Page 1

User Manual

EE260

Heated Humidity and Temperature Probe

for Meteorological Applications

BA_EE260 // v1.1 // Modification rights reserved

Page 2

E+E Elektronik Ges.m.b.H. does not accept warranty and liability claims neither upon this publication nor in case of

improper treatment of the described products.

The document may contain technical inaccuracies and typographical errors. The content will be revised on a regular

basis. These changes will be implemented in later versions. The described products can be improved and changed

at any time without prior notice.

© Copyright E+E Elektronik Ges.m.b.H. All rights reserved.

EMC note USA (FCC):

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

EMC note Canada (ICES-003):

CAN ICES-3 (A) / NMB-3 (A)

Page 3

CONTENT

1 General ................................................................................................................................................. 4

1.1 Explanation of Symbols .................................................................................................................................4

1.2 Safety Instructions .........................................................................................................................................4

1.2.1 General Safety Instructions .................................................................................................................................. 4

1.2.2 Intended Use ........................................................................................................................................................ 4

1.2.3 Mounting, Start-up and Operation ........................................................................................................................ 5

1.3 Environmental Aspects ..................................................................................................................................5

2 Scope of Supply ..................................................................................................................................5

3 Product Description ............................................................................................................................ 5

3.1 General ..........................................................................................................................................................5

3.2 Dimensions ....................................................................................................................................................6

3.3 Electrical Connection .....................................................................................................................................7

4 Installation ...........................................................................................................................................8

4.1 Radiation Shield ............................................................................................................................................8

4.2 Wall Mount/Pole Mount .................................................................................................................................8

5 Setup and Adjustment ........................................................................................................................9

5.1 EE-PCS Product Configuration Software ......................................................................................................9

5.2 Digital Interface RS485 with Modbus RTU Protocol ......................................................................................9

5.3 Modbus Register Map .................................................................................................................................11

5.4 Modbus Message Example .........................................................................................................................12

6 Maintenance and Service .................................................................................................................13

6.1 Cleaning ......................................................................................................................................................13

6.2 Filter Replacement ......................................................................................................................................13

6.3 Repairs ........................................................................................................................................................13

6.4 RH / T Adjustment and Calibration ..............................................................................................................13

6.4.1 Calibration and Adjustment at E+E Elektronik ................................................................................................... 14

6.4.2 Humidity Calibration and Adjustment by the User .............................................................................................. 14

6.4.3 Temperature Calibration and Adjustment by the User ....................................................................................... 15

6.5 Error Indication on the Analogue Output (NAMUR) .....................................................................................15

6.6 Spare Parts .................................................................................................................................................15

7 Accessories .......................................................................................................................................16

8 Technical Data ...................................................................................................................................17

Page 4

1 General

This user manual serves for ensuring proper handling and optimal functioning of the device. The user

manual shall be read before commissioning the equipment and it shall be provided to all staff involved

in transport, installation, operation, maintenance and repair. The user manual may not be used for the

purposes of competition without the written consent of E+E Elektronik® and may not be forwarded to

third parties. Copies may be made for internal purposes. All information, technical data and diagrams

included in these instructions are based on the information available at the time of writing.

Disclaimer

The manufacturer or his authorized agent can be only be held liable in case of willful or gross

negligence. In any case, the scope of liability is limited to the corresponding amount of the order issued

to the manufacturer. The manufacturer assumes no liability for damages incurred due to failure to

comply with the applicable regulations, operating instructions or the specified operating conditions.

Consequential damages are excluded from the liability.

1.1 Explanation of Symbols

This symbol indicates safety information.

It is essential that all safety information is strictly observed. Failure to comply with this information can

lead to personal injuries or damage to property. E+E Elektronik® assumes no liability if this happens.

This symbol indicates instructions.

The instructions shall be observed in order to reach optimal performance of the device.

1.2 Safety Instructions

1.2.1 General Safety Instructions

The device and mainly the filter cap shall not be exposed to unnecessary mechanical stress.

When replacing the filter cap make sure not to touch the sensing elements.

The device must be operated with the filter cap on at all times.

Installation, electrical connection, maintenance and commissioning shall be performed by qualified

personnel only.

Use the EE260 only as intended and observe all technical specifications.

Do not use EE260 in explosive atmosphere or for measurement of aggressive gases.

Do not apply the nominal voltage to the RS485 data lines.

This device is not appropriate for safety, emergency stop or other critical applications where device

malfunction or failure could cause injury to human beings.

1.2.2 Intended Use

The EE260 is intended for the humidity (RH) and temperature (T) measurement in meteorology. It is

compatible with rotation symmetric radiation shields (available as accessory HA010511). By means of

a mounting clip (accessory HA010227) the EE260 can be pole/wall mounted, e.g. for deployment in

weather huts / Stevenson screens.

The use of the EE260 in any other way than described in this manual bears a safety risk for people and

the entire measurement installation and is therefore not allowed.

The manufacturer cannot be hold responsible for damages as a result of incorrect handling, installation,

and maintenance of the equipment.

In order to avoid damage to the instrument or health hazards, the measuring equipment must never be

manipulated with tools that are not specifically described in this manual.

The sensor may only be utilized in accordance with the conditions defined in the technical data.

Otherwise, measurement inaccuracies will occur and equipment failures cannot be ruled out.

4

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

Page 5

The steps recommended by the manufacturer for installation, inspections and maintenance work must

be observed and carried out for the safety of the user and for the functionality of the equipment.

Unauthorized product modification leads to loss of all warranty claims. This may be accomplished only

with an explicit permission of E+E Elektronik®!

1.2.3 Mounting, Start-up and Operation

The EE260 humidity and temperature probe for meteorological applications has been produced under

state of the art manufacturing conditions, has been thoroughly tested and has left the factory after

fulfilling all safety criteria. The manufacturer has taken all precautions to ensure safe operation of the

device. The user must ensure that the device is set up and installed in a manner that does not have a

negative effect on its safe use. The user is responsible for observing all applicable safety guidelines,

local and international, with respect to safe installation and operation on the device. This user manual

contains information and warnings that must be observed by the user in order to ensure safe operation.

Mounting, start-up, operation and maintenance of the device may be performed by qualified staff

only. Such staff must be authorized by the operator of the facility to carry out the mentioned activities.

The qualified staff must have read and understood this user manual and must follow the instructions

contained within.

All process and electrical connections shall be thoroughly checked by authorized staff before putting

the device into operation.

Do not install or start-up a device supposed to be faulty. Make sure that such devices are not

accidentally used by marking them clearly as faulty.

A faulty device may only be investigated and possibly repaired by qualified, trained and authorized

staff. If the fault cannot be fixed, the device shall be removed from the process.

Service operations other than described in this user manual may only be performed by the

manufacturer.

1.3 Environmental Aspects

Products from E+E Elektronik® are developed and manufactured in compliance with all relevant

environmental protection requirements. Please observe local regulations for the device disposal.

For disposal, the individual components of the device must be separated according to local recycling

regulations. The electronics shall be disposed of correctly as electronics waste.

2 Scope of Supply

EE260 – Heated Humidity and Temperature Probe for Meteorological Applications

Inspection certificate according to DIN EN 10204-3.1

Quick guide

3 Product Description

3.1 General

The EE260 probe is optimized for accurate and reliable relative humidity (RH) and temperature (T)

measurement in meteorology and demanding outdoor applications.

Mounted in its upright position, the air first passes over EE260‘s Pt100 temperature sensing element,

then over the heated probe shaft and over the heated humidity sensing element. This dual heating

system prevents condensation or icing of the RH sensing element, on the probe head and on the filter

cap. This leads to short response times and fast recovery as well as to precise RH measurement even

under continuously high humidity and condensing conditions.

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

5

Page 6

The proprietary E+E sensor coating, the encapsulated electronics and the UV resistant and T stable

elastomere enclosure make the probe reliable, long-term stable and very well protected against

environmental influences.

The EE260 measures RH and T and calculates the following humidity related parameters:

Dew point temperature (Td)

Frost point temperature (Tf)

Wet bulb temperature (Tw)

Water vapour partial pressure (e)

Mixing ratio (r)

Absolute humidity (dv)

Specific enthalpy (h)

The RH and T measured values are available on two freely congurable and scalable voltage outputs as

well as on the RS485 interface with Modbus RTU protocol. The values of the calculated parameters are

available on RS485/Modbus RTU.

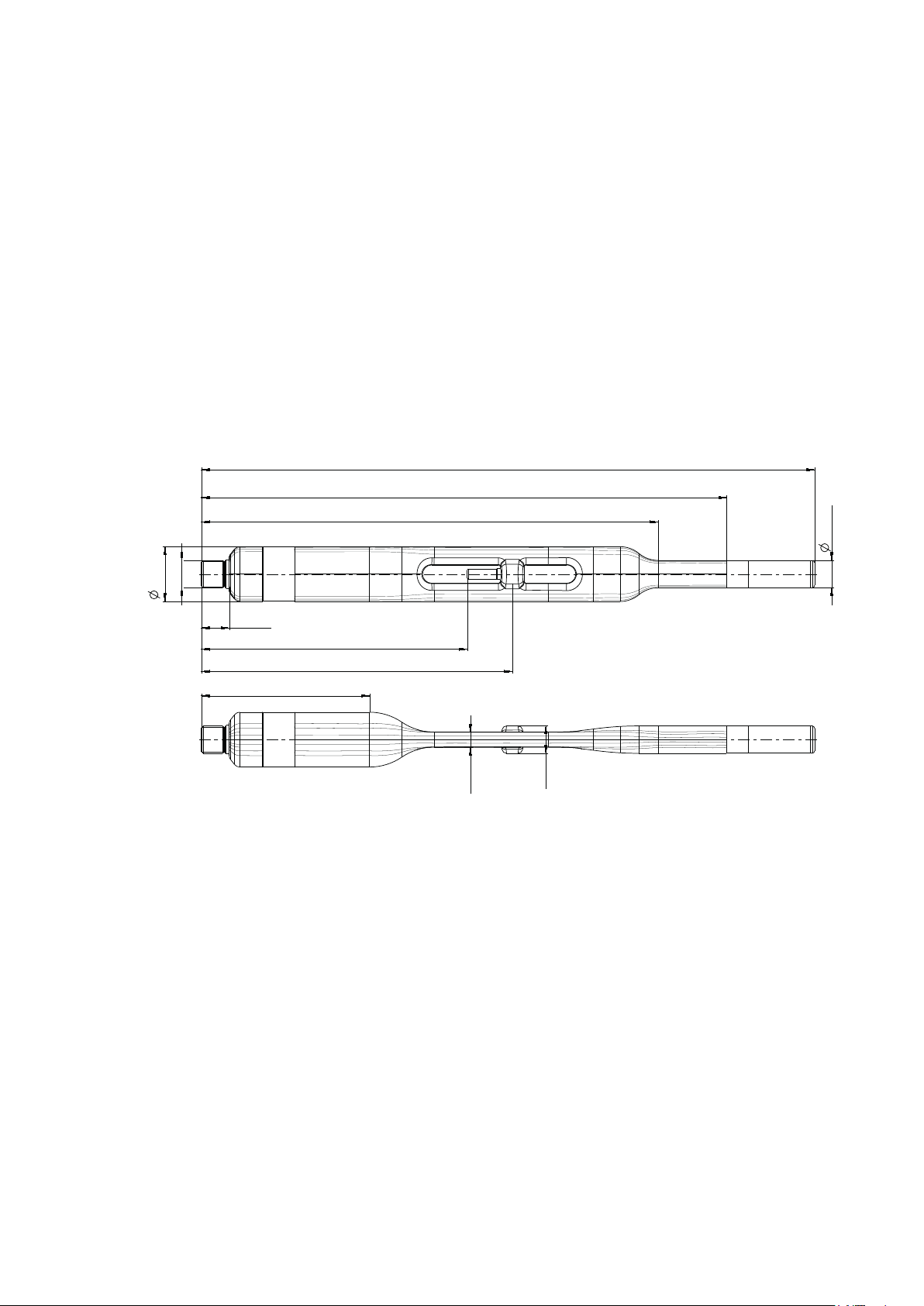

3.2 Dimensions

200

268 (10.6)

230 (9.1)

(7.9)

12 (0.5)

24 (0.94)

M12x1

12 (0.5)

116 (4.6)

136 (5.4)

74 (2.9)

Fig. 1 Dimensions of EE260 in mm (inch)

(0.5)

6.5 (0.3)

12

6

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

Page 7

Strahlungsschutz mit künstlicher Belüftung HA010511

Radiation shield with artificial ventilation HA010511

E+E Elektronik GmbH

Langwiesen 7

4209 Engerwitzdorf

AUSTRIA

Tel.: +43 7235 605-0

Fax: +43 7235 605-8

info@epluse.com

www.epluse.com

R

Ges.m.b.H.

Ø 150

front view

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Ø 120

296

488

max. Ø 50

min. Ø 25

142

80

62

Ø 25 (Ø 18...25)

ca. 335

Fig. 2 Dimensions (in mm) of optional radiation shield (ordering code HA010511)

3.3 Electrical Connection

Pin number Function Wire colors for accessories:

1 Analogue output 1 white

2 RS485 B (D-) brown

3 GND analogue output green

4 Analogue output 2 yellow

front view

M12 device plug

Tab. 1 EE260 pin assignment

To meet the EMC Directive 2004/108/EC a shielded connection cable must be used.

The connection cable mentioned above (accessory HA0103xx ,8 pole, M12x1 socket – free ends, PUR

insulation), has a shielding included and is available in several lengths (refer to chapter 6.6).

5 n.c. grey

6 RS485 A (D+) pink

7 Supply voltage blue

8 GND red

- Connection cable HA010322/23/24/25

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

7

Page 8

4 Installation

4.1 Radiation Shield

With its rotation symmetric design, the EE260 is very well suited for mounting in a radiation shield, thus

protecting the device against rain, snow, ice and solar radiation. The probe is fixed by means of a cable

gland.

Best measurement performance is achieved in the optionally available radiation shield with artificial

ventilation. Please refer to the HA010511 data sheet for more information.

Fig. 3 EE260 mounted within the optional radiation shield HA010511

4.2 Wall Mount/Pole Mount

The probe may be installed on a wall or a pole with the help of the mounting clip HA010227 (not

included in the scope of supply, see data sheet “Accessories”). This also allows a placement in a

Stevenson screen / wheather hut.

Please note:

The probe shall be mounted vertically with the filter cap upside, a proper air circulation around the

probe must be ensured (e.g. with HA010511). Please avoid any improper mechanical stress onto the

probe.

Avoid unnecessary stress here

60 mm (2.4") clamping zone

Fig. 4 EE260 mounted with the optional clip HA010227

8

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

Page 9

5 Setup and Adjustment

The EE260 is ready to use and does not require any configuration by the user. The factory setup of

EE260 corresponds to the type number ordered. Please refer to the data sheet at www.epluse.com/

EE260. The user can change the factory setup with the help the EE-PCS Product Configuration Software,

the Modbus configuration adapter (order code HA011018) and the EE260 conguration cable (order

code HA011020).

Besides the measurand selection of the analogue and digital outputs and their scaling, the digital

interface settings may be changed. The RH and T measurement is offset and 2-point adjustable. It is

possible to enable or disable the sensing element and the probe heating (separated from each other;

factory setting for both: enabled) and the NAMUR error indication (factory setting: disabled). For the

purpose of pressure compensation, the barometric air pressure at the operating site may be set.

Please note: The EE260 may not be connected to any additional power supply when using the Modbus

configuration adapter HA011018.

HA011018 HA011020

PC

Fig. 5 Configuration

5.1 EE-PCS Product Configuration Software

To use the software for performing adjustments and changes in settings, please proceed as follows:

1. Download the EE-PCS Product Configuration Software from www.epluse.com/configurator and

install it on the PC.

2. Connect the EE260 to the PC using the Modbus configuration adapter and the EE260 configuration

cable.

3. Start the EE-PCS software.

4. Follow the instructions on the EE-PCS opening page for scanning the ports and identifying the

connected device.

5. Click on the desired setup or adjustment mode from the main EE-PCS menu on the left and follow

the online instructions of the EE-PCS

5.2 Digital Interface RS485 with Modbus RTU Protocol

Item Factory settings Selectable values (via EE-PCS)

Baud rate 9 600 9 600, 19 200, 38 400, 57 600, 76 800, 115 200

Data bits 8 8

Parity Even None, odd, even

Stop bits 1 1, 2

Slave address 235 1...247

Tab. 2 Digital interface default settings

The recommended settings for multiple devices in a Modbus RTU network are 9600, 8, even, 1.

The EE260 represents 1 unit load on an RS485 network.

Device address, baud rate, parity and stop bits can be set via:

1. EE-PCS Product Configuration Software, the Modbus configuration adapter HA011018 and the

EE260 configuration cable HA011020.

The EE-PCS can be downloaded free of charge from www.epluse.com/configurator

2. Modbus protocol in the register 60001 (0x00) and 60002 (0x01).

See Modbus Application Note AN0103 (available at www.epluse.com/EE260)

The serial number as ASCII-code is located in the register addresses 0x00...0x07 (16 bits per address).

The firmware version is located in the register address 0x08 (bits 15...8 = major release; bits 7...0 =

minor release). The sensor name is located in register address 0x09. The beforementioned registers can

be read out with function code 0x03 or 0x04.

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

9

Page 10

Please note: When reading the serial number or the sensor name, it is always necessary to read all 8

registers, even if the desired information requires less.

Please note: For obtaining the correct floating point values, both registers have to be read within

the same reading cycle. The measured value can change between two Modbus requests, therefore,

exponent and mantissa may get inconsistent.

Communication settings (INTEGER 16 bit)

Parameter Register number

Write register: function code 0x06

Slave ID (Modbus address) 1 0x00

Modbus protocol settings

1) Register number starts from 1.

2) Protocol address starts from 0.

3) For Modbus protocol settings see Application Note Modbus AN0103 (available at www.epluse.com/EE260).

3)

INFO (read register)

Parameter Register number

Read register: function code 0x03 / 0x04

Serial number (as ASCII) 1 0x00

Firmware version 9 0x08

Sensor Name 10 0x09

1) Register number starts from 1.

2) Protocol address starts from 0.

1)

[DEC] Protocol address2) [HEX]

2 0x01

1)

[DEC] Protocol address2) [HEX]

Air pressure

Parameter Register number

1)

[DEC] Register address2) [HEX]

Read and write register: function code 0x03 / 0x10

Air pressure

1) Register number starts from 1

2) Register address starts from 0

3) Ambient pressure in mbar, with 2 decimal digits (e.g. 1 008.25), default value 1 013.25 mbar

3)

5001 0x1388

10

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

Page 11

5.3 Modbus Register Map

The measured data is saved as a 32 bit floating point values (data type FLOAT) and as 16 bit signed

integer values (data type INTEGER).

FLOAT 32 bit:

Parameter Unit Register number

Read register: function code 0x03 / 0x04

Temperature T

Relative humidity RH, Uw % RH 1021 0x3FC

Water vapour partial pressure e

Dew point temperature Td

Wet bulb temperature Tw

Absolute humidity dv

Mixing ratio r

Specific enthalpy h

Frost point temperature Tf

Volume concentration Wv

Saturation vapor pressure

above water ew

Saturation vapor pressure

above ice ei

Ice bulb temperature Ti

Specific humidity qv

1) Register number starts from 1

2) Register address starts from 0

1)

[Dec] Register address

°C 1003 0x3EA

°F 1005 0x3EC

°K 1009 0x3F0

mbar 1101 0x44C

psi 1103 0x44E

°C 1105 0x450

°F 1107 0x452

°K 1147 0x47A

°C 1109 0x454

°F 1111 0x456

°K 1145 0x478

g/m³ 111 3 0x458

gr/ft³ 1115 0x45A

g/kg 1121 0x460

gr/lb 1123 0x462

kJ/kg 1125 0x464

ft lbf/lb 1127 0x466

BTU/lb 1129 0x468

°C 1131 0x46A

°F 1133 0x46C

°K 1149 0x47C

ppm 1151 0x47E

% 1155 0x482

‰ 1157 0x484

mbar 1221 0x4C4

psi 1223 0x4C6

mbar 1225 0x4C8

psi 1227 0x4CA

°C 1237 0x4D4

°F 1239 0x4D6

°K 1241 0x4D8

g/kg 1247 0x4DE

gr/lb 1249 0x4E0

2)

[HEX]

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

11

Page 12

INTEGER 16 bit:

3)

Parameter Unit Scale

Read register: function code 0x03 / 0x04

°C 100 4002 0xFA1

Temperature T

Relative humidity RH, Uw % RH 100 4011 0xFAA

Water vapour partial pressure e

Dew point temperature Td

Wet bulb temperature Tw

Absolute humidity dv

Mixing ratio r

Specific enthalpy h

Frost point temperature Tf

Volume concentration Wv

Saturation vapor pressure

above water ew

Saturation vapor pressure

above ice ei

Ice bulb temperature Ti

Specific humidity qv

1) Register number starts from 1

2) Register address starts from 0

3) Examples: For scale 100, the reading of 2550 means a value of 25.5. For scale 50, the reading of 2550 means a value of 51.

°F 50 4003 0xFA2

°K 50 4005 0xFA4

mbar 10 4051 0xFD2

psi 1000 4052 0xFD3

°C 100 4053 0xFD4

°F 100 4054 0xFD5

°K 100 4074 0xFE9

°C 100 4055 0xFD6

°F 100 4056 0xFD7

°K 100 4073 0xFE8

g/m³ 10 4057 0xFD8

gr/ft³ 10 4058 0xFD9

g/kg 10 4061 0xFDC

gr/lb 10 4062 0xFDD

kJ/kg 1 4063 0xFDE

ft lbf/lb 1 4064 0xFDF

BTU/lb 1 4065 0xFE0

°C 100 4066 0xFE1

°F 100 4067 0xFE2

°K 100 4075 0xFEA

ppm 0.1 4076 0xFEB

% 1000 4078 0xFED

‰ 100 4079 0xFEE

mbar 100 4111 0x100E

psi 100 4112 0x100F

mbar 100 4113 0x1010

psi 100 4114 0x1011

°C 100 4119 0x1016

°F 100 4120 0x1017

°K 50 4121 0x1018

g/kg 10 4124 0x101B

gr/lb 10 4125 0x101C

Register number1) [Dec] Register address

2)

[HEX]

5.4 Modbus Message Example

Example of Modbus RTU command for reading the temperature (float value) T = 24.625015 °C

from the register 0x3EA

Device EE260; slave ID 235 [0xEB]

Reference document, chapter 6.3: www.modbus.org/docs/Modbus_Application_Protocol_V1_1b3.pdf

See Application Note Modbus AN0103 (available on www.epluse.com/EE260)

Modbus ID

address

Request [Hex]: EB 03 03 EA 00 02 F3 71

Modbus ID

address

Response Hex]: EB 03 04 00 08 41 C5 C0 3C

12

Function

code

Function

code

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

Starting

address Hi

Byte

count

address Lo

Register 1

value Hi

Starting

Register 1

value Lo

No. of

register Hi

Register 2

value Hi

No. of

register Lo

Register 2

value Lo

CRC

CRC

Page 13

Decoding of oating point values:

Floating point values are stored according IEEE754 standard. The byte pairs 1, 2 and 3, 4 are inverted

as follows:

MMMMMMMM MMMMMMMM SEEEEEEE EMMMMMMM

Byte 3 Byte 4 Byte 1 Byte 2

Example:

Response [Hex] Value in decimal

Byte 1 (Register 2 - Hi) Byte 2 (Register 2 – Lo) Byte 3 (Register 1 - Hi) Byte 4 (Register 1 - Lo)

44

C5 00 08 24.625015

6 Maintenance and Service

EE260 does not require any special maintenance, nevertheless for high accurate measurements

especially over wide RH and T ranges it is recommended to calibrate the probe every 12 months. If

needed, the enclosure may be cleaned and the device may be re-adjusted as described below.

6.1 Cleaning

Use a damp soft cloth to remove deposits of dust or dirt from the exterior of the probe. Do not use any

solvents or abrasive cleaning agents and no isopropanol (isopropyl alcohol).

In case of dusty, oily and polluted environment:

Use a damp soft cloth to remove deposits of dust or dirt from the exterior of the probe. Do not use

any solvents or abrasive cleaning agents.

The filter cap shall be replaced once in a while with an E+E original one (see below).

If needed, the sensing element of the humidity probe can be cleaned by the user (see the E+E

cleaning instructions)

6.2 Filter Replacement

In a dusty or polluted environment it might be necessary to replace the filter cap or the filter membrane,

respectively, once in a while. In most of the cases, a clogged filter shows visible contamination or dirt.

Longer response time of the humidity measurement also indicates a clogged filter cap. In such cases,

replace the filter cap or the filter membrane by a new, original one, see chapter „6.6 Spare Parts“.

Procedure

Turn the filter cap counter-clockwise for removing it.

Install the new filter cap finger tight by turning it clockwise.

While replacing the filter cap take very good care to not touch or rub the sensing element.

6.3 Repairs

Repairs may be carried out by the manufacturer only. The attempt of unauthorized repair excludes any

warranty claims.

6.4 RH / T Adjustment and Calibration

In meteorological applications there might arise the need for periodical humidity and temperature

calibration or adjustment.

Definitions

Calibration documents the accuracy of a measurement device. The device under test (specimen) is

compared with the reference and the deviations are documented in a calibration certificate. During

the calibration, the specimen is not changed or improved in any way.

Adjustment improves the measurement accuracy of a device. The specimen is compared with the

reference and brought in line with it. An adjustment can be followed by a calibration which documents

the accuracy of the adjusted specimen.

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

13

Page 14

6.4.1 Calibration and Adjustment at E+E Elektronik

Calibration and/or adjustment can be performed in the E+E Elektronik calibration laboratory. For

information on the E+E capabilities in ISO or accredited calibration please see www.eplusecal.com.

6.4.2 Humidity Calibration and Adjustment by the User

Depending on the level of accuracy required, the humidity reference can be:

Handheld device (e.g. Omniport 30), please see www.epluse.com/omniport30.

Humidity standards (e.g. Humidity Calibration Kit), please see www.epluse.com/EE260.

Please note: It is of very high importance that for the RH calibration the RH and T sensing elements

are at the same temperature.

Please contact your sales representative for assistance.

Please note: When the calibration/adjustment procedure with the help of EE PCS starts, both heating

modes of the EE260 are disabled automatically if they have on status. At the end of the procedure the

heating comes back to on automatically.

14

Fig. 6 Setting the Heating Mode in E+E Configurator

Please observe these important notes on changing the sensing element data:

■ The sensing element data generally only has informational character.

■ For all applications, an alleged drift of the device can be corrected using the offset correction or the

one/two point adjustment offered by the EE-PCS.

■ For very special requirements, the drift can be corrected acting upon the characteristic of the sensing

elements, i.e. upon the sensor data such as nominal capacity or humidity coefficient. This requires

deep knowledge about the sensing elements and the design of the measuring device.

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

Page 15

■ Important! Contact the E+E sales representative before any attempt of acting upon the sensing

element data!

■ Caution! Upon changing the sensing element data, the original data is lost. There is no way to

automatically return to the original sensor data. Please make sure to note and save the original

sensing element data before making any change!

6.4.3 Temperature Calibration and Adjustment by the User

For a reproducible T calibration or adjustment, it is recommended to measure the Pt100 of the EE260

in a liquid bath. This reduces the T inhomogeneity surrounding the probe to a minimum. It must be

ensured to use an inert, nonconductive liquid which does not chemically contaminate the sensor

element (e.g. GALDEN HT200).

Please note: When the calibration/adjustment procedure with the help of EE PCS starts, both heating

modes of the EE260 are disabled automatically if they have on status. At the end of the procedure the

heating comes back to on automatically.

The temperature reference (T-Ref) shall be located at the same level as the Pt100 of the EE260.

T-Ref

Fig. 7 Temperature calibration/adjustment in a liquid bath

PC

Pt100

Mounting clip HA0102277

EE-PCS

6.5 Error Indication on the Analogue Output (NAMUR)

The EE260 features an error indication on its analogue outputs according to the NAMUR NE 043

recommendations (Standardization of the Signal Level for the Failure Information of Digital Transmitters,

Edition 2003-02-03, see www.namur.net/en/recommendations-and-worksheets/current-nena.html).

The feature is enabled by factory default and can be disabled with the EE-PCS Product Configuration

Software, see above.

Output signal NAMUR signal level

0-1 V 1.1 V

0-2.5 V 2.75 V

0-5 V 5.5 V

0-10 V 11 V

6.6 Spare Parts

Description Order code

Filter PTFE membrane on stainless steel body HA010114

PTFE membrane for filter HA010114ME

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

15

Page 16

7 Accessories

Please also refer to the “Accessories“ data sheet.

Description Order code

Radiation shield, articially ventilated HA010511

Modbus configuration adapter1) HA011018

EE260 conguration cable1) HA011020

E+E Product Configuration Software (Download: www.epluse.com/configurator) EE-PCS

M12x1 cable connector, 8 pole socket HA010704

Connection cable, 8 pole, M12x1 socket - free ends

1.5 m (4.9 ft) HA010322

3 m (9.8 ft) HA010323

5 m (16.4 ft) HA010324

10 m (32.8 ft) HA010325

Wall mounting clip Ø25 mm HA010227

Protection cap M12 female connector HA010781

Protection cap M12 male connector HA010782

1) Both accessories are necessary for conguration

16

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

Page 17

8 Technical Data

Measurands

Relative humidity

Measuring range 0…100 % RH

Sensing element E+E HMC01, heated

Response time t

Accuracy

1)

-15...40 °C

-15...40 °C (5…104 °F) for RH > 90 % ± 2.0 % RH

-25...60 °C

-40...-25 °C

Temperature

Measuring range -60...60 °C

Temperature sensor Pt100 1/3 DIN B

Accuracy

0.6

0.5

0.45

0.4

0.3

0.2

0.15

0.1

0

-60 -50 -10-20-30-40 100 605020 30 40

Outputs

Analogue 0 - 1 V / 0 - 2.5 V / 0 - 5 V / 0 - 10 V

Freely selectable and scalable 0 < I

Digital interface RS485 (EE260 = 1 unit load)

Protocol Modbus RTU

Default settings Baud rate 9

General

Supply voltage 7 - 30 V DC

Power consumption, typ. 300 mW (25 mA @ 12 V DC, heating included)

Electrical connection M12x1, 8 poles, stainless steel 1.4404

Filter PTFE membrane, stainless steel body

Protection class IP67

Enclosure material Thermoplastic elastomer, UV resistant and T stable

Electromagnetic compatibility

at 20 °C (68 °F) < 15 s

90

(incl. hysteresis, non-linearity and repeatability)

(5…104 °F) for RH ≤ 90 % ± (1.3 + 0.3 % *mv) % RH mv = measured value

(-13…140 °F) ± (1.4 + 1 % *mv) % RH

(-40…-13 °F) ± (1.5 + 1.5 % *mv) % RH

2)

(-76...140 °F)

Analogue output

0.4

0.3

0.2

0.1

0

-60 -50 -10-20-30-40 100 605020 30 40

< 1 mA

L

600

4)

EN 61326-1 EN 61326-2-3

RS485 interface

3)

, parity even, stop bits 1, slave ID 235

Operating and -60...60 °C

(-40...140 °F)

storage conditions 0...100 % RH (operation)

0...95 % RH non-condensing (storage)

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was

calculated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

2) The EE260 simultaneously features two analogue voltage outputs and the RS485 interface.

3) Supported baud rates: 9 600, 19 200, 38 400, 57 600, 76 800 and 115 200; find more details about communication setting in the User Manual and the Modbus

Application Note at www.epluse.com/ee260

4) Compliance with EN61000-4-3 and EN 610004-6: Electromagnetic interferencees may cause additional deviations <2 % RH.

User Manual EE260 Heated Humidity and Temperature Probe for Meteorological Applications

17

Page 18

HEADQUARTERS

E+E Elektronik Ges.m.b.H.

Langwiesen 7

4209 Engerwitzdorf

Austria

Tel.: +43 7235 605-0

E-mail: info@epluse.com

Web: www.epluse.com

SUBSIDIARIES

E+E Elektronik China

18F, Kaidi Financial Building,

No.1088 XiangYin Road

200433 Shanghai

Tel.: +86 21 6117 6129

E-mail: info@epluse.cn

E+E Elektronik France

Le Norly III, 136 chemin du Moulin

69130 Ecully

Tel.: +33 4 74 72 35 82

E-mail: info@epluse.fr

E+E Elektronik Germany

Schöne Aussicht 8 C

61348 Bad Homburg

Tel.: +49 6172 13881-0

E-mail: info@epluse.de

E+E Elektronik Italy

Via Alghero 17/19

20128 Milano (MI)

Tel.: +39 02 2707 86 36

E-mail: info@epluse.it

E+E Elektronik Korea

Suite 2001, Heungdeok IT

Valley Towerdong, 13,

Heungdeok 1-ro, Giheung-gu

16954 Yongin-si, Gyeonggi-do

Tel.: +82 31 732 6050

E-mail: info@epluse.co.kr

E+E Elektronik USA

333 East State Parkway

Schaumburg, IL 60173

Tel.: +1 847 490 0520

E-mail: office@epluse.com

Loading...

Loading...