Page 1

Installation Instructions for 116EXMLED Series

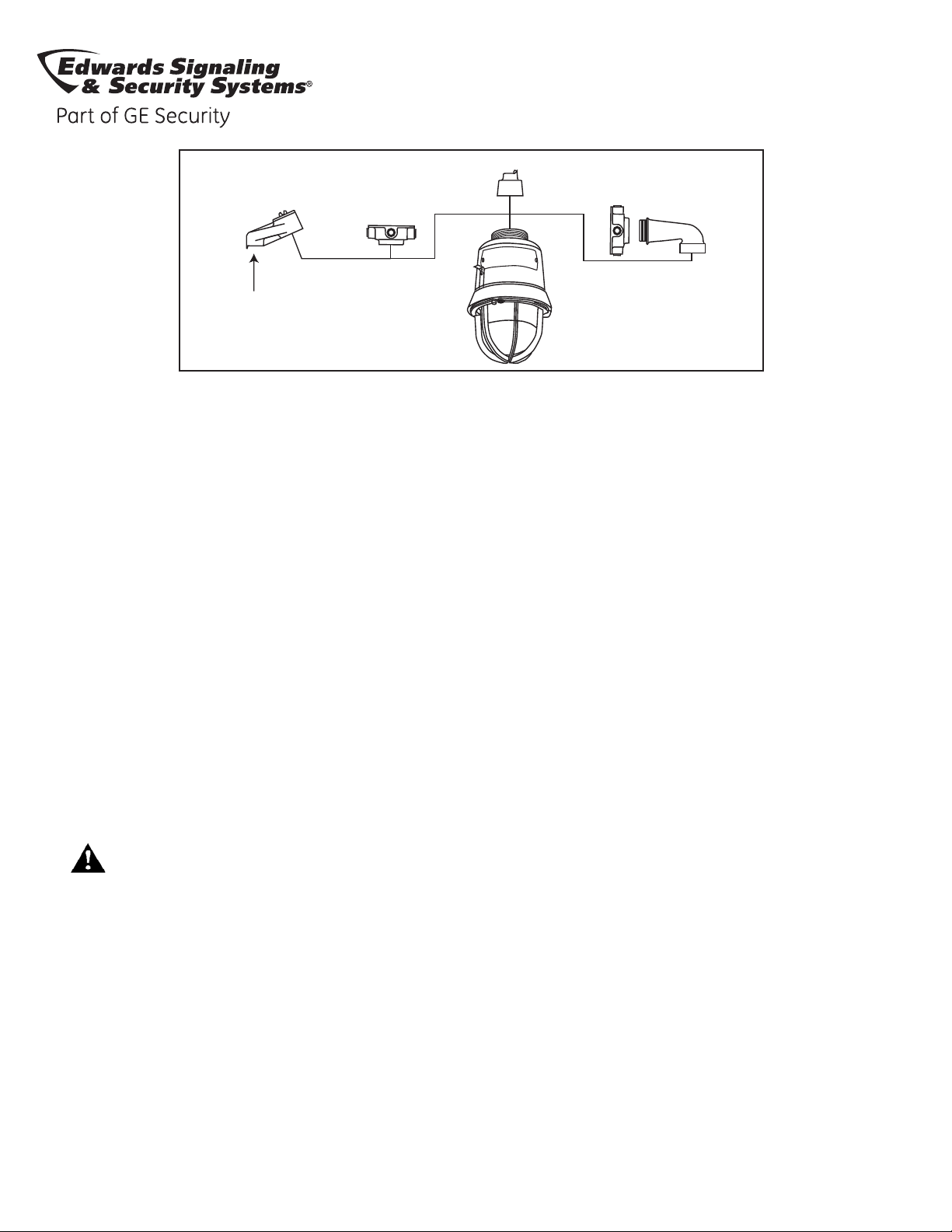

CEILING 116EX-C

3/4" CONDUIT

ENTRIES

PENDANT 116EX-P

3/4" CONDUIT

ENTRY

116EX-C

(WALL MOUNTED)

3/4" CONDUIT

ENTRIES

116 SERIES HOUSING AND GLOBE

ASSEMBLY WITH GUARD

WALL 116EX-B

3" HUB

1 1/4"CONDUIT

ENTRY

STANCHION 116EX-S

AdaptaBeacon® LED Lights for Use in Hazardous

Locations

Figure 1. Mounting Options

Description

The 116EXMLED Series AdaptaBeacon LED signaling appliances

are intended for general utility signaling use. When assembled

with an available mounting subassembly (116EX-P, 116EX-C,

116EX-S, or 116EX-C with 116EX-B) and in accordance with

these instructions, the 116EXM LED visual signal is UL Listed as

a Visual Signal Appliance. The 116EXMLED is UL and cUL listed

for use in Class I, Division 1, Groups C and D, Class I, Division 2,

Groups A, B, C and D, Class II, Division 1, Groups E, F and G,

Class II, Division 2, Groups F and G, and Class III Division 1 and

2 hazardous locations with operating temperature codes per

Table 2.

The beacons are UL and cUL Listed for outdoor use with

Type 3R, 4X, and Marine rated enclosures.

The LED beacon ashes a 360-degree beam of light with 14 user

selectable ash patterns.

The LED beacons are available in pendant, bracket , ceiling, or

stanchion mount models (Figure 1).

Installation

Install this unit in accordance with the applicable requirements

in the latest edition of the National Electrical Code and Canadian

Electrical Code.

1. Mount using the following applicable method.

PLAINVILLE, CT 800-336-4206 FAX 800-454-2363

WARNING

To reduce the risks of ignition of hazardous

atmospheres and shock, do not apply power to

the unit until installation has been completed

and unit is tightly assembled and secured.

a. Pendant Mount Models (Figure 2): Install the catalog

number 116EX-P, pendant mounting module, to the

main housing, tighten set-screw. Install explosion-proof

hanger box (not supplied). Secure 3/4" (19 mm) NPT

threaded conduit (not supplied) to the box. Install the

unit on the conduit. Ensure conduit engages at least

5 full threads and then tighten the set-screw to secure

the pendant mount module to the conduit. Make

electrical connections in accordance with Figure XX.

Refer to Table 2 for required supply wire temperature

ratings.

b. Ceiling Mount Models (Figure 3): Install the catalog

number 116EX-C, ceiling/wall mounting module, using

appropriate hardware (not supplied) suitable for the

mounting surface. Make electrical connections in

accordance with Figure 6. Refer to Table 2 for required

supply wire temperature ratings. Install main housing

to ceiling mount module. Tighten the set-screw to

secure the 116EXMLED main housing to the ceiling

mount module.

c. Bracket Mount Models (Figure 4): Install the catalog

number 116EX-C ceiling/wall mounting module using

appropriate hardware (not supplied) for the mounting

surface. Connect eld earth ground wire to ground

screw or earth ground via conduit system. Install

the catalog number 116EX-B wall mounting elbow to

the 116EXMLED main housing (feed the units wiring

through the 116EX-B elbow). Tighten the set-screw to

secure the 116EX-B elbow to the main housing. Make

electrical connections in accordance with Figure 6.

Refer to Table 2 for required supply wire temperature

ratings. Install main housing and 116EX-B elbow

subassembly to ceiling mount module. Tighten the

set-screw to secure the 116EX-B elbow to the ceiling

mount module.

d. Stanchion Mount Models (Figure 5): Install the catalog

number 116EX-S, stanchion mount module to the main

housing and tighten set-screw. Mount the 116EX-S to

the 1-1/4" conduit, tighten set-screw. Ensure conduit

is connected to the appropriate junction box. Install

the unit on the conduit. Make electrical connections in

accordance with Figure 6. Refer to Table 2 for required

supply wire temperature ratings.

P/N 3101456 ISSUE 1 © 2008

Page 2

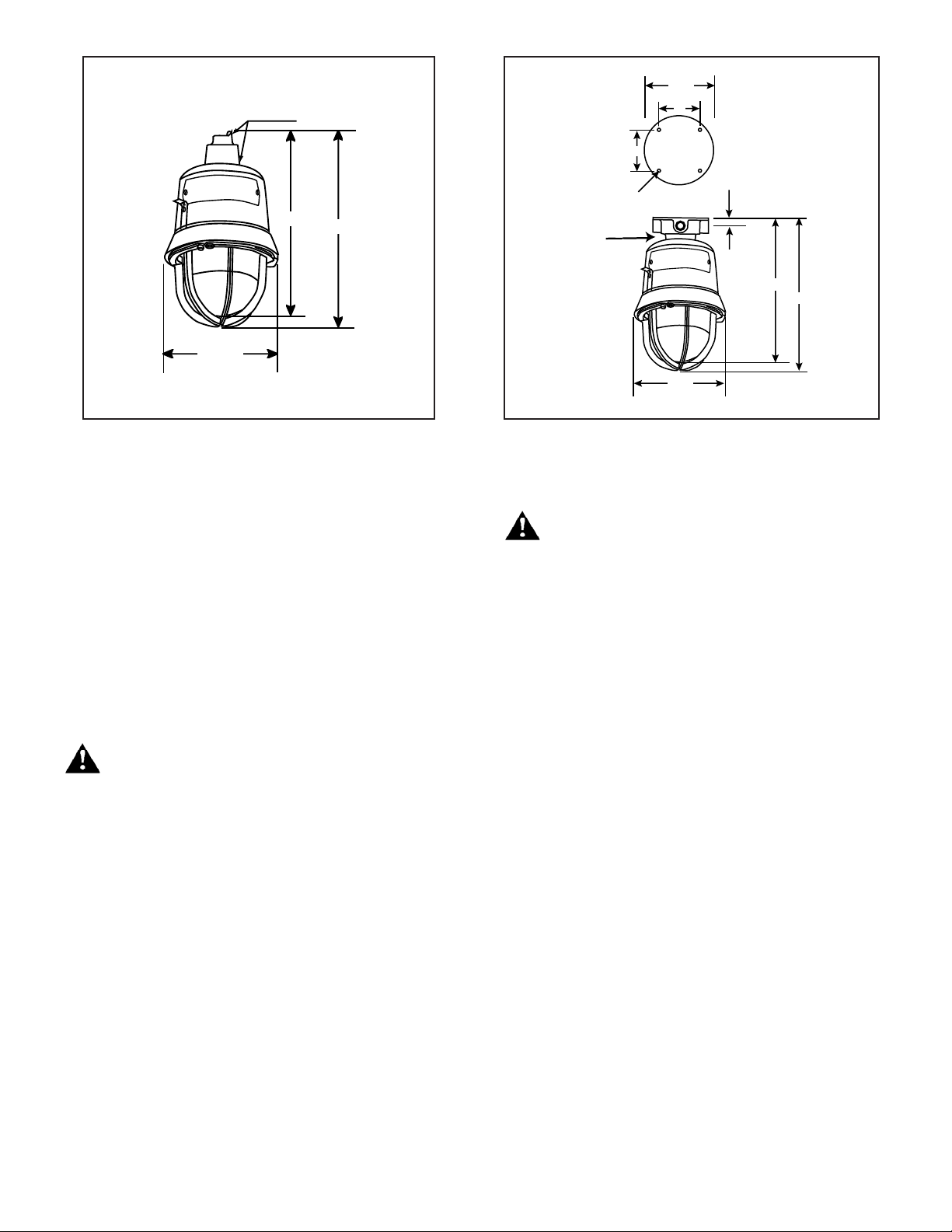

Figure 2. Detail of Pendant Mounting Figure 3. Detail of Ceiling Mounting

12"

12 3/4"

7 1/4"

Set Screw(s)

1"

13"

13 3/4"

7 1/4"

5/16"

4"

4"

6 3/4"

Set

Screw

2. Adjust ash rate. Beacons are factory defaulted to mode

"Flash 3" (65 ashes per minute).

a. Remove globe section; loosen the globe and ring

assembly set screw. Insert a suitable tool into the

notches in the globe and ring assembly and loosen the

assembly by prying in a counterclockwise direction.

Remove the ring and globe assembly.

b. Set dipswitch (Figure 7) for desired ash rate. Refer

to Table 3 for dipswitch settings.

c. To replace, simply screw the globe assembly unit

on until it seats rmly onto its gasket. Tighten the unit

another 1/8 to 1/4 turn. Tighten the set-screw.

WARNING

To reduce the risk of ignition of hazardous

atmospheres and shock, keep assembly tightly

closed when circuits are energized.

To reduce the risk of ignition of hazardous

atmospheres and shock, disconnect from the

supply and circuit and allow ve (5) minutes for

stored energy to dissipate before disassembling

the unit.

3. Apply power to the unit and ensure proper function.

Maintenance

WARNING

To reduce the risk of ignition of hazardous

atmospheres and shock, keep assembly tightly

closed when circuits are energized.

Disassemble the unit as follows (Figure 8):

1. Loosen the (3) guard screws and remove the guard.

2. Loosen the globe and ring assembly set screw. Insert a

suitable tool into the notches in the globe and ring assembly

and loosen the assembly by prying in a counterclockwise

direction. Remove the ring and globe assembly.

3. Refer to Table 1 for the correct replacement catalog number

and replace the necessary part.

4. To replace, simply screw the unit on until it seats rmly onto

its gasket. Tighten the unit another 1/8 to 1/4 turn. Tighten

the setscrew.

5. Reinstall the guard, where applicable, and secure using the

three supplied screws.

6. After the unit is assembled, apply power and make sure the

unit functions properly.

P/N 3101456 ISSUE 1

PAGE 2

Page 3

Figure 4. Detail of Wall Bracket Mounting Figure 5. Detail of Stanchion Mounting

1"

12 9/16"

9 7/16"

16 1/16"

16 13/16"

5/16"

4"

4"

6 3/4"

Set Screws

1 1/4"

25°

1 1/4"

Conduit

13 1/4"

12 3/4"

13 1/2"

Set

Screw

Set

Screw

Light Source

Globe & Guard

Assembly

Lens

ON

S1

FLASH MODE

OFF

S1

FLASH MODE

1

2

3

1. Connect field earth ground wire to ground screw or

earth ground via conduit system

2. Using wire nuts, connect unit’s two white wires to

incoming neutral (AC) or incoming (-) (DC)

3. Using wire nuts, connect unit’s two black wires to

incoming hot (AC) or incoming (+) (DC)

Figure 6. Wiring (Bracket Mount Version Shown)

3

1

24

PAGE 3

Figure 7. Detail of Dipswitch Location

Figure 8. Disassembly of the 116EXMLED Series

AdaptaBeacons

P/N 3101456 ISSUE 1

Page 4

Table 1. 116 Series AdaptaBeacons

Catalog Electrical Conduit Flash LED

Description Number Ratings Size Rate Replacement

Housing Less 116EXMLED*-Y6 120 - 240V 50/60 Hz, .215A N/A ADJUSTABLE N/A

Mounting Module 125-250V DC, .176A

Ceiling/Wall 116EX-C N/A 3/4" NPT N/A N/A

Mounting Module

Pendant 116EX-P N/A 3/4" NPT N/A N/A

Mounting Module

Stanchion 116EX-S N/A 1 1/4" NPT N/A N/A

Mounting Module

Wall Bracket 116EX-B N/A N/A N/A N/A

Mounting Elbow

*Letter in this position denotes color of the lens: A - amber, B - blue, W - clear, G - green, R - red

Table 2. Ratings

Operating Temperature

Ambient Supply Wire Class I, Div. 2 Class I, Div. 1 & 2 Class II & III, Div. 1 Class II & III, Div. 2

Temp. Temp. Marking Groups A, B Groups C, D Groups E, F, G Group F, G

40°C 75°C T4 (135°C) T6 (85°C) T4A (120°C) T4A (120°C)

55°C 90°C T3C (160°C) T6 (85°C) T4 (135°C) T4 (135°C)

65°C 105°C T3C (160°C) T6 (85°C) T4 (135°C) T4 (135°C)

Table 3. Flash Mode Selection

S4 S3 S2 S1 DESCRIPTION PATTERN

OFF OFF OFF OFF Steady Steady On

OFF OFF OFF ON Multiburst 1 7 Bursts - Delay - Repeat

OFF OFF ON OFF Multiburst 2 5 Bursts - Delay - Repeat

OFF OFF ON ON Multiburst 3 10 Bursts - 3 Bursts - Repeat

OFF ON OFF OFF Multiburst 4 8 Bursts - delay w/ slight illumination - Repeat

OFF ON OFF ON Flash 1 65 FPM 10% Duty Cycle

OFF ON ON OFF Flash 2 65 FPM 25% Duty Clyle

OFF ON ON ON Flash 3 65 FPM 50% Duty Clyle

ON OFF OFF OFF Flash 4 65 FPM 75% Duty Clyle

ON OFF OFF ON Flash 5 80 FPM 10% Duty Clyle

ON OFF ON OFF Flash 6 80 FPM 25% Duty Clyle

ON OFF ON ON Flash 7 80 FPM 50% Duty Clyle

ON ON OFF OFF Flash 8 80 FPM 75% Duty Clyle

ON ON OFF ON Ramper Ramps up and then ramps down

Contacting Edwards:

Phone: (800) 336-4206

E-Mail: techsupport@edwards-signals.com

customerservice@edwards-signals.com

Website: http://www.edwardssignaling.com

P/N 3101456 ISSUE 1

PAGE 4

Page 5

TO ACTUAL SIZE.

RETURN MECHANICALS TO:

TECHNICAL WRITING

EDWARDS SIGNALING

& SECURITY SYSTEMS

PLAINVILLE, CT 06062

MATERIAL: STANDARD WHITE OFFSET STOCK

CHARACTERS: TO BE BLACK ON WHITE BACKGROUND

NOTE: MECHANICALS HAVE ALREADY BEEN REDUCED

P/N 3101456 OFFSET SPEC

INSTALLATION INSTRUCTIONS FOR CATALOG SERIES

116EX ADAPTABEACONS FOR USE IN HAZARDOUS LOCA-

TIONS

(1) 11" X 17" SHEET PRINTED BOTH SIDES. FOLD THREE

TIMES TO DIMENSIONS SHOWN ON DETAIL WITH PART

NUMBER ON THE OUTSIDE.

ECN: 07-C1818

Issue: 1

File: 3101456

Approved by: GM

FOLD DETAIL REFERENCE ONLY

P/N 3100756

Loading...

Loading...