Page 1

PLAINVILLE, CT 06062

41 WOODFORD AVE.

EDWARDS SIGNALING

TECHNICAL WRITING

RETURN MECHANICAL TO:

TO ACTUAL SIZE.

NOTE: MECHANICALS HAVE ALREADY BEEN REDUCED

CHARACTERS: TO BE BLACK ON WHITE BACKGROUND

MATERIAL: STANDARD WHITE OFFSET STOCK

WITH PART NUMBER ON THE OUTSIDE.

(1) 11" X 17" SHEET PRINTED BOTH SIDES. FOLD IN HALF

5553 SERIES ADAPTATONE SPEAKER

INSTALLATION INSTRUCTIONS FOR CATALOG SERIES

P/N 3101297 OFFSET SPEC

ECN: 13-C2085

FILE: 3101297

ISSUE: 2

APPROVED: GM

FOLD DETAIL REFERENCE ONLY

P/N 3101297

Page 2

5553 Series Adaptatone Millennium Speaker

P/N 3101297• REV 02 • REB 20FEB13

installation and

operation

Page 3

PAGE

2

Description and Operation

8 7/8"

(225 mm)

8 1/4"

(210 mm)

13"

(330 mm)

2.0" (51mm)

7.5"

(191mm)

1. Mount Adaptatone as shown in Figure 2.

Edwards 5553 series Adaptatone Speakers are UL Listed Audible

Signaling Appliances that are designed to accept system audio input

levels of 25 or 70 volts RMS. They are designed to be used in conjunction

with compatible control equipment for high intelligibility reproduction

of audible emergency and protecive signals as well as voice messages.

They comply with the requirements of UL Standard 1480, Fire Protective

Signaling Speakers. The speakers are suitable for outdoor use with a

UL1480 wet locations rated enclosure.

The speakers include a supervisory capacitor and are suitable for

installation in systems employing supervised circuitry (25V/70.7V).

Maximum supervised circuit voltage is 24VDC.

Speaker direction and the output level are easily adjustable. Output

wattage is easily adjusted by an internal rotary switch.

Additionally, the Adaptatone series are UL Listed as Audible Signal

Appliances for use in the following hazardous locations.

Catalog

Number

5553-25/70-G

5553-25/70-R

Class I, Div. 2, Groups A, B, C, D T4 (135)

Hazardous

Locations

Class II, Div. 2, Groups F, G

Class III, Div. 1 and 2

Temp.

Code

T5 (100C)

NOTE: C

2. Install wires through a knockout hole in the bottom of the box

a. Flat Surface Mounting. Secure unit to mounting surface

using the (4) mounting holes in the mounting plate on the

rear of the box. Use #10 x 3" (76 mm) wood screws (furnished

loose) or other hardware (not supplied) suitable for the

mounting surface.

b. Rigid Pipe Mounting. Loosen the (4) cover screws from the

signal box and lift off signal box cover.

over screws are captive. Do not remove from cover.

Remove the center knockout in lower wall of box and

mount box to a 1/2" (12.7 mm) conduit pipe using suitable

connector.

from a raceway that is, with its connections to the 1/2" (12.7 mm)

conduit knockout hole, approved for the same degree of protection

and enclosure type needed by the application.

WARNING

To prevent fire and shock, wire the Adaptatone only as described

in this installation instruction.

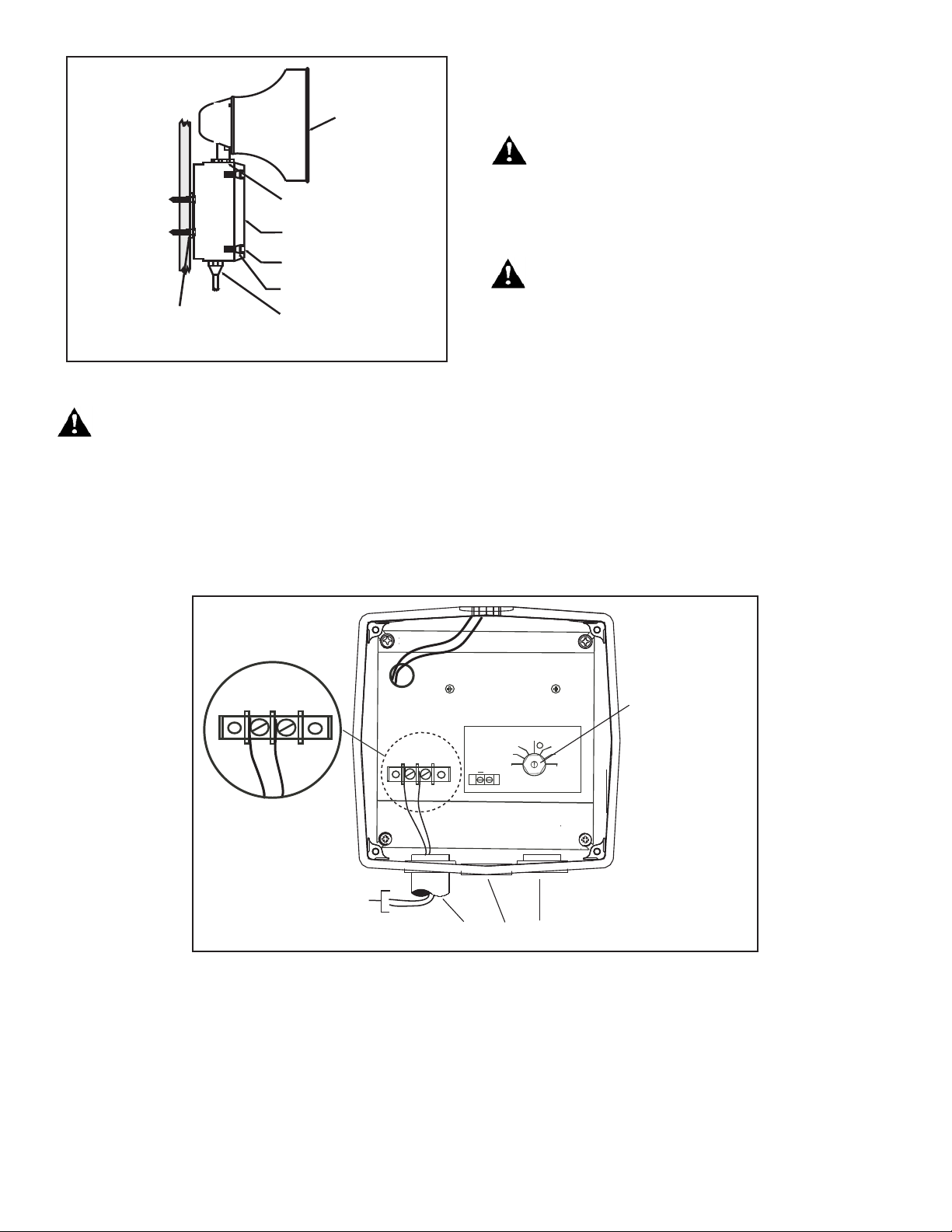

3. Wire as follows referring to Figure 3:

a. Connect audio in (+) and audio in (-) to the "AUDIO INPUT/

OUTPUT CONNECTIONS", 2-place terminal on faceplate.

Obser ve polarity on faceplate lab el. Sh ielded cabl e

recommended.

Side

Back

Figure 1. Speaker/Amplifier Dimensions

Specifications

Weight - Speaker/Amplifier .................................. 9 Pounds (4.1 kg)

Hazardous.Locations,.UL.Standard.UL1604

Ambient Temp. .................................................... -40F to +104F (-40C to +40C)

Non-Hazardous.Locations

Variable Ambient Temp. ..................................... -40F to +151F (-40C to +66C)

Frequency Range.............................................400Hz to 4,000Hz

Hazardous Locations and Variable Ambient Conditions apply only where UL

listings ar e accepted.

Installation

The Adaptatone Speaker may be mounted to any .at surface or may

be used as a freestanding unit mounted to a rigid pipe. The Adaptatone

must be installed in accordance with the latest edition of the National

Electrical Code or other regulations applicable to the country and locality of installation and by a trained and qualified electrician.

b. When connecting multiple speakers or supervised circuits;

Connect wires leading to next signal or end-of-line resistor

on the same INPUT/OUTPUT terminals (+) and (-) on the 2place terminal as shown in Figure 4. Again, polarity must be

observed.

4. Adjust voltage/wattage level by turning rotary switch located

on internal faceplate (Figures 3 & 4). See Table 1 for Power Tap

Selection Settings.

WARNING

To ensure integrity of the enclosure: Ensure the cover gasket,

part number P-007549-0069, is adhered into groove at cover

perimeter before replacing the signal box cover.

WARNING

Ensure that the (4) collar gaskets, part number P-041930-0362,

are in place on each cover screw before securing the signal

box cover.

When securing cover, start screws by hand, making sure

they are threaded into tapped holes in housing bosses before

securing with a screwdriver. Torque signal box cover screws to

a minimum of 20 in-lbs. This ensures the required tight fit.

5. Tightly secure the signal box cover using (4) retained cover

screws.

6. Torque signal box cover screws to a minimum of 20 in-lbs.

P/N 3101297 ISSUE 02

Page 4

Speaker

Large star nut to

adjust speaker

direction

Signal Box

(4) Cover

screws

(4) Collar

gaskets

Raceway and connections

(not supplied) to

1/2" (12.7 mm) knockout

hole

(4) #10 x 3" (76 mm)

screws or other hardware

suitable for the mounting surface

Figure 2. Adaptatone Mounting

15W 25V *

.9W70V

1.8W70V

0.48W25V

7.5W70V

15W7 0V

7.5W25V *

1.8W25V

0.94W25V

3.8W70V

* DO NOTUSE

FOR 70V

+

AUDIO INPUT CONNECTIONS

From Amplifier

+

_

1/2" Conduit Entries

Power Tap

Selection Switch

(See table 1)

+

_

WARNING

To ensure integrity of the Adaptatone assembly when

adjusting the speaker direction, make sure threads in the

enclosure remain fully engaged and do not turn speaker more

than 360 degrees from the original factory installed position.

8. Regardless of speaker direction adjustment, it is important that the

star nut be tightened wrench tight to ensure the speaker position

is maintained securely.

WARNING

High volume may cause harm to personnel in close proximity.

9. Verify operability.

Maintenance and Test

WARNING

Ensure that power is disconnected before cleaning inside of

unit.

Examine the unit semi-annually for accumulation of dirt. Clean if

necessary.

The Adaptatone should be tested annually or as required by the authority having jurisdiction to ensure continuous service.

7. To adjust speaker direction, loosen large star nut (Figure 3) and

turn speaker to the approximate desired position.

Figure 3. Wiring a Single 5553 Series Speaker (non supervised)

P/N 3101297 ISSUE 02

PAGE 3

Page 5

1/2" Conduit Entries

U.S.

T 800-336-4206

F 800-454-2363

Canada

T 519 376 2430

F 519 376 7258

Asia

T 852 2907 8108

F 852 2142 5063

Australia

T 61 3 9259 4700

F 61 3 9259 4799

Europe

T 32 2 725 11 20

F 32 2 721 86 13

Latin America

T 305 593 4301

F 305 593 4300

www.edwardssignaling.com

Table 1. Power Tap Selector Switch

Switch

Position Impedance

1 5.0K - - .9W 93

2 2.5K - - 1.8W 96

3 1.3K .48W 91 3.8W 98

4 666 .94W 93 7.5W 101

5 333 1.8W 96 15.0W 103

6 89 7.5W 101 Do Not Use

7 45 15.0W 103

25V

Line

SPL dB(A)

@ 10 ft.

70V

Line

SPL dB(A)

@ 10 ft.

on 70V

CAUTION

To ensure proper supervision of connection, do not use looped

wires under terminal screws. Break wire run. Use both sides

of terminal screws as shown.

Note: To conform with UL requirements, wires must be connected as shown in wiring diagram.

Wire size; 18 Gauge minimum, 12 Gauge maximum.

_

+

From Supervised

or Non Supervised

Amplifer

0.94W25V

7.5W70V

0.48W25V

3.8W70V

_

+

1.8W70V

.9W70V

+

AUDIO INPUT CONNECTIONS

1.8W25V

15W7 0V

7.5W25V *

15W 25V *

* DO NOT USE

FOR 70V

Power Tap

Selection Switch

(See table 1)

To Next Speaker or

End-of-Line Resistor

Figure 4. Wiring Multiple 5553 Seres Speakers and/or supervised circuits

PAGE 4 P/N 3101297 ISSUE 02

Loading...

Loading...