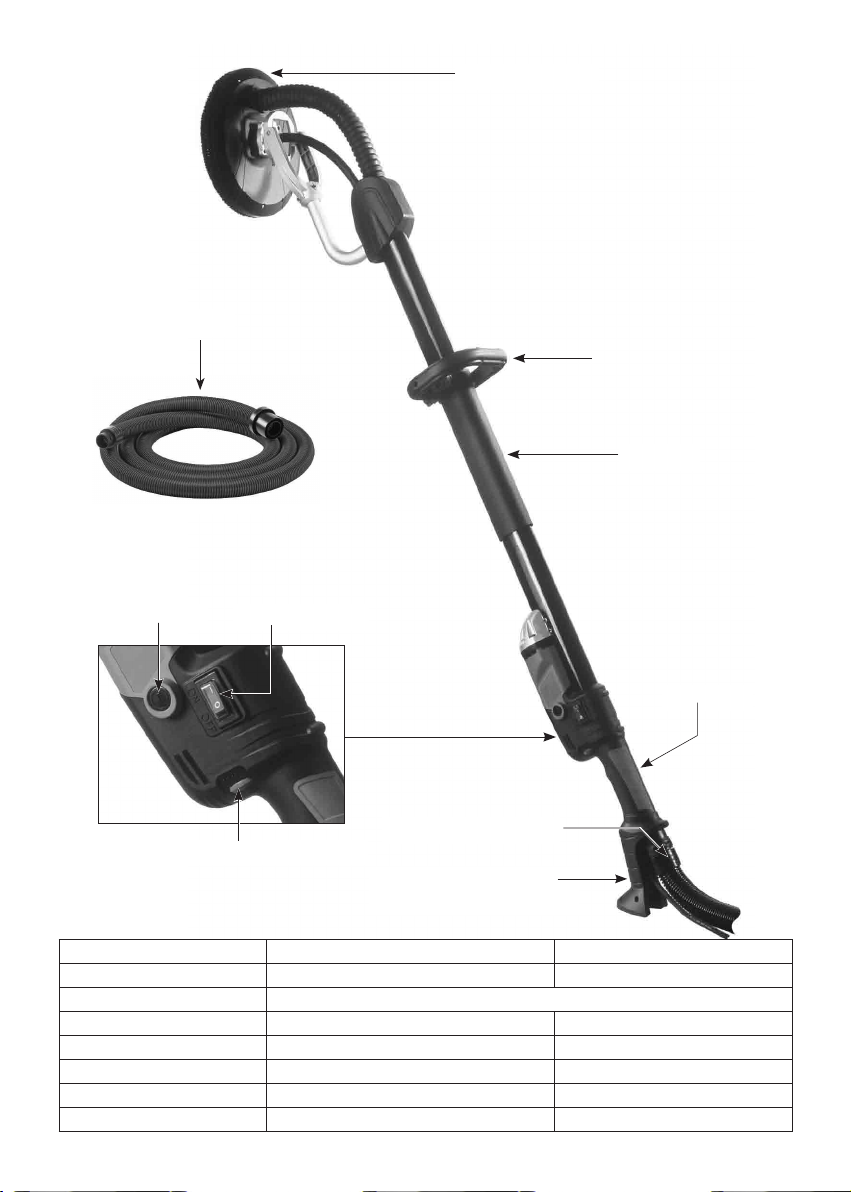

DW20

DW10

For your personal safety,

READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR

FUTURE REFERENCE.

Hose

Sanding Head

D-Handle(Optional)

Sponge

Brush Cap

Speed Adjustor Thumb Wheel

Model DW20 DW10

Length 1540mm (Long-Reach type) 1090mm (Compact type)

Voltage 115V / 60Hz or 230V /50Hz

No load speed 650 ~1600/min 650 ~1600/min

Full load speed 280 ~ 950/min 280 ~ 950/min

Power input 550W 550W

Sanding disc diameter 225mm 225mm

Net weight 4.7 kg (10 lbs.) 3.8 kg (8.4 lbs)

On/Off Switch

Soft Grip

Vacuum Swivel Mount

Hose Protection Device

(Optional)

2

GENERAL SAFETY RULES

W A R N I N G ! Re ad a n d u n d e r s t a n d all

instructions. Failure to follow all instructions

listed below, may result in electric shock, fire

and / or ser ious pe rsona l injur y. The term

“p ower tool ” in all of the war nings liste d

b elo w re f e r s to your ma in s -ope ra t ed

(corded) power tool.

SAVE THESE INSTRUCTIONS.

Work area safety

Ke ep your work are a clean and we ll lit.

Cluttere d worksite s and dar k areas invite

accidents.

Do not operate power to ols in explo si ve

atmos phere s, such as in the prese nce of

flammable liquid, gases, or dust. Power tools

create sparks which may ignite the dust or

fumes.

Keep bystanders, children, and visitors away

while operating a p ower tool. Distractio ns

can cause you to lose control.

Electrical Safety

Groun ded too ls must be plugged into an

outlet properly in stalled and grounded in

accordance with all codes and ordinances.

Nev er re mo v e th e gr oun d in g pro ng or

modify the plug in any way. Do not use any

ada pto r pl ugs . Che ck w ith a qu a li f ie d

electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools

sh ou ld electricall y mal function or bre ak

down, grounding provides a low resistance

path to carry electricity away from the user.

Avoid body contact with grounded surfaces

s uch as pi p e s , radi a t o rs, ra ng e s a nd

refriger ators. The re is an incr eased risk of

electric shock if your body is grounded.

Do n’ t exp os e p ow er tools to rain or we t

conditions. Water entering a power tool will

increase the risk of electric shock.

Don’t abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges

or moving parts. Replace damaged cords

immediately. Damaged cords increase the

risk of electric shock.

When operating a power tool outside, use an

outdoor extension cord mar ked “W-A” or

“W.” These cords are rated for outdoor use

and reduce the risk of electric shock.

Personal Safety

Stay alert, watch what you are doing and use

co mmon sense when ope rating a pow er

tool. Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A

momen t of in at ten ti on whi le ope ra ting

power to ols may result in seriou s personal

injury.

Us e safety equipment . Always we ar eye

protection. Safety equipment such as dust

mask, non-sk id safety shoes, har d hat, or

3

he aring protect ion us ed for appro pr iate

conditions will reduce personal injuries.

preventive safety measures reduce the risk of

starting the tool accidentally.

Avoid accidental starting. Be sure switch is

off before plugging in. Plugging in tools that

have the switch on invites accidents.

Remove adjusting keys or switches before

turning the tool on. A wrench or a key that is

left attached to a rotating part of the tool

may result in personal injury.

Do not overreach. Keep a proper footing and

ba lance at all times. Prope r fo oting and

balance enables better control of the tool in

unexpected situations.

Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

aw ay from movin g par ts . Loose clo th es ,

jewelry or long hair can be caught in moving

parts.

Tool use and care

Do not force tool. Use the co rre ct to ol fo r

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it on or

off. Any tool that cannot be controlled with

the sw i t ch is da n g ero us a n d mus t be

repaired.

Disconnect the plug from the power source

before making any adjustments, changing

acc e s sor i es, or s tor i n g the to ol. Su c h

Store idle tools out of reach of children and

do not al low pe rs ons un fa mi liar wit h the

power tool or these instructions to operate

the power tool. Tools are dangerous in the

hands of untrained users.

Maintain tools with care. Properly maintained

tools are less likely to bind and are easier to

control.

Check for misalignment or binding of moving

pa rt s, breakage of par ts , and any ot her

condition that may affect the tools operation.

If damaged, have the tool serviced before

using. Many accidents are caused by poorly

maintained tools.

Use the power tool, accessories and blades

etc., in accordance with these instructions

and in the manner intended for the particular

type of power tool, taking into account the

worki ng con di tio ns and th e wo rk to be

per f orm ed. Us e of th e pow e r to o l fo r

opera tions different from th ose intended

could result in a hazardous situation.

Service

Have your tool serviced by a qualified repair

person usin g on ly identica l re place ment

parts. This will ensure that the safety of the

power tool is maintained.

-WARNING- To reduce the risk of injury, user

must read instruction manual.

4

Symbols used in this manual

V……..volts

A……..amperes

Hz……hertz

W……..watt

~………alternating current

n0………no load speed

/min……..revolutions or reciprocation per

minute

………….class II tool

SPECIFIC SAFETY RULES

1. Keep hands away from rotating sanding

head area at all times!

2. Prolonge d breathing of ai rborne dust

f rom d rywa ll sa nd i n g m a y e f f e ct

respiratory function:

Al way s use a vacuum clea ner with a

bag approved for drywall dust installed.

Always wear a respirator approved for

dust and mist.

3. Sanding LEAD-BASED paint is extremely

toxic and should not be attempted. Only

allow professionals with special training

and equipment perform this task.

4. Maintain proper footing and balance at

all times. Do not overreach. Use proper

scaffolding

5. A l w a y s we ar a p p r o p r i a t e sa fety

equipment when operating.

6. Importan t: After com ple ting sanding,

switch off the switch and wait for the

c o a st i n g s a n di n g h e a d t o s t o p

co mpl et ely be fo re p ut ting t he tool

down.

7. Never operate the tool in an area with

flamm abl e soli ds , li qui ds , or gases .

Spark s from the commuta tor/carb on

brushes could cause a fire or explosion.

8. There are certain applications for which

t h i s t o o l w a s d e s i g n e d . T h e

manufacturer strongly recommends that

this tool NOT be modified and/or used

for any application other than for which

i t w as desi g n e d. If you hav e an y

questions relative to its application DO

NOT use the tool until you have written

the m anu f act u rer a nd ha v e be e n

advised.

9. Use the machine with both hands at all

t imes. Loss of c ontro l can cause

personal injury.

10. Keep power supply cord clear from the

working range of the machine. Always

lead the cable away behind you.

11. Immediately switch off the machine if

u n u s u a l v i b r a t i o n s o r i f o t h e r

malfunctions occur. Check the machine

in order to find out the cause.

12. The dust that arises when working with

this tool can be harmful to health. Use a

du st absorpt io n sys tem and wea r a

sui tab le dust p ro t ec tio n mas k an d

remove deposited dust with a vacuum

cleaner.

FUNCTIONAL DESCRIPTION

This Elec tr ic D ry wal l Sand er i s spec ia lly

designed for the most efficient sanding of

drywall or plaster walls and ceilings for both

new construction and renovation work. It is

5

de signed t o w or k in conjun ct io n with a

vacuum cleaner for minimum dust and best

sanding results. The pivoting sanding head

allows excellent results with minimum time

and effort.

Electrical connection

The netw ork voltage must confo rm to the

voltage indicated on the tool name plate.

Under no circumstances should the tool be

use d w hen t h e po w er su p ply ca ble is

dam ag ed. A da mag ed c abl e mu st be

re pl ac ed immediate ly by an aut ho ri ze d

Customer Service Center. Do not try to repair

th e da ma ged cable yoursel f. The use of

da maged power ca bles can lead to an

electric shock.

● UNPACKING

Carefully remove the tool and all loose items

from the shipping container.

Retain all packing materials until after you

have inspected and satisfactorily operated

the machine.

● CARTON CONTENTS

1. Drywall Sanding Machine

2. Vacuum cleaner hose

3. Instruction manual

DO NOT OPERATE THIS TOOL UNTIL YOU READ

AND UNDERSTAND THE ENTIRE INSTRUCTION

MANUAL

Extension cable

If an extension cable is required, it must have

a sufficient cross-section so as to prevent an

excessive drop in voltage or overheating. An

excessive drop in voltage reduces the output

and can lead to fail ure of the moto r. The

following table shows

you the correct cable diameter as a function

of the cable length for this machine. Use only

U.L. and CSA listed extension cables. Never

use two extension cables together. Instead,

use one long one.

Total Extension Cord Size (AWG)

Cord Length (feet)

25 16

50 12

100 10

150 8

200 6

● To install a sandpaper disc:

1. Unplug the machine.

2. Peel away the worn out sandpaper disc,

le av ing the sp onge ba cking pad in

place.

3. Ca refully cent er the new sandpa per

disc and press into place. It will be held

securely by the hook and loop backing.

● To replace the Hook and Loop Sponge Pad:

The sponge pad must be perfectly flat to get

go od sanding resu lt s. If it is def ormed or

damaged it will cause very uneven sanding.

Always replace it when damaged. It is hook

and loop on both sides, so to Replace it, peel

it aw ay from the ho ok an d loo p on the

6

Sanding Plate Base and, taking great care to

keep it perfectly centered, affix a new one.

● Th e Br us h Br ist les on t he edg e of the

Sanding Plate Cover:

The brush bristles on the edge of the Sanding

Plate Cover serve two purposes, they keep

the sanding disc properly aligned with the

work surface without gouging and they also

help the efficiency of the dust collection by

the vacuum cleaner. These brush bristles will

wear with continued use.

The Sanding Plate Cover should be replaced

when the bri stles are too worn to ensur e

effective dust collection and stabilization of

the sanding head.

To replace the cover, follow these steps:

Th en , pre ss the cover down aga in st th e

spring and, using snap-ring pliers, remove the

circlip which holds the sanding plate cover

to the bracket.

Finally, carefully work the vacuum hose free

then lift sanding plate cover away.

Replacem ent is the oppos ite of removal.

Don’t forget the spring. Entrust all repairs to

an authorized service center.

Hold the sanding plate in one hand and with

the other, using the L-hex wrench (supplied),

first break free the center bolt clockwise (1/8

turn only!).

Then only use the L-hex wrench to hold the

center bo lt from turning and spi n of f the

sanding plate counterclockwise.

● To install the vacuum cleaner hose:

1. Unplug the machine.

2. Plug the vacuum cleaner hose bayonet

mount into the swivel mount in the back

7

of the machine. Once the tangs of the

bayonet mount are fully inserted in the

slots, hold the swivel mount from turning

and t urn the h ose b ay o net m ou n t

clockwise to lock.

3. Removal is the opposite of assembly.

● The vacuum cleaner:

Ensure that you have a bag installed in your

va cuum cleaner which is ap proved and

rated for drywall dust.

power circuit.

● Switching the machine on and off

To switch on:

Wh il e holding with the left ha nd on th e

co lu mn and th e right han d on th e main

handle, Press the rocker switch to the right

with the thumb of the right hand. Anticipate

and be ready for the start up torque when

the machine first starts.

To switch off:

Press the rocker switch to the left. After the

machine has been switched off, the sanding

disc will still rotate for a time. Take care that

parts of your body do not come into contact

with the disc and do not set the machine

down while it is still rotating!

On/Off Switch

WARNING: Failure to use an approved dust

bag in your vacuum will increase the level of

air borne dust in the work area. Prolonged

exposure to such dust may cause respiratory

harm.

● STARTING AND STOPPING TOOL

Make sure that the power circuit voltage is

the same as that shown on the specification

pl at e of the mac hi ne and th at sw itch is

“OFF” befor e co nnect ing the tool to the

● Adjusting the rotation speed:

The speed of the machine is variable to suit

different tasks. It can be adjusted from 650/

mi n up to 1600/m in by us in g the th um b

wh eel. Using the rig ht thu mb, tu rn in the

downward (counterclockwise) direction to

incre ase th e sp ee d an d in th e up wa rd

(clockwise) direction to decrease the speed.

8

Generally, you should use the higher speed

02

03

04

05

02

01

for fast stock removal and the lower speed

for more precise control.

Speed Adjustment

HOW TO USE THE TOOL

Effective control of this powerful saw requires

two-handed operation for maximum safety

and control.

The proper hold is to keep one hand on the

ma in han dle and th e ot he r ha nd on the

spo ng e gr ip o n th e colu mn. It is vita lly

important to keep stable footing at all times,

especially when standing on scaffolding or

stilts.

■ MOUNTING THE OPTIONAL BAIL HANDLE:

1. Lo osen the 2 thu mb scr ews (05) and

remove the clamp cap (04).

2. Place the handle in the desired position

on the column.

3. Clamp the handle in place by replacing

the clamp cap and tight ening the 2

thumb screws.

● SANDING OPERATIONS

1. O n c e th e m a c h i ne a n d vacuum

clea n e r are se t u p a nd all sa f ety

measures and equipment are in place,

begin by turning on the vacuum cleaner

and then the machine. (If you are using

a va cuu m cl ea ner wit h in teg ra ted

switching, then simply turn the machine

on.)

2. Begin sanding and carefully contact the

work surface as lightly as p ossible-just

enough to keep the sanding head flat

against the surface.

3. The joints in the sanding head allow the

sanding disc to follow the contours of

the work surface.

4. The best technique is to use overlapping

sweeps and keep the head in constant

motion. Never stop too long in any one

place or there will be swirl marks. With

experience it will be very easy to create

excellent results.

NOTE: Ensu re that the sandpaper yo u are

using is suited to the task. Overly coarse grit

9

paper may remove material too quickly to

control. While overly fine grit paper may clog

too often and not shape down the surface.

CAU T ION : Tak e c ar e t o av o id po i nt e d

projections and nails, etc. This will wipe out

the sandpaper and probably damage the

sponge pad as well.

MAINTENANCE

● KEEP TOOL CLEAN

Periodically blow out all air passages with dry

compressed air. All plastic parts should be

cleaned with a soft damp cloth. NEVER use

solvents to clean plastic parts. They could

possibly dissolve or otherwise damage the

material.

Wear safety glasses while using compressed

air.

Clean the vacuum swivel connector as too

much dust will keep it from turning freely.

● THE CARBON BRUSHES

The carbon brushes are a normal wearing

part and must be replaced when they reach

their wear limit. When the brushes are worn to

a length of 1/4", they should be replaced.

NOTE: Checking and replacing the carbon

brushes should be entrusted to a qualified

service center.

TO CHANGE THE BRUSHES

1. Unplug the machine.

2. Remove the brush cap with a slothead

screwdriver

3. Remove the brush.

4. Install new brushes in reverse order and

replace covers

Brush Cap

If the replacement of the power supply

cord is necessary, this has to be done

by the manufacturer or their agent in

order to avoid a safety hazard.

10

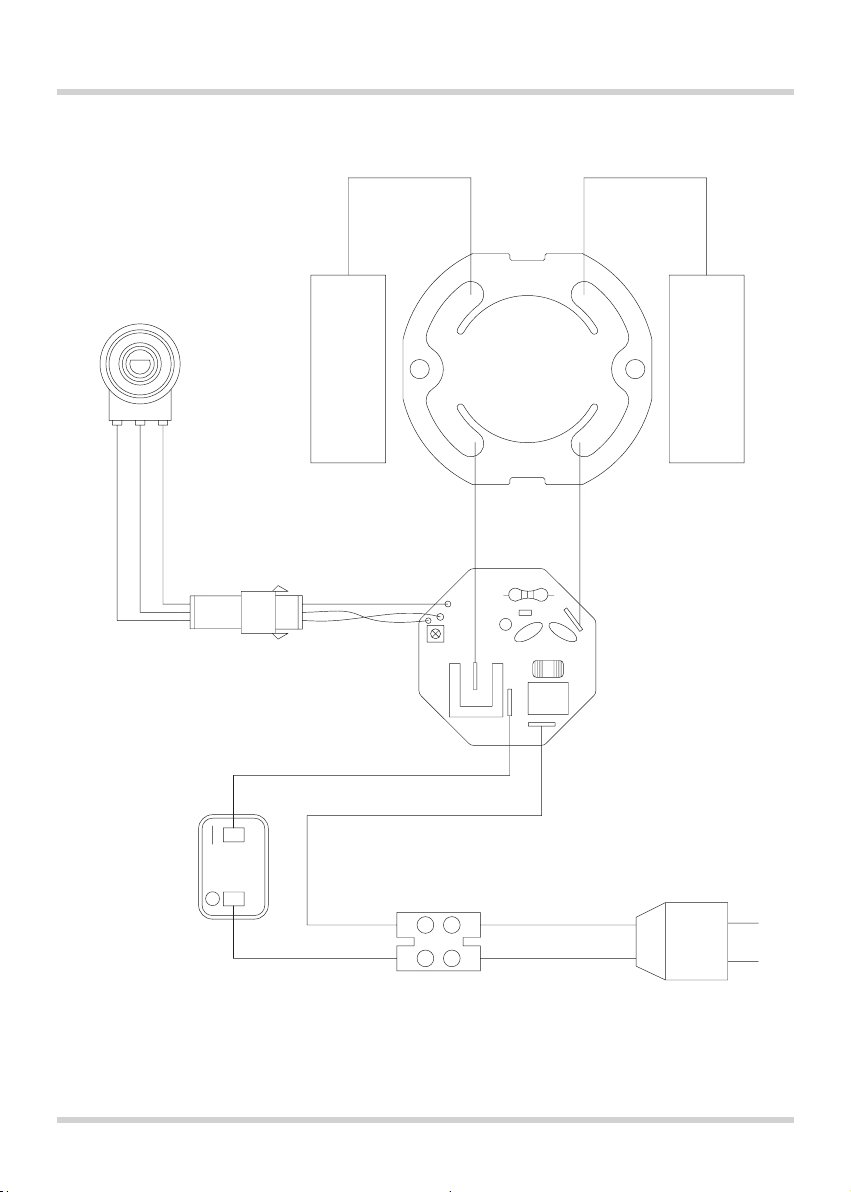

WIRING

BLACK

RED

WHITE

CARBON

BRUSH

OVERLOAD

SPEED

CONTROL

UNIT

MOTOR

CARBON

BRUSH

BLACKBLACK

RED

SWITCH

TERMINAL

AC

BLACK BLACK

AC

11

EXPLODED VIEW

01 02

08

03 04

25

26

27

28

26

29

30

71

39

34

31

35

39A

40

40A

64

65

66

67

68

69 70

31

44

51

53

09

12

13

10

11

19

18

75

05

32

33

38

38A

45

49

57

23

24

06

36

37

41

42

43

72

57

60

61

62

OPTIONAL

73

74

63

14

15

16

75

18

19

07

20

21

22

23

48

47

46

52

57

58

57

59

A3

A2

A1

12

PARTS LIST

No. Parts Name Q'TY

1 POWER SUPPLY CABLE 1

2 CORD ARMOR 1

3 VACUUM EXTENSION HOSE 4M 1

4 QUICK RELEASE HOSE CONNECTOR 1

5 SCREW M4 x 16 6

6 RIGHT HANDLE COVER 1

7 LEFT HANDLE COVER 1

8 CABLE CLIP 1

9 SCREW M4 x 14 2

10 SCREW M4 x 25 2

11 SPEED CONTROL 1

12 WIRE CONNECTOR 1

13 WIRE LEADER 1

14 WIRE LEADER 1

15 WIRE LEADER 1

16 MOTOR SWITCH 1

17 N/A -

18 CARBON BRUSH 2

19 CARBON BRUSH HOLDER 2

20 MOTOR HOUSING 1

21 STATOR 1

22 STATOR SCREW M4 x 50 2

23 BALL BEARING 608 2RS 2

24 ARMATURE 1

25 GEAR PLATE 1

26 BUSHING 6 x 10 x 8 3

27 INTERMEDIATE GEAR 1

28 INTERMEDIATE GEAR PINION 1

29 INTERNAL CIRCLIP S-8 1

30 OUTPUT GEAR 1

31 SCREW M5 x 10 4

32 GEAR CASE 1

33 SCREW W/ WASHER M4 x 30 3

34 INTERNAL CIRCLIP S-10 1

35 BALL BEARING 6200 2RS 1

36 WOODRUFF KEY 3 x 8 1

37 SPINDLE 1

38 FIRST DRIVE SHAFT 254mm 1

38A FIRST DRIVE SHAFT 704mm 1

39 EXTENSION COLUMN 577.3mm 1

39A EXTENSION COLUMN 1027.3mm 1

No. Parts Name Q'TY

40 FOAM HANDLE GRIP 1

40A FOAM HANDLE GRIP 1

41 SHAFT CONNECTOR 1

42 BALL BEARING 6001 2RS 1

43 INTERNAL CIRCLIP S-12 1

44 SCREW M4 x 20 4

45 RIGHT DRIVE COVER 1

46 LEFT DRIVE COVER 1

47 SECONDARY DRIVE SHAFT 1

48 DRIVE SHAFT COVER 1

49 HOLDING PIN 6 x 39 1

50 N/A -

51 RIGHT SANDER BRACKET 1

52 LEFT SANDER BRACKET 1

53 SCREW M4 x 8 2

54 N/A -

55 N/A -

56 N/A -

57 SCREW M5 4

58 PIVOT BASE 1

59 PIVOT CONNECTING BRACKET 1

60 CONNECTING SPINDLE 1

61 BALL BEARING 6002 2RS NSK 1

62 EXTERNAL CIRCLIP R-32 1

63 SPRING ø2 x ø49 x 40L x 4T 1

64 VACUUM HOSE 1

65 SPRING ø1 x ø32 x 363L x 30T 1

66 PLASTIC CLIP 1

67 SANDING PLATE COVER 1

68 INTERNAL CIRCLIP S-40 1

69 SANDING PLATE BASE 1

70 VELCRO SPONGE PAD 1

71 EXTERNAL CIRCLIP R-30 1

72 DUST GUIDE 1

73 SHAFT RACE M14 x ø20 x 6.5 1

74 RADIAL SHAFT SEAL ø20 x ø32 x 5 1

75 BRUSH CAP 2

Optional

A1 RIGHT HOSE SUPPORT 1

A2 LEFT HOSE SUPPORT 1

A3 SCREW M4 x 14 4

13

London Dublin

Aristospray UK, Granville House Aristospray, Unit 45

Wallingford Road, Uxbridge Baldoyle Industrial Estate

Middlesex UB8 2RW Baldoyle, Dublin 13

T +44 (0) 1895 276751 T +353 (0) 1 806 3003

F +44 (0) 1895 276755 F +353 (0) 1 806 3075

E sales@aristospray.com E sales@aristospray.ie

W www.aristosprayuk.com

Loading...

Loading...