Page 1

Cheshire, CT 06410 203-699-3300 (Ph)

203-699-3365 (Cust. Serv. Fax)

203-699-3078 (Tech. Serv. Fax)

Installation and Operation of the

Catalog Number 5541M-Y6

Millennium System Master

Millennium System Master

EDWARDS SIGNALING

MASTER MODE

FUNC

BATTERY

EXT. INPUT

TROUBLE

P/N 3100471 ISSUE 3 © 2003

Page 2

DEVELOPED BY EDWARDS SIGNALING

COPYRIGHT NOTICE

© 2003

IMPORTANT IMFORMATION

Limitation of liability

This product has been designed to meet the requirements of Underwriters

Laboratories, Inc., Standard 2017 and 864. Installation in accordance with

this manual, applicable codes, and the instructions of the Authority Having

Jurisdiction is mandatory. The manufacturer shall not under any

circumstances be liable for any incidental or consequential damages

arising from loss of property or other damages or losses owing to the

failure of products beyond the cost of repair or replacement of any

defective products. The manufacturer reserves the right to make product

improvements and change product specifications at any time.

While every precaution has been taken during the preparation of this

manual to ensure the accuracy of its contents, the manufacturer assumes

no responsibility for errors or omissions.

FCC Warning

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful intereference in which case the user will be required to

correct the interference at his own expense.

Compliance Statement

Millennium System Master, when properly installed, operates with a Local

Protected Premises Fire Alarm System in accordance with the following

standard:

• Underwriters Laboratories Standard 864

Millennium System Master, when properly installed, can also be

configured to operate as a self-monitored evacuation device, in

accordance with the following standard:

• Underwriters Laboratories Standard 2017

Content

Chapter 1 System overview and operation 1

1.1 System overview.................................................................. 1

1.2 Operations Review ............................................................... 1

1.3 Controls and Indicators ....................................................... 1

1.4 Operating the Panel ............................................................. 5

Chapter 2 Installation 7

2.1 Installation checklist ............................................................ 7

2.2 Installing the cabinet ........................................................... 7

2.3 Installing Power .................................................................. 7

2.4 Wiring a Satellite Panel ..................................................... 10

2.5 Connecting Speaker/Amplifiers ......................................... 11

2.6 Connecting External Initiating Inputs ................................. 11

2.7 Connecting to Output Relay ............................................... 12

2.8 Connecting External Initiating Input to Fire

Alarm Panel ....................................................................... 12

2.9 Connecting to a UL Listed Telephone Access

Module .............................................................................. 13

2.10 Connecting to Remote Paging Units .................................. 14

2.11 Adjusting Audio Levels ..................................................... 15

Chapter 3 Programming 16

3.1 Overview ............................................................................ 16

3.2 Local Alarm Input Assignment .......................................... 16

3.3 Relay Output Assignment .................................................. 16

3.4 Device Commission ........................................................... 16

3.5 Dynamic Zone Control

3.6 Communications Setup ..................................................... 17

3.7 Panel Address Assignment ................................................ 17

3.8 Panel Mode ....................................................................... 17

3.9 Auto Learn Mode ............................................................... 17

3.10 Zone to Input Assignment ................................................. 18

3.11 Voice Message Setup ........................................................ 18

3.12 Standby Power Mode ........................................................ 19

3.13 Remote Programming ...........................................................

3.14 Text Output String .................................................................

3.15 Security ............................................................................. 19

TM

...........................................................................................

17

P/N 3100471 ISSUE 3

Chapter 4 Maintenance 20

4.1 Preventive Maintenance ..................................................... 20

4.2 Preventive Maintenance Schedule ..................................... 20

Chapter 5 LCD Messages and Troubleshooting 21

5.1 Normal Mode ..................................................................... 21

5.2 Troubleshooting and Trouble Messages ............................ 22

Appendix A Calculations 26

Battery calculation worksheet ........................................................ 26

5532M Audio amplifier voltage drop calculation ........................... 27

5532M Audio am. circuit max. wire length calculation ................. 28

Suggested RS-485 Network topology ........................................... 28

Appendix B Programming template 29

Appendix C Panel specifications 30

Appendix D Wiring 31

PAGE 2

Page 3

Chapter 1 - System Overview and Operation

When panel encounters either an emergency or non-emergency

event, the panel conducts the following:

1.1 - System overview

The Millennium System Master is a Four Zone Emergency Evacuation and Routine Signaling control panel that can be programmed

to operate in two mode types: Master Mode or Satellite Mode. In

either mode, the panel provides reliable emergency and non-emergency notification. In addition to signaling notification, the panel

provides area and plant wide voice communications for emergency

and non-emergency use. See Figure 1.

The following features are built in:

• 67 field selectable audible tones (See Table 1)

• Audio, voice & power supervision

• Microphone and input supervision

• Up to 4 five-second field recordable voice messages

• Hand-held microphone paging

• Standby power by using EBPS10 Booster Power Supply

• Up to 64 Satellite units addressable through RS485 network

• Output & Trouble Relays designed for fail-safe operation

• Multiple knockouts for easy cabinet entry

• LED Alarm & Status Indication

• 40 character LCD display for system status messages

• Program lockout key

• Adjustable output volume control

• Text output capable with Edwards message center signs

1.1.1 - Master Mode

• Energizes appropriate output relays (K1-K4) associated with

programmed input

• Activates programmed alarm tone/voice audio output

• Enables the appropriate alarm LED on the front panel

• Runs the appropriate programmed output response for the

local or external input that signaled the event

• Communicates programmed Dynamic Zone Control event

information to appropriate serial devices (Master Mode only)

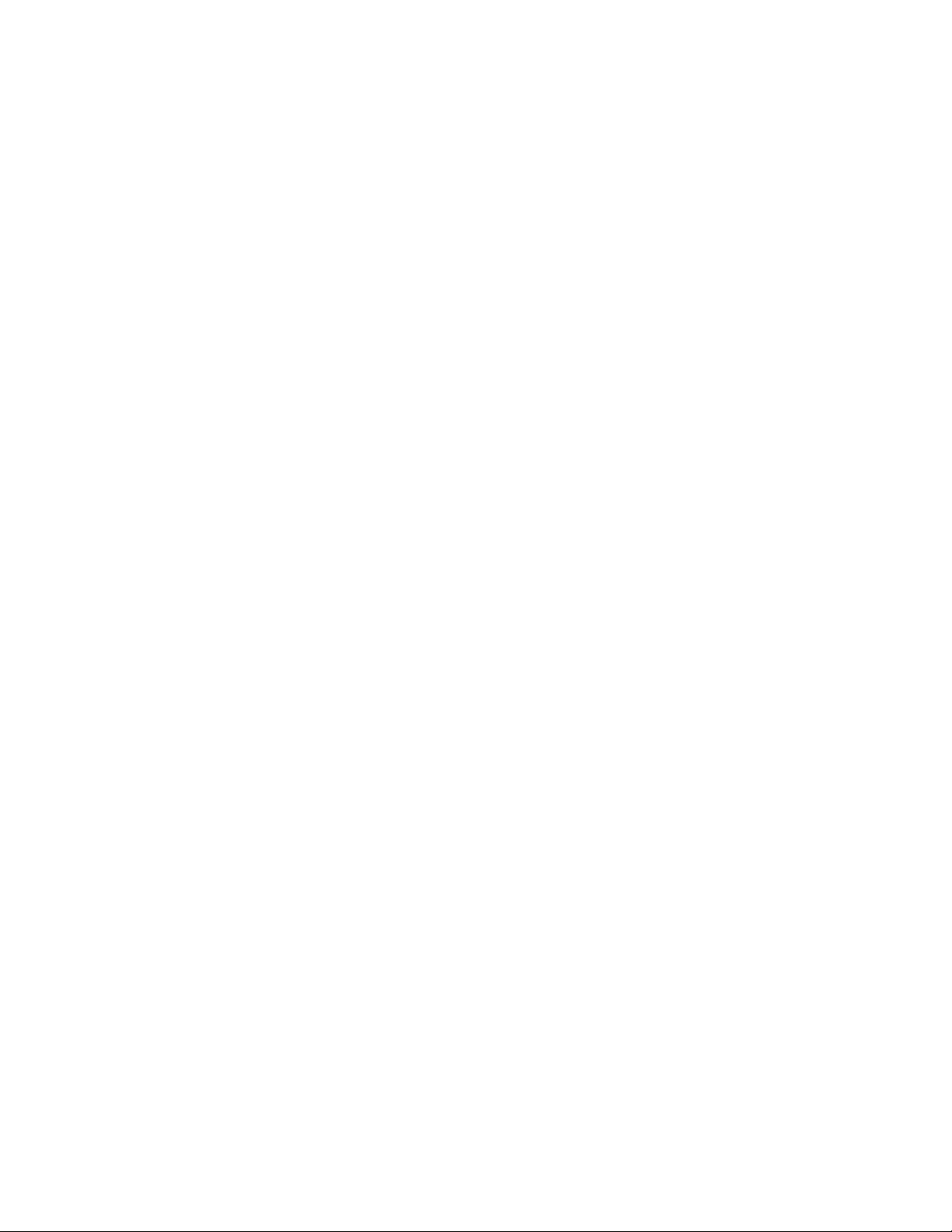

1.3 - Controls and Indicators

Millennium System Master

BATTERY

EXT. INPUT

TROUBLE

FUNC

CHG

(1) Function Buttons

Button Description

In Setup mode: changes currently selected

program variable to next available program

variable.

From Master/Satellite mode: Initiates zone

paging menu.

From Master/Satellite mode: Selects panel

setup mode.

In Master mode, the panel will be in standby normal operation

waiting for either emergency or non-emergency keypad or external

initiation. While there is no keypad or external initiation, the panel

will perform continuous supervision on the following: RS-485 network via serial polling of configured devices, audio signal output

wires, external input channels, remote power loss sense, microphone, audio amplifier and STDBY power input (when enabled).

Any encountered troubles will be posted both visually, on the panel’s

LCD screen, and audibly from the panel’s internal piezo buzzer.

During panel initiation of emergency and non-emergency activity,

supervision (with the exception of RS-485 polling) will occur after

30 seconds of operation from the start of the initiation request.

Polling will continue regardless of the panel’s activity state.

1.1.2 - Satellite Mode

When in this mode, the panel will operate the same as in Master

mode, except it will not supervise RS-485 network devices. It may,

however, respond to serial commands from another panel configured as a master. All supervisory updates will occur once every 30

seconds.

1.2 - Operations overview

In the absence of any alarm, supervisory trouble, or non-emergency events, the control panel monitors the entire system for

integrity.

From Setup mode: Selects next program

function.

In Setup mode: Selects next available input or

output to be programmed or assigned.

From Master/Satellite: Allows viewing of current

trouble condition(s).

In Setup mode: changes currently selected

program variable to previous selection.

From Master/Satellite: Allows silencing of local

trouble buzzer.

(2) Local Alarm Initiating Inputs

Button Description

From Master/Satellite mode: Initiates local

alarm program 1 or selects Zone A for local

paging. On steady until either CANCEL button is

pressed or another local alarm is initiated.

From Master/Satellite mode: Initiates local

alarm program 2 or selects Zone B for local

paging. On steady until either CANCEL button is

pressed or another local alarm is initiated.

From Master/Satellite mode: Initiates local

alarm program 3 or selects Zone C for local

paging. On steady until either CANCEL button is

pressed or another local alarm is initiated.

From Master/Satellite mode: Initiates local

alarm program 4 or selects Zone D for local

paging. On steady until either CANCEL button is

pressed or another local alarm is initiated.

PAGE 3

P/N 3100471 ISSUE 3

Page 4

(2) Local Alarm Initiating Inputs

Button Description

From Master/Satellite mode: Cancels active local alarm

program and transmits zone broadcast serial data to serial

devices.

From Setup mode: Terminates setup mode and returns

panel to normal operation.

(3) Common System LEDs

LED Description

Alarm Flashing Green when there is an active alarm event occurring

on local alarm program inputs.

(buttons 1 - 4)

Trouble Flashing Red when there is a fault with a monitored circuit or

system component, when in Setup mode or when the panel

is in STDBY power mode.

EXT Input Flashing Green when there is one or more active external

input(s) occurring on the external input channels or if the

system audio channel is enabled coming from a Master

panel.

BATTERY Steady Green when the panel has sensed AC

power loss and is on STDBY power

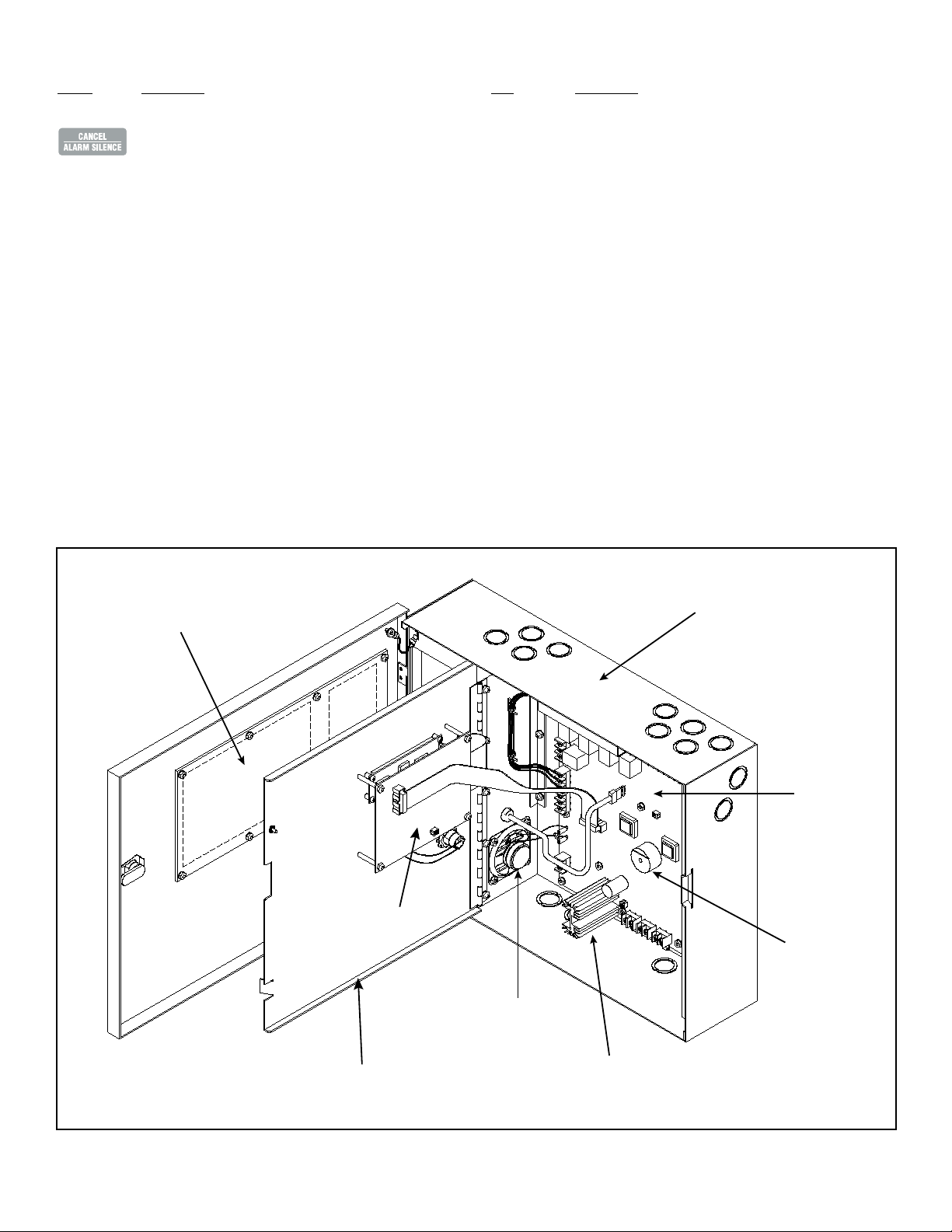

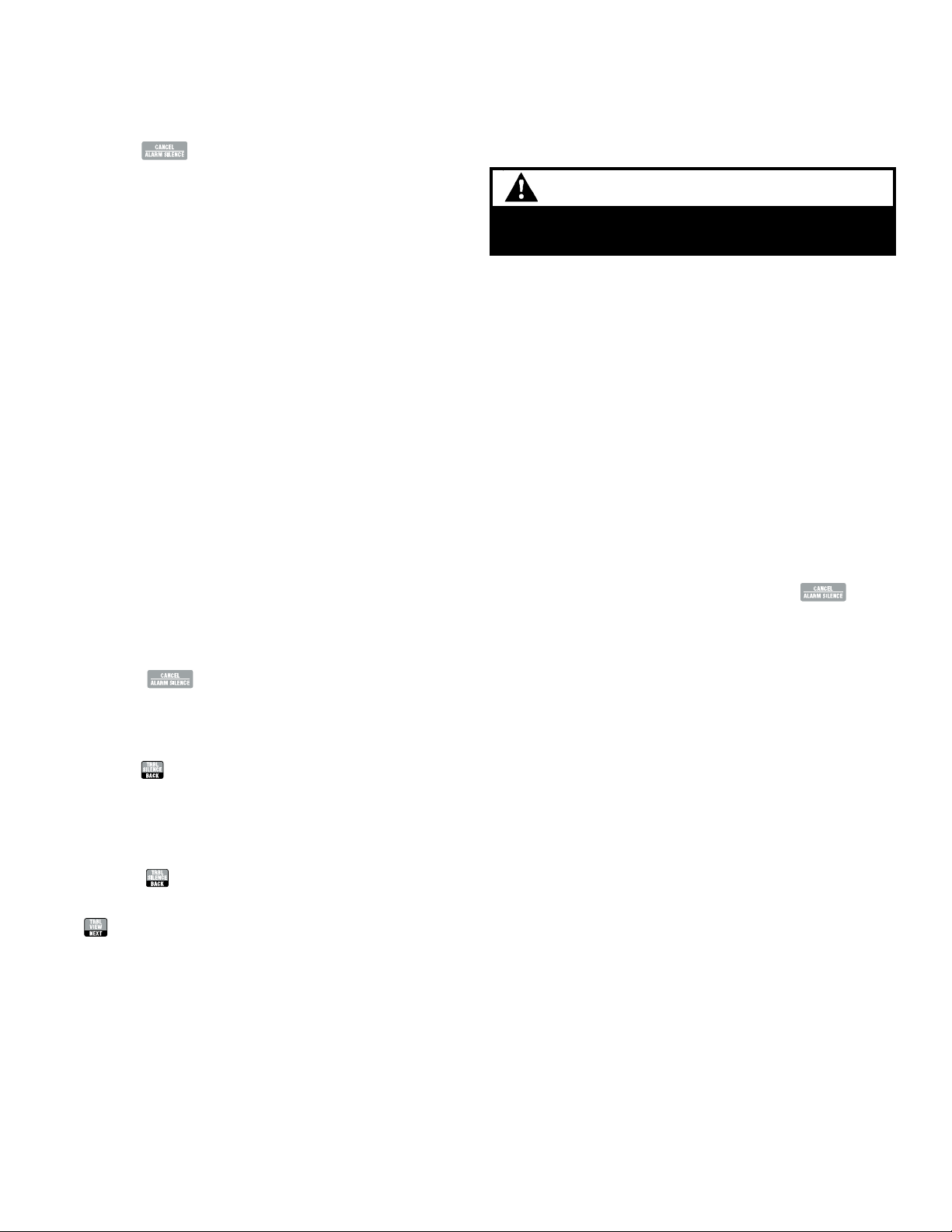

Viewing area

Cabinet

Main Board

Interface

LCD & Keypad

Interface

Local

Trouble Buzzer

Local

Speaker

P/N 3100471 ISSUE 3

Dead Front

Amplifier

Figure 1. Millennium System Master

PAGE 4

Page 5

1.4 - Operating the Panel

1.4.3 - External Input Devices (EID)

1.4.1 - Resetting the panel

Pressing the button places the panel in the alarm-reset

state. The panel should not be reset until the appropriate authority

has determined that the hazard is no longer present.

When you reset the panel:

• All local alarm program input LEDs will turn off.

• Active tone/voice audio output is disabled.

• All dynamic zones are disabled (Master panel only).

• All output relays are de-energized.

• Trouble LED will turn off temporarily until supervisory status

update is restored. If the panel is configured as Master mode,

supervisory status update will occur immediately; if the panel

is configured as a Satellite mode, supervisory status will update

within 30 seconds. The LED will remain off until it detects

system trouble.

• When reset is complete, the local panel buzzer will turn off.

In this state:

• Alarm, trouble, and output relays are returned to the inactive

state.

• STDBY POWER detection remains off until supervisory status

update resumes.

If at the conclusion of the reset an active external input is detected,

the panel will treat the event as a new event and activate the programmed responses.

External Input Devices (EID) connected to the panel’s external input channels cannot be reset from the front panel. If an EID is active

and the alarm condition must be cleared, the EID must then be

manually reset at the point of origin.

WARNING

The EID should not be disabled until the cause of the

alarm is determined and problem is resolved.

Resounding an alarm condition

Pressing the local alarm buttons (1-4) turns the audible devices

back on if they were previously disabled or cancelled.

1.4.4 - Performing an Evacuation Drill or Walk Test

You can perform an EVAC drill or Walk Test by simply activating any

one of the local alarm buttons. Tone/Voice, output relays and zones

associated with the selected alarm button will be enabled. See the

programming section for Local Input, Output Relays and Zone assignment. It is recommended that the user reserve a single local

alarm button for EVAC drill, Walk Test or both. When programming

the local alarm button, all zones and outputs relays should be assigned to this alarm button.

To perform an Evacuation Drill or Walk Test:

1. Press the user defined local alarm button.

2. To stop the EVAC drill or Walk Test, press the button.

To reset the panel:

1. Press the button.

1.4.2 - Silencing the local panel Trouble buzzer

Pressing the button silences the local buzzer on the panel.

While in silence mode, the buzzer will sound once every 10 seconds

for 0.5 seconds. This silence mode is restored to continuous mode

only after a panel reset.

To silence the panel Trouble buzzer:

1. Press the button on the panel.

2. Determine the cause of the trouble condition by pressing the

button.

PAGE 5

P/N 3100471 ISSUE 3

Page 6

THIS PAGE

INTENTIONALLY

LEFT BLANK

P/N 3100471 ISSUE 3

PAGE 6

Page 7

Chapter 2 - Installation

2.1 - Installation checklist

Prepare the site. Make sure the installation location is free

from construction dust and debris and extreme temperature

ranges and humidity.

3. Break audio & power leads to test supervision. Panel

should go into trouble.

4. Adjust audio levels.

5. Check program switch is locked, deadfront is installed

and door is locked.

2.2 - Installing the cabinet

Unpack the equipment.

Install the cabinet. See "Installing the Cabinet" for dimensions.

Plan wire routing. See Appendix D or the panel label.

WARNING

Prior to making any electrical connections, ensure

power is disconnected.

Connect the field wiring. See Appendix D or the panel label.

Meter for opens, grounds, and shorts before connecting.

Connect AC power and ground. See Figure 4 and Appendix D

or the panel label.

Connect Standby power. See Figure 5 and Appendix D or the

panel label.

alarm panel, Standby Power MUST be installed and enabled.

Program the panel. Refer to Chapter 3.

Verify operation.

1. Initiate contacts--listen for tones

2. Push initiation buttons - listen for tones

NOTE: When the System Master is used with a fire

Cabinets can be surface mounted or semi-flush mounted. See Figure 2 for framing and mounting dimensions.

2.2.1 - Surface Mounting

1. Position the cabinet on the finished wall surface.

2. Fasten the cabinet to the wall surface where indicated in

Figure 2 using (4) 1/4" x 2" lag screws for wood, (4) 1/4" x 1"

sheetmetal screws for steel, or (4) 1/4" x 2 1/4" wedge anchors

for cement.

2.3 - Installing Po wer

DANGER

High voltage present when power applied. Prior to

making any electrical connections, ensure power is

disconnected.

1. Review specifications Appendix C for power requirements.

Provide branch circuit wiring rated for panel requirements.

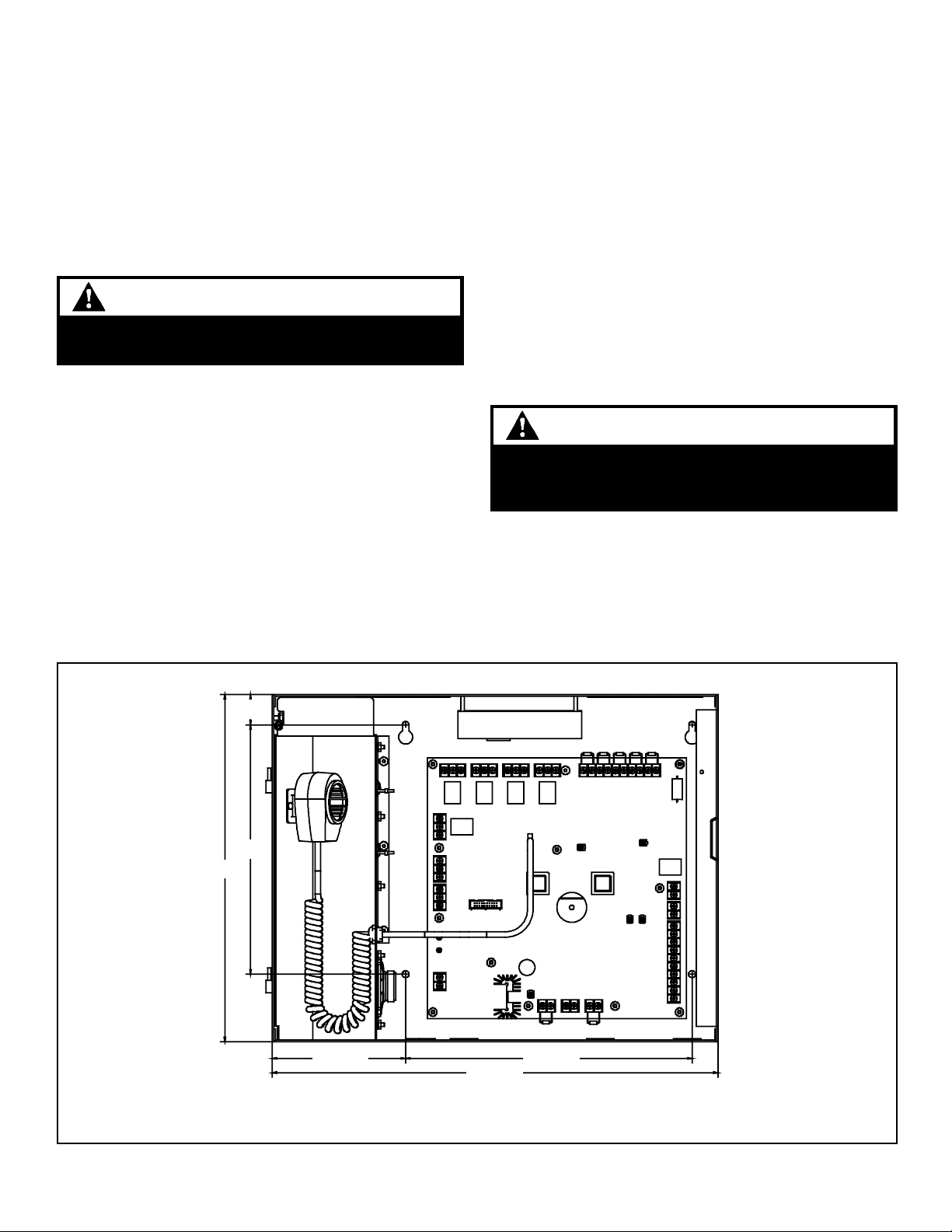

2. Connect green ground wire to terminal "G" on terminal block

TB5 (Figures 3 and 4).

3. Connect incoming Neutral to terminal "N" on terminal block

TB5. Connect incoming Hot to terminal "L" on terminal block

TB5 (Figures 3 and 4).

14.00"

1.22"

10.06"

3.39"

18.00"

11.56"

NOTE: System Master Shown without Doors Installed

Figure 2. Panel Dimensions

PAGE 7

P/N 3100471 ISSUE 3

Page 8

4. When using an auxiliary power supply, connect Stdby Power

(-) terminal (TB9) on the panel to the (-) connection on the

auxiliary power supply. Connect Stdby Power (+) terminal (TB9)

on the panel to the (+) connection on the auxiliary power supply.

(See Figures 3 and 5.)

EXTERNAL OUTPUTS

NO1 C1 NC1 NO2 C2 NC2 NO3 C3 NC3 NO4 C4 NC4

TB1 TB2 TB3 TB4

NOTE: For detailed wiring information, refer to the installation

instructions supplied with the auxiliary power supply.

Test EOL resistors (supplied)

NOTE: Resistors replaced with Cat. No. EOL-4.7 for operation.

See Section 2.6

IN1

12345678910

IN2 IN3 IN4 TAM

TB14

EXTERNAL INPUTS

TROUBLE

NC5

C5

NO5

WHT

BLK

G

N

L

K1

TB15

TB6

120-240 V AC

TB5

K2 K3 K4

K5

PAGE ADJ

PLAYBACK ADJ

LOCAL ADJ

TAM LEVEL ADJ

TB13

+24 VDC

TB7

+

_

+vs -vs

RPU/AUD

+

_

P_OUT PQ+

TB9

+

P/N 3100471 ISSUE 3

TAM_AUD

STDBY POWER

MAIN ADJ

MAIN OUT

TB10

TB8

+TX/RX -TX/RX

POWER

SUPERVISION

TB11

+-+-

_

+

SYS_AUD

_

+

Figure 3. PC Board Locations

PAGE 8

Page 9

Incoming Power

Source Wiring

120 - 240V AC 50/60 Hz

TROUBLE

NC5

C5

NO5

K1

TB15

WHT

BLK

TB6

120-240 V AC

Ground

Neutral

Hot

G

N

L

TB5

Figure 4. Installing AC Power

K5

PAGE 9

STDBY POWER

TB9

+

+

NAC1

_

+

Millennium System Master

NAC2

_

+

NAC3/AUX (NAC3 configured as AUX)

_

+

NAC4/AUX

_

Edwards Power Booster Panel

EBPS Series

Figure 5. Connecting to an Auxiliary Booster Power Supply

P/N 3100471 ISSUE 3

Page 10

2.4 - Wiring a Satellite Panel

The Millennium System Master is capable of driving up to 64 Satellite Panels. Connect the System Masters together as described here

(See Figures 3 and 6).

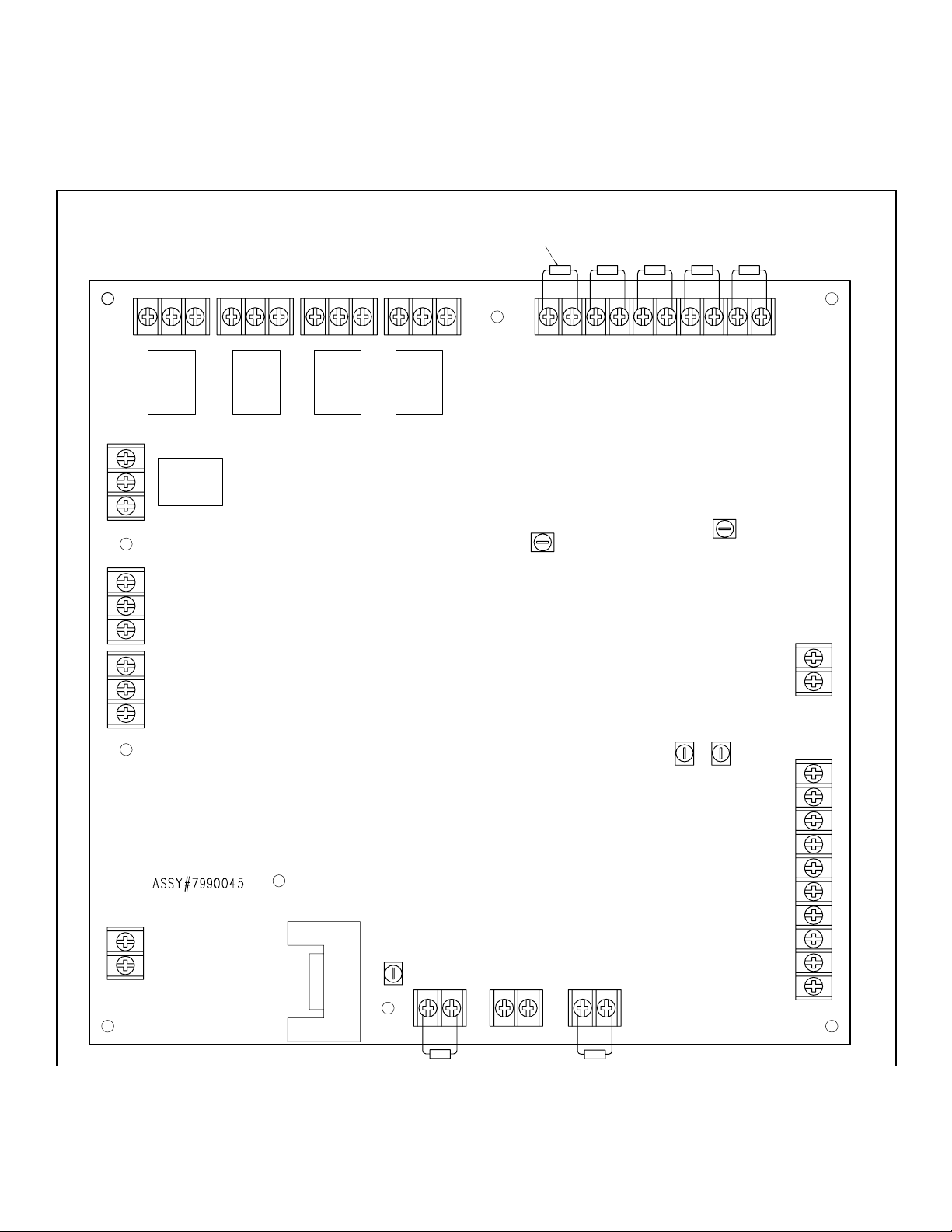

1. Connect the RS485 wire from +TX/RX (TB8) on the Master

Panel to terminal +TX/RX (TB8) on the Satellite Panel. Connect

the RS485 wire from -TX/RX (TB8) on the Master Panel to -TX/

RX (TB8) on the Satellite Panel.

Master Panel

MAIN ADJ

MAIN OUT

+TX/RX -TX/RX

POWER

SUPERVISION

MAIN OUT

2. Connect from MAIN OUT (+) (TB10) on the Master Panel to

SYS_AUD (+) (TB13) on the Satellite Panel. Connect from MAIN

OUT (-) (TB10) on the Master Panel to SYS_AUD (-) (TB13) on

the Satellite Panel ending the loop with a 2.2K ohm end-of-line

resistor (Part No. EOL-2.2).

3. Speaker/Amplifiers can be connected to the Satellite Panel as

described in Section 2.5. NOTE: Speaker/Amplifiers connected

to a Satellite Panel are NOT addressable and connections from

+TX/RX and -TX/RX are unnecessary.

Satellite Panel

+vs -vs

RPU/AUD

+

_

P_OUT PQ+

TB13

TAM_AUD

_

+

SYS_AUD

POWER

SUPERVISION

_

+

TB10

-

Out

In

Correct--separate incoming and outgoing conductors

In

TB8

10V RMS Audio

(or 5V RMS for live

voice evacuation)

Out

TB11

+-+

Incorrect Wiring Method

TB10

TB8

+TX/RX -TX/RX

Figure 6. Connecting Satellite Panels to the Master Panel

TB11

+-+-

To 5532M Series Speaker/Amplifiers

For speaker installation, see Figure 6

or the speaker instructions.

To Other Satellite Panels

or 2.2K ohm End of Line

Resistor (Cat. No. EOL-2.2)

P/N 3100471 ISSUE 3

PAGE 10

Page 11

d

2.5 - Connecting Speaker/Amplifiers

The Millennium System Master is capable of driving a total of 200

(64 of which can be addressable) 5532M Series speaker/amplifiers.

Connect the console to the speaker/amplifiers as described below

(See Figures 3 and 7).

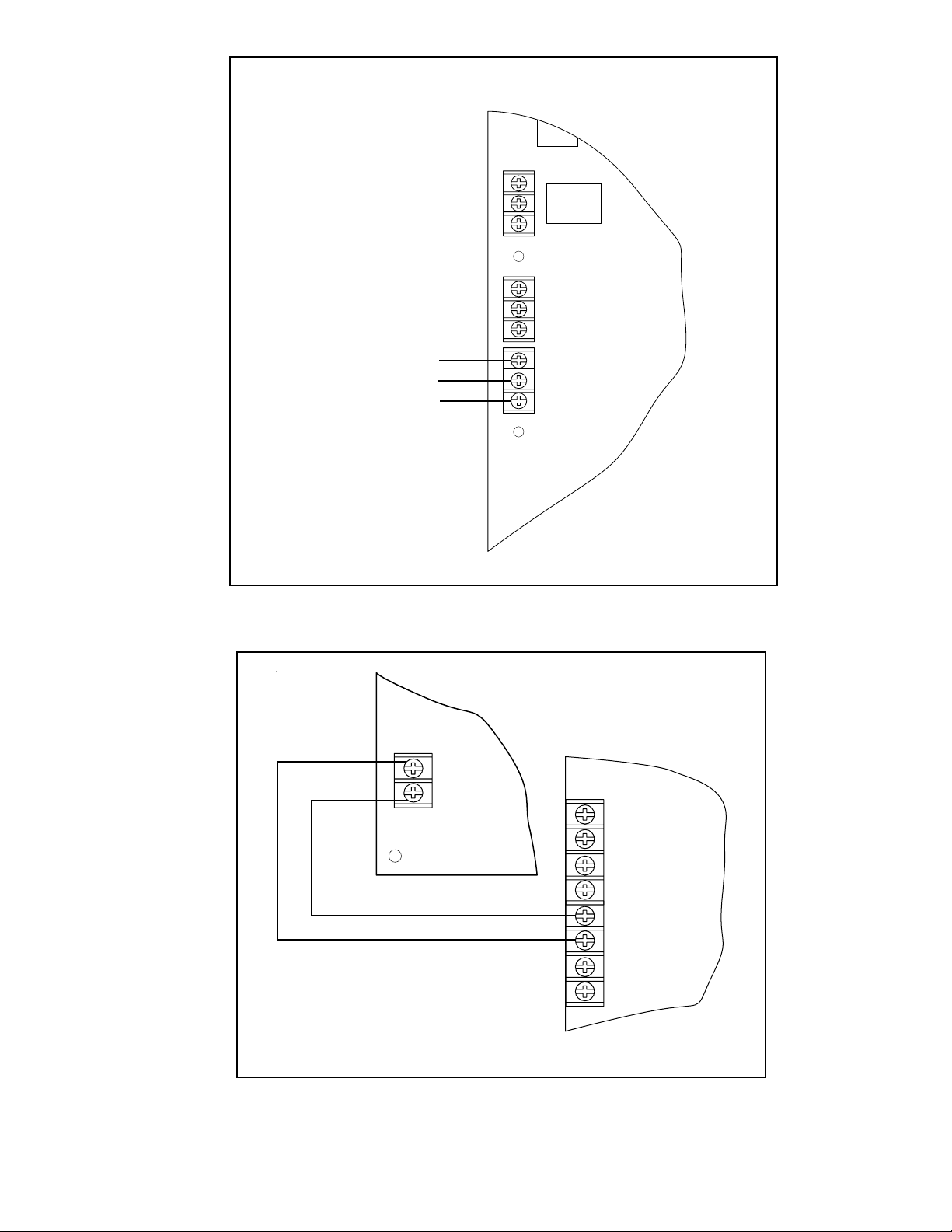

1. Connect 10V RMS audio line (or 5V RMS for live voice

evacuation) from "Main Out" (terminal block TB10) to the first

5532M speaker/amplifier. For connections to the 5532M

speaker/amplifier, refer to the instructions supplied with the

unit.

MAIN ADJ

MAIN OUT

TB10

-

+TX/RX -TX/RX

TB8

POWER

SUPERVISION

TB11

+-+

(-)

For systems with 5532M-485 Series Speaker/Amplifers installed,

To TX/RX terminals on RS485 comm board on 5532M speaker/amp

(+)

2. Continue to connect remaining 5532M series speaker/

amplifiers as shown in Figure 7 ending the loop with a 2.2K

end-of-line resistor (Part Number EOL-2.2).

3. For 5532M-485 Series speaker/amplifiers, connect the RS485

wire from +TX/RX (TB10) on the console board to terminal

+TX/RX on the RS485 COMM board. Connect the RS485 wire

from -TX/RX (TB10) on the console board to -TX/RX on the

RS485 COMM board. For further installation details for 5532M485 series, refer to installation instructions P/N 3100345.

RS485 COMM

EARTH

Board

-RELAY

5532M-485

Assembly

Processor Board

End-of-line resistor - 2.2K

Cat. No. EOL-2.2

NOTE: Do NOT use test

resistor (supplied) installe

on the MAIN OUT terminal

+TX/RX

-TX/RX

+RELAY

Potentiometer for

Volume Adjustment

10V RMS

Audio (or

5V RMS for

live voice evac)

AB

AUD + AUD -

5532M Series Audio Coupler Board

For detailed installation of 5532M

Series Speaker Amplifiers, refer

to the instructions supplied with

the unit.

AUD + AUD -

AB

Figure 7. Connecting 5532M Series Speaker/Amplifiers to Audio Main Out

2.6 - Connecting External Initiating Inputs

The initiating contacts operate on a pyramid-type priority system.

Output from a contact closure on Input 1 overrides the output from

a contact closure on Inputs 2, 3 and 4. The output from a contact

closure on Input 2 overrides the output from a contact closure on

Inputs 3 and 4. Likewise, the output from a contact closure on

Input 3 overrides the output from a contact closure on Input 4. The

output from a contact closure on Input 4 cannot override the output from any other external input.

Pri 1 Pri 2 Pri 3 Pri 4

Normally-open

initiating contacts

IN1 IN2 IN3 IN4

123456 78

AUD + AUD -

AB

AUD + AUD -

AB

In

Incorrect Wiring Method

Out

Correct--separate incoming and outgoing conductors

In

Out

1. Remove all test resistors from the input terminals. Install 4.7K

ohm resistors, Cat. No. EOL-4.7, on terminals that will not have

initiating contacts connected to them.

2. Connect normally-open initiating contact(s) to input terminals

IN1, IN2, IN3, IN4 on External Input terminal block, TB14 (see

Figures 3 and 8) as required. Install 4.7K ohm resistors, Cat.

No. EOL 4-7, at the end of each circuit as shown in Figure 8.

NOTE: If connecting an external input to a Fire Alarm Panel, refer to

Section 2.8.

End-of-line resistor 4.7K

Cat. No. EOL-4.7

TAM

910

TB14

PAGE 11

EXTERNAL INPUTS

Figure 8. Connecting Normally-Open Initiating Contacts

P/N 3100471 ISSUE 3

Page 12

2.7 - Connecting to Output Relay

Up to four loads can be connected to the external output relays.

Refer to Figures 3 and 9 for connections and to Appendix C, Panel

NOTE: See Appendix C, Panel Specifications,

for Maximum Contact Ratings

LOAD 1 LOAD 2 LOAD 3 LOAD 4

(L) 120V AC / + 24V DC

(N) 120V AC / -24V DC

NO1 C1 NC1 NO2 C2 NC2 NO3 C3 NC3 NO4 C4 NC4

TB1 TB2 TB3 TB4

Figure 9. Connecting Output Relays (General Purpose)

Specifications, for maximum contact ratings. Output relays are failsafe; if the relay coil is faulty, power to the panel is lost or the relay

driver fails, the relay, although de-energized, will activate and the

load will be energized.

2.8 - Connecting External Initiating Input to Fire

Alarm Panel

The System Millennium Control Master can be connected to a fire

alarm panel for use in evacuation of the building. Connect the fire

alarm panel through a Cat. No. 6254B-003 relay to the console as

shown in Figure 10.

1

22K

2

680 OHM

3

4

Fire Alarm Relay Cat. No. 6254B-003

Listed under: URRQ.S6604

Fire Alarm Panel

Polarity in

alarm condition

Polarity reverses

when in supervisory

mode

Fire Alarm

Panel EOL

Resistor

+

-

NOTE: When the System Master is used with a fire alarm panel,

Standby Power MUST be installed and enabled.

11

End-of-line resistor 4.7K

Cat. No. EOL-4.7

10

K1

9

K1

8

7

6

K1

5

End-of-line resistor 4.7K

Cat. No. EOL-4.7

Pri 2Pri 1 Pri 3 Pri 4

IN1 IN2 IN3 IN4

123456 78

TAM

910

TB14

P/N 3100471 ISSUE 3

EXTERNAL INPUTS

Figure 10. Connecting External Initiating Input to Fire Alarm Panel

PAGE 12

Page 13

2.9 - Connecting to a UL Listed Telephone

Access Module

Connect the System Millennium Master to a Telephone Access Module (TAM) as shown in Figure 11. Use only a UL Listed telephone

access module with a dry contact initiation and 600 ohm balanced

or unbalanced output

Test EOL resistors (supplied)

NOTE: Resistors replaced with Cat. No. EOL-4.7 for operation.

See Section 2.6.

IN1 IN2 IN3 IN4 TAM

123456 78910

TB14

EXTERNAL INPUTS

PLAYBACK ADJ

TB7

LOCAL ADJ

TAM LEVEL ADJ

TB13

UL Listed Telephone

Access Module (TAM)

Phone System

Paging Out

Contact Closure

+24 VDC

+

_

+vs -vs

RPU/AUD

+

_

P_OUT PQ+

TAM_AUD

_

+

SYS_AUD

_

+

T

R

PT

PR

N.O

COM

EOL 4.7K

p/n EOL-4.7

To Telephone System

POTS Line

PAGE 13

Figure 11. Connecting to Telephone Access Module (TAM)

P/N 3100471 ISSUE 3

Page 14

2.10 - Connecting to Remote Paging Units

Up to twenty-five 5542RPUs can be connected to the panel. The

first paging unit connected has the highest priority on the system

followed by decreasing priorities for the remainder of the 5542RPU

paging units connected in series. (Refer to Figures 3 and 12.)

All connections referred to below are made from terminals on terminal block TB13 on the System Master to terminal block TB1 on the

5542RPU.

1. Connect from +VS on the System Master to +VS on the

5542RPU.

2. Connect from -VS on the System Master to GND on the

5542RPU.

3. Connect from RPU/AUD + on the System Master to A+ on the

5542RPU.

4. Connect from RPU/AUD - on the System Master to A- on the

5542RPU.

5. Connect from P_OUT on the System Master to Pin on the

FIRST

5542RPU in the series.

6. Connect from PQ+ on the System Master to PQ on the 5542RPU.

7. Connect from Pout on the first 5542RPU in the series to Pin on

the next 5542RPU in the series. Repeat for each 5542RPU in

the series.

8. For ancillary use only--NOT supervised.

TB7

TB13

+24 VDC

+

_

+vs -vs

RPU/AUD

+

_

P_OUT PQ+

TAM_AUD

_

+

SYS_AUD

_

+

5542RPU 5542RPU

AUDO+

AUDO-

A

B

TB2

Pout

Pin

GND

A-

A+

Pq

+VS

TB1

Pout

Pin

AUDO+

AUDO-

A

B

TB2

A-

GND

+VS

Pq

A+

TB1

P/N 3100471 ISSUE 3

Figure 12. Connecting to a Cat. No. 5542RPU Remote Paging Unit

PAGE 14

Page 15

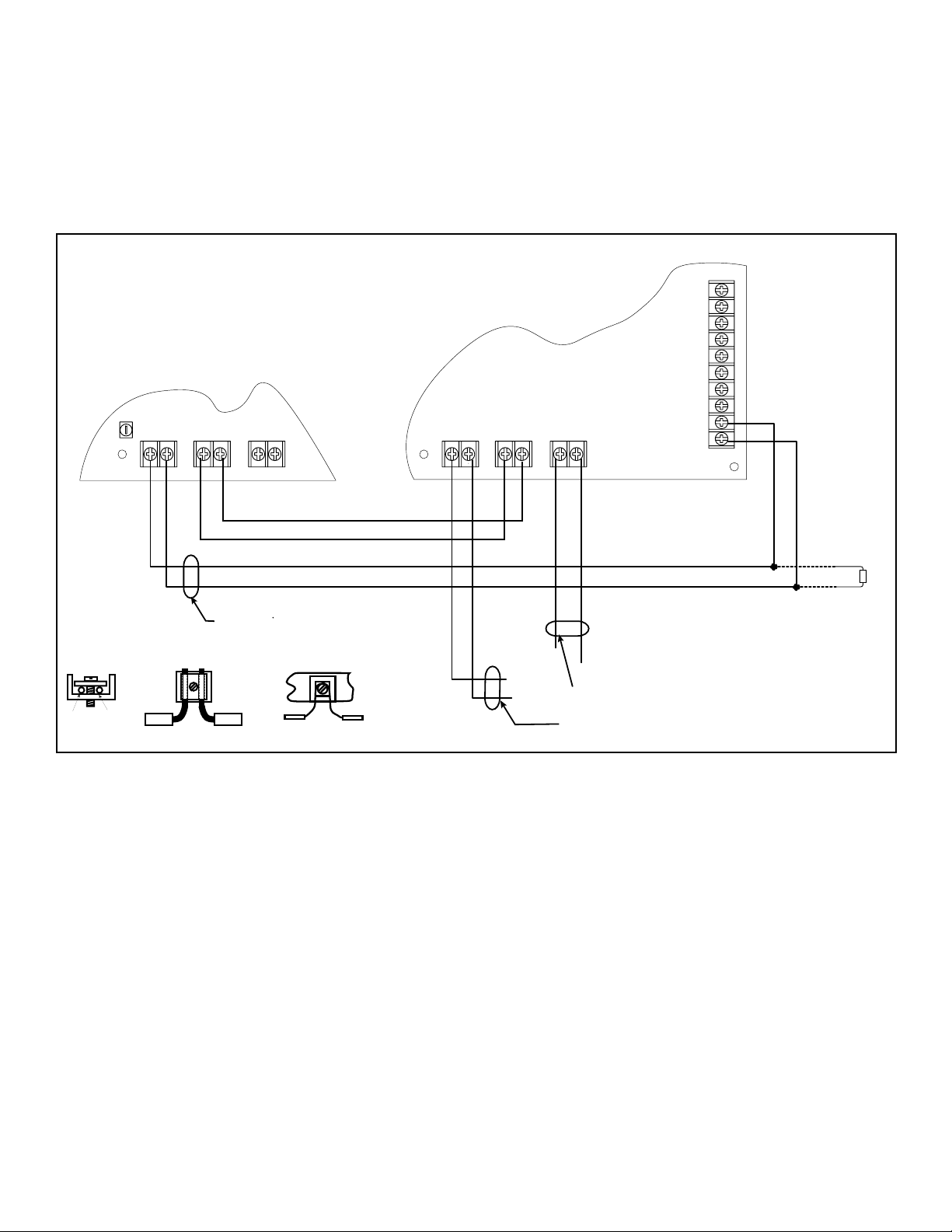

2.11 - Adjusting Audio Levels

Volume levels can be adjusted for main output, paging, playback,

local monitor speaker, and for telephone access module (TAM) audio. Refer to Figure 13 to see locations for potentiometers.

NOTE: Volume increases by turning the potentiometer clockwise.

Page Adjust - Adjusts local microphone level

Playback Adjust - Adjusts voice message level

Local Adjust - Adjusts level of local monitor speaker

EXTERNAL OUTPUTS

NO1 C1 NC1 NO2 C2 NC2 NO3 C3 NC3 NO4 C4 NC4

TB1 TB2 TB3 TB4

TAM Level Adjust - Adjusts level of external telephone audio coming from telephone access module

Main Adjust - Adjusts main system audio out. Needs to be at

minimum of 2.5V RMS. Adjusting the main system audio to less

than 2.5V RMS will result in a trouble indication.

Test EOL resistors (supplied)

NOTE: Resistors replaced with Cat. No. EOL-4.7 for operation.

See Section 2.6

IN1

IN2 IN3 IN4 TAM

12345678910

TB14

EXTERNAL INPUTS

TROUBLE

NC5

C5

NO5

WHT

BLK

G

N

L

+

K1

TB15

TB6

120-250 V AC/DC

TB5

STDBY POWER

TB9

K2 K3 K4

K5

MAIN ADJ

MAIN OUT

PAGE ADJ

SUPERVISION

POWER

LOCAL ADJ

PLAYBACK

ADJ

TAM

LEVEL

ADJ

+24 VDC

+

TB7

_

+vs -vs

RPU/AUD

+

_

P_OUT PQ+

TB13

TAM_AUD

_

+

SYS_AUD

_

+

PAGE 15

TB10

TB8

+TX/RX -TX/RX

TB11

Figure 13. Potentiometer Locations

+-+-

P/N 3100471 ISSUE 3

Page 16

Chapter 3 - Programming

3.1 - Overview

Program options and settings

The features and functions of the Millennium System Master are

programmable. To customize the panel, program it as described in

this chapter.

Programming Notes

To enable programming, you must insert the key (supplied with the

console) into the lock on the inside door (below the LCD panel) and

turn it clockwise 90°.

NOTE: The key cannot be removed when programming is enabled.

Pressing at any time during a setup will advance to the next

available setup screen.

Pressing (cancel button) at any time during setup mode will

exit the setup mode.

have made to the panel programming.

The panel will automatically exit setup mode if no buttons are

pressed for 60 seconds.

3.2 - Local Alarm Input Assignment

Allows any of the selected tone or voice messages to be programmed

to local alarm inputs 1 through 4 located on the front panel.

Using the LCD screen and the tone chart in Table 1 or located on the

inside front cover of the panel, press the button to enter the

"Setup mode." The LCD displays "Tone Label" with Input 1 and its

tone assignment as shown here.

1. Change the tone assignment on Input 1 by pressing the

(change button) button until the desired tone is reached.

NOTE: Pressing the (back button) at any time will change the

tone selection to the previously selected tone.

2. To change the tone assignment on Local Input 2 press the

(next button) and repeat step 1.

3. To change the tone assignment on Local Inputs 3 and 4 repeat

steps 1 and 2.

4. After changing the tone assignment on Local Input 4, press

to advance to Relay Setup Mode. Relay Assignment is

discussed in Section 3.3.

3.3 - Relay Output Assignment

Relay output assignment allows local alarm inputs, once activated,

to latch and control up to four relay outputs simultaneously. Relays

will deactivate once the user cancels the alarm input. Trouble relay

latches when supervisory or communication troubles are encountered.

From the LCD screen, press button until LCD displays:

P/N 3100471 ISSUE 3

Pressing cancel will not cancel changes you

Relays: R1 R2 R3 R4

Input 01 Y Y Y Y

In this program mode, both Local and External Inputs are assigned

to a combination of output relays K1-K4. When a Local or External

Input Alarm is selected, the configured relays will stay energized as

long as the alarm input is active. This is useful for driving other

industrial or control signals during tone and voice activation from

the panel.

1. In the “Relays: R1 R2 R3 R4” program mode, press the

button to deactivate the current relay R1 selection for

Input 1.

NOTE: "N" - the relay WILL NOT activate upon alarm or trouble

conditions on the displayed input

"Y" - the relay WILL activate upon alarm or trouble

conditions on the displayed input

2. Press to advance to the next available relay. Repeat step 1.

NOTE: Press to return to the previously programmed relay.

3. Repeat steps 1 and 2 to finish relay output assignment on

Relays R3 and R4 on Input 1.

4. Press to advance to the next alarm input, Input 2.

5. Repeat steps 1 - 4 for each of the 4 local inputs as required.

6. Pressing after activation/deactivation of Relay 4 on Local

Input 4 will advance to "Device Commission" setup. See Section

3.4.

3.4 - Device Commission

Device Commission allows for manual entry of serial devices located on the RS-485 data network. Once the device map is configured, devices will be continuously polled for their activity status.

Devices not responding to a POLL command from the Master Panel,

or devices reporting supervisory trouble can be viewed from the

Trouble View on the front panel.

When the panel is in Master mode, the setup screen allows manual

assignment and entry of serial devices into the device map and is

used for future polling and zoning of devices on the RS-485 communications network.

IMPORTANT: This should only be done when devices are being com-

missioned for the very first time or devices are removed or added to

the network. When a serial device is commissioned on the RS-485

network, it is assigned a unique physical address ranging from 00-3F

Hex (64 decimal addresses). No two devices should be assigned the

same address.

1. From the Master LCD screen, press until LCD displays:

Device Commission

Device: 00 Erased

NOTE: Device commission is only for use on the Master panel. If

Satellite panels are connected to the Master panel, all

devices on the satellite panel are non-addressable.

1. For each serial device on the network, press to display the

device address. Once that device is displayed, press to

store the device (or if the device has been removed from the

network, press to change it to "Erased.")

NOTE: Pressing the button at any time will jump back to the

previous serial device address.

NOTE: A device that is "Stored" will be polled by the Millennium

System Master. A device that has been "Erased" is NO

PAGE 16

Page 17

longer active in the device map and will not be addressed

during supervisory polling from the panel.

NOTE: "Stored" devices can also support zoning functions during

panel output activity.

3.7 - Panel Address Assignment

The panel address assignment is used only when the panel is in

Satellite mode. Each satellite panel must be assigned a unique

station address.

The valid address range is 00-3F.

3.5 - Dynamic Zone Control

When the panel is in Master mode, the Dynamic Zone Control (DZCTM)

program setup provides zone assigned for each of the serial devices "Stored" in the device map (See Section 3.4). The panel supports up to four zones but only one zone can be assigned to each

serial device.

The zone assignment assigns a zone to each serial device. If the

zone is not set, it will automatically default to Zone A.

TM

NOTE: Non-serial devices connected to the Millennium System

Master will be activated with any zone activation.

1. From the Master LCD screen, press until LCD displays:

Device Zone Assign

Device: 00 Zone: A

2. Press to change the displayed device to the desired zone

(A - D).

3. Press to advance to the next available serial device

configured in the device map.

4. Repeat steps 2 and 3 until all serial devices have been assigned

a zone.

NOTE: Serial devices not manually assigned zones will default to

Zone A.

NOTE: In order for a device to receive a new Dynamic Zone

Control assignment, the panel must complete one

successful poll to the unit. Please allow approximately 1

minute for poll completion prior to testing and verification

of zones.

3.6 - Communications Setup

Communications Setup allows for setup of the baud rate. Supported baud rates are: 1200, 2400, 9600, 19200. Default is 9600

BPS. Parity, data and stop bits are not programmable and are restricted to No Parity, 8 data bits and 1 stop bit.

NOTE: Before setting the panel baud rate, be sure to properly

1. From the LCD screen, press until LCD displays:

configure remote devices to the same baud rate as the

panel baud rate. This will avoid a trouble alarm associated

with communication failures on remote serial devices.

Refer to instructions supplied with remote devices for

settings.

CAUTION

T o av oid a comm unication failure, do not assign an

address that has been assigned to another serial

device on the network. See Section 3.4.

1. From either the LCD screen, press until LCD displays:

Set Panel Address

Address: 00

2. Press the button to advance to the next available address.

The valid address range is 00-3F.

3. Press the button to return to the previous address selection.

3.8 - Panel Mode

The panel must be configured as either a Master or Satellite panel.

Panels configured as Master will initiate poll requests, assign dynamic zones and communicate to serial devices. Panels configured

as Satellite will only reply to poll/status requests and accept dynamic zone commands from the Master Panel.

1. From the LCD screen, press the button until LCD displays:

Panel Mode

Mode: MASTER

2. Press the button to select the desired mode of operation.

NOTE: When changing from "Satellite" to "Master" mode, be sure

that previously "Stored" devices in the device map have

been configured properly for baud rate (Section 3.6) and

device commission selection (Section 3.4). This will

eliminate any possible communication trouble conditions

encountered once the panel resumes the polling sequence.

3.9 - Auto Learn Mode

The Auto Learn Mode allows for automatic entry and storage of

serial devices into the device map. During this program setup, the

panel will detect active devices on its RS-485 network and build a

device map based on the active devices found. The device map is

then stored in the panel's non-volatile memory indefinitely. As new

serial devices are added or removed from the network, this utility

should be run for updating the device map.

1. From the LCD screen, press the button until LCD displays:

Communications Setup

BAUD: 9600,N,8,1

2. Press to advance to the desired baud rate.

PAGE 17

AUTO LEARN MODE

<chg> - Yes, <func> - No

2. Press the button to begin auto learn mode detection.

NOTE: If you do not want to use the auto learn mode, pressing

will advance to the next setup screen.

P/N 3100471 ISSUE 3

Page 18

When the button is pressed, the panel will begin to poll all unit

addresses beginning at address 00 and ending at address 3F. As

devices are found, they are stored in the panel's device map. The

program setup will run two times for redundancy and reliability.

Once complete, the LCD screen with display:

AUTO LEARN COMPLETE

<func> - continued

Press button to advance to the next setup screen.

7. Pressing after activation/deactivation of Zone D on Input

4 will advance to "Voice Message Setup" menu. See

Section 3.11.

3.11 - Voice Message Setup

The panel features voice messaging capability. This program setup

allows the user to easily record and store voice messages in four

separate message locations. Voice messages can then be selected

and assigned to Local Alarm Inputs in the "Local Inputs" Assignment program setup screen.

After running the Auto Learn mode, devices detected and stored in

the device map should be verified by the user in the Device Commission program setup (See Section 3.4). Each configured device

can be viewed.

When devices are first stored in the device map, they are assigned

Dynamic Zone A. Dynamic zones for the individual devices can be

changed in the Device Zone Assignment Program Setup (See Section 3.5).

NOTE: In order for a device to receive a new Dynamic Zone

assignment, the panel must complete one successful poll

to the serial unit. Please allow approximately 1 minute for

poll completion prior to testing and verification of zones.

Only Master panels support Dynamic Zones.

3.10 - Zone to Input Assignment

Each serial device on the panel's RS-485 network can be assigned

a specific dynamic zone from A through D. Dynamic zone assigned

for each device configured in the device map is stored in nonvolatile memory. Each time a serial device is polled, its stored Dynamic Zone assignment command is sent out. When system audio

is initiated from the Master panel, those devices with matching

Dynamic Zones will broadcast the Master panel's system audio; all

other serial devices will be prohibited from the current audio broadcast.

NOTE: Non-serial devices connected to the Master panel will

broadcast system audio for any and all zones.

1. From the LCD screen, press the button until LCD displays

"Zones: A B C D" as shown below. From this mode, both local

and external alarm inputs can be assigned to a combination of

zones (up to 4 zones maximum for each alarm input)

CAUTION

The panel supervision must detect recorded audio in

each location or the panel will receive a trouble

indication.

From the LCD screen, press the button until LCD displays:

Voice Message Setup

Location: 01 REC-OFF

This mode allows recording and storage of voice messages for later

playback. The panel supports up to four five-second voice messages. Message lengths greater than five seconds are possible by

extending the recording length.

Note: Voice messages that become longer than five seconds will

physically require two or more message locations. For

example, a 20-second message would occupy all four

message locations limiting the user to only ONE message.

If a 20-second message is desired, record only in the first

message location (tone 17) and assign this location to any

four of the Local Alarm Inputs for playback. If other

locations are assigned for playback, the message may be

partial or incomplete. For a 15-second message, record in

the second message location (tone 18); for a 10-second

message, record in the third message location (tone 19).

Any of these messages can be assigned to any of the Local

Alarm Inputs.

To record a message:

ZONES: A B C D

Input 01 Y Y Y Y

2. To activate or deactive the current Zone for Alarm Input 1,

press the button. More than one zone can be active for

each input.

NOTE: "N" - the zone WILL NOT broadcast when the input is active

"Y" - the zone WILL broadcast when the input is active

3. Press to advance to the next zone. Repeat step 2.

NOTE: Press to return to the previously programmed relay.

4. Repeat steps 2 and 3 to finish zone to input assignment on

Input 1.

5. Press to advance to the next alarm input, Input 2.

6. Repeat steps 2 - 5 for each of the 4 local inputs as required.

P/N 3100471 ISSUE 3

1. Press the microphone's press-to-talk (PTT) button and speak

clearly into the microphone. When finished recording, release

the PTT button.

2. To advance to the next voice message location, press the

button.

3. Repeat steps 1 and 2 until all desired messages have been

recorded.

NOTE: To play back the message(s) that you have recorded,

cancel out of programming mode (by pressing) and activate

the local input with the voice message programmed on it.

If the voice message does not play, ensure that the input is

programmed to play the recorded message. See Section

3.2 and Table 1.

PAGE 18

Page 19

3.12 - Standby P o wer Mode

The panel can be programmed to accept standby power from

an Edwards EBPS10 auxiliary power supply or other UL regulated standby power source listed f or fire . When this f eature

is enabled, the standby power input is continuously monitored for integrity . When disabled, the standby power input is

only monitored when the panel has detected the loss of AC

main power .

NOTE: When the System Master is used with a fire alarm

panel, Standby P ower MUST be installed and

enabled.

3.14 - T e xt Output String

Millennium System Master Panel is capable of interfacing to Edwards

Message Center signs. Key inputs 1-4 can be programmed to recall

message sign file labels A-Z. Up to two file labels can be assigned to

each of the four key inputs. Each input can also address individual

signs between addresses 00 and FF.

Text Output String Format is as follows:

1. From the LCD screen, press the

displays:

Standby Power Mode

Mode: DISABLED

2. Press the button to enable/disable the standby power mode.

button until LCD

3.13 - Remote Programming

Millennium System Master panels can be programmed remotely

using Edwards System Master programmer P/N XXXXXX. Enabling

program mode to 'ready' begins to upload and download the sequence to the programmer. Once programming is complete, mode

will change back to disabled.

The panel will be inoperative until the program sequence is completed and the panel has timed out of setup mode.

Example: Text Output String

3.15 - Security

The panel programming can be secured after programming is complete. Using the keys supplied with the console, turn the lock on

the inside door (below the LCD panel) until it stops. In this position, all alarm and paging inputs can be activated but the function

key is disabled.

PAGE 19

P/N 3100471 ISSUE 3

Page 20

Table 1. Tone Programming

Tone Description HEX

Ding-Dong Percussive pairs of 700 and 570 Hz tones, each damped to zero 01

Warble 575 and 770 Hz alternately, 87 ms each 02

Siren 600-1250 Hz up and down sweep in 8 seconds and repeat 03

Stutter Percussive 470 Hz, 83 ms on, 109 ms off 04

Slow Whoop 600-1250 Hz upward sweep in 4 seconds and repeat 05

Beep 470 Hz, 0.55 seconds on, 0.55 seconds off 06

Chime 1 700 Hz percussive repeat at 1 Hz 07

Fast Whoop 600-1250 Hz upward sweep in 1 second and repeat 08

Hi/Lo 780 to 600 Hz alternately, 0.52 seconds each 09

Rapid Siren 600-1250 Hz up and down sweep in 0.25 seconds and repeat 0A

Yeow 1250-600 Hz downward sweep in 1.6 seconds and repeat 0B

Horn 470 Hz continuous 0C

Air Horn 370 Hz continuous 0D

Dual Tone 450-500 Hz, 0.4 to 0.5 second cycle 0E

Chime 2 575 Hz percussive repeat at 1 Hz 0F

Westminster Two measures, 411 Hz, 520 Hz, 407 Hz, 312 Hz 10

Three Blind Mice Four measures, 787 Hz, 714 Hz, 625 Hz, 952 Hz, 333 Hz 11

Phasor 416-625 Hz up and down sweep in 13 ms and repeat 12

Telephone 570 and 770 Hz alternately, 50 ms each for 1.2s, 1.5s delay and repeat 13

Staircase 440-2000 Hz up and down steps, 750 ms delay and repeat 14

3 Tone Alert 463, 641 and 896 Hz, 200 ms each, 1 second delay and repeat 15

Presignal Chime 470 Hz percussive repeat at 1.5 Hz, followed by Message 1 16

Message 1 Field recorded voice message 17

Message 2 Field recorded voice message 18

Message 3 Field recorded voice message 19

Message 4 Field recorded voice message 1A

NFPA Whoop Three 422-775 Hz upward sweeps, 850 ms each, 1s delay and repeat 1B

3 Pulse Horn 470 Hz, 3 0.5 second pulses separated by 0.5 seconds followed by a 1.5 second delay and repeat-3 Pulse Air Horn 370 Hz, 3 0.5 second pulses separated by 0.5 seconds followed by a 1.5 second delay and repeat-3 Pulse Dual Tone 450-500 Hz, 0.4 to 0.5 second cycle, 3 0.5 second pulses separated by 0.5 seconds followed by a 1.5 second delay and repeat-3 Pulse Chime 2 575 Hz, 3 0.5 second pulses separated by 0.5 seconds followed by a 1.5 second delay and repeat-European Police 969 Hz and 800 Hz alternately 0.250 seconds each 20

European Fire 982 Hz and 864 Hz downward sweep in 0.134 seconds 21

European Slow Whoop 658 Hz to 1312 Hz upward sweep in 3 seconds followed by 0.5 second delay and repeat 22

European General 1087 Hz for 0.5 seconds followed by 0.5 second delay and repeat 23

European Toxic 982 Hz continuous 24

European Police 2 554 Hz and 440 Hz alternately 0.800 seconds each 25

European Stutter 3876 Hz for 0.146 seconds followed by 0.102 seconds delay and repeat 26

European Sweep 1315 Hz to 413 Hz downward sweep in 1.17 seconds and repeat 27

Telephone 2 Alternate tones at 567 Hz and 326 Hz, for 0.052 seconds each 28

Buzzer 1 1315 Hz and 746 Hz alternating for 0.003 seconds each 29

Genesis Horn Cont. Continuous Genesis horn 2A

Genesis Horn Temp. Temporal Genesis horn 2B

Warning 1 1207 Hz and 493 Hz, alternately 0.002 seconds each 2C

Warning 2 2336 Hz and 493 Hz, alternately 0.005 seconds each 2D

Warning 2 Beep 0.500 second of 2336 Hz and 493 Hz, each alternating for 0.005 seconds, followed by 1 second delay 2E

Caution 453 Hz for 0.040s, 235 Hz for 0.020s, 235 Hz for 0.160s, 260 Hz for 0.050s, 260 Hz for 0.1009s, 235 Hz for 0.050s 2F

Multi-Tone 376, 357, 352, 382, 355, 375, 384, 375 and 364 Hz alternately on for 0.050 seconds 30

Attention 2232, 4545, 3704, 2777, 4347, 3704, 2500 Hz alternately on for 0.003 seconds 31

High Freq. StdyAlert 2500 Hz continuous 32

High Freq. Fast Siren 2500 to 3048 Hz up and down sweep in 0.130 seconds 33

High Freq. Slow Siren 2500 to 3048 Hz up and down sweep in 0.500 seconds 34

DIN PFEER Ramp downward from 1336 Hz to 522 Hz in 1.2 seconds and repeat 35

NFS 32 001 584 Hz for 0.100 seconds and 461 Hz for 0.400 seconds 36

Ode to Joy 6.45 seconds of melody followed by 1 second delay and repeat 37

Twinkle Little Star 13.2 seconds of melody followed by 1 second delay and repeat 38

Dueling Banjos 10.84 seconds of melody followed by 1 second delay and repeat 39

La Cucaracha 7.10 seconds of melody followed by 1 second delay and repeat 3A

Yellow Rose of Texas 19.34 seconds of melody followed by 1 second delay and repeat 3B

Presignal Message 2 470 Hz percussive repeat at 1.5 Hz, followed by Message 2 3C

Presignal Message 3 470 Hz percussive repeat at 1.5 Hz, followed by Message 3 3D

Presignal Message 4 470 Hz percussive repeat at 1.5 Hz, followed by Message 4 3E

Non Repeating Voice Msg 1 Non Repeating Field Recorded Voice Message 3F

Non Repeating Voice Msg 2 Non Repeating Field Recorded Voice Message 40

Non Repeating Voice Msg 3 Non Repeating Field Recorded Voice Message 41

Non Repeating Voice Msg 4 Non Repeating Field Recorded Voice Message 42

For Evacuation Use Only

For Evacuation Use Only

For Evacuation Use Only

For Evacuation Use Only

1C

1D

1E

1F

P/N 3100471 ISSUE 3

PAGE 20

Page 21

Chapter 4 - Maintenance

4.1 - Preventive Maintenance

Before commencing testing, notify all areas where the alarm sounds

and off-premises locations that receive alarm and trouble transmissions that testing is in progress.

• Records of all testing and maintenance shall be kept as required

by the authority having jurisdiction.

• A complete check of installed field wiring and devices should

be made at regular intervals in accordance with NFPA 72

requirements. This includes testing all alarm and supervisory

initiating devices and circuits and any off-premises connections.

• Panel operation should be verified in the alarm, supervisory

and trouble modes.

• To ensure that the panel can be powered when primary power

is lost, standby power to the panel should be periodically

inspected, tested, and replaced (at a minimum) every four years.

• Required tools:

- Slotted or Phillip style #2 screwdriver, insulated

- Alligator style jumper clips (12 inch lead length)

- Digital multi-meter

- Front panel door key

- Program mode security key

- Sound level meter

4.2 - Preventive Maintenance Schedule

Refer to NFPA 72, Chapter 7, Inspection, Testing and Maintenance

for more information on required inspection and testing methods

and frequency of fire alarm systems and devices. For detector

sensitivity and functionality testing, refer to the detector

manufacturer's installation instructions.

PAGE 21

P/N 3100471 ISSUE 3

Page 22

Chapter 5 - LCD Messages and Troubleshooting

5.1 - Normal Mode

When in normal mode, the following messages will be displayed on the LCD screen of the Millennium System Master. It should be noted

that the zones shown below will not appear if the panel is in satellite mode.

Display Illuminated LED's Description

None Displayed when the panel is in St andby

mode. If panel is set for Master , bottom

line will be as shown. If panel is set as

Satellite, bottom line on LCD display will

read "SA TELLITE MODE." Panel is

performing supervision while this message is being displayed.

None Displayed when the panel microphone

push to talk (PTT) button is depressed.

Message will return to normal upon

release.

Input LED (1, 2, 3, or 4) When alarm is activated using local

based on input key selected inputs 1, 2, 3 or 4 on the keypad, the

display will show "TONE OR VOICE

LABEL." Message will return to standby

message when cancel/alarm silence key

is pressed.

External Input Displayed when the telephone access

input is activated via contact closure from

the UL Listed telephone access module

interface. Message will return to standby

message upon contact release.

P/N 3100471 ISSUE 3

PAGE 22

Page 23

Display Illuminated LED's Description

External Input Displayed while a message is being sent

via a 5542RPU microphone. Message

will return to standby message once the

RPU request line is inMactive.

External Input on Displayed with the panel is in Satellite

Satellite panel Mode and a serial system audio com-

mand is received, along with the zone

qualifier, the panel will switch on and

pass sytem audio through to its conventional system amplifiers. Message will

return to standby message when either a

serial system audio disable command is

received or if the user presses the

cancel/alarm silence key .

5.2 - Troubleshooting and Trouble Messages

When in trouble mode, the following messages will be displayed on the LCD screen of the Millennium System Master. When a trouble

indication is received, the trouble LED will illuminate and the display will read as shown below. The number after "TROUBLE STATUS"

indicates the number of troubles the panel has received. To view the trouble, press the button. If more than one trouble status exists,

you can press the button again to see each of the remaining indications. The following information will describe the trouble

indications, what they mean and possible solutions to the problem.

Display Illuminated LED's Description

Trouble Wiring is faulty on MAIN OUT terminals.

The panel is not able to detect the end-ofline resistor on the line. Ensure that endof-line resistor is properly connected and

wiring loop is not broken or shorted.

PAGE 23

P/N 3100471 ISSUE 3

Page 24

Display Illuminated LED's Description

Trouble The panel has detected a missing end-of-

line resistor, trouble with wiring (break in

wiring or fault wiring), or a speaker/

amplifier has lost power.

Trouble The panel has detected bad wiring or a

faulty or missing end-of-line resistor on

one of the external input contacts.

Trouble The amplifier or associated circuitry is

faulty , MAIN OUT volume adjustment is

set below 2.5V RMS.

T o increase MAIN OUT volume, turn the

potentiometer located on the main PC

board clockwise. Press the

button

to silence the trouble see if the trouble

has been cleared.

Trouble (1) or more message locations are empty

or the associated circuitry is faulty .

Message locations can be checked by

pressing the input button that the message location is associated with. If the

message location is not being used, it

can be temporarily assigned to an input

contact. See Chapter 3 - Programming.

NOTE: In the case of voice message failure,

the System Master will automatically generate

a 3 Pulse evacuation tone within 30 seconds of

an evacuation alarm activation. All four LEDs

associated with the input keys will be illuminated during this activation.

Trouble Indication caused by a decrease of the

battery backup voltage to less than 19V .

Check to see that the battery backup is

connected properly and that the batteries

are properly charged.

P/N 3100471 ISSUE 3

PAGE 24

Page 25

Display Illuminated LED's Description

Trouble Indication occurs when the microphone is

missing or wiring is faulty .

Trouble When Standby Power Mode is enabled

and AC power is lost, this indicates that

the panel is running on battery backup

Trouble Panel has lost communication with serial

device indicated.

Trouble Satellite panel assigned to this device

address is reporting a trouble condition

on one or more functions. To see the

trouble indications, you must use the

TRBL VIEW on the satellite panel.

PAGE 25

P/N 3100471 ISSUE 3

Page 26

Appendix A - Calculations

NOTE: Base panel includes the main controller board with no

system audio output loading and only EOL resistors.

Battery calculation worksheet

Use this worksheet to determine the minimum amperage capacity

required for the panel's standby power source. You can obtain

operating current requirements for amplifier units from their respective installation sheets. For 5532M series amplifiers, the audio

signal draw for each audio amplifier is approximately 2 mA at

470 Hz.

Standby

Current (mA)

Base Millennium System Master

Panel [1]

RPU Current draw

(See Form A)

Audio Amplifier Loading

(See Form B)

Total Current

Required standby and alarm time x

0

Standby time

24 or 60 hour

Standby current: Master and Satellite - 230 mA

Alarm current: Master and Satellite - 215 mA

NOTE: Alarm current with no amplifier loading is less because EOL

resistor path is opened during alarm condition and closed

during supervision.

Alarm

Current (mA)

0

x

Alarm time 5 min = 0.083

10 min = 0.167

15 min = 0.250

30 min = 0.500

mAh +

mAh = mAh

Battery amp hour total =

Minimum battery size [2] =

/1000

Ah

x 1.2

+ 0.25

Ah

Form A

Product Quantity current current (mA) current current (mA)

5542RPU 5 22

Standby Qty x Standby Paging Qty x Paging

(mA)

Total RPU

Current [2]

[1] See Appendix C for the maximum number of amplifiers supported by the panel.

[2] RPU power supplied by panel cannot exceed 0.55A (paging current). If more than 0.55A is required, you must reduce number of RPU

devices supplied by the panel.

P/N 3100471 ISSUE 3

PAGE 26

Page 27

Form B

a

Audio Audio Amplifiers [1] Amplifier Current (quantity x Amplifier current in mA)

Amplifier Draw (mA)

5532M

Quantity of Individual Total Current Draw

Total current draw for all amplifiers =

[1] See Appendix C for the maximum number of amplifiers supported by the panel.

5532M Audio Amplifier Voltage Dr op Calculation

Circuit length (single conductor) Total Circuit Wire resistance Voltage

feet x 2 x Amps X ohms /1000 =

current to unit per 1000 ft [1] drop

Audio output from panel or Voltage drop End of line

previous unit's End of line circuit voltage [3]

-=

Itotal = 6 mA

2 mA

Panel

Panel Audio

Ouput Voltage

Voltage drop between

Panel and Unit 1

Unit

End of Line Voltage

Voltage drop Audio output from Voltage

Unit N

End of Line Volt

2 mA

12N

Voltage drop between

Unit 1 and Unit N

panel or previous unit's drop %

end of line circuit [2]

/=

2 mA

Example -- Determine voltage drop from Panel to Unit 2

Steps

1. Obtain single conductor wire legnth from Panel to Unit 2.

2. Obtain total circuit current from Panel's audio output

3. Using wire type from below and table from above, calculate voltage drop to Unit 2.

4. Unit 2 End of Line Voltage = Panel Audio Output or Previous Unit's End of Line V oltage - Unit 2 V oltage Drop

Notes

[1] Use 1.6 for 12 A WG and 2.5 sq mm wire, 2.6 for 14 A WG and 1.5 sq mm wire, 4.2 f or 16 AWG and 1.0 sq mm wire and 6.6

for 18 A WG and 0.75 sq mm wire

[2] Panel audio output voltage is 10.6V

[3] In order to produce a minimum 75 dBA output, voltage should not be less than 9V

PAGE 27

rms

rms

P/N 3100471 ISSUE 3

Page 28

5532M Amplifier Circuit Maximum Wire Length Calculation

Use this worksheet to determine the maximum wire length of

an Audio Amplifier appliance circuit. Fill in one worksheet for

each Audio Amplifier appliance circuit connected to the panel.

Wire length matrix

Wire lengths in the following table are based on a voltage drop

of 1.6 volts or 15% of the Panel's audio output End of line

appliance.

Maximum signal loss allowed [1]

Wire resistance per 1000 ft/pair x 2 [2]

(2x the number in note 2)

Total operating current required

Maximum wire length

x 1000

/

/

V

ohms

ohms

A

ft

Current Maximum wire length (ft)

required (A) 18 AWG 16 AWG 14 AWG 12 AWG

0.25 584 950 1460 2170

0.50 292 474 730 1084

0.75 194 316 486 722

1.00 146 236 364 542

1.25 116 190 292 434

1.50 92 158 242 362

Notes

[1] 1.6V

loss in order to produce 75 dBA minimum.

rms

[2] Use 1.6 for 12 A WG and 2.5 sq mm wire, 2.6 for 14 A WG and 1.5 sq mm wire, 4.2 for 16 A WG and 1.0 sq mm wire and 6.6

for 18 A WG and 0.75 sq mm wire

P/N 3100471 ISSUE 3

PAGE 28

Page 29

Suggested Network Topology Node Schemes

(b)(a)

(d)(c)

PAGE 29

P/N 3100471 ISSUE 3

Page 30

Appendix B - Programming Template

(1) Project Name Project Address

Programmed by Date Tested by Date

(2) Local Input Assignment

Input 1 - Tone #

Input 2 - Tone #

Input 3 - Tone #

Input 4 - Tone #

(3) Output Relay Assignment

Relays R1 R2 R3 R4

YN YN YN YN

Input 1

Input 2

Input 3

Input 4

(4) Alarm Input to Zone Assignment

Zones ZA ZB ZC ZD

YN YN YN YN

Input 1

Input 2

Input 3

Input 4

(5) Communications Setup

Baud Rate 1200 2400 9600 19200

(6) Satellite Panel Address

Satellite Unit Name Address

(7) Panel Mode

Mode Master Satellite

(8) Standby Power Mode

Mode Enabled Disabled

(9) Device Map and Dynamic Zone Assignment

Device

Address Description Zone Erased Stored

(Circle one only)

00 A B C D

01 A B C D

02 A B C D

03 A B C D

04 A B C D

05 A B C D

06 A B C D

07 A B C D

08 A B C D

09 A B C D

0A A B C D

0B A B C D

0C A B C D

0D A B C D

0E A B C D

0F A B C D

10 A B C D

11 A B C D

12 A B C D

13 A B C D

14 A B C D

15 A B C D

16 A B C D

17 A B C D

18 A B C D

19 A B C D

1A A B C D

1B A B C D

1C A B C D

1D A B C D

1E A B C D

1F A B C D

P/N 3100471 ISSUE 3

PAGE 30

Page 31

Appendix B - Programming Template (Cont'd)

(1) Project Name Project Address

Programmed by Date Tested by Date

(9) Device Map and Dynamic Zone Assignment (Cont'd)

Device

Address Description Zone Erased Stored

(Circle one only)

20 A B C D

21 A B C D

22 A B C D

23 A B C D

24 A B C D

25 A B C D

26 A B C D

27 A B C D

28 A B C D

29 A B C D

2A A B C D

2B A B C D

2C A B C D

2D A B C D

2E A B C D

2F A B C D

30 A B C D

31 A B C D

32 A B C D

33 A B C D

34 A B C D

35 A B C D

36 A B C D

37 A B C D

38 A B C D

39 A B C D

3A A B C D

3B A B C D

3C A B C D

3D A B C D

3E A B C D

3F A B C D

PAGE 31

P/N 3100471 ISSUE 3

Page 32

Appendix C - Panel Specifications

External Initiating Contact Closure

Device Circuits (EID) Initiating Circuit 4 total

5532M Series Audio

Amplifier Circuits Class B, Style Y 200 maximum

Maximum System Audio Output to

5532M Amplifier units 1.0 amp @ 10V RMS at ambient 25C

Standby Current Alarm Current

AC input* 120V AC 50/60 Hz 0.14A 0.37A

240V AC 50/60 Hz 0.10A 0.22A

Base panel DC current draw** 230 mA 215 mA

Battery standby voltage 19 - 25.7V DC

+VS RPU supply current (max.) 0.55A (used for Remote Paging Units)

+VS RPU output voltage +24V DC + 10% (main AC power present),

19 - 25.7V DC (battery standby)

System Audio Output Circuit Maximum loop resistance: 26 ohms

Maximum loop capacitance: 440

External Initiating Device Circuit Maximum loop resistance: 13 ohms

Maximum loop capacitance: 15 µF

Alarm and Trouble Output Contact Form C: 4A @ 30V DC (resistive load)

Form C: 5A @ 240V AC (general use)

Environmental Temperature: 0 - 49C (32 - 120F)

Humidity: 5 - 93% relative humidity, non-condensing

Terminal rating All terminals rated for 12 to 18 AWG (0.75 to 2.5 sq mm)

Serial communications Style 4 Asynchronous communications

Communication Maximum resistance: 13 ohms

Circuit Maximum capacitance: 0.03

*Full system load (except max. RPU loading)

**No load except EOL resistors on System Audio Out and External Initiating Input contacts

µF

µF

P/N 3100471 ISSUE 3

PAGE 32

Page 33

Appendix D - Wiring

MAINTAIN 1/2” (12.7mm) SEPARATION BETW EEN

LISTED FOR FIRE

POWER SOURCE

UL REGULATED

EBPS10 OR A

STANDBY

1 = NON PO W ER LIMITED

ROUTING OF A LL PO W ER LIMITED TO NON PO W ER

LIMITED WIRING . USE SEPARATE CONDUIT

KNOCKOUTS W HERE REQUIRED

TO

SUPERVISED

+

-

1

STDBY

POW ER

PRIMARY POWER SOURCE

BATTERY. DISCONNECT

WAIT 30 SECONDS FOR

PROPER CAPACITANCE

DISCHARGE

2 = POW ER LIMITED

COMM BOARD ON 5532M

SPEAKER/AMPLIFIERS

TERMINALS ON RS485

STYLE 4 SLC CIRCUIT

SUPERVISED

FOR SERVICE CONTACT:

TELEPHONE NUMBER ____________________________________

AUDIO COUPLER BOARD ON 5532M

ADDRESS ____________________________________

NAME ____________________________________

10VRMS 1 AMP MAX

CLASS B, STYLE Y SUPERVISED

SPECIAL HANDLING

PRECAUTIONS

REQUIRED

P/N 3301978 ISS 2

SPEAKER/AMPLIFIER

2.2K

UNIT

AUD -

AUD -

EOL

OR TO

NEXT

INSTALLED, TO TX/RX

AUD +

AUD +

SENSITIVE

FOR SYSTEMS WITH

5532M-485 SERIES

+

-

AB

AB

EOL

2.2K

CONFIGURED AS A SATELLITE

SUPER VISED

OUT TERMINALS OF MASTER PANEL. SEE

INSTRUCTION MANUAL IF

WHEN CONNECTED TO MAIN

CONTENTS STATIC

ATTEN TION

THIS UNIT IS

CIRCUIT

SUPERVISED

DISCONNECT LEADS FROM

BEFORE SERVICING

-

+

+

-

-

+

10VRMS

SYSTEM

120/240 VAC

DEDICATED

BRANCH

TO

N

L

W ARNING

MAIN

OUT

TX/RX+

TX/RX-

POW ER

SUPERVISION

SYS

AUD

-

+

PR

PT

T

R

NO

C

TERMINALS

9 & 10 (TAM)

TO PHONE

INSTALLED

FACTORY

WHT

BLK

1

N05

N05

C5

TROUBLE

K6

1

INSTRUCTION MANUAL

P/N 3100471

MAIN

ADJ

WIRING AND WARRANTY

INFORMATION PLEASE

REFER TO THE

FOR SPECIFIC

CONTACT CLOSURE

SUPERVISED

2

LOCAL

2

NON-SUPERVISED

TAM

PQ

+POUT

AUD

-

+

UL LISTED TAM

TO PANELS

EXT. INPUT

ADJ

LEVEL

ADJ

RPU

VS

AUDVS- +24VDC

+

TO NEXT

5542RPU

(Pin)

WIRING

INITIATING

TAM

A+A-PinPo

PQ

+VSGND

POWER LIMITED

INDICATES NON

SHADED AREA

FROM L TO N AND L TO G

HIGH +VOLTAGE

W ARNING

K1 K4

K3K2

N01

NC1 NC2 NC3 NC4 EXTERNAL INPUTSC1

N02 N03 N04

EXTERNAL OUTPUTS

FAIL SAFE RELAYS

C2 C3 C4

EOL 4.7K

2

1 2

IN 1

3 4

IN 2

5 6

IN 3

EOL

TO TAM

NO, C

PAG E

ADJ

ADJ

PLAYBACK

4.7K

N.O. CONTACTS

7 8

IN 4

TAMB

9 10

CONTACTS

2

-

+

INSTALLED

FACTORY

ALL SOURCES OF POWER PRIOR TO

ADDITIONAL POWER SOURCES MAY

WITHIN THIS PANEL. DISCONNECT

BE CONNECTED TO CONTACTS

WORKING ON THIS SYSTEM.

W ARNING

5542RPU-M

PAGE 33

P/N 3100471 ISSUE 3

Loading...

Loading...