuries or damage to property. E+E Elektronik® assumes no liability if this happens.

This symbol indicates instructions.

The instructions shall be observed in order to reach optimal performance of the device.

1.1.1 General safety instructions

• Avoid any unnecessary mechanical stress and inappropriate use.

• Installation, electrical connection, maintenance and commissioning shall be performed by

qualified personnel only.

• Use the EE600 only as intended and observe all technical specs.

• Do not blow into the pressure connections.

• Connecting to EE600 a pressure beyond the measurement range according to the product specification may permanently damage the device.

• Do not use EE600 in explosive atmosphere or for measurement of aggressive gases.

• Do not apply the nominal voltage to the output terminals.

1.1.2 Mounting, start-up and operation

The EE600 differential pressure sensor has been produced under state of the art manufacturing conditions, has been thoroughly tested and has left the factory fulfilling all safety criteria. The manufacturer

has taken all precautions to ensure safe operation of the device. The user must ensure that the device

is set up and installed in a manner that does not have a negative effect on its safe use.

The user is responsible for observing all applicable safety guidelines, local and international, with respect to safe installation and operation on the device. This operating manual contains information and

warnings that must be observed by the user in order to ensure safe operation.

• Mounting, start-up, operation and maintenance of the device may be performed by qualified staff only.

Such staff must be authorised by the plant operator to carry out the mentioned activities.

• The qualified staff must have read and understood this operating manual and must follow the instructions contained within.

• All process and electrical connections shall be thoroughly checked by authorised staff before putting

the device into operation.

• Do not install or start-up a device supposed to be faulty. Make sure that such devices are not

accidentally used by marking them clearly as faulty.

• A faulty device may only be investigated and possibly repaired by qualified, trained and authorised

staff. If the fault cannot be fixed, the device shall be removed from the process.

• Service operations other than described in this operating manual may only be performed by the

manufacturer.

4

User Manual EE600 Differential Pressure Sensor

Page 5

Disclaimer

The manufacturer or his authorised agent can only be held liable in case of willful or gross negligence.

In any case, the scope of liability is limited to the corresponding amount of the order issued to the

manufacturer. The manufacturer assumes no liability for damages incurred due to failure to comply with

the applicable regulations, operating instructions or the operating conditions. Consequential damages

are excluded from the liability.

1.2 Environmental aspects

Products from E+E Elektronik® are developed and manufactured observing of all relevant requirements

with respect to environment protection. Please observe local regulations for the device disposal.

For disposal, the individual components of the device must be separated according to local recycling

regulations. The electronics shall be disposed of correctly as electronics waste.

2 Scope of Supply

• EE600 differential pressure sensor according to ordering guide

• Quick user guide

• Test report according to DIN EN 10204 – 2.2

• Pressure connection kit, straight, including 2 m hose

• Mounting materials

• For digital version (J3 ordering code): one additional M16 x 1.5 cable gland for “Daisy chain” wiring

User Manual EE600 Differential Pressure Sensor

5

Page 6

3 Product Description

0.2“

V+

GND

AV

1

2

3

+

-

~

~

+

V/mA

±0.3

90

mm

±0.11

“

3.54

46 mm

1.81“

FOR CONDUIT

INSTALLATION

5 mm

0.2“

3.17“

80.6 mm

Pressure ttings Ø 5mm

+ : High pressure

- : Low pressure

5 mm

CABLE GLAND M16x1.5

Fig. 1 Dimensions

Analogue version (A7) Digital version (J3)

2

4

5

2

4

3

1

6

7

5

6

3

1

89

1. Pressure connection nipples

2. DIP switches: Configuration (Ranges, response

time, ...)

3. Terminals: spring loaded

4. Push buttons for zero point and span point adjust

ment

5. Status LED

6. Cable gland for wiring

1. Pressure connection nipples

2. DIP switches: RS485 addressing

3. Terminals: screw

4. Push buttons for zero point and span point adjust

-

ment

5. Status LED

6. Slide switch termination resistor

7. Service interface connector

8. Cable gland for wiring

9. Additional cable gland for daisy chain wiring

Fig. 2 Design and components

Analogue version (A7) Digital version (J3)

15...35 V DC

24 V AC ±20 %

power supply

24 V AC ±20 %

15...35 V DC

-

~

~

RS485

V+

GND

A (=D+)

B (=D-)

1

2

3

4

Fig. 3 Connection diagram

6

User Manual EE600 Differential Pressure Sensor

Page 7

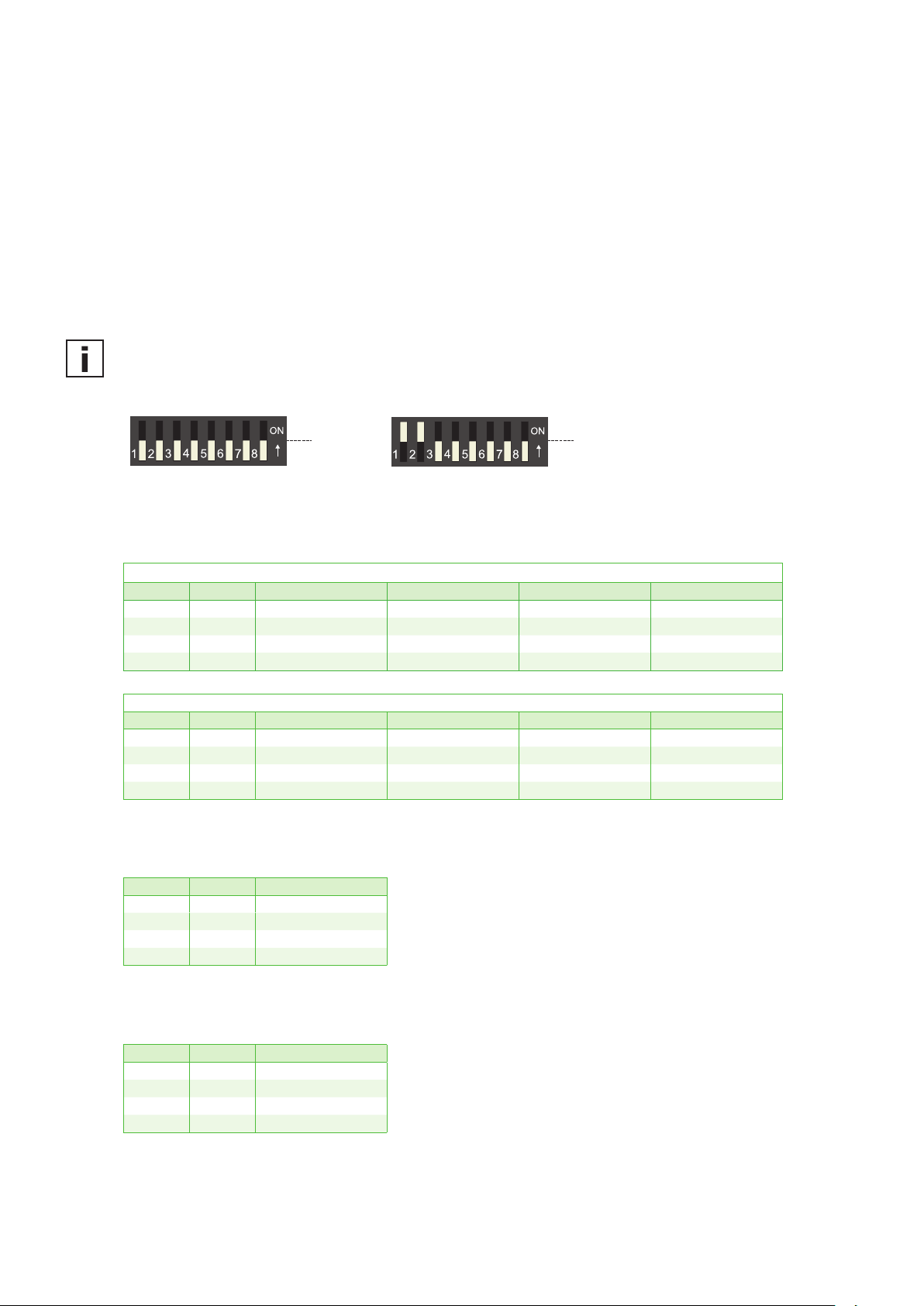

4 Setup

0 0 0 0 0 0 0 0

1 1 0 0 0 0 0 0

4.1 Analogue version

Each EE600 leaves the E+E factory with the default setup (all switches on „0“):

• Measurement range: 100 % of the full scale (1000 Pa or 10000 Pa)

• Response time: 50 ms

• Display unit: Pa

• Backlight display: on

• Output signals: 0-10 V and 4-20 mA

EE600 is fully configurable. Before commissioning, set the individual configuration of EE600 according

to the application requirements using the DIP switches S1 to S8 as described below. The function of the

DIP switches is indicated also on the interior of the EE600 front cover.

1

0

Fig. 4 DIP switches examples

4.1.1 Select the measurement range with S1 and S2

EE600-HV52A7:

S1 S2 Pa mbar inch WC kPa

0 0 1000 10 4 1

1 0 750 7.5 3 0.75

0 1 500 5 2 0.5

1 1 250 2.5 1 0.25

EE600-HV53A7:

S1 S2 Pa mbar inch WC kPa

0 0 10000 100 40 10

1 0 7500 75 30 7.5

0 1 5000 50 20 5

1 1 2500 25 10 2.5

Tab. 1 DIP switch settings - Measurement range

4.1.2 Select the response time with S3 and S4

1

0

Tab. 2 DIP switch settings - Response time

4.1.3 Select the display unit with S5 and S6

Tab. 3 DIP switch settings - Display unit

User Manual EE600 Differential Pressure Sensor

S3 S4 Response time

0 0 50 ms

1 0 500 ms

0 1 2 s

1 1 4 s

S5 S6 Display unit

0 0 Pa

1 0 mbar

0 1 inch WC

1 1 kPa

7

Page 8

4.1.4 Select the backlight for the display with S7

S7 Backlight

0 on

1 off

Tab. 4 DIP switch settings - Blacklight

4.1.5 Select the output signal with S8

EE600 provides simultaneously a voltage and a current output signal at the spring terminals.

S8 Output signals

0 0-10 V and 4-20 mA

1 0-5 V and 0-20 mA

Tab. 5 DIP switch settings - Output signals

4.1.6 Outputs

The measured data is available at the spring terminals as 0-10 V and 4-20 mA or as 0-5 V

and 0-20 mA signals (see „4.1.5 Select the output signal with S8“).

Additionally, the analogue outputs indicate measurement out of range as follows.

Indication of Δp < -5 % MR and of negative difference pressure due to inverted pressure connection:

Output signal

0-10 V -0.5 V

0-5 V -0.25 V

4-20 mA 3.2 mA

0-20 mA -1 mA

Tab. 6 Indication of Δp < -5 % MR

Indication of negative

differential pressure

Indication of Δp > 105 % MR

Output signal Indication of overload

0-10 V 10.5 V

0-5 V 5.25 V

4-20 mA 20.8 mA

0-20 mA 21 mA

Tab. 7 Indication of Δp > 105 % MR

4.2 Digital version

The EE600 is ready to use and does not require any configuration by the user. The factory setup of

EE600 corresponds to the type number ordered. For ordering guide please see data sheet at

www.epluse.com/ee600. If needed, the user can change the factory setup by using the USB configuration adapter (code HA011066) and the EE-PCS, Product Configuration Software.

One can change the application settings (see chapter „4.2.7 Application settings“), the display visualisation (see chapter „7.2.2 Digital version“), the digital communication parameters (see chapter „4.2.2

RS485 Digital Interface settings“) and the response time.

Note: The EE600 may not be connected to any additional power supply when using the USB configuration adapter HA011066.

8

User Manual EE600 Differential Pressure Sensor

Page 9

PC

0 0 0 0 0 0 0 0

1 1 0 0 0 0 0 0

1

0

1

0

1 1 0 0 0 0 0 0

1

0

Fig. 5 Configuration adapter

4.2.1 EE-PCS Product Configuration Software

1. Download the EE-PCS Product Configuration Software from www.epluse.com/configurator and

install it on the PC.

2. Connect the E+E device to the PC using the appropriate configuration cable.

3. Start the EE-PCS software.

4. Follow the instructions on the EE-PCS opening page for scanning the ports and identifying the

connected device.

5. Click on the desired setup or adjustment mode from the main EE-PCS menu on the left and follow

the online instructions of the EE-PCS.

Service interface connector

HA011066

4.2.2 RS485 Digital Interface settings

Hardware Bus Termination

The bus termination can be realised enabling the slide switch on board (120 Ohm resistor). Factory

setting disabled (see „Fig. 2 Design and components“, Digital version J3).

Address setting via Software

All DIP switches at position 0 → address has to be set via Software (via EE-

PCS Product Configuration Software or via protocol BACnet / Modbus).

Default address 43.

Example: Slave address is set via configuration software.

Address setting via Dip-Switch

Setting the DIP switches to any other address than 0, overrules the default

address (43) or the address set via Software.

Example: Slave address set to 3 (0000 0011 binary).

4.2.3 BACnet Protocol Settings

Baud rate As per type number ordered 9600, 19200, 38400, 57600, 76800, 115200

Data bits 8 8

Parity None None

Stop bits 1 1

Slave address 43 0…127

Tab. 8 BACnet Protocol settings

Factory settings Selectable values

User Manual EE600 Differential Pressure Sensor

The recommended settings for multiple devices in a BACnet MS/TP network are 38400, 8, None, 1.

The EE600 PICS (Product Implementation Conformance Statement) is available on the website at

www.epluse.com/EE600.

ID address, baud rate can be set via:

1. EE-PCS, Product Configuration Software and the USB configuration adapter cable code

HA011066. BACnet protocol, see the PICS.

9

Page 10

4.2.4 Modbus Protocol Settings

Baud rate As per type number ordered 9600, 19200, 38400, 57600, 76800, 115200

Data bits 8 8

Parity Even None, odd, even

Stop bits 1 1 or 2

Slave address 43 1…247

Tab. 9 Modbus Digital Settings

The recommended settings for multiple devices in a Modbus RTU network are 9600, 8, Even, 1.

ID address, baud rate, parity and stop bits can be set via:

1. EE-PCS, Product Configuration Software and the appropriate configuration cable.

2. Modbus protocol in the register 60001 (0x00) and 60002 (0x01). See Application Note Modbus

AN0103 (available on www.epluse.com/EE600).

The measured values are saved as a 32 bit float value and as 16 Bit signed integer, see the Modbus

Register map below.

The serial number as ASCII-code is located at read register address 30001-30008 (16 bit per address).

The firmware version is located at register address 30009 (bit 15...8 = major release; bit 7...0 = minor

release).

The sensor name is located at register address 30010.

Factory settings Selectable values

4.2.5 Modbus Register Map

FLOAT 32 bit

Measured value Unit Register number

Read register: function code 0x03 / 0x04

Differential pressure mm WC 1211 0x4BA

Differential pressure mbar 1213 0x4BC

Differential pressure Pa 1215 0x4BE

Differential pressure kPa 1217 0x4C0

Differential pressure inch WC 1219 0x4C2

Air velocity m/s 1041 0x410

Air velocity ft/min 1043 0x412

Volume flow m

Volume flow l/s 1057 0x420

Volume flow m

Volume flow ft

Filter monitoring % 1075 0x432

Level indicator cm 1077 0x434

Level indicator inch 1079 0x436

INTEGER 16 bit

Measured value Unit Scale

Read register: function code 0x03 / 0x04

Differential pressure mm WC 10 4106 0x1009

Differential pressure mbar 100 4107 0x100A

Differential pressure Pa 1 4108 0x100B

Differential pressure kPa 1000 4109 0x100C

Differential pressure inch WC 100 4110 0x100D

Air velocity m/s 100 4021 0xFB4

Air velocity ft/min 1 4022 0xFB5

Volume flow m

Volume flow l/s 1 4029 0xFBC

Volume flow m

Volume flow ft

Filter monitoring % 10 4038 0xFC5

Level indicator cm 10 4039 0xFC6

Level indicator inch 10 4040 0xFC7

1)

[DEC] Protocol Address 2) [HEX]

3

/h 1055 0x41E

3

/s 1059 0x422

3

/min 1181 0x49C

3)

3

/h 1 4028 0xFBB

3

/s 1000 4030 0xFBD

3

/min 1 4091 0xFFA

Register number1) [DEC] Protocol Address 2) [HEX]

10

User Manual EE600 Differential Pressure Sensor

Page 11

INTEGER 16 bit INFO (read register)

Parameter

name

Read and write register: function code 0x03 / 0x06 Read register: function code 0x03 / 0x04

4)

Slave-ID

modbus

address

Modbus

protocol settings

1)

Register number starts from 1

2)

Register address starts from 0

3)

100 is scale 1:100 (2550 is equivalent to 25.50)

4)

If the ID is set via DIP-switch the response will be NAK

5)

For Modbus protocol settings please see Application Note Modbus

AN0103 (available on www.epluse.com/EE600)

5)

4.2.6 Reading example

Example of MODBUS RTU command for reading the differential pressure (float value) Δp = 497,965972

Pa from the register 0x4BE:

Device EE600; slave ID 43 [2B in Hex]

Reference document, chapter 6.3: www.modbus.org/docs/Modbus_Application_Protocol_V1_1b.pdf

Request [Hex]: 2B 04 04 BE 00 02 17 15

Modbus ID

address

Request

[Hex]:

Register

number

1)

[Dec]

0001 0x00

Register

address2) [Hex]

Parameter

name

Serial number

(as ASCII)

Register

number1) [Dec]

0001 0x00

Register

address2) [Hex]

0002 0x01 Firmware version 0009 0x08

Sensor Name 0010 0x09

Function

code

Starting

address Hi

Status / Error

information

Starting

address Lo

No. of

register Hi

0602 0x259

No. of

register Lo

CRC

2B 04 04 BE 00 02 17 15

Response [Hex]: 2B 04 04 FB A5 43 F8 61 F3

Modbus ID

address

Response

[Hex]:

2B 04 04 FB A5 43 F8 61 F3

For decoding of float values (stored according standard IEEE754), please refer to AN0103, chapter 7

(available on www.epluse.com/EE600).

Example of decoding

Byte 1

(Register 2 - Hi)

43 F8 FB A5 497,965972

4.2.7 Application settings

Beside differential pressure measurement (Pa, kPa, mbar, mm WC, inch WC), the EE600 can be set up

for the following applications:

• volume flow (k-factor input)

• air velocity (k-factor input)

• filter monitoring

• level indication

Function

code

Response [Hex] Value in decimal

Byte 2

(Register 2 – Lo)

Byte

count

(Register 1 - Hi)

Register 1

value Hi

Byte 3

Register 1

value Lo

(Register 1 - Lo)

Register 2

value Hi

Byte 4

Register 2

value Lo

CRC

Using the EE-PCS Product Configuration Software and the USB configuration adapter (code

HA011066) the user can set the required parameters for each application.

With an optional display (ordering code D2) different units and limit bars can be set. Please see chapter

„7.2.2 Digital version“ for display settings.

User Manual EE600 Differential Pressure Sensor

11

Page 12

Volume flow measurement

By entering a k-factor under application settings, the EE600 is able to calculate the volume flow (q)

according to the formula:

q = volume flow [m3/h]

∆p = differential pressure [Pa]

k = k-factor

The k-factor is a characteristic theoretical parameter for each fan model, specified by the manufacturer

in the datasheet of the fan.

Note: If the data sheet of the fan manufacturer specifies a different method or unit of calculating the

volume flow, the k-factor must be converted accordingly to fit the above formula.

For example: If the k-factor (kspecific) in the data sheet of the fan manufacturer applies for volume

flow calculation in m³/s it has to be converted as follows:

Fig. 6 Application settings - volume flow rate measurement

The calculated volume flow (q) is available via BACnet or Modbus protocol in four different units: m3/h,

m3/s, ft3/min, l/s.

The default air density (ρ20) value at standard conditions is defined as follows:

Air density (ρ20): 1,204 kg/m3 @: T = 20 °C (68 °F), p = 1013 mbar (14,7 psi)

If the air density deviates from standard conditions, a compensation for the calculated volume flow is

necessary.

By entering the specific air density (ρ´) [kg/m3] at the operating point, the EE600 applies a compensation to the calculated volume flow (q´) according to the formula:

q’= volume flow at specific density [m3/h]

∆p = differential pressure [Pa]

k = k-factor

ρ´ = specific air density [kg/m3]

ρ20 = air density at 20 °C (68 °F) [kg/m3]

Air velocity measurement

By entering a k-factor and the dimensions of the duct (round or square), the EE600 is able to calculate

the air velocity (v) out of the volume flow (q) and the area of the duct.

12

v = air velocity [m/s]

q = volume flow [m3/h]

A = Area [m2]

User Manual EE600 Differential Pressure Sensor

Page 13

Details for k-factor see application settings for volume flow measurement.

Fig. 7 Application settings - Air velocity measurement

The calculated air velocity (v) is available via BACnet or Modbus protocol in two different units: m/s and

ft/min.

Details for setting air density (when deviating from default air density at standard conditions) see application settings for volume flow measurement.

Filter monitoring

By entering filter limits for differential pressure, the EE600 is able to calculate a contamination level for

the observed filter in order to plan for maintenance purposes.

Fig. 8 Application settings - Filter monitoring

For the given application setting (∆p change filter = 800 Pa, ∆p new filter = 100 Pa) a measured differential pressure at the filter of ∆p = 450 Pa, would mean a contamination level of 50 %:

The filter contamination level is available via BACnet or Modbus protocol expressed in percentage [%].

User Manual EE600 Differential Pressure Sensor

13

Page 14

Level indicator

By entering the density [kg/m3] of a fluid the EE600 can act as a level indicator. The differential pressure

level measurement uses the pressure values and the specific weight of the fluid to represent the level in

a tank (see „Fig. 14 Mounting examples“).

Fig. 9 Application settings - Level indicator

h = Level (cm)

∆p = Differential pressure (Pa)

ρ = Density of fluid (kg/m3)

g = Gravitational acceleration (9,81 m/s2)

By applying the positive pressure connection into the tank, the user can measure the height of the column of that fluid.

The level measurement is available via BACnet or Modbus protocol in two different units: cm and inch.

The maximum measurable level is limited by the highest differential pressure range 0…10000 Pa.

For example, for water with density 998 kg/m3, at 10000 Pa the maximum height is 102 cm (40 inch).

5 Installation

• Mount the EE600 onto a vertical, smooth surface.

• Important: The pressure connection nipples must point downwards.

• Avoid installation close to heaters and sources of strong electromagnetic interference.

• Insert the cable for supply voltage and output signal through the cable gland and connect it to the

spring terminals according to the wiring diagram („Fig. 3 Connection diagram“).

• Important: Make sure that the connecting cable or wires do not impact with the push buttons in order

to prevent unintentional trigger of the span or zero point adjustment.

• Close tightly the cable gland. This is essential for the compliance with the IP65 / NEMA4 protection

class of the EE600 enclosure.

14

Fig. 10 Mounting orientation

User Manual EE600 Differential Pressure Sensor

Page 15

5.1 Pressure connection

Ø16

Ø 7.3

Fig. 11 Pressure connection

Ø7

Ø 6.5

60∞

2x Ø2.2

80 18.5

Fig. 12 Dimension of pressure connection nipples

• Install first the pressure connection nipples (included in the scope of supply) onto the duct.

Use a Ø 7.5 mm drill.

• Connect the pressure hose (included in the scope of supply) first to the EE600 and then to the nipples

at the duct. Route the pressure hose for avoiding sharp bends which might lead to the hose

obstruction („Fig. 13 Pressure hose route“).

Fig. 13 Pressure hose route

Important: Make sure to connect the higher pressure at the “+” pressure connector and the lower

pressure at the “-“ pressure connector. Inverted connection leads to “out of range” information on the

optional display and at the analogue outputs, see „4.1.6 Outputs“ and „7.2.3 Out of range“.

User Manual EE600 Differential Pressure Sensor

15

Page 16

Fig. 14 Mounting examples

6 Maintenance and service

EE600 does not require any special maintenance, nevertheless it is recommended to perform a zero

point adjustment every 12 month. If needed, the enclosure may be cleaned and the device may be

re-adjusted as described below.

Level indication

h

6.1 Cleaning

Use a damp soft cloth to remove deposits of dust or dirt from the exterior of the device and from the

display. Do not attempt to clean the interior of the device. Do not use any solvents, alcohol or abrasive

cleaning agents.

6.2 Repairs

Repairs may be carried out by the manufacturer only. The attempt of unauthorised repair excludes any

warranty claims.

6.3 Readjustment of EE600

A periodical readjustment of EE600 might be required by the regulations of certain industries or by the

need of best long-term measurement accuracy. The zero point and the span point can be adjusted with

push buttons on the EE600 electronics board.

For adjustment the device must be powered and the enclosure cover removed. Consequently, the

adjustment may be performed by authorised staff only, observing the handling of electrical sensitive

devices (ESD).

6.3.1 Zero Point Adjustment

16

The zero point adjustment is used to correct an eventual zero point deviation.

a. Remove the tubes from both pressure connections of the EE600. By this the pressure equal on

both connections.

b. Press “zero point” button 1-2 sec. (see „3 Product Description“).

c. The successful zero point adjustment is confirmed by the green LED turning on for 2 seconds.

d. The red LED turning on for 2 seconds indicates that the zero point adjustment did not succeed. In

this case repeat b.

User Manual EE600 Differential Pressure Sensor

Page 17

e. The zero point adjustment (b.) may not succeed because of a deviation higher than 5 % of the

original full scale of the device. This is 50 Pa for the 0 – 1000 Pa range and 500 Pa from the 0 –

10000 Pa range. In such a case, the zero point adjustment can be forced by pressing and holding

the zero point button for min. 10 sec.

f. The successful zero point adjustment is confirmed by the green LED turning on for 2 seconds.

6.3.2 Span Point Adjustment

The span point adjustment is used to correct an eventual deviation of the span value.

Important:

Make sure to perform a zero point adjustment as above before any span point adjustment.

a. Connect the differential pressure reference device/calibrator to the EE600 and set it according to

the EE600 span value to be adjusted.

b. Note: The span value has to be set according to the selected measurement range.

Example:

Analogue version: (see „4.1.1 Select the measurement range with S1 and S2“, Tab. 1)

EE600-HV53A7, S1 = 0, S2 = 1, span value = 5000 Pa

Digital version: EE600-HV52J3, span value = 1000 Pa

EE600-HV53J3, span value = 10000 Pa

Observe the operation manual of the reference device.

c. Press the span point adjustment button (see „3 Product Description“).

d. The successful span point adjustment is confirmed by the green LED turning on for 2 seconds.

e. The red LED turning on for 2 seconds indicate that the span point adjustment did not succeed. In

this case repeat b.

f. The span point adjustment (b.) may not succeed because of a deviation higher than 5 % of the

original full scale of the device.

This is 50 Pa for the 0 – 1000 Pa range and 500 Pa from the 0 – 10000 Pa range. In such a case,

the set point adjustment can be forced by pressing and holding the span point button for 10 sec.

g. The successful span point adjustment is confirmed by the green LED turning on for 2 seconds.

6.3.3 Return to Factory Adjustment

a. Press and hold simultaneously both “zero” and “span” buttons for 5 sec.

b. The successful return to factory adjustment is confirmed by the green LED turning on for 2 seconds.

c. The red LED turning on for 2 seconds indicates that the return to factory adjustment

did not succeed. In this case repeat b.

Important:

Return to factory adjustment affects both zero and span.

User Manual EE600 Differential Pressure Sensor

17

Page 18

7 User Interface

9000

40.15 2.00

15.0

7.1 LED indication

Green LED

flashing (1 s interval) = EE600 operates normally, the

one flash (2 s) = confirms adjustment or return

off = no power supply or

7.2 Display

7.2.1 Analogue version

The display shows the measured differential pressure and the selected unit (see „4.1.3 Select the display unit with S5 and S6“).

Additionally, the bar graph indicates the actual pressure within the selected range (see „4.1.1 Select the

measurement range with S1 and S2“).

measured data is within the

selected measuring range

to factory settings

(see 6.3)

electronics failure

Red LED

flashing (1 s interval) = the measured data is out of

the selected range (overload

or reversed pressure

connection)

one flash (2 s) = indicates the failure of the

attempt to adjust zero point

or span point, or to return to

factory adjustment (see 6.3)

Fig. 15 Display units

7.2.2 Digital version

The factory setting of the display (if present) shows the measured differential pressure in Pascal [Pa].

Using the optional USB configuration adapter HA011066 and the EE-PCS Product Configuration

Software, the user can change the display layout and the visualised parameter according the selected

application:

Differential pressure measurement

Unit: Pa, kPa, mbar, mm H2O, inch WC,

Layout: one line with limit bar

Volume flow measurement

Unit: m3/h, m3/s, ft3/min, l/s

Layout: one line with limit bar or two lines (volume flow and differential pressure) without limit bar.

Air velocity measurement

Unit: m/s, ft/min

Layout: one line with limit bar or two lines (air velocity and differential pressure) without limit bar.

Filter monitoring

Unit: %

Layout: one line with limit bar or two lines (filter monitoring and differential pressure) without limit bar.

inch WCPa

mbar

kPa

18

User Manual EE600 Differential Pressure Sensor

Page 19

Level indicator

-5 % of span

+5 % of span

Unit: cm, inch

Layout: one line with limit bar or two lines (level indicator and differential pressure) without limit bar.

Examples of display visualisation

15.0

Fig. 16 Display with one line with limit bar and two lines without limit bar

7.2.3 Out of range

In case of differential pressure out of the measuring range or negative pressure due to inverse pressure

connection the display indicates:

mbar

919.0

Pa

7580

m³/h

out of range

Δp < scale value low,

Fig. 17 Out of ranges indication

out of range

Δp > scale value high,

User Manual EE600 Differential Pressure Sensor

19

Page 20

8 Technical Data

Measured Value

Differential Pressure (Δp)

Measurement principle Piezoresistive, no flow-through

Accuracy at 20 °C

(incl. hysteresis, non-linearity and repeatability)

Response time t

Analogue outputs 50 ms / 500 ms / 2 s / 4s selectable with DIP switches

RS485 selectable in the range from 0.5 to 30 s using EE-PCS

Temperature dependency typ. < 0.03 % from FS/K

Long-term stability < 0.5 % from FS/year

Overload limits

0...1000 Pa

0...10000 Pa (40 inch WC) ± 80000 Pa (± 320 inch WC)

Outputs

Analogue outputs3) 0-5 V or 0-10 V -1 mA < I

selectable with and

DIP switches

Measurement range I: 0...250 / 500 / 750 / 1000 Pa (0...1 / 2 / 3 / 4 inch WC)

selectable with DIP switches

Digital interface RS485 (EE600 = 1/2 unit load)

Protocol Modbus RTU or BACnet MS/TP

General

Power supply 15-35 V DC or 24 V AC ±20 %

Current consumption, typ. at 0 Pa / 24 V DC

Analogue outputs RS485

without display 23 mA 8 mA

with display and backlight 49 mA 29 mA

Display Graphic, with backlight

Display units Pa, mbar, inch WC, kPa

Analogue outputs selectable with DIP switches

RS485 configurable using EE-PCS

Connection

Analogue outputs spring terminals, max. 1.5 mm

RS485 screw terminals, max. 2.5 mm2 (AWG14)

(68 °F) ± 0.5 % FS FS = full scale (1000 Pa or 10000 Pa)

90

(4 inch WC) ± 10000 Pa (± 40 inch WC)

1)

0-20 mA or 4-20 mA (3-wire) R

1)

2)

< 1 mA IL = load current

L

≤ 500 Ohm RL = load resistor

L

1)

II: 0...2500 / 5000 / 7500 / 10000 Pa (0...10 / 20 / 30 / 40 inch WC)

1)

2)

2

(AWG16)

1) Factory setup analogue outputs: measurement range 0...100 % FS; response time t90: 50 ms; display unit: Pa; display backlight: on; analogue outputs: 0-10 V and 4-20

mA. Other ranges upon request.

2) Factory setup RS485: response time t90: 500 ms; display unit: Pa; display backlight: on

3) Voltage and current output signals available simultaneously at the spring loaded terminals.

20

User Manual EE600 Differential Pressure Sensor

Page 21

HEADQUARTERS

E+E Elektronik Ges.m.b.H.

Langwiesen 7

A-4209 Engerwitzdorf

Austria

Tel: +43 7235 605 0

Fax: +43 7235 605 8

info@epluse.com

www.epluse.com

SUBSIDIARIES

E+E Elektronik Germany

info@epluse.de

Office Bad Homburg

Tel: +49 6172 13881-0

Office Hamburg

Tel: +49 160 9050 6460

Office Stuttgart

Tel: +49 151 538 37 500

E+E Elektronik Italy

info@epluse.it

Tel: +39 02 2707 86 36

E+E Elektronik France

info@epluse.fr

Tel: +33 4 74 72 35 82

E+E Elektronik USA

office@epluse.com

Office Boston

Tel: ++1 847 490 0520

Office Chicago

Tel: +1 847 490 0520

E+E Elektronik Korea

Tel: +82 31 732 6050

info@epluse.co.kr

E+E Elektronik China

info@epluse.cn

Office Beijing

Tel: +86 10 8499 2361

Office Shanghai

Tel: +86 21 6117 6129

Office Guangzhou

Tel: +86 20 3898 7052

Loading...

Loading...