Page 1

www.edwardssignaling.com

Description

141 Series interlock/position switches are specially designed for use in

washdown/chemical applications, such as commercial dishwashers and parts

cleaning machines.

Warning! To avoid switch failure determine the actual load of the switch circuit and

take steps to protect the switch from voltage spikes, current inrush and line/load

capacitance using the following recommendations.

• Surges from coils, motors, contactors, solenoids and tungsten filaments. Transient

protection, such as back-to-back zener diodes (Transorb) or an RC network, is

recommended for such loads to ensure that maximum ratings of the switch are

not exceeded.

• Line capacitance and load capacitance. An in-line resistor can be added in series

immediately before the load to limit the inrush current. The resistor can only be

added in series with the last wire just before the load. The voltage drop and the

power rating of the resistor must also be calculated as follows:

Voltage drop = I • R

2

Watts = I

( I = maximum continuous current of the load)

To verify switch operation with an ohmmeter:

Set range at 20 mega ohms (switches with triac output, set ohm range at 20 kilo

ohms). For a normally open switch, the meter will read a high impedance with the

actuator away. It will read very high to infinity range (triac switches will read high kilo

ohm to infinity range) with the actuator within sense range. You will see the opposite

reading for a normally closed switch.

• R

Dimensions

0.19''

0.48cm

2.13"

5.41cm

1.75"

4.45cm

0.86"

2.18cm

0.22"

0.56cm dia.

2.74cm

1. 08"

0.57"

1.45cm

0.28cm

0.11"

GuardSwitch™ Series 100

Non-Contact Interlock/Position Switch

141-6Y-06M

141

141-6Y-12J

141-6Y-12M

141-8Y-06M

141-8Y-12M

141-17Y-06K

141-17Y-12K

Installation

Use non-removable screws, bolts, or nuts to mount the switch and actuator. Do not

over-torque mounting hardware.

1. Using the following guidelines, determine a suitable mounting location:

• The switch and actuator must be within the listed sense range. See Ordering/

Electrical Specifications.

• The actuator must be aligned with the switch—labels facing the same direction.

(See Figure 1.)

Important: When mounting in proximity to ferrous material (steel), the sense

range can be reduced 50% minimum depending on the shape and type of

material. Test the switch in specific applications to determine the actual

sense range.

•When mounting on a ferrous material (steel), a 1/4" nonferrous (plastic or

aluminum) spacer may be used under the actuator and switch to restore most of

the lost gap.

•When mounting on a hinged gate or door, mount the switch and actuator at least

6" away from the hinges to achieve the maximum movement.

• The switch and actuator must move in one of the approved directions.

See Figure 2.

• The actuator can be mounted at a 90° rotation to the switch.

•Do not mount for parallel actuation. An on-off-on signal may result when the

actuator passes by the switch.

2. Mount the switch on the stationary frame of the machine and connect the

electrical wiring. When mounting the switch on an ungrounded machine, connect

the ground lead to one of the mounting screws.

3. Mount the actuator on the movable guard, door, or gate.

141-17N-12K

141-18Y-03M

141-18Y-06M

141-18Y-12M

141-18N-03M

141-18N-12M

141-

_________

Page 2

General Specifications

P/N 1031295 • REV E • REB 17MAY13

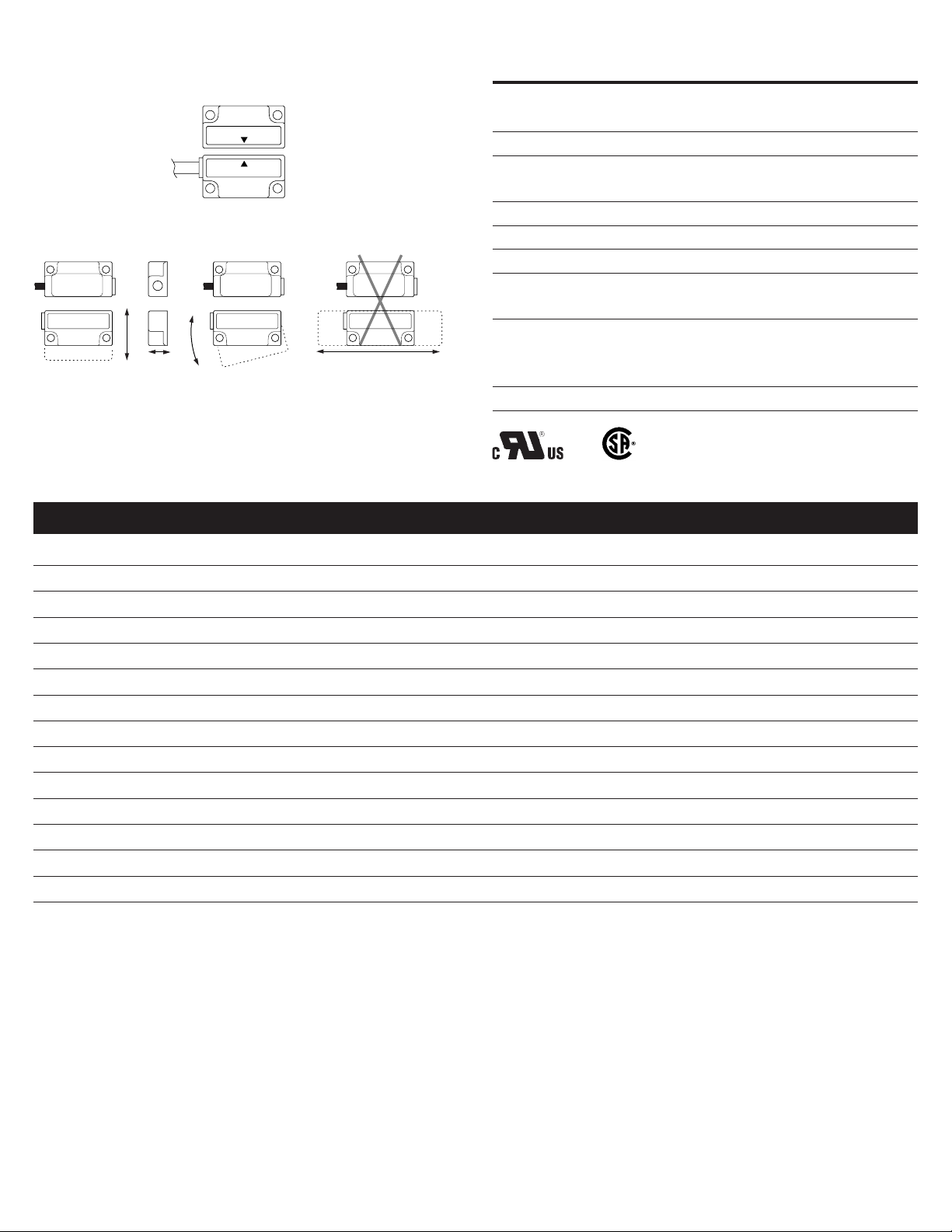

Figure 1

sensing face

Enclosure Kynar® Polyvinylidene Flouride

with sonic welded lid

Temperature Range 14°F to 150°F (-10°C to 65°C)

sensing face

Environmental Hermetically Sealed Contact Switch

Sealed in Polyurethane

Figure 2

Perpendicular

Actuation

Door

Actuation Pivot Actuation

Parallel Actuation

NEMA Rating 1, 2, 3, 4, 4X, 5, 6, 12, 13

Protection Class IP 67

Response Time 10 msec

Life Cycles 100,000 Under Full Load;

Up to 200,000,000 Under Dry Circuit

Lead Types/O.D. 18/2 SJTOW(M)/0.29" (0.74cm)

18/2 SJTOW(K)/0.30" (0.76cm)

Best Best Good

Three configurations are appropriate for interlock applications. The parallel actuation

Not Recommended

22/2 Jacketed(J)/0.16" (0.40cm)

UL/CSA All Models

can result in on/off/on signal if the actuator passes by the switch rather than

coming to rest in proximity to it. This is NOT a recommended configuration for

interlock applications.

Ordering/Electrical Specifications

File E 122942 LR89176

PART NUMBER CONTACT

1

LOAD RATING SWITCHING VOLTAGE SWITCHING CURRENT SENSE RANGE

CONFIG. MAXIMUM, AC/DC MAXIMUM, AC/DC MAXIMUM, AC/DC NOMINAL NOMINAL NOMINAL

141-6Y-06M N.O. 25VA/25W 120V @0.2A 120V @0.2A 0.7A @35V 1.0A @25V 1.0"(2.5cm) 1.6"(4.1cm) 6'(1.8m)

141-6Y-12J N.O. 25VA/25W 120V @0.2A 120V @0.2A 0.7A @35V 1.0A @25V 1.0"(2.5cm) 1.6"(4.1cm) 12'(3.6m)

141-6Y-12M N.O. 25VA/25W 120V @0.2A 120V @0.2A 0.7A @35V 1.0A @25V 1.0"(2.5cm) 1.6"(4.1cm) 12'(3.6m)

141-8Y-06M N.O./ 150VA/NA 120V @1.25A NA 1.25A3/NA NA 1.0"(2.5cm) 1.2"(3.0cm) 6'(1.8m)

141-8Y-12M N.O./ 150VA/NA 120V @1.25A NA 1.25A3/NA NA 1.0"(2.5cm) 1.2"(3.0cm) 12'(3.6m)

triac

output

triac

output

141-17N-12K N.O. 100VA/100W 250V @0.4A 250V @0.4A 3.0 @34V 3.0 @34V Switch Only Switch Only 12'(3.6m)

141-17Y-06K N.O. 100VA/100W 250V @0.4A 250V @0.4A 3.0 @34V 3.0 @34V 0.7"(1.8cm) 1.6"(4.1cm) 6'(1.8m)

141-17Y-12K N.O. 100VA/100W 250V @0.4A 250V @0.4A 3.0 @34V 3.0 @34V 0.7"(1.8cm) 1.6"(4.1cm) 12'(3.6m)

141-18N-03M N.O./ 220VA/NA 220V @1.0A NA 1.0A/NA NA Switch Only Switch Only 3'(0.9m)

141-18N-12M N.O./ 220VA/NA 220V @1.0A NA 1.0A/NA NA Switch Only Switch Only 12'(3.6m)

141-18Y-03M N.O./ 220VA/NA 220V @1.0A NA 1.0A/NA NA 0.7"(1.8cm) 1.6"(4.1cm) 3'(0.9m)

141-18Y-06M N.O./ 220VA/NA 220V @1.0A NA 1.0A/NA NA 0.7"(1.8cm) 1.6"(4.1cm) 6'(1.8m)

141-18Y-12M N.O./ 220VA/NA 220V @1.0A NA 1.0A/NA NA 0.7"(1.8cm) 1.6"(4.1cm) 12'(3.6m)

triac

output

triac

output

triac

output

triac

output

triac

output

141-Y Actuator Only Included with all switches unless otherwise noted.

Warning— Each electrical rating is an individual maximum and cannot be exceeded!

1

Configuration with actuator away from the switch

2

Proximity of ferrous materials usually reduces sense range — typically by 50%. The shape and type of material cause a wide diversity of effects.

Testing is required to determine actual sense range for specific applications.

3

Can withstand inrush surge up to 4 Amps. Volage Drop 1.5V. Minimum Switch Current 30mA. Maximum 10 switches in series.

2

BREAK RANGE LEAD LENGTH

Loading...

Loading...