Page 1

Installation Instructions for Triliptical

Stackable Beacon Lighting System

TM

Description

The Edwards Triliptical Stackable Beacon Lighting System is a

unique audible-visual signaling device that can contain up to 5

light modules and either a single or multiple tone module in a

single "stack."

All components of the Triliptical Stackable Beacon Lighting System are UL and cUL listed subassemblies. The units, when assembled, are UL and cUL listed for indoor and outdoor applications. The enclosures are NEMA 3R, 4X, and IP65 rated. CE

Marked Visual Signal.

The optically designed lenses are available in five colors. See

Table 1. Each lens module contains a removable cover to allow

for easy relamping. The lens module cover features a molded-in

gasket for weather tight reliability.

The unit's bases are available in three models. Two models feature shorter bases that are used when a lower profile is desired:

one for surface mounting and one for pendant mounting. The

other model features a larger base with a terminal block for use

with an optional horn assembly. The larger base also functions as

a junction box.

A pipe mount kit, Cat. No. 102PMF (sold separately) and one of

three extension pipes (sold separately) allows the status indicator

to be raised above the mounting surface for increased visibility.

It can be used with either the Cat. No. 102TBS or Cat. No.

102PMBS mounting bases.

PLC Compatibility

The electrical input characteristics for PLC compatible signals

are listed in Table 2. Signals with these characteristics may be

directly connected to PLC output cards that do not exceed these

input characteristics.

insulation is protected from abrasion by the gasket

(without interfering with the mounting screw holes), or

provide other appropriate wire insulation abrasion

protection as needed.

c. Screw the pipe extension (purchased separately) into the

mounting flange.

d. Ground the flange by pulling the ground wire through

the mounting surface clearance hole and center hole of

the gasket. Connect earth ground to the bottom of the

base mount flange using the ground screw (G) and wire

retention terminal cup washer (H).

e. Pull the remaining field wiring through center clearance

hole of mounting surface, center hole of the gasket, pipe

mount flange and extension pipe.

f. Align the mounting gasket (D) and flange (A) on the

panel. Secure using (4) #10-24 x 1" (25 mm) pan head

screws (B), (4) external tooth #10 star washers (E) and

(4) #10-24 hex nuts (F).

g. Mount the base as instructed below.

2. Mount the base using one of the following methods:

NOTE: For indoor applications, the base may be panel

mounted or conduit mounted. For NEMA3R, 4X, and

outdoor applications, it is recommended that the unit

be conduit mounted vertically facing up using either

the Cat. No. 102TBS or Cat. No. 102PMBS base.

a. Cat. No. 102TBS Install base on 3/4" (19 mm) conduit

(not supplied). Pull field wiring through conduit entrance

hole.

b. Cat. No. 102PMBS Install base on 3/4" (19 mm) conduit

(not supplied). Pull field wiring through conduit entrance

hole.

Installation

Installation must be in accordance with the latest edition of the

National Electrical Code and other governing standards and codes

for standard installation.

WARNINGS

To prevent electrical shock, do not connect power

until instructed to do so.

To prevent abrasion of wiring insulation, ensure

that wire passage holes are adequately protected.

1. If using the 102PMF mounting kit, perform the following:

NOTE: All references below are to Figure 4.

a. Using the supplied gasket (D) as a guide, mark the four

mounting holes and the center clearance hole on an

appropriate surface.

b. Punch the four mounting holes. Punch the wiring

clearance hole in the mounting surface to be sufficiently

larger than that in the gasket to ensure the wiring

c. Cat. No. 102DMBS Using the supplied mounting gasket

as a template, punch the four mounting holes. Punch

the wiring clearance hole in the mounting surface to be

sufficiently larger than that in the gasket to ensure the

wiring insulation is protected from abrasion by the gasket

(without interfering with the mounting screw holes), or

provide other appropriate wire insulation abrasion

protection as needed. Mount the base to the surface using

the (2) screws (supplied).

3. Connect field wiring.

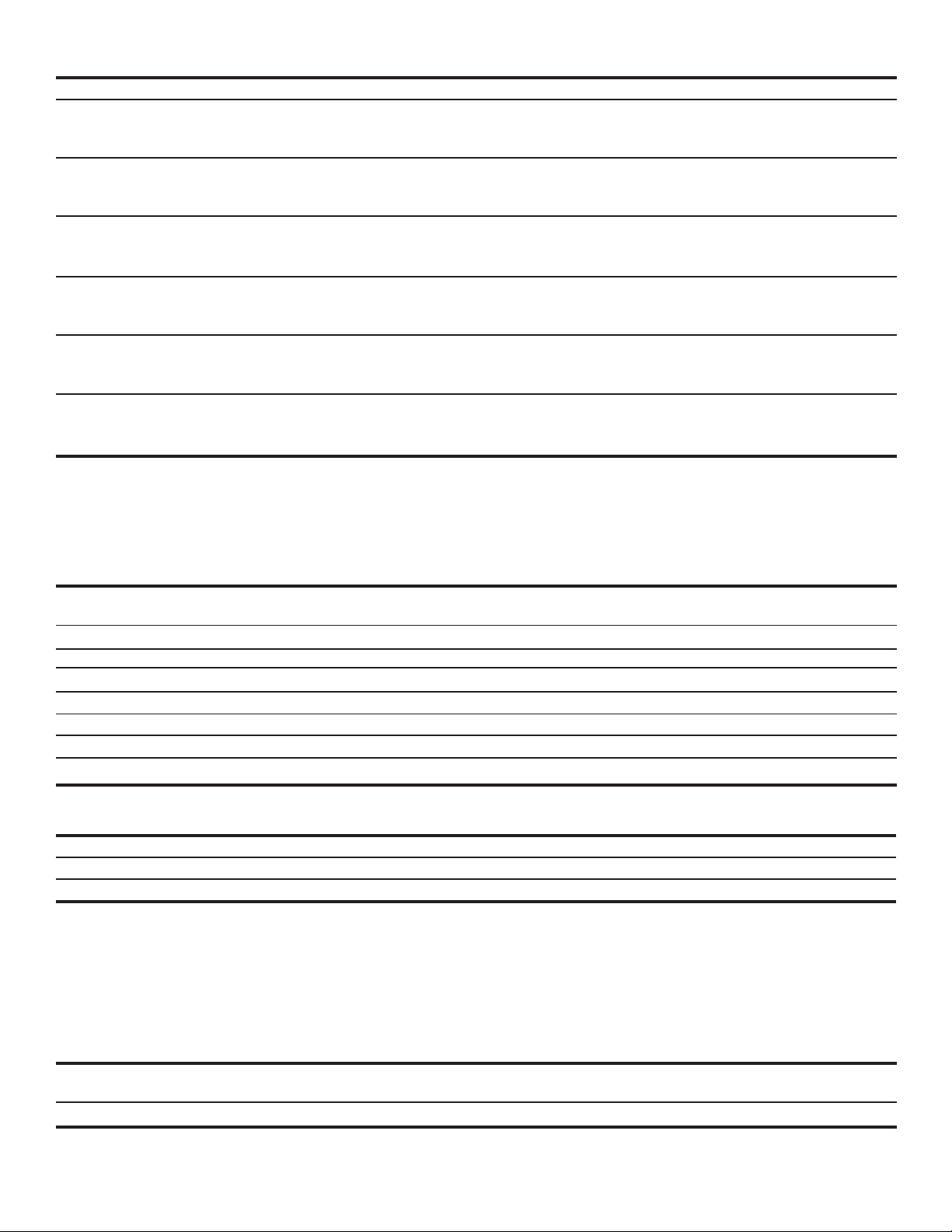

a. Cat. No. 102TBS Connect field wiring to the terminal

block as shown in Figure 1.

b. Cat. No. 102PMBS or Cat. No. 102DMBS Using wire

nuts, connect 18" (457 mm) wire leads to field wiring.

The six wire leads are marked as follows: Neutral, 1

Bottom, 2, 3, 4 & 5. 1 Bottom denotes the lead for the

bottom-most signal in the stack.

c. If using the optional Cat. No. 102SIGST single tone

module or Cat No. 102SIGMT multi-tone module,

connect additional field wiring to the terminal block

mounted on the signal assembly as shown in Figure 2.

NOTE: The tone module may be wired to sound independently

or in conjunction with a light signal.

P/N 3100669 ISSUE 1 © 2003

Page 2

(1) To sound tone module independently, connect to

separate hot lead.

(2) To sound tone module with a particular light, connect

horn hot terminal to selected light terminal on Cat.

102TBS terminal block.

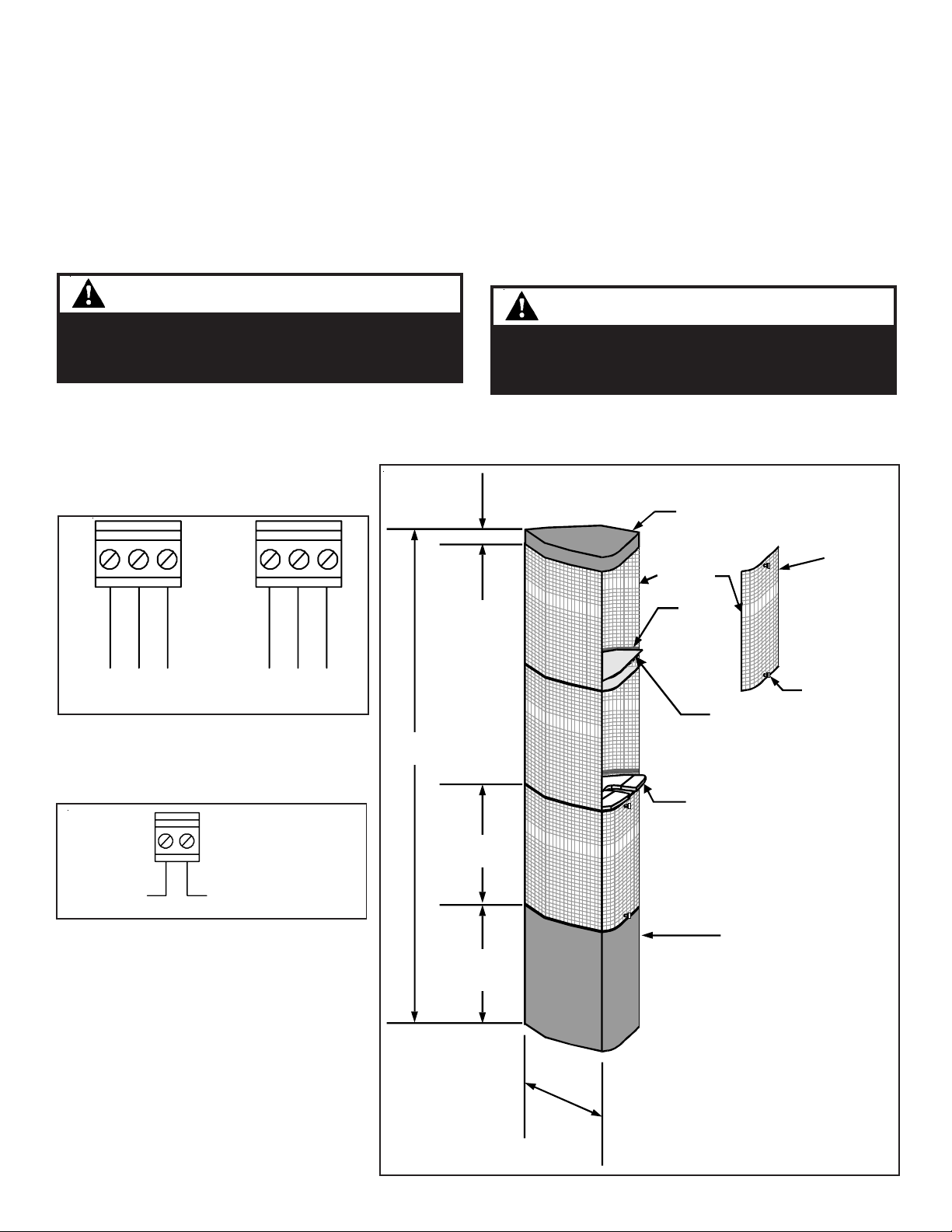

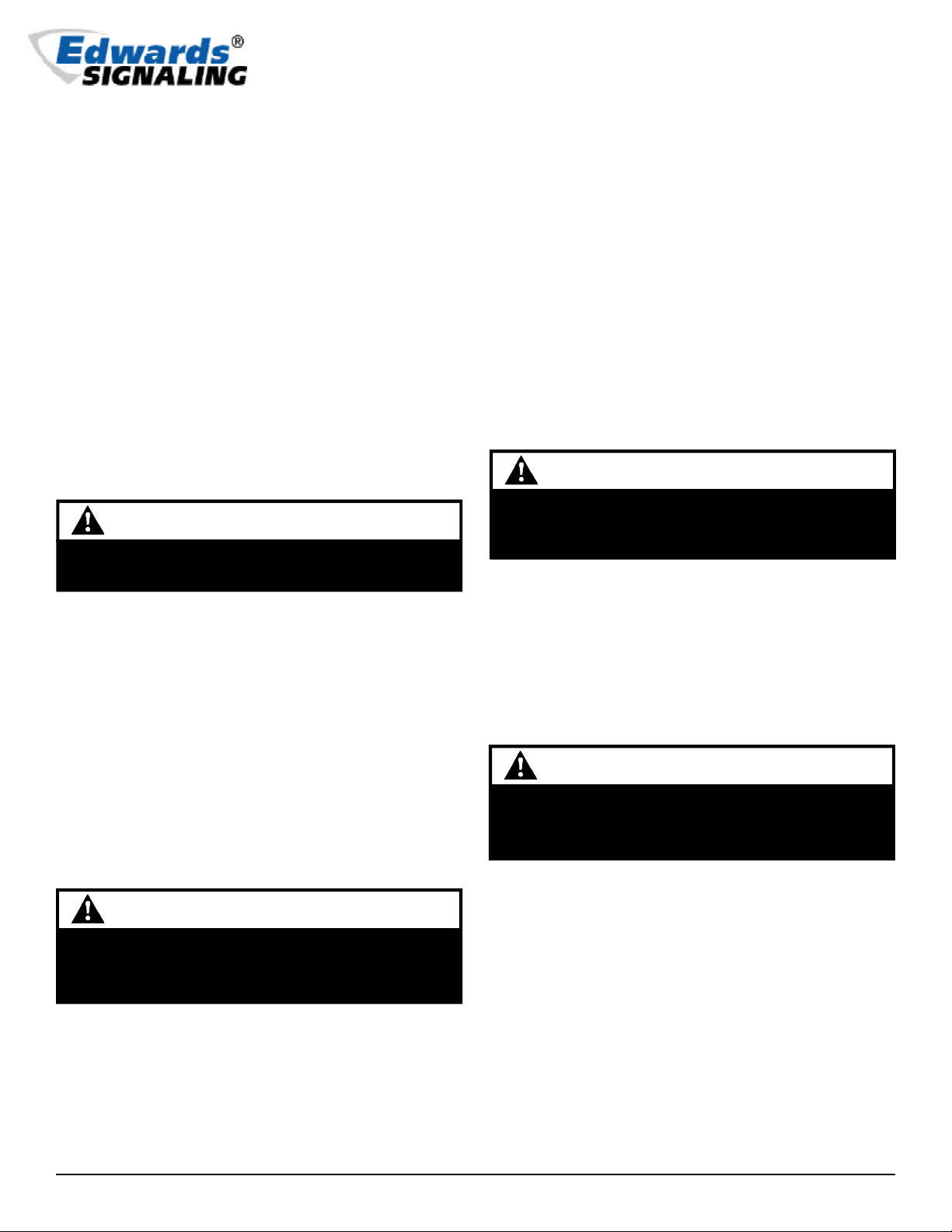

4. Assemble the stackable beacon lighting system (Figure 3).

a. Pull the captive key in the lens module into the "out"

position.

b. Place the first lens module on top of the base.

c. Push in the captive key to secure the lens module.

bottom of lens module, ensuring that the four prongs on

the PC board are aligned with the plug located in the

back of the lens assembly.

NOTE: When using LED light sources, ensure that the color of

the LED light source and the lens assembly match.

e. Place the lens assembly cover on the front of the lens

module and secure using two captive screws.

f. Repeat steps a through e for any remaining modules (up

to 5).

g. Once the last module has been assembled, place the cap

on top and secure the cap with the captive screw.

WARNING

To prevent leakage, ensure the magnifier ring on

the lens cover and the magnifier ring on the lens

module are aligned (Figure 3).

d. Insert the appropriate light source into board grooves at

NEUTRAL/COMMON

MODULE 1

MODULE 2

BOTTOM

Figure 1. Wiring Cat. No. 102TBS

MODULE 3

MODULE 4

MODULE 5

15"

(381mm)

WARNING

To prevent electrical shock, disconnect power to all

modules. Wait 5 minutes for stored energy in strobe

modules to dissipate bef ore working on unit.

5. Apply power to the unit and verify proper operation.

Cap (supplied with base)

Magnifier

Ring

1/2"

(13mm)

Board

Groove

Light Source

Assembly

Lens Module

Cover

(2) Captive

Screws

TO NEUTRAL

ON CAT. 102TBS

TERMINAL BLOCK

NH

SEPARATE HOT LEAD OR

CONNECTED TO APPROPRIATE

LIGHT MODULE TERMINAL ON

CAT. 102TBS TERMINAL BLOCK

Figure 2. Wiring Cat. No. 102SIG*T

P/N 3100669 ISSUE 1

Captive Key

3 5/8"

(92mm)

Signal Base

(Cat. No. 10STBS shown)

3 5/8"

(92mm)

3"

(76mm)

Figure 3. Assembling the Stackable Status Indicator (Cat. No. 102TBS shown for

illustration purposes only)

Page 3

Maintenance

Light Source Replacement

1. Loosen captive screws and remove cover of affected lens

module.

2. Remove the light source assembly from the lens module.

3. Install new light source assembly ensuring that the four prongs

on the PC board are aligned with the plug located in the back

of the lens module.

WARNING

To prevent leakage, ensure the magnifier ring on

the lens cover and the magnifier ring on the lens

module are aligned (Figure 3).

4. Replace lens cover and secure using two captive screws.

Cleaning

The lens surfaces should be periodically dusted and cleaned with

a dry soft clean cloth to maintain optimum light visibility. If

necessary, the outside of the lens may be cleaned with water and

a mild detergent on a well rung-out, soft, clean cloth.

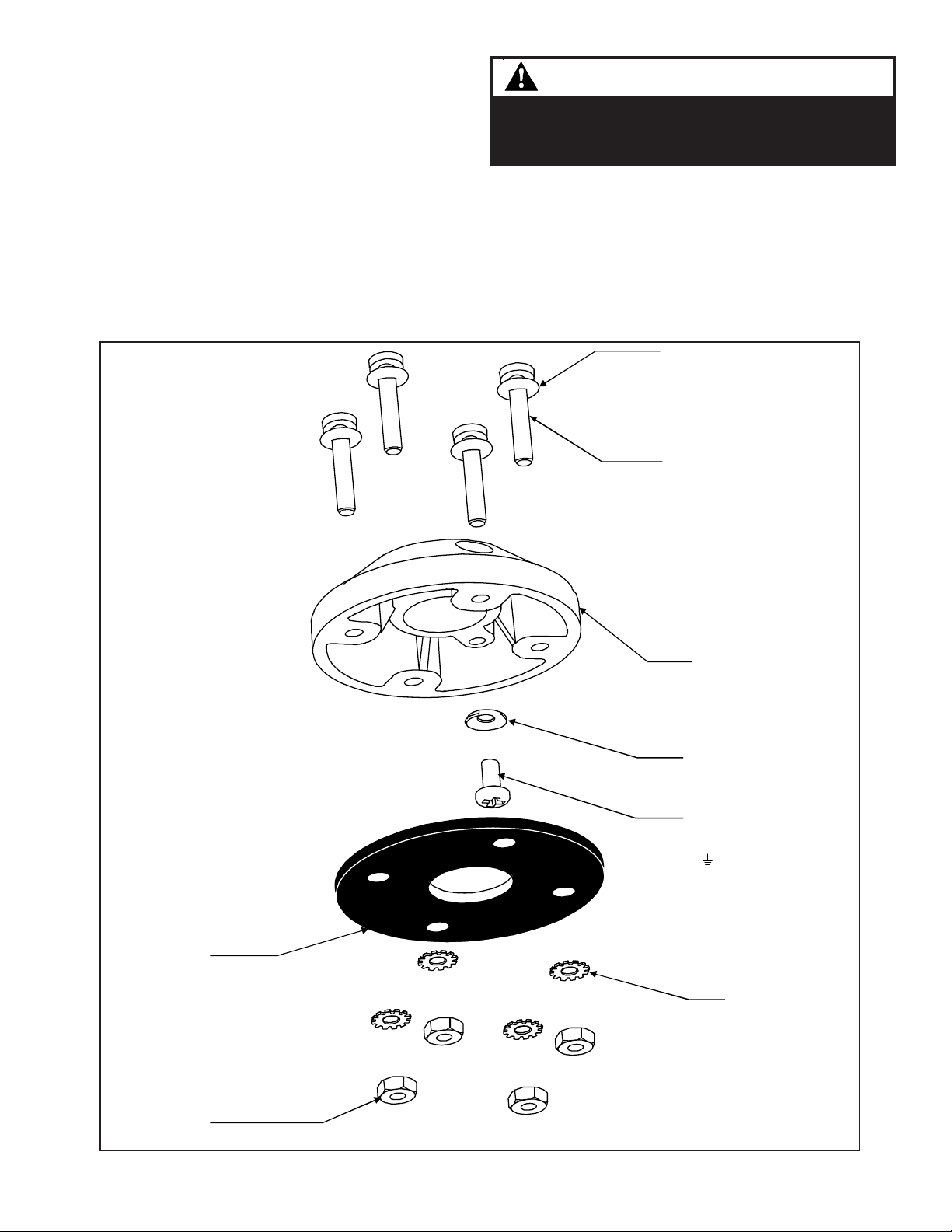

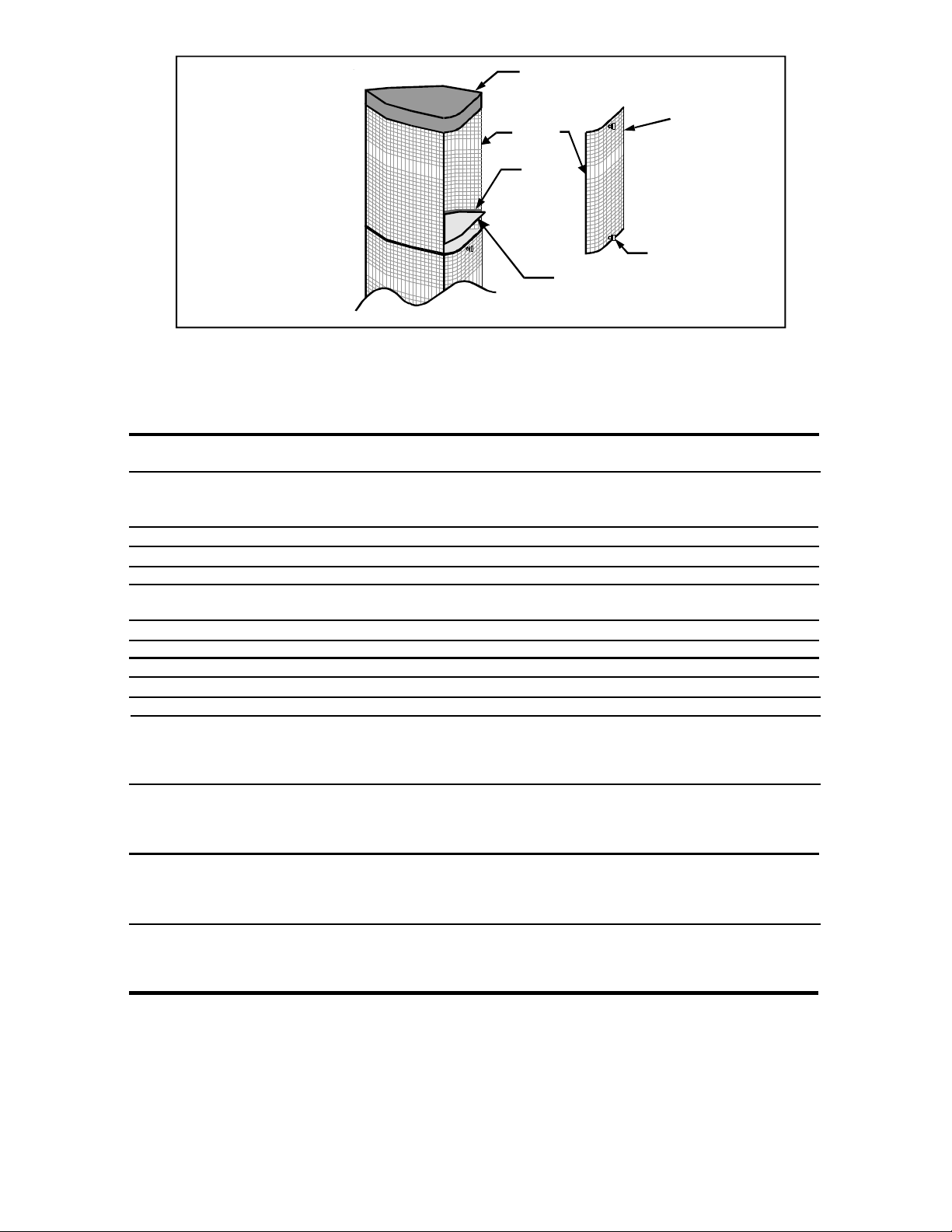

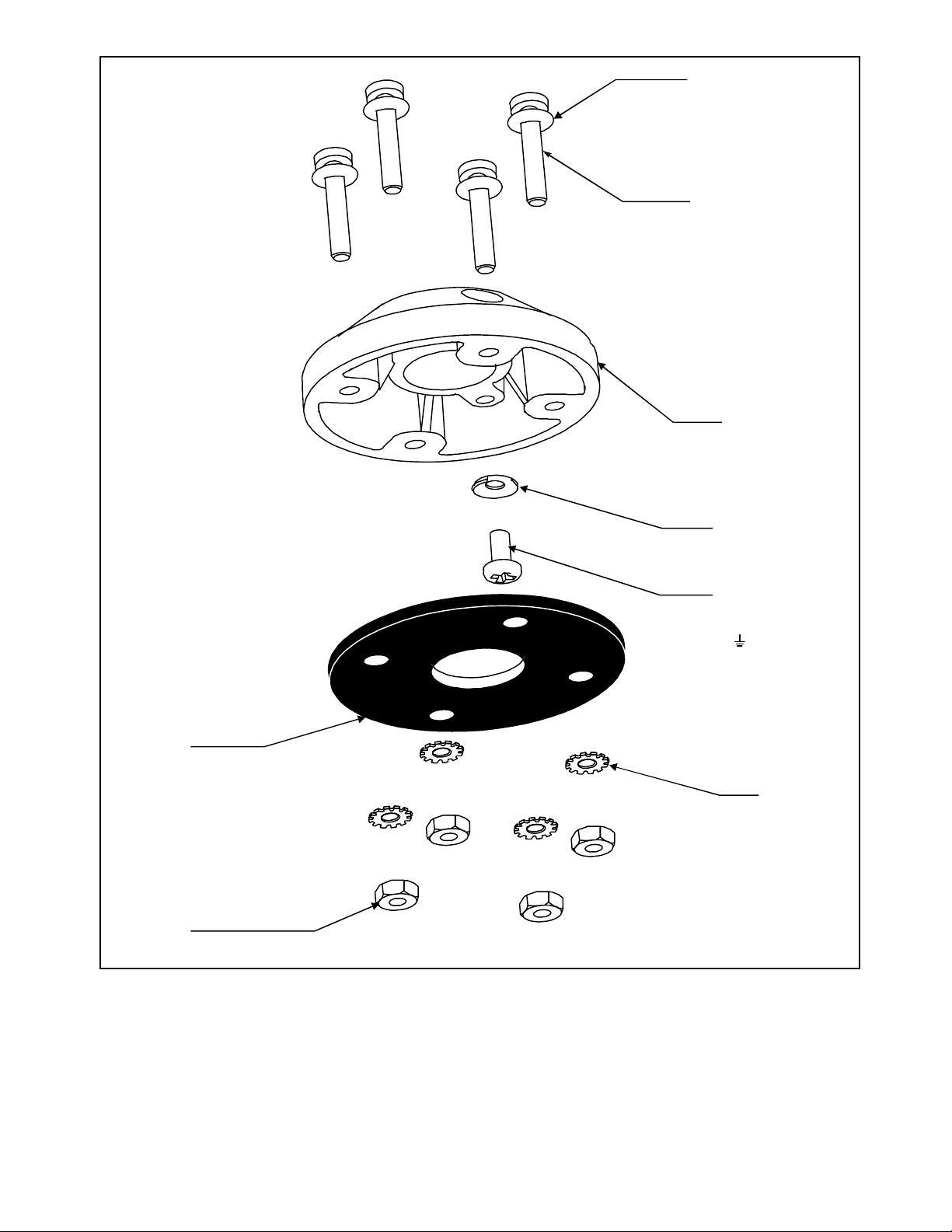

C

(4) o-rings

(4) #10-24 x 1" (25 mm)

B

pan head screws

A

Cat. No. 102PMF

Pipe mount flange

H

Wire retention

terminal cup washer

G

#10-16 x 3/8"

Pan head, thread forming,

ground ( ) screw

D

Mounting gasket

F

#10-24 Hex nut

E

External tooth

#10 Star washer

Figure 4. Optional 102PMF Mounting Kit Assembly

P/N 3100669 ISSUE 1

Page 4

Table 1. Specifications

Electrical Manufacturers Replacement Lamp Life (hours)

Catalog No. Ratings Lamp Ratings Lamp Calculated#Projected

##

Base Units

102TBS-G1 24V DC, 1.75A

102TBS-N5 120V AC, 0.60A

102DMBS-G1 24V DC, 1.75A

102DMBS-N5 120V AC, 0.60A

102PMBS-G1 24V DC, 1.75A

102PMBS-N5 120V AC, 0.60A

+

+

+

+

+

+

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A

Optional Pipe Mount Flange

102PMF N/A N/A N/A N/A N / A

Optional Extension Pipes

102MP-4 N/A N / A N /A N/ A N/A

102MP-10 N/ A N / A N/ A N /A N/A

102MP-15 N/ A N / A N/ A N /A N/A

Optional Horn Assembly

102SIGST-G1 24V DC, 0.05A N/A N/A N/ A N/A

102SIGST-N5 120V AC, 0.07A

102SIGMT-G1 24V DC, 0.05A N/A N/ A N / A N/ A

102SIGMT-N5 120V AC, 0.07A

Lens Modules

102LM-* N/ A N / A N/ A N /A N/A

Light Sources

102LS-SINH-G1 24V DC, 0.32A 9 Watts 50LMP-9WH 12,000 --

or Ind. Trade 303***

102LS-SINH-N5 120V AC, 0.11A 12 Watts 50LMP-12WH 20,000 -102LS-SIN-G1 24V DC, 0.32A 10 Watts Ind. Trade 303 10,000 -102LS-SIN-N5 120V AC, 0.08A 10 Watts 50LMP-10W 2,500 -102LS-FINH-G1 24V DC, 0.32A 9 Watts 50LMP-9WH 12,000 15,000

or Ind. Trade 303***

102LS-FINH-N5 120V AC, 0.11A 12 Watts 50LMP-12WH 20,000 25,000

102LS-FIN-G1 24V DC, 0.32A 10 Watts Ind. Trade 303 10,000 12,500

102LS-FIN-N5 120V AC, 0.08A 10 Watts 50LMP-10W 2,500 3,000

102LS-ST-G1 24V DC, 0.30A 3 Joule Strobe -- 3,000

102LS-ST-N5 120V AC, 0.12A 3 Joule Strobe -- 3,000

###

###

--

--

102LS-SLEDA-G1** 24V DC, 0.062A -- N/A 100,000 -102LS-SLEDB-G1**

102LS-SLEDG-G1**

102LS-SLEDR-G1**

102LS-SLEDA-N5** 120V AC, 0.022A -- N/A 100,000 -102LS-SLEDB-N5**

102LS-SLEDG-N5**

102LS-SLEDR-N5**

102LS-FLEDA-G1** 24V DC, 0.062A -- N/A 100,000 -102LS-FLEDB-G1**

102LS-FLEDG-G1**

102LS-FLEDR-G1**

102LS-FLEDA-N5** 120V AC, 0.022A -- N/A 100,000 -102LS-FLEDB-N5**

102LS-FLEDG-N5**

102LS-FLEDR-N5**

+

Currents shown are for a stackable indicator with 5 light modules.

*Signifies lens module color (A - amber/orange, B - blue, C - clear, G - green, R - red, Y - yellow)

**Signifies lens and LED module color (A - amber/orange, B - blue, G - green, R - red)

NOTE: LED light sources must be used with the

corresponding color lens module (e.g., a blue LED light source, 102LS-SLEDB-G1, must be used with a blue lens, 102LM-B).

***A non-halogen lamp, as listed, may be used in place of the halogen lamp.

#

At nominal operating voltage.

##

Projected lamp life based on manufacturer's calculated lamp life @ 65 fpm and 50% duty cycle.

###

Strobe tube life @ operating power to 75% ef ficiency.

P/N 3100669 ISSUE 1

Page 5

Table 2. PLC Compatibility

Operating Maximum off state Continuous on Surge (inrush/duration)

Cat. No. voltage* leakage current (mA) current (mA) (A/ms**)

102SIGST-G1 24V DC 5 50 0.24/0.2

102SIGST-N5 120V AC 5 70 0.35/0.5

102SIGMT-G1 24V DC 5 50 0.24/0.2

102SIGMT-N5 120V AC 5 70 0.35/0.5

102LS-SIN-G1 24V DC 25 32 0.36/1

102LS-SIN-N5 120V AC 25 80 0.15/8

102LS-SINH-G1 24V DC 25 320 0.36/1

102LS-SINH-N5 120V AC 25 110 0.5/8

102LS-FIN-G1 24V DC 25 32 1.4/100

102LS-FIN-N5 120V AC 25 80 0.3/8

102LS-FINH-G1 24V DC 25 320 1.2/100

102LS-FINH-N5 120V AC 25 110 1.15/8

102LS-ST-G1 24V DC 1.5 300 0.33/1

102LS-ST-N5 120V AC 5 120 50/1

102LS-SLED( )-G1 24V DC 5 65 0.07/1

102LS-SLED( )-N5 120V AC 5 25 0.09/8

102LS-FLED( )-G1 24V DC 5 65 0.07/1

102LS-FLED( )-N5 120V AC 5 25 0.09/8

*All AC volts at 60 Hz

**Amps/milliseconds

P/N 3100669 ISSUE 1

Page 6

Installation Instructions for Triliptical

TM

Stackable Beacon Lighting System Light Sources

Description

The Edwards Triliptical Stackable Beacon Lighting System is a

unique audible-visual signaling device that can contain up to 5

light modules and either a single or multiple tone module in a single

"stack."

All components of the Triliptical Stackable Beacon Lighting System

are UL and cUL listed subassemblies. The units, when assembled,

are UL and cUL listed for indoor and outdoor applications and CSA

certified. The enclosures are NEMA 3R, 4X and IP65 rated. CE

Marked Visual Signal.

Each light source module contains a removable cover to allow for

easy relamping. The light module cover features a molded-in gasket for dust tight reliability.

WARNING

To prevent electrical shock, do not connect power

until instructed to do so.

Installation

c. Place the lens module cover on the front of the lens module

and secure using two captive screws.

d. Repeat steps a through c for any remaining modules (up

to 5).

e. Once the last module has been assembled, place the cap

on top and secure the cap with the captive screw.

2. Apply power to the unit and verify proper operation.

NOTE: For further installation details, see the instructions supplied

with the lens modules, P/N 3100700, or the instructions

supplied with the base, P/N 3100669.

Maintenance

WARNING

To prevent electrical shock, disconnect power to all

modules. Wait 5 minutes for stored energy in

strobe modules to dissipate working on unit.

Light Source Replacement

1. Loosen captive screws and remove cover of affected lens

module.

Installation must be in accordance with local codes.

1. Assemble the stackable beacon lighting system (Figure 1).

a. Loosen captive screws and remove cover of affected lens

module.

b. Insert the appropriate light source into board grooves at

bottom of lens ensuring that the four prongs on the PC

board are aligned with the plug located in the back of the

lens assembly.

NOTE: When using LED light sources, ensure that the color of the

LED light source and the color of the lens assembly match.

WARNING

To prevent leakage, ensure the magnifier ring on

the lens cover and the magnifier ring on the lens

module are aligned (Figure 1).

2. Remove the light source assembly from the lens module.

3. Install new light source assembly ensuring that the four prongs

on the PC board are aligned with the plug located in the back of

the lens module.

WARNING

To prevent leakage, ensure the magnifier ring on

the lens cover and the magnifier ring on the lens

module are aligned (Figure 1).

4. Replace lens cover and secure using two captive screws.

Cleaning

The lens surfaces should be periodically dusted and cleaned with a

dry soft clean cloth to maintain optimum light visibility. If necessary, the outside of the lens may be cleaned with water and a mild

detergent on a well rung out soft clean cloth.

P/N 3100701 ISSUE 2 © 2003

Page 7

Cap (supplied with base)

Magnifier

Ring

Board

Groove

(2) Captive

Light Source

Assembly

Screws

Figure 1. Assembling the Stackable Beacon Lighting System

Table 1. Specifications

Lens Module

Cover

Electrical Lamp Replacement Lamp Life (hours)

Catalog No. Ratings Ratings Lamp Calculated#Projected

##

Light Sources

102LS-SINH-G1 24V DC, 0.32A 9 Watts, 52 Lumens 50LMP-9WH 12,000 --

or Ind. Trade 303**

102LS-SINH-N5 120V AC, 0.11A 12 Watts, 70 Lumens 50LMP-12WH 20,000 -102LS-SIN-G1 24V DC, 0.32A 10 Watts Ind. Trade 303 10,000 -102LS-SIN-N5 120V AC, 0.08A 10 Watts 50LMP-10W 2,500 -102LS-FINH-G1 24V DC, 0.32A 9 Watts 50LMP-9WH 12,000 15,000

or Ind. Trade 303**

102LS-FINH-N5 120V AC, 0.11A 12 Watts 50LMP-12WH 20,000 25,000

102LS-FIN-G1 24V DC, 0.32A 10 Watts Ind. Trade 303 10,000 12,500

102LS-FIN-N5 120V AC, 0.08A 10 Watts 50LMP-10W 2,500 3,000

102LS-ST-G1 24V DC, 0.30A 3 Joule Strobe -- 3,000

102LS-ST-N5 120V AC, 0.12A 3 Joule Strobe -- 3,000

###

###

--

--

102LS-SLEDA-G1* 24V DC, 0.062A -- N/A 100,000 -102LS-SLEDB-G1*

102LS-SLEDG-G1*

102LS-SLEDR-G1*

102LS-SLEDA-N5* 120V AC, 0.022A -- N/A 100,000 -102LS-SLEDB-N5*

102LS-SLEDG-N5*

102LS-SLEDR-N5*

102LS-FLEDA-G1* 24V DC, 0.062A -- N/A 100,000 -102LS-FLEDB-G1*

102LS-FLEDG-G1*

102LS-FLEDR-G1*

102LS-FLEDA-N5* 120V AC, 0.022A -- N/A 100,000 -102LS-FLEDB-N5*

102LS-FLEDG-N5*

102LS-FLEDR-N5*

*Signifies lens and LED module color (A - amber, B - blue, G - green, R - red) NOTE: LED light sources must be used with the

corresponding color lens module (e.g., a blue LED light source, 102LS-SLEDB-N5, must be used with a blue lens, 102LM-B).

**A non-halogen lamp, as listed, may be used in place of the halogen lamp.

#

At nominal operating voltage.

##

Projected lamp life based on manufacturer's calculated lamp life @ 65 fpm and 50% duty cycle.

##

Strobe tube life @ operating power to 75% efficiency.

P/N 3100701 ISSUE 2

Page 8

Installation Instructions for Mounting Flange Kit

for use with the 102 Series Triliptical

TM

Stackable Status Indicator

Contents

A (1) 102PMF pipe mount flange

B (4) #10-24 x 1" (25 mm) pan head, phillips screws

C (4) o-rings

D (1) mounting gasket

E (4) external tooth #10 star washers

F (4) #10-24 hex nuts

G (1) green #10-16 x 3/8" pan head, thread forming ground

screw

H (1) brass terminal cup washer

Accessories

102MP-4 4" Extension Pipe

102MP-10 10" Extension Pipe

102MP-15 15" Extension Pipe

Description

The Edwards Triliptical Stackable Beacon Lighting System is a

unique audible-visual signaling device that can contain up to 5

light modules and either a single or multiple tone module in a

single "stack."

The pipe mount flange, 102PMF, and one of the thr ee extension

pipes (sold separately) allow the status indicator to be raised above

the mounting surface for increased visibility. It can be used with

either the Cat. No. 102TBS or Cat. No. 102PMBS mounting bases.

Installation

Installation must be in accordance with the latest edition of the

National Electrical Code and other governing standards and codes

for standard installation.

1. Panel mount the 102PMF pipe mount flange (A) as follows.

a. Using the supplied gasket (D) as a guide, mark the four

mounting holes and the center clearance hole on an

appropriate surface.

b. Punch the four mounting holes. Punch the wiring

clearance hole in the mounting surface to be sufficiently

larger than that in the gasket to ensure the wiring

insulation is protected from abrasion by the gasket

(without interfering with the mounting screw holes), or

provide other appropriate wire insulation abrasion

protection as needed.

c. Screw the pipe extension (purchased separately) into the

mounting flange.

d. Ground the flange by pulling the ground wire through

the mounting surface clearance hole and center hole of

the gasket. Connect earth ground to the bottom of the

base mount flange using the ground screw (G) and wire

retention terminal cup washer (H).

e. Pull the remaining field wiring through center clearance

hole of mounting surface, center hole of the gasket, pipe

mount flange and extension pipe.

f. Align the mounting gasket (D) and flange (A) on the

panel. Secure using (4) #10-24 x 1" (25 mm) pan head

screws (B), (4) external tooth #10 star washers (E) and

(4) #10-24 hex nuts (F). See Figure 1.

2. Mount the base as follows.

a. Install either Cat. No. 102TBS or Cat. No. 102PMBS

base on 3/4" (19 mm) conduit (not supplied). Pull field

wiring through conduit entrance hole.

3. Connect field wiring as instructed in the installation

instructions, P/N 500002, provided with themounting base.

4. Assemble the stackable beacon lighting system as described

in the installation instructions provided with either the

mounting base or the appropriate components.

WARNINGS

To prevent electrical shock, do not connect power

until instructed to do so.

To prevent abrasion of wiring insulation, ensure

that wire passage holes are adequately protected.

P/N 500034 ISSUE 2 © 1998

Page 9

C

(4) o-rings

(4) #10-24 x 1" (25 mm)

B

pan head screws

A

Cat. No. 102PMF

Pipe mount flange

H

Wire retention

terminal cup washer

G

#10-16 x 3/8"

Pan he a d , thread form i ng,

ground ( ) screw

Mounting g a s ket

#10-24 Hex nut

P/N 500034 ISSUE 2

D

E

External tooth

#10 Star washer

F

Figure 1. Mounting Kit Assembly

Page 10

Installation Instructions for 102 Series Triliptical

®

DeviceNet Stackable Beacon Lighting System

DescriptionDescription

Description

DescriptionDescription

The Edwards Triliptical DeviceNet Stackable Beacon Lighting System is a unique audible-visual signaling device that can

contain up to 5 light modules and a multiple tone module in a single "stack."

All components of the Lighting System are UL listed subassemblies and cUL Listed. The enclosures are Type 3R, Type 4X

and IP65 Rated. The unit has been tested by ODVA's authorized independent test lab and found to comply with ODVA

conformance test software.

The optically designed lenses are available in five colors. Each lens module contains a removable cover to allow for

easy relamping. The lens module cover features a molded-in gasket for weather tight reliability.

The Lighting System's base is supplied with a terminal block and may be used with an optional horn assembly. See

Tables 1 and 2 for specification information.

NOTE: The DeviceNet Electronic Data Sheet is available on the Edwards Signaling website at:

http://www.edwards-signals.com/index.cfm?Level=147&PG=3&PID=19. Scroll down to "Installation

Instructions" and click on "102 DeviceNet Electronic Data Sheet"

Device Profile

Revision 1.00

Firmware Revision 1.02

The DeviceNet interface is in the Triliptical DeviceNet Base, 102TBS-DN. The base interfaces between the network and all

installed stacklight modules.

The Triliptical DeviceNet Stackable Beacon is a slave device. It is a general purpose status indicator designed to

indicate the status of a machine or process.

The Triliptical DeviceNet Stackable Beacon has LED, halogen, incandescent or strobe light sources which display the

status of the machine or the process. The power required to drive the lamps is supplied separately from the bus

power for the 120V AC (N5) version. DC power for the 24V DC (G1) version may be taken locally or from the

DeviceNet Network. A standard open style 2 pin connector is used to connect 24V DC @ 1.75A (max) or 120V AC at

0.6A (max) to drive the 5 light sources.

The unisolated physical layer contains DeviceNet required mis-wiring protection circuitry. A standard open style

(unsealed) 5 pin connector is used to connect the Stackable Beacon to the DeviceNet bus. The current draw from the

bus is 0.12A for both the AC and DC versions.

The Triliptical DeviceNet Stackable Beacon contains a preprogrammed microcontroller which implements the Group

2 pre-defined Master/Slave Connection Set. This allows for one Explicit Messaging Connection and one Poll Connection. The objects (classes) supported are described in the next section. The Stackable Beacon resets automatically when

DeviceNet power is applied.

1.0 Object Model

1.1 Object Present in the 102TBS-DN:

OBJECT Optional/Required # of Instances

Identity (1) Required 1

Message Router (2) Required 1

Devicenet (3) Required 1

Assembly (4) Required 1

Connection (5) Required 1

1.2 Object that Effect Behavior:

OBJECT Effect on Behavior

Identity (1) Supports the reset service

Message Router (2) No effect

Devicenet (3) Configures port attributes

Assembly (4) I/O assembly for lamps

Connection (5) Establishes the number of connections

P/N 3100125 ISSUE 3 © 2003

PAGE 1

Page 11

1.3 Object Interfaces:

OBJECT Effect on Behavior

Identity (1) Message router

Message Router (2) Explicit message connection instance

Devicenet (3) Message router

Assembly (4) I/O connection or message router

Connection (5) Message router

1.4 Identification of I/O Assembly Interfaces:

Instance Number Type Name

1 Input/Output Lamps ON/OFF, Lamp diagnostics, and sounder control

1.5 Format of I/O Assembly data Attribute:

Input to the DeviceNet bus as a response to the poll command from master node.

Data Byte 0 value indicates the lamp is OK or it is either burned out or missing.

Data Byte 1 value indicates the lamp was on or off when last poll command was received.

Data Byte 2 value indicates the current sounder module control value.

For Units Configured with 5 Light Modules

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 PWR FAIL DON'T DON'T LMP 5 LMP 4 LMP 3 LMP 2 LMP 1

1=PWR LOST CARE CARE 1 = REP 1 = REP 1 = REP 1 = REP 1 = REP

2=PWR OK 0 = OK 0 = OK 0 = OK 0 = OK 0 = OK

1 DON'T DON'T DON'T LMP 5 LMP 4 LMP 3 LMP 2 LMP 1

CARE CARE CARE 1 = ON 1 = ON 1 = ON 1 = ON 1 = ON

0 = OFF 0 = OFF 0 = OFF 0 = OFF 0 = OFF

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

For Units Configured with 4 Light Modules

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 PWR FAIL DON'T DON'T DON'T LMP 4 LMP 3 LMP 2 LMP 1

1=PWR LOST CARE CARE CARE 1 = REP 1 = REP 1 = REP 1 = REP

2=PWR OK 0 = OK 0 = OK 0 = OK 0 = OK

1 DON'T DON'T DON'T DON'T LMP 4 LMP 3 LMP 2 LMP 1

CARE CARE CARE CARE 1 = ON 1 = ON 1 = ON 1 = ON

0 = OFF 0 = OFF 0 = OFF 0 = OFF

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

P/N 3100125 ISSUE 3 PAGE 2

Page 12

For Units Configured with 3 Light Modules

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 PWR FAIL DON'T DON'T DON'T DON'T LMP 3 LMP 2 LMP 1

1=PWR LOST CARE CARE CARE CARE 1 = REP 1 = REP 1 = REP

2=PWR OK 0 = OK 0 = OK 0 = OK

1 DON'T DON'T DON'T DON'T DON'T LMP 3 LMP 2 LMP 1

CARE CARE CARE CARE CARE 1 = ON 1 = ON 1 = ON

0 = OFF 0 = OFF 0 = OFF

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

For Units Configured with 2 Light Modules

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 PWR FAIL DON'T DON'T DON'T DON'T DON'T LMP 2 LMP 1

1=PWR LOST CARE CARE CARE CARE CARE 1 = REP 1 = REP

2=PWR OK 0 = OK 0 = OK

1 DON'T DON'T DON'T DON'T DON'T DON'T LMP 2 LMP 1

CARE CARE CARE CARE CARE CARE 1 = ON 1 = ON

0 = OFF 0 = OFF

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

For Units Configured with 1 Light Module

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 PWR FAIL DON'T DON'T DON'T DON'T DON'T DON'T LMP 1

1=PWR LOST CARE CARE CARE CARE CARE CARE 1 = REP

2=PWR OK 0 = OK

1 DON'T DON'T DON'T DON'T DON'T DON'T DON'T LMP 1

CARE CARE CARE CARE CARE CARE CARE 1 = ON

0 = OFF

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

P/N 3100125 ISSUE 3PAGE 3

Page 13

Output to the 102TBS-DN with the poll command from master node.

Data Byte 0 value indicates the lamps to be turned ON or OFF.

Data Byte 1 value indicates the ON lamps to be Steady ON or Flashing and the Flashing rate (45, 60 or 80 flashes

per minute) selected. Strobe units should always be set to Steady ON.

Data Byte 2 value indicates the sounder to be turned ON or OFF and the tone to be chosen.

For Units Configured with 5 Light Modules

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 DON'T DON'T DON'T LMP 5 LMP 4 LMP 3 LMP 2 LMP 1

CARE CARE CARE 1 = ON 1 = ON 1 = ON 1 = ON 1 = ON

0 = OFF 0 = OFF 0 = OFF 0 = OFF 0 = OFF

1 0 0 1 LMP 5 LMP 4 LMP 3 LMP 2 LMP 1

45 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY 0 = STDY 0 = STDY

1 0 1 0 LMP 5 LMP 4 LMP 3 LMP 2 LMP 1

60 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY 0 = STDY 0 = STDY

1 1 DON'T DON'T LMP 5 LMP 4 LMP 3 LMP 2 LMP 1

80 CARE CARE 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY 0 = STDY 0 = STDY

1 0 0 0 LMP 5 LMP 4 LMP 3 LMP 2 LMP 1

80 FPM 80 FPM 80 FPM 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH

DEFLT DEFLT DEFLT 0 = STDY 0 = STDY 0 = STDY 0 = STDY 0 = STDY

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

For Units Configured with 4 Light Modules

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 DON'T DON'T DON'T DON'T LMP 4 LMP 3 LMP 2 LMP 1

CARE CARE CARE CARE 1 = ON 1 = ON 1 = ON 1 = ON

0 = OFF 0 = OFF 0 = OFF 0 = OFF

1 0 0 1 DON'T LMP 4 LMP 3 LMP 2 LMP 1

45 CARE 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY 0 = STDY

1 0 1 0 DON'T LMP 4 LMP 3 LMP 2 LMP 1

60 CARE 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY 0 = STDY

1 1 DON'T DON'T DON'T LMP 4 LMP 3 LMP 2 LMP 1

80 CARE CARE CARE 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY 0 = STDY

1 0 0 0 DON'T LMP 4 LMP 3 LMP 2 LMP 1

80 FPM 80 FPM 80 FPM CARE 1 = FLSH 1 = FLSH 1 = FLSH 1 = FLSH

DEFLT DEFLT DEFLT 0 = STDY 0 = STDY 0 = STDY 0 = STDY

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

P/N 3100125 ISSUE 3 PAGE 4

Page 14

For Units Configured with 3 Light Modules

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 DON'T DON'T DON'T DON'T DON'T LMP 3 LMP 2 LMP 1

CARE CARE CARE CARE CARE 1 = ON 1 = ON 1 = ON

0 = OFF 0 = OFF 0 = OFF

1 0 0 1 DON'T DON'T LMP 3 LMP 2 LMP 1

45 CARE CARE 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY

1 0 1 0 DON'T DON'T LMP 3 LMP 2 LMP 1

60 CARE CARE 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY

1 1 DON'T DON'T DON'T DON'T LMP 3 LMP 2 LMP 1

80 CARE CARE CARE CARE 1 = FLSH 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY 0 = STDY

1 0 0 0 DON'T DON'T LMP 3 LMP 2 LMP 1

80 FPM 80 FPM 80 FPM CARE CARE 1 = FLSH 1 = FLSH 1 = FLSH

DEFLT DEFLT DEFLT 0 = STDY 0 = STDY 0 = STDY

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

For Units Configured with 2 Light Modules

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 DON'T DON'T DON'T DON'T DON'T DON'T LMP 2 LMP 1

CARE CARE CARE CARE CARE CARE 1 = ON 1 = ON

0 = OFF 0 = OFF

1 0 0 1 DON'T DON'T DON'T LMP 2 LMP 1

45 CARE CARE CARE 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY

1 0 1 0 DON'T DON'T DON'T LMP 2 LMP 1

60 CARE CARE CARE 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY

1 1 DON'T DON'T DON'T DON'T DON'T LMP 2 LMP 1

80 CARE CARE CARE CARE CARE 1 = FLSH 1 = FLSH

FPM 0 = STDY 0 = STDY

1 0 0 0 DON'T DON'T DON'T LMP 2 LMP 1

80 FPM 80 FPM 80 FPM CARE CARE CARE 1 = FLSH 1 = FLSH

DEFLT DEFLT DEFLT 0 = STDY 0 = STDY

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

P/N 3100125 ISSUE 3PAGE 5

Page 15

For Units Configured with 1 Light Module

BYTE BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

0 DON'T DON'T DON'T DON'T DON'T DON'T DON'T LMP 1

CARE CARE CARE CARE CARE CARE CARE 1 = ON

0 = OFF

1 0 0 1 DON'T DON'T DON'T DON'T LMP 1

45 CARE CARE CARE CARE 1 = FLSH

FPM 0 = STDY

1 0 1 0 DON'T DON'T DON'T DON'T LMP 1

60 CARE CARE CARE CARE 1 = FLSH

FPM 0 = STDY

1 1 DON'T DON'T DON'T DON'T DON'T DON'T LMP 1

80 CARE CARE CARE CARE CARE CARE 1 = FLSH

FPM 0 = STDY

1 0 0 0 DON'T DON'T DON'T DON'T LMP 1

80 FPM 80 FPM 80 FPM CARE CARE CARE CARE 1 = FLSH

DEFLT DEFLT DEFLT 0 = STDY

2 DON'T DON'T DON'T DON'T Sounder Tone Tone Tone

CARE CARE CARE CARE 1 = ON MSB LSB

0 = OFF

2.0 Standard Objects.

2.1 Identity Object (Class ID = 1).

There is a single instance of the identity object for the Triliptical DeviceNet Stackable Beacon. No class attributes

are supported. All of the instance attributes are contained in rom and are gettable but not settable. The table

below shows the values.

ATTRIBUTE ACCESS DATA

ID RULES NAME TYPE VALUE

1 Get Vendor Code Uint 0x201 (513)

2 Get Product Type Uint 0x0000

3 Get Product Code Uint 0x0001

4 Get Revision Word 01.01

5 Get Status UDINT 0x0000

6 Get Serial # Uint UNIQUE SERIAL #

7 Get Product Name STRUCT 102

Identity Object Services:

SERVICE SERVICE CODE PARAMETERS

Get Attribute Single 0x0E Attribute ID

Reset 0x05 0, 1

2.2 Message Router Object (Class ID = 2).

There is no externally visible interface to the Message Router Object.

2.3 DeviceNet Object (Class ID = 3).

There is a single instance of the DeviceNet Object for the Triliptical DeviceNet Stackable Beacon.

DeviceNet Object Class Attributes:

ATTRIBUTE ACCESS DATA

ID RULES NAME TYPE VALUE

1 Get Revision Uint 0x0002

P/N 3100125 ISSUE 3 PAGE 6

Page 16

DeviceNet Object Class Services:

SERVICE SERVICE CODE PARAMETERS

Get Attribute Single 0x0E Attribute ID

DeviceNet Object Instance Attributes:

ATTRIBUTE ACCESS DATA

ID RULES NAME TYPE VALUE

1 Get Macid Uint Dipswitch

2 Get Baud rate USINT Dipswitch

3 Get BOI BOOL 0x01 Auto-Reset 0x00 Hold

4 Get/Set Bus off counter USINT 0x00 (Set) Value (Get)

5 Get Allocation info STRUCT Allocate Serv

DeviceNet Object Instance Services:

SERVICE SERVICE CODE PARAMETERS

Get Attribute Single 0x0E Attribute ID

Set Attribute Single 0x10 Attribute ID

Allocate 0x4B Allocation Choice Master MACID

Release 0x4C Release Choice

2.4 Assembly Object (Class ID = 4)

There is a single instance of the Assembly Object for the Triliptical DeviceNet Stackable Beacon. No class

attributes or services are supported for the Assembly Class.

Assembly Object Instance Attributes:

ATTR ACCESS DATA

ID RULES NAME TYPE VALUE

3 Get/Set Data Struct See Sect 1.5

Assembly Object Instance Services:

SERVICE SERVICE CODE PARAMETERS

Get Attribute Single 0x0E Attribute ID

Set Attribute Single 0x10 Attribute ID

P/N 3100125 ISSUE 3PAGE 7

Page 17

2.5 Connection Object (Class ID = 5).

There are two instances of the Connection object in the 102TBS-DN. Instance #1 is assigned to the Explicit

Messaging Connection. Instance #2 is assigned to the Polled I/O Connection. The following table shows the

attributes and the pre-defined values where applicable. No class attributes are supported.

Connection Object - Explicit Message Connection (Instance #1)

ATTR ACCESS DATA

ID RULES NAME TYPE VALUE

1 Get State USINT 0x03

2 Get Instance type USINT 0x00

3 Get Xport class trigger USINT 0x83

4 Get Produced CONN. ID UINT 0x5FB for MACID 63

5 Get Consumed CONN. ID UINT 0x5FC for MACID 63

6 Get Initial COMM. Characteristics UINT 0x21

7 Get Produced CONN. size UINT 0x0007

8 Get Consumed CONN. size UINT 0x0007

9 Get/Set Expected packet rate UINT Application dependent

10 N/A N/A N/A Not used

11 N/A N/A N/A Not used

12 Get/Set Watchdog timeout action USINT 0x01 Default

13 Get Produced path length UINT 0x0000

14 Get Produced path ARRAY OF USINT <NULL>

15 Get Consumed path length UINT 0x0000

16 Get Consumed path ARRAY of USINT <NULL>

Connection Object - Poll I/O Message Connection (Instance #2)

ATTR ACCESS DATA

ID RULES NAME TYPE VALUE

1 Get State USINT State Dependent

2 Get Instance type USINT 0x01

3 Get Xport class trigger USINT 0x82

4 Get Produced CONN. ID UINT 0x3FF for MACID 63

5 Get Consumed CONN. ID UINT 0x5FD for MACID 63

6 Get Initial COMM. Characteristics UINT 0x01

7 Get/Set Produced CONN. size UINT 0x03

8 Get/Set Consumed CONN. size UINT 0x03

9 Get/Set Expected packet rate UINT Application dependent

10 N/A N/A N/A Not used

11 N/A N/A N/A Not used

12 Get/Set Watchdog timeout action USINT (0x00 Default) 0, 1, 2

13 Get Produced path length UINT 0x0006

14 Get Produced path ARRAY OF USINT 20.04.24.01.30.03

15 Get Consumed path length UINT 0x0006

16 Get Consumed path ARRAY of USINT 20.04.24.01.30.03

Connection Object Services:

SERVICE SERVICE CODE PARAMETERS

Get Attribute Single 0x0E Attribute ID

Set Attribute Single 0x10 Attribute ID

P/N 3100125 ISSUE 3 PAGE 8

Page 18

InstallationInstallation

Installation

InstallationInstallation

WARNING

To prevent electrical shock, do not connect po wer

until instructed to do so.

Safety Message to Installers, Users, and Maintenance Personnel

The Triliptical DeviceNet Status Indicator must be installed in accordance with the latest edition of the National

Electrical Code and/or other applicable local regulations, by a trained and qualified electrician. The selection of the

mounting location, its controls and the routing of the wiring is to be accomplished under the direction of the

facilities engineer.

WARNING

To prevent electrical shock, do not connect to the

system when power is on.

NOTE: For NEMA Type 4X applications, it is recommended that the unit be conduit mounted vertically facing up.

1. Mount the Triliptical DeviceNet Stackable Beacon Base (102TBS-DN) by installing on 3/4" (19 mm) conduit (not

supplied). Pull field wiring (if required) and DeviceNet wiring through the conduit entrance hole.

2. Assemble the stackable beacon lighting system (Figure 1).

a. Pull the captive key in the lens module into the "out" position.

b. Place the first lens module on top of the base.

c. Push in the captive key to secure the lens module.

d. Insert the appropriate light source into board grooves at bottom of lens module, ensuring that the four

prongs on the PC board are aligned with the plug located in the back of the lens assembly.

WARNING

Ensure the magnifier ring on the lens co ver and the

magnifier ring on the lens module are aligned

(Figure 1).

NOTE: When using LED light sources, ensure that the color of the LED light source and the lens assembly match.

e. Place the lens assembly cover on the front of the lens module and secure using two captive screws.

f. Repeat steps a through e for any remaining modules (up to 5).

g. Once the last module has been assembled, place the cap on top and secure the cap with the captive screw.

Network & Field ConnectionsNetwork & Field Connections

Network & Field Connections

Network & Field ConnectionsNetwork & Field Connections

CAUTION

Observe precautions for handling electrostatic

sensitive devices while handling printed cir cuit

boards.

P/N 3100125 ISSUE 3PAGE 9

Page 19

WARNING

To avoid electrical shock hazards, do not connect

wires when po wer is applied.

1. Make DeviceNet connections to the 5 position female terminal block plug as indicated in the below table. The 5

DeviceNet bus terminals are silkscreened near the terminals on the printed circuit board. Make connections as

follows:

Pin 5 V + Red Wire

Pin 4 CAN_H White Wire

Pin 3 Drain Bare Wire

Pin 2 CAN_L Blue Wire

Pin 1 V - Black Wire

2. A two (2) position screw terminal is provided to connect either separate 24V DC or 120V AC (depending on version

-G1 (24V DC) or -N5 (120V AC) light source operating power to the Triliptical DeviceNet Stackable Beacon. The

terminals for the 24V DC unit are labeled as "+" and "-". Polarity is not important for the 120V AC unit. Make

connections as follows:

Pin 1 (+) + 24V DC Red Wire

Pin 2 (-) - 24V DC Black Wire

or

Pin 1 120V AC Black Wire

Pin 2 120V AC White Wire

3. For the 24V DC unit only, if it is desired to power the light sources from DeviceNet power, jumper (V+) and (V-) on

the 5 position DeviceNet terminal block to (+) and (-) respectively on the 2 position screw terminal.

Set DIPSWITCH S1 for the BAUD RATE and MAC ID required as follows:

Note the legend on the dipswitch for the sense of 0 and 1 (0 = OFF and 1 = ON)

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

BAUD RATE - 125 Kbps 0 0

BAUD RATE - 250 Kbps 0 1

BAUD RATE - 500 Kbps 1 0

BAUD RATE - 125 Kbps 1 1

MAC ID 0 000000

MAC ID 1 000001

MAC ID 2 000010

MAC ID 3 000011

MAC ID 4 000100

MAC ID 5 000101

MAC ID 6 000110

MAC ID 7 000111

MAC ID 8 001000

MAC ID 9 001001

MAC ID 10 (0x0A) 001010

MAC ID 11 (0x0B) 001011

MAC ID 12 (0x0C) 001100

MAC ID 13 (0x0D) 001101

MAC ID 14 (0x0E) 001110

MAC ID 15 (0x0F) 001111

MAC ID 16 (0x10) 010000

P/N 3100125 ISSUE 3 PAGE 10

Page 20

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

MAC ID 17 (0x11) 010001

MAC ID 18 (0x12) 010010

MAC ID 19 (0x13) 010011

MAC ID 20 (0x14) 010100

MAC ID 21 (0x15) 010101

MAC ID 22 (0x16) 010110

MAC ID 23 (0x17) 010111

MAC ID 24 (0x18) 011000

MAC ID 25 (0x19) 011001

MAC ID 26 (0x1A) 011010

MAC ID 27 (0x1B) 011011

MAC ID 28 (0x1C) 011100

MAC ID 29 (0x1D) 011101

MAC ID 30 (0x1E) 011110

MAC ID 31 (0x1F) 011111

MAC ID 32 (0x20) 100000

MAC ID 33 (0x21) 100001

MAC ID 34 (0x22) 100010

MAC ID 35 (0x23) 100011

MAC ID 36 (0x24) 100100

MAC ID 37 (0x25) 100101

MAC ID 38 (0x26) 100110

MAC ID 39 (0x27) 100111

MAC ID 40 (0x28) 101000

MAC ID 41 (0x29) 101001

MAC ID 42 (0x2A) 101010

MAC ID 43 (0x2B) 101011

MAC ID 44 (0x2C) 101100

MAC ID 45 (0x2D) 101101

MAC ID 46 (0x2E) 101110

MAC ID 47 (0x2F) 101111

MAC ID 48 (0x30) 110000

MAC ID 49 (0x31) 110001

MAC ID 50 (0x32) 110010

MAC ID 51 (0x33) 110011

MAC ID 52 (0x34) 110100

MAC ID 53 (0x35) 110101

MAC ID 54 (0x36) 110110

MAC ID 55 (0x37) 110111

MAC ID 56 (0x38) 111000

MAC ID 57 (0x39) 111001

MAC ID 58 (0x3A) 111010

MAC ID 59 (0x3B) 111011

MAC ID 60 (0x3C) 111100

MAC ID 61 (0x3D) 111101

MAC ID 62 (0x3E) 111110

MAC ID 63 (0x3F) 111111

P/N 3100125 ISSUE 3PAGE 11

Page 21

4. If using the optional Cat No. 102SIGMT-DN multi-tone module, connect the five position female connector on the

tone module to the upper set of male pins in the Triliptical DeviceNet Stackable Beacon Base. Set the selected tone

in accordance with the table below. Set the third Byte (Data Byte 2) in accordance with the table below in order to

access the required tone. "X" is the "Don't Care" State.

Switch Settings*

Tone Bit3 Bit2 Bit1 Bit0

Tone Off 0 X X X

Stutter Beep 1 0 0 0

Continuous 1 0 0 1

3 Pulse Horn 1 0 1 0

Rapid Siren 1 0 1 1

Hi/Lo 1 1 0 0

Fast Whoop 1 1 0 1

Yeow 1 1 1 0

Beep 1 1 1 1

*1 is ON. 0 is OFF.

5. Install the 102TBS-* front cover or the optional 102SIGMT-DN-G1 multi-tone module by tightening the two captive

front screws.

6. Test the Triliptical DeviceNet Stackable Beacon to ensure that it operates as intended.

To test the device for functionality the unit must be connected to a DeviceNet network via the five (5) pin

connector. Turn on the network power supply and local power (if so configured) for the lamps. All lamps will

flash instantaneously (some lamps may not be visible) as the unit checks for proper lamp operation. The value of

the data byte in the master poll will be displayed on the lamps until it is changed by subsequent poll command.

The pre-defined poll connection has consume size of three (3) bytes, and a produce size of three (3) bytes. When

all the connections are released the lamps will display the last poll command data before release of the connection.

7. The following is an Output Data Byte example

Byte 2

XXXX 1 001

Set

Tone

On

Set

Tone

Value 1

8. The following is an Input Data Byte example:

Byte 2

XXXX 1001

Sounder is

ON with

Tone

Value 1

Byte 1

000 00001

Set

Flash

Rate =

8OFPM

Set

Lamp 1

to

Flashing

Byte 1

XXX 00011

Lamp 2

was ON

before last poll

command

Byte 0

XXX 11111

Byte 0

0XX 00001

Local

Power

is OK

Lamp 1 is

burned out

or missing

Set

Five

Lamps

ON

P/N 3100125 ISSUE 3 PAGE 12

Page 22

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

WARNING

To prevent electrical shock, disconnect network

and local power to the unit. Wait 5 minutes for

stored energy in str obe modules to dissipate before

working on unit.

Light Source Replacement

1. Loosen captive screws and remove cover of affected lens module.

2. Remove the light source assembly from the lens module.

3. Install new light source assembly ensuring that the four prongs on the PC board are aligned with the plug

located in the back of the lens module.

WARNING

Ensure the magnifier ring on the lens co ver and the

magnifier ring on the lens module are aligned

(Figure 1).

4. Replace lens cover and secure using two captive screws.

Cleaning

The lens surfaces should be periodically dusted and cleaned with a dry soft clean cloth to maintain optimum light

visibility. If necessary, the outside of the lens may be cleaned with water and a mild detergent on a well rung out soft

clean cloth.

P/N 3100125 ISSUE 3PAGE 13

Page 23

15"

(381mm)

1/2"

(13mm)

3 5/8"

(92mm)

3 5/8"

(92mm)

Cap (supplied with base)

Magnifier

Ring

Board

Groove

Light Source

Assembly

Captive Key

Signal Base

(Cat. No. 10STBS shown)

Lens Module

Cover

(2) Captive

Screws

3"

(76mm)

Figure 1. Assembling the Stackable Status Indicator

P/N 3100125 ISSUE 3 PAGE 14

Page 24

Table 1. Triliptical DeviceNet Status Indicator Specifications

Electrical Manufacturers Replacement Lamp Life (hours)

Catalog No. Ratings Lamp Ratings Lamp Calculated#Projected

##

Base Units

102TBS-DN-G1 24V DC, 1.75A

102TBS-DN-N5 120V AC, 0.60A

+

+

N/A N/A N/A N/A

Optional Horn Assembly

102SIGMT-DN-G1 24V DC, 0.05A N/A N/A N/A N/A

Lens Modules

102LM-* N/A N/A N/A N/A N/A

Light Sources

102LS-SINH-G1 24V DC, 0.32A 9 Watts 50LMP-9WH 12,000 --

or Ind. Trade 303*** 3,000 -102LS-SINH-N5 120V AC, 0.11A 12 Watts 50LMP-12WH 20,000 -102LS-SIN-G1 24V DC, 0.32A 10 Watts 50LMP-10W or 10,000 --

Ind. Trade 303 3,000 -102LS-SIN-N5 120V AC, 0.08A 10 Watts 50LMP-10W 2,500 - 102LS-ST-G1 24V DC, 0.30A 3 Joule Strobe -- 3,000

102LS-ST-N5 120V AC, 0.12A 3 Joule Strobe - - 3,000

###

###

--

--

102LS-SLEDA-G1** 24V DC, 0.062A -- N/A 100,000 -102LS-SLEDB-G1**

102LS-SLEDG-G1**

102LS-SLEDR-G1**

102LS-SLEDW-G1**

102LS-SLEDA-N5** 120V AC, 0.022A -- N/A 100,000 -102LS-SLEDB-N5**

102LS-SLEDG-N5**

102LS-SLEDR-N5**

102LS-SLEDW-N5**

+

Currents shown are for a stackable indicator with 5 light modules.

*Signifies lens module color (A - amber, B - blue, C - clear, G - green, R - red)

**Signifies lens and LED module color (A - amber, B - blue, G - green, R - red) NOTE: LED light sources must be used with

the corresponding color lens module (e.g., a blue LED light source, 102LS-SLEDB-G1, must be used with a blue lens,

102LM-B).

***A non-halogen lamp, as listed, may be used in place of the halogen lamp.

#

At nominal operating voltage.

##

Projected lamp life based on manufacturer's calculated lamp life @ 65 fpm and 50% duty cycle.

###

Strobe tube life @ operating power to 75% efficiency.

Table 2. Pertinent DeviceNet Specifications

Operating DeviceNet Bus Current 0.12A

Current Draw supplied by separate power supply (per Light Module) DC: 0.062 to 0.320A

AC: 0.022 to 0.120A

In-Rush Current supplied by separate power supply (per Light Module) DC: 1.2A

AC: 0.5A

Flash Rate (selectable via second data byte of POLL command) 45, 60 or 80 fpm

Operating Temperature 32F to 158F (0C to 70C)

P/N 3100125 ISSUE 3PAGE 15

Page 25

Installation Instructions for Triliptical

TM

Stackable Beacon Lighting System Lens Modules

Description

The Edwards Triliptical Stackable Beacon Lighting System is a

unique audible-visual signaling device that can contain up to 5

light modules and either a single or multiple tone module in a single

"stack."

All components of the T riliptical Stackable Beacon Lighting System

are UL and cUL listed subassemblies. The units, when assembled,

are UL and cUL listed for indoor and outdoor applications. The

enclosures are NEMA 3R, 4X, and IP65 rated. CE Marked Visual

Signal.

The optically designed lens modules are available in five colors-amber, blue, clear, green and red. Each lens module contains a

removable cover to allow for easy relamping. The lens module

cover features a molded-in gasket for weather tight reliability.

NOTE: LED light sources must be used with the matching lens

color and are only available in four colors--amber , blue, red

and green.

Installation

WARNING

To prevent electrical shock, do not connect power

until instructed to do so.

Installation must be in accordance with local codes.

1. Assemble the stackable beacon lighting system (Figure 1).

NOTE: When using LED light sources, ensure that the color of the

LED light source and the lens assembly match.

NOTE: For further details, see the instructions supplied with the

light source, P/N 3100701, or the instructions supplied with

the base, P/N 3100669.

WARNING

To prevent leakage, ensure the magnifier ring on

the lens cover and the magnifier ring on the lens

module are aligned (Figure 1).

e. Place the lens module cover on the front of the lens module

and secure using two captive screws.

f. Repeat steps a through e for any remaining modules (up

to 5).

g. Once the last module has been assembled, place the cap

on top and secure the cap with the captive screw.

4. Apply power to the unit and verify proper operation.

WARNING

To prevent electrical shock, disconnect power to all

modules. Wait 5 minutes for stored energy in strobe

modules to dissipate bef ore working on unit.

a. Pull the captive key in the lens module into the "out"

position.

b. Place the first lens module on top of the base.

c. Push in the captive key to secure the lens module.

d. Insert the appropriate light source into board grooves at

bottom of lens ensuring that the four prongs on the pc

board are aligned with the plug located in the back of the

lens module.

Maintenance

Cleaning

The lens surfaces should be periodically dusted and cleaned with a

dry soft clean cloth to maintain optimum light visibility. If necessary, the outside of the lens may be cleaned with water and a mild

detergent on a well rung out soft clean cloth.

P/N 3100700 ISSUE 1 © 2003

Page 26

15"

(381mm)

1/2"

(13mm)

3 5/8"

(92mm)

3 5/8"

(92mm)

Cap (supplied with base)

Magnifier

Ring

Board

Groove

Light Source

Assembly

Captive Key

Signal Base

(Cat. No. 102TBS shown)

Lens Module

Cover

(2) Captive

Screws

3"

(76mm)

Figure 1. Assembling the Stackable Status Beacon Lighting System (Cat. No. 102TBS shown for

illustration purposes only)

P/N 3100700 ISSUE 1

Page 27

Installation Instructions for Triliptical

TM

Stackable Status Indicator Tone Modules

Description

The Edwards Triliptical Stackable Status Indicator is a unique audible-visual signaling device that can contain up to 5 light modules

and either a single or multiple tone module in a single "stack."

All components of the Triliptical Stackable Status Indicator are UL

and cUL listed subassemblies. The units, when assembled, are UL

and cUL listed for indoor and outdoor applications. The enclosures are NEMA 3R, 4X, and IP65 rated. See Table 1 for specifications.

The indicator bases are available in three models. Two models

feature a shorter base that is used when a lower profile is desired;

the other model features a larger base with a terminal block designed to function as a junction box for use with an optional horn

assembly.

Installation

WARNING

To prevent electrical shock, do not connect power

until instructed to do so.

Installation must be in accordance with local codes.

1. Mount the base using one of the following methods:

NOTE: For NEMA 3R, 4X, and outdoor applications, it is

recommended that the unit be conduit mounted vertically

facing up.

a. Cat. No. 102TBS Pull field wiring through conduit entrance

hole. Install base on 3/4" (19 mm) conduit (not supplied).

2. Connect field wiring.

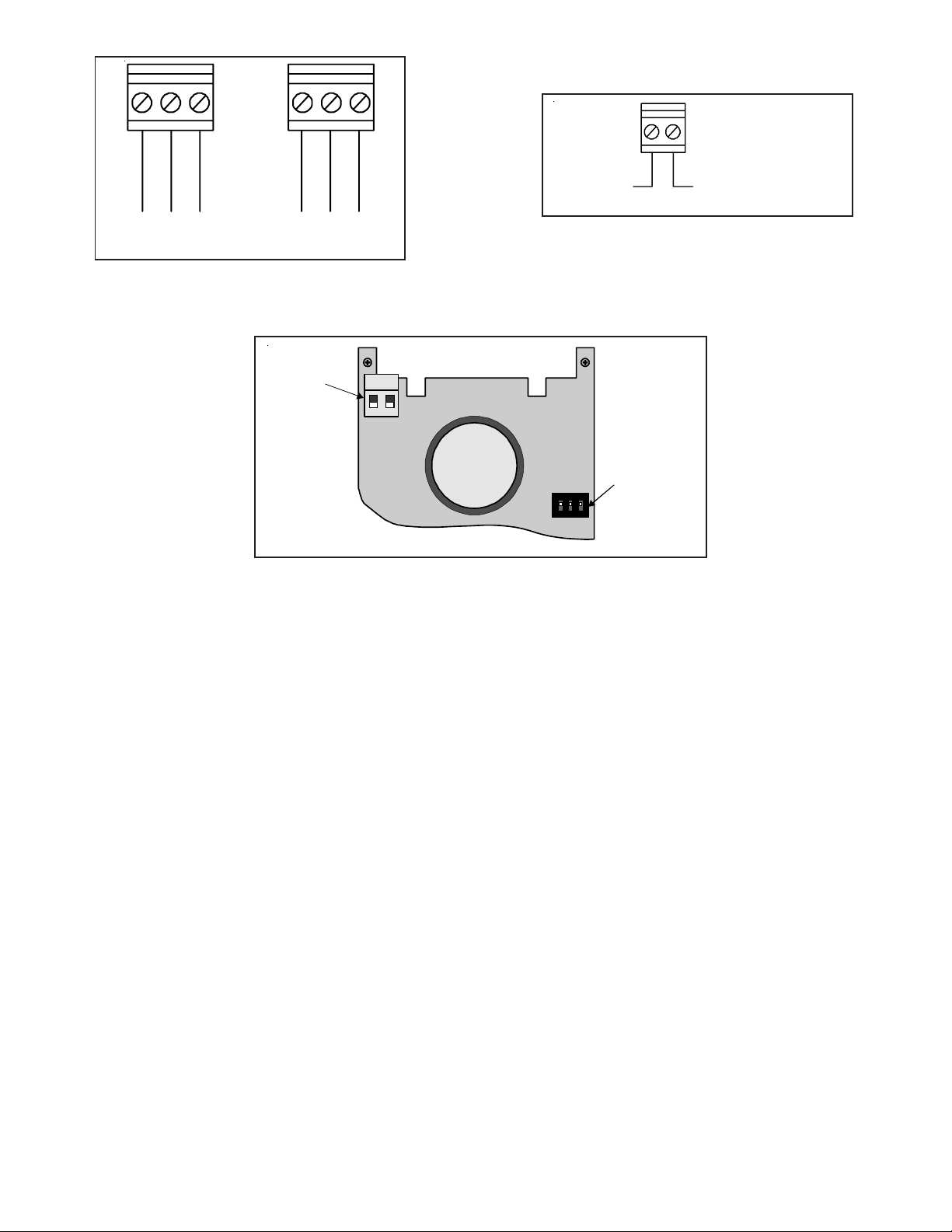

a. Cat. No. 102TBS Connect field wiring to the terminal block

as shown in Figure 1.

b. Connect additional field wiring to the terminal block

mounted on the signal assembly as shown in Figure 2.

NOTE: The tone module may be wired to sound independently or in

conjunction with a light signal.

(1) To sound tone independently, connect to separate

hot lead.

(2) To sound tone with a particular light, connect tone

module hot terminal to selected light terminal on Cat.

102TBS terminal block.

3. If using the multi-tone module, Cat. No. 102SIGMT, set the

selected tone. See Table 2 and Figure 3.

NOTE: For further installation details, see the instructions supplied

with the lens modules, P/N 3100700, with the base, P/N

Table 1. Specifications

Catalog No. Voltage Current (A)

102SIGST-G1 24V DC 0.05

102SIGST-N5 120V AC 0.07

102SIGMT-G1 24V DC 0.05

102SIGMT-N5 120V AC 0.07

Table 2. Switch Settings

Tone 1 2 3

Stutter beep OFF OFF OFF

Hi / Lo ON OFF OFF

3 Pulse Horn OFF ON OFF

Continuous OFF OFF ON

Yeow ON ON OFF

Fast Whoop ON OFF ON

Rapid Siren OFF ON ON

Beep ON O N ON

*ON is in the "UP" position (see Figure 3).

3100669, or with the light sources, P/N 3100701.

Switch Settings*

P/N 3100702 ISSUE 1 © 2003

Page 28

NEUTRAL/COMMON

MODULE 1

MODULE 2

BOTTOM

MODULE 3

Figure 1. Wiring Cat. No. 102TBS

TERMIN AL

BLOCK

MODULE 4

MODULE 5

TO NEUTRAL

ON CAT. 102TBS

TERMINAL BLOCK

NH

SEPARATE HOT LEAD OR

CONNECTED TO APPROPRIATE

LIGHT MODULE TERMINAL ON

CAT. 102TBS TERMINAL BLOCK

Figure 2. Wiring Cat. No. 102SIG*T with Optional

Tone Module

COM

VAC

120

ON

123

TONE SELECTI

DIPSWITCH

(SEE TABLE 2))

Figure 3. Cat. No. 102SIGMT PC Board (120V version shown)

P/N 3100702 ISSUE 1

Loading...

Loading...