Page 1

Installation Instructions for 125 Class Beacons,

HALOGEN Models

Description

Edwards 125 Class halogen beacons are UL and cUL listed

signaling appliances rated for NEMA 4X applications. Two

versions of 125 Class Halogen Beacons are available: Flashing (125HALF) and Steady-On (125HALS). Both versions

can be either surface or conduit mounted.

A protective wire guard, Cat. No. 125GRD, is available.

Electrical Specications

GRAY BASE BLACK BASE

Catalog Number Catalog Number Voltage Current

Flashing Halogen

125HALF*24D 125HALF*24DB 24V DC 0.770A

125HALF*24A 125HALF*24AB 24V AC 50/60 Hz 0.770A

125HALF*120A 125HALF*120AB 120V AC 50/60 Hz 0.200A

Steady-On Halogen

125HALS*24D 125HALS*24DB 24V DC 0.770A

125HALS*24A 125HALS*24AB 24V AC 50/60 Hz 0.770A

125HALS*120A 125HALS*120AB 120V AC 50/60 Hz 0.200A

*Letter in this position indicates lens color:

A - Amber, B - Blue, C - Clear, G - Green, R - Red

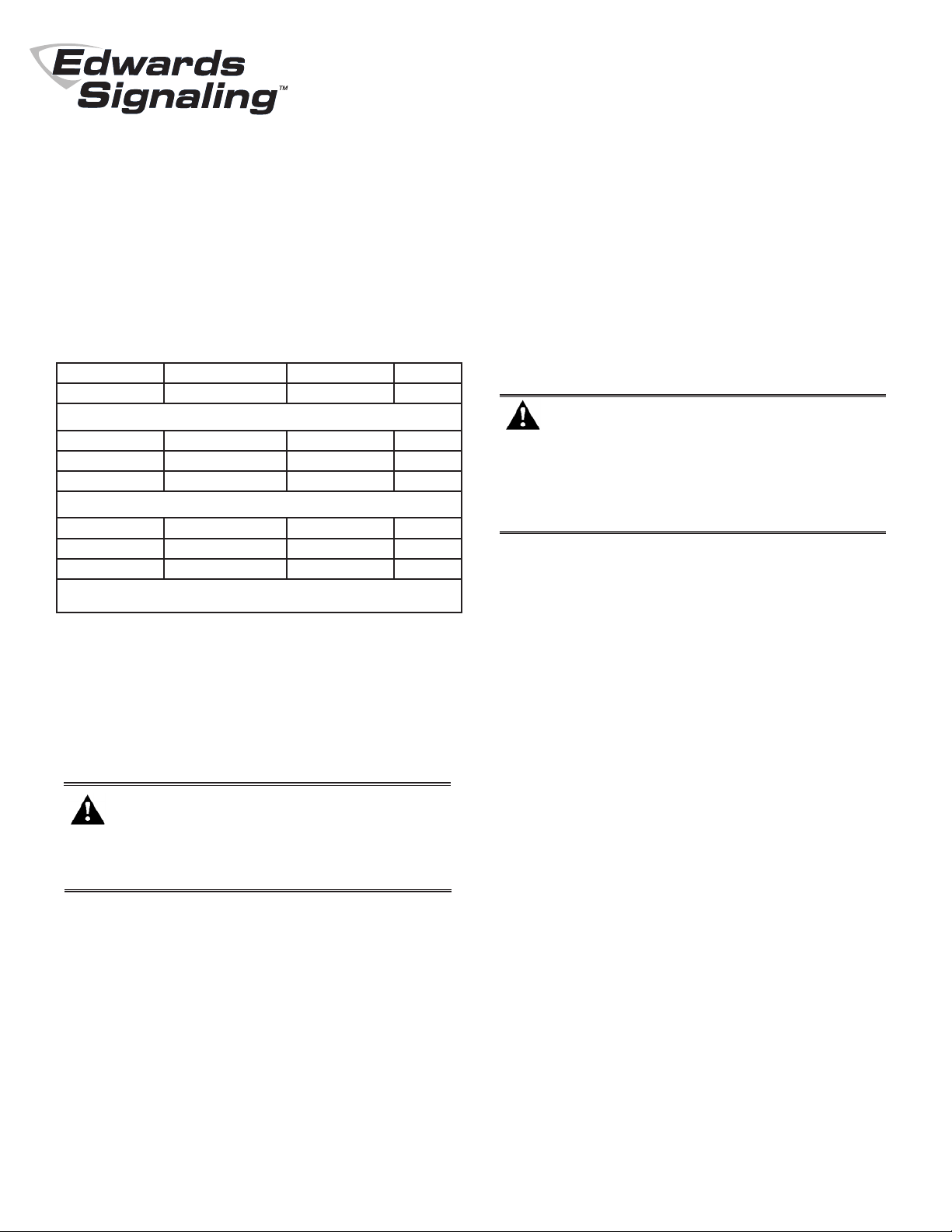

2. Wire the beacon as follows:

a. For AC models, use wire nuts (not supplied) and

connect the signal's black and white wire leads to the

power source wires as shown in Figure 1. Polarity

is not relevant.

b. For DC models, connect the signal's red wire to the

positive power source wire and connect the signal's

black wire to the negative power source wire using

wire nuts (not supplied). Polarity must be observed.

Refer to Figure 1.

3. Thread the conduit onto the base of the signal.

WARNINGS

To avoid risk of injury, install lens before

energizing the unit.

To avoid the risk of injury, do not remove or

insert lamp when unit is energized.

4. Turn on power and verify that the signal operates

properly.

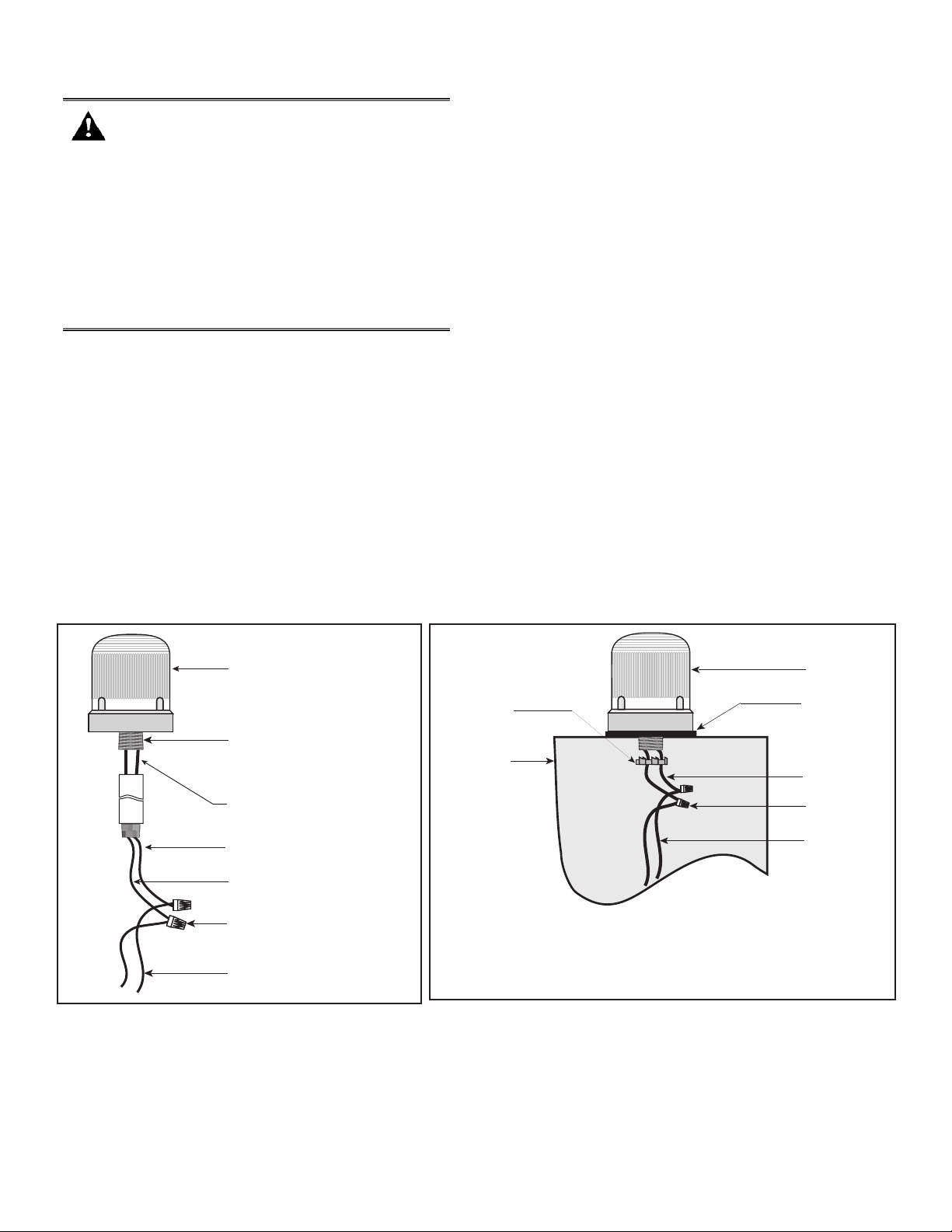

Panel Mounting (Figure 2)

Mechanical Specications

Outdoor Locations

Temperature Ratings ........... -31F to +150F (-35C to +66C)

Installation

WARNING

To prevent electrical shock, ensure that

power is turned off before installing the

signal.

Conduit Mounting (Figure 1)

1. Thread the 18" (45.7 cm) signal wire leads through either

1/2" or 3/4" conduit into an approved conduit outlet box.

(Product is supplied with a double threaded - 1/2" internal

and 3/4" external - conduit hub.)

Note: When panel mounting the beacon, the surface and

construction details of the panel must be taken into

consideration in order to ensure that the integrity

of the outdoor, NEMA 4X rating is fully maintained.

Installer should evaluate.

1. Place the mounting gasket (supplied) over the hole in

the panel and route the signal wires through the gasket

and the hole in the panel.

2. Insert the base through the hole in the panel and screw

the locking nut (supplied), with the raised locking edge

facing the mounting surface, onto the base to secure the

beacon.

3. Wire the beacon as follows:

a. For AC models, use wire nuts (not supplied) and

connect the signal's black and white wire leads to the

power source wires as shown in Figure 2. Polarity

is not relevant.

b. For DC models, connect the signal's red wire to the

positive power source wire and connect the signal's

black wire to the negative power source wire using

wire nuts (not supplied). Polarity must be observed.

Refer to Figure 2.

4. Turn on power and verify that the signal operates

properly.

http://www.edwardssignaling.com Phone: (800) 336-4206 Fax: (800) 454-2363

P/N 3101650 ISSUE 3

© 2010

Page 2

Maintenance

WARNINGS

To avoid risk of injury, install lens before

energizing the unit.

Lamp Replacement

1. Conduit Mounted Modules: Disconnect wiring and, if

necessary, unscrew base from conduit (Figure 1).

Panel Mounted Modules: Disconnect wiring and

remove locking nut that secures the base to the panel

(Figure 2).

To avoid the risk of injury, do not start any

maintenance when unit is energized.

To prevent electrical shock, disconnect all

power and wait ve (5) minutes for stored

energy in strobe modules to dissipate

before starting work on unit.

Cleaning

Disconnect power before cleaning. The module lens exterior

surfaces should be periodically cleaned with a soft clean

cloth using water and a mild detergent to maintain optimum

light visibility.

Figure 1. Conduit Mounting (3/4" Shown)

2. Remove (4) screws that secure the lens to the base from

bottom of base (Figure 3) and remove lens.

3. Replace halogen lamp as follows (Figure 3):

a. Grasp the metal base of the halogen lamp and push

the lamp down while turning counterclockwise. Then,

pull the lamp directly upward to remove from the

socket.

b. Grasp the new halogen lamp by its base and insert

in the socket. Push down and rotate clockwise to

lock in place.

CAUTION: Do not touch glass surface of lamp at

any time.)

4. Reattach lens to base and fasten with screws removed

in step 2.

Figure 2. Panel Mounting

125 Class

Visual Indicator

3/4” NPT external (shown)

1/2” NPT internal

conduit (not supplied)

18” Wire Leads

DC units; Red positive (+)

AC units; Black Hot

DC units; Black negative (-)

AC units; White neutral

Wire nuts

(not supplied)

Power Source

Wires

Locking Nut -

1.3625" OD

(supplied)

Control panel

(enclosure)

125 Class

Visual Indicator

Gasket

(supplied)

18” Wire Leads

Wire Nuts

(Not Supplied)

Power Source

Wires

P/N 3101650 ISSUE 3

Page 3

Figure 3. Lamp Replacement

Lens

Lamp

(Halogen Lamp Shown)

Lamp Socket

O-Ring (in groove)

(supplied)

Base

(4) Screws securiing

lens to base

Table 1. Replacement Parts

Catalog Number

(gray base)

Catalog Number

(black base)

Replacement

Lens Replacement Lamp

Flashing Halogen

125HALF*24D 125HALF*24DB

125HALF*24A 125HALF*24AB

125HALF*120A 125HALF*120AB 50LMP-12WH-D or industry trade

125L(*)

50LMP-9WH-D or industry trade

no. 1692** (incandescent)

no. 15T7DC** (incandescent)

Steady-On Halogen

125HALS*24D 125HALS*24DB

125HALS*24A 125HALS*24AB

125HALS*120A 125HALS*120AB 50LMP-12WH-D or industry trade

*Letter in this position indicates lens color:

A - Amber, B - Blue, C - Clear, G - Green, R - Red

**The listed non-halogen lamp may be used in place of the halogen lamp.

125L(*)

50LMP-9WH-D or industry trade

no. 1692** (incandescent)

no. 15T7DC** (incandescent)

P/N 3101650 ISSUE 3

Page 4

U.S.

T 800-336-4206

F 800-454-2363

Canada

T 519 376 2430

F 519 376 7258

Asia

T 852 2907 8108

F 852 2142 5063

Australia

T +61 3 9239 1200

F +61 3 9239 1299

Europe

T 32 2 725 11 20

F 32 2 721 86 13

Latin America

T 305 593 4301

F 305 593 4300

www.edwardssignaling.com

Loading...

Loading...