Page 1

Installation Instructions &

Owner’s Operation Manual

for Two to Eight Zone

2400 Series

Fire Alarm Control Panels

P/N 46000-1320, Rev . 1.6

Page 2

© Edwards

This product has been designed to meet t he r equirements of NFPA Standard 72, 1990 Edit ion;

Underwriters Laboratory, Inc., Standard 864, May 2, 1991 Edition; and Underwriters Laboratory

of Canada, Inc. Standard ULC S527. I nstallation in accordance with this manual, applicable

codes, and the instructions of the Aut hor it y Having Jurisdiction is m andat ory.

FCC WARNING: This equipment can generate and r adiate radio frequency energy. If this

equipment is not installed in accordance with this manual, it may cause interference to radio

communications. This equipment has been t est ed and found to comply within the limits for

Class A computing devices pursuant to Subpart J of part 15 of the FCC Rules. These rules ar e

designed to provide reasonable protection against such int er ference when this equipment is

operated in a commercial environment. Oper at ion of this equipment in a residential environment

is likely to cause interference, in which case the user at his own expense, will be required to

take whatever measures may be required to correct t he interference.

CAUTION

1. Read and thoroughly understand this manual befor e pr oceeding to install and operate the

control panel.

2. To ensure proper operation of t h e cont r ol of the panel, only those initiating, signaling, and

other devices whose compatibility with the panel has been established by Underwriters

Laboratories may be connected to the control panel. Refer to the compatability inform ation

supplement supplied with the panel for a complete list of compatible devices.

3. Test all installation wiring for opens, short s or grounds and correct any fault found before

connecting wiring to the control panel.

4. Do not connect AC or battery power until indicated.

5. Servicing of the control panel must be per formed by qualified fire alarm service

technicians only.

i

Page 3

FCC Information

1. The dialer complies with Part 68 of the FCC rules. The Dialer’ FCC registration number and the Ringer

Equivalence Number (REN) are on the back of the dialer. This information must be provided to the telephone

company, if requested.

2. An FCC compliant telephone cord and modular plug cord is supplied with the dialer. The dialer is designed to be

connected to the telephone network using the supplied cord and an RJ31X or RJ38X jack, which must also

comply with FCC Part 68 rules.

3. The REN is used to determine the quantity of devices which may be connected to the telephone line. Excessive

RENs on the telephone line may result in the devices not ringing in response to an incoming call. In most, but

not all areas, the sum of RENs should not exceed five (5). To be certain the number of devices that may be

connected to a line, as determined by the total RENs, contact the local telephone company.

5. If the dialer causes harm to the telephone network, the telephone company will notify you in advance that

temporary discontinuance of service may be required. If advance notice isn’t practical, the telephone company

will notify you as soon as possible. You will also be advised of your right to file a complaint with the FCC, if you

believe it is necessary.

6. The telephone company may make changes in it’s facilities, equipment, operations, or procedures that could

affect the operation of the dialer. If this happens, the telephone company will provide advance notice in order for

you to make necessary modifications to maintain uninterrupted service.

7. If trouble is experienced with the dialer, for repair or warranty information, contact Edwards Co. 90 Fieldstone

Court, Cheshire, Ct 06410-1212 Telephone: 1-203-699-3000. If the dialer is causing harm to the telephone

network, the telephone company may request you disconnect the dialer until the problem is resolved.

8. No repairs may be performed on the dialer by the user.

9. The dialer cannot be used on public coin phone or party line service provided by the telephone company.

CANADA DOC Information

NOTICE: The Canadian Department of Communications label identifies certified equipment. This

certification means that the equipment meets certain telecommunications network protective, operational,

and safety requirements. The Department does not guarantee the equipment will operate to the user’s

satisfaction

Before installing this equipment, users should ensure that is permissible to be connected to the facilities of

the local telecommunications company. The equipment must also be installed using an acceptable

method of connection. The customer should be aware that compliance with the above conditions may not

prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility

designated by the supplier. Any repairs or alterations made by the user to this equipment, or equipment

malfunctions, may give the telecommunications company cause to request the user disconnect the

equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility,

telephone lines, and internal metallic water pipe system, if present, are connected together. This

precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but should contact the

appropriate electric inspection authority, or electrician, as appropriate

NOTICE: The Load Number (LN) assigned to each terminal device denotes the percentage of the total

load to be connected to a telephone loop which is used by the device, to prevent overloading. The

termination on a loop may consist of any combination of devices subject only to the requirements that the

sum of the Load Numbers of all the devices does not exceed 100.

ii

Page 4

FOR TECHNICAL ASSISTANCE PLEASE CALL YOUR LOCAL REPRESENTATIVE

LISTED ON THE FOLLOWING PAGE.

Effectivity Page for P/N 46000-1320, Edwards 2400 Manual

Revision Description

0.0 Initial Release

0.1 Editorial Corrections

0.2 Add 2400-ADM, 2400 -ADS, & 2400-RTU Module Information

1.0 Renamed Table 2.1 to Table 1.1. Add Table 1.2. Correct Cat. # 2245

to 2445.

1.3 Revise part numbers; Delete Table 5.9; Add Table 10.11

1.4 Add Battery Box & revise battery tables; Revise 4-wire EOL Relay;

Add Auxiliary Power note; Revise RCT; d elete remote station from

RCT module; Add 2400-DL1 Dialer Module; Revise 2400-ADMM

supervisory operation; add additional replacement parts.

1.5 Revised dialer and compatibility information

1.6 Editorial corrections. Revised: Dialer Information. Added

programming warning.

iii

Page 5

Table of Contents

1.0 DESCRIPTION

1.1 Components.....................................................................................................2

................................................................................................. 1-4

2.0 APPLICATION......................................................................................................5

2.1 Fire Alarm System Limitations..........................................................................5

3.0 THEORY OF OPERATION........................................................................... 5-8

3.1 Initiating Device Circuits (IDCs)........................................................................5

3.2 Indicating Appliance Circuits (IACs).................................................................8

4.0 INSTALLATION.............................................................................................. 9-15

4.1 Codes and Standards.......................................................................................9

4.2 Site Storage......................................................................................................9

4.3 Drawing References.........................................................................................9

4.4 Installation Instructions...................................................................................10

5.0 PROGRAMMING......................................................................................... 16-20

5.1 Programming Initiating Device Circuits (IDCs)...............................................17

5.2 Programming Indicating Appliance Circuits (IACs).........................................18

5.3 Configuring System Timers............................................................................19

5.4 Programming Auxiliary Power........................................................................19

5.5 Returning to Panel Default Settings...............................................................20

5.6 Dialer Module.................................................................................................20

6.0 OPERATION..................................................................................................22-26

Normal Mode............................................................................................................22

Alarm Mode..............................................................................................................22

Reset Mode..............................................................................................................23

Trouble Mode...........................................................................................................23

Supervisory Mode....................................................................................................24

Drill Mode.................................................................................................................24

IDC Zone Disable.....................................................................................................24

Test Mode................................................................................................................25

Dialer Module...........................................................................................................26

Remote Trouble Unit................................................................................................26

7.0 TROUBLESHOOTING.....................................................................................27

iv

Page 6

8.0 PREVENTIVE MAINTENANCE

8.1 Preventive Maintenance Schedule ................................................................29

8.2 Testing Procedures for the Dialer Module .....................................................31

8.3 Testing Procedures for Compatible 2-Wire Smoke Detectors....................... 31

8.4 Replacement Parts........................................................................................ 32

...............................................................29-32

9.0 SPECIFICATIONS.......................................................................................33-36

10.0 APPENDICES.............................................................................. 37-59

10.1 Appendix 1 - Battery Calculations.................................................................. 37

Using the Battery Tables ...............................................................................40

Example #1....................................................................................................41

Example #2....................................................................................................42

Battery Calculation Worksheets..................................................................... 43

Example #3....................................................................................................44

Example #4....................................................................................................45

10.2 Appendix 2 - Compatible Devices.................................................................. 46

ULI Compatibility Listings...............................................................................46

ULC Compatibility Listings.............................................................................49

10.3 Appendix 3 - Glossary ...................................................................................53

10.4 Appendix 4 - Standards Relevant to the Installation of this Product.............. 55

10.5 Appendix 5 - Fire Alarm Trouble & Maintenance Log....................................56

10.6 Appendix 6 - Panel Configuration & Programming Worksheet...................... 57

v

Page 7

List of Tables, Figures, & Illustrations

Table 1.1 Base Panel Capacity................................................................................. 2

Table 1.2 2400-RCT Battery Standby Requirements ............................................... 3

Table 3.1 IDC Operation........................................................................................... 5

Table 4.1 Drawing References ................................................................................. 9

Table 5.1 Programmable Features ......................................................................... 16

Table 5.2 Programming Step Indications................................................................ 17

Table 5.3 IDC Zone Type Codes............................................................................ 17

Table 5.4 Panel Indicating Appliance Circuit Status ............................................... 18

Table 5.5 IAC Signal Output Rates......................................................................... 18

Table 5.6 Alarm Silence Inhibit Timer Status.......................................................... 19

Table 5.7 Automatic Alarm Silence Timer Status.................................................... 19

Table 5.8 Auxiliary Power on Reset Status............................................................. 19

Table 6.1 Front Panel Controls and Indicators........................................................ 22

Table 6.2 Test Mode............................................................................................... 25

Table 6.3 Dialer LED Indications............................................................................. 26

Table 7.1 Trouble LEDs.......................................................................................... 27

Table 7.2 Panel Trouble.......................................................................................... 27

Table 7.3 Dialer Module Trouble Codes ................................................................. 28

Table 8.1 Preventive Maintenance Schedule.......................................................... 29

Table 8.2 Related/Spare Parts................................................................................ 32

Table 9.1 Specifications

(Base Panel Assemblies, BPA)............................................................... 33

Table 9.2 Specifications

(2400-BPA Class A (Style D/Z) Converter Module)................................ 34

Table 9.3 Specifications

(2400-2IDC IDC Module)........................................................................ 34

Table 9.4 Specifications

(2400-IDCA IDC Class A (Style D) Zone Converter Module) ................. 34

Table 9.5 Specifications

(2400-RCT Relay/City-Tie Module)......................................................... 34

Table 9.6 Specifications

(2400-ADM Annunciator Driver Master Module)..................................... 35

Table 9.7 Specifications

(2400-ADS Annunciator Driver Slave Module)........................................ 35

Table 9.8 Specifications

(Remote Annunciators)........................................................................... 35

Table 9.9 Specifications

(2400-BATBOX) Battery Box .................................................................. 35

Table 9.10 Specifications

(2400-DL1) Dialer Module....................................................................... 36

Table 10.1 24 Hours Supervisory, 5 Minutes of Alarm.............................................. 37

Table 10.2 60 Hours Supervisory, 5 Minutes of Alarm.............................................. 38

Table 10.3 24 Hours Supervisory, 30 Minutes of Alarm............................................ 39

Table 10.4 ULI Control Unit Compatibility Specifications - Edwards......................... 46

Table 10.5 ULI Compatible Receivers for the 2400-DL1 Dialer................................ 46

Table 10.6 ULI Device & Panel Compatibility - Initiating Devices............................. 47

Table 10.7 ULI Compatibility Signaling Appliances................................................... 47

Table 10.8 ULI Compatibility Accessories................................................................. 48

Table 10.9 ULC Control Unit Compatibility Specification - Edwards......................... 49

Table 10.10 ULC Compatible Receivers for the 2400-DL1 Dialer .............................. 49

vi

Page 8

Table 10.11 ULC Device & Panel Compatibility - Initiating Devices............................ 50

Table 10.12 ULC Compatible Signaling Appliances ................................................... 51

Table 10.13 ULC Compatible Accessories ................................................................. 51

Table 10.14 Mixed Ion/Photo Detector Maximum Devices per Circuit........................ 52

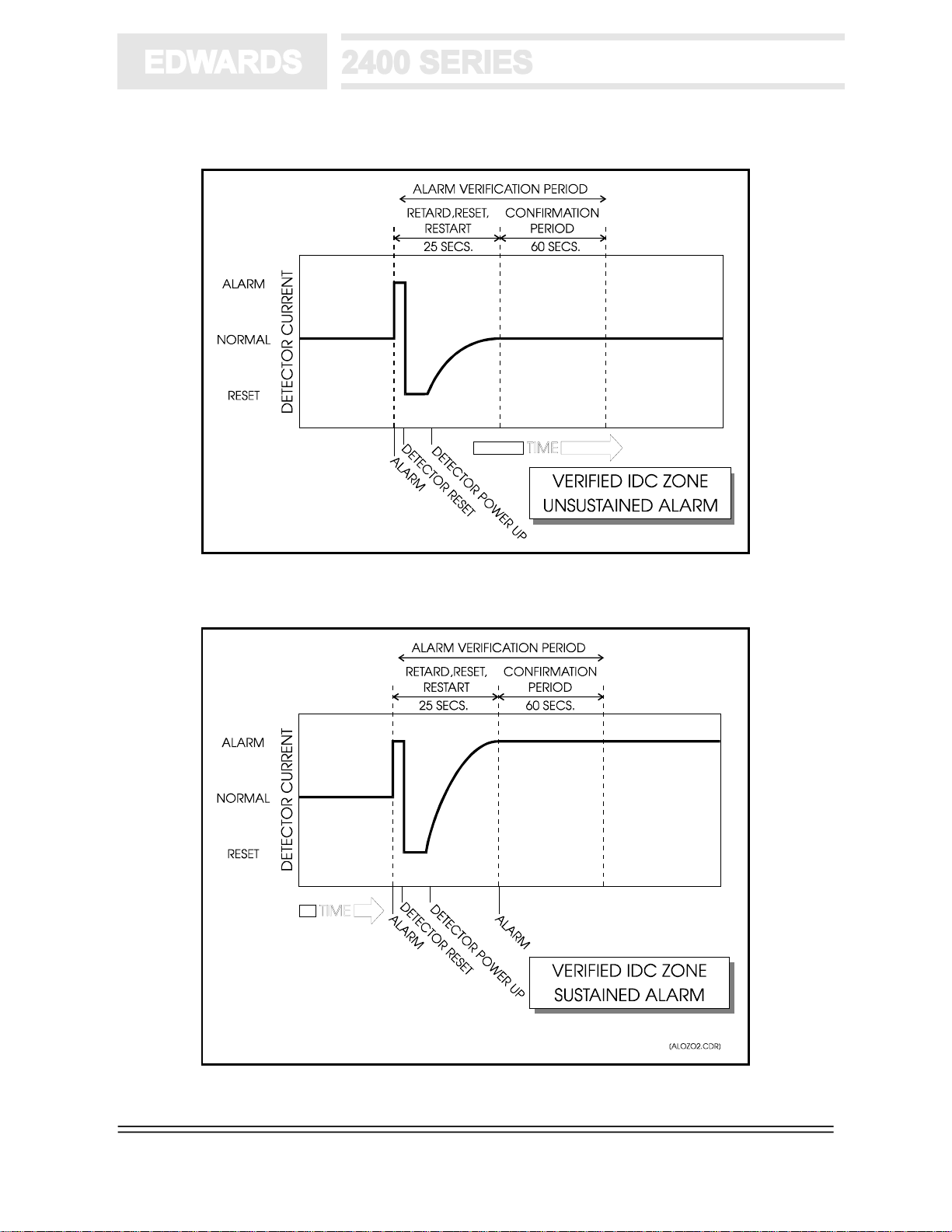

Figure 3.1 Unsustained Alarm Operation................................................................... 7

Figure 3.2 Verified Alarm Operation........................................................................... 7

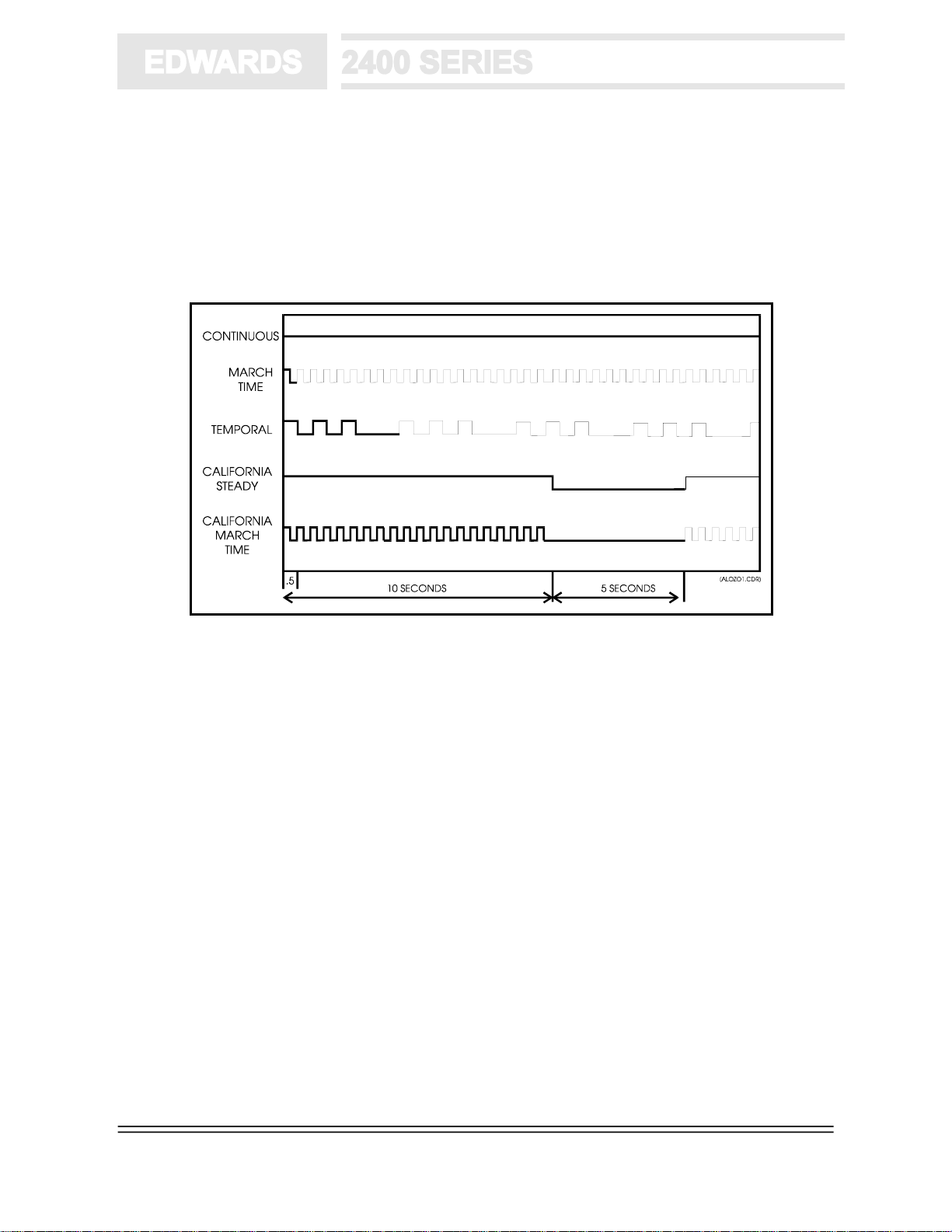

Figure 3.3 IAC Signal Rates....................................................................................... 8

Drawing #1.......................................................

Drawing #2........................................................CONTROL PANEL INSTALLATION 2

Drawing #3.........................................................................................CONTROL PANEL

Drawing #4....................................................INITIATING DEVICE CIRCUIT WIRING

Drawing #5...........................................................................RELAY/CITY-TIE MODULE

Drawing #6.......................................................................................... DIALER MODULE

Drawing #7........................................................................ REMOTE ANNUNCIATORS

Drawing #8......................................................CONTROL PANEL APPLICATIONS 1

Drawing #9......................................................CONTROL PANEL APPLICATIONS 2

Drawing #10......................................................................... PANEL PROGRAMMING

Drawing #11................................................................................... PANEL OPERATION

Drawing #12................................................................................DIALER OPERATIONS

CONTROL PANEL INSTALLATION 1

vii

Page 9

Fire Alarm Control Panel

Two Zone, Three Expansion Space Panel, Cat. # 2412(R)

Four Zone, Two Expansion Space Panel, Cat. # 2414(R)

Eight Zone, Six Expansion Space Panel, Cat. # 2418(R)

1.0 DESCRIPTION

The 2412, 2414, & 2418 Fire Alarm Control Panels are protective signaling systems which feature modular

construction and installer programmable microprocessor technology.

m Panel Supervisory Features include: continuous internal testing; a CPU watchdog timer; and module

placement supervision.

m Operational Features include: alarm, supervisory, and trouble resound; fire drill mode; one man test

mode; lamp test; alarm silence inhibit; and automatic alarm silence.

m Programmable Options include: verified or non-verified alarm; waterflow with or without retard; and

supervisory Initiating Device Circuits (IDCs). Verified circuits support dry contact alarm initiating

devices when used with high impedance smoke detectors. Indicating Appliance Circuits (IACs) may be

programmed as silenceable or non-silenceable with continuous, March Time at 120 Strokes per

Minute (SPM), California, or temporal rates (Figure 3.3). The temporal rate meets the requirements of

the national emergency evacuation signal. Alarm silence/reset inhibit, automatic alarm silence, and offpremise AC/brownout 6 hr. trouble delay timers are provided. Resettable power for 4-wire smoke

detectors is provided.

m Hardware Options include an 2400-RCT Relay/City-Tie Module with provisions for municipal box,

reverse polarity and dry relay contact operation. The 2400-BPA Class A Base Panel Converter is

available to convert the IDC and IAC circuits on the Base panels to Class A (Style D) IDC and Class A

(Style Z) IAC wiring. The 2400-IDCA Class A (Style D) IDC Converter is available to convert 24002IDC Two Zone IDC Modules to Class A (Style D) wiring. The 2400-DL1 Dialer Module provides a

supervised connection to a Central Monitoring Station via dial-up telephone lines. The 2400-ADM Four

Circuit Remote Anunciator Driver Master Module and the 2400-ADS Four Circuit Remote Annunciator

Driver Slave Module are available to supervise and drive remote annunciation panels. All circuits

external to the panel are transient protected. All circuits except the AC power wiring, municipal box,

and relay contacts are power limited. Panel option module capacity is indicated in Table 2.1. The

panels have steel enclosures with a textured baked enamel finish. The enclosure has a Lexan™

viewing window, key lock, and is suitable for semi-flush or surface mounting. Room is provided in the

enclosure for standby batteries. Conduit and nail knockouts, and keyhole style mounting holes help

support quick installation. An optional battery enclosure, model 2400-BATBOX (R), is available when

10 Amp-Hour batteries are required.

The panel is listed by ULI to standard UL 864 and ULC to standard ULC S527.

1

Page 10

1.1 Components

2412

Two Zone Base Panel w/3 Option Module Expansion Spaces, Gray Enclosure (Cat.# 2412)

Two Zone Base Panel w/3 Option Module Expansion Spaces, Red Enclosure (Cat.# 2412-R)

This panel provides two Class B (Style B) Initiating Device Circuits (IDCs) and two Class B (Style Y)

Indicating Appliance Circuits (IACs). There is space for three option modules. Option modules include a

Relay/City-Tie, Two Zone Initiating Device, a Dialer Module, and Remote Annunciator Driver Modules.

Space for standby batteries is provided in the enclosure. Refer to the Appendix to select the proper battery

for your application.

2414

Four Zone Base Panel w/2 Option Module Expansion Spaces, Gray Enclosure (Cat.# 2414)

Four Zone Base Panel w/2 Option Module Expansion Spaces, Red Enclosure (Cat.# 2414-R)

This panel provides four Class B (Style B) Initiating Device Circuits (IDCs) and two Class B (Style Y)

Indicating Appliance Circuits (IACs). There is space for two option modules. Option modules include a

Relay/City-Tie, Two Zone Initiating Device, a Dialer Module, and Remote Annunciator Driver Modules.

Space for standby batteries is provided in the enclosure. Refer to the Appendix to select the proper battery

for your application.

2418

Eight Zone Base Panel w/3 Option Module Expansion Spaces, Gray enclosure (Cat.# 2418)

Eight Zone Base Panel w/3 Option Module Expansion Spaces, Red enclosure (Cat.# 2418-R)

This panel provides eight Class B (Style B) Initiating Device Circuits (IDCs) and two Class B (Style Y)

Indicating Appliance Circuits (IACs). There is space for three option modules. The available option

modules include a Relay/City-Tie Module, a Dialer Module, and Remote Annunciator Driver Modules.

Space for standby batteries is provided in the enclosure. Refer to the Appendix to select the proper battery

for your application.

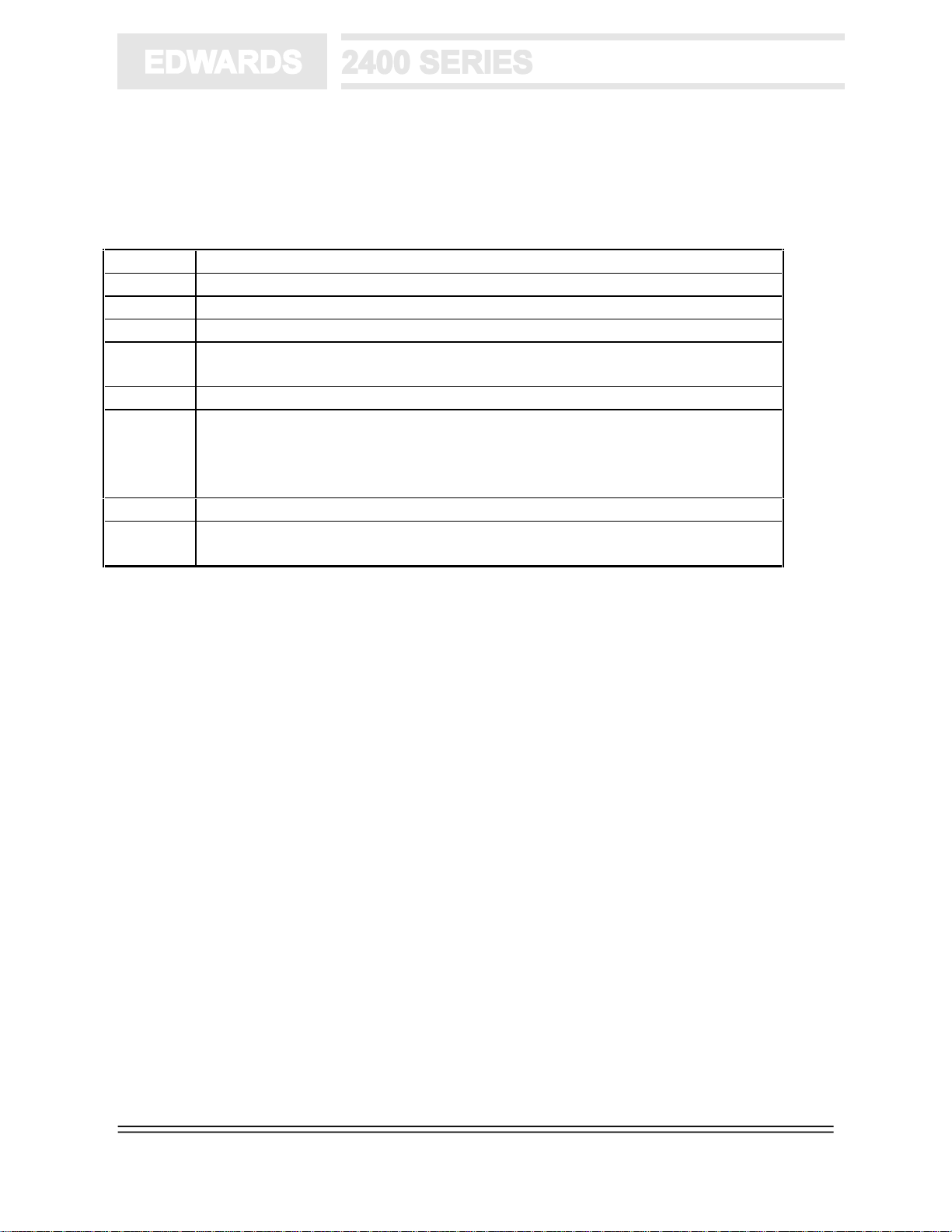

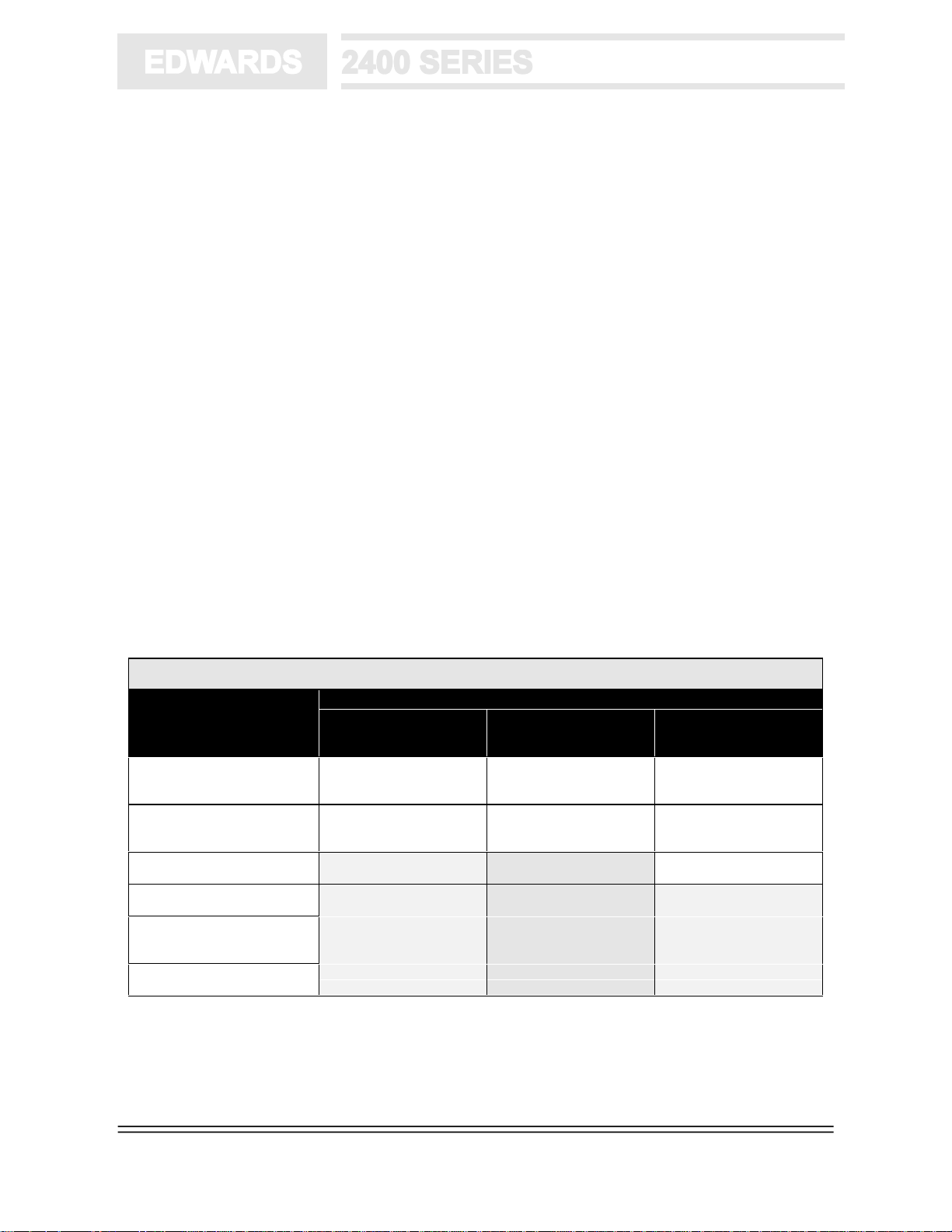

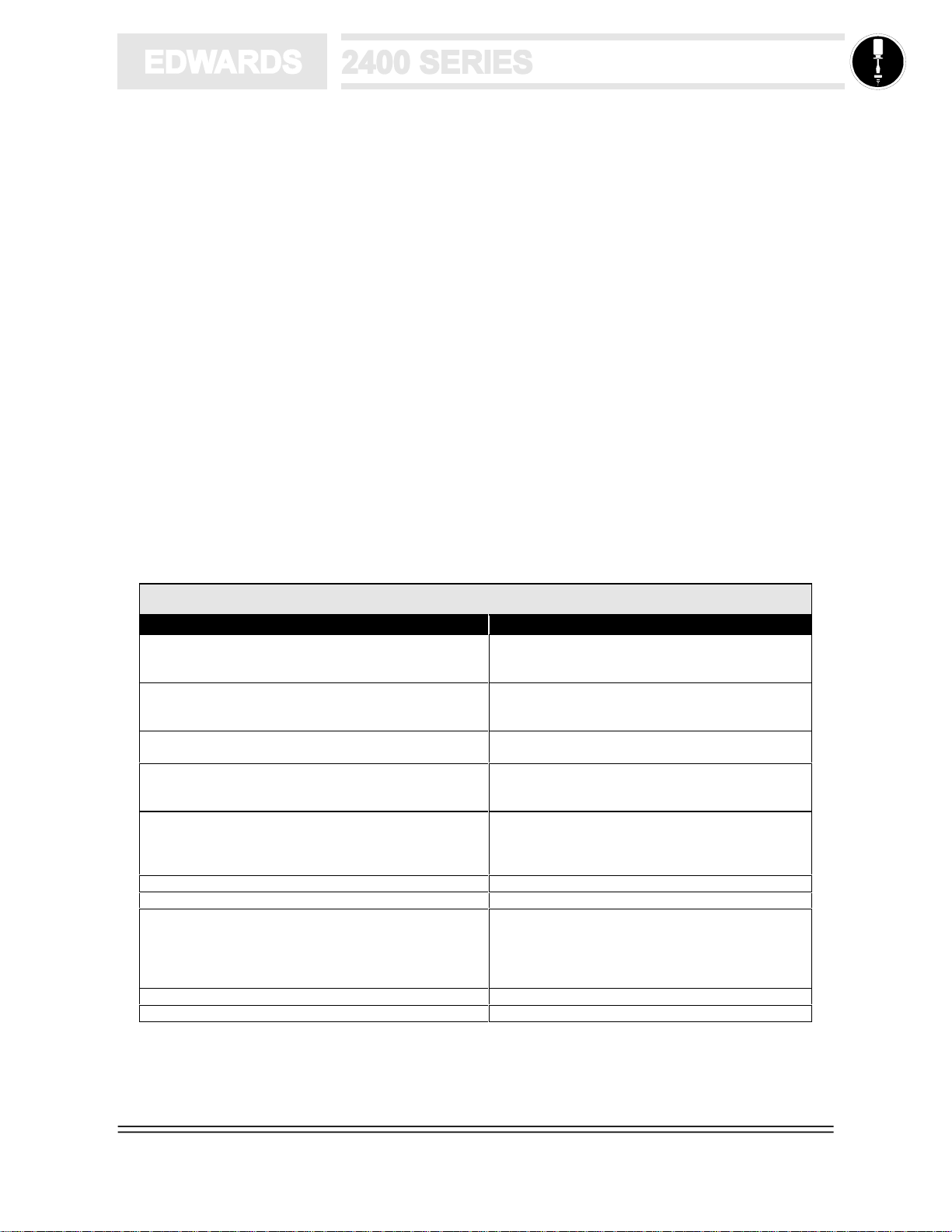

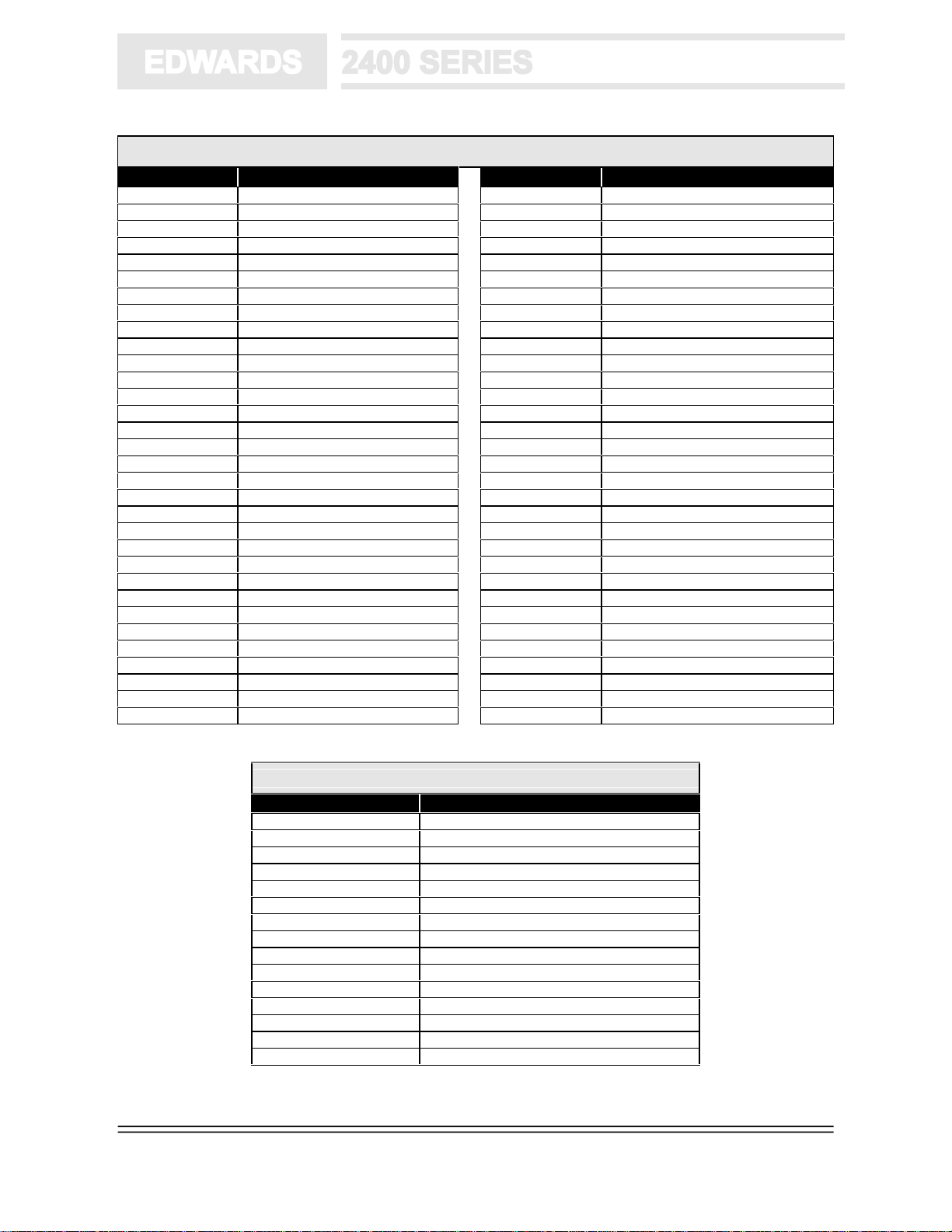

Table 1.1 - Base Panel Capacity

Base Panel

Accessory/Option

Module

Internal Batteries Two 12 V @ 4.5 AH

External Batteries 2400-BATBOX(R)

2 Zone Initiating Device Circuit

2400-2IDC (P/N 240457)

Relay/City-Tie Module

2400-RCT (P/N 240459)

Annunciator Driver Mast er

Module

2400-ADM (P/N 240461)

Dialer Module

2400-DL1 (P/N 240508)

Any Combination of 3, Max Any Combination of 2, Max

2412

Panel Capacity:

3 Option Modules

Two 12 V @ 6.5 AH

2 ea. P/N 12V10,

12 V @ 10 AH

2414

Panel Capacity:

2 Option Modules

Two 12 V @ 4.5 AH

Two 12 V @ 6.5 AH

2400-BATBOX(R)

2 ea. P/N 12V10,

12 V @ 10 AH

2418

Panel Capacity:

3 Option Modules

Two 12 V @ 4.5 AH

Two 12 V @ 6.5 AH

Four 6 V @ 8.0 AH

2400-BATBOX(R)

2 ea. P/N 12V10,

12 V @ 10 AH

0

Any Combination of 3, Max

2400-BPA Base Panel Class A (Style D/Z) Converter Module (P/N 46199-1072)

This Class A (Style D/Z) Base Panel Converter changes the base panel to Class A (Style D) Initiating

Device Circuits and Class A (Style Z) Indicating Appliance Circuits. The Class A Base Panel Converter

does NOT require any option module expansion spaces.

2

Page 11

2400-2IDC Two Zone Initiating Device Circuit Module (P/N 240457)

This module provides two additional Class B (Style B) Initiating Device Circuits. Each circuit is provided

with an

ENABLE/DISABLE switch and a tri-color LED. The module requires one option module expansion

space.

2400-IDCA Class A (Style D) IDC Converter Module (P/N 46199-1074)

This Class A (Style D) IDC Converter changes the two Class B (Style B) Initiating Device Circuits on a Two

Zone Initiating Device Circuit Module to Class A (Style D) operation. The module does NOT require any

option module expansion space.

2400-RCT Relay/City-Tie Module (P/N 240459)

The Relay/City-Tie Module is a configurable Normally-Open (N.O.) or Normally-Closed (N.C.) relay

contact, which is configurable to operate on panel Alarm, Trouble, Supervisory, or Reset conditions. The

Relay/City-Tie Module may be configured for, municipal box, reverse polarity, or dry contact operation.

Relay contacts are rated for 24 VDC @ 1A. The module has a disconnect switch and an amber Trouble

LED. The module requires one option module expansion space. Off premise power failure trouble

signaling using this module has a 6 hour delay.

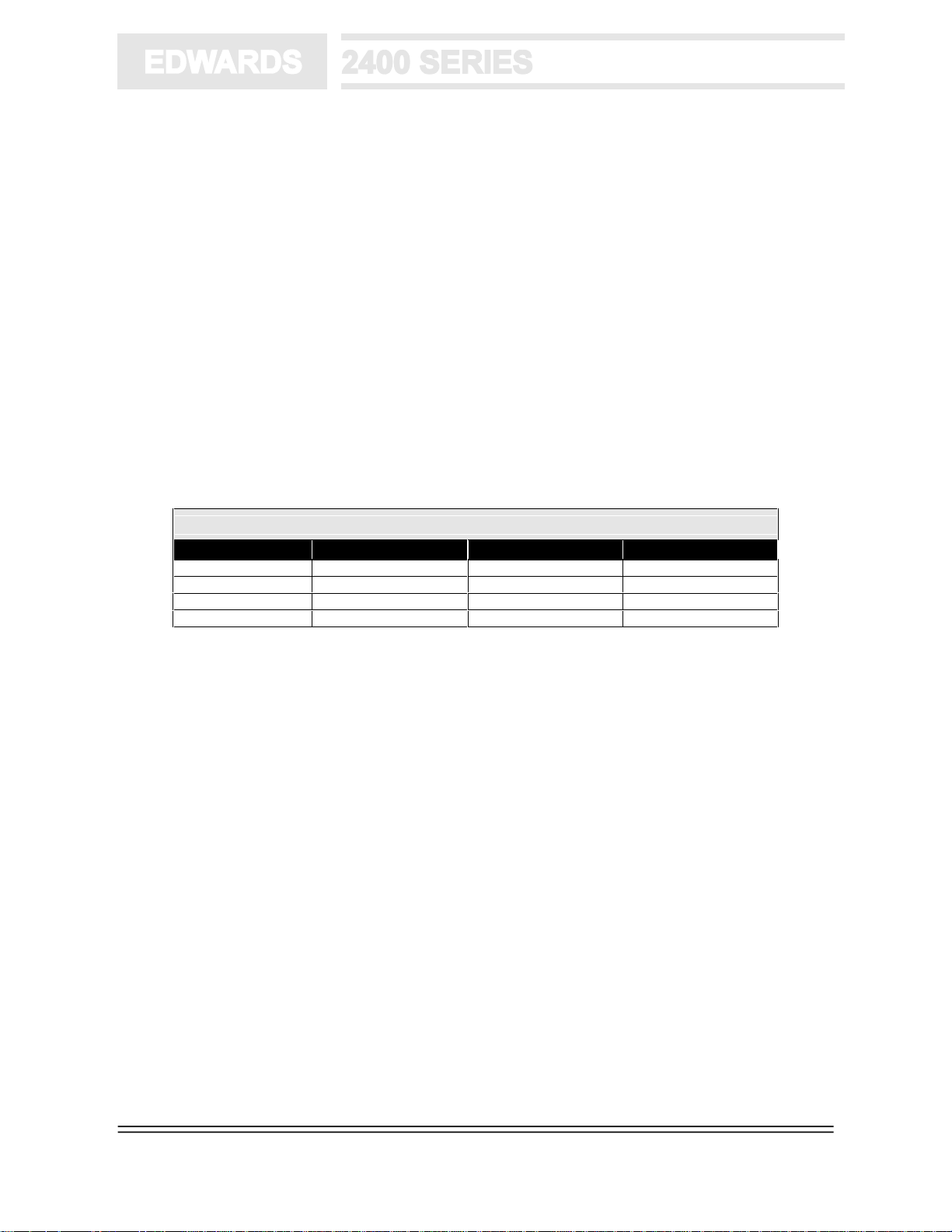

Table 1.2 - 2400-RCT Battery Standby Requirements

Feature 2412 2414 2418

Dialer Up to 60 Hrs. Up to 60 Hrs. Up to 60 Hrs.

Dry Contact (Shunt) Up to 60 Hrs. Up to 60 Hrs. Up to 60 Hrs.

Master Box Up to 60 Hrs. Up to 60 Hrs. Up to 60 Hrs.

Reverse Polarity Up to 60 Hrs. Up to 60 Hrs. Up to 60 Hrs.

NOTES:

1. Refer to battery calculations.

2. NFPA 72 requires 60 hours of stand by battery when connecting to an off premises

monitoring location

DL1 Dialer (Digital Alarm Communicator Transmitter) (P/N 240508)

The DL1 dialer module is a Digital Alarm Communicator Transmitter (DACT) for transmitting alarm,

supervisory and trouble information to a compatible Digital Alarm Communicator Receiver (DACR) via two

dial-up telephone lines. The dialer supports 20 PPS 3/2 or 4/2 format for communicating between the

panel and the DACR (see specifications). Both Dual Tone Multi Frequency (DTMF) and Pulse dialing are

automatically supported. AC power failure reporting may be delayed. The dialer performs an automatic

test call every 24 hours to verify communications between the fire alarm panel and the receiving

equipment. Dialer module programming is performed with any standard tone dial(DTMF) telephone. All

programming is password protected.

2400-ADM Four Circuit Annunciator Driver Master Module (P/N 240461)

The Four Circuit Remote Annunciator Driver Module is used to supervise and operate the connection to

four individual alarm zone LEDs on a conventional zone annunciator. The -ADM is automatically

configured for IDC zones 1 to 4. The Annunciator Driver Master Module requires one expansion module

space in the enclosure.

3

Page 12

2400-ADS Four Circuit Annunciator Driver Slave Module (P/N 240463)

The Four Circuit Remote Annunciator Driver Slave Module is used to supervise and operate the

connection to four additional alarm zone LEDs on a conventional zone annunciator. The -ADS is

automatically configured for IDC zones 5 to 8. The Remote Annunciator Driver Slave Module mounts on

the 2400-ADM Master, module and does NOT require any expansion module space.

2400-RTU Remote Trouble Unit (P/N 46199-1076)

The 2400-RTU Remote Trouble Unit is a remote trouble annunciator which displays fire alarm normal and

trouble conditions. The unit is provided with a power LED and an integral trouble buzzer. A trouble silence

switch with ring-back is also provided.

2400-xZA Remote Zone Annunciators

The 2400-xZA Remote Zone Annunciators duplicate the control panel’s individual zone alarm LEDs at a

location remote from the control panel. Model 2400-4ZA provides 4 zone LEDS, model 2400-8ZA provides

8 zone LEDs.

2400-RTUxZA Combination Remote Annunciators

The 2400-RTUxZA Remote Annunciators combine the features of the 2400-RTU and the 2400-xZA

annunciators in a single package. Model 2400-RTU4ZA provides remote trouble annunciation and 4 zone

LEDS, model 2400-RTU8ZA provides remote trouble annunciation and 8 zone LEDs.

Batteries are available in a variety of sizes to meet the 24 and 60 hour standby requirements, followed by

5 or 30 minutes in alarm. Table 1.1 shows the batteries suitable for each panel. Appendix 1 provides

information on battery sizing.

4

Page 13

2.0 APPLICATION

The 2412, 2414, and 2418 panels are suitable for small to medium size buildings, requiring from two to

eight Initiating Device Circuits (IDCs), and two Indicating Appliance Circuits (IACs).

2.1 Fire Alarm System Limitations

Fire Alarm Systems provide the occupants of a facility with early warning of smoke and fire conditions. Fire

alarm systems use a variety of components to meet the requirements of each installation. The fire alarm

panel, automatic and manual detection devices, alarm annunciators, and the installation wiring are all

factors in a reliable system. To maintain proper operation, fire codes require, and this manufacturer

recommends preventive maintenance and testing on a routine basis by qualified personnel.

3.0 THEORY OF OPERATION

3.1 Initiating Device Circuits (IDCs)

The supervised IDCs operate with compatible smoke detectors (refer to Appendix) and normally-open

alarm initiating devices. An IDC may be programmed as an Alarm, Waterflow/Supervisory, or Supervisory

zone. Alarm zones may have verified or non-verified operation. Waterflow/Supervisory zones programmed

with or without a 15 second retard period, also support a single supervisory input device with a

Wseries resistor. IDC circuits may take one of four operating states: Normal, Trouble, Alert, or Alarm.

1.1K

Table 3.1 defines the states for the various IDC zone types.

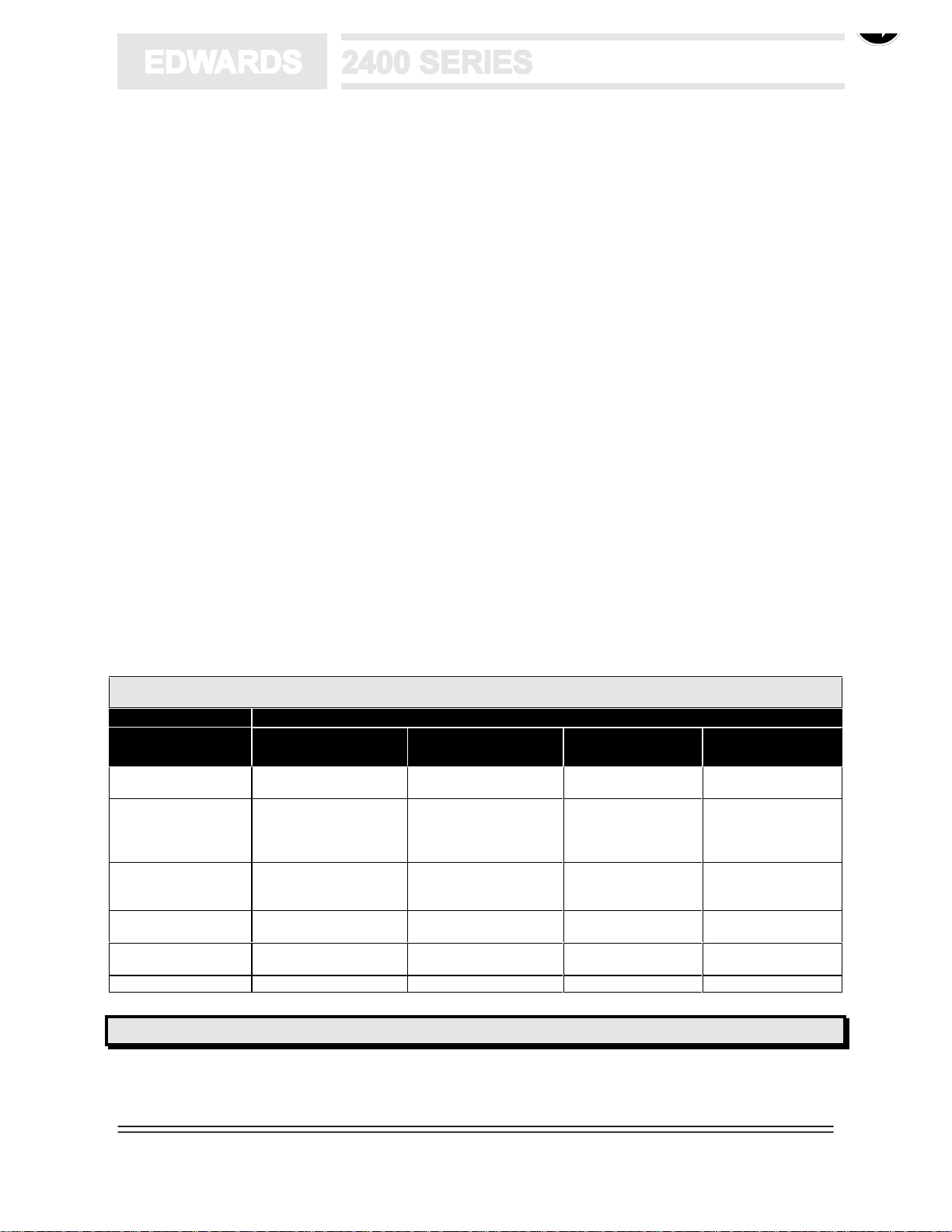

Table 3.1 - IDC Operation

State of Operation

Zone Type Alarm

(Low Impedance)

Non-Verified

Alarm Zone

Verified Alarm Zone

with high impedance

smoke detectors and

N.O. contact devic es

Verified Alarm Zone

with smoke detectors

only

Waterflow/Supervisory

Zone

Waterflow/Supervisory

Zone with Retard

Supervisory Zone Supervisory Condition Supervisory Condition Normal Operation Trouble

Alarm after 15 seconds S upervisory Condition Normal Operation Trouble

Alarm Alarm Normal Operation Trouble

Alarm Verifying the Alarm Normal Operation Trouble

Verifying the Alarm Verifying the Alarm Normal Operation Trouble

Alarm Supervisory Condition Normal Operation T roubl e

(High Impedance)

Alert

Normal Open

WARNING! Do NOT put contact devices on Low Impedance Verified Circuits.

An active IDC defined as an Alarm or Waterflow Zone may be identified by a steady red zone LED. Active

IDCs defined as supervisory zones may be identified by a rapid flashing amber zone LED.

5

Page 14

When an IDC is programmed as a waterflow zone, the IACs DO NOT respond to the ALARM SIL ENCE

switch or automatic alarm silence until the waterflow device is no longer active. Both an alarm initiating

device and a supervisory contact may co-exist on the same circuit by putting a 1.1K

supervisory contact. When the waterflow with retard option is programmed, a special algorithm samples

the circuit repeatedly. If 66% of the samples taken in any 15 second period indicate a waterflow (shorted)

condition, the circuit activates a waterflow alarm.

When an IDC is programmed as a verified zone and a smoke alarm is detected, the panel enters the

Alarm Verification state. A twenty five second sequence in which the detector is reset, delayed, and

restarted is initiated, as shown in Figure 3.1. If auxiliary power is programmed as resettable, it is deenergized for the reset period. Following the reset-delay-restart sequence, a 60 second verification

window is opened. If the verifying zone should go into the Alert, Alarm, or Trouble conditions within the 60

second window as shown in Figure 3.2, the panel enters the alarm mode. If any other IDC on the panel

goes into the alert or alarm state during the verification period, the panel immediately enters the alarm

mode. Dry contact alarm initiating devices may be combined with High Impedance 2-wire smoke detectors

on verified zones. The closing of a normally open dry contact alarm initiating device generates an Alarm

state immediately, and the panel enters the alarm mode.

Initiating Device Circuit, Class A (Style D) Operation

To convert a Class B (Style B) IDC zone to a Class A (Style D) IDC zone, install a 2400-BPA Class A

Ω in series with the

NOTE

2- Wire Relay Bases are NOT supported on Initiating Device Circuits (IDCs).

(Style D/Z) Converter on the base panel, or a 2400-IDCA Class A (Style D) Converter on the Two Zone

IDC Module. The converters provides an alternate path to the zone module for all Initiating Devices in the

event of a single wire break in an IDC.

6

Page 15

Figure 3.1 - Unsustained Alarm Operation

Figure 3.2 - Verified Alarm Operation

7

Page 16

3.2 Indicating Appliance Circuits (IACs)

Two supervised Indicating Appliance Circuits (IACs) operate using compatible 24 VDC (nominal) polarized

signaling appliances. Each circuit is rated at nominal 24 VDC @ 2.5 Amps, with a total of 4.0 Amps

available for both circuits. An IAC may be programmed as either silenceable or non-silenceable. Signal

rate selection is independently programmable for each IAC as shown in Figure 3.3. Refer to the Appendix

for compatible Indicating Appliances.

Figure 3.3 - IAC Signal Rates

IACs generate a trouble indication (slow flashing LED) when field wiring is open or shorted. In an open

fault condition, the panel will attempt to energize the signal appliances (i.e., all appliances up to the circuit

break will operate). An IAC with shorted field wiring will NOT operate in the event of an alarm. If an IAC

develops a short during an alarm, the IAC will automatically shut off and continuously monitor the field

wiring. When the fault is cleared, the IAC will re-energize. These actions protect the power supply and

other panel components from damage caused by the short circuit.

Indicating Appliance Circuit, Class A (Style Z) Operation

To convert Class B IAC zones to Class A (Style Z) IAC zones, install a 2400-BPA Class A (Style D/Z)

Converter Module on the base panel. The converter provides alternate paths to the base panel for both

Indicating Appliance Circuits in the event of a single wire break in an IAC.

8

Page 17

4.0 INSTALLATION

4.1 Codes and Standards

Install this panel in accordance with all applicable codes and standards to the satisfaction of the Authority

Having Jurisdiction (AHJ). A partial list of codes and standards appears in the Appendix.

US Installations: For Class B (Style B/Y) circuits, the End-Of-Line resistor is installed on the last device.

Canadian Installations: For Class B (Style B/Y) circuits, purchase End-Of-Line resistor plates separately

from your Distributor. Use the specified resistors and install in a separate electrical box in an accessible

location beyond the last device on a circuit.

4.2 Site Storage

Remove backbox from top of carton. Place extra modules in panel carton and store safely in a dry location

during rough-in, to avoid damage to electronic parts.

4.3 Drawing References

Table 4.1 lists the drawings that are included at the end of this manual.

Table 4.1 - Drawing References

Subject Drawing Title

Assembly Details

Ribbon Connectors

Battery Interconnec t

Base Panel Circuits

IAC Wiring Diagram

IAC Wire Chart

Initiating Device Circuits

IDC Wire Chart

2IDC Two Zone Initiating Devic e Ci rcuit Module INITIATING DEVICE CIRCUIT WIR IN G

Relay/City-Tie Module

Applications.

Connections and Jumper Sett i ngs

Remote Annunciators & Annunciator Driver Modules REMOTE ANNUNCIATORS

4-Wire Smoke Detectors Control Panel A p plications 2

Class A Wiring CONTROL PANEL

Panel Programming Instruc t i ons Panel Programming

Panel Operations Panel Operatio n

Control Panel Inst allation 1

Control Panel Inst allation 2

Control Panel

Initiating Device Circuit Wirin g

or see the Installation S heet supplied with the Two

Zone IDC Module

Relay/City Tie Module

Control Panel A p plications 1

or see the Installation S heet supplied with the

Relay/City-Tie Module

INITIATING DEVICE CIRCUIT WIRING

or see the Installation S heets supplied with the BPA

Base Panel Class A Conv erter Module & IDCA, 2IDC

Module Class A Converter

9

Page 18

4.4 Installation Instructions

Mounting the Backbox

Install backbox per drawings Control Panel INSTALLATION 1 and Control Panel INSTALLATION 2. If a

2400- BATBOX Battery Cabinet is required, refer to the CONTROL PANEL APPLICATIONS 2 drawing for

information.

Utility or Primary Power Circuit

NOTE

Install primary power conduit on lower left side or left bottom of backbox.

The panel requires a dedicated 120 VAC, 15A, 50/60 Hz branch circuit. Label the circuit breaker "Fire

Alarm Control Panel." Within the fire alarm enclosure, route wire away from power limited circuit wiring.

WARNING

Do NOT apply power at this time.

System Control Wiring

1. Refer to the drawings at the end of this manual for circuit wiring diagrams and wire charts showing

maximum wire runs and loading. Install system wiring using the wire type and gauge per the Authority

Having Jurisdiction. Locate field wiring conduit on the upper sides and top of the backbox. At the

panel, leave approximately 5’ (1.5 m) of wire available for dressing and termination. Pair and

label wires according to zone and function. Do not mix power limited and non-power limited wiring in

the same conduit.

2. Do not remove the factory installed test resistors from the panel at this time. The test resistors are

used for panel testing in the next steps. Refer to the drawings provided with each initiating and

signaling device for installation details. Install End-Of-Line resistors at the end of Class B circuits.

3. Use an ohm meter to check circuit continuity and verify that the wiring is free of shorts and ground

faults, as follows:

Class B (Style B) IDC meter readings should show 4.7K

Each wire should show an open to ground.

Class A (Style D) IDC meter readings should show a short between each set of outgoing and

incoming wires, and an open between each side of the circuit.

Class B (Style Y) IAC meter readings should show 4.7K

one direction and a short (polarized signals conducting) with the meter leads reversed. Each wire

should show open to ground.

Class A (Style Z) IAC meter readings should show a short between each set of outgoing and

incoming wires. Readings should show an open in one direction and a short (polarized signals

conducting) with the meter leads reversed between each side of the circuit.

Ω (EOL Resistor) between circuit pairs.

Ω (EOL Resistor) between circuit pair in

10

Page 19

Base Panel Assembly

CAUTION

The electronic components used in this system are sensitive to static electricity. Always

discharge any static buildup on your body by touching the panel enclosure before

handling any electronic components.

WARNING

The System Power Supply (the printed circuit board on the back of the Base Panel

Assembly) handles 170 VDC when powered. DO NOT handle this board with power on.

1. Remove the Base Panel Assembly from its anti-static carton.

2. Remove and place the anti-static foam packing on a flat work area.

3. Place the Base Panel Assembly Display face down on the foam packing. Leave the factory end-of-line

resistors in place on the base panel and expansion modules until making final connections.

Option Module Installation

If your system requires no optional expansion modules, skip to the section entitled Base Panel Assembly

Installation.

1. Refer to the CONTROL PANEL INSTALLATION 1 and CONTROL PANEL INSTALLATION 2 drawings.

2. Remove the Power Supply from the Base Panel Assembly to allow for first module installation.

3. Install Expansion Modules on the Base Panel Assembly from left to right (front view) starting with IDC

Modules, Remote Annunciator Driver Modules, then the Relay/City-Tie Modules. Before installing

the ADM & ADS Annunciator Driver Modules, verify that all jumpers are installed. Before

installing the RCT Relay/City-Tie Modules, verify that jumpers 1 & 2 are installed. Refer to

RELAY/CITY-TIE & REMOTE ANNUNCIATOR drawings for additional jumper information.

NOTE

The Dialer Module MUST be installed in position number 3 or higher to prevent

mechanical interference with other system components.

Do NOT connect the Dialer Module’s ribbon cable to the adjacent module until the rest of the

system has been installed and tested.

4. Insert all ribbon connectors (except the Dialer Module) into the adjacent socket, and re-install the

Power Supply on the back of the Base Panel Assembly. The Dialer Module will be connected later.

5. For Class A (Style D/Z) circuits, install the 2400-BPA Class A Converter modules on the back of the

Base Panel Board and 2400-IDCA on the back of the IDC Expansion Modules. Refer to CONTROL

PANEL INSTALLATION 1, CONTROL PANEL INSTALLATION 2, and INITIATING DEVICE CIRCUIT

drawings.

Base Panel Assembly Installation

11

Page 20

1. Refer to the CONTROL PANEL INSTALLATION 1 or CONTROL PANEL INSTALLATION 2 drawings. If a

2400-BATBOX Battery Cabinet is required, refer to the CONTROL PANEL APPLICATIONS 2 drawing

for information.

2. Lift wiring up and away from the backbox, and install the Base Panel Assembly using the four quick

fasteners. Do not connect control circuit wiring at this time.

3. Install the panel door and make the ground connection (green wire) from the power supply to the

middle door mounting stud.

WARNING

Batteries can deliver extremely high currents. To prevent serious burns caused by short

circuiting the battery, remove all jewelry before handling.

4. Place the batteries in the lower right area of the backbox. If using the external battery cabinet, put the

batteries in the battery cabinet.

5. Interconnect the cells per the CONTROL PANEL INSTALLATION 1 or CONTROL PANEL INSTALLATION

2 drawings. If a Battery Cabinet is being used, refer to the CONTROL PANEL APPLICATIONS 2

drawing for information. Connect panel battery leads at this time. Observe polarity: Red =

positive (+); Black = negative (-)

CAUTION

Observe polarity. Red is positive(+), Black is negative(-). A non-replaceable fuse

protects the system from damage caused by a reversed battery connection.

Power Up

1. Verify that all factory installed end-of-line resistors are still in place, all -ADM & -ADS module jumpers

are all installed, and -RCT module jumpers 1 & 2 are installed.

2. Connect primary power wires: Line, Neutral, and Ground to the input terminals of the power supply.

3. Energize AC power to the system. When you first apply power to the system it will follow an

initialization procedure. This procedure programs all connected IDCs as non-verified alarm inputs and

identifies the configuration of all output modules (it can take up to 15 seconds). You will see zone

LEDs turning on and off in sequence and communication LEDs (lower edge of expansion module

boards) flashing. Allow the system to complete this procedure before touching any controls. At the end

of the process, all LEDs except the Power On LED should be off. If the system trouble LED is on and

the trouble signal is sounding, refer to the trouble shooting procedures in this manual. If module LEDs

remain on steady, refer to the Programming section for additional information.

4 Install the lower protective plastic barrier over the high voltage terminals. Make sure to install this

cover strip. It protects you from the high voltage input terminals and traces on the power

supply printed circuit board.

Programming the Panel

1. Remove the Common Control insert card, reverse it, and then return it to its panel location. The

Common Control switches are now labeled for programming functions.

2. Refer to Table 5.1 for panel default operations and the PANEL PROGRAMMING drawing for

programming information. For Dialer Module programming, refer to the DIALER MODULE drawing

12

Page 21

3. Fill-in the Panel Configuration & Programming Worksheets (located in the Appendix) and program the

panel for the desired operation. Save the Panel Configuration Worksheets for future reference.

4. Remove, label, and re-insert the IDC, Relay/City-Tie, and Anunciator Driver Module insert cards. Use

the Panel Configuration Worksheets in this manual to assist in labeling. Reverse the Base Panel insert

card to display Fire Alarm Control functions.

Panel Function Testing

1. Test panel operations by shorting (Alarm) or opening (Trouble) the factory installed End-Of-Line

resistors.

2. To activate IDC circuits which combine high impedance smoke detectors and contact devices, or

supervisory signal operation of a waterflow/supervisory circuit, use a 1.2K

End-Of-Line resistor.

3. Remove the End-Of-Line resistor to verify proper trouble response.

4. Reset the panel, allowing 20 seconds for the panel to return to normal.

IDC & IAC Field Wiring Connections

1. Refer to the CONTROL PANEL INSTALLATION, initiating device circuit wiring, control panel

applications 1, & control panel applications 2 drawings for wiring details.

2. Dress all wires to allow "hinging" the Base Panel Assembly on the left by dressing your connections

from right to left. This allows you to rotate the Base Panel Assembly out of the enclosure for access to

system modules, facilitating additions or changes.

3. Leaving the system powered up, install the IDC & IAC circuits one at a time. The system will go into

Trouble mode. Remember to remove the factory installed End-of-Line resistor from the panel or

module terminals.)

4. Use the

5. Connect the appropriate field wiring, observing circuit polarity. If the wiring is correct, the trouble

condition will clear (Trouble LED and amber Zone LED turn off).

TROUBLE SILENCE switch to silence the Trouble signal.

Wresistor in parallel with the

2400-DL1 Dialer Panel and Field Wiring Connections

To eliminate excessive calls to the Central Monitoring Station, the Dialer Module panel

connection (ribbon cable) and programming should be performed after the balance of the

panel has been tested and verified operational.

1. Verify the Central Monitoring Station (CMS) is properly programmed and ready for connection.

2. Refer to the

3a. Dress all wiring to allow "hinging" the Base Panel Assembly on the right by dressing your connections

from right to left. This allows you to rotate the Base Panel Assembly out of the enclosure for access to

system modules, facilitating additions or changes.

3b. Fasten the dialer module to the panel assembly with the screws and standoffs provided.

3c. Fasten the bus interface adapter to the rear of the dialer, using the screws provided.

3d. Connect the ribbon cable to the next module in line. The system and dialer module will indicate trouble

conditions.

4a. Set the panel’s program switch to program mode (UP), and push the RESET switch.

4b. Wait for the Power LED to flash, then return the program switch to normal mode (down). This process

installs the Dialer Module in the panel’s data base. The panel will remain in trouble until the dialer is

properly wired and programmed.

DIALER drawing and DACR technical manual for wiring and programming details.

CAUTION

13

Page 22

The telephone jacks must be installed by an authorized representative of the telephone

company. Phone lines must be loop start on the public switched network.

PBX, ground start, and party lines are not acceptable

5. Using the supplied 7Ft. (2.13 M) phone jack extension cables, connect J1 & J2 to the RJ31X, or

RJ38X (CA31A or CA38A in Canada) telephone jacks. A protective grommet is supplied for the

enclosure knockout. The telephone jacks must be installed by an authorized representative of the

telephone company. The phone lines must be loop start on the public switched network. PBX, ground

start, and party lines are not acceptable.

6. With system powered up, program the dialer as shown in the drawing. A new dialer module will

remain in disabled until completely programmed. Use the TROUBLE SILENCE switch to silence

the Trouble signal.

7. If the telephone lines are wired properly and the panel is programmed correctly, the trouble condition

will clear (panel and module trouble LEDs turn off), when the dialer is enabled.

8. Activate and open all IDCs and IACs, verifying proper reception at the CMS.

9. Verify that failure of the primary signal path (phone line connected to J1) results in a trouble signal

being transmitted via the secondary signal path (phone line connected to J2) within 4 minutes.

10. Verify that failure of the secondary signal path (phone line connected to J2) results in a trouble signal

being transmitted via the primary signal path (phone line connected to J1) within 4 minutes.

NOTE

If a DL1 Dialer Module is installed, it will introduce a panel trouble until programmed.

NOTE

The Dialer Module will be disabled, with the LED “double flashing” amber until both

phone numbers and both site ID numbers are set. Pressing the disconnect switch will

have no effect.

WARNING

The DL1 Dialer Module requires separate programming in order to operate.

Refer to the DIALER MODULE Drawing.

14

Page 23

2400-ADM & 2400-ADS Field Wiring Connections

1. Refer to the REMOTE ANUNCIATOR drawing for wiring details.

2. Dress all wires to allow "hinging" the Base Panel Assembly on the left by dressing your connections

from right to left. This allows you to rotate the Base Panel Assembly out of the enclosure for access to

system modules, facilitating additions or changes.

3. Leaving the system powered up, connect the (+)24 VDC wire from the annunciator to the (+) Auxiliary

Power terminal.

4. Connect the NO (Normally Open) and NC (Normally Closed) wires from the annunciator to the NO

and NC trouble relay contacts on the control panel. Install a jumper between the trouble relay common

terminal and the (-) Auxiliary Power terminal.

5. Install all supervision jumpers

6. Connect the ADM & ADS LED circuits one at a time by removing the corresponding supervision

jumper.

7. Use the

TROUBLE SILENCE switch to silence the Trouble signal.

8. Connect the appropriate field LED wiring. If the wiring is correct, the trouble condition will clear

(Trouble LED and amber Zone LED turn off).

2400-RCT Field Wiring Connections

1. Refer to the RELAY/ CITY-TIE drawing and receiving station technical manual for wiring details.

2. Dress all wires to allow "hinging" the Base Panel Assembly on the left by dressing your connections

from right to left. This allows you to rotate the Base Panel Assembly out of the enclosure for access to

system modules, facilitating additions or changes.

3. Use the

TROUBLE SILENCE switch to silence the Trouble signal, if sounding.

4. Connect the appropriate field wiring, observing circuit polarity. If the supervised wiring is correct, the

trouble condition will clear (Trouble LED and amber Zone LED turn off).

Field Wiring Trouble (Also refer to Troubleshooting)

1. Clear any wiring faults as you install the field wiring. When a fault on a Class B circuit is cleared, the

panel will automatically return to the Normal mode. When a fault on a Class A circuit is cleared, the

panel must be manually reset to return it to the Normal mode.

2. If an IAC is shorted (or a signal appliance connection is reversed) or open, the circuit will continue to

display trouble. If an IAC has a ground fault, the trouble signal will resound and the Ground Fault LED

will turn on.

If an IDC has a short, the zone LED will change to red and the system will go into Alarm mode

(delayed 25 seconds if the circuit is programmed as a Low Impedance verified smoke detector circuit).

If an IDC has a ground fault, the trouble signal will resound and the Ground Fault LED will turn on.

3. Continue to complete supervised circuit connections one at a time using the panel to verify proper

wiring.

4. Connect ancillary circuits and remote monitoring and remote annunciator circuits per installation

drawings in this manual.

5. Test each circuit for proper function by putting the system into Alarm, Supervisory, or Trouble modes.

Refer to Operating the Panel for a description of testing procedures.

15

Page 24

5.0 PROGRAMMING

Panel Configuration Worksheets may be found at the end of this manual. These worksheets should be

filled out prior to programming the panel, and saved with this manual should further programming be

required at a later date. Refer to the

PANEL PROGRAMMING drawing during the programming process.

The reverse side of the base panel identification labels are programming templates. Remove, reverse, and

re-insert the template labels as a programming aid. Dialer programming is covered in section 5.6.

CAUTION

The panel MUST be reprogrammed whenever permanently adding (or removing) option

modules to (from) the system. Replacing a module with another module of the same type does

NOT require reprogramming.

DO NOT DISCONNECT AC POWER WHI L E IN THE PROGRAMMING MO DE!

The panel is shipped from the factory with the default configuration denoted by ✹ in Table 5.1. The panel

defaults may be re-programmed any time during the programming sequence by simultaneously pressing

the

TROUBLE SILENCE and RESET switches for one second, which also returns you to the start of the

programming process. The programming step (of the panel being programmed) is indicated by the flash

phase of the green Power LED. The program variable and flash phase is indicated in Table 5.2.

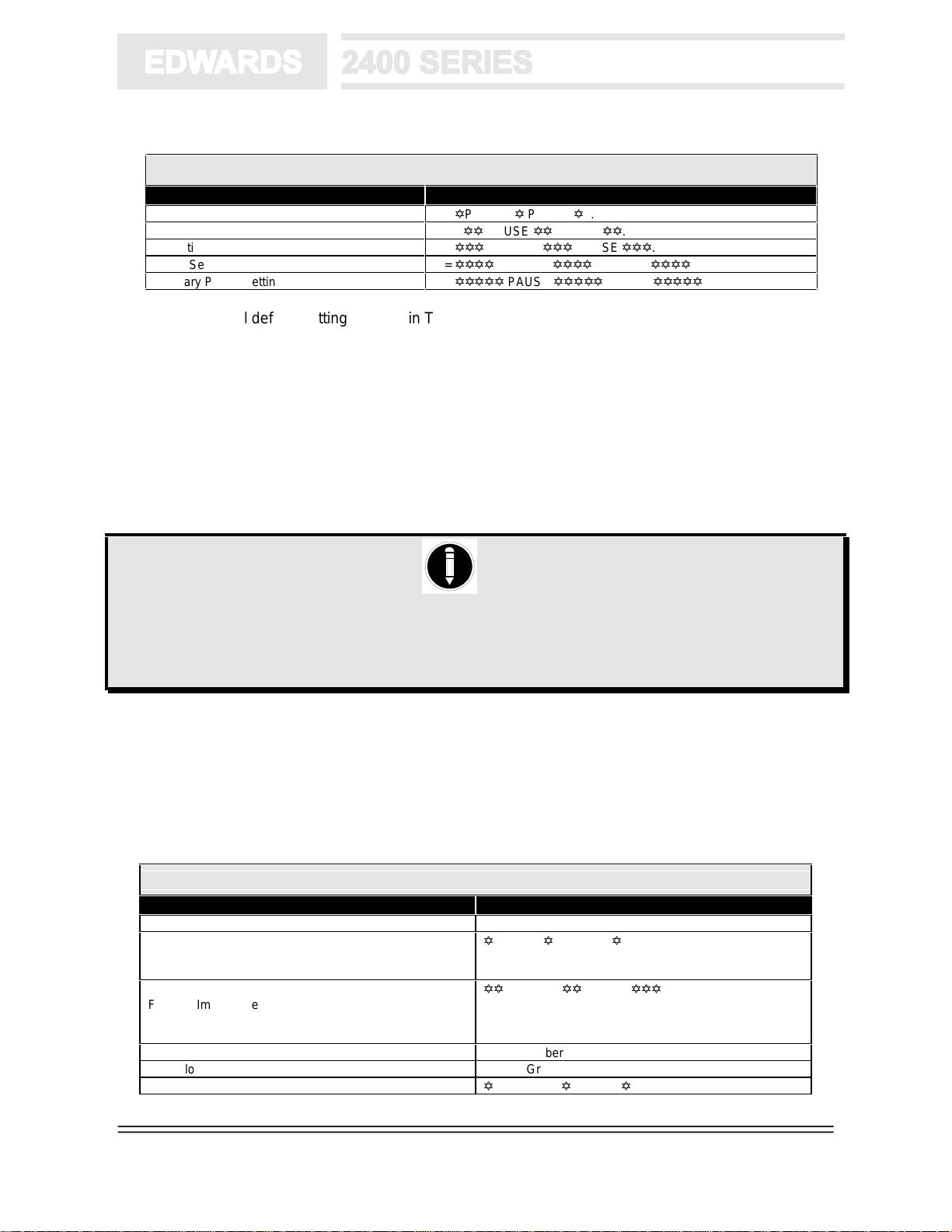

Table 5.1 - Programmable Features

✹ = Default

Initiating Device Circuit (IDC)

1✹ Non-Verified Alarm

2 Verified High Impedance Detec tor w/Contact Device (See Not e)

3 Verified Low Impedance Detector Only

4 Supervisory

5 Waterflow & Supervisory

6 Waterflow w/retard & Supervi sory

Indicating Appliance Circuit (IAC)

1✹ Affected by Alarm Si l ence Features

2 Not affected by Alarm S i l ence Features

IAC Signal Rates

1✹ Continuous

2 March Time @ 120 SPM

3 Temporal 3-3-3

4 Continuous ON for 10 Seconds., 5 S econds. OFF

5 March Time ON for 10 Seconds., 5 Seconds. OFF

Alarm Silence Inhibit Timer

1✹ No Timer

2 One Minute Inhibit

3 Two Minute Inhibit

4 Three Minute Inhibit

Automatic Signal Silence Timer

1✹ No Timer

2 10 Minutes to Silence

3 20 Minutes to Silence

4 30 Minutes to Silence

Auxiliary Power Reset

1✹ Auxiliary Power NOT Reset

2 Auxiliary Power Reset

NOTE: Do Not use this option. High Impedance detectors are not presently available.

16

Page 25

Table 5.2 - Programming Step Indications

Program Step Power LED Flash Phase

Module Placement & Verif i cation 1 = YPAUSE Y PAUSE Y...

Initiating Device Circuits (IDC) 2 =

Indicating Appliance Circuits (IAC) 3 =

Timer Settings 4 =

Auxiliary Power Setting 5 =

YY

PAUSE YY PAUSE YY..

YYY

PAUSE

YYY

YYYY

YYYYY

PAUSE

PAUSE

PAUSE

YYYY

YYYYY

YYY

PAUSE

PAUSE

..

YYYY

YYYYY

..

..

To modify the panel default settings shown in Table 5.1, enter the programming mode as follows:

1. Move the

2. Press the

PROGRAMMING MODE switch to the ON (down) position.

RESET switch. The green Power LED will display a single-phase flash after approximately 20

seconds. The trouble buzzer sounds at a four pulse/minute rate, indicating you are in the automatic

module placement & verification step of the programming process.

The panel automatically identifies all option modules installed in the panel by lighting each installed

module's amber trouble LED. This process can take up to 30 seconds. Failure to light a module’s

trouble LED indicates a defective module or connection.

NOTE

If no front panel switches are activated for 15 minutes after entering the programming

mode, the panel automatically exits the programming mode. The trouble buzzer will

remain active as long as the PROGRAMMING MODE switch is in the ON (programming)

position.

5.1 Programming Initiating Device Circuits (IDCs)

1. Press the RESET switch to enter the Initiating Device Circuit configuration step. The program IDC step

is indicated by the 2-phase flashing green Power LED. IDC zones are programmed individually,

starting with zone #1. The IDC zone actively being programmed is identified by an active zone LED.

The IDC circuit type may be identified by the LED color and flash rate, using Table 5.3.

Table 5.3 - IDC Zone Type Codes

IDC Zone Type Zone LED Code

Alarm, Non-Verified Detec tor Steady Red

Alarm, Verified Detec tor & Dry Contact Alarm Initiating

Devices. (Do NOT select this option. High Impedance

Detectors are not presently available.)

Alarm, Verified Detec t or ONLY

For Low Impedance devices only .

(ex. 2400 series detectors)

No contact devices perm itted.

Normally-Open Supervisory Steady Amber

Waterflow Steady Green

Waterflow with Retard

Y

PAUSE Y PAUSE Y... RED

YY

PAUSE YY PAUSE

Y

PAUSE Y PAUSE Y... GREEN

17

YYY

.. RED

Page 26

2. Use the TROUBLE SILENCE switch to step through the various IDC zone types, until the desired IDC

type code is displayed by the LEDs.

3. Select the IAC circuit to be operated by this zone by pressing the

ALARM SILENCE switch until the

desired configuration is reached. Signal circuits selected for activation by the IDC are indicated by the

respective IAC’s Trouble LED illuminating.

4. To program the next Initiating Device Circuit, press the

5. When the last installed IDC has been programmed, press the

RESET switch and repeat steps 2 and 3 above.

RESET switch; the panel is now ready for

programming Indicating Appliance Circuits (IACs).

5.2 Programming Indicating Appliance Circuits (IACs)

1. The panel is automatically ready to program Indicating Appliance Circuits. The program IAC step is

indicated by the 3-phase flashing green Power LED. Each IAC zone is programmed individually,

starting with IAC #1. The IAC circuit actively being programmed is identified by its active Signal Circuit

trouble LED. The IAC circuit type may be identified by the status of the alarm silenced LED and by the

flash pattern of the respective IAC trouble LED as shown in tables 5.4 and 5.5.

Table 5.4 - Panel Indicating Appliance Circuit Status

IAC Mode Alarm Silenced LED

Silenceable

Non-Silenceable OFF

Table 5.5 - IAC Signal Output Rates

IAC Circuit Type Signal Circuit Trouble LED

Continuous Steady

120 Strokes per Minute (SPM ) 120 Flashes per Minute

Temporal (3-3-3) FLASH-FLASH-FLASH-PAUSE

Continuous California Rate 10 Seconds ON, 5 Seconds OFF...

March Time California Rate 10 Seconds @ 120 SPM, 5 Seconds OFF...

Y

PAUSE Y PAUSE Y...

2. Use the ALARM SILENCE switch to set IAC #1 as Silenceable or Non-Silenceable, as shown in Table 5.4

and indicated by the Alarm Silenced LED.

3. Use the

TROUBLE SILENCE switch to step through the various IAC output signal rates, until the desired

flash pattern is displayed for IAC #1.

4. Press the

5. Use the

RESET switch to program IAC #2.

ALARM SILENCE switch to set IAC #2 as Silenceable or Non-Silenceable, as shown in Table 5.4

and indicated by the Alarm Silenced LED.

6. Use the

TROUBLE SILENCE switch to step through the various IAC output signal rates, until the desired

flash pattern is displayed for IAC #2.

7. When IAC #2 has been programmed, press the

RESET switch; the panel is now ready for Configuring

the System Timers.

18

Page 27

5.3 Configuring System Timers

1. The configure System Timers step is indicated by the 4-phase flashing green Power LED. The status

of the panel’s Alarm Silence Inhibit Timer is indicated by the zone disabled LED as shown in Table 5.6.

Table 5.6 - Alarm Silence Inhibit Timer Status

Alarm Silence Inhibit Timer Setting Zone Disabled LED

Disabled OFF

1 Minute

2 Minutes

3 Minutes

2. Use the TROUBLE SILENCE switch to select between the four states. The status of the panel’s automatic

Alarm Silence Timer is indicated by the alarm silenced LED as shown in Table 5.7.

Table 5.7 - Automatic Alarm Silence Timer Status

Timer setting Alarm Silenced LED

No timer OFF

10 Minutes

20 Minutes

30 Minutes

3. Use the ALARM SILENCE switch to toggle between the four states.

Y

PAUSE Y PAUSE YY..

YY

PAUSE YY PAUSE YY...

YYY

PAUSE

YYY

Y

PAUSE Y PAUSE Y...

YY

PAUSE YY PAUSE YY...

YYY

PAUSE

YYY

PAUSE

PAUSE

YYY

YYY

...

...

4. When the proper LED combination is displayed, press the

RESET switch; the panel is now ready to

program Auxiliary Power.

5.4 Programming Auxiliary Power

1. The program Auxiliary Power step is indicated by the 5-phase flashing green Power LED. Use the

ALARM SILENCE switch to program the auxiliary power as shown in Table 5.8.

Table 5.8 - Auxiliary Power on Reset Status

Auxiliary Power Alarm Silenced LED

Remains energized during reset OFF

De-energize on reset

(alarm, verificati on, & test modes)

2. Use the ALARM SILENCE switch to toggle between the two states.

3. Press the

RESET switch to return to the automatic module configuration step (1-phase flash), where the

programming process started. You may modify any panel configuration by repeating the programming

cycle.

To exit the programming mode, return the

PROGRAMMING MODE switch to the OFF (down) position. The

panel should return to the Normal mode. You may exit the Programming mode at any time. This is useful

when changing only one system parameter.

Y

PAUSE Y PAUSE Y...

19

Page 28

5.5 Returning to Panel Default Settings

To restore the panel to system default settings, before exiting the programming mode, press the TROUBLE

SILENCE

settings (Table 5.1), and return the panel to the beginning of the programming sequence.

and RESET switches simultaneously for one second. This will return all parameters to default

5.6 Dialer Module Programming

Refer to the DIALER MODULE drawing

You will need to know the following information in order to program the dialer module:

• The primary and secondary telephone numbers at the CMS used to receive the signals.

• The DL1 Password = 4727 (GSBS).

• Site primary and secondary ID numbers for the dialer. The site ID numbers are supplied by the CMS.

• Number of retry attempts to CMS. Valid entries are 5 to 10.

• The retry interval. This is the delay time between subsequent attempts to call the CMS.

• The AC power fail notification delay time, if any.

• Daily dialer supervision message delay period. This is the delay interval from power until the first dialer

supervision message is transmitted to the CMS. Valid entries are 0 to 18 hours, with a 12 Hour default

time. The panel must be powered down, then powered up for a change in the delay time to take effect.

• Status retransmission enable/disable setting. Enable this option if the CMS requires all off-normal

status to be re-transmitted with the daily dialer supervision message.

A Put the dialer in the programming mode by plugging any tone dial telephone into J3 on the Dialer

Module and lift the handset off-hook. The touch pad dial on this phone is used for all dialer module

programming. If the Dialer Module is unresponsive, verify that steps 1 & 2 in the DL1 Dialer Panel

and Field Wiring Connections section were performed.

B Enter the dialer password using the programming phone. A beep indicates that a program item has

been entered. NOTE: The dialer will make one attempt to call the monitoring station and report that

it is disabled before you can proceed with programming.

C When the LED goes solid green, you may select any programming item by entering an asterisk “*”

followed by the item number, e.g.”*08” for AC fail delay. The suggested sequence is listed in the

following steps:

1 Enter the primary site ID number supplied by the Central Monitoring Station (CMS). Always enter

four (4) digits. If ID has less than four digits, enter leading zeros, i.e. 0012.

2 Enter the primary CMS phone number. This is the primary phone number of the DACR

receiving equipment, not the administrative phone numbers.

3 Enter the secondary site ID number supplied by the Central Monitoring Station (CMS). Always enter

four (4) digits. If ID has less than four digits, enter leading zeros, i.e. 0012.

4 Enter the secondary CMS phone number. This is the secondary phone number of the DACR

receiving equipment, not the administrative phone numbers.

5 Select the number of phone lines to be used. NOTE:

6 Enter the number of times the module attempts to call the CMS receiving equipment.

7 Enter the retry interval. This is the time between subsequent attempts to reach the CMS in the event

of line trouble or busy signals.

8 Enter the AC failure delay time. This is the length of the delay between the time AC power fails and

the CMS is notified of the failure.

period. Valid entries are 0 to 18 hours.

NFPA requires a delay of 25% to 50% of rated standby power

This setting does NOT effect any other trouble signals.

Two lines are required to comply with NFPA 72.

20

Page 29

9 Enter the daily supervisory message delay time. The module sends a supervisory message to the

CMS once every 24 hours to verify the communications path and message receipt. The delay is used

to set the time the daily message is transmitted based on a delay from the time the panel is powered

up.

EXAMPLE: If the CMS requires the daily supervisory message to be sent at 0300 (3 AM) and the

current time is 1400 (2 PM), set the delay for 13 hours, power down, then power up.

10 Enable or disable the status message re-transmission option. The dialer can optionally re-transmit

all status messages when the daily dialer supervision message is sent. Status retransmission is in

addition to the message sent when the event occurred.

11 Select the order in which the zone number and status code are sent, zone first (default) or code first.

D Hang up the handset and remove the programming telephone from Dialer Module jack J3 to end

programming.

NOTES:

1 If no activity occurs in programming mode for one hour, the DL1 will exit from programming

mode. To re-enter programming mode, hang up the programming phone, then start at step B

of the programming procedure.

2 Factory new dialers remain disabled until both phone numbers and both site ID’s are

programmed. Once programmed, the dialer will attempt to call the monitoring station on power

up. Programming mode cannot be entered until the call is completed, or all call attempts have

failed.

3 When dialer programming step 10 is enabled, it causes all off-normal status, including alarms,

to be retransmitted along with the 24 hour test call.

21

Page 30

6.0 OPERATION

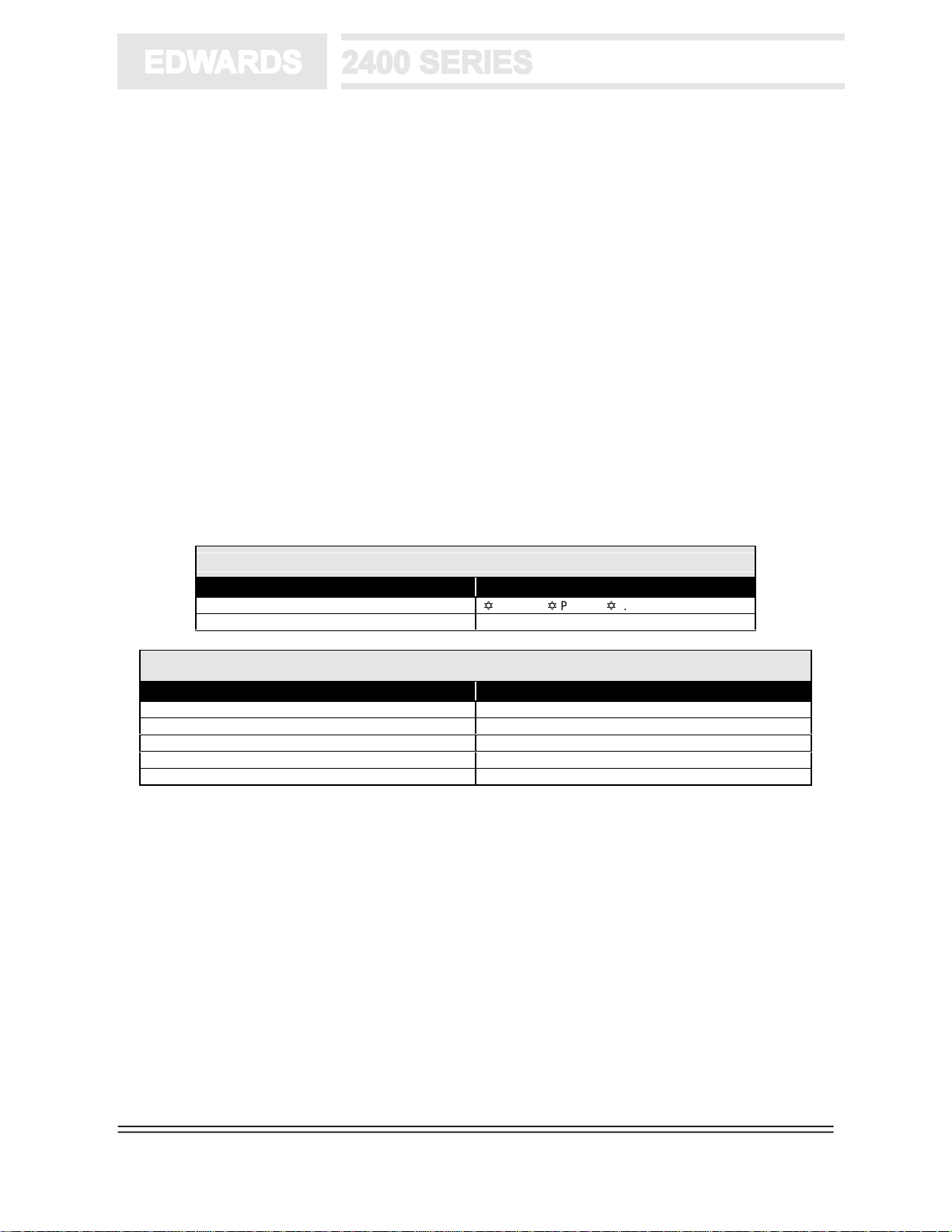

Table 6.1 - Panel Indicators

Indicator Function

Zone Disabled LED

Power LED ON - AC power normal

Zone Alarm (Red) LED STEADY - Zone in alarm

Zone Trouble (Amber) LED STEADY - Supervisory condition restored

Alarm Silenced LED ON - The audible alarm signals have been silenced

Alarm LED ON - System in the alarm state

System Trouble LED SLOW FLASHING - System in Trouble state

Signal Trouble, Ckt #1 LED SLOW FLASHING - Open/short on IAC #1 wiring

Signal Trouble, Ckt #2 LED SLOW FLASHING - Open/short on IAC #2 wiring

Ground Fault LED SLOW FLASHING - A ground fault condition exists on the panel or field wi ri ng

Normal Mode

In the Normal Mode, the panel is operating properly and has not detected any Alarm, Supervisory, or

Trouble conditions. The green power LED is ON and all other LEDs are OFF in the normal mode.

YY

PAUSE

YYY

YYYY

OFF - AC power fail

RAPID FLASHING - Zone in supervisory alarm.

SLOW FLASHING - Zone in trouble condition.

YY

PAUSE YY PAUSE YY... - Zone disabled

RAPID FLASHING - System in Supervisory state

STEADY - Trouble buzzer sil enced

PAUSE

PAUSE

YY

PAUSE YY... - One or more zones disabled

YYY

PAUSE

YYY

... - Audible test mode

YYYY

PAUSE

YYYY

... - Silent test mode

Alarm Mode

When a fire alarm condition is detected, the common alarm LED is ON (RED), and the panel is in Alarm

Mode. If the alarm occurs while in trouble or supervisory mode, the panel displays the system trouble LED

steady ON, and silences the trouble buzzer. The trouble relay continues to indicate panel trouble. Zone

Trouble and Supervisory LEDs not in conflict with the alarm LEDs remain ON.

WARNING

Do NOT silence fire signals until certain that a fire condition does not exist.

In the alarm mode, the Indicating Appliance Circuits operate as programmed. The system alarm LED turns

on, the alarm relay operates, and the Relay/City-Tie Module transmits a fire alarm condition, if so

configured. The red IDC zone LED lights, indicating the area of the alarm. The appropriate alarm zone

LED on the Remote Annunciator operates via the Annunciator Driver Module. The dialer will transmit a

zone specific alarm signal to the Central Monitoring Station.

To silence the Indicating Appliances, press the

respond to the

ALARM SILENCE switch until all waterflow zones are no longer in the active alarm condition.

Reactivation of the waterflow zone will reactivate the IACs.

ALARM SILENCE switch. Indicating Appliance Circuits will not

22

Page 31

Reset Mode

When the facility is safe to re-enter, the panel may be Reset. Manual stations and other manually

restorable devices must be returned to their normal condition. Non-restorable devices which have been

activated by the fire must be replaced. In the event replacement is not immediately feasible, disable the

affected zone using its disable switch. Pressing the

RESET switch automatically resets the smoke detectors

and returns the panel to the normal (trouble mode if zones have been disabled) mode. If all alarm initiating

devices have not been restored, the panel will re-enter the alarm mode. The entire reset process takes

about 20 seconds to complete. The panel can NOT be reset while the alarm silence inhibit timer is active.

Panel reset does not change a zone’s enabled/disabled status.

Reset the panel by pressing the

buzzer to sound, and the trouble relay to go into the trouble state. Operation of the

RESET switch. Reset causes the system trouble LED to light, the trouble

RESET switch also

causes all front panel LEDs to turn on, verifying their operation. After internal processing is completed, the

panel returns to the normal mode.

Trouble Mode

When the panel is in the Trouble Mode, some portion of the panel or field wiring is in an abnormal

condition and the proper operation of the fire alarm system may be affected. If an alarm is detected while

in the trouble mode, the panel will enter the alarm mode and sound an alarm. If a supervisory condition is

detected while in the trouble mode, the panel will enter the supervisory mode mode and the trouble

contacts will remain activated.

In the trouble mode: the system trouble LED flashes, the trouble buzzer sounds at a 20 pulse/minute rate,

the trouble relay operates, and the Relay/City-Tie Module transmits a trouble signal if it is configured to

transmit trouble. The dialer will transmit a trouble signal to the Central Monitoring Station. If the trouble

occurs on an Initiating Device Circuit, the trouble message will be zone specific.

The Relay/City-Tie Module (if configured to transmit trouble) delays its trouble output for 6 hours when

activated by a loss of AC power. The base panel trouble relay activates 6 seconds after the loss of AC

power. The relay’s 6 second contact transfer delay minimizes nuisance troubles due to brownouts and

power line failures. All other trouble conditions are transmitted off premise without delay. In addition to the

system trouble LED, IDC zones, IAC zones, and option modules light a unique trouble LED, further

identifying the cause of the problem.

To silence the trouble buzzer, press the

TROUBLE SILENCE switch. The system trouble LED will light

steadily. New trouble conditions resound the trouble buzzer, and cause the system trouble LED to flash

slowly. Correction of the problem causing a trouble condition automatically returns the panel to the normal

mode, if no other faults exist. Certain critical internal faults and Class A trouble conditions latch the panel

into the trouble mode, requiring the panel to be reset before exiting the trouble mode. Module placement

trouble conditions remain active until the panel is reprogrammed.

23

Page 32

Supervisory Mode

When the panel is in the Supervisory Mode, a portion of the building fire protection system (not the panel)

is in an abnormal condition and its proper operation is affected. If an alarm occurs while in the supervisory

mode, the panel will enter the alarm mode and sound an alarm. If a supervisory condition is detected while

in the trouble mode, the panel enters the supervisory mode.