Page 1

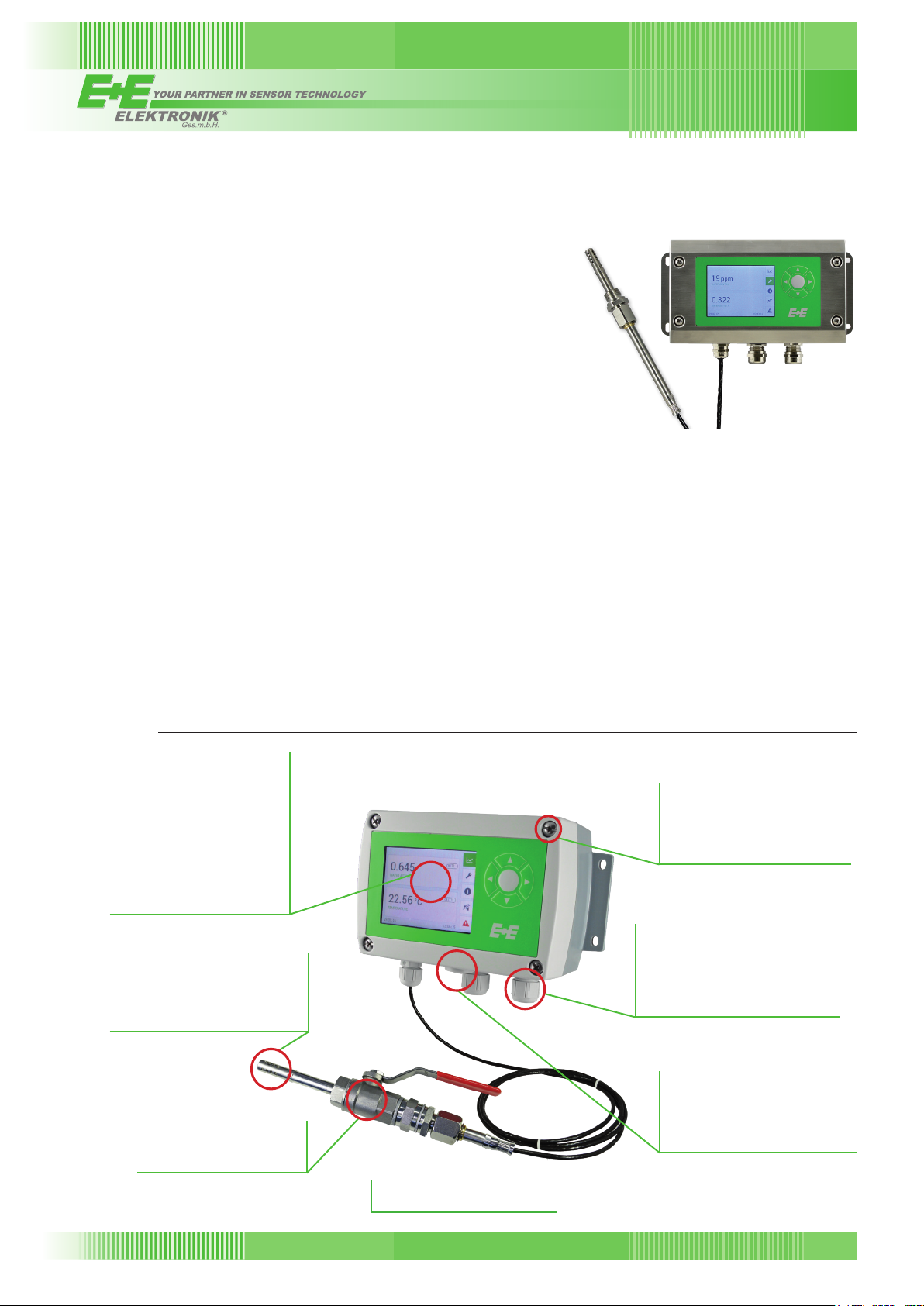

EE360

High-End

Moisture in Oil Sensor

EE360 is dedicated for reliable monitoring of lubrication, hydraulic

and insulation oils as well as diesel fuel. In addition to highly accurate

measurement of water activity (aw) and temperature (T), EE360 calculates

the absolute water content (x) in ppm.

Measurement Performance

The EE360 employs high-end E+E humidity sensing elements

manufactured in state-of-the-art thin lm technology, which are the

prerequisite for outstanding measurement accuracy.

Process Connection

The sensing probe can be employed up to 180 °C (356 °F),

20 bar (290 psi) and is available with either ISO or NPT slide tting, which

allows for variable immersion depth. Using the optional ball valve, the

probe can be mounted or removed even without process interruption.

Enclosure

The EE360 features an IP65 / NEMA 4 polycarbonate or stainless steel enclosure which facilitates installation and

maintenance. The enclosure can accommodate a 100…240 V AC supply unit or various extension modules.

Display and Outputs

The measured data is available on two analogue outputs, on the RS485 (Modbus RTU) or Ethernet-PoE (Modbus TCP)

interface and on the alarm (relay) outputs.

The TFT colour display shows simultaneously up to four measurands and offers extensive setup and diagnosis features.

The data logging function saves up to 20 000 measured values for each physical quantity. The logged data can be displayed

graphically directly on the device or easily downloaded over the USB interface.

Congurable and Adjustable

The conguration and adjustment of the EE360 can be performed either using the display and the push buttons or with the

free EE-PCS Product Conguration Software via the USB interface.

Features

3.5“ TFT Colour Display

» shows up to 4 measurands

simultaneously

» layout and measurands

freely selectable

» data logger for 20 000 values

per measurand

» logged data shown graphically

» diagnosis functions

» intuitive device setup with push

buttons

Probe

» oil temperature -40...180 °C (356 °F)

» pressure tight up to 20 bar (290 psi)

» ISO or NPT process connection

» pluggable probe option

Ball valve set

» probe mounting and removal

without process interruption

130

Inspection certicate

according to DIN EN 10204 – 3.1

v2.2 / Modification rights reserved

Enclosure

» IP65 / NEMA 4 protection class

» polycarbonate or stainless steel

» easy mounting and service

» screws secured in cover

Outputs

» 2 analogue outputs current / voltage

» error indication according NAMUR

» Modbus RTU / Modbus TCP

» 2 alarm outputs

» congurable via display or software

USB Service Interface

» download logged data

» perform conguration, adjustment

and rmware update

» 4 status LEDs

EE360

EE360

Page 2

Measurement of water activity aw / water content x

The moisture in oil can be expressed in absolute or relative terms.

» Water activity aw is the relative measure for moisture in oil. It represents the ratio between the actual amount of

dissolved water and the maximum possible amount of dissolved water in the oil at a certain temperature. Independently

of the oil type, the water activity shows how close to saturation is the oil at any moment in time.

aw = 0 indicates completely dry oil, while aw = 1 fully saturated oil.

EE360 measures directly the water activity.

» The water content x is an absolute measure equal to the amount of water in the oil. The water content is measured

in ppm (parts per million) and is independent from the oil temperature. For assessing how far is the oil from saturation,

x must be regarded together with T.

EE360 calculates x out of the measured aw and T values. The calculation is oil dependent and requires a set of oil

specic parameters.

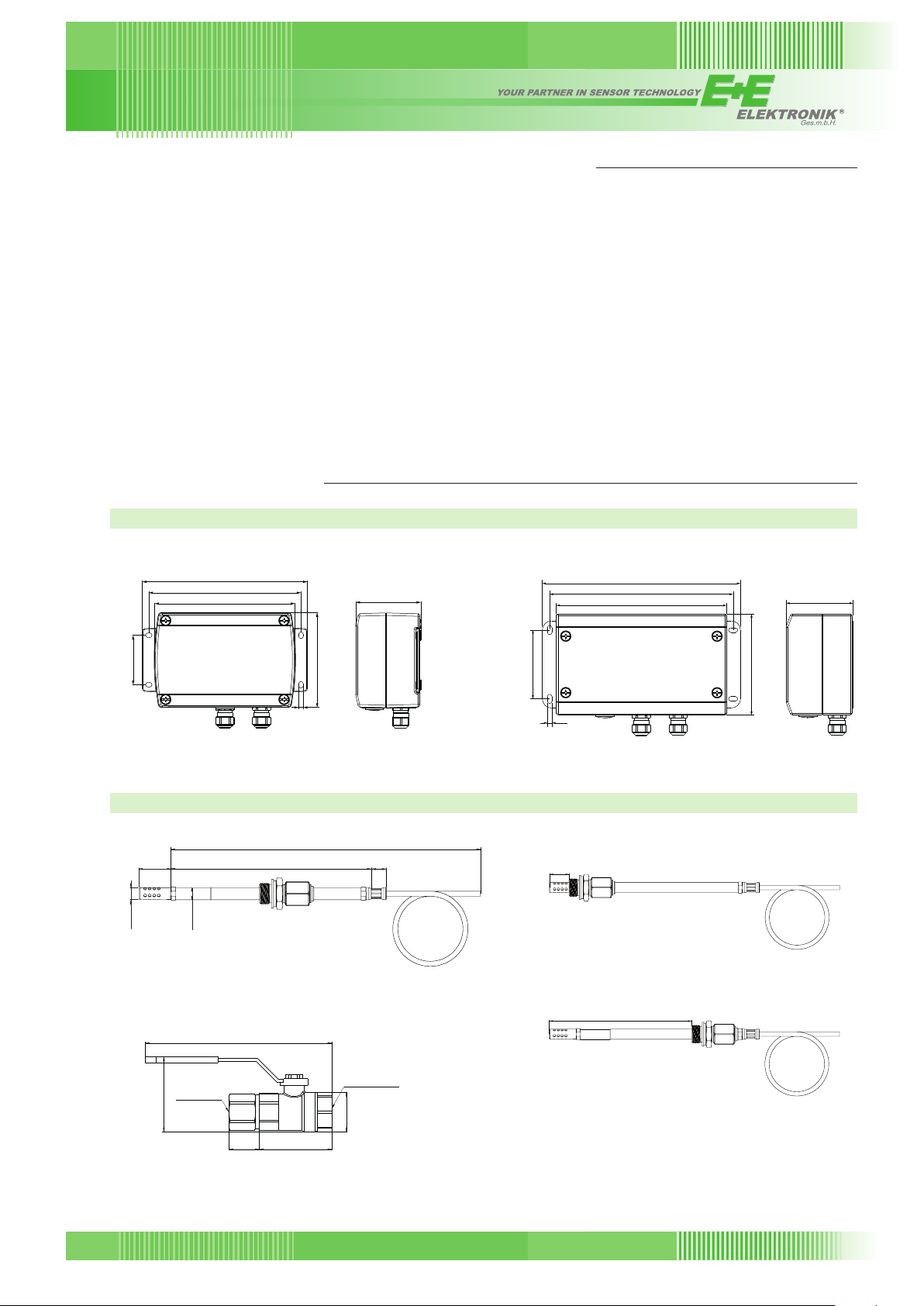

Dimensions in mm (inch)

ENCLOSURE

Polycarbonate

180 (7.09“)

166 (6.54“)

153 (6.02“)

54 (2.13“)

5.1

(0.20“)

PROBE

code “cable length”

32

(1.3”)

∅13

(0.51”)

1) Refer to ordering guide

code “probe length”

∅12

(0.47”)

Ball valve set 1/2” ISO or NPT

155 (6.1”)

1)

104 (4.09“)

71

(2.80“)

1)

15 (0.59”)

Stainless steel

218 (8.58“)

200 (7.87“)

186 (7.32“)

75 (2.95“)

5.1

(0.20“)

Minimum insertion depth

23 (1”)

23 (1”)

Maximum insertion depth

64 mm (2.5”) for 100 mm (3.94“) probe

164 mm (6.5”) for 200 mm (7.87“) probe

364 mm (14.3”) for 400 mm (15.75“) probe

110 (4.33“)

73

(2.87“)

EE360

1/2” ISO or

1/2” NPT

63 (2.48”)

60 (2.36”)25

(0.98”)

v2.2 / Modification rights reserved

1/2” ISO or

1/2” NPT

∅33

(1.30”)

131

Page 3

Technical data

Measurands

Water activity (aw) / Water content (x)

Measuring range 0...1 aw / 0...100,000 ppm

Accuracy

-15...40 °C

2)

(5...104 °F) ≤0.9 a

w

-15...40 °C (5...104 °F) >0.9 aw ± 0.023 a

-25...70 °C (-13...158 °F) ± (0.014 + 1%*mv) a

-40...180 °C

(-40...356 °F) ± (0.015 + 1.5%*mv) a

Temperature dependence of electronics, typ. ± 0.0001 [1/°C] (typ. ± 5.6 * 10

Temperature dependence of sensing probe, typ. ± (0.00002 + 0.0002 x aw) x

Response time at 20 °C

(68 °F) / t

, typ. 10 min in still oil

90

Temperature (T)

Working range sensing probe -40...180 °C (-40...356 °F)

Accuracy 2)

Temperature dependence of electronics, typ. ± 0.005°C/°C

Outputs

Two analogue outputs 0 - 1 / 5 / 10 V -1 mA < IL < 1 mA

freely selectable and scalable 4 - 20 mA 3-wire R

0 - 20 mA 3-wire R

Digital interface / protocol RS485 / Modbus RTU, max. 32 unit load devices on one bus

Ethernet-PoE with Modbus TCP

1)

± (0.013 + 0.3%*mv) a

w

± Δ °C

(EE360 = 1 unit load; factory settings: 9600 bps, parity even, stop bit 1 / slave-ID 231)

w

w

w

-5

[1/°F])

∆T [°C] ∆T = T - 20 °C

< 500 Ohm

L

< 500 Ohm

L

mv = measured value

°C

General

Power supply class III (EU) / class 2 (NA) 8...35 V DC 12...30 V AC

100...240 V AC, 50/60 Hz

Current consumption at 24 V DC/AC, typ. 15 mA / 40 mA

35 mA / 100 mA

50 mA / 150 mA

30 mA / 90 mA

Pressure range for pressure tight probe 0.01...20 bar

Probe material stainless steel 1.4404 / AISI 316L

Enclosure material polycarbonate, UL94-V0 approved

stainless steel 1.4404 / AISI 316 L

Protection class IP65 / NEMA 4

Cable glands for polycarbonate enclosure M16 x 1.5, for cable Ø 3 - 7 mm

for metal enclosure M16 x 1.5, for cable Ø 4.5 - 10 mm (0.18 - 0.39”)

Electrical connection

screw terminals max. 1.5 mm² (AWG 16)

Working and storage temperature range -40...60 °C (-40...140 °F) without display

of electronics -20...50 °C

Electromagnetic compatibility EN61326-1 EN61326-2-3 ICES-003 ClassA

Industrial Environment FCC Part15 ClassA

Two alarm outputs

3)

changeover contact

250 V AC / 6 A 28 V DC / 6 A

System requirements for EE-PCS software Windows XP or higher; USB port

1) ppm output is valid in the range 0...100 °C (32...212 °F)

2) Including hysteresis, non-linearity and repeatability, traceable to intern. standards, administrated by NIST, PTB, BEV...

3) Appropriate for outdoor use, wet location, degree of pollution 2, overvoltage category II, altitude up to 3000 m (9843 ft).

The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation).

The accuracy was calculated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

for 2 voltage outputs

rms

for 2 current outputs

rms

additional for display

rms

additional for Ethernet

rms

(0.15...300 psi)

(-4...122 °F) with display

(0.12 - 0.28”)

132

v2.2 / Modification rights reserved

EE360

Page 4

Ordering Guide

Enclosure

Cable length

(incl. probe length)

Probe length

Process connection

Electrical connection

Hardware Configuration

Optional features

Output 1

Output signal 1

Scaling 1 low

Scaling 1 high

Output 2

Setup - Analogue outputs

Output signal 2

Scaling 2 low value SBLvalue

Scaling 2 high value SBHvalue

1) Only with polycar bonate enclos ure. 2) No combination of alarm output (AM2), Ethernet module (J4) and integrated power supply (AM3) is possible.

3) Integrated power supply includes 2 plugs for power supply and outputs, other plug options are not possible. 4) Both analogue ou tputs shall b e either volt age or curren t.

4)

4)

polycarbonate no code

stainless steel HS2

(6.6 ft) no code

2 m

(16.4 ft) K5

5 m

(32.8 ft) K10

10 m

(3.94“) L100

100 mm

(7.87“) no code

200 mm

(15.75) L400

400 mm

1/2" ISO thread no code

1/2” NPT thread PA25

cable glands no code

1 plug for power supply and outputs E4

1 cable gland / 1 plug for Modbus RTU (requires option J3) E5

2 plugs for power supply / outputs and for Modbus RTU (requires option J3) E6

3 plugs for power supply / outputs and Modbus RTU (requires option J3)

3.5“ TFT display with integrated data logger D2

RS485 module - Modbus RTU J3

Ethernet module - Modbus TCP

pluggable probe

alarm outputs with cable glands

integrated power supply 100...240 V AC, 50/60 Hz

water activity a

other measurand (xx see measurand code below) MAxx

0-1 V GA1

0-5 V GA2

0-10 V GA3

0-20 mA GA5

4-20 mA GA6

0 no code

value SALvalue

1 no code

value SAHvalue

temperature T [°C] no code

other measurand (xx see measurand code below) MBxx

0-1 V GB1

0-5 V GB2

0-10 V GB3

0-20 mA GB5

4-20 mA GB6

1)

[ ] no code

w

1) 2)

2)

2) 3)

1)

EE360-

E12

J4

PC4

AM2

AM3

Measurand Code for output 1 and 2 in the ordering guide

Temperature

Water activity aw 67

Water content x in mineral transformer oil ppm 70

Water content x in customer specific oil ppm 70PPMxxx

°C 1

°F 2

Mx

Order Example

EE360-D2J3GA3GB3SBL-40SBH180

Enclosure: no code polycarbonate

Cable length: no code 2 m

(6.6 ft)

Probe length: no code 200 mm (7.87“)

Process connection: no code 1/2“ ISO thread

Electrical connection: no code cable glands

Optional features: D2 3.5“ TFT display with

integrated data logger

J3 RS485 module - Modbus RTU

Output 1: no code water activity

Output signal 1: GA3 0-10 V

Scaling 1 low: no code 0

Scaling 1 high: no code 1

Output 2: no code temperature °C

Output signal 2: GB3 0-10 V

Scaling 2 low: SBL-40 -40

Scaling 2 high: SBH180 180

Accessories (for further information, see data sheet "Accessories")

Bracket for installation onto mounting rails HA010203 (Two pieces for each EE360; for polycarbonate enclosure only)

Determination of oil specific parameters ppm-cal

Humidity calibration kit refer to data sheet „Humidity calibration kit“

Ball valve set 1/2“ ISO HA050101

Ball valve set 1/2“ NPT HA050104

EE360

v2.2 / Modification rights reserved

133

Loading...

Loading...