Page 1

Installation Instructions for Catalog Series 5536M-24 and

5536MHV-24 Adaptatone

®

Millennium Local/System Signal

Electrical SpecificationsElectrical Specifications

Electrical Specifications

Electrical SpecificationsElectrical Specifications

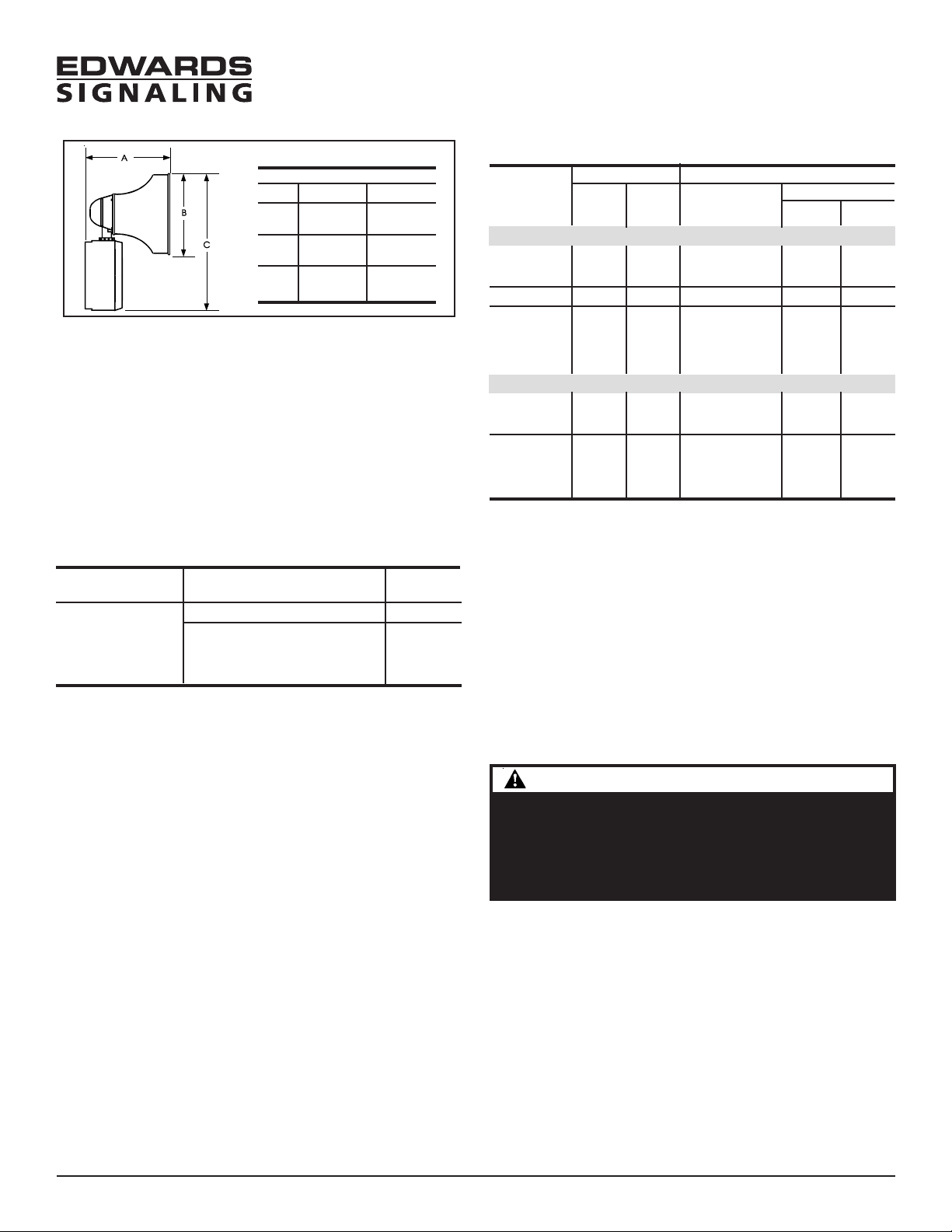

Dimensions

5536M 5536MHV

A 8 7/8" 11 1/2"

(225 mm) (292 mm)

B 8 1/4" 9 3/4"

(210 mm) (248 mm)

C 13" 16 1/2"

(330 mm) (419 mm)

Figure 1. Dimensions

Description and OperationDescription and Operation

Description and Operation

Description and OperationDescription and Operation

Edwards Adaptatone is a heavy-duty , tone-selectable, stand

alone, indoor/outdoor audible signaling device intended

for industrial applications where high audible output and

microcomputer reliability are required. Catalog Numbers

ending with suffixes -24AQ or -24Y6 are CE Marked and

TUV-RHEINLAND Certified for compliance to the European

Union's Electromagnetic Compatibility (Industrial) and Low

Voltage Safety Directives (see Declaration of Conformtiy,

available upon request). Additionally, the Adaptatone

Millennium series are UL and cUL Listed as Audible Signal

Appliances for use in the following hazardous locations.

Catalog Hazardous Temp.

Number Locations Code

5536M-24AQ Class I, Div. 2, Groups A, B, C, D T4 (135C)

5536M-24N5 Class II, Div. 2, Groups F, G T5 (100C)

5536M-24Y6 Class III, Div. 1 and 2

5536MHV-24AQ

5536MHV-24Y6

The Adaptatone operates from local power and sounds a

high decibel signal determined by the setting of miniature programming switches inside the unit. The

Adaptatone may be programmed for any of the 27 tones

listed in Figure 11.

Three tones may be programmed into the unit at any time.

These tones operate on a pyramid-type priority system.

The tone programmed on SW2 overrides the tones programmed on SW3 and SW4. The tone on SW3 overrides

the tone programmed on SW4. An external audio signal

up to 12V RMS can be connected to take priority over all

internally generated tone signals.

The decibel output level and speaker lateral position are

both easily adjustable.

Mechanical SpecificationsMechanical Specifications

Mechanical Specifications

Mechanical SpecificationsMechanical Specifications

Weight ...................................................9 Pounds (4.1 kg)

Hazardous Locations, UL Standard UL1604

Ambient T emp. ................... +41F to +104F (+5C to +40C)

Non-Hazardous Locations

Variable Ambient Temp. .....-40F to +151F (-40C to +66C)

Hazardous Locations and Variable Ambient Conditions apply only

where UL listings are accepted and do not apply to CE conformity or

TUV-Rheinland Certification.

Input Board Main Power

Catalog Current (A)

Number Voltage Current Voltage Standby Tone On

Standard Volume

5536M-24AQ 24V DC 6 mA 24V DC 0.10 0.74

5536M-24N5 24V DC 6 mA 120V AC 50/60 Hz 0.10 0.36

5536M-24Y6 24V DC 6 mA 125V DC* 0.10 0.21

High Volume

5536MHV-24AQ 24V DC 6 mA 24V DC 0.10 1.5

5536MHV-24Y6 24V DC 6 mA 125V DC* 0.10 0.39

*CE mark and TÜV-Rheinland Certifications do not apply to 125V DC or 250V DC.

InstallationInstallation

Installation

InstallationInstallation

24V AC 50/60 Hz 0.10 1.3

250V DC* 0.02 0.10

120V AC 50/60 Hz 0.10 0.32

240V AC 50/60 Hz 0.10 0.20

24V AC 50/60 Hz 0.10 2.3

250V DC* 0.02 0.19

120V AC 50/60 Hz 0.10 0.56

240V AC 50/60 Hz 0.10 0.34

The Adaptatone may be mounted to any flat surface or

may be used as a freestanding unit mounted to a rigid

pipe. The Adaptatone must be installed in accordance

with the latest edition of the National Electrical Code or

other regulations applicable to the country and locality

of installation and by a trained and qualified electrician.

NOTE: The increased resistance due to long wire runs

needs to be accounted for in sizing wire.

Consult Applications Engineering for details.

For catalog numbers ending in "AQ", 24V AC power must

be transformer isolated from mains or line power .

WARNINGWARNING

WARNING

WARNINGWARNING

T o prevent fire, shock and component damage, NO work,

including circuit board removal, should be performed while

the circuit is energized.

NOTE: Any kind of service or maintenance performed

while unit is energized will void the warranty.

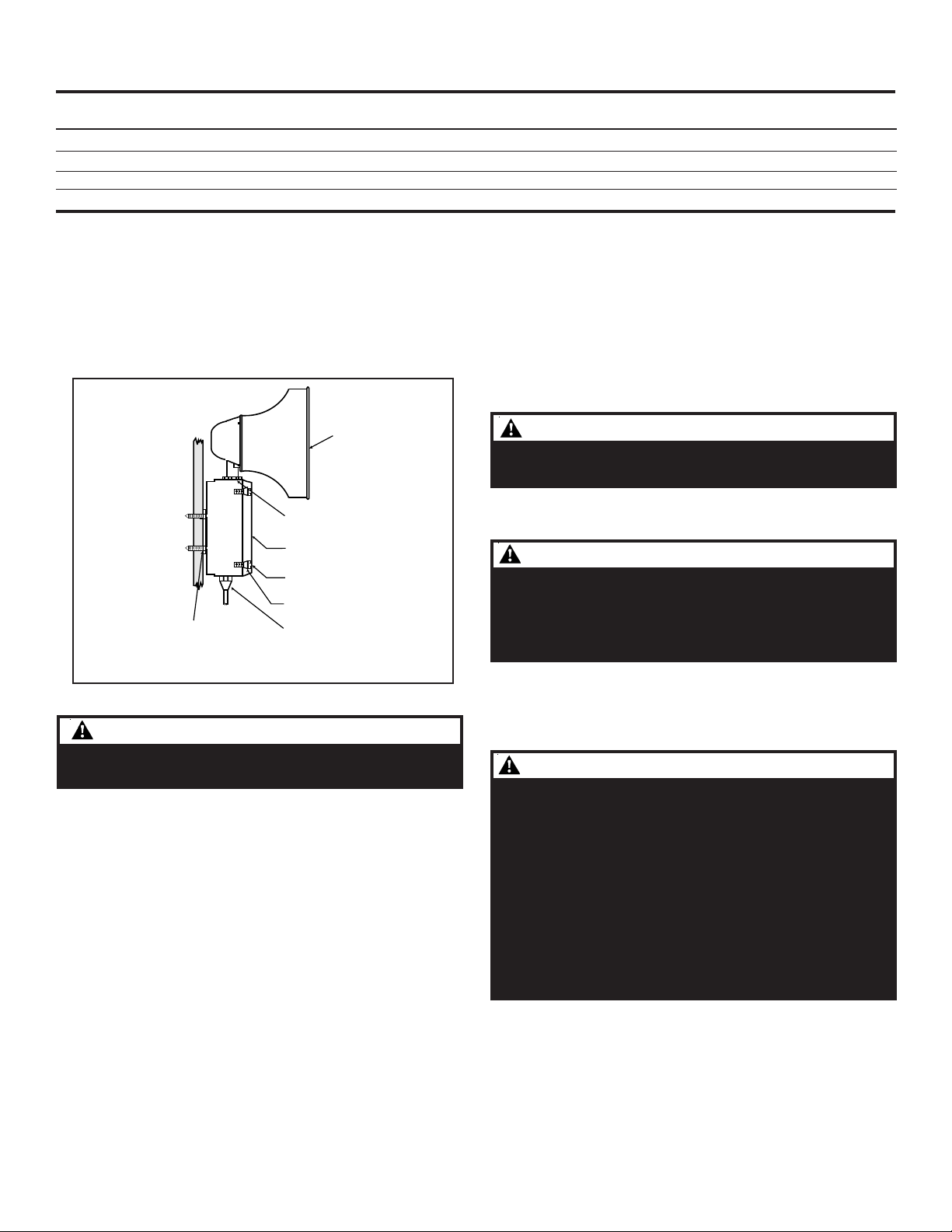

1. Mount Adaptatone as shown in Figure 2.

a. Flat Surface Mounting. Secure unit to

mounting surface using the (4) mounting holes in

the mounting plate on the rear of the box. Use

the #10 x 3" (76 mm) wood screws (furnished loose)

or other hardware (not supplied) suitable for the

mounting surface.

b. Rigid Pipe Mounting. Loosen the (4) cover screws

from the signal box and lift off signal box cover.

NOTE: Cover screws are captive. Do not remove from

cover.

Remove the center knockout in lower wall of box

and mount box to a 1/2" (12.7 mm) conduit pipe

using suitable connector .

CHESHIRE, CT 203-699-3300 FAX 203-699-3365 (CUST. SERV.) 203-699-3078 (TECH SERV.)

P/N 3100009 ISSUE 2 © 2003

Page 2

s

s

T able 1. Programming Logic Controller (PLC) Compatibility: PLC output to meet following product input

parameters. See Figure 10.

Operating voltage Max. off state Continuous on current Surge (inrush/duration)

Cat. No. (Volts*) leakage current (mA) (mA) (Amps/milliseconds)

5536M-24AQ 24V DC only 2 740 8/4

5536M-24N5 120V 60 Hz 2 360 2.82/4

5536MHV-24AQ 24V DC only 2 1500 8/4

Input Board Circuit 24V DC 2 6 --

2. Install wires through a knockout hole in the bottom

of the box from a raceway that is, with its connections

to the 1/2" (12.7 mm) conduit knockout hole, approved

for the same degree of protection and enclosure type

needed by the application. Use the provided plastic

tie-wrap, on the barrier to the electronics, to separate

incoming power leads from signal and tone initiating

leads, per NEC (Figure 3).

Speaker

Large star nut to

adjust speaker

direction

Signal Box

(4) Cover

screws

(4) Collar

(4) #10 x 3" (76 mm)

crews or other hardware

uitable for the mounting surface

gaskets

Raceway and connections

(not supplied) to

1/2" (12.7 mm) knockout

hole

Figure 2. Adaptatone Mounting

WARNINGWARNING

WARNING

WARNINGWARNING

T o prevent fire and shock, wire the Adaptatone only as

described in this installation instruction.

3. Wire as follows:

a. Connect green and yellow striped earth-ground

wire to earth-ground.

b. Select the appropriate method for wiring to the

input board (Figure 9) from Figures 5 - 10. Connect

the Adaptatone as shown.

c. Connect incoming power to wire leads using a

butt splice or other method listed, certified, or

otherwise approved by local authorities. Leads

are both black for -AQ and -N5 models and are

black for line and white for neutral for -Y6 models.

d. Optional. Connect external 24V DC battery (not

supplied) in series with separate diode assembly

part 2600010 (supplied) to TB1 terminals 3 and 4

on the main board as shown in Figure 4 and

marked on the diode assembly .

NOTE: Terminal Block TB1 can be unplugged from the

main board to complete wiring as shown in

Figure 4.

4. Refer to Figures 9 and 11 and select desired tones. Set

the miniature programming switches on the input

board.

For input connected to IN2, set on SW2; IN3, set on

SW3; IN4, set on SW4, in order of priority desired.

NOTE: Connection to IN1 is factory wired from Audio

Input Board for the external audio signal and

has priority over other signals when activated by

the 24V DC priority signal (Figures 7 and 8).

WARNINGWARNING

WARNING

WARNINGWARNING

HIGH VOLT AGE is present when product is energized. High

volume may cause harm to personnel in close proximity .

5. Adjust volume level, if desired, by turning

potentiometer located on the main board (Figure 9).

WARNINGWARNING

WARNING

WARNINGWARNING

To ensure integrity of the Adaptatone assembly when

adjusting the speaker direction, make sure threads in the

enclosure remain fully engaged and do not turn speaker

more than 360 degrees from the original factory installed

position.

6. To adjust speaker direction, loosen large star nut

(Figure 2) and turn speaker to the approximate desired

position. Retighten nut and turn speaker slightly

clockwise until locked into place.

WARNINGWARNING

WARNING

WARNINGWARNING

T o ensure integrity of the enclosure: Ensure the cover

gasket, part number P-007549-0069, is adhered into

groove at cover perimeter before replacing the signal box

cover.

Ensure that the (4) collar gaskets, part number P-0419300362, are in place on each cover screw before securing the

signal box cover .

When securing cover , start screws by hand, making sure

they are threaded into tapped holes in housing bosses

before securing with a screwdriver . Torque signal box cover

screws to a minimum of 20 in-lbs. This ensures the

required tight fit.

7. Tightly secure the signal box cover using (4) retained

cover screws.

8. Torque signal box cover screws to a minimum of 20

in-lbs.

9. Verify operability.

P/N 3100009 ISSUE 2

Page 2

Page 3

W

C

Maintenance and Maintenance and

Maintenance and

Maintenance and Maintenance and

TT

estest

T

est

TT

estest

WARNINGWARNING

WARNING

WARNINGWARNING

T o prevent fire, shock and component damage, NO work,

including circuit board removal, should be performed while

the circuit is energized.

NOTE: Any kind of service or maintenance performed

while unit is energized will void the warranty.

Examine the unit semi-annually for accumulation of dirt.

Clean if necessary .

The Adaptatone should be tested annually or as required

by the authority having jurisdiction to ensure continuous

service.

Main

Board

Power and

earth-ground

leads--black and

white or black for

power; yellow

striped green for

earth-ground.

Plastic tie-wrap (provided)-use to separate power leads

from signal and tone initiating leads

Signal/Tone leads from 5540 to be

connected to Audio Coupler Board as

applicable.

Figure 3. Wiring the Adaptatone

2

1

4

3

Terminal Block

TB-1

(-)

(-)

iring is factory

installed to internal

power supply

(+)

(+)

24

13

Diode Assembly

2600010

(-)

To optional 24V D

Battery Backup

(+)

Figure 4. Wiring to Terminal Block TB1

Page 3

P/N 3100009 ISSUE 2

Page 4

T

O

On Input Board

IN1 IN2 IN3 IN4 N +VS GND

IN1 IN2 IN3 IN4 N +VS GND

n Input Board

K3

K2

K1

Priority

Signal

Activation

Figure 5. Installing with Multiple Dry Relay Contacts

Internally Generated T ones Only

ON INPUT

BOARD

IN1 IN2 IN3 IN4 N +VS GND

CUSTOMER CIRCUIT

K3

24V DC

Priority Signal

o Command

Line

K2

K1

K1 - K3

Local Priorities

Figure 6. Connecting 24V DC Priority Signal to the

Input Board for Activation of External Audio Signal

Connected to Audio Input Board (Figure 8)

(5V DC to 24V DC +/- 1%)

FROM CUSTOMER

CIRCUIT

Figure 7. Installing with an open collector transistor for

24V DC tone initiation to IN1, IN2, IN3 or IN4

RELAY

POWER SUPERVISION

(WHERE APPLICABLE)

NOTE: Audio Signal

not to exceed 10Vrms

SYSTEM

CONSOLE

AUDIO (+)

AUDIO (-)

AUDIO+AUDIO

-

AUDIO COUPLER BOARD

TO OTHER UNITS'

AUDIO COUPLER BOARDS

Figure 8. Connecting Audio Signal, not to exceed

10Vrms, from T one Generator to

5536M Audio Input Board

AUDIO INPUT BOARD

PROCESSOR BOARD

INPUT BOARD

3

W

S

1

4

W

W

S

S

2

GND

W

S

+VS

N

IN4

IN3

IN2

IN1

POTENTIOMETER FOR

VOLUME ADJUSTMENT

Figure 9. PC Board Locations

MAIN BOARD

PROGRAMMING

SWITCHES

(ON OTHER SIDE)

P/N 3100009 ISSUE 2

Page 4

Page 5

PLC

Input Board

IN1 IN2 IN3 IN4 N +VS GND

VDC 1

OUT 0

OUT 1

OUT 2

OUT 3

OUT 1

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

OUT 7

DC COM

+24V DC (EXTERNAL POWER SOURCE)

NOTE: IN1 can be connected to a 24V DC priority si gnal for activation of external

audio signal connected to Audio Input Board.

SEE NOTE

Figure 10. Connecting 24V Input Board to a PLC. See T able 1.

Figure 11. T one Programming

Switch

Tone Description 12345HEX

No Tone 00

Ding-Dong Percussive pairs of 700 and 570 Hz tones, each damped to zero 01

Warble 575 and 770 Hz alternately, 87 ms each 02

Siren 600-1250 Hz up and down sweep in 8 seconds and repeat 03

Stutter Percussive 470 Hz, 83 ms on, 109 ms off 04

Slow Whoop 600-1250 Hz upward sweep in 4 seconds and repeat 05

Beep 470 Hz, 0.55 seconds on, 0.55 seconds off 06

Chime 1 700 Hz percussive repeat at 1 Hz 07

Fast Whoop 600-1250 Hz upward sweep in 1 second and repeat 08

Hi/Lo 780 to 600 Hz alternately, 0.52 seconds each 09

Rapid Siren 600-1250 Hz up and down sweep in 0.25 seconds and repeat 0A

Y e o w 1250-600 Hz downward sweep in 1.6 seconds and repeat 0B

Horn 470 Hz continuous 0C

Air Horn 370 Hz continuous 0D

Dual Tone 450-500 Hz, 0.4 to 0.5 second cycle 0E

Chime 2 575 Hz percussive repeat at 1 Hz 0F

Westminster Two measures, 411 Hz, 520 Hz, 407 Hz, 312 Hz 10

Three Blind Mice Four Measures, 787 Hz, 714 Hz, 625 Hz, 952 Hz, 333 Hz 11

Phasor 416-625 Hz up and down sweep in 13 ms and repeat 12

Telephone 570 and 770 Hz alternately, 50 ms each for 1.2s, 1.5s delay and repeat 13

Staircase 440-2000 Hz up and down steps, 750 ms delay and repeat 14

3 T one Alert 463, 641 and 896 Hz, 200 ms each, 1 second delay and repeat 15

Presignal Chime 470 Hz percussive repeat at 1.5 Hz, followed by Message 1 16

NFPA Whoop 422-775 Hz, upward sweeps, 850 ms each, 1 second delay and repeat 1 B

3 Pulse Horn 470 Hz, 3 0.5 second pulses separated by 0.5 seconds followed 1 C

3 Pulse Air Horn 370 Hz, 3 0.5 second pulses separated by 0.5 seconds followed 1 D

3 Pulse Dual Tone 450-500 Hz, 0.4 to 0.5 second cycle, 3 0.5 second pulses separated 1E

3 Pulse Chime 2 575 Hz, 3 0.5 second pulses separated by 0.5 seconds followed 1F

by a 1.5 second delay and repeat--For Evacuation Use Only

by a 1.5 second delay and repeat--For Evacuation Use Only

by 0.5 seconds followed by a 1.5 second delay and repeat--For

Evacuation Use Only

by a 1.5 second delay and repeat--For Evacuation Use Only

Page 5

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

The use of evacuation signals on this product, that is not specifically Listed for

Fire Alarm Use, is subject to the approval of the Authority Having Jurisdiction.

P/N 3100009 ISSUE 2

Loading...

Loading...