Page 1

User Manual

EE300Ex

HUMIDITY / TEMPERATURE

SENSOR

BA_EE300Ex_e // V1.11 // technical data are subject to change // 194916

Page 2

E+E Elektronik Ges.m.b.H. doesn‘t accept warranty and liability claims neither upon this publication nor in case of

improper treatment of the described products.

The document may contain technical inaccuracies and typographical errors. The content will be revised on a

regular basis. These changes will be implemented in later versions. The described products can be improved and

changed at any time without prior notice.

© Copyright E+E Elektronik Ges.m.b.H.

All rights reserved.

EMC note USA (FCC):

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

EMC note Canada (ICES-003):

CAN ICES-3 (A) / NMB-3 (A)

Page 3

CONTENTS

1 General ................................................................................................................................................. 4

1.1 Explanation of Symbols .................................................................................................................................4

1.2 Safety Instructions .........................................................................................................................................4

1.2.1 General safety instructions ..................................................................................................................................4

1.2.2 Mounting, start-up and operation ......................................................................................................................... 4

1.3 Environmental Aspects ..................................................................................................................................5

1.4 ESD Protection ..............................................................................................................................................5

1.5 Scope of Supply ............................................................................................................................................5

1.6 Accessories ...................................................................................................................................................5

1.6.1 EE300Ex-M1 Humidity and Temperature Sensor ................................................................................................5

1.6.2 EE300Ex-M3 Temperature sensor ....................................................................................................................... 5

2 Product description ............................................................................................................................6

2.1 General ..........................................................................................................................................................6

2.2 EE300Ex labelling ........................................................................................................................................7

2.3 Certification ...................................................................................................................................................8

2.4 Dimensions (mm / inch) ...............................................................................................................................12

2.4.1 EE300Ex-M1: Humidity and Temperature Sensor .............................................................................................12

2.4.2 EE300Ex-M3: Temperature Sensor ................................................................................................................... 12

3 Installation .........................................................................................................................................13

3.1 General ........................................................................................................................................................13

3.2 Enclosure ...................................................................................................................................................13

3.2.1 Drilling pattern for installing the enclosure (mm/inch) ........................................................................................ 14

3.3 Assembly in category 1 (Zone 0 / 20); Division 1 ........................................................................................14

3.4 Assembly in categories 2 and 3 (Zone 1 , 2 / 21 , 22); Division 2 ...............................................................16

3.5 Probe mounting ...........................................................................................................................................17

3.5.1 Probe feedthrough with cut-in fitting ..................................................................................................................18

3.5.2 Mounting flange .................................................................................................................................................19

3.5.3 Ball valve and sliding fitting ................................................................................................................................ 19

3.5.4 The optional probe retraction tool ......................................................................................................................20

4 Electrical connections ......................................................................................................................21

4.1 General ........................................................................................................................................................21

4.2 Terminal assignment ...................................................................................................................................22

4.3 Grounding and potential equalization ..........................................................................................................22

4.4 Connection cable .........................................................................................................................................23

4.5 Calculation of the maximum cable length ....................................................................................................23

4.6 Selecting a suitable Intrinsically safe supply unit for ATEX Zone concept ..................................................24

4.7 Configuration adapter ..................................................................................................................................25

4.8 Calibration of the current loop .....................................................................................................................26

5 Display (optional) ..............................................................................................................................26

6 Maintenance ....................................................................................................................................... 26

6.1 Filter cap replacement .................................................................................................................................26

6.2 Cleaning the EE300EX sensor ....................................................................................................................27

6.2.1 Cleaning the enclosure ......................................................................................................................................27

6.2.2 Cleaning the probe ............................................................................................................................................. 27

6.3 Configuration, Adjustment and Calibration ..................................................................................................27

6.4 Display error messages ...............................................................................................................................27

7 Technical Data ...................................................................................................................................28

7.1 EE300Ex-M1 Humidity and Temperature Sensor ........................................................................................28

7.2 EE300Ex-M3 Temperature Sensor ..............................................................................................................29

8 ATEX Certificate ................................................................................................................................30

9 EU Declaration of Conformity .......................................................................................................... 34

10 IECEX Certification of Conformity - COC ........................................................................................ 35

11 FM Certificate USA ............................................................................................................................36

12 FM Certificate Canada ....................................................................................................................... 43

13 Control Drawing M1_1309080 ..........................................................................................................50

User Manual EE300Ex Humidity / Temperature Sensor

3

Page 4

1 General

This user manual is part of the scope of supply and serves for ensuring proper handling and

optimal functioning of the device.

The user manual shall be read before commissioning the equipment and it shall be provided to

all staff involved in transport, installation, operation, maintenance and repair.

The user manual may not be used for the purposes of competition without the written consent of E+E

Elektronik® and may not be forwarded to third parties. Copies may be made for internal purposes. All

information, technical data and diagrams included in these instructions are based on the information

available at the time of writing.

1.1 Explanation of Symbols

This symbol indicates safety information.

It is essential that all safety information is strictly observed. Failure to comply with this information can

lead to personal injuries or damage to property. E+E Elektronik® assumes no liability if this happens.

This symbol indicates instructions.

The instructions shall be observed in order to reach optimal performance of the device.

This symbol indicates regulations that must be observed in hazardous areas at risk of

explosion.

1.2 Safety Instructions

1.2.1 General safety instructions

• Avoid any unnecessary mechanical stress and inappropriate use.

• When replacing the filter cap make sure not to touch the sensing elements.

• For sensor cleaning and filter cap replacement please see “Cleaning instructions” at www.epluse.com.

• Installation, electrical connection, maintenance and commissioning shall be performed by qualified

personnel only.

1.2.2 Mounting, start-up and operation

The device has been produced under state of the art manufacturing conditions, has been thoroughly

tested and has left the factory fulfilling all safety criteria.

The manufacturer has taken all precautions to ensure safe operation of the device. The user must ensure

that the device is set up and installed in a manner that does not have a negative effect on its safe use.

The user is responsible for observing all applicable safety guidelines, local and international, with

respect to safe installation and operation on the device. This user manual contains information

and warnings that must be observed by the user in order to ensure safe operation.

• Mounting, start-up, operation and maintenance of the device may be performed by qualified staff only.

• Such staff must be authorized by the plant operator to carry out the mentioned activities.

• The qualified staff must have read and understood this user manual and must follow the instructions

contained within.

• All process and electrical connections shall be thoroughly checked by authorized staff before putting

the system into operation.

• Do not install or start start-up a device supposed to be faulty. Make sure that such devices are not

accidentally used by marking them clearly as faulty.

• A faulty device may only be investigated and possibly repaired by qualified, trained and authorized

staff. If the fault cannot be fixed, the device shall be removed from the system.

• Service operations other than described in this operating manual may only be performed by the

manufacturer.

4

User Manual EE300Ex Humidity / Temperature Sensor

Page 5

1.3 Environmental Aspects

Products from E+E Elektronik® are developed and manufactured observing of all relevant requirements

with respect to environment protection. Please observe local regulations for the device disposal.

For disposal, the individual components of the device must be separated according to local recycling

regulations. The electronics shall be disposed of correctly as electronics waste.

1.4 ESD Protection

The sensing elements and the electronics board are ESD (electrostatic discharge) sensitive components

of the device and must be handled as such. The failure to do so may damage the device by electrostatic

discharges when touching exposed sensitive components.

1.5 Scope of Supply

• EE300Ex according to ordering guide

• User manual

• Inspection certificate according to DIN EN 10204-3.1

1.6 Accessories

1.6.1 EE300Ex-M1 Humidity and Temperature Sensor

Blind front cover for housing base HA011401

Safety barrier, 1-channel, STAHL 9002/13-280-093-001 HA011410

Intrinsically safe supply unit, 1-channel, STAHL 9160/13-11-11 HA011405

Intrinsically safe supply unit , 2-channel, STAHL 9160/23-11-11 HA011406

Sealing plug for unused M16 cable glands HA011402

Sealing plug for unused M20 cable glands HA011404

Ball valve with 1/2 ISO female thread, ATEX certified HA011403

Sensor retraction tool PN250 ZM-WA-025-040-EST

Sensor retraction tool PN40 BG-WA-103-045-EST

Product configuration adapter (see data sheet EE-PCA) EE-PCA

Connection cable for EE-PCA HA011068

1.6.2 EE300Ex-M3 Temperature sensor

Blind front cover for housing base HA011401

Safety barrier, 1-channel, STAHL 9002/13-280-093-001 HA011410

Intrinsically safe supply unit, 1-channel, STAHL 9160/13-11-11 HA011405

Intrinsically safe supply unit , 2-channel, STAHL 9160/23-11-11 HA011406

Sealing plug for unused M16 cable glands HA011402

Sealing plug for unused M20 cable glands HA011404

Product configuration adapter (see data sheet EE-PCA) EE-PCA

Connection cable for EE-PCA HA011068

User Manual EE300Ex Humidity / Temperature Sensor

5

Page 6

2 Product description

2.1 General

The EE300Ex-M1 and the EE300Ex-M3 intrinsically safe sensors are intended for the measurement of

relative humidity (RH) and temperature (T) or temperature alone, in the explosion hazard areas, in gas

and dust up to Zone 0/20. The entire device can be placed in the explosion endangered area.

The sensor may only be powered by an intrinsically safe power supply device or protective barriers.

It features a 2 wire 4…20 mA design and has two individually scalable analogue outputs.

In addition to the measured RH and T, the EE300Ex-M1 calculates also the following parameters:

• Absolute humidity dv

• Wet-bulb temperature Tw

• Specific enthalpy h

• Dew point temperature Td

• Frost point temperature Tf

• Mixing ratio r

• Water vapour partial pressure e

Besides measurement in the air, the EE300Ex-M1 with ATEX or IECEx approval is also suitable for

measuring water content (X) in ppm and water activity (aw) in isolation, lubrication and

hydraulic oils.

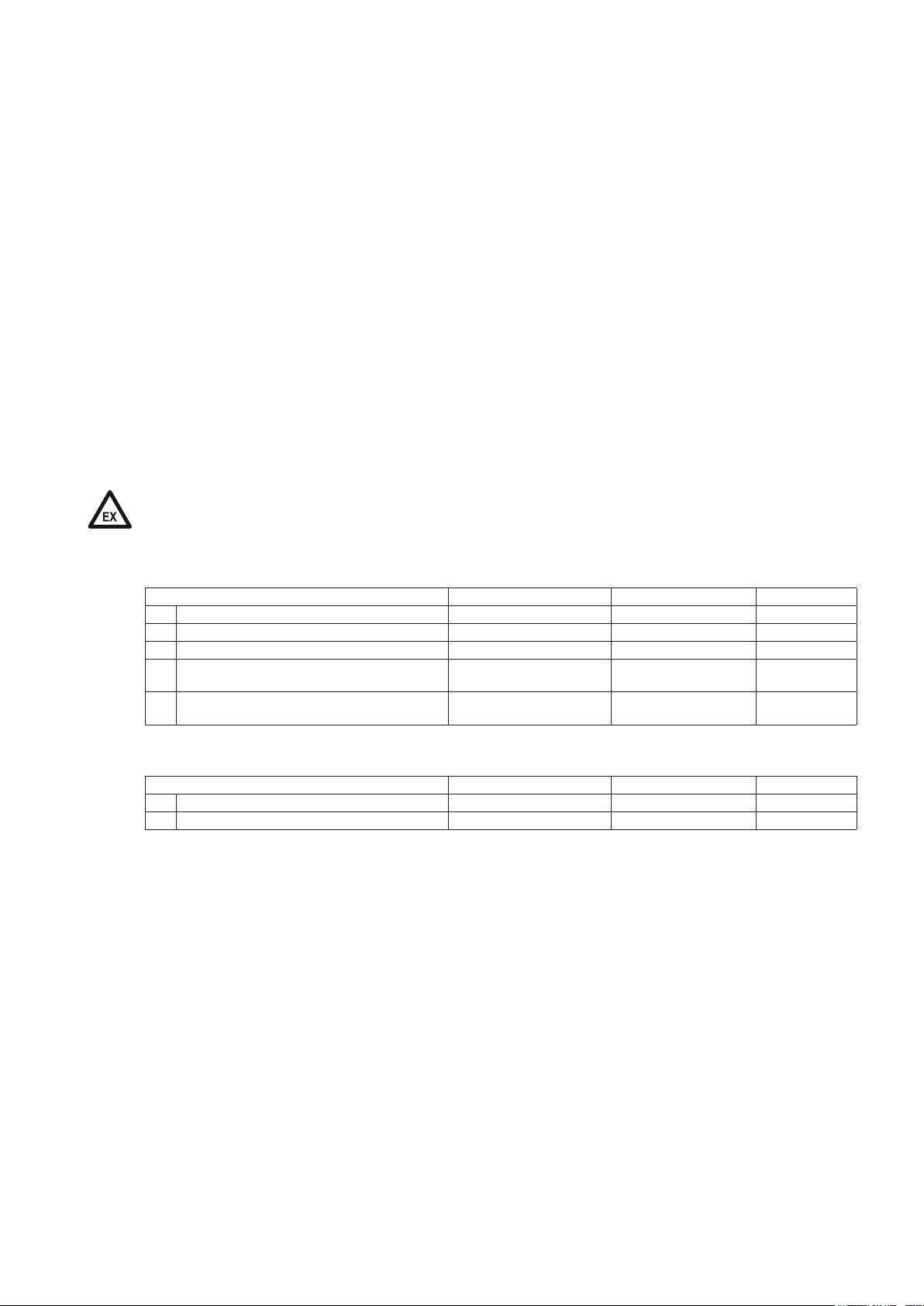

EE300Ex-M1 humidity and temperature sensor types:

Type Pressure range Temperature range Probe Ø)

T1 Wall mount ambient -40...60 °C

T7 Remote probe with cut-in fitting, pressure tight 0.1...20 bar (1.5...300 psi) -40...180 °C (-40...356 °F) 12 mm (0.47")

T9 Remote probe with cut-in fitting, pressure tight 0.01...300 bar (0.15...4 351 psi) -40...180 °C (-40...356 °F) 12 mm (0.47")

T10 Remote probe with sliding fitting for assembly /

disassembly under pressure, pressure tight

T22 Remote probe for sensor retraction tool PN250,

pressure tight

0.1...20 bar (1.5...300 psi) -40...180 °C (-40...356 °F) 13 mm (0.51")

0.01...250 bar (0.15...3 626 psi) -40...180 °C (-40...356 °F) 12 mm (0.47")

(-40...140 °F) 12 mm (0.47")

EE300Ex-M3 temperature sensor models:

Type Pressure range Temperature range Probe Ø)

T1 Wall mount ambient -40...60 °C

T24 Remote probe 0.1...20 bar (1.5...300 psi) -70...200 °C (-94...392 °F) 6 mm (0.24")

(-40...140 °F) 6 mm (0.24")

Disclaimer

The manufacturer cannot be held responsible for damages as a result of incorrect handling, installation

and maintenance of the device. Unauthorized modifications of the product lead to loss of all warranty

claims.

The manufacturer or his authorized agent can be only be held liable in case of willful or gross negligence. In any case, the scope of liability is limited to the corresponding amount of the order issued to

the manufacturer. The manufacturer assumes no liability for damages incurred due to failure to comply

with the applicable regulations, operating instructions or the operating conditions. Consequential damages are excluded from the liability.

6

User Manual EE300Ex Humidity / Temperature Sensor

Page 7

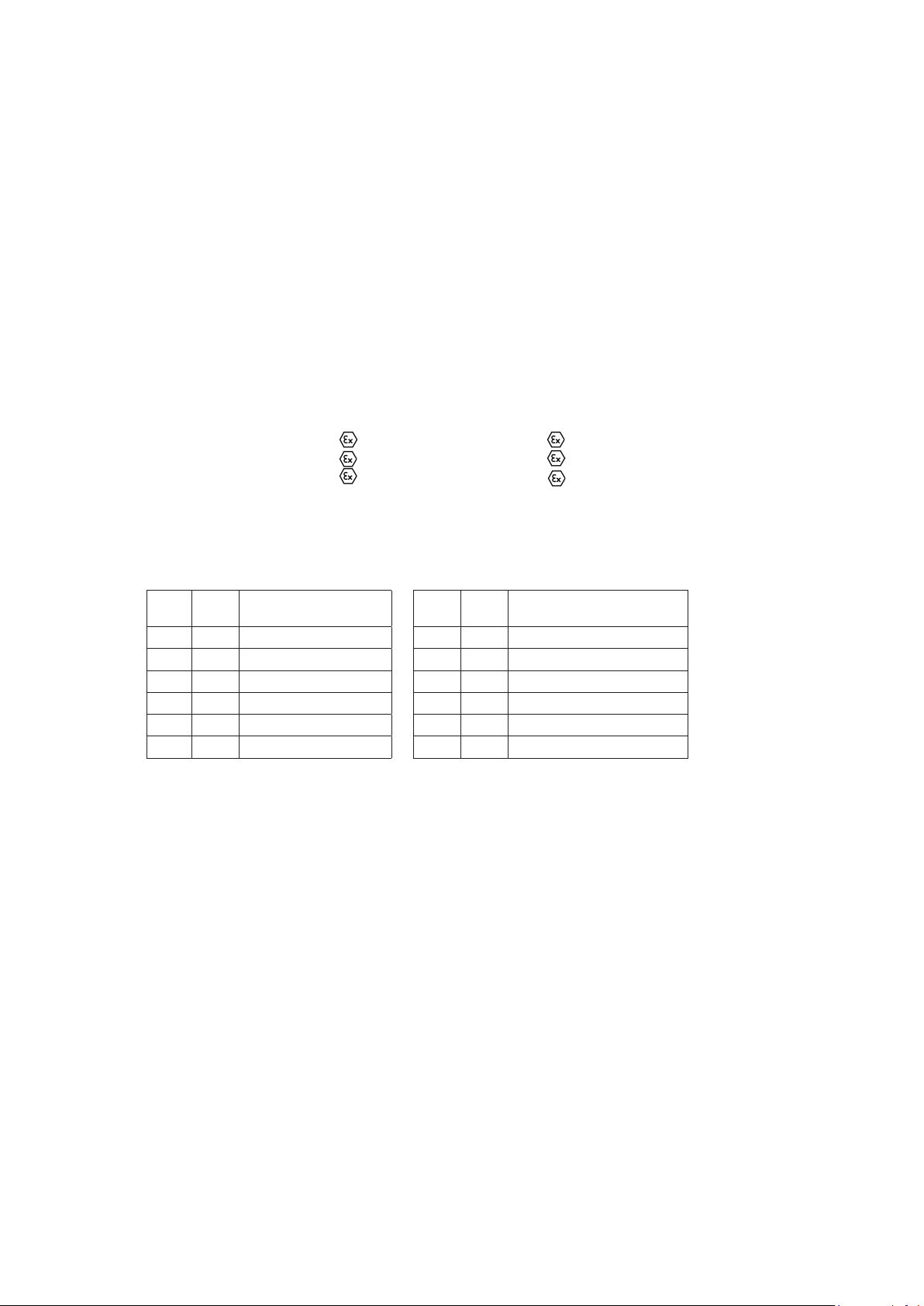

2.2 EE300Ex labelling

HUMIDITY / TEMPERATURE SENSOR

HUMIDITY / TEMPERATURE SENSOR

E+E Elektronik A-4209 Engerwitzdorf FM17US0302X

E+E Elektronik A-4209 Engerwitzdorf FM17CA0154X

HUMIDITY / TEMPERATURE SENSOR

MADE IN

HUMIDITY / TEMPERATURE SENSOR

MADE IN

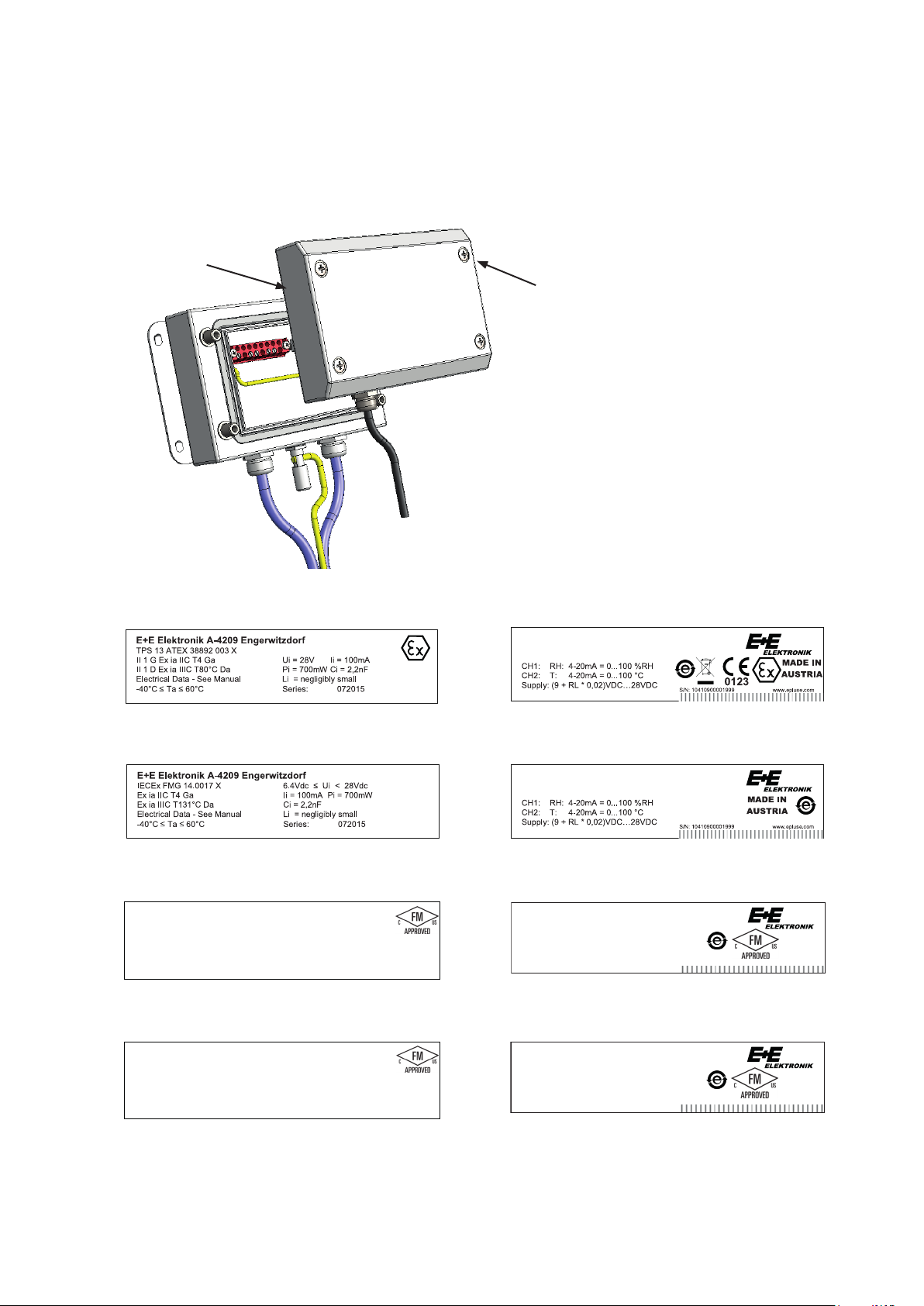

Each EE300Ex is characterized for one certification. The sensor has two labels. The “product label”

shows the ordering code and type of the Ex Certificate. The “hazardous label” shows the Ex marking

and the certificate number. See the examples below.

EE300Ex with IECEx, USA or Canada labeling must not be installed in the European Union.

Hazardous Label

(Ex marking)

Product Label

ATEX hazardous label (for EE300Ex without display) ATEX product label (Example)

EE300Ex-M1A6HS2T10D0E2K5L200PA25F4C1EX1

F

IECEx hazardous label (for EE300Ex without display) IECEx product label (Example)

EE300Ex-M1A6HS2T10D0E2K5L200PA25F4C1EX2

F

USA hazardous label (for EE300Ex without display) USA product label (Example)

EE300Ex-

CL I,II,III DIV 1 GP ABCDEFG T4

CL I,II,III DIV 2 GP ABCDEFG T4

CL I ZN 0 AEx ia IIC T4 Ga ZN 20 AEx ia IIIC T131°C Da

Ta = -40°C to 60°C, Entity - M1_1309080, IP65 Series:

122017

F

M1A6HS2T10D0E2K5L200PA25F4C1EX3

CH1: RH: 4-20mA = 0…100%RH

CH2: T: 4-20mA = 0…100°C

Supply: (9 + RL * 0,02)VDC…28VDC

S/N: 10410900001999 www.epluse.com

CANADA hazardous label (for EE300Ex without display) CANADA product label (Example)

EE300Ex-

CL I,II,III DIV 1 GP ABCDEFG T4

CL I,II,III DIV 2 GP ABCDEFG T4

ZN 0 Ex ia IIC T4 Ga ZN 20 Ex ia IIIC T131°C Da

Ta = -40°C to 60°C, Entity - M1_1309080, IP65 Series: 122017

F

M1A6HS2T10D0E2K5L200PA25F4C1EX9

CH1: RH: 4-20mA = 0…100%RH

CH2: T: 4-20mA = 0…100°C

Supply: (9 + RL * 0,02)VDC…28VDC

S/N: 10410900001999 www.epluse.com

AUSTRIA

AUSTRIA

User Manual EE300Ex Humidity / Temperature Sensor

7

Page 8

2.3 Certification

EUROPE:

The EE300Ex sensor fulfills the ATEX Directives on intrinsically safe operating equipment.

Applied standards for ATEX:

• EN 1127-1:2011

• EN 60079-0:2012

• EN 60079-11:2012

The EU-Type Examination has been carried out by TÜV SÜD Product Service GmbH.

Certified to EU-Type Examination TPS 13 ATEX 38892 003 X.

Entity parameters Ui = 28V; Ii = 100mA; Pi: = 700mW; Ci = 2,2nF; Li ≈ 0mH

Ex-Designation

Sensor without display I II 1G Ex ia IIC T4 Ga / II 1D Ex ia IIIC T80°C Da

Sensor with display I II 2G Ex ia IIC T4 Gb / II 1G Ex ia IIB T4 Ga

Remote probe II 1G Ex ia IIC T6-T1 Ga / II 1D Ex ia IIIC T80°C...200°C Da

Working temperature range for the probes:

Specification of the temperature class „TKG“ for use in gas area exposed to explosion hazards and

„TKD“ for use in dust area exposed to explosion hazards as a function of the ambient temperature

„Tamb“ for the humidity and temperature probe and the temperature probe:

TKG TKD

T6 80°C

T5 95°C

T4 130°C

T3 195°C

T2 200°C

T1 200°C

Humidity and

Temperature Probe

-40°C ≤ Tamb ≤ +60°C

-40°C ≤ Tamb ≤ +75°C

-40°C ≤ Tamb ≤ +110°C

-40°C ≤ Tamb ≤ +175°C

-40°C ≤ Tamb ≤ +180°C

-40°C ≤ Tamb ≤ +180°C

TKG TKD Temperature Probe

T6 80°C

T5 95°C

T4 130°C

T3 195°C

T2 220°C

T1 220°C

-70°C ≤ Tamb ≤ +60°C

-70°C ≤ Tamb ≤ +75°C

-70°C ≤ Tamb ≤ +110°C

-70°C ≤ Tamb ≤ +175°C

-70°C ≤ Tamb ≤ +200°C

-70°C ≤ Tamb ≤ +200°C

INTERNATIONAL:

Applied Standard for IECEx:

• IEC 60079-0:2011

• IEC 60079-11:2011

The Certificate of Conformity has been carried out by FM Approvals.

Certificate No.: IECEx FMG 14.0017 X

Entity parameters: 6.4 Vdc ≤ Ui ≤ 28Vdc; Ii = 100mA; Pi = 700mW; Ci = 2,2nF; Li = 0mH

Ex-Designation

Sensor without display Ex ia IIC T4 Ga / Ex ia IIIC T131°C Da

Sensor with display Ex ia IIC T4 Gb / Ex ia IIB T4 Ga

Remote probe Ex ia IIC T6-T1 Ga / Ex ia IIIC T80°C Da

Humidity and temperature probe:

• T6 temperature class based on -40°C (-40°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -40°C (-40°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -40°C (-40°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -40°C (-40°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

• T1 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

8

User Manual EE300Ex Humidity / Temperature Sensor

Page 9

Temperature probe:

• T6 temperature class based on -70°C (-94°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -70°C (-94°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -70°C (-94°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -70°C (-94°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

• T1 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

USA:

Applied Standard for the U.S. NEC 500, NEC505 and 506:

• FM Class 3600 2011

• FM Class 3610 2015

• FM Class 3611 2016

• FM Class 3810 2005

• ANSI/ISA 61010-1 2012

• ANSI/ISA 60079-0 2013

• ANSI/ISA 60079-11 2014

• ANSI/IEC 60529 2004

The Certificate of Conformity has been carried out by FM Approvals.

Certificate No.: FM17US0302X

Entity parameters:

6.4 Vdc ≤ V

(or Ui) ≤ 28 Vdc; I

max

(or Ii) = 100mA; Pi = 700mW; Ci = 2,2nF; Li = 0mH

max

Ex-Designation NEC 500 (Division)

Sensor without display

Class I, II, III, Division 1, Groups ABCDEFG; T4 Ta = -40°C to +60°C; Entity – M1_139080; IP65

Class I, II, III, Division 2, Groups ABCDEFG; T4 Ta = -40°C to +60°C

Sensor with display

Class I, Division 1, Groups CD; T4 Ta = -40°C to +60°C; Entity – M1_139080

Class I, Division 2, Groups ABCD; T4 Ta = -40°C to +60°C; Entity – M1_139080

Remote probe

Class I, II, III, Division 1, Groups ABCDEFG; T6…T1; Entity – M1_139080; IP65

Class I, II, III, Division 2, Groups ABCDEFG; T6…T1

Humidity and temperature probe:

• T6 temperature class based on -40°C (-40°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -40°C (-40°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -40°C (-40°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -40°C (-40°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

• T1 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

Temperature probe:

• T6 temperature class based on -70°C (-94°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -70°C (-94°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -70°C (-94°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -70°C (-94°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

• T1 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

User Manual EE300Ex Humidity / Temperature Sensor

9

Page 10

Ex-Designation NEC 505/506 (Zone)

Sensor without display

Class I, Zone 0, AEx ia IIC T4 Ta = -40°C to +60°C Ga; Entity – M1_139080; IP65

Zone 20, AEx ia IIIC T131°C Ta = -40°C to +60°C Da; Entity – M1_139080; IP65

Sensor with display

Class I, Zone 0, AEx ia IIB T4 Ta = -40°C to +60°C Ga; Entity – M1_139080

Class I, Zone 1, AEx ia IIC T4 Ta = -40°C to +60°C Gb; Entity – M1_139080

Remote probe

Class I, Zone 0, AEx ia IIC T6…T1 Ga; Entity – M1_139080; IP65

Zone 20, AEx ia IIIC T80°C Da; Entity – M1_139080; IP65

Humidity and temperature probe:

• T6 temperature class based on -40°C (-40°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -40°C (-40°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -40°C (-40°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -40°C (-40°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

• T1 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

Temperature probe:

• T6 temperature class based on -70°C (-94°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -70°C (-94°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -70°C (-94°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -70°C (-94°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

• T1 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

Canada:

Applied Standard for Canada CEC Section 18 and Annex J:

• CSA-22.2 No. 0-M91 R2006

• CAN/CSA-22.2 No. 61010-1 2012

• CSA-22.2 No. 157-92 2016

• CAN/CSA-22.2 No. 60079-0 2015

• CAN/CSA-22.2 No. 60079-11 2014

• CSA-C 22.2 No. 142-M1987 R2004

• CSA-C 22.2 No. 213 2015

• CSA-C 22.2 No. 60529 R2010

The Certificate of Conformity has been carried out by FM Approvals.

Certificate No.: FM17CA0154X

Entity parameters:

6.4 Vdc ≤ V

Ex-Designation CEC Annex J (Division)

Sensor without display

Class I, II, III, Division 1, Groups ABCDEFG; T4 Ta = -40°C to +60°C; Entity – M1_139080; IP65

Class I, II, III, Division 2, Groups ABCDEFG; T4 Ta = -40°C to +60°C

(or Ui) ≤ 28 Vdc; I

max

(or Ii) = 100mA; Pi = 700mW; Ci = 2,2nF; Li = 0mH

max

10

Sensor with display

Class I, Division 1, Groups CD; T4 Ta = -40°C to +60°C; Entity – M1_139080

Class I, Division 2, Groups ABCD; T4 Ta = -40°C to +60°C; Entity – M1_139080

User Manual EE300Ex Humidity / Temperature Sensor

Page 11

Remote probe

Class I, II, III, Division 1, Groups ABCDEFG; T6…T1; Entity – M1_139080; IP65

Class I, II, III, Division 2, Groups ABCDEFG; T6…T1

Humidity and temperature probe:

• T6 temperature class based on -40°C (-40°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -40°C (-40°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -40°C (-40°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -40°C (-40°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

• T1 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

Temperature probe:

• T6 temperature class based on -70°C (-94°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -70°C (-94°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -70°C (-94°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -70°C (-94°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

• T1 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

Ex-Designation CEC Section 18 (Zone)

Sensor without display

Zone 0, Ex ia IIC T4 Ta = -40°C to +60°C Ga; Entity – M1_139080; IP65

Zone 20, Ex ia IIIC T131°C Ta = -40°C to +60°C Da; Entity – M1_139080; IP65

Sensor with display

Zone 0, Ex ia IIB T4 Ta = -40°C to +60°C Ga; Entity – M1_139080

Zone 1, Ex ia IIC T4 Ta = -40°C to +60°C Gb; Entity – M1_139080

Remote probe

Zone 0, Ex ia IIC T6…T1 Ga; Entity – M1_139080; IP65

Zone 20, Ex ia IIIC T80°C Da; Entity – M1_139080; IP65

Humidity and temperature probe:

• T6 temperature class based on -40°C (-40°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -40°C (-40°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -40°C (-40°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -40°C (-40°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

• T1 temperature class based on -40°C (-40°F) ≤ Ta ≤ 180°C (356°F)

Temperature probe:

• T6 temperature class based on -70°C (-94°F) ≤ Ta ≤ 60°C (140°F)

• T5 temperature class based on -70°C (-94°F) ≤ Ta ≤ 75°C (167°F)

• T4 temperature class based on -70°C (-94°F) ≤ Ta ≤ 110°C (230°F)

• T3 temperature class based on -70°C (-94°F) ≤ Ta ≤ 175°C (347°F)

• T2 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

• T1 temperature class based on -70°C (-94°F) ≤ Ta ≤ 200°C (392°F)

User Manual EE300Ex Humidity / Temperature Sensor

11

Page 12

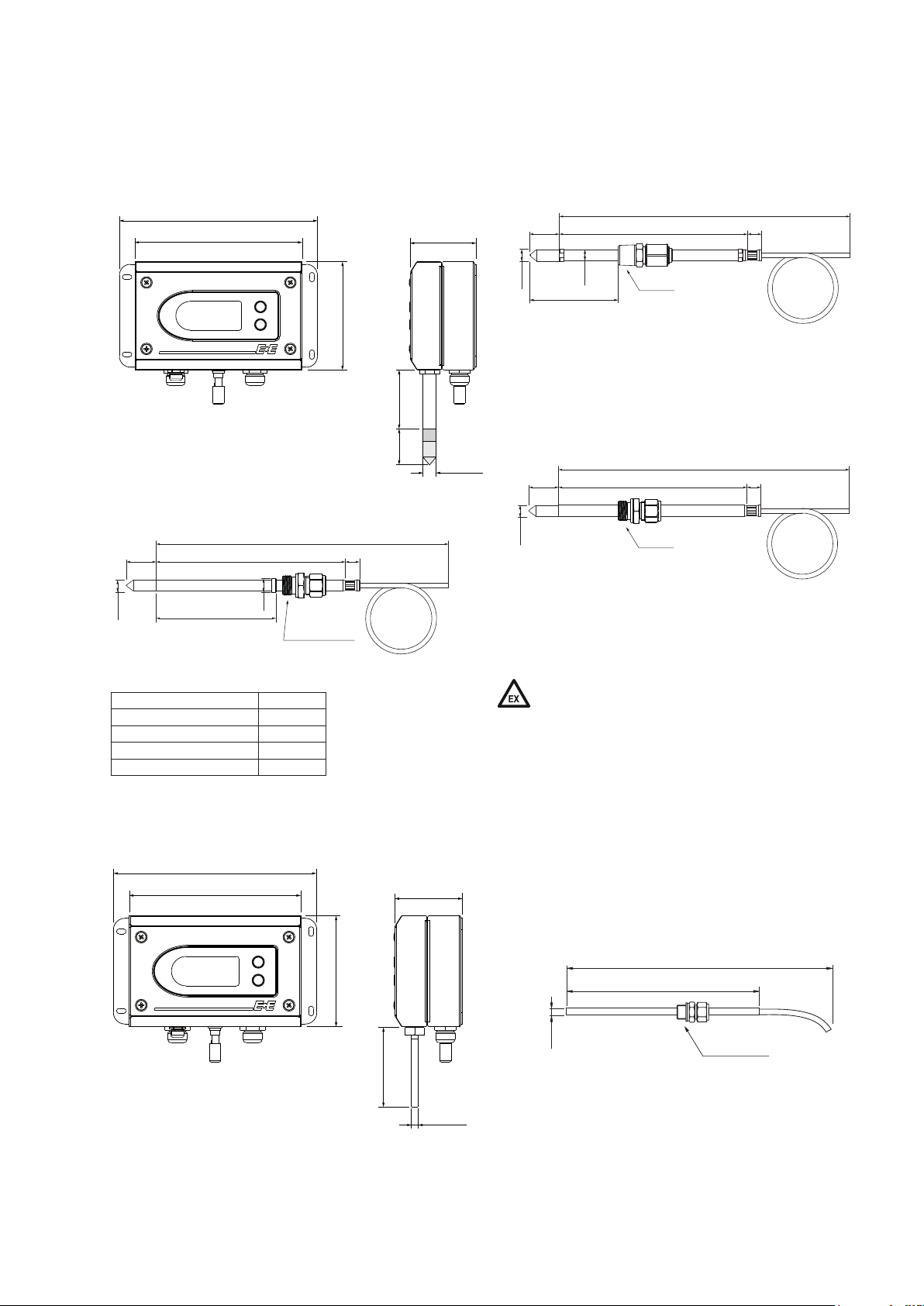

2.4 Dimensions (mm / inch)

2.4.1 EE300Ex-M1: Humidity and Temperature Sensor

179 (7)

98 (3.9)

Types: T1 / T7 / T9 / T10 / T22

Enclosure

code „cable length“

(11.81)

Ø12

L

(0.47)

186 (7.32)

300

Ø15

(0.6)

G1/2“ ISO

Type: T22

Remote probe for sensor retraction tool PN250

L - length of filter mm (inch)

Stainless steel sintered filter 33 (1.3“)

PTFE filter, H2O2 filter 33 (1.3“)

Stainless steel grid filter 39 (1.5“)

Oil filter 32 (1.26“)

15 (0.6)

60 (2.4)151 (5.9)

53 (2.1)

L

Type: T1

Wall mount

Ø 12 (0.47)

code „cable length“

L

Ø13

(0.51)

adjustable min. 23 (0.9) /

max. 164 (6.5) / 364 (14.3)

Ø12

(0.47)

code „probe length “

G1/2" ISO or 1/2“ NPT

15 (0.6)

Type: T10

Remote probe 20 bar (300 psi) with sliding fitting for assembly /

disassembly under pressure

code „cable length“

15 (0.6)

Ø12

(0.47)

L

code „probe length “

G1/2" ISO or 1/2" NPT

Types: T7 / T9

Remote probe T7: 20 bar (300 psi)

Remote probe T9: 300 bar

Pressure-tight probe up to 300 bar (4 351 psi) has leak rate A

according to EN 12266-1

Pressure-tight probe up to 20 bar (300 psi) has leak rate B

according to EN 12266-1

Leak rate can lead to gas accumulation in the enclosure

(4 351 psi) with weld or cut-in fitting

2.4.2 EE300Ex-M3: Temperature Sensor

179 (7)

151 (5.9)

98 (3.9)

Types: T1/T24

Enclosure

12

70 (2.8)

Type: T1

Wall mount

60 (2.4)

Ø 6 (0.24)

code „cable length“

150 (6)

Ø 6 (0.24)

G1/2" ISO or 1/2“ NPT

Type: T24

Remote probe 0.1...20bar (1.5...300psi) with cut-in fitting

User Manual EE300Ex Humidity / Temperature Sensor

Page 13

3 Installation

3.1 General

The EE300Ex is certified according to ATEX 2014/34/EU Directive, IECEX Scheme, National Electrical

Code ANSI-NFPA 70 (NEC©) and Canadian Electrical Code (CSA C22.1).

The use of the EE300EX in explosion hazard areas is only permitted under following atmospheric conditions:

-20°C(-4°F) ≤T≤ 40°C(104°F)

0.8bar(12psi)≤p≤ 1.1bar(16psi)

air normally 21 % (v/v)

The EE300Ex may be employed beyond above atmospheric conditions range only observing EN 1127-1

and only in line with the manufacturer‘s instructions.

The EE300Ex may only be supplied by intrinsically safe power supply devices or via protective barriers.

This applies also for the case when just the probe is located inside the explosion hazard area.

The rules for wiring intrinsically safe electrical circuits according to EN 60079-14, EN 60079-25, IEC

60079-14, IEC 60079-25 (proof of intrinsic safety in the system description) as well as all applicable

national regulations must be strictly observed. For the U.S., Canada refer to the Control

Drawing M1_1309080 (page 51) and ANSI/ISA RP12.6.01, NEC and CEC.

The intrinsically safe circuitry shall include an overvoltage protection device if the analysis according EN

1127-1 reveals a risk of lightning strike.

Requirements for the installation of overvoltage protection devices are set in European Normative EN

60079-25. For the U.S., Canada refer to ANSI/ISA RP12.6.01, NEC and CEC.

The manufacturing date of each EE300Ex is shown on the hazardous product label, at the bottom right

corner, as follows:

WWYYYY

WW .........week of the year

YYYY ........ year

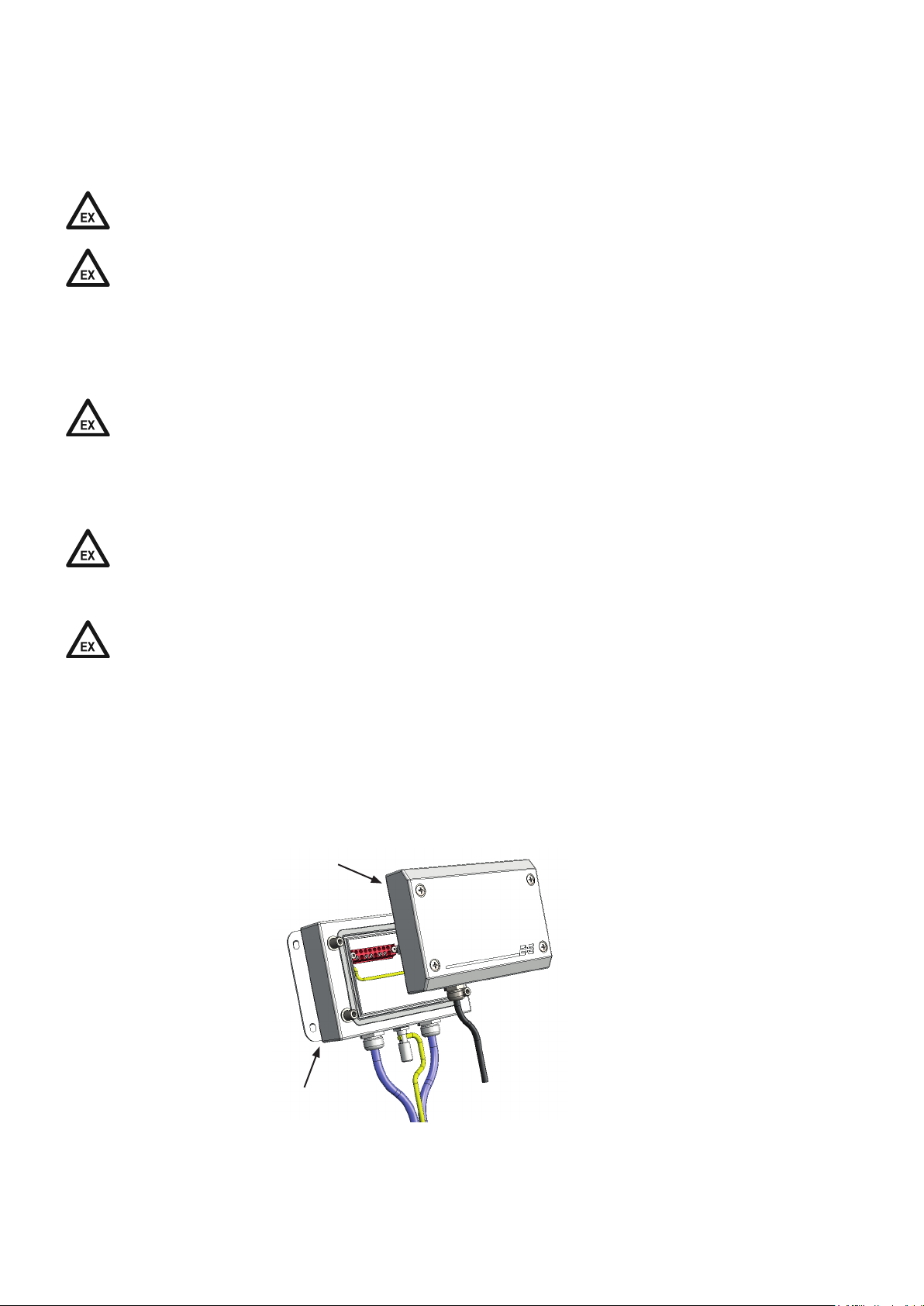

3.2 Enclosure

The EE300Ex features has a modular design and consists of:

• Bottom section with the connection and grounding terminals

• Front section with the electronics and the probe

front section

bottom section

User Manual EE300Ex Humidity / Temperature Sensor

13

Page 14

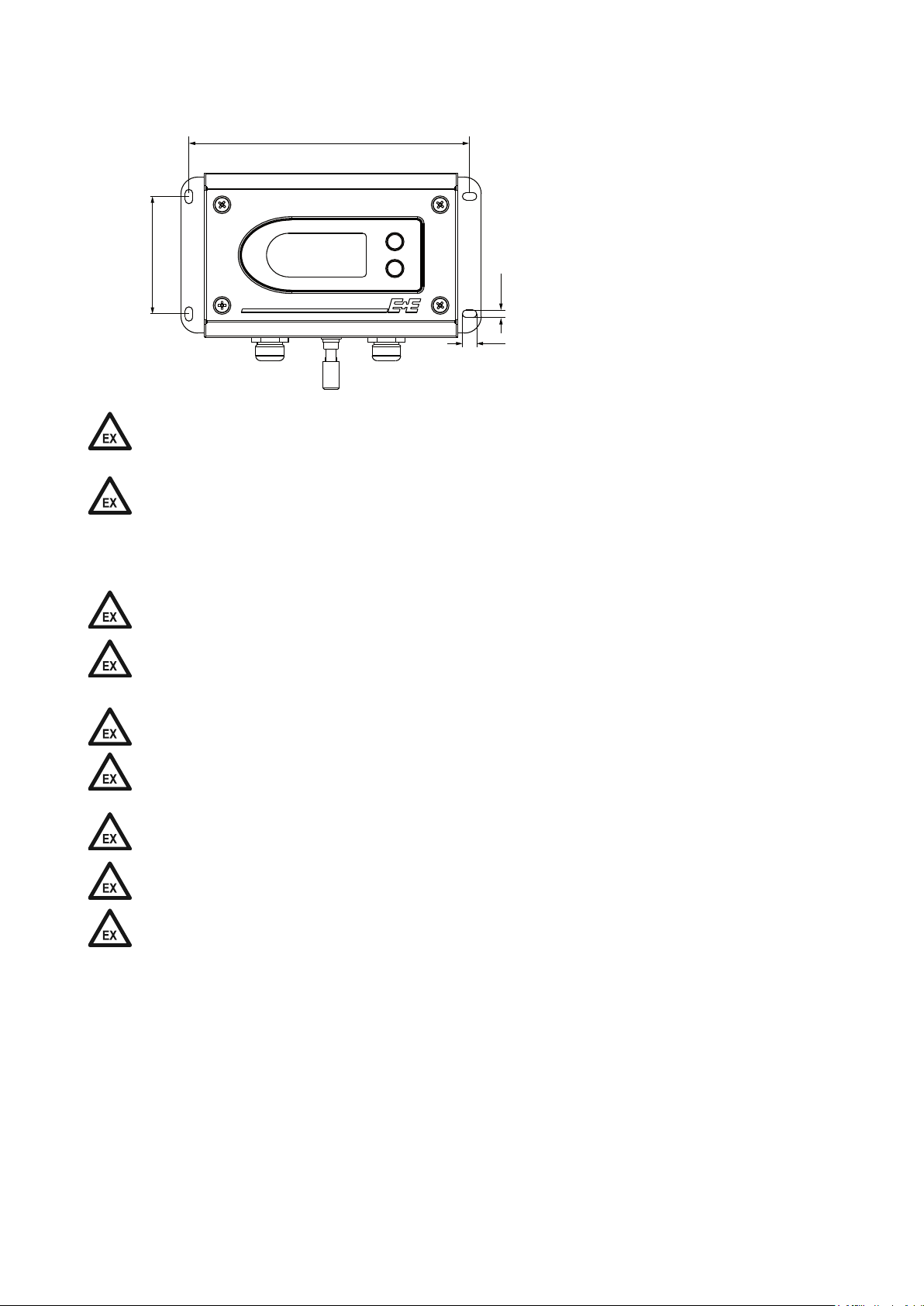

3.2.1 Drilling pattern for installing the enclosure (mm/inch)

167 (6.6“)

70 (2.8“)

4.5 (0.18“)

8.4 (0.33“)

When the front section has been removed from the hazard area, e.g. for calibration, the empty bottom

section shall be protected against dirt and electrostatic charge with the blind front cover HA011401 (see

accessories).

Unused cable glands shall be closed with appropriate sealing plugs (see accessories).

To mount the bottom section use

4 screws diameter < 4.5 mm

(0.18“)

3.3 Assembly in category 1 (Zone 0 / 20); Division 1

Only intrinsically safe power supply devices are approved to supply EE300Ex in category 1 or Division 1.

In areas belonging to gas group IIC or Class I, Division 1, Group A, B, it must be ensured that during

installation and operation, the possibility of impact and friction sparks has been excluded in rarely

occurring fault situations.

Work on open sensor must only be performed if it is guaranteed that no explosive atmosphere is present.

In category 1 or Division 1, the sensor line should be laid in an earthed metallic protective hose. With

Group III or Class II, III, ensure that there are no dust or fibers and flyings deposits in the protective

tube.

CH1 and CH2 must be galvanically isolated from one another during operation.

There is no display permitted in the gas hazard area EPL Ga for Group IIC or Class I,

Division 1, group A, B and in the dust hazard area for groups IIIA, IIIB and IIIC or Class II, III.

The probe for wall mount is not permitted to be used for Zone or Division bushing.

14

User Manual EE300Ex Humidity / Temperature Sensor

Page 15

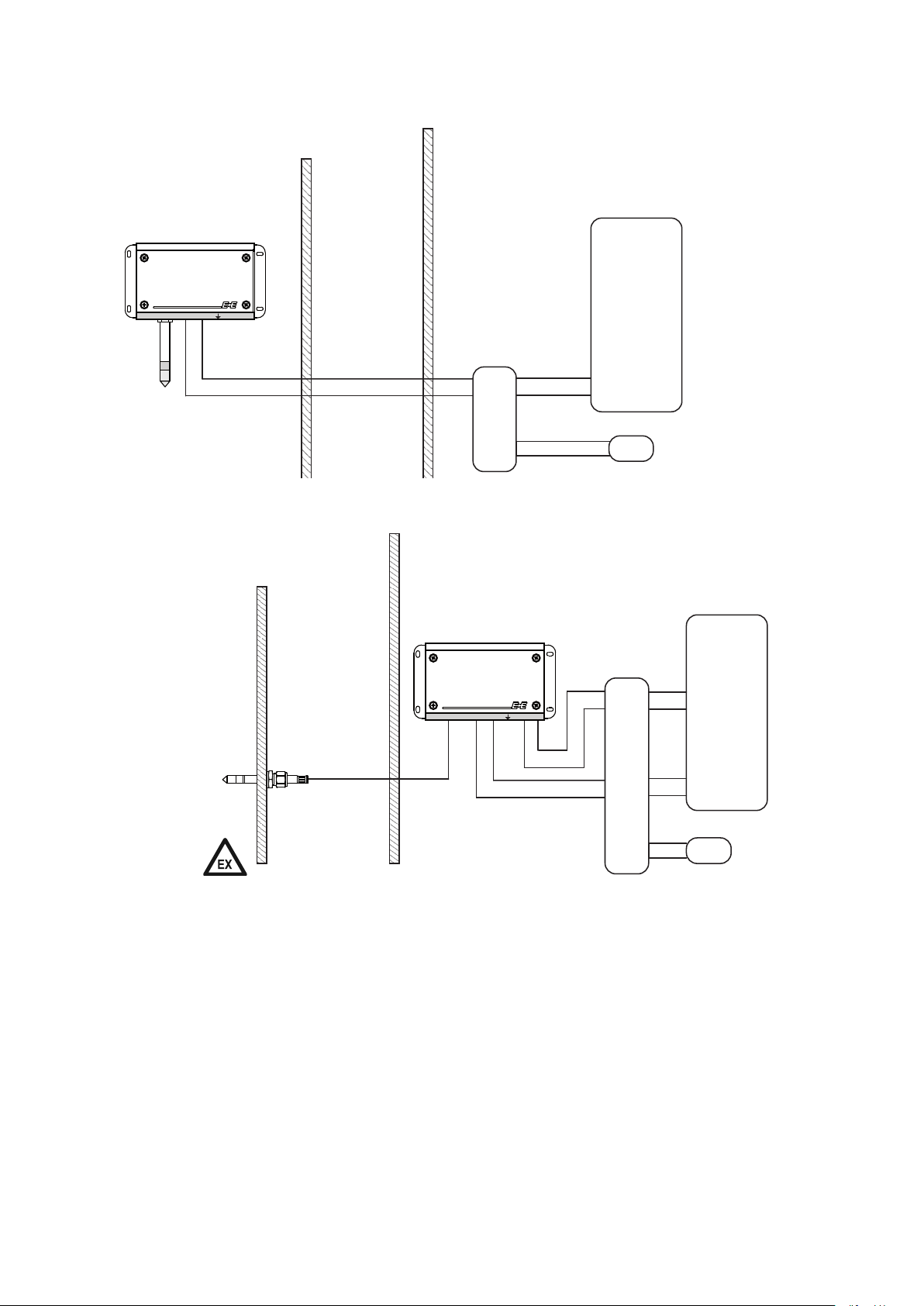

EE300Ex (wall mount) 1 channel via intrinsically safe power supply device:

Hazardous location T4...T1

Zone 0 / 20

no display with EPL Da; Db, Dc

and Ga IIC

Division 1

no display in Class II, III and

Class I, Division 1, Group A, B

CH1

CH2

Zone 1 2 / 21 22

Division 2

Unclassified location

Control

intrinsically safe

sensor supply unit

+

4-20mA ia

+

-

-

L+

L-

+

-

Power supply

EE300Ex (with remote probe) 2 channels via intrinsically safe power supply device:

Hazardous location T6...T1

Unclassified location

Zone 0 / 20

Division 1

Class I,II,III

Group A, B, C, D, E, F, G

up to T6 if EE300Ex is in

unclassified location.

Zone 1 2 / 21 22

Division 2

Class I,II,III

Group A, B, C, D, E, F, G

The bushing must

conform to the hazard requirements

of a Zone or Division implementation.

The supplied screw

connection meets

this requirement!

intrinsically safe

sensor supply unit

+

+

-

CH1

CH2

4-20mA ia

4-20mA ia

-

+

+

-

-

L+

L-

Control

+

-

Power supply

User Manual EE300Ex Humidity / Temperature Sensor

15

Page 16

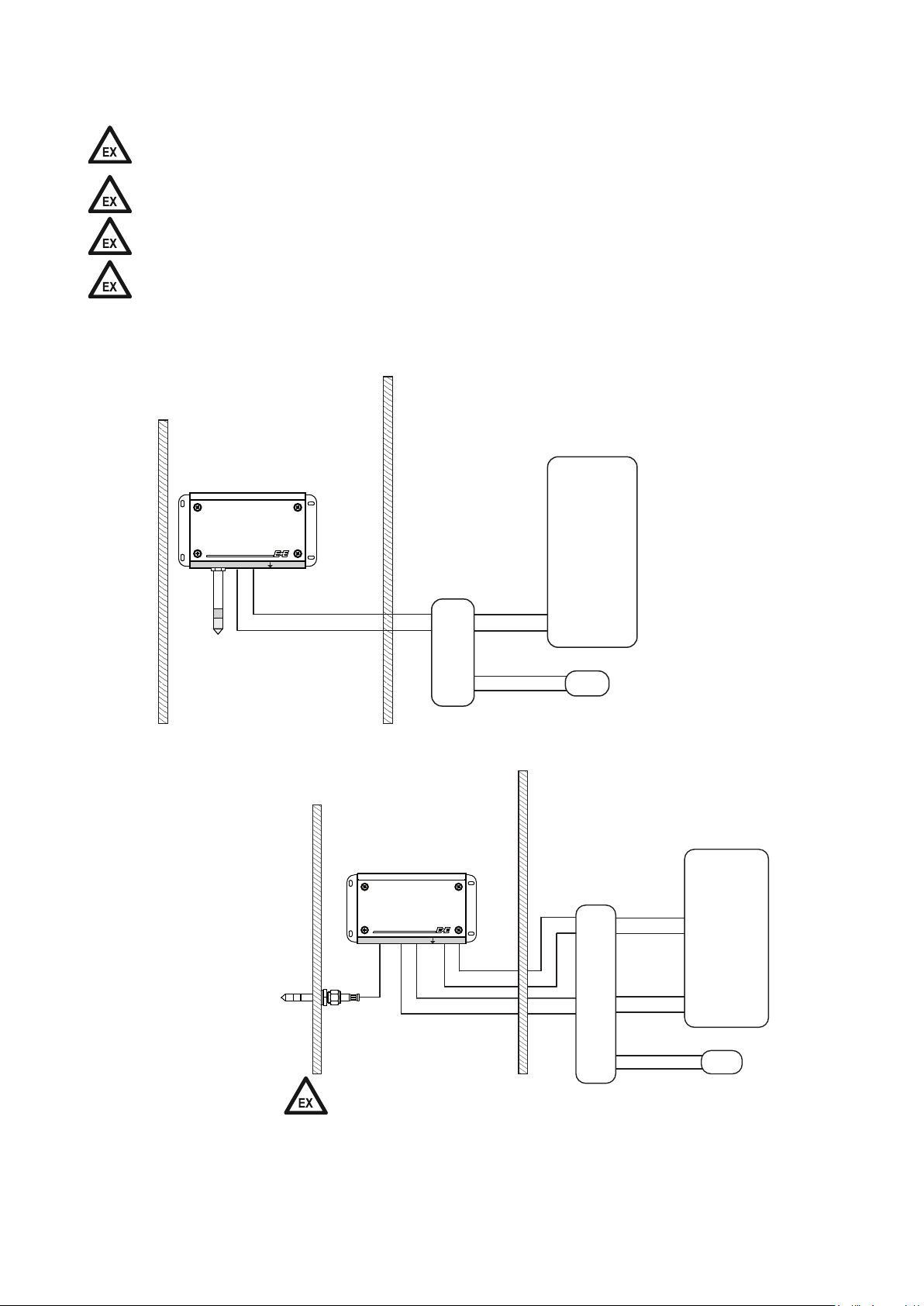

3.4 Assembly in categories 2 and 3 (Zone 1 , 2 / 21 , 22); Division 2

4-20mA ia

4-20mA ia

+

-

L+

L-

+

-

+

-

+

-

+

-

CH2

CH1

Only intrinsically safe power supply devices and protective barriers are approved to supply EE300Ex in

category 2 and 3 or Division 2.

No display is permitted in the dust hazard area (Group III) or Class II, III.

CH1 and CH2 must be galvanically isolated from one another during operation.

The probe for wall mount is not permitted to be used for Zone or Division bushing.

EE300Ex (wall mount) 1 channel via intrinsically safe power supply device:

Hazardous location T4...T1 Unclassified location

Zone 1 2 / 21 22

Division 2

Class I,II,III

Group A, B, C, D, E, F, G, H

CH1

CH2

intrinsically safe

sensor supply unit

Control

+

4-20mA ia

+

-

-

L+

L-

+

-

Power supply

EE300Ex (with remote probe) 2 channels via intrinsically safe power supply device:

Hazardous location T4...T1 Unclassified location

Zone 0 / 20

Division 1

Class I,II,III

Group A, B, C, D, E, F, G, H

Zone 1 2 / 21 22

Division 2

Class I,II,III

Group A, B, C, D, E, F, G, H

intrinsically safe

sensor supply unit

Control

16

The bushing must conform

to the hazard requirements

of a Zone or Division implementation. The supplied

Power supply

screw connection meets

this requirement!

User Manual EE300Ex Humidity / Temperature Sensor

Page 17

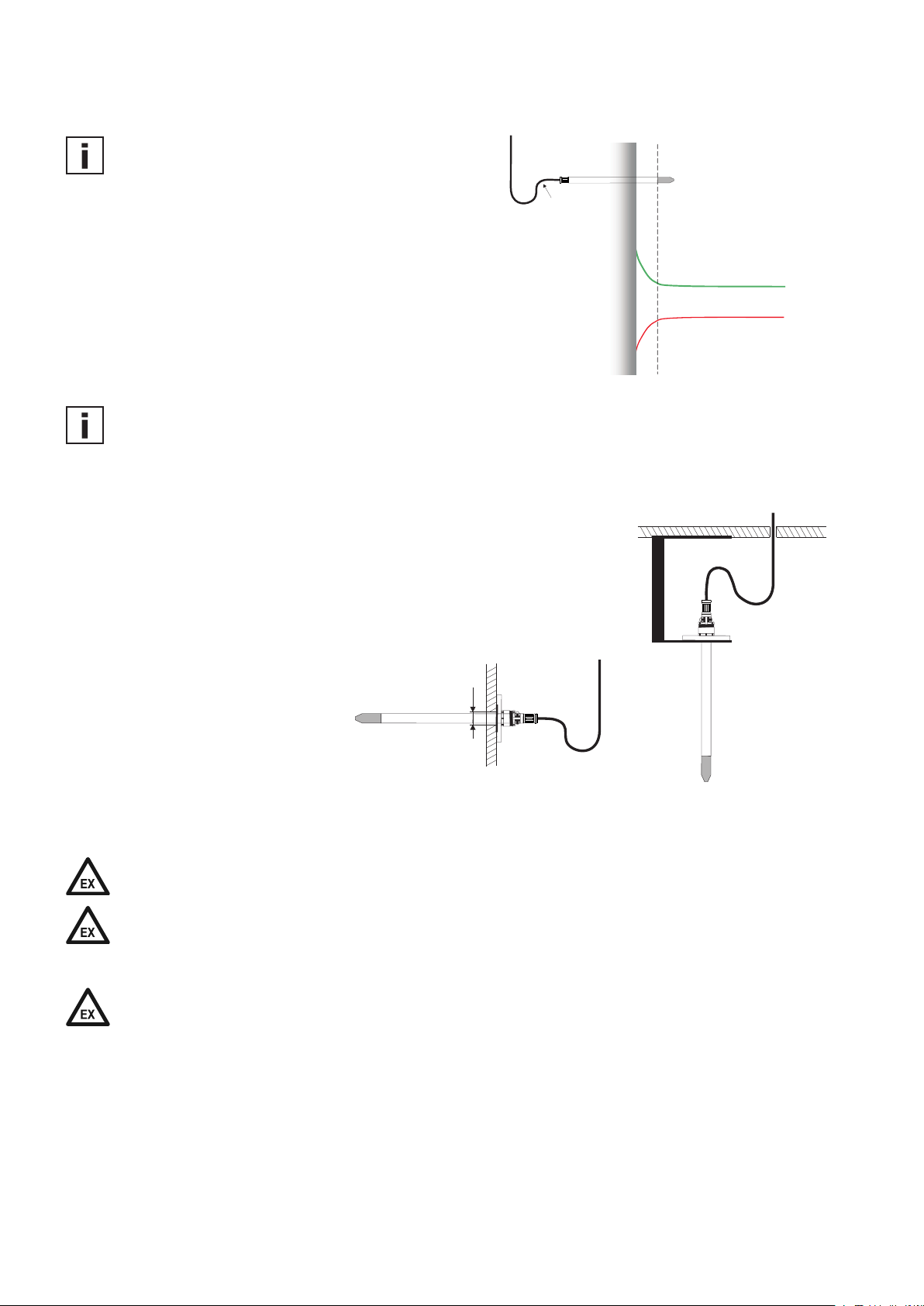

3.5 Probe mounting

The probe of the EE300EX sensor shall be located

at the most representative location for the RH and

T of the process to be monitored.

For accurate measurement it is of paramount

importance to avoid temperature gradients along

the probe.

Whenever possible, install the entire probe inside

the environment to monitor. If the probe is installed

into a wall, than isolate thermally the backend of

the probe looking out of the wall.

The probe shall be mounted horizontally or vertically, with the tip of the probe pointing downwards.

In applications where condensation is likely to happen:

• The cable shall form a drip

loop close to the probe.

• Use the drip water protection

(see datasheet accessories,

code HA010503) for vertically

mounted probe.

r>30mm

Wall

60% rH

17°C

Relative Humidity

Temperature

45% rH

21°C

Ø 13mm (0.5")

Horizontal mounting

Vertical mounting

Ensure appropriate mechanical stability and sealing of the probe mounting taking into account specific

influences at the site, such as vibrations, shocks or temperature changes.

The probe and the cabling shall be handled and installed to avoid electrostatic charges. (e.g. metal

hose)

Filter caps

The following filter caps offer good protection against electrostatic discharge for explosion group IIB, but

are not permitted for use in EPL Ga IIC or Class I, Division 1, Group A, B:

• Membrane filter (order code F2)

• PTFE filter(order code F5)

• Membrane on stainless steel body (order code F10)

• PTFE on stainless steel body (order code F11)

• H2O2 filter (order code F12)

User Manual EE300Ex Humidity / Temperature Sensor

17

Page 18

The following filter caps are permitted for use in EPL Ga IIC or Class I, Division 1, Group A, B:

• Stainless steel sintered (order code F4)

• Stainless steel grid (order code F9)

• Oil (order code F13)

3.5.1 Probe feedthrough with cut-in fitting

The feedthrough with cut-in fitting (ordering code PA20, PA21, PA22) can be used as Zone or Division

bushing. For this, the tightness of its mounting into the Zone separation wall must correspond to IP67.

Once mounted, the cut-in fitting creates a permanent clamping-ring onto the probe.

Safety instructions for pressure-tight feedthrough:

• Do not assemble the probe and tighten the feedthrough if the plant is under pressure.

• The plant must not be vented by releasing the nut (A).

• Use appropriate seal on conical probe threads.

• Never rotate the screw connection body (B) but hold the screw connection body (B) securely and turn

the nut (A).

• Avoid unnecessary disassembly of pipe screw connections.

• Position the cut in fitting >75 mm (2.95”) from the end of the filter cap to the end of the fitting!

For a probe length of 65 mm a cut in fitting is not possible.

>75 mm (2.95“)

Installation instructions:

• Tighten the nut (A) finger-tight.

• Mark the nut (A) at 6 o‘ clock position.

• Hold the screw connection body (B) tight and tighten the nut (A) with

1 ¼ turns till 9 ‚o clock position.

Assembly with high pressure applications and applications with a

high security factor:

• Tighten the nut (A) until the probe (C) can no longer be turned by

hand and moved axially in the feedthrough.

• Mark the nut (A) at 6 o‘ clock position.

• Hold the screw connection body (B) tight and tighten the nut (A) with

1 ¼ turns to 9‚ o clock position.

Re-mounting:

• Slide the measurement probe with clamping ring into the fitting as far

as it goes.

• Tighten the nut finger-tight, then tighten by approx. a ¼ turn using a

spanner.

A

B

B

A

B

A

C

18

User Manual EE300Ex Humidity / Temperature Sensor

Page 19

3.5.2 Mounting flange

The optional mounting flange (see datasheet accessories) may not be used as Zone or Division

bushing. When installed with the mounting flange, the hazard areas on the filter cap side and at the

cable outlet side must be of the same category.

HA010207

HA010201

3.5.3 Ball valve and sliding fitting

The optional ball valve HA011403 (ATEX certified)

allows for the probe to be mounted or removed without

interrupting the process to be monitored.

Only ball valve approved for use in explosion hazard

areas are permitted.

The two metal sealing rings (see figure) shall be

replaced with new ones after each removal of the

probe.

MOUNTING THE PROBE:

The process temperature may not deviate from the

mounting temperature by more than ±40 °C (104 °F).

The maximum permitted process pressure during

mounting is 10 bar (145 psi).

• Mount the probe onto the ball valve with the ball

valve closed.

• Open the ball valve.

• Slide the probe through the ball valve into the process to the desired immersion depth. For rather high process pressure a manual pressing tool might

be needed for sliding easily the probe into the process.

• For secure probe installation the closing nut shall be tightened with a torque of 30 Nm. If a torque

wrench is not available, turn first the closing nut by hand as tight as possible, then turn another

approx. 50° using a suitable open-ended spanner.

A lower tightening torque means lower clamping force of the clamp sleeve. Consequently there is a

risk for the probe being pushed out by the process pressure.

An excessive tightening torque may cause permanent deformation of the clamping sleeve and of the

probe. This makes the removal and re-mounting difficult or even impossible.

HA011403

Metal sealing ring

(as standard

with probe)

Extension

(not provided with an

NPT thread)

Metal sealing ring

(included with the ball

valve set as standard)

Internal diameter:

≥ 13.1 mm (0.51")

User Manual EE300Ex Humidity / Temperature Sensor

19

Page 20

REMOVING THE PROBE:

• Hold the probe firmly in place. While doing so, do not

bend the probe cable.

• Release slowly closing-nut using a spanner only until

the process pressure pushes out the probe. Do not

release completely the closing-nut!

• After the probe has been pushed all the way back,

close the ball valve.

• The probe can be now removed from the ball valve.

During mounting and removal, ensure that o-ring 1 is

correctly installed.

Replace a damages o-ring by an original new one,

order code HA050308, o-ring type: 13x1.5mm

(0.5“x 0.06“) - FKM-60.

3.5.4 The optional probe retraction tool

Sealing nut

Fitting body

Clamp sleeve

O-ring 2

O-ring 1

no aluminium

is permitted

The operating instructions of the probe retraction tool must be strictly observed.

The probe of the EE300EX model T22 can be installed into a pressurized environment up to 250 bar

using the sensor retraction tools ZM-WA-025-040-EST or BG-WA-103-045-EST.

The scope of supply of the EE300EX model T22 includes the copper sealing for the Swagelok

feedthrough.

Make sure that the sensor retraction tool is in the ”SERVICE“ position (see manual of the sensor

retraction tool).

• Before installing the sensor, dismount the closing plug ½“ using a

hexagonal 10 mm wrench and “park“ it at the thread hole M10

designed for that purpose.

• Insert the probe with the copper sealing, the Swagelok

union nut, the Swagelok fitting and protective cover into

the probe retraction tool as far as it goes.

protective cover

Swagelok-nut

20

Swagelok-tting

copper sealing

User Manual EE300Ex Humidity / Temperature Sensor

Page 21

• Fasten the Swagelok ½“fitting of the sensor retraction tool with appropriate wrench. Do not forget the

copper sealing!

• Close the Swagelok union nut with cutting ring finger-tight by hand.

Then adjust the probe.

• Use the appropriate wrench to tighten the union nut (A) just firmly enough

that the screw connection (B) cannot be moved manually. Mark the nut

at the 6 o‘ clock position.

• Hold the screw connection body (B) tight and tighten the union nuts (A)

with 1 ¼ turns to the 9 o‘ clock position.

• Mounting the protective cover for the Swagelok feedthrough:

1. Push the protective cover down to the adjusting device. The screws

shall point to the flat area.

2. Tighten the M3 screws.

4 Electrical connections

4.1 General

It is essential that installation, electrical connection, commissioning, operation and maintenance in

explosion hazard areas are only carried out by trained specialist staff authorised to do so by the system

operator.

The installation shall be performed according to NEC or CEC and to the Control Drawing M1_1309080

(page 50).

The installation in an explosion hazard area shall comply with EN 60079-14, EN 60079-25 or

IEC 60079-14, IEC 60079-25. Repair and maintenance shall be performed according to EN 60079-17 or

IEC 60079-17 and EN 60079-19 or IEC 60079-19.

All relevant national regulations shall be strictly observed.

Installation in the U.S. shall be performed according ANSI / ISA RP 12.6.01-2003 and

the National Electrical Code (NEC).

Installation in Canada shall comply with the Canadian Electrical Code (CEC).

The EE300Ex sensor is a loop powered (2-wire) device, both channels (outputs) are galvanic isolated.

For proper operation, Channel 1 (CH1) must always be connected. Channel 2 (CH2) may be

connected only if necessary.

Cable ends shall be fitted with the appropriate wire-end sleeves. While connected to the

terminals, the air gap must be min 2mm (0.08“) between the wires and min. 6mm (0.2“) between CH1

and CH2.

Do not shorten or extend the probe cable. Changing the length of the probe cable has a strong negative

effect onto the measurement performance and may lead to EE300EX failure.

User Manual EE300Ex Humidity / Temperature Sensor

21

Page 22

4.2 Terminal assignment

GROUND

CH1 +

CH1 -

CH2 +

CH2 -

4.3 Grounding and potential equalization

The EE300Ex shall be integrated into the potential equalization to avoid hazards from electrostatic

charges. The grounding shall comply with EN60079-14, EN60079-25 or IEC60079-14, IEC60079-25. A

remote probe shall also be grounded using a screw connection with a maximum of 1 MΩ in the potential

equalization.

The ground conductor or the potential equalization connection must have a cross-section of 4 mm²

(0.06 in²) for the external grounding. Stranded wires shall be fitted with suitable wire-end sleeves.

The resistance of the ground connection of the intrinsically safe barrier shall be max. 1 Ohm.

For installation in the U.S. use internal ground connection. The wire cross-sectional must comply with

NEC Section 250.122.

External grounding:

22

Internal grounding:

Cable cross-section

maximum 4mm² (0.06in²)

Grounding connection channel 1

Grounding connection channel 2

Grounding connection occupied

Cable cross-section

maximum 10 mm² (0.2 in

User Manual EE300Ex Humidity / Temperature Sensor

2

)

Page 23

1)

EXPLOSIONSGEFÄHRDETER

Hazardous location

BEREICH

CH1 +

CH2 +

Erde

CH1 -

CH2 -

1)

potential equalization connection

Unclassified location

SICHERER BEREICH

Instrument

Instrument

System

System

Sicherheits-

Safety barrier

barriere oder

or power

Speisegerät

supply unit

Erdung der Barrieren

grounding of barriers

central grounding

Zentrale Erdung

The braided screen should be turned back via the plastic insert on

the cable connection. The introduction of the plastic insert presses

the braided screen onto the interior wall of the metallic part.

4.4 Connection cable

A shielded cable shall be used. The shield must be grounded only at one end, at the EE300Ex side.

The connection cable shall comply to the following specifications for ATEX, as required by EN60079-14

and EN60079-25:

• Maximum cross-section 1.5mm² (0.02in²)

• Single stranded wire diameter ≥ 0.1mm (0.004“)

• Test voltage wire-wire ≥ 500V AC eff.

• Test voltage wire-shield (if a cable with shield is used): ≥ 500V AC eff.

• Cable inductivity, cable capacity and conductor resistance are to be evaluated during the proof of

intrinsic safety.

• Flame resistance acc. to IEC60332-1-2

Example of cable meeting above requirements: ÖLFLEX® EB CY from LAPP KABEL

Additional requirements if both channels (CH1, CH2) are connected with a common cable:

• The test voltage wire-wire ≥ 1000 V AC eff.

• The radial thickness of the insulation ≥ 0.2 mm (0.008").

• The conductor insulation shall withstand 500 V AC eff.

4.5 Calculation of the maximum cable length

Intrinsically safe power supply device STAHL 9160/13-11-11 (order code HA011405)

Technical data for EE300Ex

Supply voltage: U

Max. current: I

Bin

out max

Technical data for STAHL 9160/13-11-11

Nominal operating voltage: UN = 24 V

Input voltage for sensor: US = 16 V

Max. load: RL = 600 Ohm

User Manual EE300Ex Humidity / Temperature Sensor

= 9V + RL * 0.02A

= 20mA

23

Page 24

Example: Calculation of maximum cable length

Cable 0.75mm² (0.01in

2

): R

= 0.0267 Ω/m

cable

Load resistor: RL = 200 Ω

Input voltage for sensor: VS= 16 V

Min. supply voltage EE300Ex: V

= 9V + 200Ω * 0.02A = 13V

Bmin

Maximum voltage drop on cable: V

Total cable resistance: R

V

= R

Transform in accordance with L

total

L

L

L

= VS - V

cable

cable total

drop

total

total

total

= R

= R

cable total

cable

= V

drop

= 3V / (0.02A * 2 * 0.0267Ω/m )

= 2800m maximum cable length

= 16V – 13V = 3V

Bmin

* L

cable

* L

/ (I

out max

* 2 (supply and return line)

total

* I

out max

* 2 * I

total

* 2 * R

=

out max

cable

)

Caution: This is the maximum length without allowing the intrinsic safety area. Cable capacity

and inductivity may reduce the cable length.

4.6 Selecting a suitable Intrinsically safe supply unit for ATEX Zone concept

Example for evidence of the intrinsic safety in accordance with EN 60079-14:2008 12.2.5.2,

EN 60079-25:2010 13.1. CH1 and CH2 are galvanically isolated. The proof of intrinsic safety shall be

performed with appropriate equipment.

Example: Installation in Zone 0 of the EE300Ex without display

Connection cable length: 300 m (984 ft)

Explosion group: IIC

Temperature class: T4

CH1 and CH2 connected by one single cable.

Intrinsically safe power supply device STAHL 9160/13-11-11 (see accessories)

(Extract from the EC-Type Examination Certificate)

Certified according to:

II 3 (1) G Ex nA nC [ia Ga] IIC T4 Gc (certificate number: DMT 03 ATEX E 010 X)

II (1) D [Ex ia Da] IIIC (certificate number: DMT 03 ATEX E 010 X)

Entity parameters:

U0 = 27 V

I0 = 88 mA

P0 = 576 mW

C0 IIC = 90 nF

C0 IIB = 705 nF

L0 IIC = 2.3 mH

L0 IIB = 17 mH

Technical data for the connection cable:

Cable type: ÖLFLEX® EB CY from Lapp Kabel

Cable cross-section: 4 x 0.75 mm² (0.06x0.01 in²)

Operating capacity: 110 nF/km

Inductivity: 0.65 mH/km

Cable capacity for 300m (984ft): CK = 0.3km * 110nF/km = 33nF

Cable inductivity for 300m (984ft): LK = 0.3km * 0.65mH/km = 0.195mH

24

User Manual EE300Ex Humidity / Temperature Sensor

Page 25

Technical data for EE300Ex (extract from the EU-Type Examination Certificate):

Certified according to:

II 1G Ex ia IIC T4 Ga

II 1D Ex ia IIIC T80°C Da

Entity parameters:

Ui = 28V

Ii = 100mA

Pi = 700mW

Ci = 2.2nF

Li = negligibly small

Proof of the intrinsic safety according EN 60079-11:2012

EN 60079-25:2010 (Appendix A)

U0 = 27V ≤ Ui = 28V → ok

I0 = 88mA ≤ Ii = 100mA → ok

P0 = 576mW ≤ Pi = 700mW → ok

C0 = 90nF ≥ 2,2nF + 33nF → ok

L0 = 2,3mH ≥ 0mH + 0,195mH → ok

Conclusion: The protection level of the intrinsically safe current circuit is met.

Proof of the intrinsic safety according EN 60079-11:2012,

EN 60079-25:2010 (Appendix A)

Li=0

YES

Full values of C

NO

C

=0

i

YES

and L0 can be

0

utilised

Li = negligibly small → no reduced C0 and L0 values are required.

4.7 Configuration adapter

L

of L

YES

NO

≤1%

i

0

NO

Ci≤1%

of C

YES

NO

0

Use reduced C

and L0 values for

0

mixed electric circuits

For intrinsically safe electric circuits with

linear sources, simplied evaluation rule:

each half value of C

and L0 can be used,

0

limited to C0 = 600 nF (IIC) and 1 μF (IIB)

The on-board service interface is dedicated for the EE300EX configuration and for the RH and T adjustment. This is possible by the optional EE-PCA Product Configuration Adapter and HA011068 connection cable. Refer to datasheet EE-PCA and HA011068 user manual.

The EE-PCS configurator software and the drivers are available for download free of charge at

http://www.epluse.com/en/service-support/download-center/

User Manual EE300Ex Humidity / Temperature Sensor

25

Page 26

The configuration or adjustment of EE300Ex may not be performed in the hazard area.

CH1 and CH2 must be disconnected while using the configuration adapter.

When the front section has been removed from the hazard area, e.g. for calibration, the empty bottom

section shall be protected against dirt and electrostatic charge with the blind front cover HA011401 (see

accessories).

4.8 Calibration of the current loop

For the calibration of the current loop in explosion hazard areas only approved multimeters are permitted. During the measurement with these multimeters the requirements of the system description (the

proof of intrinsic safety) shall be observed

5 Display (optional)

Display is not permitted in the gas hazard area for EPL Ga IIC or Class I, Division 1,

Group A, B and in the dust hazard area for IIIA, IIIB and IIIC or Class II, III

The display shows the measured parameter on the outputs CH1 (top row) and CH2 (bottom row),

according the ordering code.

The top key change the visualization of the calculated parameter on the top row. The bottom key

change the visualization of the calculated parameter on the bottom row. Changing the display

visualization do not change the parameter on the output CH1 and CH2.

T: 32.25°C

RH: 35.5%

6 Maintenance

It is essential that operation and maintenance in explosion hazard areas are only performed by trained

specialist personnel authorised to do so by the system operator.

Maintenance and repair work in explosion hazard areas must comply with the requirements of

EN 60079-17 or IEC 60079-17, EN 60079-19 or IE C60079-19 and with all the relevant national

regulations.

In the U.S. maintenance and inspection must comply with ANSI / ISA RP12.6.01-2003 and the NEC

requirements.

In Canada maintenance and inspection must comply with the CEC requirements.

Measured parameter, value and unit CH1

Top key

Bottom key

Measured parameter, value and unit CH2

6.1 Filter cap replacement

When employed in dusty, polluted environment, the filter cap shall be replaced once in a while with an

E+E original one. A polluted filter cap causes longer response time.

When replacing a filter cap, ensure that the sensor is NOT touching the filter cap!

26

User Manual EE300Ex Humidity / Temperature Sensor

Page 27

6.2 Cleaning the EE300EX sensor

6.2.1 Cleaning the enclosure

Gently wipe the enclosure and the display with a soft damp cloth. Do not use detergents or abrasive

means.

6.2.2 Cleaning the probe

If needed, the sensing head of the probe can be cleaned. For cleaning instructions please see

www.epluse.com/ee300ex

When replacing a filter cap, ensure that the sensor is NOT touching the filter cap!

6.3 Configuration, Adjustment and Calibration

Refer to the data sheet EE-PCA Product Configuration Adapter and to the user manual HA011068

connection cable.

Definitions

Adjustment: the specimen is brought in line with the reference

Calibration: the specimen is compared with a reference and its deviation from the reference is

documented

6.4 Display error messages

Error 1 = RH sensing element damaged

Error 2 = Condensation on the RH sensor element

Error 3 = T sensing element damaged

Error 4 = Short circuit at the T sensing element

User Manual EE300Ex Humidity / Temperature Sensor

27

Page 28

7 Technical Data

7.1 EE300Ex-M1 Humidity and Temperature Sensor

Measurands

Relative humidity

Measuring range 0...100 % RH

Accuracy1)

(including hysteresis, non-linearity and repeatability,

traceable to international standards, administrated by NIST, PTB, BEV...)

-25...70 °C (-13...158 °F) ± (1.4 + 1%*mv) % RH

mv = measured value -40...180 °C (-40...356 °F) ± (1.5 + 1.5%*mv) % RH

Temperature dependence electronics, typ. 0.03 % RH/°C

Response time t

< 30 s with stainless steel filter at 20 °C (68 °F)

90

Temperature

Measuring range Wall mount: -40...60 °C (-40...140 °F)

Remote probe: -40...180 °C

Accuracy

-15...40 °C (5...104 °F) ≤90 % RH ± (1.3 + 0.3%*mv) % RH

-15...40 °C (5...104 °F) >90 % RH ± 2.3 % RH

(-40...356 °F)

∆°C

°C

Temperature dependence of electronics, typ. 0.005 °C/°C

Calculated parameters

from up to Units

wall mount remote probe

Dew point temperature Td -40 (-40) 60

(140) 100 (212) °C (°F)

Frost point temperature Tf -40 (-40) 60 (140) 100 (212) °C (°F)

Wet bulb temperature Tw 0 (32) 60 (140) 100 (212) °C (°F)

Water vapour pressure e 0 (0) 200 (3) 1 100 (15) mbar (psi)

Mixing ratio r 0 (0) 425 (2 900) 999 (9 999) g/kg (gr/lb)

Absolute humidity dv 0 (0) 150 (60) 700 (300) g/m³ (gr/ft³)

Specic enthalpy h 0 (0) 400 (150 000) 2 800 (999 999) kJ/kg (Btu/lb)

Water activity aw 0 - 1 1

Water content X 0 - 100 000 [ppm]

Outputs

Freely selectable and scalable outputs 2 x 4-20 mA (2-wire) galvanically isolated RL = (Vcc-9V)/20mA

Output 1 must be connected!

General

Supply voltage V

Current consumption Max. 20 mA per channel

Protection class of housing IP65 / NEMA 4

Cable gland M16 for cable diameter 5 - 10 mm (0.2" - 0.4")

M20 for cable diameter 10 - 14 mm (0.4" - 0.6")

Electrical connection Screw terminals max. 1.5 mm² (AWG 16)

Working temperature range Probe according measuring range

Electronics without display -40...60 °C (-40...140 °F)

Electronics with display -20...60 °C (-4...140 °F)

Storage temperature range Electronics and probe -20...60 °C (22...140 °F)

Electromagnetic compatibility EN 61326-1 EN 61326-2-3 ICES-003 ClassB

Industrial Environment FCC Part15 ClassB

Material Enclosure stainless steel 1.4404

Probe cable PTFE

Probe (without filter) stainless steel 1.4301

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was calculated in

accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

= (9+RL*0.02) V DC V

cc min

= 28 V DC RL = load resistor

cc max

28

User Manual EE300Ex Humidity / Temperature Sensor

Page 29

7.2 EE300Ex-M3 Temperature Sensor

Measurand

Temperature

Temperature sensor Pt1000 (Tolerance class A, DIN EN 60751)

Measuring range Wall mount: -40...60 °C (-40...140 °F)

Remote probe: -70...200 °C (-94...392 °F)

Accuracy1)

Temperature dependence of electronics , typ. 0.005 °C/°C

Outputs

Scalable analogue output 4-20 mA (2-wire) RL = (Vcc-9V)/20mA

General

Supply voltage Vcc min = (9+RL*0.02) V DC Vcc max = 28 V DC RL = load resistor

Current consumption Max. 20 mA

Temperature range Probe according measuring range

Electronics -40...60 °C (-40...140 °F)

Electronics with display -20...60 °C (-4...140 °F)

Storage temperature range Electronics and probe -20...60 °C (22...140 °F)

Material Enclosure stainless steel 1.4404

Probe cable PTFE

Probe stainless steel 1.4541

Protection class of housing IP65 / NEMA 4

Cable gland M16 for cable diameter 5 - 10 mm (0.2 - 0.4″)

M20 for cable diameter 10 - 14 mm (0.4“ - 0.6“)

Electrical connection screw terminals max. 1.5 mm² (AWG 16)

Electromagnetic compatibility according EN 61326-1 EN 61326-2-3 ICES-003 ClassB

Industrial Environment FCC Part15 ClassB

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was calculated in

accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

∆°C

°C

User Manual EE300Ex Humidity / Temperature Sensor

29

Page 30

8 ATEX Certificate

30

User Manual EE300Ex Humidity / Temperature Sensor

Page 31

User Manual EE300Ex Humidity / Temperature Sensor

31

Page 32

32

User Manual EE300Ex Humidity / Temperature Sensor

Page 33

User Manual EE300Ex Humidity / Temperature Sensor

33

Page 34

9 EU Declaration of Conformity

34

User Manual EE300Ex Humidity / Temperature Sensor

Page 35

10 IECEX Certification of Conformity - COC

for more information see http://www.iecex.com/

or our website http://www.epluse.com/ee300ex

User Manual EE300Ex Humidity / Temperature Sensor

35

Page 36

11 FM Certificate USA

1.

HAZARDOUS (CLASSIFIED) LOCATION ELECTRICAL EQUIPMENT PER US REQUIREMENTS

2.

Certificate No:

FM17US0302X

3.

Equipment:

EE300Ex-series

4.

Name of Listing Company:

E+E ELEKTRONIK Ges.m.b.H

5.

Address of Listing Company:

Langwiesen 7

6.

The examination and test results are recorded in confidential report number:

7.

FM Approvals LLC, certifies that the equipment described has been found to comply with the following Approval

8.

If the sign ‘X’ is placed after the certificate number, it indicates that the equipment is subject to specific conditions

9.

This certificate relates to the design, examination and testing of the products specified herein. The FM Approvals

10.

Equipment Ratings:

hazardous (classified) locations in accordance with drawing M1_1309080, IP65 with an ambient temperature

Certificate issued by:

J. E. Marquedant

VP,

Manager, Electrical Systems

Date

CERTIFICATE OF CONFORMITY

(Type Reference and Name)

3049300 dated 2

standards and other documents:

FM Class 3600:2011, FM Class 3610:2015, FM Class 3611:2016, FM Class 3810:2005,

ANSI/ISA 61010-1:2012, ANSI/ISA 60079-0:2013, ANSI/ISA 60079-11:2014, ANSI/IEC 60529:2004

of use specified in the schedule to this certificate.

surveillance audit program has further determined that the manufacturing processes and quality control

procedures in place are satisfactory to manufacture the product as examined, tested and Approved.

Intrinsically Safe for Class I, II, III Division 1, Groups A, B, C, D, E, F, and G hazardous (classified) locations in

accordance with drawing M1_1309080, Nonincendive for Class I, II, III Division 2, Groups A, B, C, D, E, F,

and G hazardous (classified) locations, Intrinsically Safe for Class I, Zone 0, Group IIC hazardous (classified)

locations in accordance with drawing M1_1309080, Intrinsically Safe for Class II and III, Zone 20, Group IIIC

Humidity and Temperature Transmitter

Engerwitzdorf 4209

Austria

nd

October 2017

To verify the availability of the Approved product, please refer to www.approvalguide.com

THIS CERTIFICATE MAY ONLY BE REPRODUCED IN ITS ENTIRETY AND WITHOUT CHANGE

FM Approvals LLC. 1151 Boston-Providence Turnpike, Norwood, MA 02062 USA

T: +1 (1) 781 762 4300 F: +1 (1) 781 762 9375 E-mail: information@fmapprovals.com www.fmapprovals.com

F 347 (Mar 16) Page 1 of 7

36

User Manual EE300Ex Humidity / Temperature Sensor

17 September 2019

Page 37

rating of -40°C to +60°C.

11.

The marking of the equipment shall include:

12.

Description of Equipment:

General - The EE300Ex transmitter is designed for gauge measurements of temperature and humidity in air.

SCHEDULE

US Certificate Of Conformity No: FM17US0302X

Equipment Group I: EE300Ex without display

Class I, II, III, Division 1, Groups A, B, C, D, E, F and G; T4 Ta = -40°C to +60°C; Entity – M1_1309080; IP65

Class I, II, III, Division 2, Groups A, B, C, D, E, F and G; T4 Ta = -40°C to +60°C

Class I, Zone 0, AEx ia IIC T4 Ta = -40°C to +60°C Ga; Entity – M1_1309080; IP65

Zone 20, AEx ia IIIC T131°C Ta = -40°C to +60°C Da; Entity – M1_1309080; IP65

Remote Probe:

Class I, II, III, Division 1, Groups A, B, C, D, E, F and G; T6…T1; Entity – M1_1309080; IP65

Class I, II, III, Division 2, Groups A, B, C, D, E, F and G; T6…T1

Class I, Zone 0, AEx ia IIC T6…T1 Ga; Entity – M1_1309080; IP65

Zone 20, AEx ia IIIC T80°C Da; Entity – M1_1309080; IP65

Equipment Group II: EE300Ex with display

Class I, Division 1, Groups C, and D; T4 Ta = -40°C to +60°C; Entity – M1_1309080

Class I, Division 2, Groups A, B, C and D; T4 Ta = -40°C to +60°C; Entity – M1_1309080

Class I, Zone 0, AEx ia IIB T4 Ta = -40°C to +60°C Ga; Entity – M1_1309080

Class I, Zone 1, AEx ia IIC T4°C Ta = -40°C to +60°C Gb; Entity – M1_1309080

Remote Probe:

Class I, II, III, Division 1, Groups A, B, C, D, E, F and G; T6…T1; Entity – M1_1309080; IP65

Class I, II, III, Division 2, Groups A, B, C, D, E, F and G; T6…T1

Class I, Zone 0, AEx ia IIC T6…T1 Ga; Entity – M1_1309080; IP65

Zone 20, AEx ia IIIC T80°C Da; Entity – M1_1309080; IP65

All signal outputs are available on two 4 to 20 mA analog outputs.

Construction - The EE300Ex transmitter consists of a single compartment electronics housing. The enclosure

is of stainless steel and has an integrated or remote humidity and/or temperature sensor.

The EE300Ex transmitter is designed for use with the Product Configuration Adapter (PCA) and Connection

cable (HA011068) in non-hazardous locations for software configuration.

THIS CERTIFICATE MAY ONLY BE REPRODUCED IN ITS ENTIRETY AND WITHOUT CHANGE

FM Approvals LLC. 1151 Boston-Providence Turnpike, Norwood, MA 02062 USA

T: +1 (1) 781 762 4300 F: +1 (1) 781 762 9375 E-mail: information@fmapprovals.com www.fmapprovals.com

F 347 (Mar 16) Page 2 of 7

User Manual EE300Ex Humidity / Temperature Sensor

37

Page 38

Ratings - The EE300Ex transmitter operates at 6.4-28 Vdc (700mW). The transmitters are rated for use in an

Terminals

Vmax or Ui

Imax or Ii

Pi

Li

Ci

CH 1: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

CH 2: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

Terminals

Vmax or Ui

Imax or Ii

Pi

Li

Ci

CH 1: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

CH 2: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

T-Code

Ambient Temperature

T6

-40°C < Ta < 60°C

T5

-40°C < Ta < 75°C

T4

-40°C < Ta < 110°C

T3

-40°C < Ta < 175°C

T2

-40°C < Ta < 180°C

T1

-40°C < Ta < 180°C

SCHEDULE

US Certificate Of Conformity No: FM17US0302X

ambient temperature range of -40°C to +60°C. The transmitter probe is rated for use in a process temperature

range of -70°C to +200°C.

Equipment Group I: EE300Ex without display

EE300EX-M1A6HS2T1D0aK0L50PA0bcEX3d

a = Electrical Connection; E2, E13, E15, E17, E18, E19, E20, E21, E22 or E32

b = Filter; F2, F4, F5, F9, F10, F11, F12 or F13

c = Sensor Protection; C0 or C1

d = Software Code: 22 to 44 Digits (Not Safety Relevant)

Entity parameters:

EE300EX-M1A6HS2aD0bcdefgEX3h

a = Model; T7, T9, T10, T15 or T22

b = Electrical Connection; E2, E13, E15, E17, E18, E19, E20, E21, E22 or E32

c = Probe – Cable Length; K0.2, K0.5, K1, K2, K3, K5 or K10

d = Probe Length; L65, L100, L200, L300, L400, L600; L800 or L1000

e = Zone Feedthrough (probe fitting): PA0, PA20, PA21, PA22, PA28, PA23 or PA25

f = Filter; F2, F4, F5, F9, F10, F11, F12 or F13

g = Sensor Protection; C0 or C1

h = Software Code: 22 to 44 Digits (Not Safety Relevant)

Entity parameters:

Remote probe - Temperature Code:

THIS CERTIFICATE MAY ONLY BE REPRODUCED IN ITS ENTIRETY AND WITHOUT CHANGE

FM Approvals LLC. 1151 Boston-Providence Turnpike, Norwood, MA 02062 USA

T: +1 (1) 781 762 4300 F: +1 (1) 781 762 9375 E-mail: information@fmapprovals.com www.fmapprovals.com

F 347 (Mar 16) Page 3 of 7

38

User Manual EE300Ex Humidity / Temperature Sensor

Page 39

EE300EX-M3A6HS2T1D0aK0L70PA0EX3b

Terminals

Vmax or Ui

Imax or Ii

Pi

Li

Ci

CH 1: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

CH 2: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

Terminals

Vmax or Ui

Imax or Ii

Pi

Li

Ci

CH 1: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

CH 2: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

T-Code

Ambient Temperature

T6

-70°C < Ta < 60°C

T5

-70°C < Ta < 75°C

T4

-70°C < Ta < 110°C

T3

-70°C < Ta < 175°C

T2

-70°C < Ta < 200°C

T1

-70°C < Ta < 200°C

Terminals

Vmax or Ui

Imax or Ii

Pi

Li

Ci

CH 1: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

CH 2: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

SCHEDULE

US Certificate Of Conformity No: FM17US0302X

a = Electrical Connection; E2, E13, E15, E17, E18, E19, E20, E21, E22 or E32

b = Software Code: 7 to 10 Digits (Not Safety Relevant)

Entity parameters:

EE300EX-M3A6HS2aD0bcdeEX3f

a = Model; T24

b = Electrical Connection; E2, E13, E15, E17, E18, E19, E20, E21, E22 or E32

c = Probe – Cable Length; K0.2, K0.5, K1, K2, K3, K5 or K10

d = Probe length; L150

e = Zone Feedthrough (probe fitting): PA0, PA26 or PA27

f = Software Code: 7 to 10 Digits (Not Safety Relevant)

Entity parameters:

Remote probe - Temperature Code:

NEW CERTIFICATE

Equipment Group II: EE300Ex with display

EE300EX-M1A6HS2T1D1aK0L50PA0bcEX3d

a = Electrical Connection; E2, E13, E15, E17, E18, E19, E20, E21, E22 or E32

b = Filter; F2, F4, F5, F9, F10, F11, F12 or F13

c = Sensor Protection; C0 or C1

d = Software Code: 22 to 44 Digits (Not Safety Relevant)

Entity parameters:

FM Approvals LLC. 1151 Boston-Providence Turnpike, Norwood, MA 02062 USA

T: +1 (1) 781 762 4300 F: +1 (1) 781 762 9375 E-mail: information@fmapprovals.com www.fmapprovals.com

F 347 (Mar 16) Page 4 of 7

User Manual EE300Ex Humidity / Temperature Sensor

THIS CERTIFICATE MAY ONLY BE REPRODUCED IN ITS ENTIRETY AND WITHOUT CHANGE

39

Page 40

EE300EX-M1A6HS2aD1bcdefgEX3h

Terminals

Vmax or Ui

Imax or Ii

Pi

Li

Ci

CH 1: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

CH 2: + and -

6.4Vdc ≤ Ui ≤28Vdc

100mA

0.7W

0mH

2.2nF

T-Code

Ambient Temperature

T6

-40°C < Ta < 60°C

T5

-40°C < Ta < 75°C

T4

-40°C < Ta < 110°C

T3

-40°C < Ta < 175°C

T2

-40°C < Ta < 180°C

T1

-40°C < Ta < 180°C

Terminals

Vmax or Ui

Imax or Ii

Pi

Li

Ci

CH 1: + and -

6.4Vdc ≤ Ui ≤28Vdc