Page 1

Series EE33

HUMIDITY/TEMPERATURE

TRANSMITTER

BA_EE33_e // v15 // technical data are subject to change // 193359

MANUAL

Hardware and Software

Page 2

E+E Elektronik Ges.m.b.H. doesn't accept warranty and liability claims neither upon this publication nor in case of improper treatment

of the described products.

The document may contain technical inaccuracies and typographical errors. The content will be revised on a regular basis. These

changes will be implemented in later versions. The described products can be improved and changed at any time without prior notice.

© Copyright E+E Elektronik Ges.m.b.H.

All rights reserved.

EMC note USA (FCC):

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

EMC note Canada (ICES-003):

CAN ICES-3 (A) / NMB-3 (A)

Page 3

HARDWARE

TABLE OF CONTENTS

1. GENERAL 4

1.1 Symbol assertion 4

1.2 Safety instructions 4

1.3 Environmental information 4

2. PRODUCT DESCRIPTION 5

2.1 Operating modes and conditions 5

2.2 Survey: Model / Environmental Condition / Operating mode 6

2.3 Product features EE33 6

3. MOUNTING / INSTALLATION 7

3.1 Model C (remote sensing probe up to 120°C (248°F)) 7

3.2 Model D (remote sensing probe) 8

3.3 Model E (remote sensing probe, pressure tight up to 20bar (300psi)) 9

3.4 Model I (remote sensing probe, pressure tight up to 100bar (1450psi)) 10

3.5 Model J (2 remote sensing probes, pressure tight up to 20bar (300psi)) 11

3.6 Model K (remote sensing probe, pressure tight up to 20bar (300psi)) 12

4. ELECTRICAL CONNECTIONS 13

4.1 Connection diagram 13

4.2 Connection diagram alarm module (option) 13

4.3 Connection configuration of bottom part of the housing with plug connections

8...35V DC; 12...30V AC (option C03/C07/C08) 13

4.4 Connection configuration of bottom part of the housing with integrated power supply

100...240V AC (option V01) 13

4.5 Connection configuration of connectable sensing probe (option P03) 14

5. OPERATING COMPONENTS 14

5.1 Circuit board 14

5.2 Display module (option) 15

CONFIGURATION

SOFTWARE

6. OPTIONAL MODULES (alarm module, integrated power supply, ethernet module, ARC-Module) 16

7. HUMIDITY/TEMPERATURE CALIBRATION 18

7.1 2-point humidity calibration 18

7.2 2-point temperature calibration 19

7.3 1-point humidity calibration 21

7.4 1-point temperature calibration 22

7.5 Resetting to factory calibration 23

7.6 Adjustment/Calibration EE33 model J with HUMOR 20 24

8. MAINTENANCE 25

8.1 Sensor cleaning 25

8.2 Automatic ReCover (ARC) 25

8.3 Fuse replacement 25

8.4 Self-diagnosis and error messages 26

9. NETWORK 27

9.1 RS485 network (option) 27

9.2 Ethernet - module (option) 29

10. SCOPE OF SUPPLY 33

11. REPLACEMENT PARTS / ACCESSORIES 33

12. TECHNICAL DATA 34

1. GENERAL INFORMATION 37

2. INSTALLATION 37

3. ICONS ON THE TOOLS BAR 38

3.1 File 38

3.2 Interface 38

3.3 Group 39

3.4 Transmitter 39

3.5 Information ? 40

4. ICON LIST 41

5. INDEX - INDEX CARDS 41

5.1 Analogue 41

5.2 Relay 42

5.3 Sensor / Probe replacement 43

5.4 Calibration 43

5.5 Parameter 45

5.6 Information 47

6. OVERVIEW 47

6.1 How to set-up a new transmitter? 47

6.2 How to read the configuration of a transmitter? 47

6.3 How to save the configuration in a transmitter? 47

Page 4

1. GENERAL

The manual is a part of the scope of supply and serves to ensure proper handling and

optimum functioning of the instrument. For this reason, the manual must be read before

start-up.

In addition, the manual is for all personnel who require knowledge concerning transport,

setup, operation, maintenance and repair.

The manual must not be used for the purpose of competition without a written consent

from E+E Elektronik

are permitted. All information, technical data and illustrations contained in these instructions are

based on information available at the time of publication.

1.1 Symbol assertion

This symbol indicates a safety instruction.

These safety instructions should always be followed carefully. By not following these

instructions injuries of persons or material damage could happen. Therefore

E+E Elektronik

This symbol indicates a note.

These notes should be observed to achieve optimum functioning of the equipment.

®

does not accept liability.

®

and must also not be forwarded to third parties. Copies for personal use

1.2 Safety instructions

General Safety Instructions

Excessive mechanical loads and incorrect usage should always be avoided.

•

• Take care when unscrewing the filter cap as the sensor element could be damaged.

• The sensor is an Electro Static Discharge sensitive component (ESD). When touching

the sensor element, ESD protective measures should be followed.

• Grip sensors only at the lead wires.

• Installation, electrical connection, maintenance and commissioning should be performed

by qualified personnel only.

• The devices are constructed for the operation of separated extra-low voltage (SELV).

Safety instructions for use of the alarm module with voltages >50V

To insulate the optional alarm module from the low-voltage side of the transmitter, the

•

partition provided for this purpose must be fitted in the lower section.

• During operation of the instrument the modular housing must be completely closed.

• The protection class of an opened housing corresponds to IP00 and direct contact

with components carrying dangerous voltages is therefore possible. In general, work on live

components should be avoided and when absolutely necessary, should be performed by

qualified personnel only.

Safety instructions for use of the integrated power supply (option V01)

During operation of the instrument the modular housing must be completely closed.

•

• The protection class of an opened housing corresponds to IP00. In general, work on live

components should be avoided and when absolutely necessary, should be performed by

qualified personnel only.

• The bottom part and the middle part of the housing must be grounded during operation.

1.3 Environmental aspects

Equipment from E+E Elektronik® is developed with due consideration to all resultant

environmental issues. When you dispose the equipment you should avoid environmental

pollution.

For disposal of the transmitter the individual components must be sorted with care. The

housing consists of recyclable metal (aluminium, Al Si 9 Cu 3). The electronics must be

collected as electronic scrap and disposed of according to the regulations in force.

Hardware

4

Page 5

2. PRODUCT DESCRIPTION

The EE33 series provides all the functions of a multifunctional humidity/temperature transmitter with one major difference - it is equipped with a heated measurement cell.

The heated measurement cell contains a combined (monolithic) humidity/temperature

sensor element and enables reliable long-term measurements in extremely humid or

chemically polluted environments.

With a special high-pressure probe the transmitter can be used at process pressures up

to 100bar (1450psi).

The operating modes of the heated measurement cell depend on the conditions. The

parameters of the different operating modes are as follows:

Heat intensity:

Automatic recover: The measurement cell can be heated intensively to evaporate chemical

residue or temporary condensation.

Warming: The measurement cell can be warmed slightly to prevent condensation

in environments with continuous high humidity.

Heating time:

The measurement cell can either be heated briefly (the heating time can be defined in the

configuration software) before returning to the ambient temperature or it can be warmed

continuously.

Start of heating:

Manual: Heating is started by a control element on the PCB.

Automatic: Heating is triggered when a defined humidity set point is exceeded

(configuration software).

Recurrent: Heating is recurrent and triggered after a defined cycle time (configuration

software).

Distinctive models, sensing probes and mounting versions allow for the EE33 series to be

utilized in numerous applications.

2.1 Operating modes and conditions

2.1.1 Automatic ReCover (ARC)

Chemical pollution:

When capacitive humidity sensors are exposed to chemical pollution (e.g. detergent

residue), the presence of foreign molecules can distort the measurement reading.

The foreign molecules can be evaporated by heating the measurement cell briefly and

intensively. Reconditioning helps to minimize distorted measurement readings during the

calibration interval.

Temporary condensation:

Temporary dew (e.g. in misty environments) is identified by defining a humidity set point

value (e.g. 99%) and can be evaporated by heating the measurement cell intensively for

10 seconds.

Thanks to its monolithic structure, the measurement cell cools off quickly (approx.

3 minutes) to reach once again the same humidity content as the environment.

If condensation is still detected at the end of the heating and cool-down times, the process

starts again after a defined cycle time (30 minutes).

Hardware

5

Page 6

2.1.2 Overheating / Warming (OH = Overheating)

Continuous high humidity:

Even the smallest deviation between the temperature of the sensor head and the ambient

temperature can cause dew on the sensor element in conditions of continuous high

humidity (e.g. in mushroom drying). Dew on the humidity sensor element prevents

accurate measurement of the actual humidity.

However, the EE33 series minimizes the relative humidity on the measurement cell

through regularly warming. The relative humidity and temperature of the warmed

measurement cell can be determined precisely thanks to its monolithic structure. The dew

point of the environment is calculated from the measuring values.

If the relative humidity has to be determined near condensation, the ambient

temperature can be measured with an additional temperature sensor to calculate

the relative humidity.

2.1.3 High process pressure up to 100 bar (1450psi) / high-pressure probe

(HPP = High Pressure Probe)

Thanks to the combination of the heated measurement cell with a new high-pressure

probe, the transmitter can be used in applications with high process pressure and wide

working range in humidity and temperature.

The special high-pressure probe's innovative pressure tight feed through sets it apart from

the remote probes in other models.

Special ball valves enable assembly without interrupting the process and are available on request.

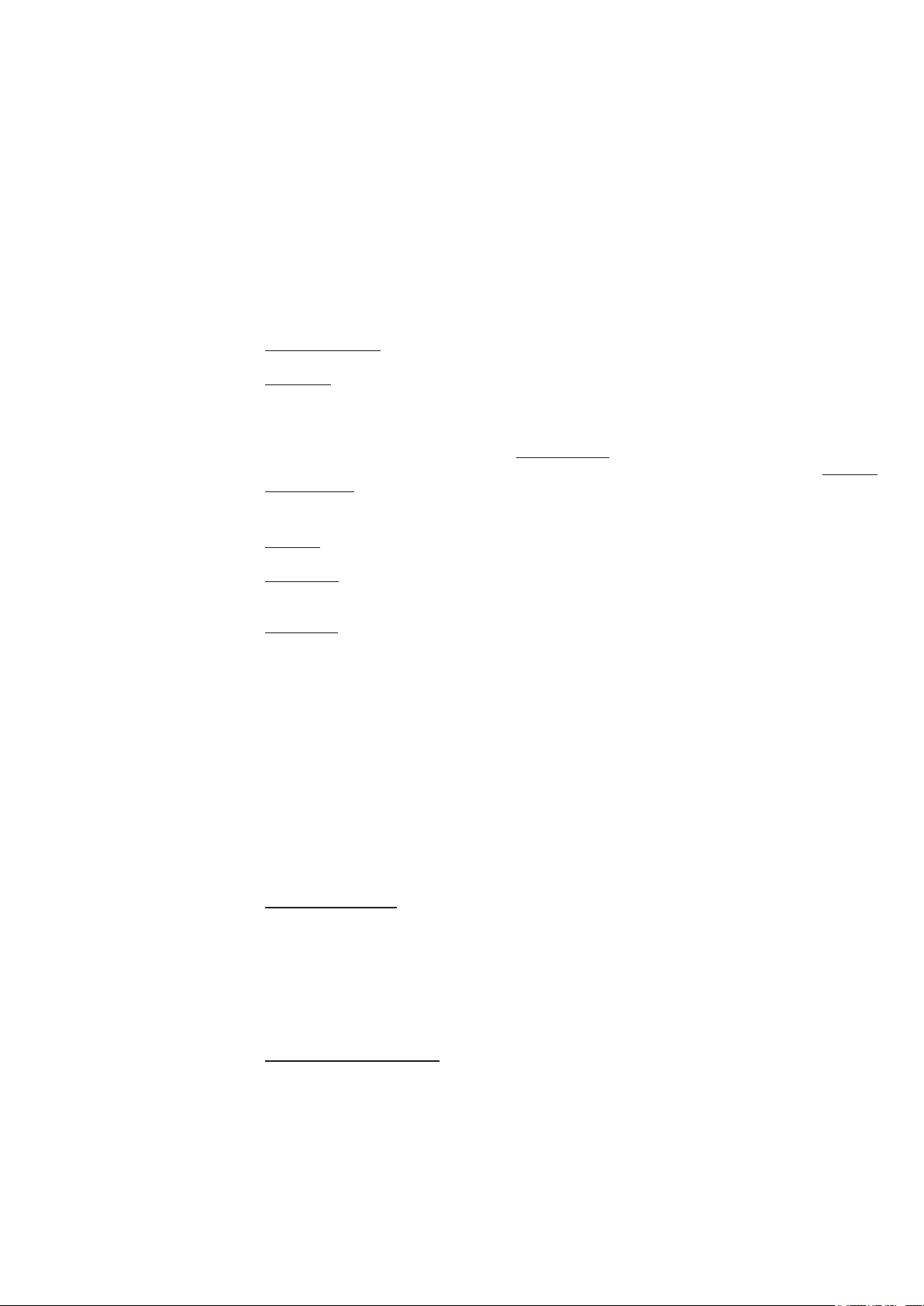

2.2 Survey: Model / Environmental Condition / Operating mode

Order Code Model Environmental Conditions ARC OH HPP

EE33-MFTC remote sensing probe

(up to 120°C

(248°F))

temporary condensation, chemical pollution

EE33-MFTD remote sensing probe temporary condensation, chemical pollution

EE33-MFTE pressure tight probe temporary condensation, chemical pollution,

process pressure up to 20bar

(300psi)

EE33-MFTI high pressure probe temporary condensation, chemical pollution,

(1450psi)

(300psi)

EE33-MFTJ 2 remote sensing

probes

process pressure up to 100bar

continuous high humidity,

condensation (RH-measurement),

process pressure up to 20bar

EE33-MFTK remote sensing probe continuous high humidity,

condensation (Td-measurement),

(300psi)

EE33-PFTM 2 remote sensing

probes

process pressure up to 20bar

continuous high humidity,

condensation (RH-measurement),

2.3 Product features EE33

Functions Comment EE33

Measurement of humidity and temperature

Calculation h, r, dv, Tw, Td, Tf, e

2 freely scaleable and configurable analogue outputs

On-site adjustment for relative humidity and temperature

LED indication of transmitter status / error diagnosis of probes

RS232 for transmitter configuration via PC

Configuration software standard supply

Alternating display with MIN/MAX indication optional

2 freely configurable alarm outputs optional

Connectable sensing probe optional

Data output via RS232 interface

Data output via RS485 interface optional

RS485 für Vernetzung von bis zu 32 Geräten optional

Ethernet interface for networking and remote monitoring optional

Data logging and analysis PC software optional

ARC-Module for external triggering of sensor-heating optional

Hardware

6

Page 7

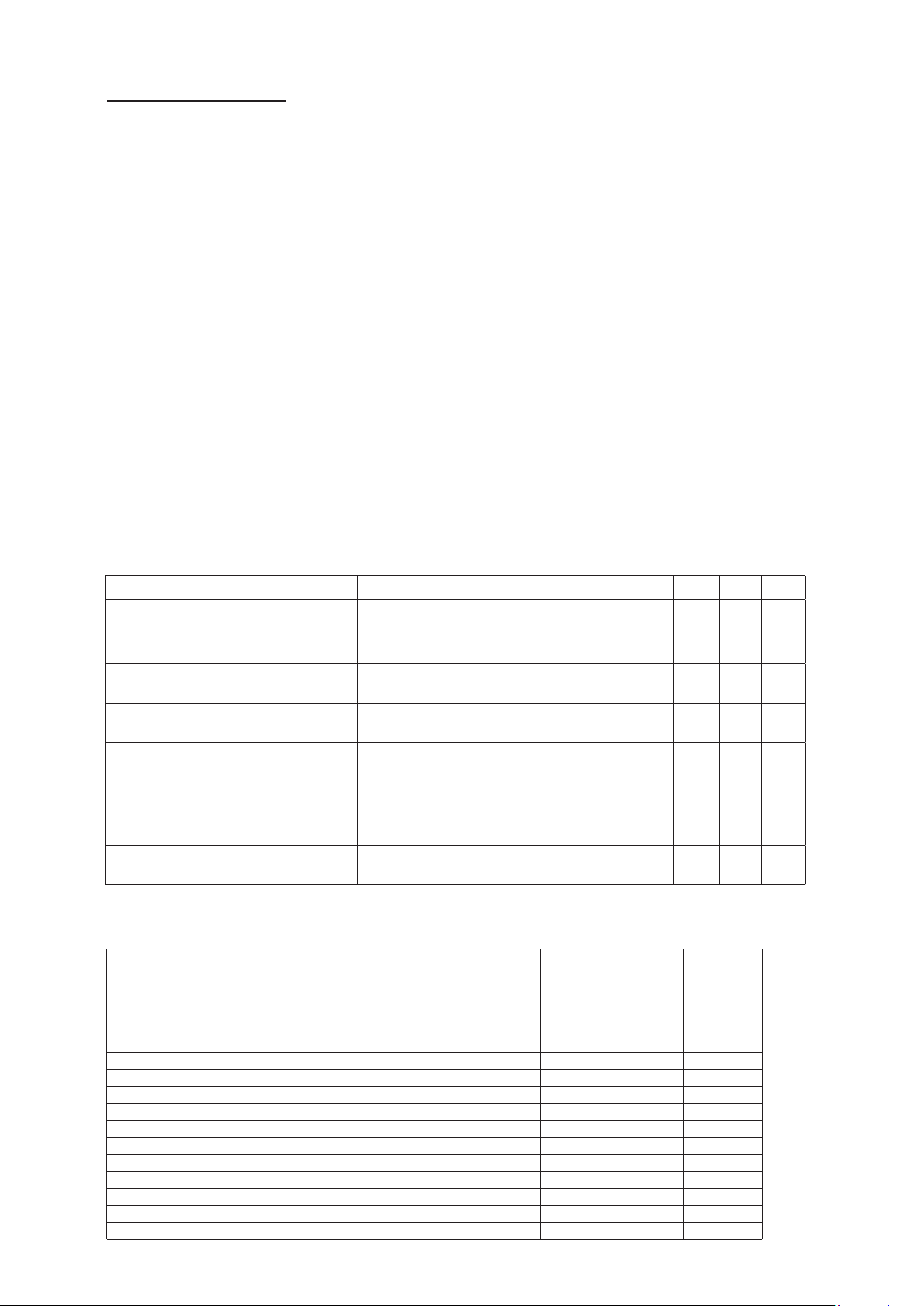

3. MOUNTING / INSTALLATION

Drilling with round hole:

150 (6”)

Ø4.2 (0.16”)

DRILLING / MOUNTING TEMPLATE:

Drill the mounting holes (with round hole or long hole)

according to the mounting template.

57 (2.24”)

Drilling with long hole:

148 (5.8”)

55 (2.16”)

4.5 (0.18”)

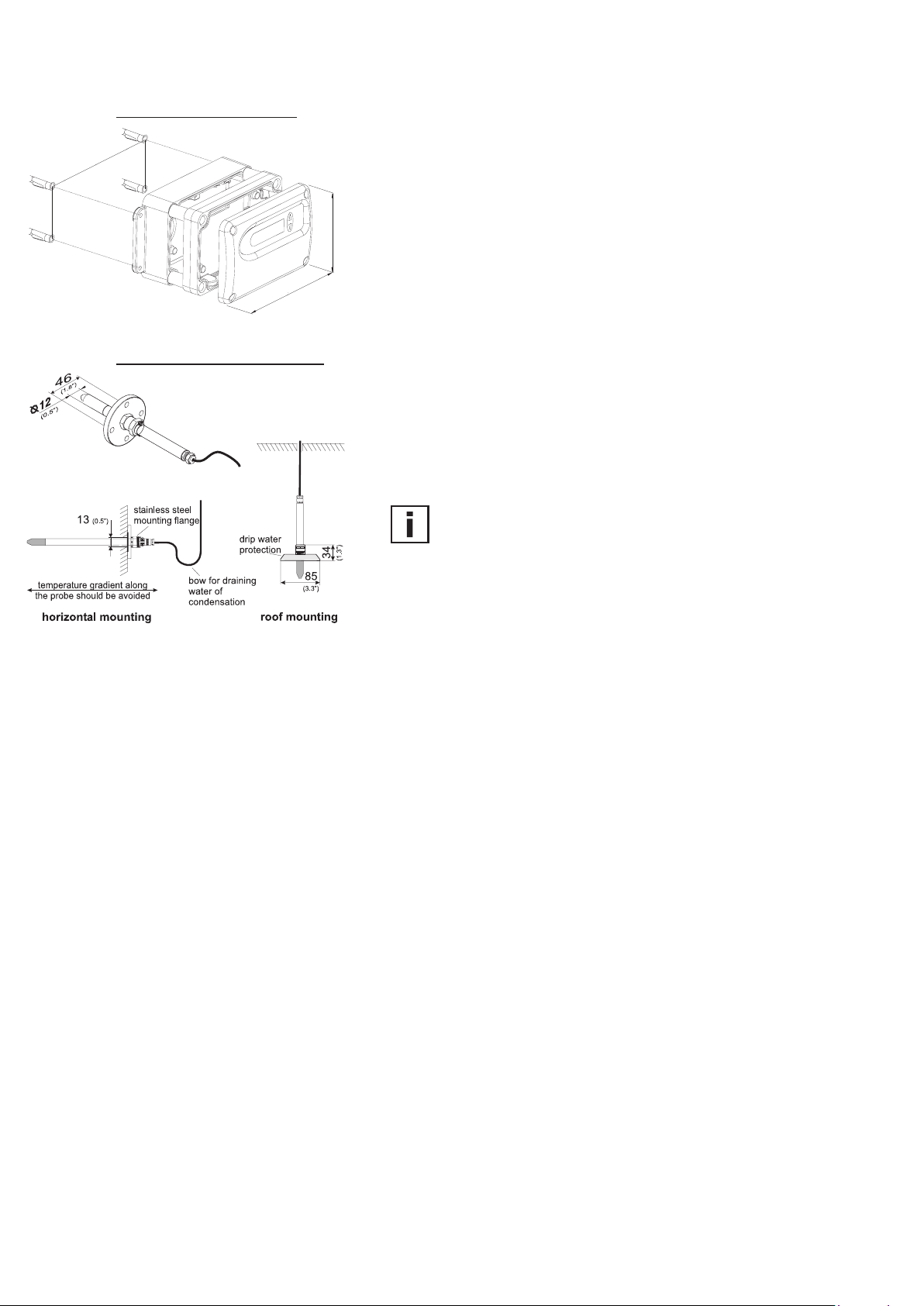

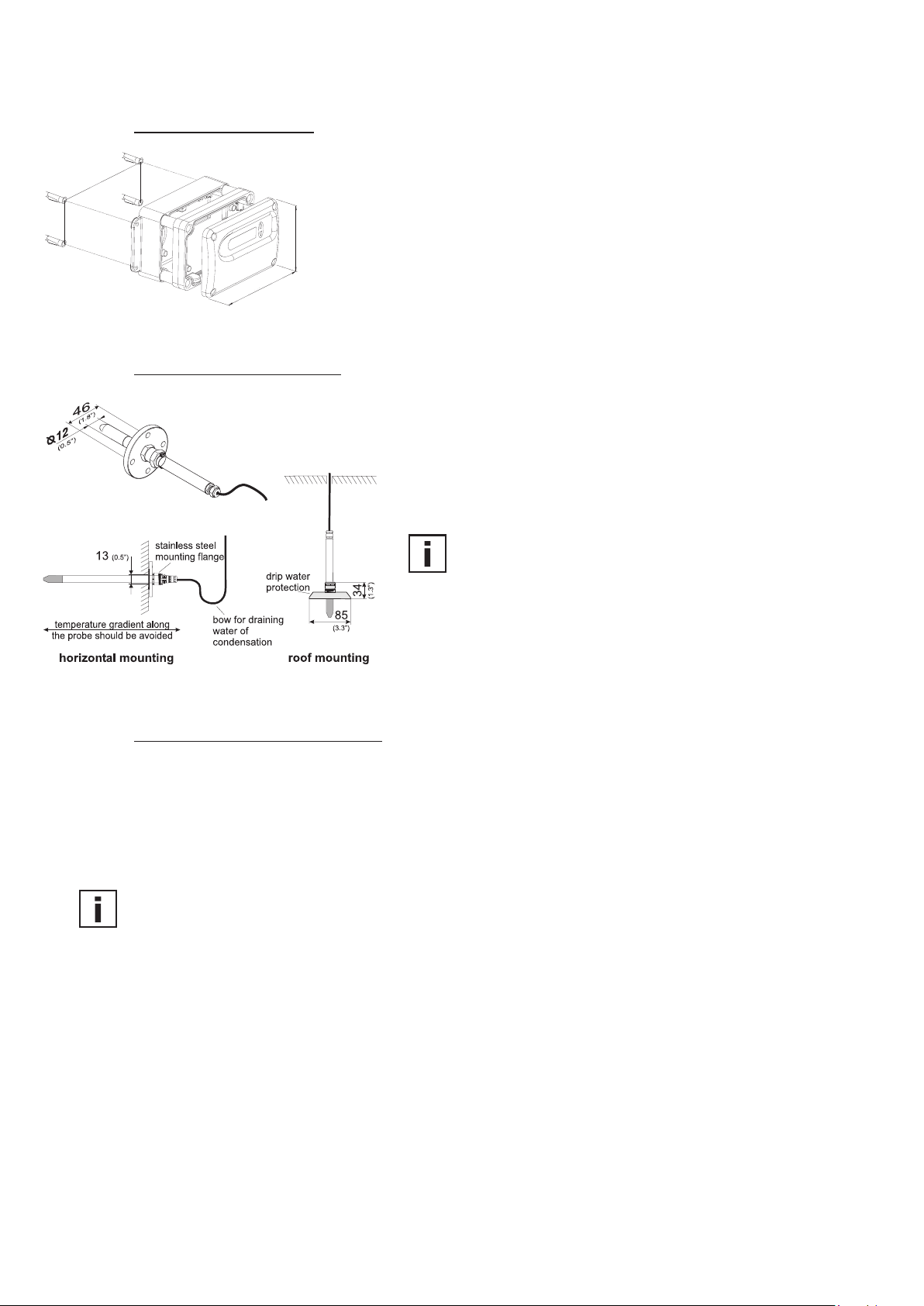

3.1 Model C (remote sensing probe up to 120°C (248°F))

Mounting of transmitter:

1. Drill the mounting holes according to the mounting template (see

drawing at the beginning of the chapter "Drilling/Mounting Template") .

2. The bottom part of the housing is mounted with 4

screws (screw diameter: < 4.2mm (0.2”) ; not included

in the scope of supply).

(3.5”)

90

3. Connection of the transmitter (see Hardware,

chapter 4 "Electrical connections").

(5.3”)

135

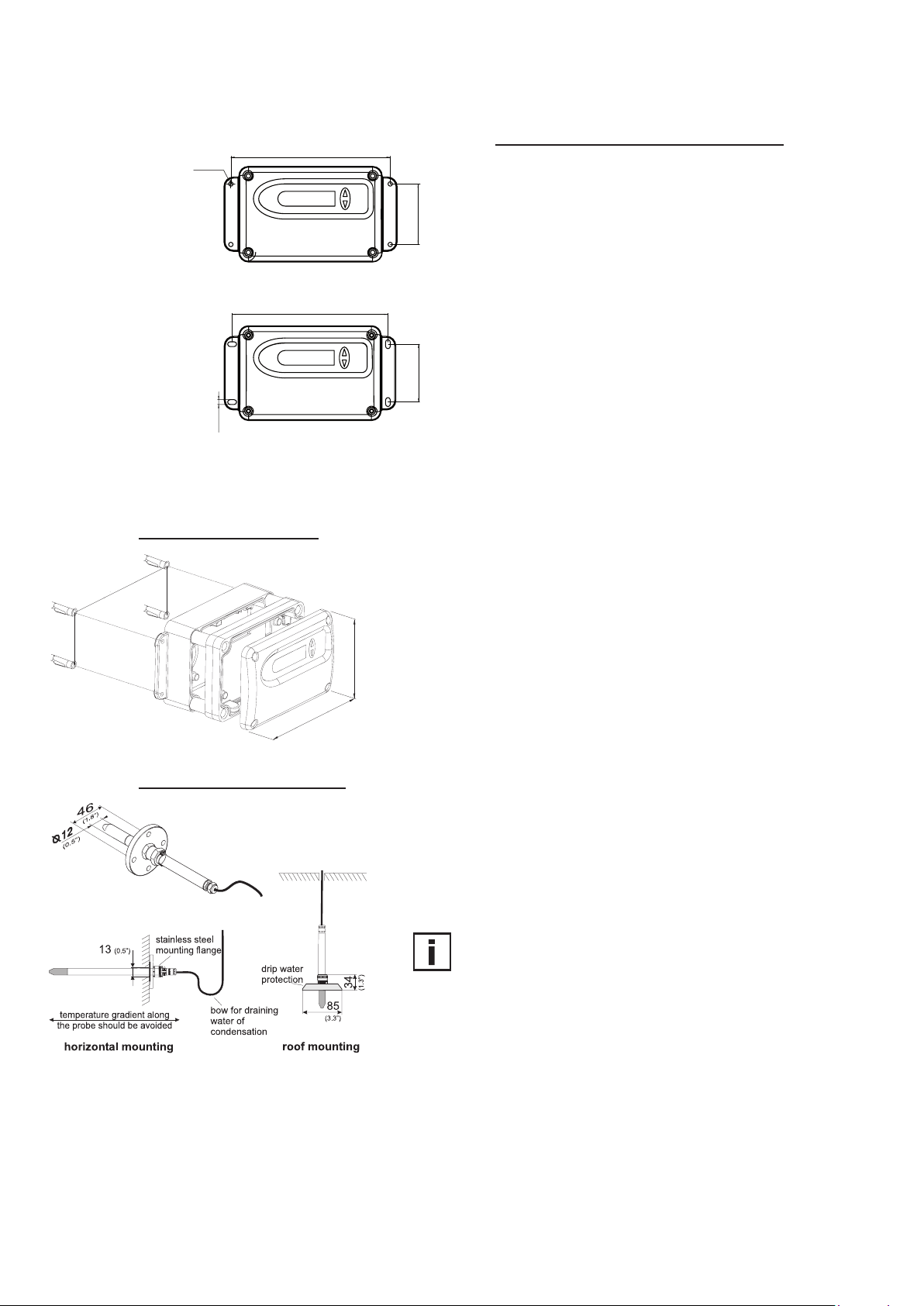

Mounting of sensing probe:

4. Mounting of the middle part and cover with 4 screws

(included in the scope of supply).

Using the stainless steel mounting flange (refer to accessories)

it is possible to mount the probe on the outer wall of the

measuring chamber.

The depth of immersion is adjustable.

For roof installations use the drip water protection (refer to

accessories) to protect the sensor head and elements against

condensed water.

The sensing probe must be mounted horizontally or vertically,

pointing downwards. When possible, a drip sheet should be

fitted for each mounting.

Working range of sensing probe: -40...120°C

(-40...248°F)

Hardware

7

Page 8

3.2 Model D (remote sensing probe)

Mounting of transmitter:

1. Drill the mounting holes according to the mounting template (see

drawing at the beginning of the chapter "Drilling/Mounting Template") .

2. The bottom part of the housing is mounted with 4

screws (screw diameter: < 4.2mm (0.2”) ; not included

in the scope of supply).

(3.5”)

90

3. Connection of the transmitter (see Hardware,

chapter 4 "Electrical connections").

(5.3”)

135

4. Mounting of the middle part and cover with 4 screws

(included in the scope of supply).

Mounting of sensing probe:

Using the stainless steel mounting flange (refer to accessories)

it is possible to mount the probe on the outer wall of the

measuring chamber.

The depth of immersion is adjustable.

For roof installations use the drip water protection (refer to

accessories) to protect the sensor head and elements against

condensed water.

The sensing probe must be mounted horizontally or vertically,

pointing downwards. When possible, a drip sheet should be

fitted for each mounting.

Working range of sensing probe: -40...180°C

(-40...356°F)

Hardware

8

Page 9

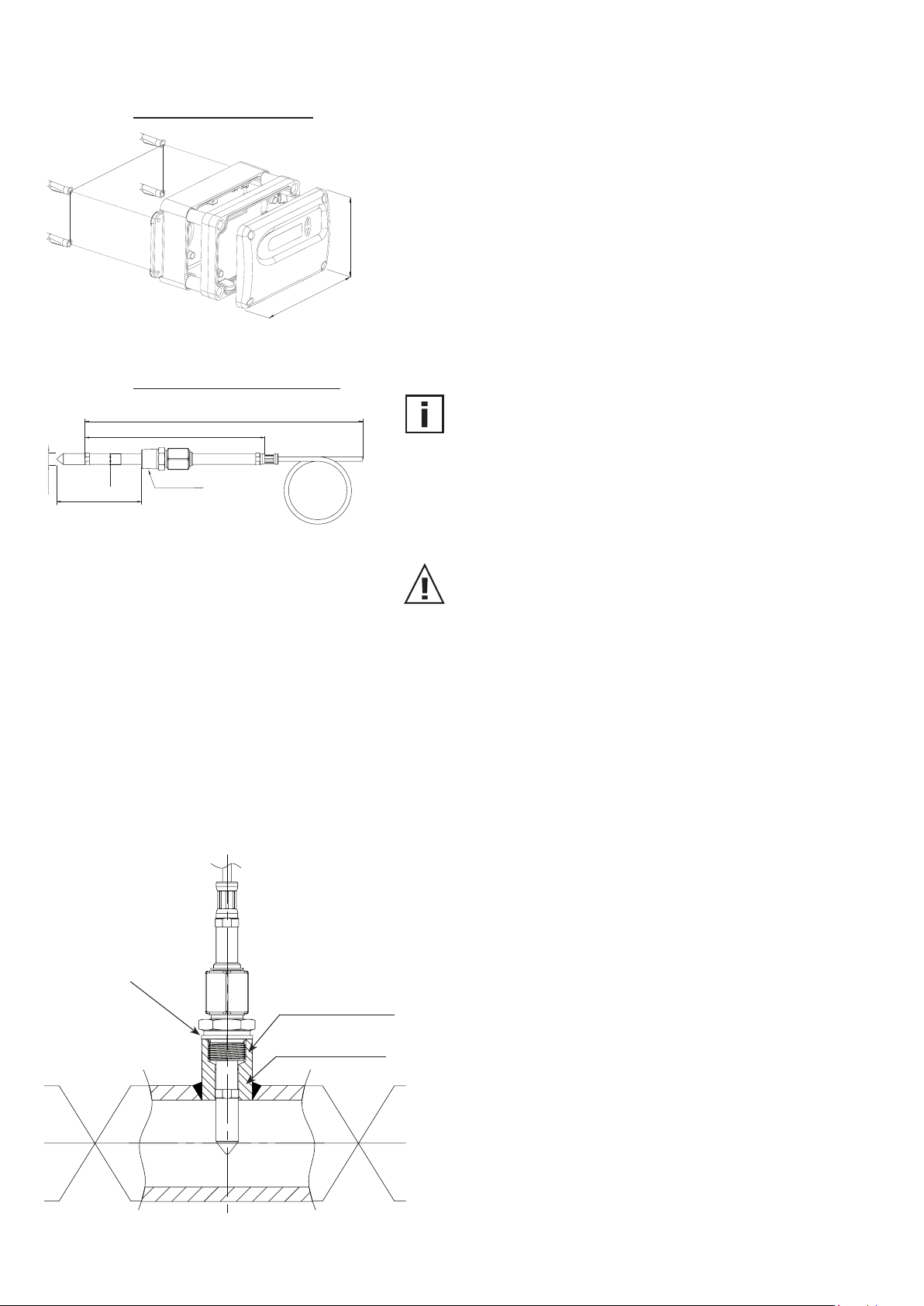

3.3 Model E (remote sensing probe, pressure tight up to 20bar (300psi))

Mounting of transmitter:

1. Drill the mounting holes according to the mounting template (see

drawing at the beginning of the chapter "Drilling/Mounting Template") .

2. The bottom part of the housing is mounted with 4

screws (screw diameter: < 4.2mm (0.2”) ; not included

in the scope of supply).

135

Mounting of sensing probe:

code “cable length”

code “probe length”

(3.5”)

90

(5.3”)

3. Connection of the transmitter (see Hardware,

chapter 4 "Electrical connections").

4. Mounting of the middle part and cover with 4 screws

(included in the scope of supply).

The sensing probe must be mounted horizontally or

vertically, pointing downwards. When possible, a drip sheet

should be fitted for each mounting.

∅13 (0.51”)

adjustable

min. 23 / max. 44/164/364

∅12

1/2” ISO or 1/2” NPT

(0.47”)

fixed installation

(pressure tight up

to 20bar

(300psi))

Working range sensing probe: -40...180°C

(-40...356°F)

Pressure range model: 0.01...20bar (0.15...300psi)

General safety instructions for installation

Because the sensing probe can be exposed to very high

pressures in the measurement environment, there is the risk

of sudden, unintentional expulsion of the probe during or

after improper installation. Therefore, special precautions

should be taken when working on the sensing probe or in its

vicinity. Bending over the sensing probe should be avoided

underany circumstances!

During the installation of the sensor probe, make sure that

the surface of the sensing probe is not damaged! Damaging

the probe could lead to damaged seals (consequence: leakage

and pressure loss) and to problems during removal (jamming).

Installation of the probe directly in the process

For direct probe installation, a stop valve should be provided on

both sides of the probe insert. This allows the sensor probe to be

removed for maintenance and calibration without any problems.

metal sealing ring

1/2” ISO or 1/2“ NPT

inside diameter

≥ 13 mm (0.55”)

stop valve stop valve

If the sensor probe is installed in a pressure chamber, make

sure that the pressure in the chamber and the ambient pressure are in equilibrium before you remove the probe.

The temperature during installation may not vary more than

±4°C (±72°F) from the operating temperature.

1st step:

Install the probe with the stop valves closed.

2nd step:

Insert the sensor probe into the process.

3rd step:

To ensure a secure installation of the probe, the lock nut must

be tightened to a defined torque of 30 Nm.

If no torque-spanner is available tighten the lock nut by hand

as far as possible. Continue to turn with an open-ended

spanner ~50°.

Hardware

9

Page 10

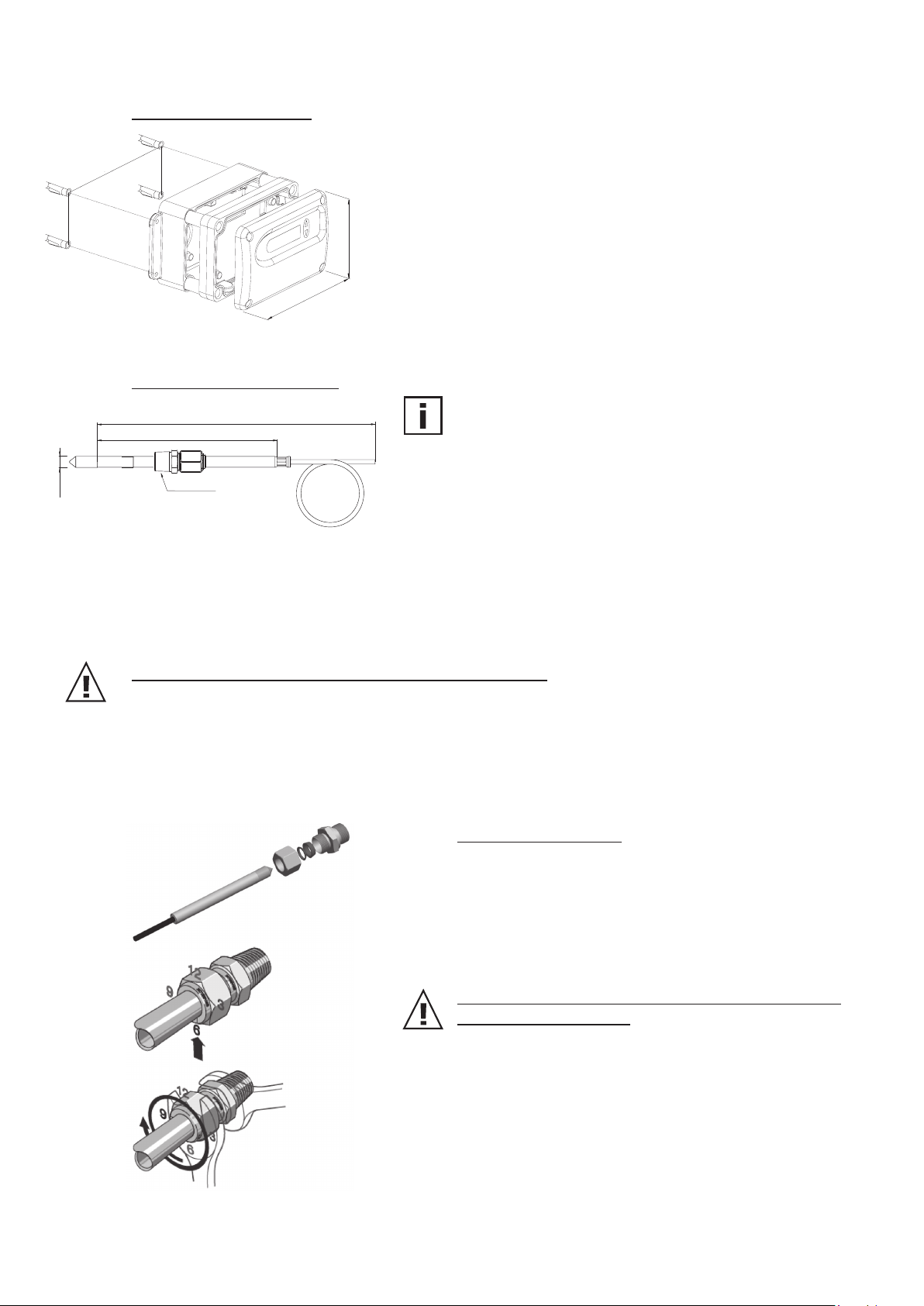

3.4 Model I (remote sensing probe, pressure tight up to 100bar (1450psi))

Mounting of transmitter:

1. Drill the mounting holes according to the mounting template (see

drawing at the beginning of the chapter "Drilling/Mounting Template") .

2. The bottom part of the housing is mounted with 4

screws (screw diameter: < 4.2mm (0.2”) ; not included

in the scope of supply).

135

(3.5”)

90

(5.3”)

3. Connection of the transmitter (see Hardware,

chapter 4 "Electrical connections").

4. Mounting of the middle part and cover with 4 screws

(included in the scope of supply).

Mounting of sensing probe:

The sensing probe must be mounted horizontally or

code “cable length”

code “probe length”

vertically, pointing downwards. When possible, a drip sheet

should be fitted for each mounting.

∅12

(0.5”)

1/2” ISO or

1/2” NPT

Working range sensing probe: -40...180°C

Pressure range model I: 0...100bar (0...1450psi)

Safety Precautions for pressure tight screw connection

- Do not bleed system by loosening fitting nut or fitting plug.

- Do not make up and tighten fittings when system is pressurized.

- Always use proper thread sealants on tapered pipe threads.

- Never turn fitting body. Instead, hold fitting body and turn nut.

- Avoid unnecessary disassembly of unused fittings.

Installation instruction

Rotate the nut finger-tight.

Mark the nut at the 6 o'clock position.

While holding the fitting body steady, tighten the nut one and

one-quarter turns to the 9 o'clock position.

(-40...356°F)

Hardware

Installation in High-Pressure Applications and High

Safety-Factor Systems

1. Rotate the nut finger-tight.

2. Tighten the nut until the tuwbing will not turn by hand or

move axially in the fitting.

3. Mark the nut at the 6 o'clock position.

4. While holding fitting body steady, tighten the nut one and

one-quarter turns to the 9 o'clock position.

10

Page 11

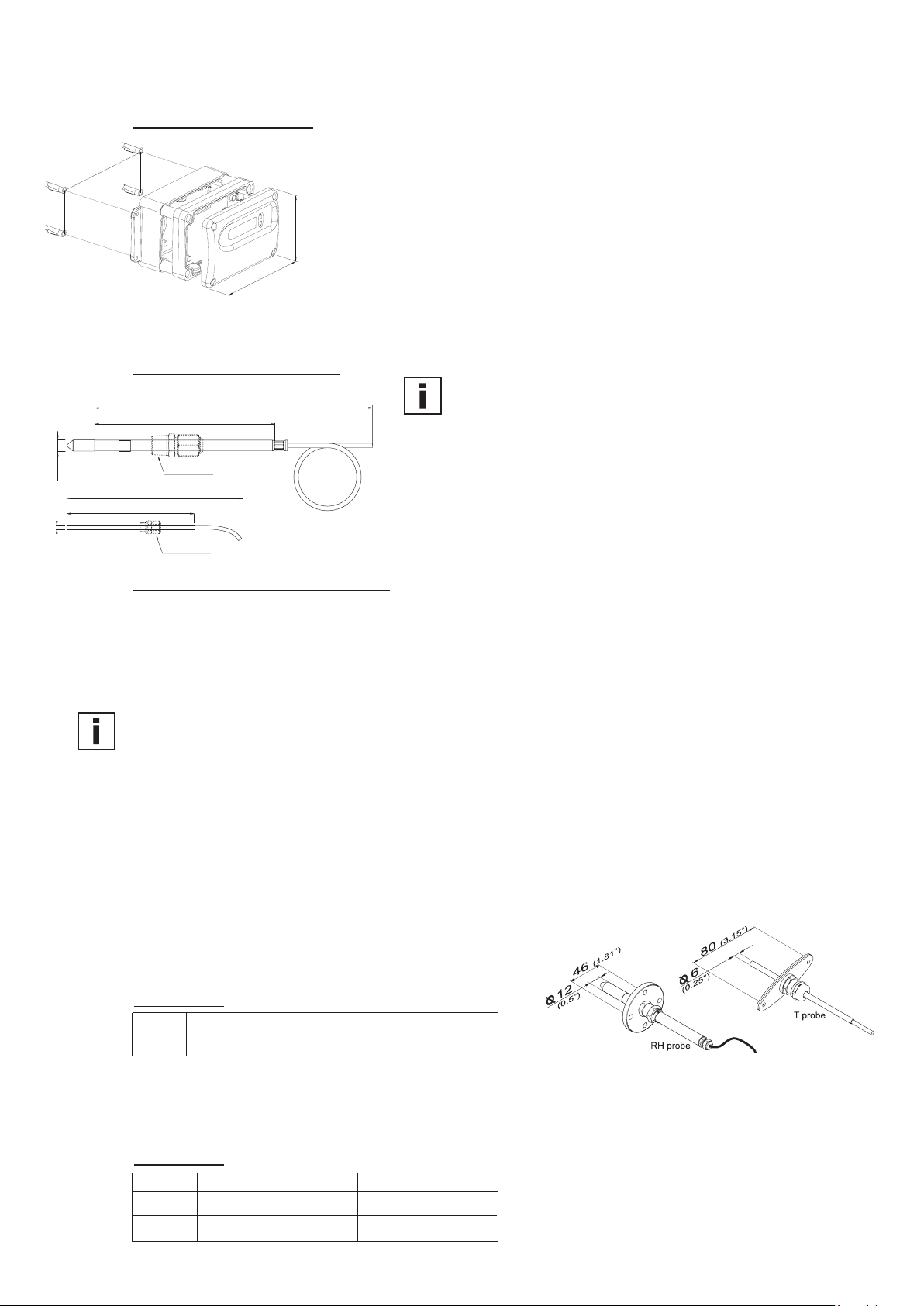

3.5 Model J (2 remote sensing probes, pressure tight up to 20bar (300psi))

Mounting of transmitter:

1. Drill the mounting holes according to the mounting template (see

drawing at the beginning of the chapter "Drilling/Mounting Template") .

2. The bottom part of the housing is mounted with 4

screws (screw diameter: < 4.2mm (0.2”) ; not included

(3.5”)

90

(5.3”)

135

Mounting of sensing probe:

The sensing probe must be mounted horizontally or

code “probe length”

code “cable length”

in the scope of supply).

3. Connection of the transmitter (see Hardware,

chapter 4 "Electrical connections").

4. Mounting of the middle part and cover with 4 screws

(included in the scope of supply).

vertically, pointing downwards. When possible, a drip sheet

should be fitted for each mounting.

∅12

∅6

(0.5”)

code “cable length”

150 (5.9”)

(0.25”)

1/2” ISO or 1/2” NPT

Mounting the two probes, please make sure that the

minimum distance is 10cm (4").

(-40...356°F)

1/2” ISO or 1/2” NPT

Working range sensing probe: -40...180°C

Pressure range: 0.01...20bar (0.15...300psi)

Pressure tight screw connections: The screw connections for pressure tight installation up to 20bar

(300psi) are available as accessories (see Hardware chapter 10.

“Replacement Parts/Acceccories”). For screw assembly refer

to Hardware chapter 3.5 “Model E (remote sensing probe,

pressure tight up to 20bar (300psi))”.

Instructions for installation in a high-humidity environment:

If the process temperature differs significantly from the ambient temperature, the sensing probe should be

fully emerged in the process to avoid incorrect measurements and condensation problems on the sensor

head due to thermal conductivity.

It is recommended not to bring the sensing probe and colder metal parts in direct contact in order to avoid

condensation problems caused by thermal conductivity.

The humidity probe (12mm (1/2")) and the temperature probe (6mm (1/4")) must be mounted at the same

temperature level respectivily same installation height.

Mounting of sensing probe with flange (accessories):

A mounting flange 12mm (1/2”) for the humidity probe and a

mounting flange 6mm (1/4") for for the temperature probe

are available as accessories.

Order codes:

RH probe (12mm (1/2")) T probe (6mm (1/4"))

flange HA010201 HA010207

Mounting of sensing probe with screw connection (accessories):

A 1/2” ISO resp. a 1/2” NPT screw connection is available as an accessories for mounting both sensing

probes (6mm (1/4") and 12mm (1/2")).

Order codes:

RH probe (12mm (1/2")) T probe (6mm (1/4"))

1/2” ISO HA011102 HA011104

1/2” NPT HA011103 HA011105

11

Hardware

Page 12

3.6 Model K (remote sensing probe, pressure tight up to 15bar (218psi))

Mounting of transmitter:

1. Drill the mounting holes according to the mounting template (see

drawing at the beginning of the chapter "Drilling/Mounting Template") .

2. The bottom part of the housing is mounted with 4

screws (screw diameter: < 4.2mm (0.2”) ; not included

(3.5”)

90

(5.3”)

135

Mounting of sensing probe:

in the scope of supply).

3. Connection of the transmitter (see Hardware,

chapter 4 "Electrical connections").

4. Mounting of the middle part and cover with 4 screws

(included in the scope of supply).

Using the stainless steel mounting flange (refer to accessories)

it is possible to mount the probe on the outer wall of the

measuring chamber.

The depth of immersion is adjustable.

For roof installations use the drip water protection (refer to

accessories) to protect the sensor head and elements against

condensed water.

The sensing probe must be mounted horizontally or vertically,

pointing downwards. When possible, a drip sheet should be

fitted for each mounting.

Working range of sensing probe: -40...180°C

(-40...356°F)

Pressure range: 0.01...20bar (0.15...300psi)

Pressure tight screw connection: The screw connection for pressure tight installation up to 15bar

(218psi) is available as an accessory (see Hardware chapter 10.

“Replacement Parts/Acceccories”). For screw assembly refer

to Hardware chapter 3.5 “Model E (remote sensing probe,

pressure tight up to 20bar (300psi))”.

Instructions for installation in a high-humidity environment:

If the process temperature differs significantly from the ambient temperature, the sensing probe should be

fully emerged in the process to avoid incorrect measurements and condensation problems on the sensor

head due to thermal conductivity.

It is recommended not to bring the sensing probe and colder metal parts in direct contact in order to avoid

condensation problems caused by thermal conductivity.

Mounting of sensing probe with flange (accessories):

A 12mm

(1/2”) mounting flange (HA010201) for the humidity probe is available as an accessories.

Mounting of sensing probe with screw connection (accessories):

A 1/2" ISO (HA011102) and 1/2" NPT (HA011103) screw connection for the sensing probe is available as an

accessories.

Hardware

12

Page 13

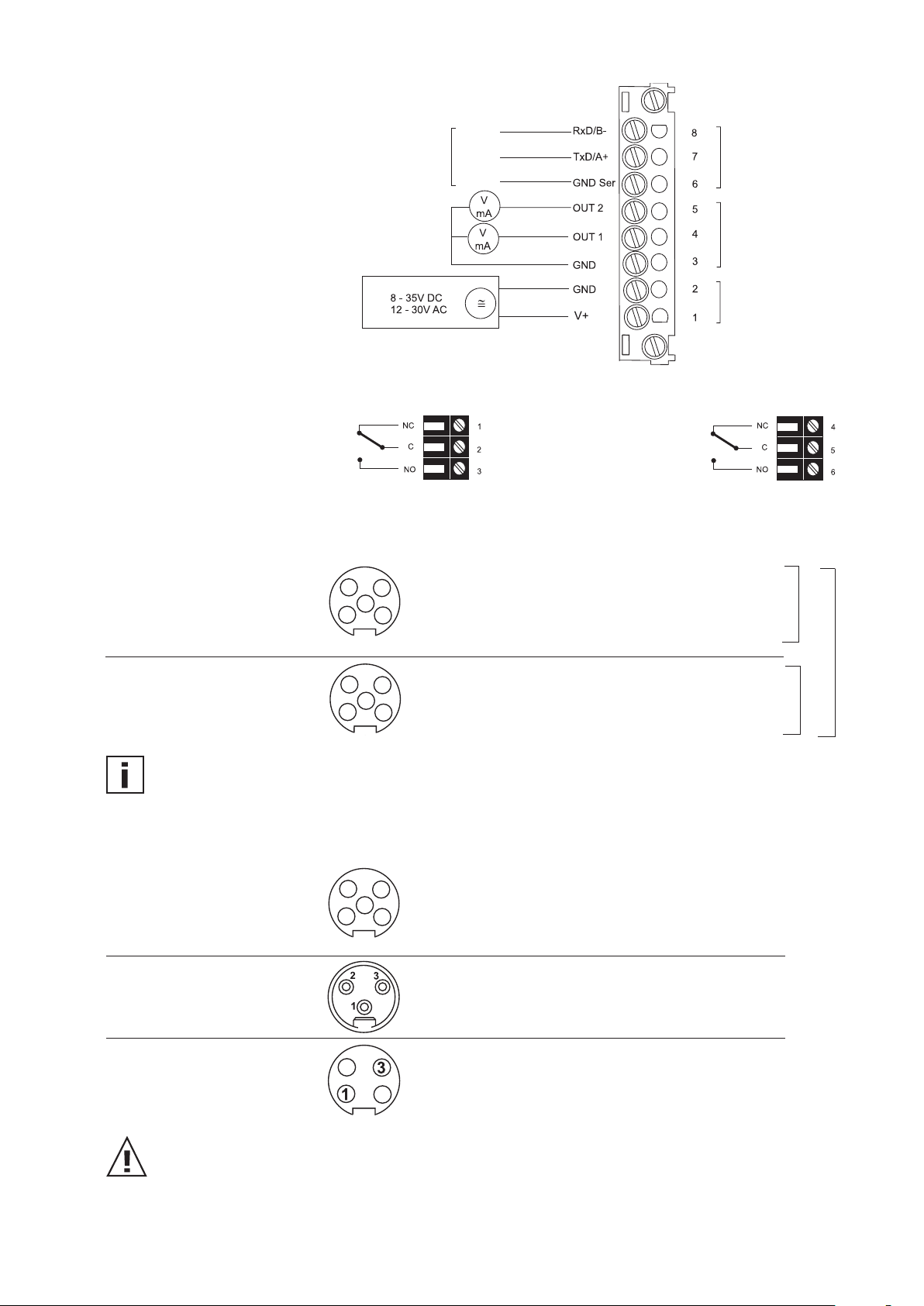

4. ELECTRICAL CONNECTIONS

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

4.1 Connection diagram

RS232 / RS485

cable

white

brown

yellow

serial data

output

analogue

output

supply

4.2 Alarm module connection diagram (option)

Rel 1

Rel 2

4.3 Connection configuration of bottom part of the housing with plug connections /

8...35V DC; 12...30V AC (option C03/C06/C07/C08)

Description: Connection assignment:

Plug for supply and

analogue output

(front view)

Euro-Standard

Plug for RS232 resp.

RS484 connection

(front view)

Euro-Standard

V+ 5

GND 4

GND 3

OUT1 2

OUT2 1

Description: Connection assignment:

GND-Ser 5

Rxd/B- 3

Txd/A+ 1

not assigned 2, 4

C03

C06

C07

C08

The cable should be connected according to the number stamped in the plug as shown in the above drawings!

4.4 Connection configuration of bottom part of the housing with integrated power supply /

100...240V AC (option V01)

Description: Connection assignment:

Plug for RS232 and

analogue output

(front view)

Euro-Standard

Plug for 100-240V

metal housing

(front view)

Plug for 100-240V

polycarbonate housing

(front view)

External diameter of supply cable: 10-12mm (0.39-0.47”)

Maximum wire cross section for connecting cable: 1.5mm² (AWG 16)

The protection of the supply cable against excess current and short-circuit must be designated

to a wire cross section of 0.8mm² (AWG 18) (6A fuse).

National regulations for installation must be observed!

RxD / B- 5

TxD / A+ 4

GND 3

OUT1 2

OUT2 1

Description: Connection assignment:

grounding (PE) 1

phase (L1) 2

neutral wire (N) 3

Description: Connection assignment:

phase (L1) 1

neutral wire (N) 3

Bottom and middle part of the metal housing must be grounded during operation!

13

Hardware

Page 14

4.5 Connection configuration of connectable sensing probe (option P03)

3 12

4

6

5

8

9

7

3 1

2

4

6

5

8

7

Rosa

Schwarz

Blau

Gelb

Braun

Grau

Schirm

Gelb/Grau

Schirm

12mm (0.5”) sensing probe:

grey

shielding

shielding (yellow/green)

9-pole terminal

(0.25”) sensing probe:

6mm

shielding

5-pole terminal

blue

grey (yellow/green)

grey

brown

yellow

black

brown

blue

black

pink

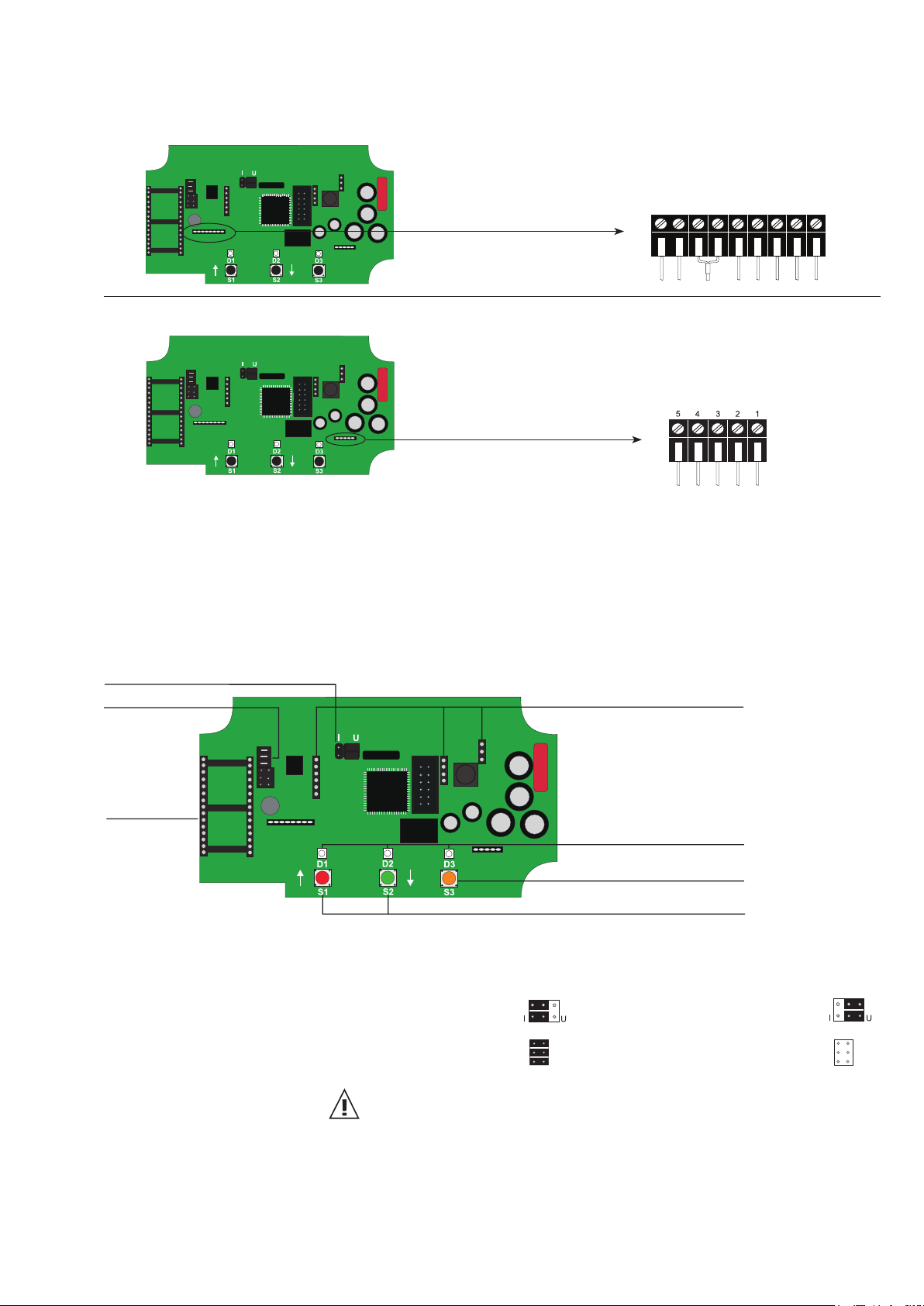

5. OPERATING COMPONENTS

5.1 Circuit board

After removal the housing cover, the following operating components on the circuit board may be accessed.

1. current/voltage output

2. RS232/RS485

3. fitting of the

network chip

1. Current/voltage output: If the transmitter will be switched from current to voltage output signals

using the configuration software supplied, then two jumpers must also be

positioned as follows:

for current signal: for voltage signal:

4. display

5. diagnosis LEDS

6. push-button (heated measurement cell)

7. push-buttons (calibration)

Hardware

2. RS232/RS485: jumper set - RS232: jumper removed - RS485:

3. Fitting of the network chip: For refitting to RS485, an IC must be used (available as an option).

The notch on the chip must match the receiver slot!

4. Display: Pinboards for connecting the display module.

5. Diagnosis LEDS: refer to Hardware, chapter 7 “Humidity/Temperature Calibration”

refer to Hardware, chapter 8.4 “Self-diagnosis and error messages”

6. Push-button (heated measurement cell): refer to Hardware, chapter 8.2 “Automatic ReCover (ARC)”

7. Push-buttons (calibration): refer to Hardware, chapter 7 “Humidity/Temperature Calibration”

14

Page 15

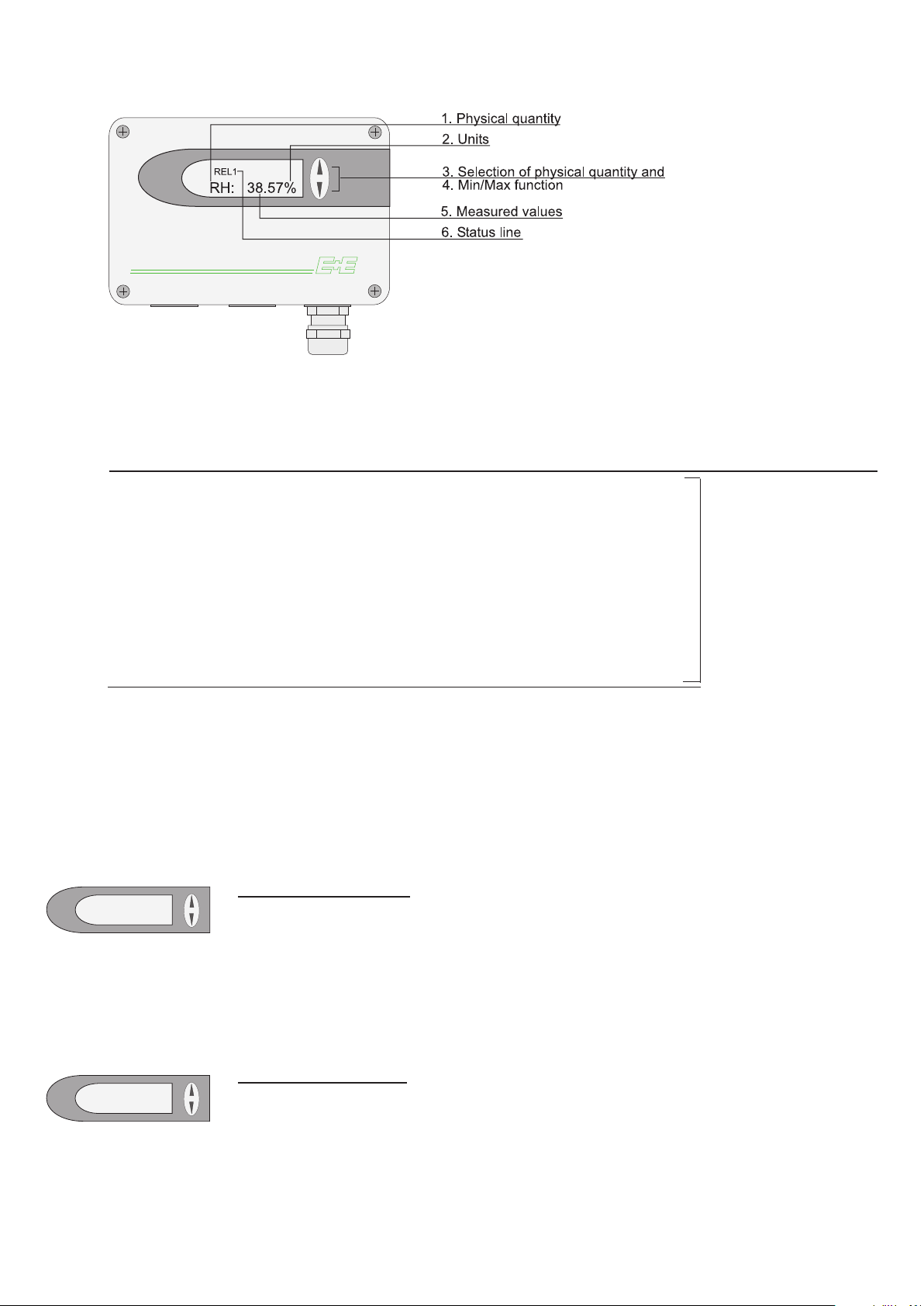

5.2 Display module (Option)

RH: 63.0%

MAX

RH: 63.0%

MIN

1. PHYSICAL QUANTITY:

2. UNITS:

3. SELECTION OF PHYSICAL QUANTITY:

SI US

RH Rel. humidity % %

T Temperature °C °F

e Water vapour partial pressure mbar psi

Td Dew point temperature °C °F

Tw Wet bulb temperature °C °F

EE33

Press the ∆ or ∇

button to select the

desired physical

quantity.

dv Absolute humidity g/m³ gr/ft³

r Mixture ratio g/kg gr/lb

h Enthalphy kJ/kg ftlbf/lb

Tf Frost point temperature °C °F

4. MIN / MAX FUNCTION:

The MIN / MAX function saves and displays the highest and lowest measured value since the last reset resp. the

last interruption of the supply voltage.

Highest measured value:

1. Select the desired physical quantity.

2. To display the maximum value of the selected physical quantity, press the ∆ button for

at least five seconds.

3.1. To reset the transmitter to its normal operating status, press the ∆ button once again

for five seconds.

3.2. If both buttons are pressed for at least five seconds while the maximum value is displayed

→ the "MAX" symbol disappears → the maximum value will be deleted (Reset).

Lowest measured value:

1. Select the desired physical quantity.

2. To display the minimum value of the selected physical quantity, press the ∇ button for

at least five seconds.

3.1. To reset the transmitter to its normal operating status, press the ∇ button once again

for five seconds.

3.2. If both buttons are pressed for at least five seconds while the minimum value is displayed →

the "MIN" symbol disappears → the minimum value will be deleted (Reset).

Hardware

15

Page 16

5. MEASURED VALUES / MAX. MEASUREMENT RANGE:

The dominant value of the appropriate quantity is displayed in this field. For the factory configuration, the

measured values may fall between the measurement ranges shown below.

EE33-C EE33-D/E/I/J EE33-K

Humidity RH 0 100 100 / % rF

Temperature T -40

Dew point temperature Td -40 (-40) 100 (212) 100 (212) 100 (212) °C (°F)

Frost point temperature Tf -40 (-40) 0 (32) 0 (32) 0 (32) °C (°F)

Wet bulb temperature Tw 0 (32) 100 (212) 100 (212) / °C (°F)

Water vapour partial pressure e 0 (0) 1100(15) 1100 (15) / mbar (psi)

Mixture ratio r 0 (0) 999 (9999) 999 (9999) / g/kg (gr/lb)

Absolute humidity dv 0 (0) 700 (300) 700 (300) / g/m

Specific enthalpy h 0 (0) 2800 (999999) 2800 (999999) / kJ/kg (Btu/lb)

The measurement ranges indicated above can be set to individual requirements using the configuration software supplied

(see Configuration software, chapter 5 "Index - Index Cards").

from to unit

(-40) 120 (248) 180 (356) / °C (°F

3

(gr/f³)

6. STATUS LINE:

MIN; MAX: see Point "MIN/MAX Function", see Hardware, chapter 5.2 “Display module”

CALIB LOW; CALIB HIGH: indicates the low or high humidity/temperature calibration point.

REL1 / REL2: status relay 1/ relay 2

"ERROR 01....06": see Hardware, chapter 8.4 “Self-diagnosis and error messages”

EE33

6. OPTIONAL MODULES

The optional modules are mounted in the lower part, that's why always only one optional module can be selected.

6.1 Alarm Module (Option)

The optional alarm module can be used for alarm and error issues and other simple control functions. This

module can be configured using the configuration software supplied.

The user thus has the option of setting the physical quantity to be monitored (RH, T, Td,...) and the threshold and

hysteresis for each relay. (For the procedure, see the Configuration sofware, chapter 5.2 “Relay”)

Max. switched voltage / max. switched current: 250 VAC / 6A

28 VDC / 6A

Minimum load: >100mA / 12V

Switching relay 1:

REL1

RH: 63.0%

If relay 1 has tripped (ON),

then REL1 is displayed.

EIN

ON

AUS

OFF

Ausschaltpunkt

switching off

relay status

11

12

13

11

12

13

Relais Status

NC

C

NO

NC

C

NO

Hysterese

8%

Einschaltpunkt

switching on

62

70

Schaltpunkt

switching point

[%,°C,kj/kg,

g/kg,g/m³,mbar,...]

Switching relay 2:

Hardware

REL2

RH: 63.0%

If relay 2 has tripped (ON),

then REL2 is displayed.

16

EIN

ON

AUS

OFF

Ausschaltpunkt

switching off

relay status

14

15

16

14

15

16

Relais Status

NC

C

NO

NC

C

NO

Hysterese

8%

Einschaltpunkt

switching on

62

70

Schaltpunkt

switching point

[%,°C,kj/kg,

g/kg,g/m³,mbar,...]

Page 17

6.2 Integrated Power Supply (Option)

see Hardware, chapter 4.4 Connection configuration of bottom part of the housing with integrated power

supply 100...240V AC (option V01)

6.3 Ethernet Module (Option)

6.4 ARC-Module (Option)

see Hardware, chapter 9.2 Ethernet - Module (Option)

The additional printed circuit board located in the lower part of the

housing offers the possibiliy to start the ARC heating function with

external signal.

During the heating process the orange LED D3 flashes at the main

printed circuit board. At the ARC-Module the red LED "heating" flashes

and the relay contact (terminal "output") is closed.

General information of the ARC function see Hardware, chapter 2.1.1

Automatic ReCover (ARC).

For changes of the parameter of the heating process, see Software,

chapter 5.5 Parameter.

6.4.1 Connection / Operating elements

Terminal „+Ub“:

supply voltage: 24V AC/DC +/-20%

1 GND

2 +Ub

Terminal „Input“:

1 GND

2 signal (24V DC; 10mA)

Terminal „Output“:

1 REL_com

2 Rel_NO

Feedback signal to the external control.

The relay contact is closed during the heating

process, otherwise opened.

Timing of switching status

Operating elements:

- LED green: LED ashes = supply voltage is switched on

- LED red: LED ashes = heating process is active

Hardware

17

Page 18

7. HUMIDITY / TEMPERATURE CALIBRATION

The EE33 transmitter series can be calibrated in two ways:

- 1-point humidity/temperature calibration: quick and simple calibration on a defined humidity/temperature

point (working point).

- 2-point humidity/temperature calibration: calibration for accurate measuring results over the whole

humidity/temperature working range.

• To reach a temperature balance it is recommended to keep the transmitter and the

reference chamber (e.g. HUMOR 20,...) for minimum 4 hours in the same room.

• During stabilisation period and calibration procedure it is important to keep the temperature constant

in the reference climate chamber.

• For calibration the humidity sensor probe must be stabilised at least 20 minutes into the reference chamber.

• Replace an used dirty filter cap before calibration!

7.1 2-point humidity calibration

For accurate adjustment over the whole humidity working range a 2-point calibration is recommended.

• Start calibration at the low humidity calibration point!

• The humidity difference between the two points should be > 30%RH

• Low humidity point < high humidity point

• 2-point calibration may be performed directly on the circuit board, or using the configuration software

supplied (for more details, see Configuration Software, chapter 5.4 ”2-point humidity calibration”)

low calibration point:

“CALIB LOW”

2-point humidity calibration procedure on the circuit board:

1. Insert the sensor probe into the reference humidity 1 (low

calibration point) and stabilise for at least 20 minutes.

2. BUTTON S2: Pressing the button for 5 seconds starts the

procedure for the calibration mode RH. The calibration mode is

indicated by the lit LED "D2" on the circuit board.

3. BUTTON S2: Pressing the button for 5 seconds starts the

procedure for the low calibration point. The calibration mode is

indicated by the lit LED "D2" and the symbol "CALIB LOW" will

appear on the optional LC display.

4. BUTTON S1 (up) and S2 (down): Pressing one of the two

buttons will adjust the measuring value in steps of 0.1% up or

down to the reference value. The actual measuring value is

indicated on the display or can be measured with the analogue

output. As soon as the measured value is changed, "D1"

flashes when pressing S1 or S2.

Hardware

5. BUTTON S1 (store): Pressing the button for 5 seconds

stores the calibration value and the procedure is ended. LED

"D2" flashes to indicate exiting of the calibration mode and the

symbol "CALIB LOW" will disappear from the optional

LC display.

BUTTON S2 (cancel): Pressing the button for 5 seconds the

calibration procedure will be ended without storing the

calibration values. LED "D2" flashes to indicate exiting of the

calibration mode and the symbol "CALIB LOW" will

disappear from the optional LC display.

18

Page 19

high calibration point:

“CALIB HIGH”

6. Insert the sensor probe into the reference humidity 2 (high

calibration point) and stabilise for at least 20 minutes.

7. BUTTON S2: Pressing the button for 5 seconds starts the

procedure for the calibration mode RH. The calibration mode is

indicated by the lit LED "D2" on the circuit board.

8. BUTTON S1: Pressing the button for 5 seconds starts the

procedure for the high calibration point. The calibration mode is

indicated by the lit LED "D2" and the symbol "CALIB HIGH" will

appear on the optional LC display.

9. BUTTON S1 (up) and S2 (down): Pressing one of the two

buttons will adjust the measuring value in steps of 0.1% up or

down to the reference value. The actual measuring value is

indicated on the display or can be measured with the analogue

output. As soon as the measured value is changed, "D1"

flashes when pressing S1 or S2.

10. BUTTON S1 (store): Pressing the button for 5 seconds

stores the calibration value and the procedure is ended. LED

"D2" flashes to indicate exiting of the calibration mode and the

symbol "CALIB HIGH" will disappear from the optional LC display.

BUTTON S2 (cancel): Pressing the button for 5 seconds the

calibration procedure will be ended without storing the

calibration values. LED "D2" flashes to indicate exiting of the

calibration mode and the symbol "CALIB HIGH" will disappear

from the optional LC display.

7.2 2-point temperature calibration

•

Start calibration at the low calibration point!

• The temperature difference between the two points should be at least 30°C (86°F)!

• Low temperature point < high temperature point

• Attention: A 2-point temperature calibration is not supported by the

configuration software and must therefore be done directly on the circuit

board! (see following page)

19

Hardware

Page 20

2-point temperature calibration procedure on the circuit board:

low calibration point:

“CALIB LOW”

1. Insert the sensor probe into the reference temperature 1 (low

calibration point) and stabilise for at least 10 minutes.

2. BUTTON S1: Pressing the button for 5 seconds starts the

procedure for the calibration mode temperature. The calibration

mode is indicated by the lit LED "D1" on the circuit board.

3. BUTTON S2: Pressing the button for 5 seconds starts the

procedure for the low calibration point. The calibration mode is

indicated by the symbol "CALIB LOW" on the optional LC display.

4. BUTTON S1 (up) and S2 (down): Pressing one of the two

buttons will adjust the measuring value in steps of 0.1 degC up

or down to the reference value. The actual measuring value is

indicated on the display or can be measured with the analogue

output. As soon as the measured value is changed, "D1"

flashes when pressing S1 or S2.

5. BUTTON S1 (store): Pressing the button for 5 seconds

stores the calibration value and the procedure is ended. LED

"D2" flashes to indicate exiting of the calibration mode and the

symbol "CALIB LOW" will disappear from the optional LC display.

BUTTON S2 (cancel): Pressing the button for 5 seconds the

calibration procedure will be ended without storing the

calibration values. LED "D2" flashes to indicate exiting of the

calibration mode and the symbol "CALIB LOW" will disappear

from the optional LC display.

high calibration point:

Hardware

“CALIB HIGH”

6. Insert the sensor probe into the reference temperature 2

(high calibration point) and stabilise for at least 10 minutes.

7. BUTTON S1: Pressing the button for 5 seconds starts the

procedure for the calibration mode temperature. The calibration mode is indicated by the lit LED "D1" on the circuit board.

8. BUTTON S1: Pressing the button for 5 seconds starts the

procedure for the high calibration point. The calibration mode

is indicated by the symbol "CALIB HIGH" on the optional LC

display.

9. BUTTON S1 (up) and S2 (down): Pressing one of the two

buttons will adjust the measuring value in steps of 0.1°C up or

down to the reference value. The actual measuring value is

indicated on the display or can be measured with the analogue

output. As soon as the measured value is changed, "D1"

flashes when pressing S1 or S2.

10. BUTTON S1 (store): Pressing the button for 5 seconds

stores the calibration value and the procedure is ended. LED

"D2" flashes to indicate exiting of the calibration mode and the

symbol "CALIB HIGH" will disappear from the optional LC

display.

BUTTON S2 (cancel): Pressing the button for 5 seconds the

calibration procedure will be ended without storing the

calibration values. LED "D2" flashes to indicate exiting of the

calibration mode and the symbol "CALIB HIGH" will

disappear from the optional LC display.

20

Page 21

7.3 1-point humidity calibration

When the working range is limited to a certain more narrow range,

a calibration at one humidity point is absolutely sufficient.

• In accordance with the working range, either the high or low

calibration point should be selected. (CP > or < 50% RH)

• This calibration causes an extra inaccuracy for the rest of the

working range.

• The 1-point humidity calibration may be done directly on the

circuit board, or for convenience, using the configuration software supplied. (for more details, see Configuration software,

chapter 5.4 “Calibration” / 1-point humidity calibration)

1-point humidity calibration procedure on the circuit board:

1. Insert the sensor probe into the reference humidity

(calibration point) and stabilise for at least 20 minutes.

“CALIB HIGH”

“CALIB LOW”

2. BUTTON S2: Pressing the button for 5 seconds starts the

procedure for the calibration mode RH. The calibration mode is

indicated by the lit LED "D2" on the circuit board.

3. BUTTON S1: Pressing the button for 5 seconds starts the

procedure. The calibration mode is indicated by the lit LED

"D2" and the symbol "CALIB HIGH" will appear on the optional

LC display (CP ≥ 50% RH).

or

BUTTON S2: Pressing the button for 5 seconds starts the

procedure. The calibration mode is indicated by the lit LED

"D2" and the symbol "CALIB LOW" will appear on the optional

LCD (CP < 50% RH).

4. BUTTON S1 (up) and S2 (down): Pressing one of the two

buttons will adjust the measuring value in steps of 0.1% up or

down to the reference value. The actual measuring value is

indicated on the display or can be measured with the analogue

output.

5. BUTTON S1 (store): Pressing the button for 5 seconds

stores the calibration value and the procedure is ended. LED

"D2" flashes to indicate exiting of the calibration mode and the

symbol "CALIB LOW" or "CALIB HIGH" will disappear from the

optional LC display.

BUTTON S2 (cancel): Pressing the button for 5 seconds the

calibration procedure will be ended without storing the

calibration values. LED "D2" flashes to indicate exiting of the

calibration mode and the symbol "CALIB LOW" or "CALIB

HIGH" will disappear from the optional LC display.

Hardware

21

Page 22

7.4 1-point temperature calibration

When the working range is limited to a certain more narrow range,

a calibration at one temperature point is absolutely sufficient.

• In accordance with the working range, either the high or low

calibration point should be selected. (CP ≥ or < 45 degC / 113°F)

• This calibration causes an extra inaccuracy for the rest of the

working range.

• The 1-point temperature calibration may be performed directly

on the circuit board, or using the configuration software supplied.

(for more details, see Calibration software, chapter

5.4 “Calibration” / 1-point humidity calibration)

1-point temperature calibration procedure on the circuit board:

1. Insert the sensor probe into the reference temperature

(calibration point) and stabilise for at least 30 minutes.

“CALIB HIGH”

“CALIB LOW”

2. BUTTON S1: Pressing the button for 5 seconds starts the

procedure for the calibration mode temperature. The calibration

mode is indicated by the lit LED "D1" on the circuit board

3. BUTTON S1: Pressing the button for 5 seconds starts the

procedure. The calibration mode is indicated by the symbol

"CALIB HIGH" on the optional LC display (CP ≥ 45°C /

or

BUTTON S2: Pressing the button for 5 seconds starts the pro-

cedure. The calibration mode is indicated by the symbol "CALIB

LOW" on the optional LC display (CP < 45°C / 113°F).

4. BUTTON S1 (up) and S2 (down): Pressing one of the two

buttons will adjust the measuring value in steps of 0.1°C up or

down to the reference value. The actual measuring value is

indicated on the display or can be measured with the analogue

output.

5. BUTTON S1 (store): Pressing the button for 5 seconds

stores the calibration value and the procedure is ended. LED

"D2" flashes to indicate exiting of the calibration mode and the

symbol "CALIB LOW" or "CALIB HIGH" will disappear from the

optional LC display.

BUTTON S2 (cancel): Pressing the button for 5 seconds the

calibration procedure will be ended without storing the

calibration values. LED "D2" flashes to indicate exiting of the

calibration mode and the symbol "CALIB LOW" or "CALIB

HIGH" will disappear from the optional LC display.

113°F).

Hardware

22

Page 23

7.5 Resetting the customer calibration to the

factory calibration on the circuit board:

1. RH + T RESET: BUTTON S1 and S2: In neutral mode

pressing both buttons simultaneously for 10 seconds customer

calibration settings are reset to factory calibration.

A short flash of the LED "D1" indicates the reset.

or

2. RH RESET: BUTTON S2: Pressing the button for 5

seconds starts the procedure for the calibration mode RH.

Pressing both buttons simultanously for 10 seconds customer

calibration settings are reset to factory calibration.

A short flash of the LED "D1" indicates the reset.

or

3. Temp. RESET: BUTTON S1: Pressing the button for 5

seconds starts the procedure for the calibration mode T.

Pressing both buttons simultanously for 10 seconds customer

calibration settings are reset to factory calibration.

A short flash of the LED "D2" indicates the reset.

23

Hardware

Page 24

7.6 Adjustment/Calibration EE33 model J

7.6.1 Adjustment/Calibration with humidity calibrator HUMOR 20

To be able to calibrate the transmitter of the series EE33-MFTJ, with the dual

probes (Td-probe and T–probe), a separate available adapter is needed (siehe

Hardware, chapter 10. replacement parts/accessories - adapter for EE33 - model J,

HA020401) to achieve the highest possible calibration result. The following steps

describe how the series EE33-MFTJ should be calibrated correctly.

1. Plug both air vents of the cover of the measurement chamber with the plugs

supplied with the adapter (see left picture).

2. Insert the Td-probe (Ø12mm) in the measuring chamber through one of the

feed-throughs of the cover and tighten the nut.

3. Insert and tighten the T-probe (Ø6mm) in the adapter and insert in the

measuring chamber through one of the feed-throughs of the cover and

tighten the nut.

4. In case that feed-throughs are not in use, close them with the blind plugs

delivered with the cover.

Transmitters delivered after June 2009 have the possibility to heat the tube

of the probe continuously to avoid condensation. This function must be

disabled prior to calibration, by detaching the cover of the transmitter and

removing the “heat”-jumper in the left top corner of the PCB

(see left picture).

5. Connect the test unit to the supply connections of HUMOR 20.

6. Connect the output signal of the test unit(s) to the internal measuring

inputs of HUMOR 20 (Unit1 RH, Unit2 RH).

7. Select the measuring ranges in accordance with the output signal of the test units.

The temperature of the measuring chamber can be displayed by selecting

"Temp." on the measuring range switch.

8. Use the humidity controller to select the setpoint of the humidity.

9. For information on the standard deviations and stabilisation times of the

test unit, refer to the manufacturer's documentation (however, a minimum

of 20 mins is recommended).

10. Compare the values shown in the display with the output signal of the

transmitter.

Hardware

After calibration, make sure that the plugs in the air vents in the cover of the

measuring chamber are removed.

7.6.2 Adjustment/Calibration with various calibrators

For an exact calibration, note especially point 4 in the above chapter.

24

Page 25

8. MAINTENANCE

8.1 Sensor cleaning

It is easy to clean the sensor if there are particle deposits (e.g. dust) on the surface of the

heated measurement cell.

Commercially available isopropyl alcohol is used for cleaning. Unscrew the filter cap and

submerge the sensor element in the alcohol for 2 minutes.

Allow the sensor element to dry or blow it dry with oil-free compressed air.

Caution: In order to avoid destroying the active sensor coating, avoid using mechanical

aids (e.g. cotton swabs or cloths) for cleaning!

8.2 Automatic ReCover (ARC)

When capacitive humidity sensors are exposed to chemical pollution (e.g. detergent

residue), the presence of foreign molecules can distort the measurement reading.

The foreign molecules can be evaporated by heating the measurement cell briefly and

intensively. Reconditioning helps to minimize distorted measurement readings during the

calibration interval.

It is recommended to heat the measurement cell by choosing Manual after the cleaning or

sterilization process or if distorted measurement readings are suspected.

To start heating, remove the housing cover and press the pushbutton S3 or trigger the

ARC-module with the external signal (see Hardware, chapter 6.4 ARC-Module).

The orange LED D3 is illuminated during heating.

8.3 Fuse replacement for option V01

If the green LED on the PCB is not flashing with the supply

voltage switched on, check the fuse and replace if required.

Fuse secondary: 250mA / T UL248-14

Nominal voltage: 250V

Replacement types:

Series: MSTU 250 Manufacturer: Schurter Order No.: 0034.7109

Series: 374 Manufacturer: Littelfuse Order No.: 374 0250

25

Hardware

Page 26

8.4 Self diagnosis and error messages

Self diagnosis via LEDs on the circuit board:

• LED D2 (green)

Flashing

⇒ Supply voltage applied / Microprocessor is active

• LED D1 (red)

Constantly lit

Flashing

⇒ Humidity sensor element damaged

⇒ Dew (condensation) at the humidity sensor element

• LED D3 (orange)

Constantly lit ⇒ Humidity sensor element will be heated (Automatic ReCover)

Flashing ⇒ Sensor and threaded element soiled

Self diagnosis via display (optional):

Error 1 ⇒ Humidity sensor element damaged

Error 2 ⇒ Humidity sensor element moistened (condensation!)

Error 3 ⇒ Temperature sensor element damaged

Error 4 ⇒ Temperature sensor short-circuit

Error 5 ⇒ Pt1000-probe element is damaged

Error 6 ⇒ Pt1000-probe short-circuit

EE33-MFTJ

Further self diagnosis:

• Error

Possible cause

⇒ Measures / Help

• Display shows incorrect values

Error during re-adjustment of the transmitter

⇒ Reset to factory calibration and repeat the calibration routine

Filter soiled

⇒ Replace filter

Measuring cell contaminated

⇒ Automatic ReCover (ARC)

Output configured incorrectly

⇒ Check output range and output signals in the configuration

• Long response time

Filter soiled

⇒ Replace filter

Incorrect filter type

⇒ Filter type should match the application

Hardware

• Transmitter failure

No supply voltage

⇒ Check wiring and supply voltage

⇒ Only green LED is illuminated continuously ⇒ electronics defect ⇒

contact the manufacturer

• High humidity values - red LED blinks

Dew (condensation) in the sensor probe head

⇒ heat the measurement cell and check the mounting of sensor probe

Incorrect filter type (e.g. storage of humidity after stainless steel sintered filter condensation)

⇒ Filter type should match the application

26

Page 27

9. NETWORK

9.1 RS485 Network (option)

EE33 transmitters (additional "N" in order code) can be connected in a RS485 bus system

to a single PC interface.

Using the software which is included in the scope of supply the transmitters can be

configurated individually or in the entire network group.

Network configuration:

1)

1)

1) Note: to enable optimum expansion, both ends of the network must be terminated with a terminating

resistorwith Ra 100 Ohm.

Technical Data:

- Max. network size: 32 transmitters

- Communication: with COM-Port (serial interface) of PC

- Max. network expansion: 1200m

(3937ft) total length

- Transmission rate: 9600 Baud

Mounting notes:

Data cables: - external diameter < 4mm

(0.16”)

- 2-core twisted pair

- Typ. 50 pF/m, impedance 100 Ohm, non-shielded

- In accordance with the RS485 standard, cables in category 5

(UTP), specified according to EIA/TIA/ANSI 568, meet these

requirements.

For high noise emissions, especially for large cable lengths, the use of shielded cables is

recommended. (Shield laid at GND Ser)

Hardware

27

Page 28

Plug connecors: To achieve a more flexible network configuration, the transmitters

should be equipped with plug connectors. (Option C08)

For the network configuration, the following plug connectors

are also necessary:

- Y splitter: Siemens 6ES7 194-1KA01-0XA0

- Plug: Lumberg RSC 5/7

Plug

Option C08

Lumberg

RKC 5/7

Y splitter*

Lumberg

RSC 5/7

RS485

Network

* Siemens 6ES7 194-1KA01-0XA0

Power supply +

Analog output

RS232/485 converter: To adapt the RS232 interface on the PC to the RS485

network protocol, a signal converter (see schematic

“network configuration” Hardware, chapter 9) is required.

USB to RS232 converter: For connecting an EE33 transmitter to an USB-interface,

following USB to R232 converter had been tested under

MS Windows 2000

®:

- inside out networks: edgeport/1 1 port USB to RS-232

converter

- keyspan: high speed usb serial adapter (p/n: USA-19QW)

Hardware

28

Page 29

9.2 Ethernet - Module (Option)

An additional PCB, located in the bottom part of the housing, allows the EE33-series to be

connected to a standardized 10/100 MBit-Ethernet network.

The standardized interface allows to integrate the transmitters in a network. It is than

possible to communicate from several remote workstations and the central administration

with different transmitters.

9.2.1 Electrical Connection /

Operating Components

Screw Terminals:

supply voltage: 8...35V DC / 12...30V AC

1 GND / ~

2 V+ / ~

Attention:

Use the Harting RJ Industrial IP67 Push

Pull Connector - in the scope of supply - or

identical types only!

It is possible that the conventional RJ45

connectors, typically used in office

environments, cannot be removed from RJ

Industrial IP67 bushing!

Power - LED (Red):

LED glowing = power supply on

LNK (Link) - LED (Green):

LED glowing = connection with Ethernet switch established

ACT (Active) - LED (Green):

LED flashing = data transfer active

RESET- button:

Press reset button for 3-5 seconds and the Ethernet module will be reset (the microcontroller is restarted). The LNK-LED is temporary off.

DHCP / STATIC - Jumper:

The jumper setting (DHCP / Static) determines the way the IP-address is assigned.

DHCP: IP-address will be assigned automatically by the DHCP server

STATIC: IP-address will be assigned manually by the network administrator

What is preferred / technical possible, should be discussed with the network administrator.

For further details please refer to chapter “9.2.3 Ethernet-interface”.

9.2.2 Technical data:

- 10/100 MBit Ethernet Interface RJ45 (Harting IP67 Push-Pull bushing)

- Cable length from transmitter to Ethernet-Switch: max. 100m

- Recommended type of cable: Harting ProfiNet Cat5-cable STP 2x2xAWG22/7

- Max. number of transmitters in a network: unlimited

29

Hardware

Page 30

9.2.3 Ethernet-interface

9.2.3.1 ComCenter

ComCenter (Communication Center) software is the communication link between the

transmitter, the Ethernet-network and the existing EE33 configuration-, data logging- and

visualization software.

The ComCenter provides the following functions:

Discovery tool:

ComCenter supports the detection and administration (Web-Interface) of all transmitters

in the network.

Creation of virtual interfaces (Com-Ports):

ComCenter allows to assign each and every detected IP-address (e.g. transmitter) with a

corresponding virtual interface (Com-Port). With MS Windows® not more than 255 virtual

Com-Ports are possible!

Communication with existing software:

The created virtual Com-Ports can be addressed by the existing EE33 configuration-, data

logging and visualization software, as long as the ComCenter software is running (active).

9.2.3.2 Installation of the ComCenter

- Insert Ethernet CD-Rom into your

CD-ROM drive

- Choose "Install ComCenter Ethernet

Software"

- Run the setup.exe

- Choose language and follow the

installation wizard

- Complete installation

9.2.3.3 Ethernet Connection

- Connect the transmitter to the Ethernet-network using the provided Harting RJ

Industrial IP67 Push Pull Connector and a standardized Ethernet Cat5-cable.

- Hook up the Ethernet module with the supply voltage (8...48VDC / 12...35VAC), Power

LED glowing, LNK - LED glowing.

- Choose mode of IP-address assignment (DHCP /STATIC) by jumper setting at the

Ethernet module.

DHCP:

- Change jumper setting to DHCP.

- Press reset-button for 3-5 seconds (LNK - LED temporary off).

- Ethernet module changes to DHCP - mode and requests an IP - address from the

DHCP server.

- Transmitter will be detected as soon as ComCenter is active.

STATIC:

- Default jumper setting is STATIC.

- Factory settings for the transmitters are the static IP - address 192.168.0.64 with the

subnet-mask 255.255.255.0

- Networking settings of the used personal computer might need to be changed in order

to use same subnet-mask (255.255.255.0) as the connected transmitter.

Hardware

30

Page 31

E.g. Windows XP - Start / Settings / Network Connections / Local Area Connection

/ General / Properties / Internet Protocol (TCP/IP) / Properties ....

Note:

In case of further questions about the assignment of IP-addresses

in DHCP or STATIC mode kindly contact the network administrator.

Otherwise please do not hesitate to contact E+E Elektronik for

support.

9.2.3.4 Working with the ComCenter

Open ComCenter by either using the corresponding icon on the desktop or

the path defined during the installation.

Check the box "show End Devices only". In the list only EE33 transmitters

(End Devices) within the network will be shown.

Note:

If the box "show End Devices only" is not checked the ComCenter will show

all other network devices as well (e.g. PC's).

Press the button "Watch Clients" and the time passed since the last

successful communication with each network device is recorded and listed.

If a network device can not be reached, it will be highlighted in red!

With a click of the right mouse button either the web-interface or the editor

for Com-Port assignment can be selected.

Web-Interface:

Home:

Overview of system settings

Configuration:

EENet Name: LAN name of the selected transmitter (End

Device) can be defined / changed

Transmission Mode:

Transparent: fast transmission of data bytes via Ethernet (high

network load)

EE33 Protocol Frames: standard setting (low network load)

IP-Address Assignment:

STATIC: IP-address is manually assigned

DHCP: IP-address is assigned by DCHP server

Tools:

Possibility to either introduce or change the passwords for each

and every transmitter (End Device)

Info:

Contact address of the manufacturer

Hardware

31

Page 32

Edit COM Port assignment

Enter a desired Com-Port number (1...255). The Com-Port number will be

assigned to the corresponding IP-address.

Note:

If a number of an existing Hardware Com-Port

(COM1, COM2) is entered, than this will be

assigned. Otherwise a virtual Com-Port will be

created.

Attention:

ComCenter needs to be active (running) as long as the virtual Com-Ports are

in use!

If the ComCenter window is minimized, it will be hidden in the "System Tray"

(right bottom, next to the system time), but it remains active (running)!

9.2.3.5 Communication without ComCenter

Transmitters with an Ethernet module can also be used straight without the

ComCenter.

Please contact E+E Elektronik if you need information regarding the EE33

protocol for Ethernet communication.

Hardware

32

Page 33

10. SCOPE OF SUPPLY

Included in

all versions

EE33 according to ordering guide x

Manual EE33 German/English/French x

EE-PCA conguration software x

Inspection certicate according to DIN EN 10204 x

Allen key 3.0 only for metal housing

Data logging and visualization software N / E

Mating plug for integrated power supply V01

Mating plug RKC 5/7 V01 / C03 / C08

Y-junction for network connection C08 & N

Mating plug RSC 5/7 C06 / C08

M16 cable gland metal except C03, C06, C08, V01

Cutting ring fitting EE33-xFTI

According to

ordering guide

11. REPLACEMENT PARTS / ACCESSORIES

Description

Order code

- Filter

- Sintered stainless steel filter

- PTFE Filter

- Metal grid filter

- Display + housing cover in metal

- Interface cable for PCB

- Interface cable for plug option C06

- Mounting flange 12mm (1/2”)

- Mounting flange 6mm (1/4”)

- 1/2” ISO screw connection 12mm (1/2”)

- 1/2” ISO screw connection 6mm (1/4”)

- 1/2” NPT screw connection 12mm (1/2”)

- 1/2” NPT screw connection 6mm (1/4”)

- M16x1.5 => 1/2” NPT adapter for conduit fittings

- Drip water protection

- 1% calibration

- Calibration set

- RS485 Kit (HW + SW) for networking

- Datalogging and analysis software

- Adapter M16x1.5 to NPT 1/2

- Radiation shield for 12mm rH-probe

- Radiation shield for 6mm T-probe

- HUMOR 20 adapter for EE33 - model J

HA010103

HA010105

HA010106

D05M

HA010304

HA010311

HA010201

HA010207

HA011102

HA011104

HA011103

HA011105

HA011101

HA010503

EE90/3H

HA0104xx

HA010601

HA010602

HA011101

HA010502

HA010506

HA020401

33

Hardware

Page 34

12. TECHNICAL DATA

Technical Data EE33

Measurement values

Relative humidity

Humidity sensor

Working range1) 0...100% RH

Accuracy

*)

-15...40°C (5...104°F) ≤90% RH ± (1.3 + 0.3%*mv) % RH

-15...40°C

-25...70°C (-13...158°F) ± (1.4 + 1%*mv) % RH

-40...180°C (-40...356°F) ± (1.5 + 1.5%*mv) % RH

Temperature dependence of electronics typ. ± 0.01% RH/°C (0.0055% RH/°F)

Response time with metal grid filter at 20°C (68°F) / t90 < 15s

Temperature

Temperature sensor element monolithic measurement cell HMC1

Working range sensing head EE33-MFTC: -40...120°C

Accuracy (typ.)

1)

heated, monolithic measurement cell HMC1

(including hysteresis, non-linearity and repeatability, traceable to intern. standards, administrated by NIST, PTB, BEV...)

(5...104°F) >90% RH ± 2.3% RH

(-40...248°F) EE33-MFTD/E/I/J/K: -40...180°C (-40...356°

∆°C

°C

Temperature dependence of electronics typ. ± 0.005°C/°C

External temperature probe Pt1000 (DIN A)

Outputs

2)

Two freely selectable and scaleable analogue outputs 0 - 1V -1mA < IL < 1mA

0 - 5V -1mA < IL < 1mA

0 - 10V -1mA < IL < 1mA

4 - 20mA RL < 500 Ohm

0 - 20mA R

< 500 Ohm

L

Digital interface RS232 optional: RS485 or ethernet

Max. adjustable measurement range

Humidity RH 0 100 100 / % rF

Temperature T -40 (-40) 120 (248) 180 (356) / °C (°F)

Dew point temperature Td -40 (-40) 100 (212) 100 (212) 100 (212) °C (°F)

Frost point temperature Tf -40 (-40) 0 (32) 0 (32) 0 (32) °C (°F)

Wet bulb temperature Tw 0 (32) 100 (212) 100 (212) / °C (°F)

Water vapour partial pressure e 0 (0) 1100 (15) 1100(15) / mbar (psi)

Mixture ratio r 0 (0) 999 (9999) 999 (9999) / g/kg (gr/lb)

Absolute humidity dv 0 (0) 700 (300) 700 (300) / g/m3 (gr/f³)

Specific enthalpy h 0 (0) 2800 (999999) 2800 (999999) / kJ/kg (Btu/lb)

2)3)

from to unit

EE33-C EE33-D/E/I/J EE33-K

General

Supply voltage 8...35V DC

12...30V AC (optional 100...240V AC, 50/60Hz)

Current consumption - 2x voltage output for 24V DC/AC: typ. 40mA / 80mA

- 2x current output typ. 80mA / 160mA

Pressure range for pressure tight probe EE33-MFTEx/Jx/Kx: 0.01...20bar

EE33-MFTIx: 0...100bar (0...1450psi)

System requirements for software WINDOWS 2000 or later; serial interface

Housing / protection class Al Si 9 Cu 3 / IP65;

(Nema 4)

Cable gland M16 x 1.5 cable Ø 4.5 - 10 mm (0.18 - 0.39”)

Electrical connection screw terminals up to max. 1.5mm² (AWG 16)

Working and storage temperature range of electronics -40...60°C (-40...140°F)

-20...50°C (-4...122°F) - housing with display

Electromagnetic compatibility according to EN61326-1 EN61326-2-3 ICES-003 ClassB

Industrial Environment FCC Part15 ClassB

1) Refer to the working range of the humidity sensor. 2) Can be easily changed by software. 3) Refer to accuracies of calculated values (page 140)

4) Operating conditions of power supply V01: Overvoltage category II; Degree of pollution class 2; Installation altitude up to 2000m (6,562 ft.) above sea level

*) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was

calculated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

(0.15...300psi)

4)

Hardware

34

Page 35

Technical Data for Options

Display graphical LC display (128x32 pixels), with integrated push-buttons for selecting

parameters and MIN/MAX function

Alarm outputs 2 x 1 switch contact

250V AC / 6A

28V DC / 6A

threshold + hysteresis: can be adjusted with configuration software

switching parameters:

freely selectable between EE33-MFTD/E/I/J EE33-MFTK

RH Relative humidity

T Temperature

Td Dew point temperature

Tf Frost point temperature

Tw Wet bulb temperature

e Water vapour partial pressure

r Mixture ratio

dv Absolute humidity

h Specific enthalpy

Working Range Humidity Sensor

The grey area shows the allowed measurement range for the

humidity sensor.

Relative humidity [%RH]

Temperature [°C]

Operating points outside of this range do not lead to destruction

of the sensor, but the specified measurement accuracy cannot

be guaranteed.

35

Hardware

Page 36

CONFIGURATION SOFTWARE

LIMITED LIABILITY

E+E Elektronik® is not liable for any damages or consequential damages (for example,

but not restricted to loss of earnings, interruption of business, loss of information and data

or any other pecuniary damages), that result from the installation, usage and also

impossibility of usage of a software product from E+E Elektronik® and supportservices

possibly associated with it or non-performance of support.

1. GENERAL INFORMATION

The configuration software was developed by E+E Elektronik Ges.m.b.H to allow fast and

easy configuration of individual transmitters as well as of transmitter networks.

This software tool is included in delivery.

System requirements: MS WINDOWS 98® or higher; RS232 serial interface

2. INSTALLATION

Insert the CD-ROM supplied with the transmitter into your PC and open the set-up

application. Follow the instructions of the dialogue menus to set the desired language

and all further parameter for installation. At the end of the routine, the software is installed

and the Readme file or the program will be automatically opened.

Note:

If the configuration software has already been installed, or for upgrade only, the older

version must first be uninstalled (the User will be notified during the installation routine

and the process will be interrupted automatically).

To remove the previous version, open the software folder in the system control panel. All

of the programs installed on your system are located here. Uninstall the EE33 Configurator

by clicking on the appropriate button and then install the upgrade.

Configurations software

36

Page 37

3. ICONS ON THE TOOLS BAR

3.1 File

Load: Loads a file with a saved transmitter configuration.

Save: Saves the current transmitter configuration in a file.

New Workspace: Opens a file for a new tree (new network).

Open Workspace: Opens existing trees (networks).

Save Workspace: Saves the current trees (networks) in an archive file.

Note:

The functions "Save Workspace" and "Open Workspace" apply to the tree

structure only, not to the configurations of individual transmitters!

Therefore only the network structure is saved. Transmitters configurations must

be reloaded using the command "Read All Transmitters."

Select: Selects the serial interface (COM port) for communication with the transmitters.

Following functions are available:

3.2 Interfaces

use / do not use: Marked COM ports are greyed out and deactivated for the configuration software

(e.g., COM for integrated Notebook Modem).

Note:

A disabled interface (shaded = do not use), can be enabled by clicking on the

"use" button.

Configurations software

37

Page 38

3.3 Group

The icon "Group" provides the option of combining transmitters in groups.

A group may consist of transmitters used in the same application, for instance

assigned to a building, or belonging to the same transmitter network.

New: Creates a group or adds another group into an existing structure.

Delete: Deletes groups within a tree.

Rename: Changes the name of a transmitter group.

3.4 Transmitter

New transmitter:

A new transmitter is created in the tree.

This procedure requires the input of a number of parameters:

Group: Assigns a transmitter to a group.

Network: The check box "network" must be selected when several transmitters are operated in a network (EE33 series).

Interface: Selects the interface for connecting the transmitter to the network.