Page 1

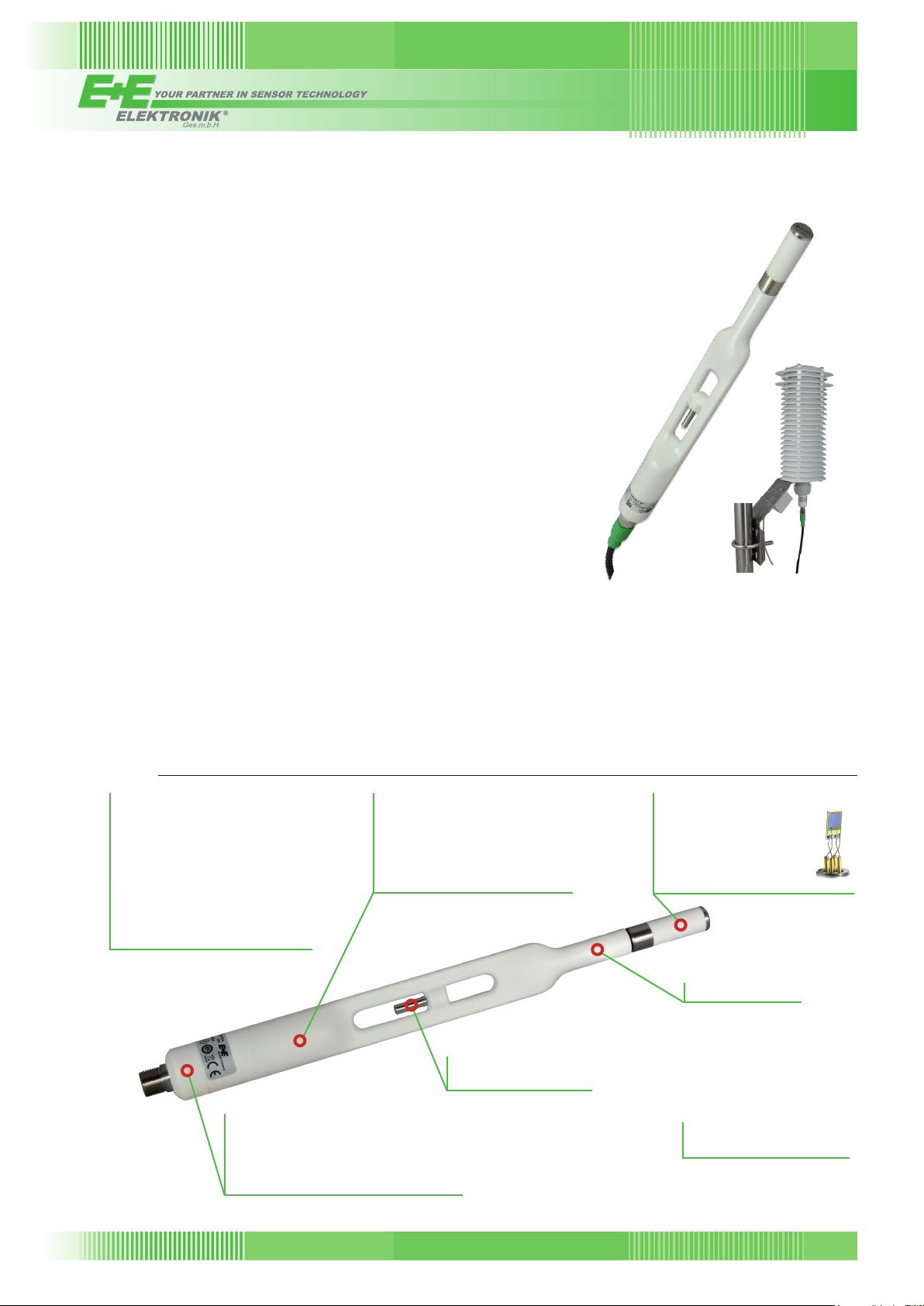

EE260

Heated Humidity and Temperature Probe

for Meteorological Applications

The EE260 probe is optimized for accurate and reliable relative humidity

(RH) and temperature (T) measurement in meteorology and demanding

outdoor applications.

Innovative, Compact Design

The design of the EE260 integrates a heated humidity sensing head and an

additional T sensing element into one single compact probe. The device is

thus compatible with rotation symmetric radiation shields.

Measurement Performance

The dual heating system prevents condensation on the RH sensing element,

on the probe head and on the lter cap, which leads to very short response

time and fast recovery after condensation. Furthermore, it enables precise

RH measurement even under continuously high humidity and condensing

conditions.

Versatility

Besides the measurement of RH and T, the EE260 calculates other humidity

related quantities like dew point temperature (Td), absolute humidity (dv) and

mixing ratio (r).

Reliability, IP67 Protection Class

The proprietary E+E coating protects the RH sensing element and its leads

against corrosive and electrically conductive pollution. The encapsulated

electronics are optimally protected against environmental inuences.

Analogue Outputs and Digital Interface

The EE260 features two freely congurable and scalable voltage outputs as

well as an RS485 interface with Modbus RTU protocol. The measured data is

available at the analogue and digital interfaces simultaneously.

User Congurable and Adjustable

An optional conguration adapter and the free EE-PCS Product Conguration Software facilitate the conguration and

adjustment of the EE260.

EE260 with radiation shield

Features

Measurands

» Relative humidity (RH)

» Temperature (T)

» Dew point temperature (Td)

» Frost point temperature (Tf)

» Wet bulb temperature (Tw)

» Water vapour partial pressure (e)

» Mixing ratio (r)

» Absolute humidity (dv)

» Specic enthalpy (h)

Electronics

» Fully encapsulated

» Two voltage outputs

» RS485 interface with

Modbus RTU protocol

» User congurable and adjustable

Enclosure

» IP67

» Flexible thermoplastic elastomer

» UV resistant and T stable

» M12x1 connector, 8 poles, stainless steel

RH and T sensing element

» Heated

» Protected by

- E+E proprietary coating

- PTFE membrane lter

on stainless steel body

Heated probe head

Unique probe design

with integrated T sensor

Inspection certicate

according DIN EN 10204-3.1

166

www.epluse.com v1.2 / Modification rights reserved

EE260

Page 2

Protective Sensor Coating

The E+E proprietary sensor coating is a hygroscopic layer applied to the sensing elements, their leads and soldering

points. The coating substantially extends sensor life-time and ensures optimal measurement performance in corrosive

environments (salts, o-shore applications). Additionally, it improves the long term stability of E+E sensors in dusty, dirty

or oily applications by preventing stray impedance caused by deposits on the active sensor surface or on the electrical

connections.

Technical Data

Measurands

Relative humidity

Measuring range 0…100 % RH

Sensing element E+E HMC01, heated

Response time t

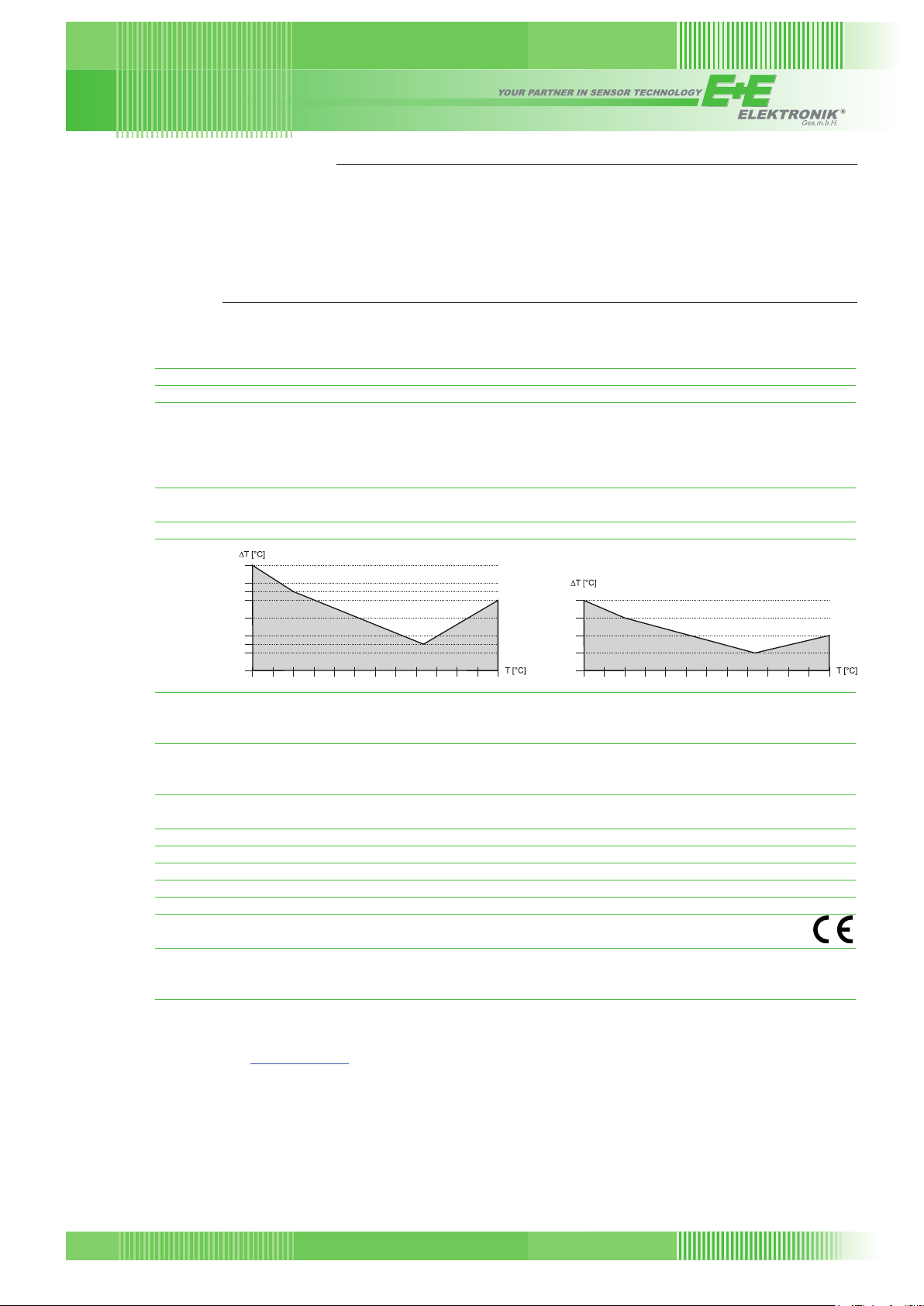

Accuracy

1)

-15...40 °C

-15...40 °C (5…104 °F) for RH > 90 % ± 2.0 % RH

-25...60 °C

-40...-25 °C

Temperature

Measuring range -60...60 °C

Temperature sensor Pt100 1/3 DIN B

Accuracy

Outputs

2)

Analogue 0 - 1 V / 0 - 2.5 V / 0 - 5 V / 0 - 10 V

Freely selectable and scalable 0 < I

Digital interface RS485 (EE260 = 1 unit load)

Protocol Modbus RTU

Default settings Baud rate 9

General

Supply voltage 7 - 30 V DC

Power consumption, typ. 300 mW (25 mA @ 12 V DC, heating included)

Electrical connection M12x1, 8 poles, stainless steel 1.4404

Filter PTFE membrane, stainless steel body

Protection class IP67

Enclosure material Thermoplastic elastomer, UV resistant and T stable

Electromagnetic compatibility

Operating and -60...60 °C

storage conditions 0...100 % RH (operation)

0...95 % RH non-condensing (storage)

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was calculated

in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

2) The EE260 simultaneously features two analogue voltage outputs and the RS485 interface.

3) Supported baud rates: 9 600, 19 200, 38 400, 57 600, 76 800 and 115 200; find more details about communication setting in the User Manual and the Modbus

Application Note at www.epluse.com/ee260

4) Compliance with EN61000-4-3 and EN 610004-6: Electromagnetic interferencees may cause additional deviations <2 % RH.

at 20 °C (68 °F) < 15 s

90

(incl. hysteresis, non-linearity and repeatability)

(5…104 °F) for RH ≤ 90 % ± (1.3 + 0.3 % *mv) % RH mv = measured value

(-13…140 °F) ± (1.4 + 1 % *mv) % RH

(-40…-13 °F) ± (1.5 + 1.5 % *mv) % RH

(-76...140 °F)

0.6

0.5

0.45

0.4

0.3

0.2

0.15

0.1

0

-60 -50 -10-20-30-40 100 605020 30 40

Analogue output

4)

EN 61326-1 EN 61326-2-3

0.4

0.3

0.2

0.1

< 1 mA

L

(-76...140 °F)

0

-60 -50 -10-20-30-40 100 605020 30 40

3)

600

, parity even, stop bits 1, slave ID 235

RS485 interface

EE260

www.epluse.comv1.2 / Modification rights reserved

167

Page 3

Dimensions

Values in mm (inch)

200

(7.9)

24 (0.94)

M12x1

12 (0.5)

116 (4.6)

136 (5.4)

74 (2.9)

Ordering Guide

0 - 1 V GA1

Output signal

1)

Output 1 measurand

Scaling 1 low

Scaling 1 high

Output 2 measurand

Software Configuration

Scaling 2 low

Scaling 2 high

1) Applies to both outputs

Measurand code MAxx / MBxx

Temperature

Relative humidity [%] 10

Water vapor partial pressure e

Dew point temperature Td

Wet bulb temperature Tw

0 - 2.5 V GA8

0 - 5 V GA2

0 - 10 V no code

Relative humidity [% RH] no code

Other measurand (xx see measurand code below) MAxx

0 no code

Value SALvalue

100 no code

Value SAHvalue

Temperature [°C] no code

Other measurand (xx see measurand code below) MBxx

-40 no code

Value SBLvalue

60 no code

Value SBHvalue

[°C] 1

[°F] 2

[mbar] 50

[psi] 51

[°C] 52

[°F] 53

[°C] 54

[°F] 55

230 (9.1)

6.5 (0.3)

268 (10.6)

(0.5)

12

12 (0.5)

EE260-

Measurand code MAxx / MBxx

Absolute humidity dv

Mixing ratio r

Specic enthalpy h

Frost point temperature Tf

3

] 56

[g/m

3

] 57

[g/ft

[g/kg] 60

[g/lb] 61

[kJ/kg] 62

[BTU/lb] 64

[°C] 65

[°F] 66

Ordering Example

EE260

Output signal: 0 - 10 V

Output 1 measurand: relative humidity [%RH]

Output 1 scaling range: low 0

high 100

Output 2 measurand: temperature [°C]

Output 2 scaling range: low -40

high 60

168

www.epluse.com v1.2 / Modification rights reserved

EE260-GA8MB2SBL20SBH120

Output signal: 0 - 2.5 V

Output 1 measurand: relative humidity [%RH]

Output 1 scaling range: low 0

high 100

Output 2 measurand: temperature [°F]

Output 2 scaling range: low 20

high 120

EE260

Page 4

Accessories

(for further information, see data sheet “Accessories“)

Radiation shield, articially ventilated HA010511

Modbus conguration adapter

EE260 conguration cable

E+E Product Conguration Software EE-PCS

(free download: www.epluse.com/congurator)

M12x1 connector, 8 pole socket HA010704

Connection cable, 8 poles, M12x1 – free ends

1.5 m

3 m

5 m

10 m

(4.9 ft) HA010322

(9.8 ft) HA010323

(16.4 ft) HA010324

(32.8 ft) HA010325

Wall mounting clip Ø25 mm HA010227

Protection cap M12 female connector HA010781

Protection cap M12 male connector HA010782

1) Both accessories are necessary for conguration

1)

HA011018

1)

HA011020

EE260

www.epluse.comv1.2 / Modification rights reserved

169

Loading...

Loading...