Page 1

Installation Instructions for 106DEXST-FJ AdaptaBeacon

Strobe Lights for Use in Hazardous Locations

®

DescriptionDescription

Description

DescriptionDescription

The 106DEXSTC-FJ (clear lens only) AdaptaBeacons are inrush current limited strobe lights that are UL1971 listed as

Special Application 20-30V DC Signaling Appliances for

the Hearing Impaired, with CSFM Listing as well. They

are intended for indoor use in UL listed compatible fire

alarm systems and other applications requiring electrical

supervision of signaling circuit field wiring. The strobe

flashes a 360-degree beam of light approximately 65 times

per minute with a 55 cd ceiling light output (35 cd other)

per Figure 5.

When assembled in accordance with these instructions,

these 106DEX Series visual strobe signals are UL listed for

use in Class I, Division 1, Group C and D, Class I, Division 2,

Group A, B, C and D, Class II, Division 1, Group E, F and G,

Class II, Division 2, Group F and G, and Class III Division 1

and 2 hazardous locations with Operating Temperature

Codes per the following chart.

Operating Temperature Codes

Class I, Div. 2, Groups F, G;

Groups C and D Class III, Div. 2

Ambient Class I, Div. 2 Class I, Div. 1 Groups E, F, G;

Temp. Groups A and B Groups C and D Class III, Div. 1

40°C 260°C (T2B) 85°C (T6) 120°C (T4A)

55°C 280°C (T2A) 100°C (T5) 135°C (T4)

65°C 280°C (T2A) 120°C (T4A) 160°C (T3C)

InstallationInstallation

Installation

InstallationInstallation

Class II, Div. 2,

Class II, Div. 1,

box (not supplied). Secure 3/4" (19 mm) NPT

threaded conduit (not supplied) to the box. Install

the hood on the conduit. Proceed to step 2.

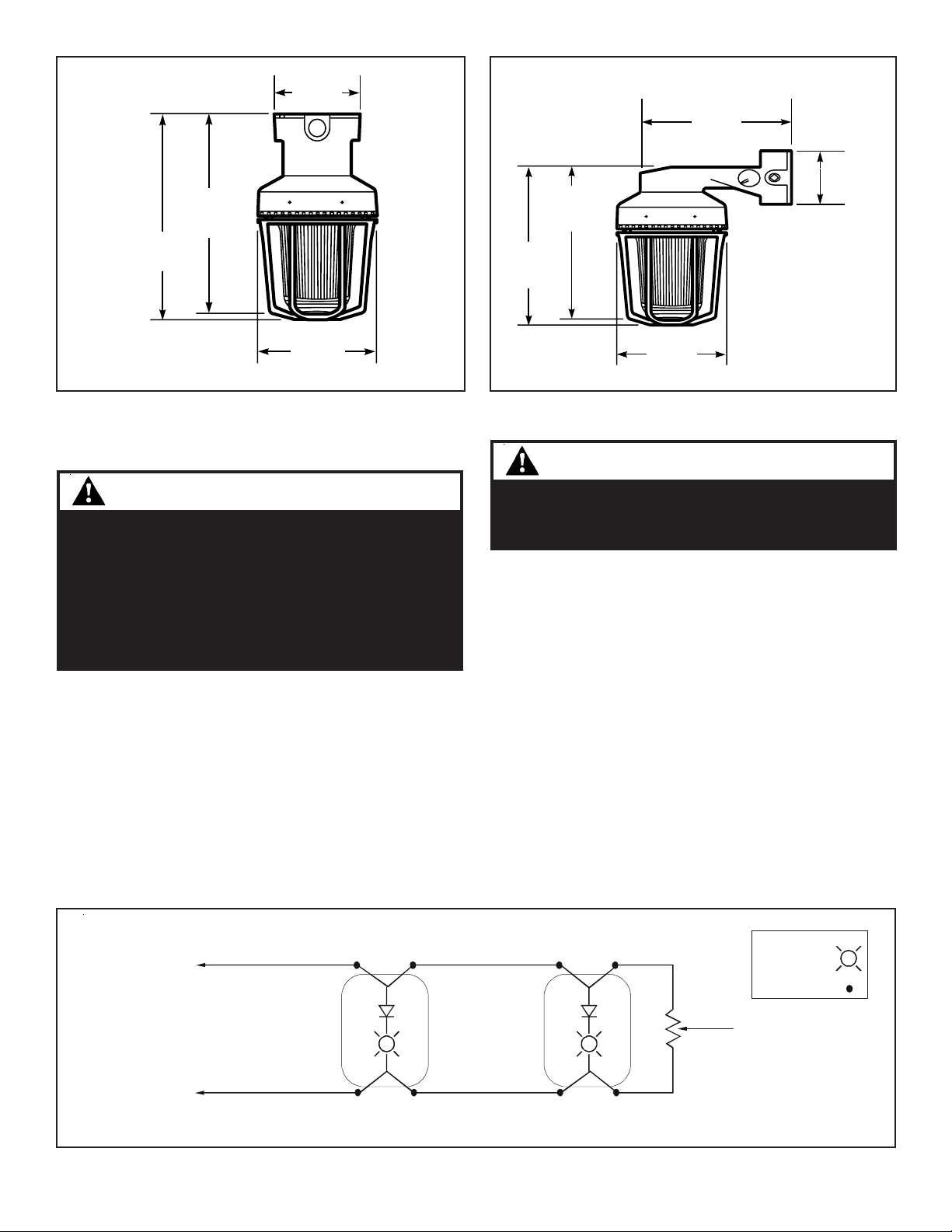

b. Ceiling Mount Models (Figures 2 and 4):

Unscrew the globe assembly from the ceiling

mount box. Mount the ceiling box using

appropriate hardware (not supplied) suitable for

the mounting surface. Proceed to step 2.

c. Bracket Mount Models (Figures 3 and 4):

Unscrew the globe assembly from the wall bracket.

Install the mounting bracket using appropriate

hardware (not supplied) for the mounting surface.

Pull the field wiring through the mounting

bracket. Proceed to step 2.

2. Extend the required power source wiring down

through the mounting hood. See T able 4 for required

supply wire temperature ratings.

3. A ground screw is provided in the wiring compartment

for attachment of field earth ground wire.

4. Connect the two red positive (+) and two black

negative (-) wire leads to the supervised circuit in

accordance with Figure 4.

5. Install the fixture on the mounting hood, bracket or

box as applicable.

WARNING

To reduce the risk of ignition of hazardous atmospheres and shock, keep assembly tightly closed

when circuits are energized.

Install this unit in accordance with the applicable require-

6. Apply power to the unit and ensure proper function.

ments in the latest edition of the National Electrical Code.

WARNING

To reduce the risk of ignition of hazardous atmospheres and shock, do not apply power to the unit

until installation has been completed and unit is

tightly assembled and secured.

NOTE: This unit must be mounted vertically with the

globe assembly vertically facing down in

Hearing Impaired Applications.

1. Mount using the following applicable method.

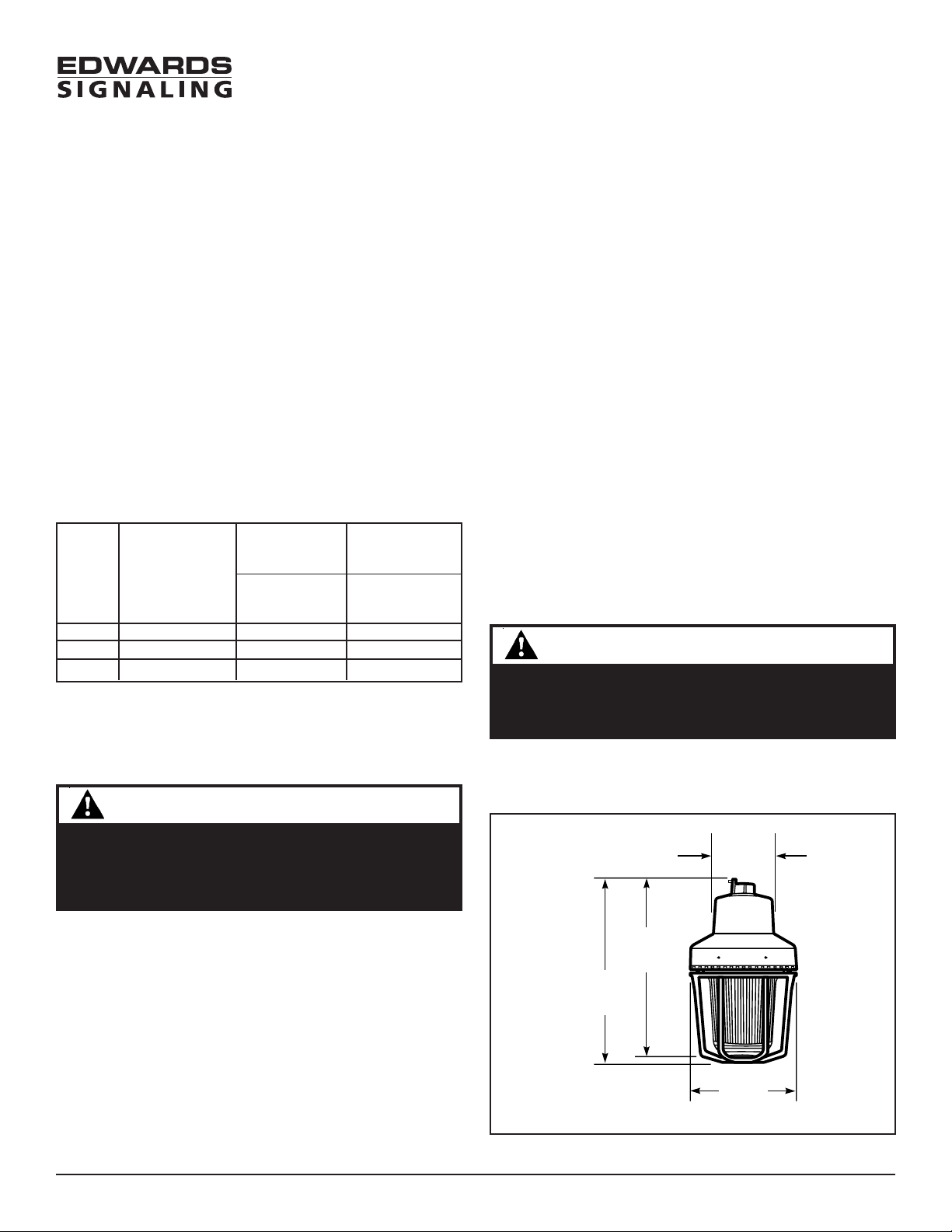

a. Pendant Mount Models (Figures 1 and 4):

Unscrew the globe assembly from the mounting

hood and set aside. Install explosion-proof hanger

CHESHIRE, CT 203-699-3300 FAX 203-699-3365 (CUST. SERV.) 203-699-3078 (TECH. SERV.)

13.53"

(343.66mm)

Figure 1. Detail of Pendant Mounting

4.50"

(114.3mm)

13.15"

(334.01mm)

7.80"

(198.12mm)

P/N 3100101 ISSUE 6 © 2003

Page 2

(330.2mm)

13.38"

(339.85mm)

13.0"

5.95"

(151.13mm)

13.88"

(352.6 mm)

4.93"

(125.2mm)

12.38"

(314.45mm)

13.75"

(349.25mm)

7.80"

(198.12mm)

Figure 2. Detail of Ceiling Mounting Figure 3. Detail of Bracket Mounting

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

WARNING

To reduce the risk of ignition of hazardous atmospheres and shock, keep assembly tightly closed

when circuits are energized.

To reduce the risk of ignition of hazardous atmospheres and shock, disconnect from the supply and

circuit and allow five (5) minutes for stored energy to

dissipate before disassembling the unit.

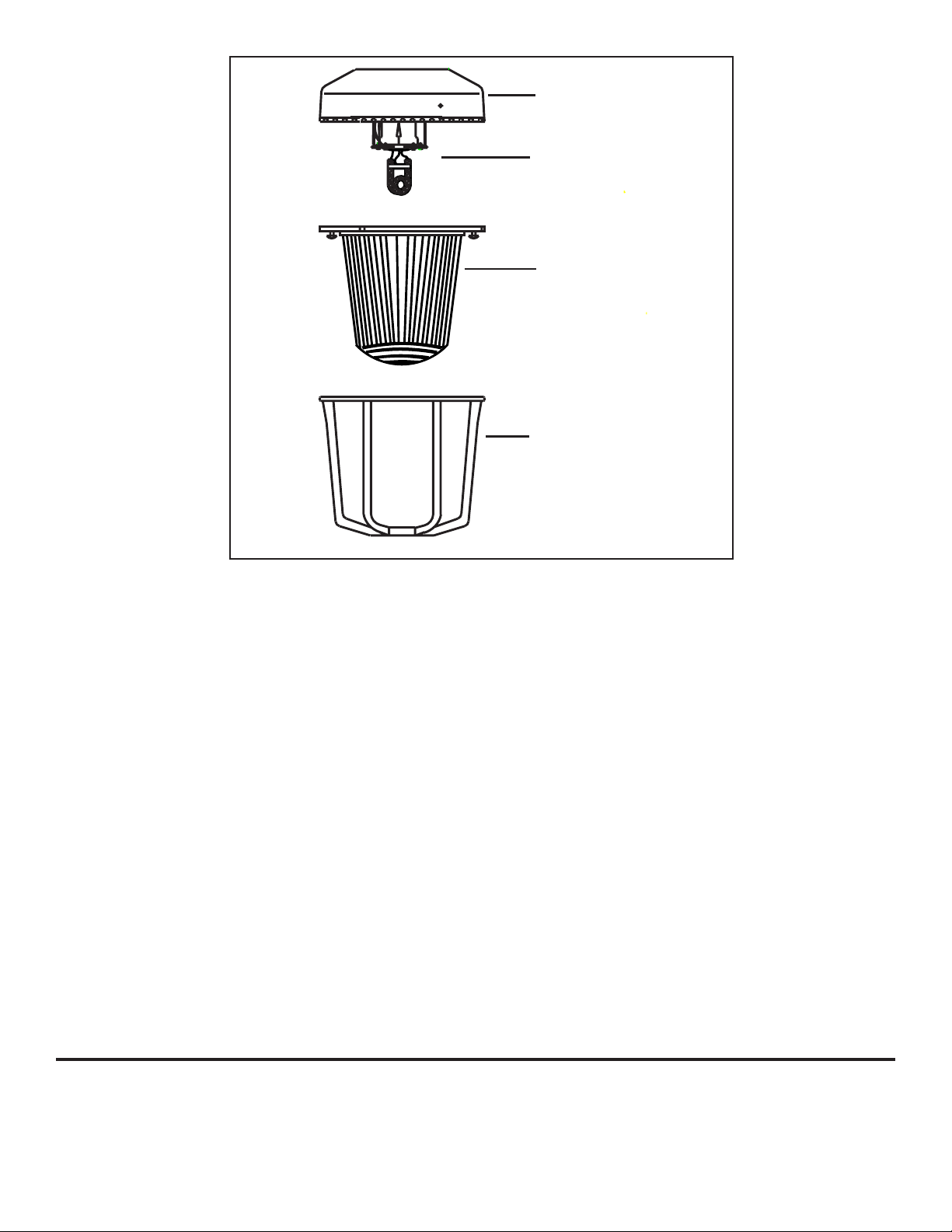

For strobe tube replacement, disconnect from the supply

circuit and allow five (5) minutes for stored energy to dissipate before starting work or disassembly (Figure 6).

1. Loosen the (3) guard screws and remove the guard.

2. Loosen the globe and ring assembly set screw. Insert

a suitable tool into the notches in the globe and ring

assembly and loosen the assembly by prying in a

counterclockwise direction. Remove the ring and

globe assembly .

7.80"

(198.12mm)

CAUTION

When replacing the strobe tube, do not handle the

tube. Hold the strobe tube only by its base to prevent damage to the tube.

3. Refer to Table 2 for the correct replacement catalog

number and replace the necessary part.

4. To replace, simply screw the unit on until it seats firmly

onto its gasket. Tighten the unit another 1/8 to 1/4

turn. Tighten the setscrew .

5. Reinstall the guard, where applicable, and secure using

the three supplied screws.

6. After the unit is assembled, apply power and make

sure the unit functions properly .

NOTE: DC polarity of circuit shown in supervisory state (signal inactive). Circuit polarity to reverse to activate signal.

Electrical supervision requires wire run to be broken at each device.

Device for constant input voltage. Do not connect to “coded” or pulsating voltage.

(-)

From Power Source

Previous Signaling Device

or

Series

106DEX

(+)

Red

Black

(-)

(+)

Red

Black

(-)

Series

106DEX

(+)

Red

Black

(-)

(+)

Red

Black

(-)

KEY:

Light symbol -

Wire nut symbol -

End-of-Line Resistor,

when required with

supervised system

(+)

NOTE: For non-fire alarm use without field wire supervision installer can tie the two red leads together and

tie the two black leads together .

Figure 4. Wiring Diagram

P/N 3100101 ISSUE 6

Page 3

T able 1. 106DEX AdaptaBeacon Strobe Light Electrical Specifications

Operating Current* Initial Surge Inrush Current Repetitive Surge Current

Voltage** RMS Current (A) Mean Current (A) Current (A) Time (mS) Current (A) Time (mS)

20V DC 1.08 0.84 2.70 1.10 2.24 450

24V DC 0.95 0.69 2.97 1.13 2.21 400

28V DC 0.85 0.66 3.06 1.24 2.16 381

30V DC 0.83 0.64 3.14 1.27 2.14 360

*Use the operating current to establish the wire gauge and standby power requirements. Consult the control unit manufacturer to

determine surge and peak current effects and maximum number of strobes on the system.

**CAUTION: To prevent damage to the visual signal's internal circuit and to assure its continued proper functioning, DO

NOT operate the unit outside of the Special Application Voltage range of 20-30V DC.

T able 2. 106DEX AdaptaBeacon Strobe Light Specifications

Cat. No. Method Size Rate Output

106DEXPSTC-FJ Pendant 3/4" 360° beam 55 cd/35 cd

106DEXCSTC-FJ Ceiling ~65 fpm Figure 5

106DEXBSTC-FJ Bracket

Mounting Conduit Flash Rated Light

Figure 1 NPT of light at per

Figure 2

Figure 3

T able 3. 106DEX AdaptaBeacon Strobe Light Replacement Parts

Cat. No. Method Strobe

106DEXPSTC-FJ Pendant Cat. No.

106DEXCSTC-FJ Ceiling

106DEXBSTC-FJ Bracket

Mounting Replacement

Figure 1 92-ST

Figure 2

Figure 3

T able 4. Supply Wire T emperature Markings

Ambient Supply Wire

Temperature Temperature Marking

40°C 75°C

55°C 90°C

65°C 105°C

P/N 3100101 ISSUE 6

Page 4

WALL

A

OR 55

G

p

BRACKET

MOUNT ING

NGLE

(DEGREES)

zero 100% 100%

5 90% 90%

10 90% 90%

15 90% 90%

20 90% 90%

25 90% 90%

30 90% 75%

35 65% 75%

40 46% 75%

45 34% 75%

50 27% 55%

55 22% 45%

60 18% 40%

65 16% 35%

70 15% 35%

75 13% 30%

80 12% 30%

85 12% 25%

90 12% 25%

Compound

45

UL1971 REQUIRED

DISPERSION AS % O F CD

RATING

VERTICAL

PLANE

HORIZONTAL

PLANE

24%

UL 1971 Hearing Impaired: 35 cd wall

UL 1638 General Utility: 35 cd at 0o axis

Effective Candela Light Output for Wall Bracket Mount

Vertical Plane

(Zero degree angle at side of globe)

-90

-85

100

90

80

70

60

50

40

30

20

10

0

-80

-75

-70

-65

-60

-55

-50

-45

TYPICAL CD

UL REQUIRED CD

FOR 35 RATING

-40

40

45

50

55

60

65

70

75

80

85

90

-35

-30

-25

-20

-15

-10

-5

0 degrees

5

10

15

20

25

30

35

CEILING

MOUNTING

ANGLE

(DEGREES)

0 100%

5 90%

10 90%

15 90%

20 90%

25 90%

30 75%

35 75%

40 75%

45 75%

50 55%

55 45%

60 40%

65 35%

70 35%

75 30%

80 30%

85 25%

90 25%

Com

ound 45 24%

UL 1971 Hearing Impaired: 55 cd ceiling

UL 1638 General Utility: 94 cd at 0

UL1971

REQUIRED

X & Y PLANE

DISPERSION

AS % OF CD

RATING

o

axis

Effective Candela Light Output for Ceiling Mount

X & Y Planes

(Zero degree angle at bottom of of globe)

180

100

170

165

160

155

150

145

140

135

130

125

120

115

110

105

100

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

90

80

70

60

50

40

30

20

10

15

5

10

175

170

TYPICAL CD

UL RE QUIR ED CD

F

0

10

5

degrees 0

165

RATIN

15

160

20

155

25

150

30

145

35

140

40

135

130

125

120

115

110

105

100

95

90

85

80

75

70

65

60

55

50

45

P/N 3100101 ISSUE 6

Figure 5. Light Output Patterns for 105DHISTC-FJ (Unit with clear lens only)

Page 5

Mounting

Hood

Strobe Tube

Globe & Ring

Assembly

Guard

(optional)

Figure 6. Disassembly of the 106DEX Series AdaptaBeacons

Contacting Edwards:

Phone: (203) 699-3000

E-Mail: techsupport@edwards-signals.com

customerservice@edwards-signals.com

Website: http://www.edwards-signals.com

P/N 3100101 ISSUE 6

Loading...

Loading...