Page 1

Installation Instructions for Catalog Series 5530M-485

Adaptatone

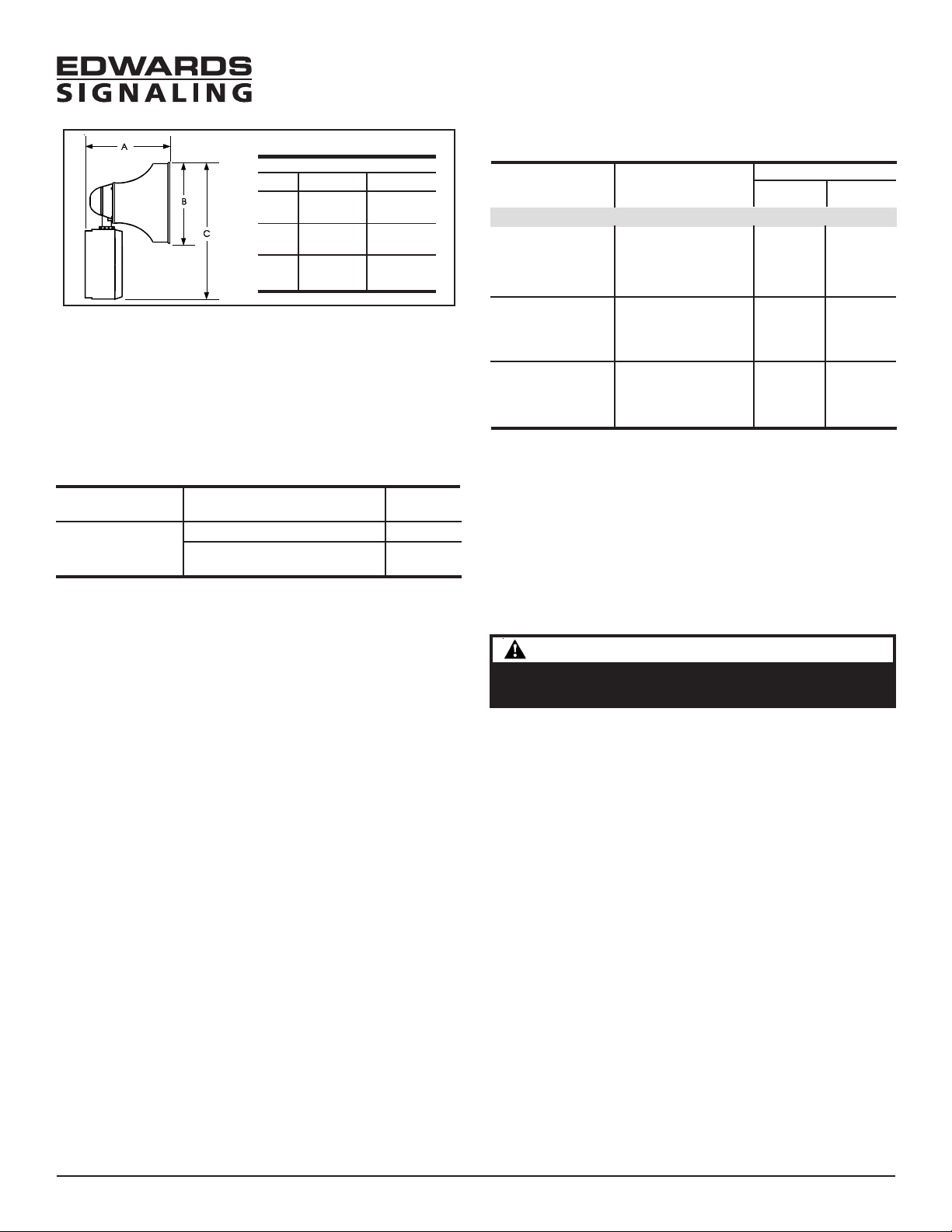

Dimensions

5530M 5530MHV

A 8 7/8" 11 1/2"

(225 mm) (292 mm)

B 8 1/4" 9 3/4"

(210 mm) (248 mm)

C 13" 14 1 /4"

(330 mm) (362 mm)

Figure 1. Dimensions

Description and OperationDescription and Operation

Description and Operation

Description and OperationDescription and Operation

Edwards Adaptatone is a heavy-duty , tone-selectable, stand

alone, indoor/outdoor audible signaling device intended

for industrial applications where high audible output and

microcomputer reliability are required. The Adaptatone

Millennium series are UL and cUL Listed as Audible Signal

Appliances for use in the following hazardous locations.

Catalog Hazardous Temp.

Number Locations Code

5530M-485Y6 Class I, Div. 2, Groups A, B, C, D T4 (135C)

5530MHV-485Y6 Class II, Div. 2, Groups F, G T5 (100C)

5530MV-485Y6 Class III, Div. 1 and 2

The Adaptatone operates from local power and sounds a

high decibel signal determined by the setting of miniature programming switches inside the unit. The

Adaptatone may be programmed for any of the 27 tones

listed in Figure 7.

Speaker direction and the output level are easily adjustable.

®

Millennium Signal

Electrical SpecificationsElectrical Specifications

Electrical Specifications

Electrical SpecificationsElectrical Specifications

Catalog Current (A)

Number Voltage Standby Tone On

Standard Volume

5530M-485Y6 125V DC 0.10 0.21

5530MHV-485Y6 125V DC 0.10 0.39

5530MV-485Y6 125V DC 0.10 0.20

InstallationInstallation

Installation

InstallationInstallation

250V DC 0.02 0.10

120V AC 50/60 Hz 0.10 0.32

240V AC 50/60 Hz 0.10 0.20

250V DC 0.02 0.19

120V AC 50/60 Hz 0.10 0.56

240V AC 50/60 Hz 0.10 0.34

250V DC 0.02 0.10

120V AC 50/60 Hz 0.10 0.31

240V AC 50/60 Hz 0.10 0.20

The Adaptatone may be mounted to any flat surface or

may be used as a freestanding unit mounted to a rigid

pipe. The Adaptatone must be installed in accordance

with the latest edition of the National Electrical Code or

other regulations applicable to the country and locality

of installation and by a trained and qualified electrician.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

During installation, care must be taken so that components

on the printed circuit board are not damaged.

Mechanical SpecificationsMechanical Specifications

Mechanical Specifications

Mechanical SpecificationsMechanical Specifications

Weight ...................................................9 Pounds (4.1 kg)

Hazardous Locations, UL Standard UL1604

Ambient T emp. ................... +41F to +104F (+5C to +40C)

Non-Hazardous Locations

Variable Ambient Temp. .....-40F to +151F (-40C to +66C)

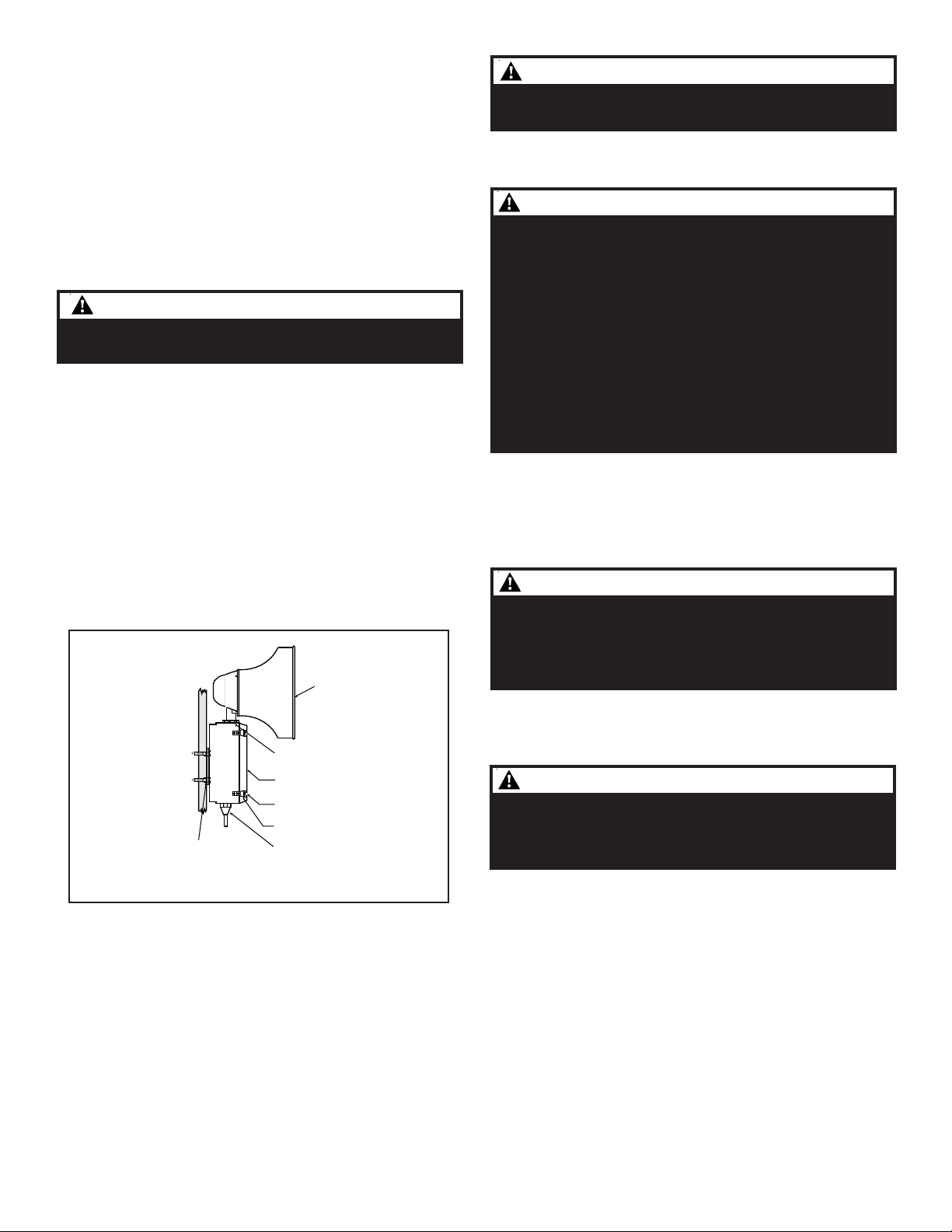

1. Mount Adaptatone as shown in Figure 2.

a. Flat Surface Mounting. Secure unit to

mounting surface using the (4) mounting holes in

the mounting plate on the rear of the box. Use

the #10 x 3" (76 mm) wood screws (furnished loose)

or other hardware (not supplied) suitable for the

mounting surface.

b. Rigid Pipe Mounting. Loosen the (4) cover screws

from the signal box and lift off signal box cover.

CHESHIRE, CT 203-699-3300 FAX 203-699-3365 (CUST. SERV.) 203-699-3078 (TECH SERV.)

P/N 3100345 ISSUE 2 © 2002

Page 2

NOTE: Cover screws are captive. Do not remove from

cover.

Remove the center knockout in lower wall of box

and mount box to a 1/2" (12.7 mm) conduit pipe

using suitable connector .

2. Install wires through a knockout hole in the bottom

of the box from a raceway that is, with its connections

to the 1/2" (12.7 mm) conduit knockout hole, approved

for the same degree of protection and enclosure type

needed by the application. Use the provided plastic

tie-wrap, on the barrier to the electronics, to separate

incoming power leads from signal and tone initiating

leads, per NEC (Figure 5).

WARNINGWARNING

WARNING

WARNINGWARNING

T o prevent fire and shock, wire the Adaptatone only as

described in this installation instruction.

3. Wire as follows referring to Figures 5 and 6.

a. Connect green and yellow-striped earth-ground

wires to earth-ground.

b. Connect the RS485 wires to terminals +TX/RX and

-TX/RX on the RS485 COMM board (Figure 6).

c. If using the optional MR201/C relay, connect the

relay to +RELA Y and -RELA Y on the RS485 COMM

board (Figure 6).

d. Connect incoming power to wire leads using a

butt splice or other method listed, certified, or

otherwise approved by local authorities. Leads

are black and white.

Speaker

Large star nut to

adjust speaker

direction

Signal Box

(4) Cover

screws

(4) Collar

(4) #10 x 3" (76 m m)

screws or other hardware

suitable for t he mounting surf ace

gaskets

Raceway and connections

(not supplied) to

1/2" (12.7 mm ) knockout

hole

Figure 2. Adaptatone Mounting

WARNINGSWARNINGS

WARNINGS

WARNINGSWARNINGS

HIGH VOLT AGE is present when product is energized. High

volume may cause harm to personnel in close proximity .

5. Adjust volume level, if desired, by turning

potentiometer located on the main board (Figure 11).

WARNINGWARNING

WARNING

WARNINGWARNING

T o ensure integrity of the enclosure: Ensure the cover

gasket, part number P-007549-0069, is adhered into

groove at cover perimeter before replacing the signal box

cover.

Ensure that the (4) collar gaskets, part number P-0419300362, are in place on each cover screw before securing the

signal box cover .

When securing cover , start screws by hand, making sure

they are threaded into tapped holes in housing bosses

before securing with a screwdriver . Torque signal box cover

screws to a minimum of 20 in-lbs. This ensures the

required tight fit.

6. Tightly secure the signal box cover using (4) retained

cover screws.

7. Torque signal box cover screws to a minimum of 20

in-lbs.

WARNINGWARNING

WARNING

WARNINGWARNING

To ensure integrity of the Adaptatone assembly when

adjusting the speaker direction, make sure threads in the

enclosure remain fully engaged and do not turn speaker

more than 360 degrees from the original factory installed

position.

8. To adjust speaker direction, loosen large star nut

(Figure 2) and turn speaker to the approximate desired

position.

WARNINGWARNING

WARNING

WARNINGWARNING

T o ensure integrity of the Adaptatone assembly, prior to

completion of installation, make sure threads in the

enclosure are fully engaged and ensure that the star nut is

wrench tight.

9. Regardless of speaker direction adjustment, it is

important that the star nut be tightened wrench tight

to ensure the speaker position is maintained securely .

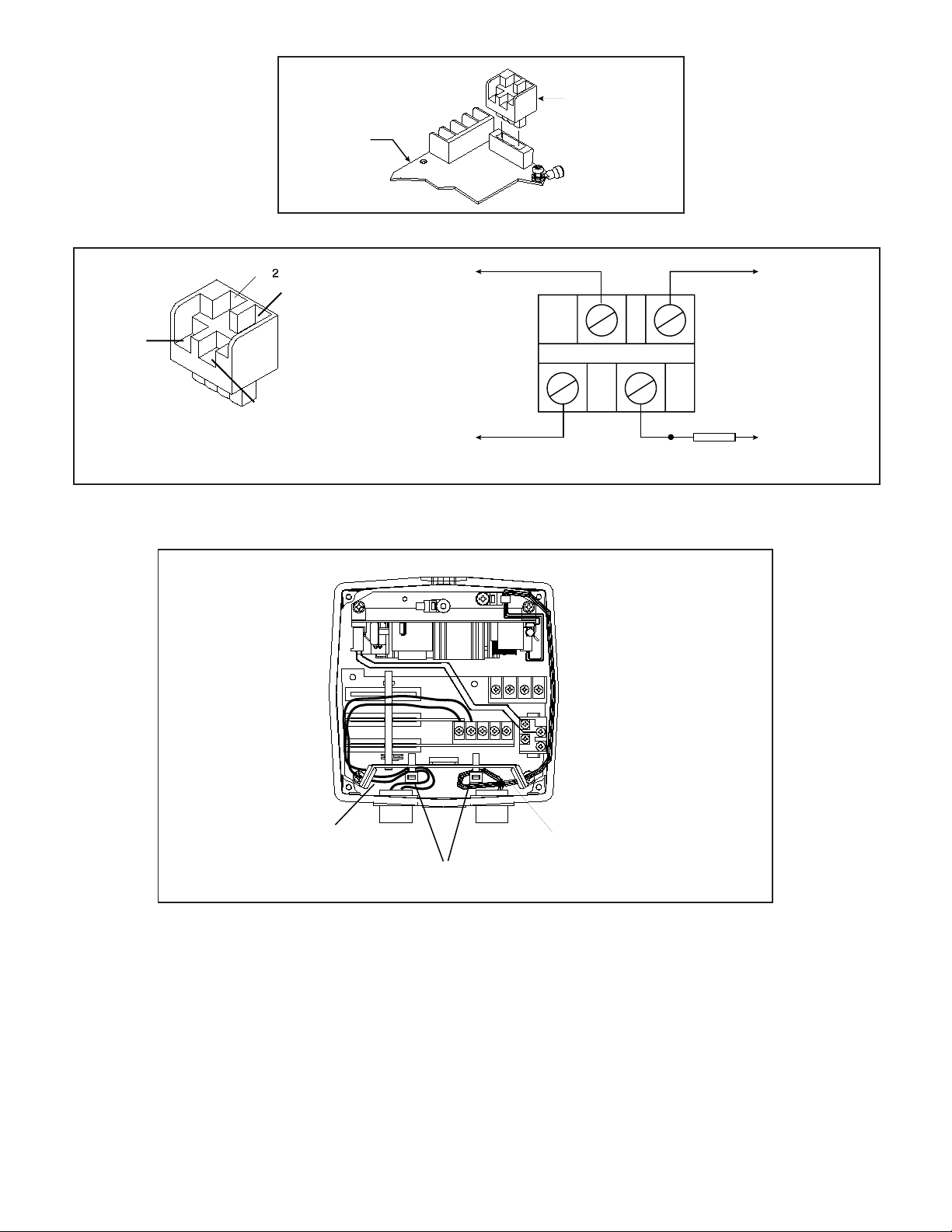

e. Optional. Connect external 24V DC battery (not

supplied) in series with separate diode assembly

part 2600010 (supplied) to TB1 terminals 3 and 4

on the main board as shown in Figures 3 and 4

and marked on the diode assembly .

NOTE: Terminal Block TB1 can be unplugged from the

main board to complete wiring as shown in

Figure 3.

P/N 3100345 ISSUE 2

10. Verify operability.

11. For tone selection and operation, refer to Figure 7

and the "Protocol" section of these installation

instructions.

PAGE 2

Page 3

Maintenance and Maintenance and

Maintenance and

Maintenance and Maintenance and

Ensure that power is disconnected before cleaning inside of

unit.

TT

estest

T

est

TT

estest

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

The Adaptatone should be tested annually or as required

by the authority having jurisdiction to ensure continuous

service.

Examine the unit semi-annually for accumulation of dirt.

Clean if necessary .

ProtocolProtocol

Protocol

ProtocolProtocol

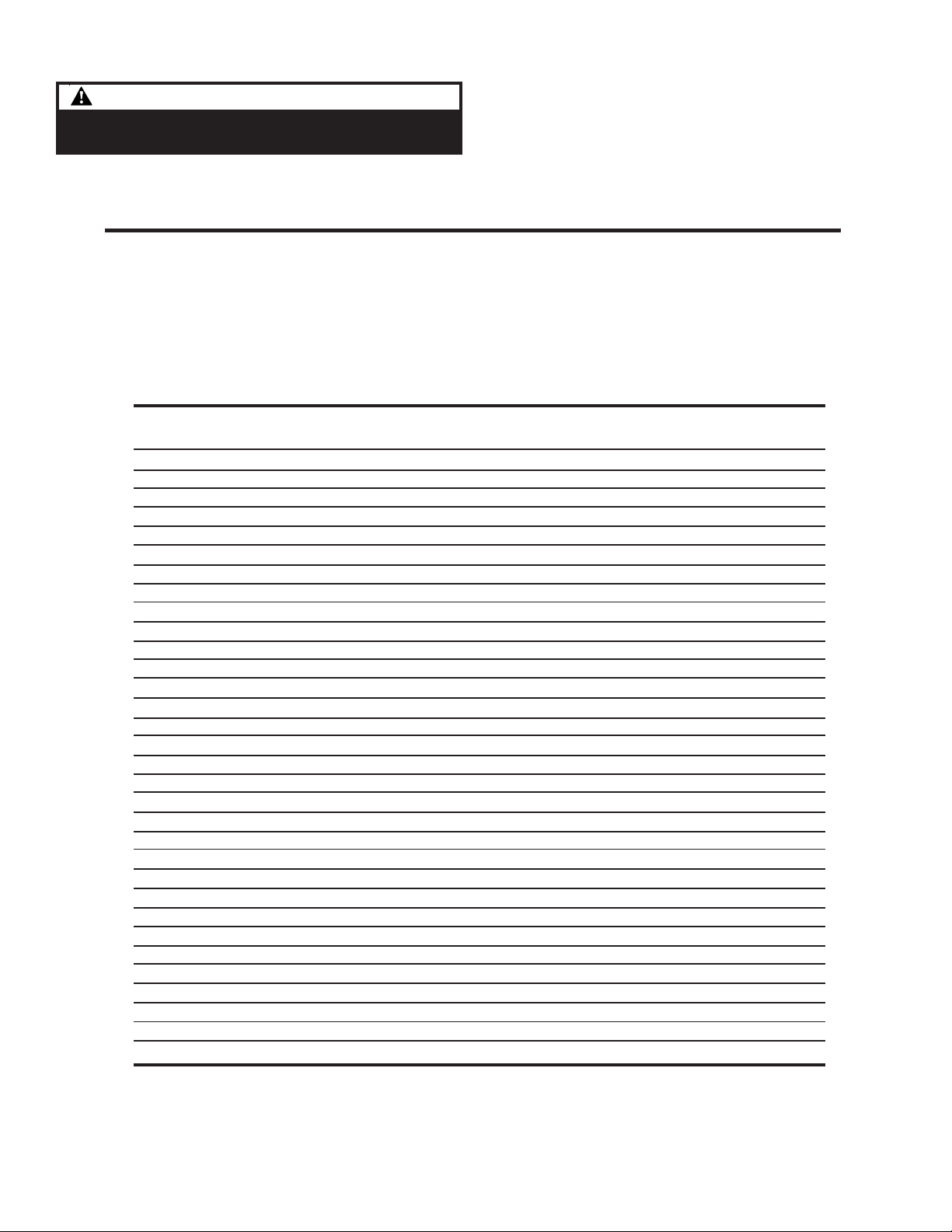

1.0 Setting Unit Address and Network Baud Rate

1.1 Locate the 8-position dip switch, S1, on the top edge of the RS485 COMM board (Figure 6).

1.2 Unit address range is 00-1F hex. (00-31 decimal). Refer to Table 2.2 for unit address configuration. Set S1

positions 1-5 for the desired unit address configuration.

T able 2.2 Unit Address Switch Configuration

Unit Address S1-1 S1-2 S1-3 S1-4 S1-5

Hex Decimal

00 00 OPEN OPEN OPEN OPEN OPEN

01 01 CLOSED OPEN OPEN OPEN OPEN

02 02 OPEN CLOSED OPEN OPEN OPEN

03 03 CLOSED CLOSED OPEN OPEN OPEN

04 04 OPEN OPEN CLOSED OPEN OPEN

05 05 CLOSED OPEN CLOSED OPEN OPEN

06 06 OPEN CLOSED CLOSED OPEN OPEN

07 07 CLOSED CLOSED CLOSED OPEN OPEN

08 08 OPEN OPEN OPEN CLOSED OPEN

09 09 CLOSED OPEN OPEN CLOSED OPEN

0A 10 OPEN CLOSED OPEN CLOSED OPEN

0B 11 CLOSED CLOSED OPEN CLOSED OPEN

0C 12 OPEN OPEN CLOSED CLOSED OPEN

0D 13 CLOSED OPEN CLOSED CLOSED OPEN

0E 14 OPEN CLOSED CLOSED CLOSED OPEN

0F 15 CLOSED CLOSED CLOSED CLOSED OPEN

10 16 OPEN OPEN OPEN OPEN CLOSED

11 17 CLOSED OPEN OPEN OPEN CLOSED

12 18 OPEN CLOSED OPEN OPEN CLOSED

13 19 CLOSED CLOSED OPEN OPEN CLOSED

14 20 OPEN OPEN CLOSED OPEN CLOSED

15 21 CLOSED OPEN CLOSED OPEN CLOSED

16 22 OPEN CLOSED CLOSED OPEN CLOSED

17 23 CLOSED CLOSED CLOSED OPEN CLOSED

18 24 OPEN OPEN OPEN CLOSED CLOSED

19 25 CLOSED OPEN OPEN CLOSED CLOSED

1A 26 OPEN CLOSED OPEN CLOSED CLOSED

1B 27 CLOSED CLOSED OPEN CLOSED CLOSED

1C 28 OPEN OPEN CLOSED CLOSED CLOSED

1D 29 CLOSED OPEN CLOSED CLOSED CLOSED

1E 30 OPEN CLOSED CLOSED CLOSED CLOSED

1F 31 CLOSED CLOSED CLOSED CLOSED CLOSED

PAGE 3

P/N 3100345 ISSUE 2

Page 4

1.3 RS485 COMM supports 1200, 2400, 9600 and 19200 baud rate using 8 data bits and one stop bit. Parity is not

supported. Refer to T able 1.3 for Baud Rate switch configuration. Set S1 positions 6-7 for the desired Baud

Rate configuration.

T able 1.3 Network Baud Rate setting

Baud Rate S1-6 S1-7

1200 OPEN OPEN

2400 CLOSED OPEN

9600 OPEN CLOSED

19200 CLOSED CLOSED

1.4 Set 100-ohm termination resistor (if required). Network termination is required if the unit is located at the

beginning or end of the network bus. Termination reduces unwanted reflections caused by data signal

propagation due to long wire runs. Refer to T able 1.4 for switch configuration. Set S1 position 8 for network

termination if required.

T able 1.4 T ermination setting

Termination (100 ohms) S1-8

Enabled CLOSED

Disabled OPEN

2.0 Messaging Format

2.1 The RS485 COMM utilizes the Edwards SigNet ASCII protocol for data messaging. Each unit is capable of

consuming and/or producing messages from the master controller. SigNet message format is illustrated

below.

<STX> <UA> <DDDD> <ZONE> <ETX> <CHKSUM>

<STX> The <STX> character has a value of 2 hexadecimal and is required at the start of

<UA> Two byte ASCII representation of the hex Unit. Example - If unit address 0A is

<DDDD> ASCII data field. (4 bytes total). These bytes contain commands, tone/message

<ZONE> Programmable unit Zone issued by the master or controlling computer

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

<CHKSUM> Optional two byte Message Block checksum (2 bytes). Refer to Section 4.0 for

3.0 Message Command Set

3.1 T one/Message Command - 00-1F

Send Format: <STX><UA><TONE> <TIME> <ZONE> <ETX> <CHKSUM>

<UA> Unit address characters (2 bytes). See Section 2.0, Messaging Format

every message (1 byte).

chosen, the two byte <UA> data field would contain ASCII ‘0’ and ‘A’ written in

ASCII format as 0A. Valid data range is ASCII 00 - 1F.

and timed sequence data.

Range ASCII A-D (1 byte). Note – Zone value is not retained after power loss unless

battery backup is installed. Value defaults to Zone A on power up.

every message (1 byte)

Block checksum calculation and verification. If checksum is not desired, must pad

these two bytes with two ASCII zeros 00.

P/N 3100345 ISSUE 2

<TONE> Tone/Message to be played by the unit. Example - If tone 06 is chosen, the two

byte <TONE> data field should contain ASCII ‘0’ and ‘6’ written in ASCII format as

06. Range ASCII 00-1F(2 bytes). See Tone Chart for a list of available tones or

messages.

<TIME> Time sequence for Tone/Message to be played (00-99 seconds). For continous play

of T one/Message, use ‘00’ in this data field. Range ASCII 00-99 (2 bytes)

<ZONE> Units matching this zone field will play Tone/Message indicated in the <TONE>

data field for specified time indicated in <TIME> data field. All other zones remain

in standby mode.

PAGE 4

Page 5

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte)

<CHKSUM> Optional two byte Message Block checksum (2 bytes). Refer to Section 4.0 for

Block checksum calculation and verification. If checksum is not desired, must pad

these two bytes with two ASCII zeros 00.

3.2 BROADCAST COMMAND - 41

Send Format: <STX> 41 <TONE> <TIME> <ZONE> <ETX> <CHKSUM>

<41> In this command type, two byte ASCII ‘41’ replaces <UA> characters. This command

is issued to all units containing the identical <ZONE> field.

<TONE> Tone/Message to be played by the unit. See tone chart for a list of available tones/

messages. Range ASCII 00-1F (2 bytes).

<TIME> Time sequence for Tone/Message (00-99 seconds). For continous play of Tone/

Message, use ‘00’ in this data field. Range ASCII 00-99 (2 bytes)

<ZONE> Units matching this zone field will play Tone/Message indicated in the <TONE>

data field for specified time indicated in <TIME> data field. All other zones remain

in standby mode.

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte)

<CHKSUM> Optional two byte Message Block checksum (2 bytes). Refer to Section 4.0 for

Block checksum calculation and verification. If checksum is not desired, must pad

these two bytes with two ASCII zeros 00.

Unit Response: None

Example: <STX>410530B<ETX>00

Units programmed with Zone ‘B’ only to play T one 05 for 30 seconds then shut off

automatically . Checksum characters not used in this example.

Note: do not use spaces between message characters in the above example.

3.3 POLL COMMAND and SET UNIT ZONE - 43

Send Format: <STX><UA>43<00><ZONE><ETX><CHKSUM>

<UA> Unit address, ASCII Range 00-1F (two bytes)

<43> Two byte ASCII Command denoting POLL Command or Zone Assignment (2 byte).

<00> Two byte ASCII ‘00’ used as protocol padding (two byes)

<ZONE> Programmable unit zone character. Range ASCII A-D. (1byte)

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte)

<CHKSUM> Optional two byte Message Block checksum (2 bytes). Refer to Section 4.0 for

Block checksum calculation and verification. If checksum is not desired, must pad

these two bytes with two ASCII zeros 00.

Unit Response: <STX><UA>43<STATUS><ZONE><ACK><ETX><CHKSUM>

<UA> Unit address, ASCII Range 00-1F (two bytes)

<43> Two byte ASCII Command echoed back from receiving unit (2 byte).

<STATUS> Unit’s current diagnostic state. Range ASCII A - D. (1byte)

A = T one/Message is active and Local Power is absent

B = T one/Message is active and Local Power is present

PAGE 5

C = T one/Message is not active and Local Power is absent

D = T one/Message is not active and Local Power is present

<ZONE> Unit's programmed zone character

<ACK> This <ACK> character has a value of 6 hexadecimal and represents

acknowledgement of the received command with valid checksum (1byte).

P/N 3100345 ISSUE 2

Page 6

Note: In the event that a bad checksum is calculated, by the receiving unit, it will reply with a <NAK>

character instead. The <NAK> character has a value of 15 hexadecimal.

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte)

<CHKSUM> Receiving unit calculates two-byte checksum and returns ASCII value. Refer to

Section 4.0 for Block checksum calculation and verification.

Example 1: <STX>014300A<ETX>00

Unit 01 is being polled and programmed to Zone A

Unit Response: <STX>0143DA<ACK><ETX>56

The unit returned a <STATUS> ‘D’ for its current diagnostic state and an <ACK>

character because both message and checksum are valid. The unit is not actively

playing T one/Message. The calculated two-byte message checksum was ‘56’.

Example2: <STX>014300A<ETX>00

Unit 01 is being polled and programmed to Zone A. Unit 01 is currently playing a

T one/Message.

Unit Response: <STX>0143BA<ACK><ETX>54

The unit returned a <STATUS> ‘B’ for its current diagnostic state and an <ACK>

character. The unit is actively playing a Tone/Message at the time this command

was received. The calculated two-byte message checksum was ‘54’.

3.4 TIME SEQUENCE, TIME REMAINING COMMAND - 44

Send Format: <STX><UA>44 00 <ZONE> <ETX> <CHKSUM>

<UA> Unit address characters (2 bytes). See Section 2.0, Messaging Format

<44> Two byte ASCII Command denoting a Time Sequence (2 bytes).

<00> Two byte ASCII ‘00’ used as protocol padding (two byes)

<ZONE> Programmable unit Zone issued by the master or controlling computer

Range ASCII A-D (1 byte).

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte)

<CHKSUM> Optional two byte Message Block checksum (2 bytes). Refer to Section 4.0 for

Block checksum calculation and verification. If checksum is not desired, must pad

these two bytes with two ASCII zeros 00.

Unit Response: <STX><UA> 44 <TIME LEFT><ACK><ETX> <CHKSUM>

<UA> Unit address characters (2 bytes). See Section 2.0, Messaging Format

<44> Two byte ASCII Command 43 echoed back from the receiving unit (2 bytes).

<TIME LEFT> Represents seconds left, in hexadecimal format, until the unit stops playing active

T one/Message. Range 00-63 hex (2 bytes). The unit’ s internal counter returns the

time remaining in seconds represented by a two byte hexadecimal value in the

above data field.

Note: For non-timed events, the unit returns two ASCII zeros ‘00’.

<ACK> Unit received a complete message and checksum characters are valid.

Note: In the event that a bad checksum is calculated, by the receiving unit, it will

reply with a <NAK> character instead. The <NAK> character has a value of 15

hexadecimal.

P/N 3100345 ISSUE 2

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte)

<CHKSUM> Receiving unit calculates two-byte checksum and returns ASCII value. Refer to

Section 4.0 for Block checksum calculation and verification.

Example 1: Prior to issuing Command 44, the master issues a 99 second timed sequence event

for T one/Message 03 to play on unit address 1F.

PAGE 6

Page 7

Command: <STX>1F0399A<ETX>00

9 seconds after issuing command from above, the master issues the “Time

Remaining” Command 44

Command: <STX>1F4400A<ETX>00 and the unit replies with the following message.

Reply: <STX>1F445A<ACK><ETX>5E

Value 5A (90 decimal) is the hexadecimal representation of seconds left before the

timed sequence event completes and T one/Message stops.

3.5 DEVICE TYPE COMMAND - 45

Send Format: <STX><UA>45<00> <ZONE> <ETX> <CHKSUM>

<UA> Unit address characters (2 bytes). See Section 2.0, Messaging Format

<45> Two byte ASCII Command 45 denoting receiving unit’s Device type (2 bytes).

<00> Two byte ASCII ‘00’ used as protocol padding (two byes)

<ZONE> Programmable unit Zone issued by the master or controlling computer

Range ASCII A-D (1 byte).

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte)

<CHKSUM> Optional two byte Message Block checksum (2 bytes). Refer to Section 4.0 for

Block checksum calculation and verification. If checksum is not desired, must pad

these two bytes with two ASCII zeros 00.

Unit Response: <STX> <UA> <DEVICE TYPE> <vXX> <ETX> <CHKSUM>

<UA> Unit address characters (2 bytes). See Section 2.0, Messaging Format

<45> Two byte ASCII Command 45 echoed back from the receiving unit (2 bytes).

<DEVICE TYPE> Device type is an ASCII string transmitted by the receiving unit that defines the

unit family product code. For Millennium devices, the return ASCII string is “M-

485”. For Edward’s V isual devices, the return ASCII string is “S-485”.

<vXX> Receiving Unit’s Firmware version and revision level.

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte).

<CHKSUM> Receiving unit calculates two-byte checksum and returns ASCII value. Refer to

Section 4.0 for Block checksum calculation and verification.

Example: Command: <STX>014500A<ETX>00

Response: <STX>01M-485v1.0<ETX>84

Unit address 01 returns “M-485” string and is configured with version 1, rev.0

firmware. Calculated two-byte checksum is ‘84’.

3.6 RELA Y ENERGIZE COMMAND - 31

Send Format: <STX><UA>31<TIME> <ZONE> <ETX> <CHKSUM>

<UA> Unit address characters (2 bytes). See Section 2.0, Messaging Format

<31> ASCII Command 31 denoting Relay Energize (2 bytes).

<TIME> Time sequence for relay ‘ON’ duration (00-99 seconds). For Continuos ‘ON’, use

<ZONE> Programmable unit Zone issued by the master or controlling computer

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

<CHKSUM> Optional two byte Message Block checksum (2 bytes). Refer to Section 4.0 for

Response: <STX><UA>31<TIME> <ACK> <ETX> <CHKSUM>

PAGE 7

ASCII ‘00’ in this data field. Range ASCII 00-99 (2 bytes)

Range ASCII A-D (1 byte).

every message (1 byte)

Block checksum calculation and verification. If checksum is not desired, must pad

these two bytes with two ASCII zeros 00.

P/N 3100345 ISSUE 2

Page 8

Example: <STX>1F3105<ACK><ETX>00

Unit address 1F energizes relay for 5 seconds then shut off automatically . Checksum

characters not used in this example.

<UA> Unit address

<31> Two byte ASCII Command 31 echoed back from receiving unit.

<TIME> Received two byte ASCII time value

<ACK> Unit received valid message and checksum

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte).

<CHKSUM> Receiving unit calculates two-byte checksum and returns ASCII value. Refer to

Section 5.0 for Block checksum calculation and verification.

Note: Relay output commands are only valid when there is no tone/voice message

actively playing. Any tone/voice messages automatically overrides any relay output

commands sent to the unit.

3.7 RELAY DE-ENERGIZE COMMAND - 30

Send Format: <STX><UA>30<00> <ZONE> <ETX> <CHKSUM>

<UA> Unit address characters (2 bytes). See Section 2.0, Messaging Format

<30> ASCII Command 30 denoting Relay De-Energize (2 bytes).

<00> Two byte ASCII ‘00’ used as protocol padding (two byes)

<ZONE> Assigned unit Zone. Range ASCII A-D (1 byte)

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte).

<CHKSUM> Receiving unit calculates two-byte checksum and returns ASCII value. Refer to

Section 4.0 for Block checksum calculation and verification.

Response: <STX><UA>3000 <ACK> <ETX> <CHKSUM>

Example: <STX>1F3000<ACK><ETX>43

Unit address 1F de-energizes relay output

<UA> Unit address

<30> Two byte ASCII Command 30 echoed back from receiving unit.

<00> Two byte ASCII ‘00’ used as protocol padding (two byes)

<ACK> Unit received valid message and checksum

<ETX> The <ETX> character has a value of 3 hexadecimal and is required at the end of

every message (1 byte).

<CHKSUM> Receiving unit calculates two-byte checksum and returns ASCII value. Refer to

Section 4.0 for Block checksum calculation and verification.

4.0 Verify and Calculate Message Block Checksum

4.1 Message Block checksum can be verified by adding up all the hexadecimal characters in the received message

string, excluding the first character <STX> and the very last two checksum characters.

4.2 The sum of these characters will produce a three-byte hexadecimal value. The higher order byte is not used

and should be dropped. The lower two bytes are used for comparison to the received checksum characters.

See example Message String received below:

Message String Received:

<STX> 0 1 4 3 D A <ACK> <ETX> 5 6

Message characters

included

Not included in calculation

Two byte ASCII checksum data field

not included in calculation, but used

for comparison to calculated results

P/N 3100345 ISSUE 2

PAGE 8

Page 9

4.3 Calculating the checksum is done by first converting each ASCII character, found in the message string, to

the hexadecimal equivalent and then summing these characters. See below.

ASCII HEXADECIMAL

0 0x30

1 0x31

4 0x34

3 0x33

D 0x44

A 0x41

✓ (ACK) 0x06

(ETX) 0x03

0x156 hexadecimal total

4.4 Dropping the upper hexadecimal byte from the above total yields a final result of 56 hexadecimal. The

calculated hexadecimal checksum value should match the ASCII value received in the message string. If it

does not match, a possible error occurred during transmission and the message is considered unreliable.

The master or controlling computer should try to resend the message again.

Example of a POLL Command 43 issued to unit 05, Zone B

<STX>054300B<ETX>

ASCII HEXADECIMAL

0 0x30

5 0x35

4 0x34

3 0x33

0 0x30

0 0x30

B 0x42

(ETX) 0x03

0x171 hexadecimal total

The calculated Message Block checksum are appended to the message string. Two bytes, ASCII 7 and

ASCII 1, consume these two checksum data fields. See below.

Send format: <STX>054300A<ETX>71

5.0 Wiring applications

IBM PC or Terminal

RS-232 to RS-485 Multi or Single drop

RS-232 Port

DB9 F/M

(MCN485CB2323A9)

RS232/485 Converter

(MCN485CB2EOLT)

RS-485 cable

(up to 4000 ft)

Up to 32 units

(maximum)

Adaptatone

55XX-485Y6

Adaptatone

55XX-485Y6

PAGE 9

P/N 3100345 ISSUE 2

Page 10

PLC to RS-485 Multi or Single drop

RS-232 Port

PLC Controller

IBM PC or PLC

1 DCD

2 RXD

3 TXD

4 DTR

5 COM

6 DSR

7 RTS

8 CTS

9 RI NOT USED

DB9 F/M

(MCN485CB2323A9)

RS-232/485 Converter

(MCN485CB2EOLT

1 DCD

2 RXD

3 TXD

4 DTR

5 COM

6 DSR

7 RTS

8 CTS

9 RI

RS232/485 Converter

(MCN485CB2EOLT)

RS-485 cable

(up to 4000 ft)

Adaptatone

55XX-485Y6

Adaptatone

55XX-485Y6

Up to 32 units

(maximum)

RS-485 Port

PLC Controller

or

IBM PC with

RS485 Serial Port

RS-485 Multi or Point to Point

RS-485 cable

(up to 4000 ft)

Adaptatone

55XX-485Y6

Adaptatone

55XX-485Y6

Up to 32 units

(maximum)

P/N 3100345 ISSUE 2

PAGE 10

Page 11

Suggested Network Topology Node Schemes

(b)(a)

(d)(c)

9 VOLT AC

-NOMINAL

Wiring to RS-232/485 Convert Box (MCN485CB2EOLT)

RS-232

TO IBM PC

OR PLC

RS-232 PORT

RS-485 (+)

SHIELD

BLACK

DRAIN

WIRE OF

CABLE

RS-485 (-)

RED

UNTERMINATED

NOT A

TELEPHONE

CONNECTION

RS-485

TERMINATED

BOARD

#2990041 REV 01

RJ11 PINOUT

12 34 56

1 = NC

2 = RS-485 (+)

3 = SHIELD

4 = NC

5 = RS-485 (-)

6 = NC

RS-485

TWISTED PAIR

SHIELDED

+TX/RX -TX/RX +RELAY -RELAY EARTH

SUPPLIED

BY

INSTALLER

PAGE 11

P/N 3100345 ISSUE 2

Page 12

W

2

4

d

4

3

Terminal Block

TB-1

Main

Board

1

Figure 3. Terminal Block TB1

(-)

2

(-)

24

(-)

1

3

See Figure 3 for terminal block location

on the main board

Figure 4. Wiring to Terminal Block TB1 Input Circuit

iring is factory

installed to internal

power supply

(+)

(+)

To optional 24V DC

Battery Backup

13

(+)

Diode Assembly

2600010

RS485 twisted pair

Plastic tie-wrap (provided) use to separate power leads

from signal and tone initiating leads

Power and

earth-groun

leads

Figure 5. Wiring the Adaptatone

P/N 3100345 ISSUE 2

PAGE 12

Page 13

RS485 COMM

Board

Processor Board

-TX/RX

+TX/RX

EARTH

-RELAY

+RELAY

Potentiometer for

Volume Adjustment

Figure 6. PC Board Locations

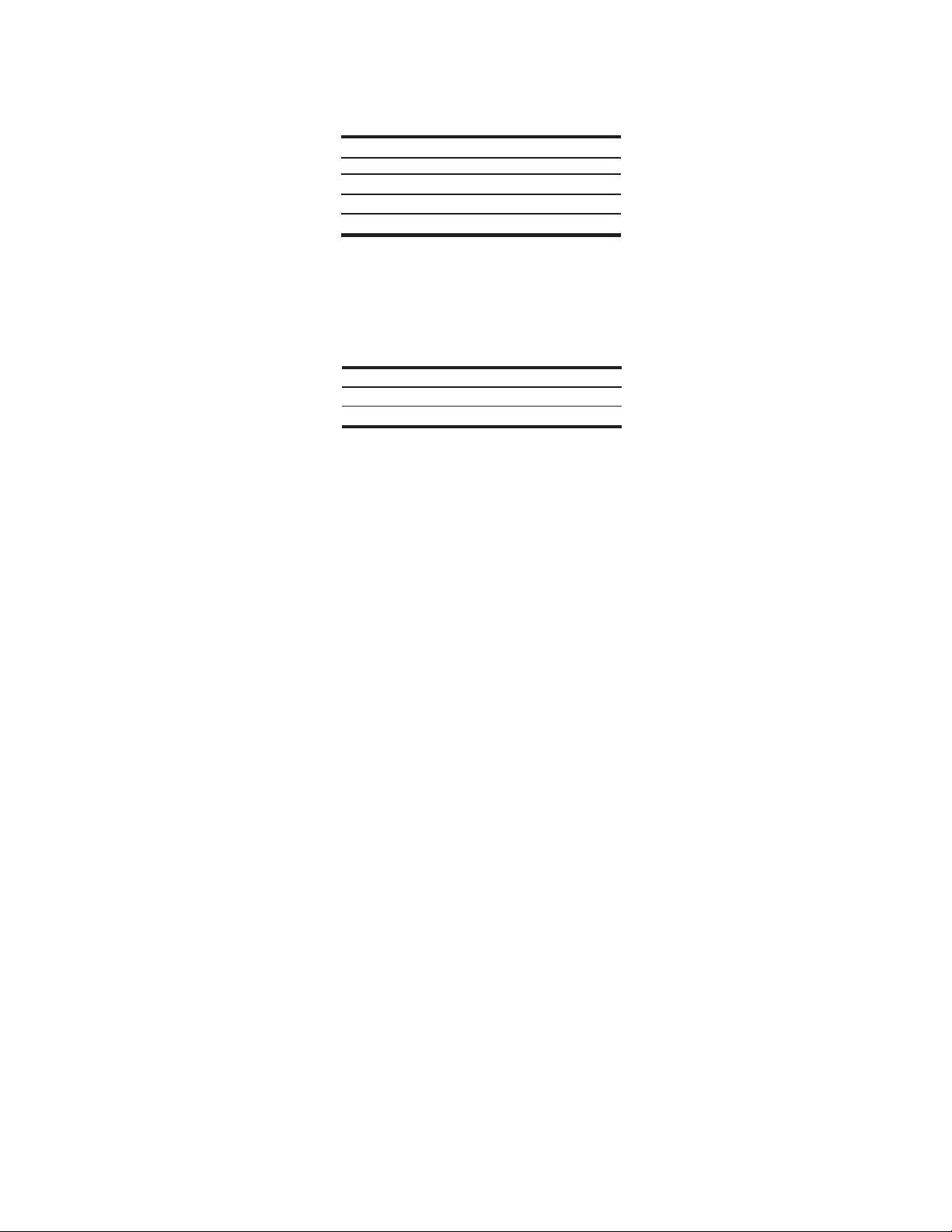

Figure 7. T one Programming

Switch

Tone Description 12345HEX

No Tone 00

Ding-Dong Percussive pairs of 700 and 570 Hz tones, each damped to zero 01

Warble 575 and 770 Hz alternately, 87 ms each 02

Siren 600-1250 Hz up and down sweep in 8 seconds and repeat 03

Stutter Percussive 470 Hz, 83 ms on, 109 ms off 04

Slow Whoop 600-1250 Hz upward sweep in 4 seconds and repeat 05

Beep 470 Hz, 0.55 seconds on, 0.55 seconds off 06

Chime 1 700 Hz percussive repeat at 1 Hz 07

Fast Whoop 600-1250 Hz upward sweep in 1 second and repeat 08

Hi/Lo 780 to 600 Hz alternately , 0.52 seconds each 09

Rapid Siren 600-1250 Hz up and down sweep in 0.25 seconds and repeat 0A

Y e o w 1250-600 Hz downward sweep in 1.6 seconds and repeat 0B

Horn 470 Hz continuous 0C

Air Horn 370 Hz continuous 0D

Dual Tone 450-500 Hz, 0.4 to 0.5 second cycle 0E

Chime 2 575 Hz percussive repeat at 1 Hz 0F

Westminster Two measures, 411 Hz, 520 Hz, 407 Hz, 312 Hz 10

Three Blind Mice Four Measures, 787 Hz, 714 Hz, 625 Hz, 952 Hz, 333 Hz 11

Phasor 416-625 Hz up and down sweep in 13 ms and repeat 12

Telephone 570 and 770 Hz alternately, 50 ms each for 1.2s, 1.5s delay and repeat 13

Staircase 440-2000 Hz up and down steps, 750 ms delay and repeat 14

3 T one Alert 463, 641 and 896 Hz, 200 ms each, 1 second delay and repeat 15

Presignal Chime 470 Hz percussive repeat at 1.5 Hz, followed by Message 1 16

NFPA Whoop 422-775 Hz, upward sweeps, 850 ms each, 1 second delay and repeat 1B

3 Pulse Horn 470 Hz, 3 0.5 second pulses separated by 0.5 seconds followed 1 C

3 Pulse Air Horn 370 Hz, 3 0.5 second pulses separated by 0.5 seconds followed 1D

3 Pulse Dual Tone 450-500 Hz, 0.4 to 0.5 second cycle, 3 0.5 second pulses separated 1E

3 Pulse Chime 2 575 Hz, 3 0.5 second pulses separated by 0.5 seconds followed 1F

by a 1.5 second delay and repeat--For Evacuation Use Only

by a 1.5 second delay and repeat--For Evacuation Use Only

by 0.5 seconds followed by a 1.5 second delay and repeat--For

Evacuation Use Only

by a 1.5 second delay and repeat--For Evacuation Use Only

PAGE 13

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

The use of evacuation signals on this product, that is not specifically Listed for

Fire Alarm Use, is subject to the approval of the Authority Having Jurisdiction.

P/N 3100345 ISSUE 2

Loading...

Loading...