Page 1

Installation Instructions for 107DDV2*-G1 AdaptaBeacon

DC Strobes for Use in Hazardous Locations

®

DescriptionDescription

Description

DescriptionDescription

The 107DDV2*-G1 24V DC AdaptaBeacon DC Strobe signaling appliances are heavy duty diode-polarized strobe

lights intended for use in general utility signaling (nonfire alarm) applications requiring electrical supervision of

signaling circuit field wiring. They are available in pendant, bracket, or ceiling mount configurations. These devices are UL and cUL Listed for use in Class I, Division 2,

Group A, B, C and D hazardous locations; pendant-mount

versions with clear globes are also listed for use in Class II,

Division 1, Group E, F and G, Class II, Division 2, Group F

and G, and Class III, Division 1 and 2 hazardous locations.

Operating T emperature Codes are per the following chart.

Temperature Codes

NOTE: Class II and Class III Listings only apply to

Ambient Class I, Div. 2 Class II, Div. 1, Groups E, F, G

They are UL and cUL listed as Type 3R and 4 enclosures.

The series 107DDV2*-G1 strobe flashes a 360-degree beam

of light approximately 65 times per minute.

InstallationInstallation

Installation

InstallationInstallation

Pendant Mount with clear globes

Class II, Div. 2 Groups F, G

Class III, Div. 2

Temp. Groups A, B, C, D Class III, Div. 1

40°C 300°C (T2) 120°C (T4A)

55°C 450°C (T1) 135°C (T4)

65°C 450°C (T1) 160°C (T3C)

2. Bracket Mount Models (Figure 2): Remove the

outlet box from the end of the mounting bracket.

Install the outlet box using appropriate hardware (not

supplied) for the mounting surface. Pull the field

wiring through the outlet box.

Ground the unit in accordance with National Electrical

Code (NFPA 70) and local requirements.

Wire in accordance with Figure 4.

Mount the wall bracket back onto the outlet box.

3. Ceiling Mount Installation (Figures 3 and 5):

Unscrew and remove the clear outer globe. Remove

the two screws holding the circuit assembly to the

bottom of the fixture. T o separate the ceiling junction

box from the fixture housing, remove the remaining

two screws at the bottom of the fixture.

Mount the ceiling junction box using appropriate

hardware. Pull power source wiring through the

ceiling junction box.

Ground the unit in accordance with National Electrical

Code (NFPA 70) and local requirements.

Wire in accordance with Figure 4.

Secure the fixture housing on the junction box by

replacing the two screws removed above. Reinstall

the circuit assembly to the bottom of the fixture using

the two screws removed above.

Screw the clear outer globe back on the fixture

housing.

4. Where applicable, install the optional guard assembly

over the clear outer globe and secure using three

screws (provided).

WARNING

To reduce the risk of ignition of hazardous atmospheres and shock, do not apply power to the unit

until installation has been completed and unit is

tightly assembled and secured.

Install this unit in accordance with the applicable requirements in the latest edition of the National Electrical Code

or Canadian Electrical Code, using supply wire rated per

T able 2.

1. Pendant Mount Models (Figure 1): Install explosionproof hanger box (not supplied). Pull the unit's wire

leads through the 3/4" (19 mm) NPT threaded conduit

(not supplied). Secure the 3/4" (19 mm) threaded

conduit to the mounting hood.

Ground the unit in accordance with National Electrical

Code (NFPA 70) and local requirements.

Wire in accordance with Figure 4.

Secure the 3/4" (19 mm) threaded conduit to the outlet

box.

CHESHIRE, CT 203-699-3300 FAX 203-699-3365 (CUST. SERV.) 203-699-3078 (TECH. SERV.)

To reduce the risk of ignition of hazardous atmospheres and shock, keep assembly tightly closed

when circuits are energized.

5. Apply power to the unit and ensure proper function.

10 1/4"

(260mm)

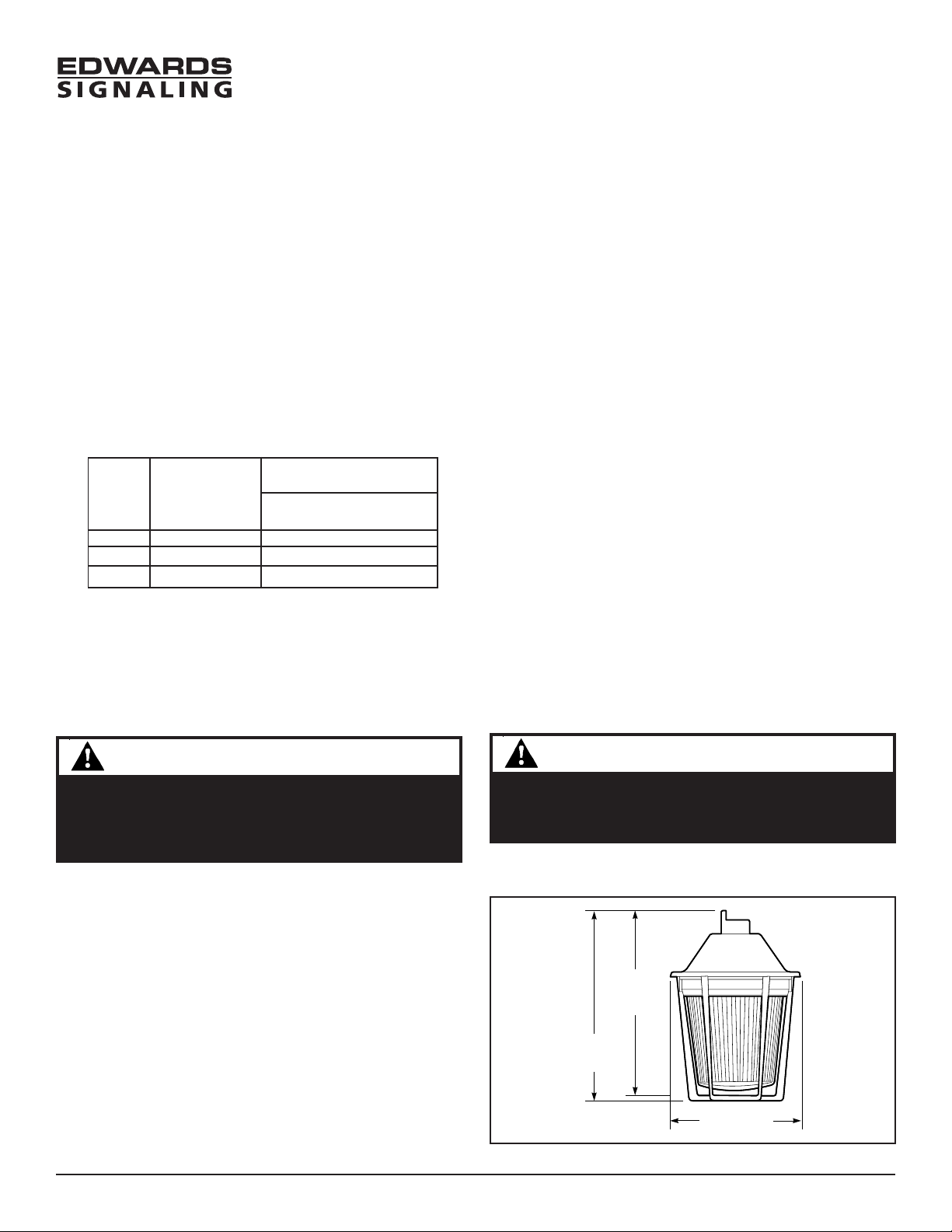

Figure 1. Detail of Pendant Mounting

WARNING

9 7/8"

(251mm)

7"

(172mm)

P/N 3100106 ISSUE 2 © 2002

Page 2

10 1/2"

(267mm)

11 3/8"

(289mm)

10 7/8"

(276mm)

Figure 2. Detail of Bracket Mounting Figure 3. Detail of Ceiling Mounting

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

WARNING

To reduce the risk of ignition of hazardous atmospheres and shock, keep assembly tightly closed

when circuits are energized.

To reduce the risk of ignition of hazardous atmospheres and shock, disconnect from the supply and

circuit and allow five (5) minutes for stored energy to

dissipate before disassembling the unit.

4"

(102mm)

9 3/4"

(248mm)

10 1/8"

(260mm)

7"

(178mm)

2. Unscrew and remove the clear outer globe.

3. T o replace the strobe tube, remove the inner lens and

replace the appropriate tube as listed in T able 1.

4. Reinstall the inner lens. Screw the clear outer globe

back onto the fixture housing.

5. Where applicable, install the guard assembly over the

clear outer globe by rotating clockwise until it snaps

into place.

Disassemble the unit as follows (Figure 4):

1. Where applicable, remove the guard by rotating

counterclockwise.

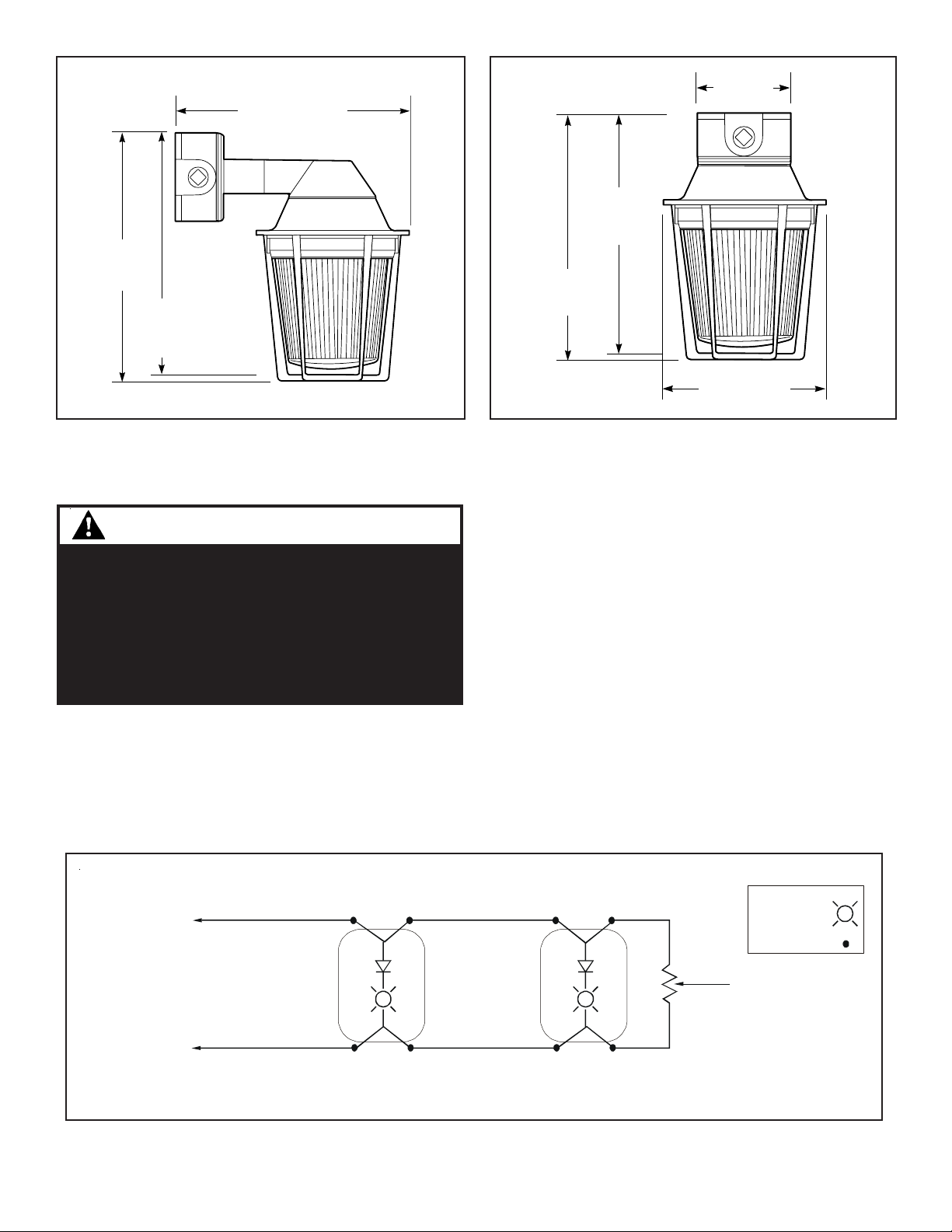

NOTE: DC polarity of circuit shown in supervisory state (signal inactive). Circuit polarity to reverse to activate signal.

Electrical supervision requires wire run to be broken at each device.

Device for constant input voltage. Do not connect to “coded” or pulsating voltage.

(-)

From Power Source

Previous Signaling Device

or

Series

107DDV2

(+)

Red

Black

(-)

(+)

Red

Black

(-)

Series

107DDV2

(+)

Red

Black

(-)

(+)

Red

Black

(-)

KEY:

Light symbol -

Wire nut symbol -

End-of-Line Resistor,

when required with

supervised system

(+)

NOTE: For use without field wire supervision installer can tie the two red leads together and tie the two

black leads together .

Figure 4. Wiring Diagram

P/N 3100106 ISSUE 2

Page 3

T

GASKET

CEILING MOUNT

OUTLET BOX

(2) SCREWS HOLDING CIRCUI

ASSEMBLY TO THE FIXTURE

OUTER GLOBE

Figure 5. Disassembly of the 107DDV2 Series Adaptabeacons

T able 1. 107DDV2*-G1 Series AdaptaBeacon Strobes

Mounting Conduit Flash Strobe Tube

Catalog Number Method Voltage Current Size Rate Replacement

107DDV2PST*-G1 Pendant 24V DC 1.4A 3/4" NPT Approx. 92-ST

107DDV2BST*-G1 Bracket 65 fpm

107DDV2CST*-G1 Ceiling

*Letter in this position denotes color of the globe: A - amber, B - blue, C - clear, G - green, R - red or

M - magenta

T able 2. Supply Wire T emperature Markings

Ambient Supply Wire

Temperature Temperature Marking

40°C 60°C

55°C 75°C

65°C 90°C

P/N 3100106 ISSUE 2

Page 4

Contacting Edwards:

Phone: (203) 699-3000

E-Mail: techsupport@edwards-signals.com

customerservice@edwards-signals.com

Website: http://www.edwards-signals.com

Loading...

Loading...