Page 1

W959-000-01

Revision

F

October,

96

Instruction

Manual

TCU

40/80

Single

Channel

Temperature

Control

Unit

EDWARDS

Edwards

High

Vacuum

International

One

Edwards

Park

301

Ballardvale

Street

Wilmington,MA01887

Telephone:

(508)

658-5410

Telex:

710-347-7672

Fax:

(508)658-7969

Page 2

Declaration

of

Conformity

We,

Edwards

High

Vacuum

International,

One

Edwards

Park

301

Ballardvale

St.

Wilmington,MA01887

declare

under

our

sole

responsibility

that

the

product(s)

TCU

40/80

Temperature

Control

Unit

W95000000

to

which

this

declaration

relatesisin

confonnity

with

the

following

standard(s)

or

other

normative

document(s)

BSIEC1010-1

BS

EN50O81-1

BSEN50082-1

following

the

provisions

of

89/392/EEC

89/336/EEC

73/023/EEC

Safety

Requirements

for

Electrical

Equipment

for

Measurement,

Control

and

Laboratory

Use.

Electromagnetic

Compatibility,

General

Emission

Standard.

Generic

Standard

Class:

Domestic,

Commercial&Light

Industry.

Electromagnetic

Compatibility,

General

Immunity

Standard.

Generic

Standard

Class:

Domestic,

Commercial&Light

Industry

Machinery

Safety

Directive

Electromagnetic

Compatibility

Directive

Low

Voltage

Directive

0

Dr.A.P.

Troup,

DirectorofTechnology

Date

and

Place

This

product

has

been

manufactured

underaquality

system

registered

to

ISO900I

EDWARDS

Page 3

CONTENTS

Section

Title

Page

1

PREFACE

1

1.1

Safety

considerations

1

2

TCU

40/80

3

2.1

Scopeofthe

manual

3

2.2

Descriptionofthe

TCU

40/80

3

2.3

Lockout

procedure

3

2.4

Safety

features

4

3

QUICK

START

PROCEDURE

5

3.1

Power

up

5

3.2

Sctpoint

verification

5

4

PRODUCT

DESCRIPTION

6

4.1

Refrigeration

and

coolant

circuits

6

4.2

Refrigeration

9

4.2.1

If

coolingisrequired:

9

4.2.2

If

coolingisnot

required:

10

4.3

Coolant

circuit

10

4.4

Temperature

monitoring

10

4.5

Front panel

1

]

4.6

Rear

panel

13

4.7

Specifications

14

4.8

Dimensions

15

5

INSTALLATION

]6

5.1

Receiving

and

unpacking

16

5.2

Location

16

5.2.1

Securing

the

unit

16

5.2.2 Installing

the

secondary

containment

receptacle

16

5.2.3

Floor

levclers

16

5.3

Stacking

17

5.3.1

Tie-bolts

17

5.4

Facilities

17

5.4.1

Water

and

coolant

connections

18

5.4.2

Water

19

5.4.3

Coolant

19

5.4.4

Remote

connections

19

6

OPERATION

20

6.1

Preparation

20

6.2

Poweringupthe

TCU

40/80

20

6.3

Changing

the

setpoint

value

(SV1)

21

6.4

Temperature

controller

Pid

settings

21

6.5

Remote

set-point

22

6.6

Flow

rate

adjustment

22

/?^v

TCU

40/80

Temperature

Control

Unit

Page 4

7

MAINTENANCE

23

7.1

Hazard

warnings

23

7.2

Hazards

25

7.3

Filling

the

reservoir

26

7.4

Draining/bleeding

the

coolant

reservoir

26

7.5

Temperature

probe

calibration

27

7.6

Preventive

maintenance

schedule

27

7.7

Semi-annual

preventative

maintenance

28

7.7.1

Required

equipment

28

7.7.2

Preparation

28

7.7.3

Verify

system

status

28

7.7.4

Refrigeration

leak

check

28

7.7.5

Fluorinert

leak

check

28

7.7.6

Water

leak

check

28

7.7.7

Insulation repair

28

7.7.8

Lamp

check/replacement

29

7.8

Annual

preventative

maintenance

30

7.8.1

Required

equipment

30

7.8.2

Required

supplies

30

7.8.3

Solenoid

valve

coil

replacement

30

7.8.4

System

check

32

7.9

Preventive

maintenance

checklist

41

8

TROUBLESHOOTING

42

9

ACCESSORIES

AND

SPARE

PARTS

52

APPENDIX

54

ReturnofEdwards

Equipment-Procedure

(Form

HS1)

58

ReturnofEdwards

Equipment-

Declaration

(FormHS2)

59

Legal

notices,

limitations

and

disclaimers

60

MSDS

(material

safety

data

sheet)-

"SUVA"

HP62

61

'-""5\

TCU

40/80

Temperature

Control

Unit

Page 5

ILLUSTRATIONS

Figure

Title

Page

Figure1-Refrigeration

and

coolant

components

6

Figure2-

Refrigeration

and

coolant

components

7

Figure3-Refrigeration

and

coolant

circuits

9

Figure4-

Front panel

11

Figure5-

Electrical

rear

panel

13

Figure6-

TCU

dimensions

15

Figure7-Stacked

TCU

40/80

systems

17

Figure

8-System

rear

view

18

Figure9Water

connections

J9

Figure10-

Temperature

controller

21

Figure11-

Lamp

replacement

29

Figure12-

Solenoid

coil

replacement

31

Figure13-Electrical

drawer

51

Figure

14-Electrical

drawer

schematic

54

Figure15-

Remote

interface

56

Table

Title

Page

Table1-

Safety

features

4

Table2

-Frontpanel

Indicators

5

Table3-

Refrigeration

and

coolant

components

8

Table4-

Front

panel

controls

11

Table5-

Front

panel

LED

indicators

12

Table6-

Temperature

controller

12

Table7-

Description

of

rear

panel

components

and

indicators

13

Table8-

Front panel

powerupindicator

conditions

20

Table9-

Electrical

hazards

classifications

25

Table10-

Preventive

maintenance

schedule

27

Table

11-

Faults

identified

by

front

panel

lamps

42

Table12-

Faults

indicated

by

the

front

panel

LED

indicators

44

Table13-Faults

identified

by

rear

panel

indicators

48

Table14-

Miscellaneous

fault

conditions

49

Table15-Accessories

52

Table16Spare

parts

53

TCU

40/80

Temperature

Control

Unit

Hi

Page 6

TRANSLATIONS

The

TCU

40/80

Instruction

Manualisavailable

in

the

following

translations:

Language

English

French

German

Italian

Japanese

Edwards

part

number

W95900001

W95900004

W95900005

W95900006

W95900007

For

each

TCU

40/80

purchased,

you

are

entitledtoone

translated

manual

freeofcharge.

This

is

in

additiontothe

English

version

provided.

Fax

this

completed

formtothe

nearest

Edwards

locationtoreceive

your

complimentary

translation.

Name:

Title:

Company:

Address:

TCU

serial

number:

Language:

(circle

one)

French

German

Italian

Japanese

TCU

40/80

Temperature

Control

Unit

Page 7

1

PREFACE

1.1

Safety

considerations

Many

safety features

have

been

designed

into

the

TCU

40/80toprotect

the

operator

and

the

equipment.

The

following

symbols

are

usedinthis

manualtoindicate

the

various

safety

conditions.

General

Alert

General

Alert

symbol

denotes

the

potential

of

personal

hazards

or

equipment

failure.

Warnings

are

given

when

failuretoobserve

the

instruction

could

resultininjuryordeathtopersons.

Cautions

are

given

where

failuretoobserve

the

instruction

could

resultindamagetothe

equipment,

associated

equipment

and

process.

Statementonavoiding

the

hazard.

Electric

Shock

Electric

Shock

symbol

denotes

the

presenceofhigh

voltage

or

current.Itcalls

attentiontothe

procedure,

practice,orthe

like,

whichifnot

done

correctlyoradheredtocould

resultininjury

or

death.

Statementonavoiding

the

hazard.

Eye

Protection

Eye

Protection

symbol

denotesahazard

which

could

cause

injuryorirritation

to

the

eyes.

Statementonavoiding

the

hazard.

Toxic

Gases

Toxic

Gases

symbol

denotesapersonal

hazard.

It

calls

attentiontothe

procedure,

practice,orthe

like,

which

if

not

done

correctly

or

adheredtocould

resultininjury or death.

Statementonavoiding

the

hazard.

TCU

40/80

Temperature

Control

Unit

Page 8

Hot

Surfaces

Hot

Surfaces

symbol

denotes a

hazard

which

could

cause

injury

or burns.

Statementonavoiding

the

hazard.

Hand

Protection

Hand

Protection

symbol

denotes a

hazard

which

could

cause

injuryorburns

Statementonavoiding

the

hazard.

High

Pressure

High

Pressure

symbol

denotesapersonal

hazardorequipment

failure.

It

calls

attention

to

the

procedure,

practice,

or

the

like,

whichifnot

done

correctlyoradheredtocould

result

in

equipment

damage,

injury

or death.

Statementonavoiding

the

hazard.

Extreme

Temperature

Extreme

Temperature

symbol

denotesahazard

which

could

cause

injuryorburns.

Statementonavoiding

the

hazard.

^

TCU

40/80

Temperature

Control

Unit

Page 9

2

TCU

40/80

2.1

Scopeofthe

manual

This

manual

provides

informationonthe

installation,

start-up

and

operationofEdwards

High

Vacuum

Model

40/80

Temperature

Control

Unit

(TCU

40/80).

The

Quick

Start

Procedureonpage5isastepbystep

guide

for

the

startupand

use

of an

installed,

working

system.

Installation,

startingonpage

16,

provides

instructions

and

information

for

installing

the

system.

The

installer

must

have

sufficient

technical

understanding

of

electrical

and

mechanical

systemstoproperly

use

this

information.

Operation,

starting

on page

20,

provides

more

complete

instructions

on

the

preparation

and

useofthe

system.

2.2

Description

of

the

TCU

40/80

The

TCU

40/80isa

single-channel

temperature

control

unit

engineered

for

temperature

controlofremote

heat

loads.

From

distancesuptoSOfeet,

the

TCU

40/80

can

cool

the

heat

load

generatedbythe

process

equipment.

The

coolant

circulates

through

the

TCU

40/80,

whereitis

cooledorheatedasrequired,

thenistransferred

to

the

process

equipment,

and

returnsina closed

loop.

The

TCU

40/80

maintains

supply

coolantata

temperature

between

-40°Cand

+80

°C,

selectable

in

0.1°Cincrements,

withatoleranceof±1.0

°C.

2.3

Lockout

procedure

To

prevent

accidental

or

unauthorized

startingofthe

TCU

40/80

during

maintenance,

disconnect

the

power

cord

from

the

receptacle

and

installanappropriate

lock-out

device

(Hubbell

Small

Plugout™

or

equivalent)

on

the

endofthe

power

cord.

0

TCU

40/80

Temperature

Control

Unit

Page 10

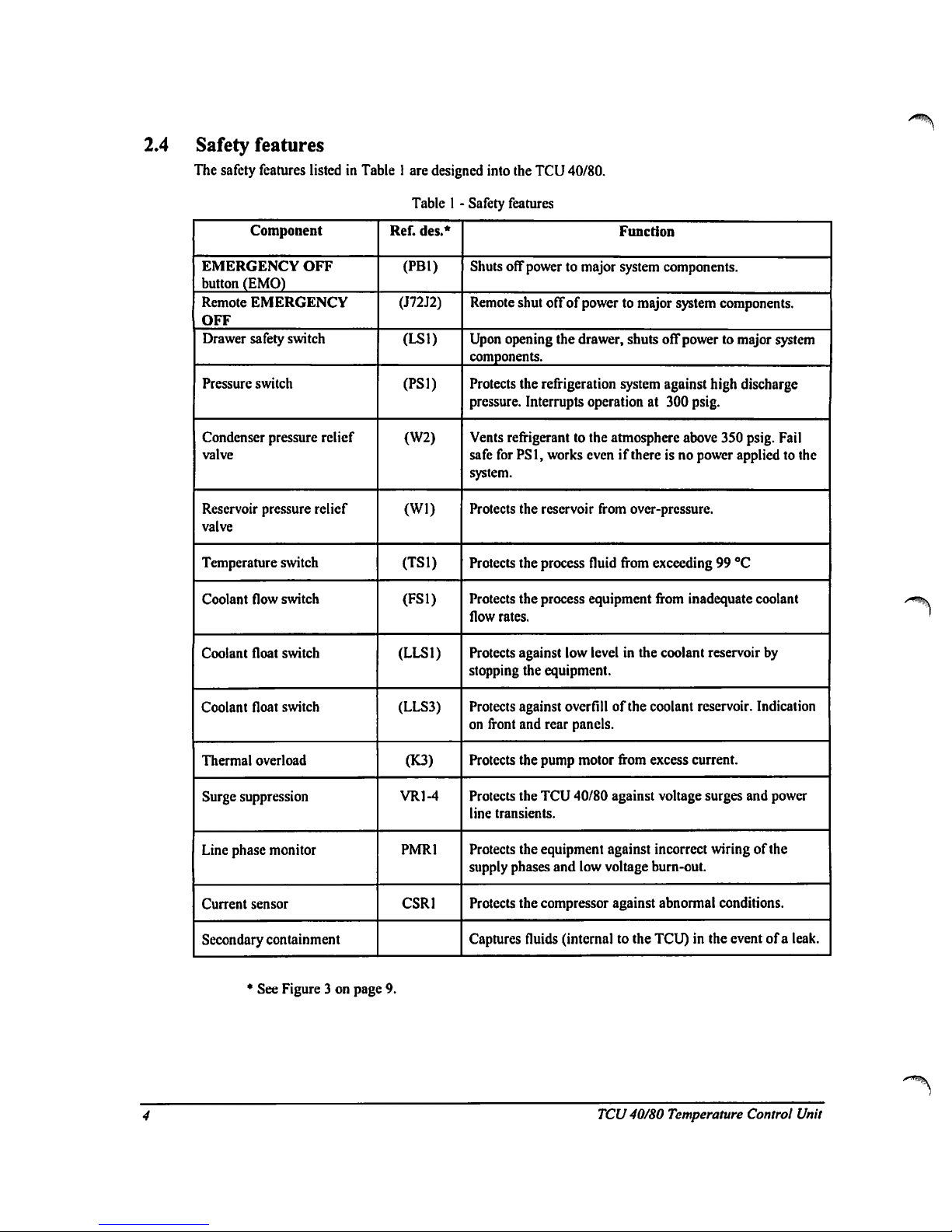

2.4

Safety

features

The

safety

features

listedinTable1are

designed

into

the

TCU

40/80.

TableI-

Safety

features

Component

EMERGENCY

OFF

button

(EMO)

Remote

EMERGENCY

OFF

Drawer

safety

switch

Pressure

switch

Condenser

pressure

relief

valve

Reservoir

pressure

relief

valve

Temperature

switch

Coolant

flow

switch

Coolant

float

switch

Coolant

float

switch

Thermal

overload

Surge

suppression

Line

phase

monitor

Current

sensor

Secondary

containment

Ref.

des.*

(PB1)

(J72J2)

(LSD

(PS1)

(W2)

(Wl)

(TS1)

(FS1)

(LLS1)

(LLS3)

(K3)

VR1-4

PMR1

CSR1

Function

Shuts

off

powertomajor

system

components.

Remote

shut

offofpowertomajor

system

components.

Upon

opening

the

drawer,

shuts

off

powertomajor

system

components.

Protects

the

refrigeration

system

against

high

discharge

pressure.

Interrupts

operationat300

psig.

Vents

refrigerant

to

the

atmosphere

above

350

psig.

Fail

safe

for

PS1,

works

evenifthereisno

power

appliedtothe

system.

Protects

the

reservoir

from

over-pressure.

Protects

the

process

fluid

from

exceeding99°C

Protects

the

process

equipment

from

inadequate

coolant

flow

rates.

Protects

against

low

levelinthe

coolant

reservoir

by

stopping

the

equipment.

Protects

against

overfill

of

the

coolant

reservoir.

Indication

on

front

and

rear

panels.

Protects

the

pump

motor

from

excess

current.

Protects

the

TCU

40/80

against voltage

surges

and

power

line

transients.

Protects

the

equipment

against

incorrect

wiringofthe

supply

phases

and low

voltage

burn-out.

Protects

the

compressor

against

abnormal

conditions.

Captures

fluids

(internaltothe

TCU)inthe

eventofa

leak.

•

See

Figure3on

page

9.

TCU

40/80 Temperature

Control

Unit

Page 11

3

QUICK

START

PROCEDURE

This

Quick

Start

procedureisfor

easy

start

up

and

operation

of an

installed

and

fully

working

TCU

40/80.Ifyour

TCU

40/80

is

not

installed,

gotoInstallation

on

page

16.

Detailed

operating

instructions

are

in

Operation

on page

20.

Ifatany

time an

alarm

occurs,

press

STOP

and

correct

the

fault

indicatedbythe

display

as

directedinthe

Troubleshooting

Guide

on

page

42.

Press

RESET

and

START

to

continue

operation.

3.1

Power

up

Before

applying

power,

verify

that

all

water

and

coolant

lines

are

connectedtothe

system.

The

handlesonboth

coolant

line

valves

shouldbein

the

open

position.

For

the

locationofthese

connections,

refer

to

Figure8on

page

18.

To

power up

the

TCU

40/80:

1.

READY

light

shouldbeon.Ifthe

ready

lightisnotonsee

Powering

Up

the

TCU

40/80onpage

20.

2.

Press

RESET.

Verify

that

front

panel

indicators

areasshowninthe

Reset

columnofTable2on

this

page.

3.

Press

START.

Verify

that front

panel

indicators

areasshowninthe

Start

Condition

columnofTable2on

this

page.

If in

steps

twoorthree

any

front

panel

indicators

do

not

match

Table2,refertothe

Troubleshooting

Guideonpage42for

corrective

action.

4.

Verify

that

the

coolant

pressure

gauge

(locatedonthe

front

access

panel)

reads

less

than

100

psig.

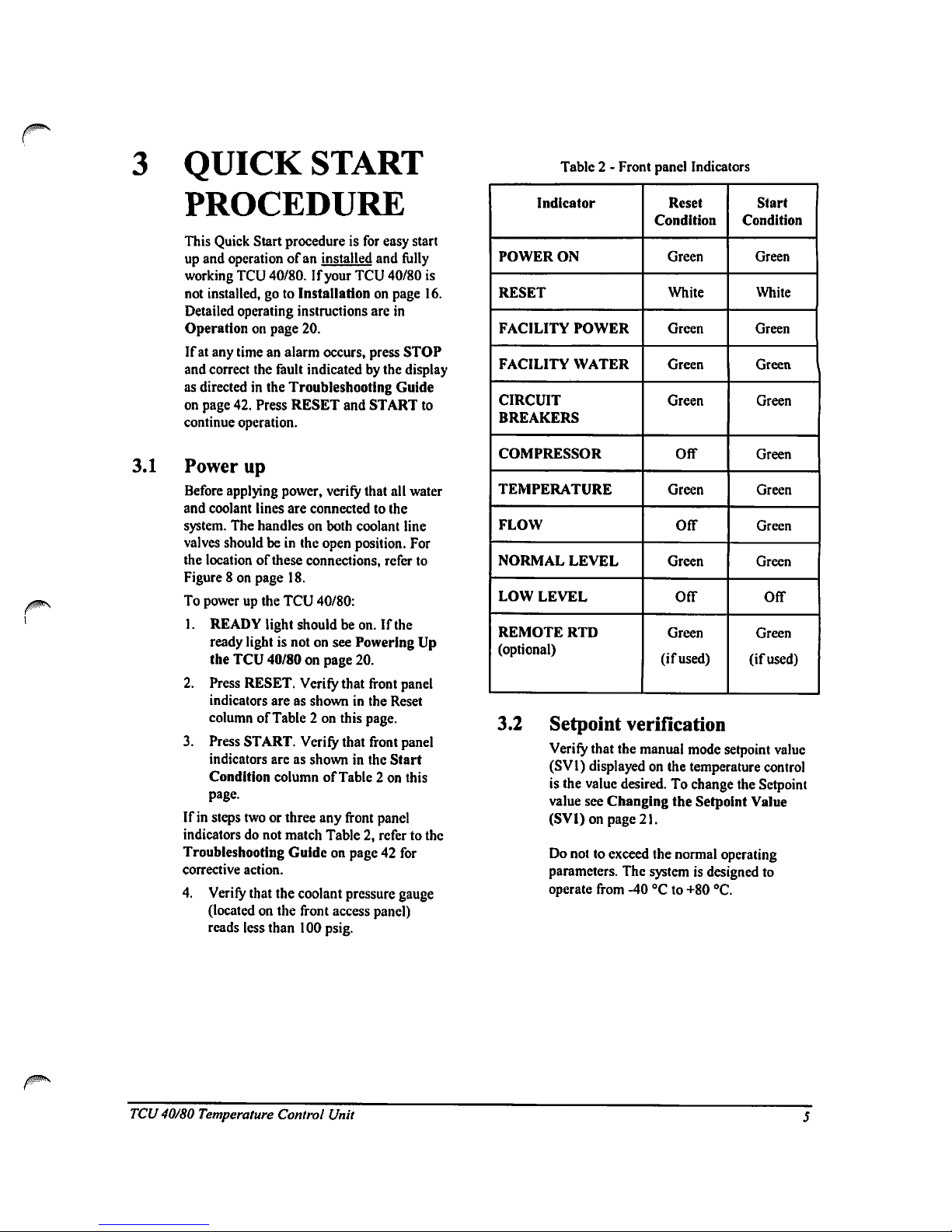

Table 2-Front

panel

Indicators

Indicator

POWER

ON

RESET

FACILITY

POWER

FACILITY

WATER

CIRCUIT

BREAKERS

COMPRESSOR

TEMPERATURE

FLOW

NORMAL

LEVEL

LOW

LEVEL

REMOTE

RTD

(optional)

Reset

Condition

Green

White

Green

Green

Green

Off

Green

Off

Green

OfT

Green

(if

used)

Start

Condition

Green

White

Green

Green

Green

Green

Green

Green

Green

Off

Green

(if

used)

3.2

Setpoint

verification

Verify

that

the

manual

mode

setpoint

value

(SV1)

displayedonthe

temperature

control

is

the

value

desired.Tochange

the

Setpoint

value

see

Changing

the Setpoint

Value

(SVl)onpage21.

Do

nottoexceed

the

normal

operating

parameters.

The

systemisdesigned

to

operate

from

-40°Cto

+80

°C.

TCU

40/80

Temperature

Control

Unit

Page 12

4

PRODUCT

DESCRIPTION

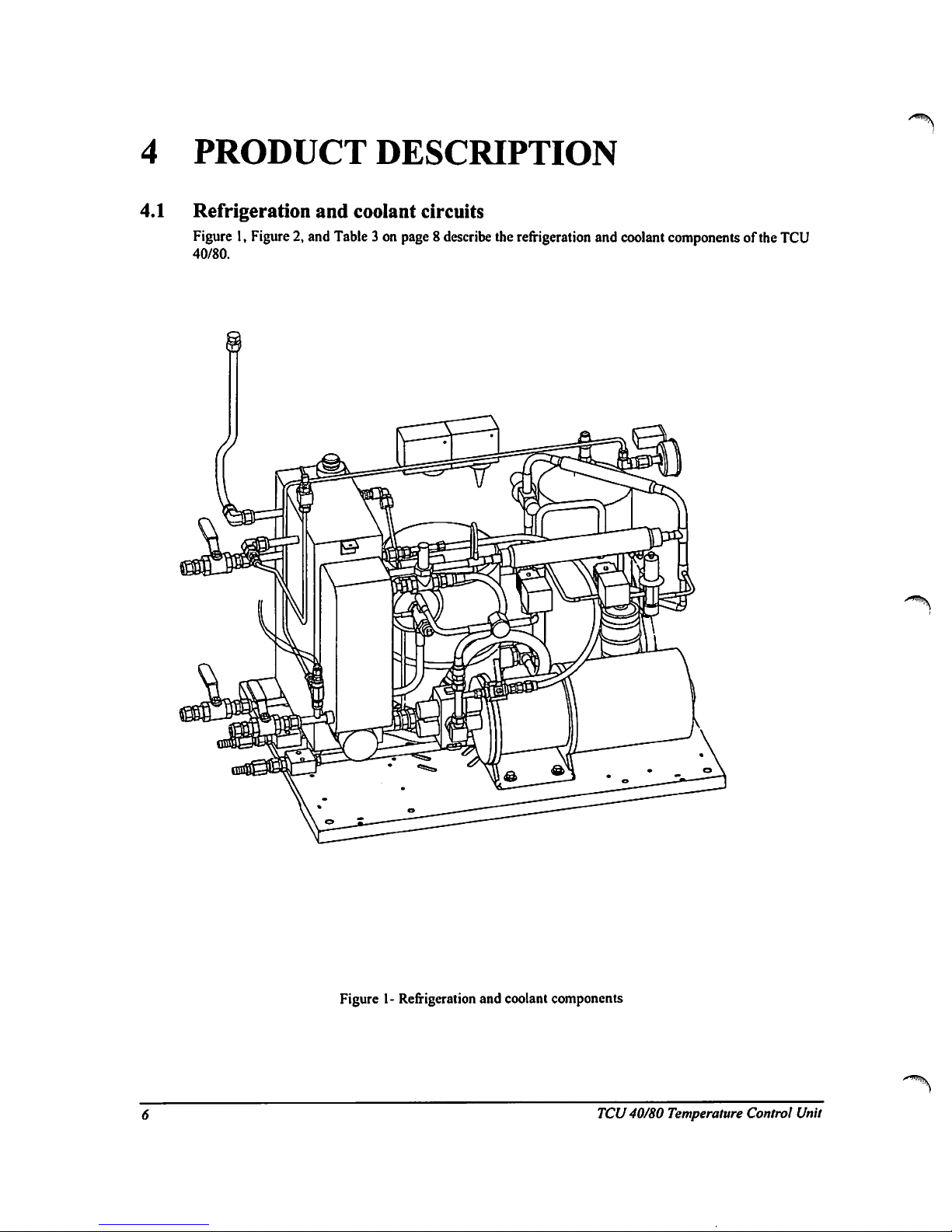

4.1

Refrigeration

and

coolant

circuits

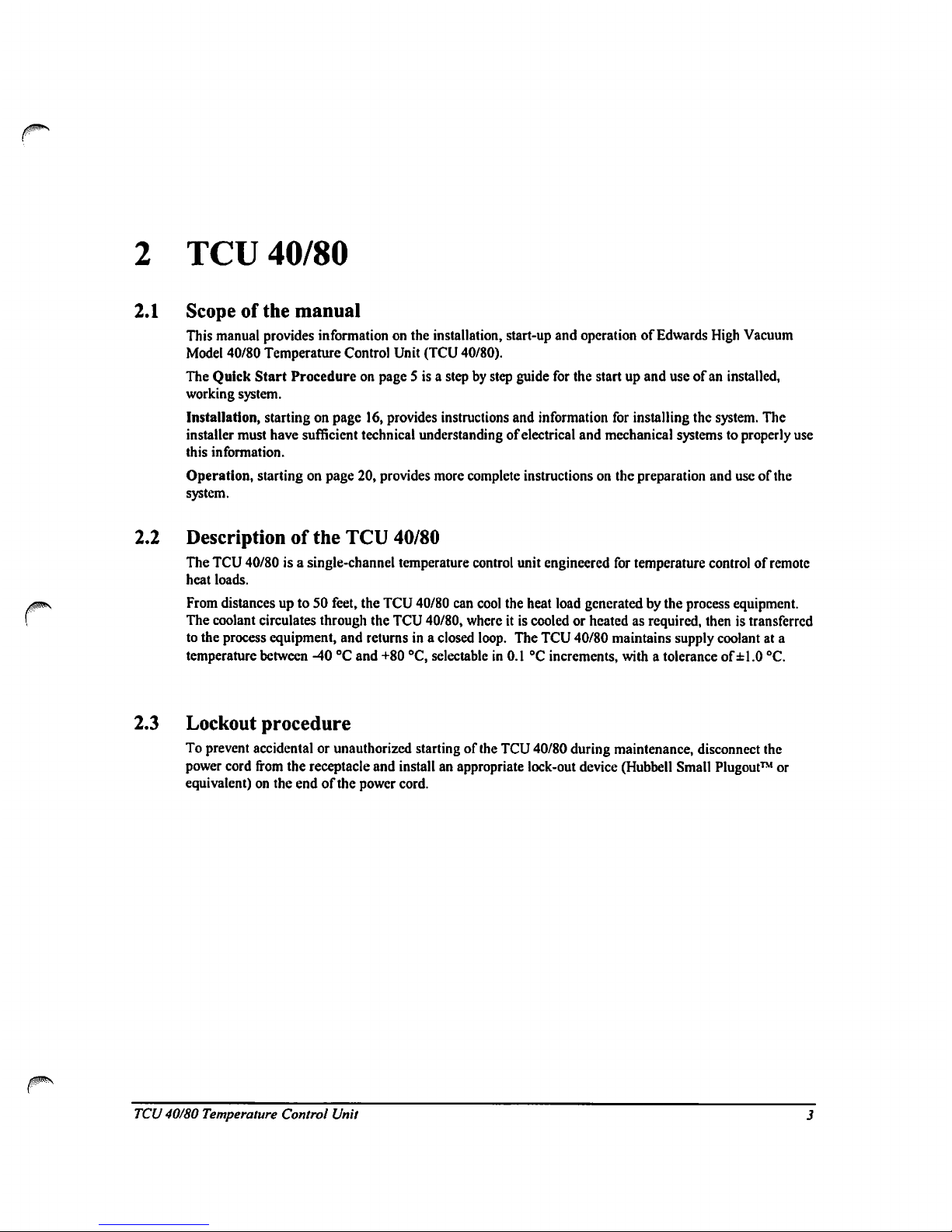

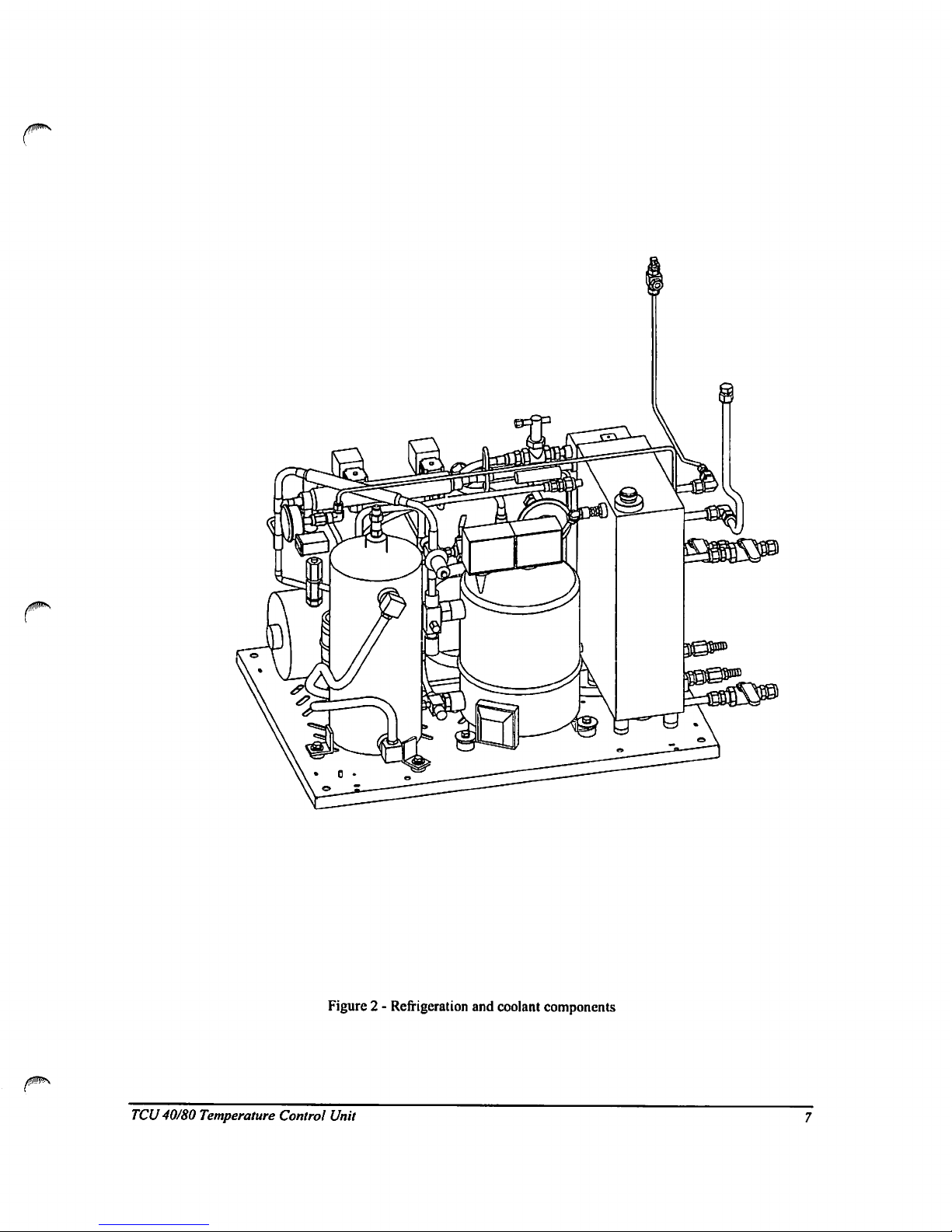

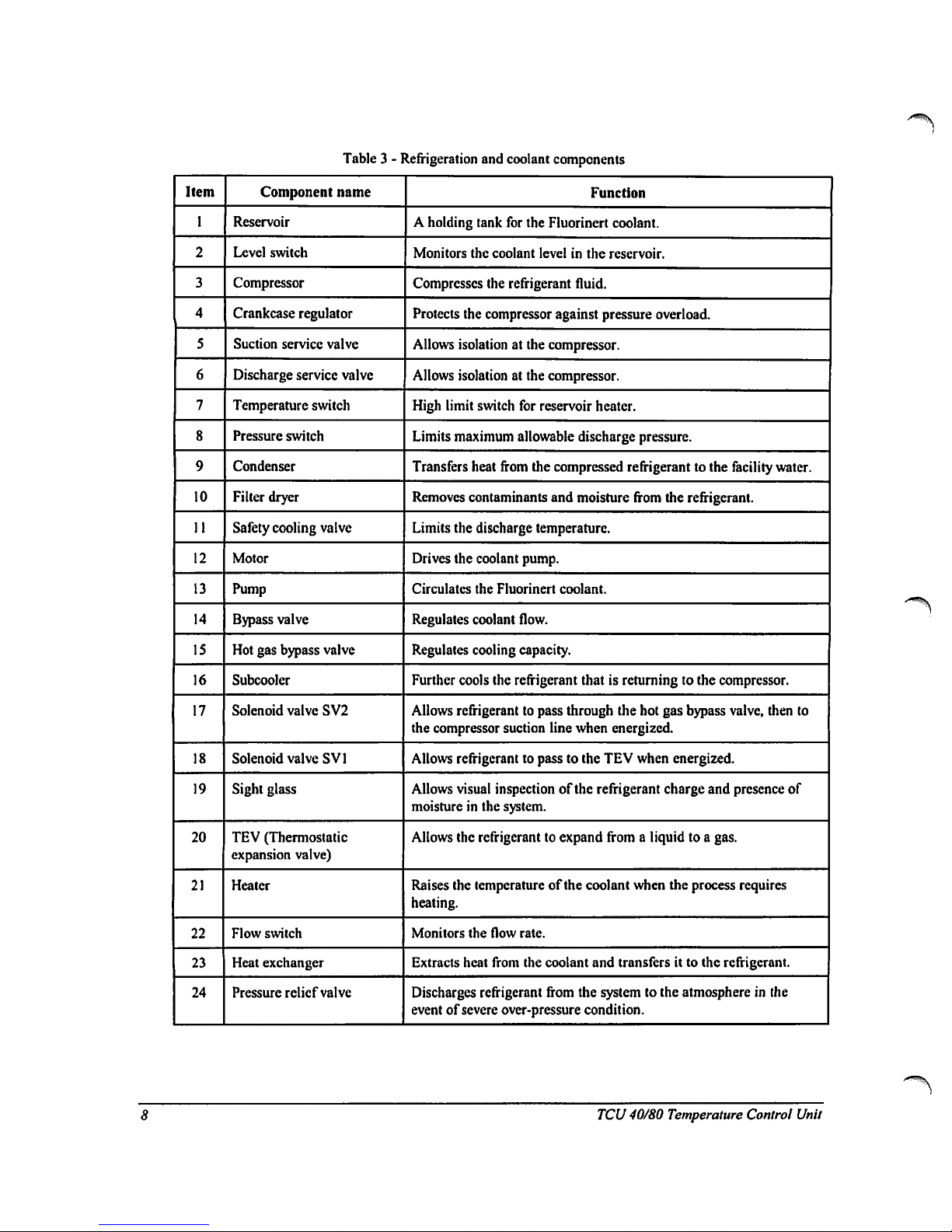

Figure1,Figure2,and

Table3on page8describe

the

refrigeration

and

coolant

componentsofthe

TCU

40/80.

Figure1-Refrigeration

and

coolant

components

TCU40/80

Temperature

Control

Unit

Page 13

Figure2-

Refrigeration

and

coolant

components

TCU

40/80

Temperature

Control

Unit

Page 14

/^\

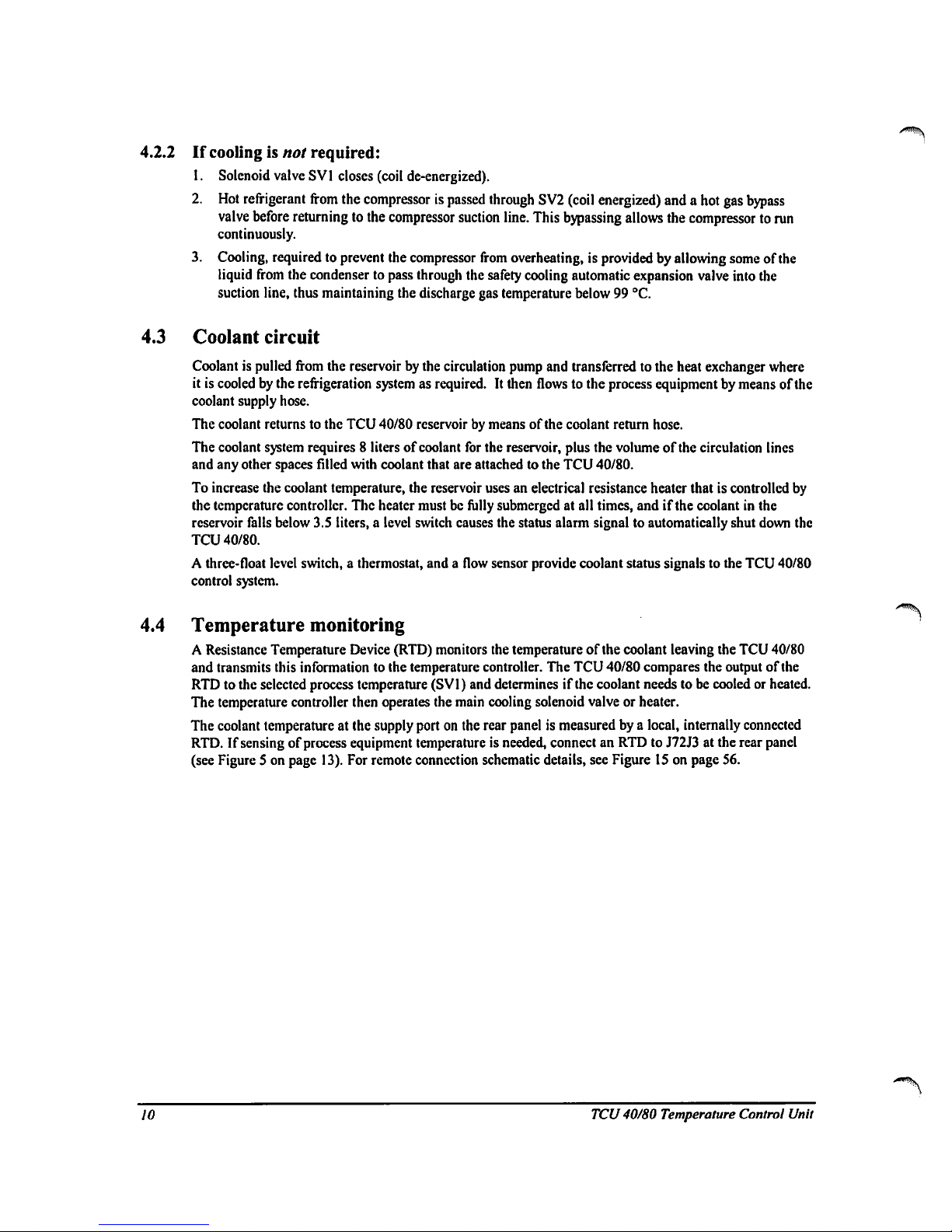

Table3-

Refrigeration

and

coolant

components

Item

I

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Component

name

Reservoir

Level

switch

Compressor

Crankcase

regulator

Suction

service

valve

Discharge

service

valve

Temperature

switch

Pressure

switch

Condenser

Filter

dryer

Safety

cooling

valve

Motor

Pump

Bypass

valve

Hot

gas

bypass

valve

Subcooler

Solenoid

valve

SV2

Solenoid

valve

SV1

Sight

glass

TEV

(Thermostatic

expansion

valve)

Heater

Flow

switch

Heat

exchanger

Pressure

relief

valve

Function

A

holding

tank

for

the

Fluorinert

coolant.

Monitors

the

coolant

levelinthe

reservoir.

Compresses

the

refrigerant

fluid.

Protects

the

compressor

against

pressure

overload.

Allows

isolation

at

the

compressor.

Allows

isolationatthe

compressor.

High

limit

switch

for

reservoir

heater.

Limits

maximum

allowable

discharge

pressure.

Transfers

heat

from

the

compressed

refrigerant

to

the

facility

water.

Removes

contaminants

and

moisture

from

the

refrigerant.

Limits

the

discharge

temperature.

Drives

the

coolant

pump.

Circulates

the

Fluorinert

coolant.

Regulates

coolant

flow.

Regulates

cooling

capacity.

Further

cools

the

refrigerant

thatisreturningtothe

compressor.

Allows

refrigerant

to

pass

through

the

hot

gas bypass

valve,

then

to

the

compressor

suction

line

when

energized.

Allows

refrigerant

to

passtothe

TEV

when

energized.

Allows

visual

inspectionofthe

refrigerant

charge

and

presence

of

moistureinthe

system.

Allows

the

refrigerant

to

expand

fromaliquidtoa

gas.

Raises

the

temperature

of

the

coolant

when

the

process

requires

heating.

Monitors

the

flow

rate.

Extracts

heat

from

the

coolant

and

transfers

ittothe

refrigerant.

Discharges

refrigerant

from

the

systemtothe

atmosphereinthe

eventofsevere

over-pressure

condition.

TCU

40/80

Temperature

Control

Unit

Page 15

/

Bypass

vaSn

Oran

valve

I

RID

temperature

probe

Profisure

Gwlttfc

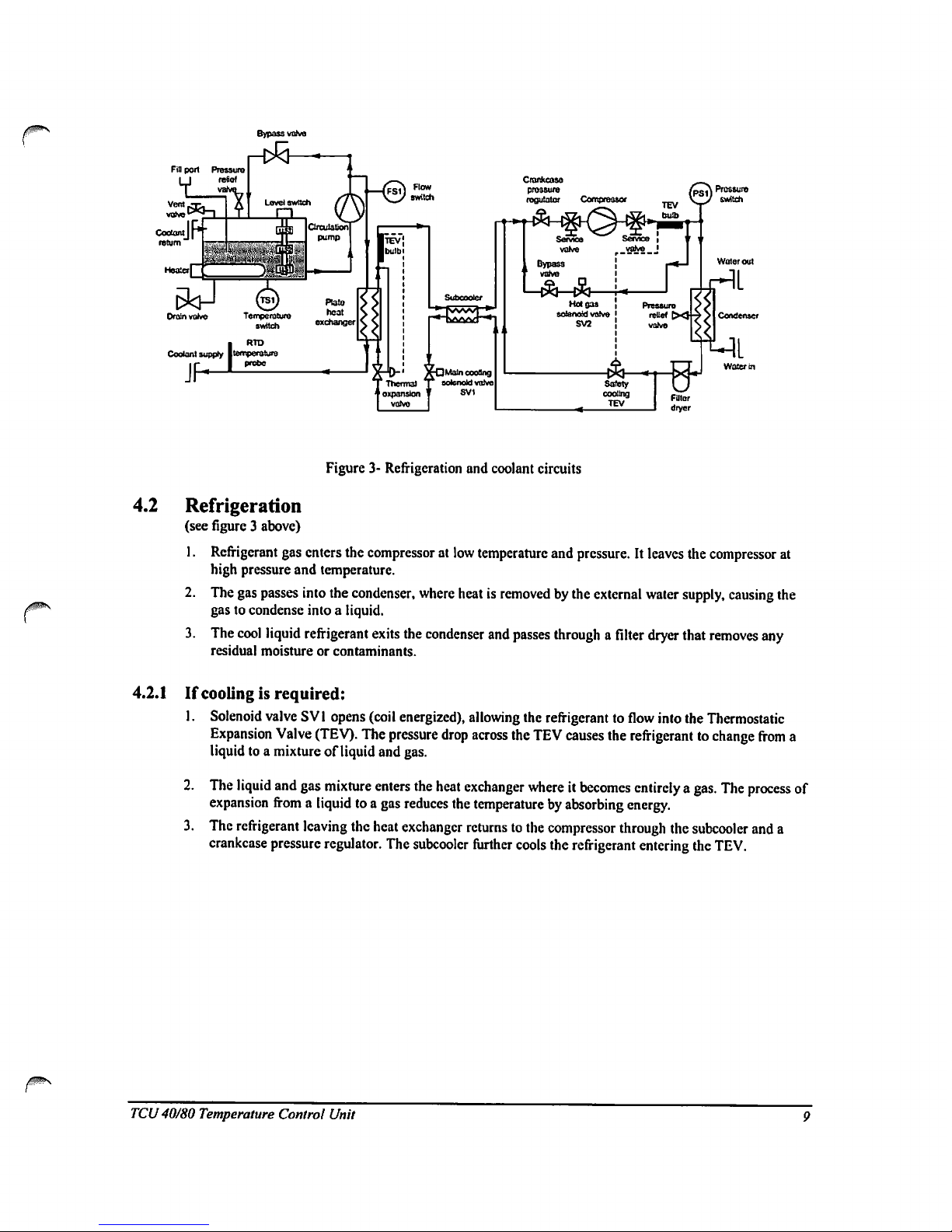

Figure3-Refrigeration

and

coolant

circuits

4.2

Refrigeration

(see

figure3above)

1.

Refrigerant

gas

enters

the

compressor

at

low

temperature

and

pressure.

It

leaves the

compressor

at

high

pressure

and

temperature.

2.

The

gas

passes

into

the

condenser,

where

heatisremovedbythe

external

water

supply,

causing

the

gastocondense

intoaliquid.

3.

The

cool

liquid

refrigerant

exits

the

condenser

and

passes

throughafilter

dryer

that

removes

any

residual

moistureorcontaminants.

4.2.1Ifcoolingisrequired:

1.

Solenoid

valve

SV1

opens

(coil

energized),

allowing

the

refrigerant

to

flow

into

the

Thermostatic

Expansion

Valve

(TEV).

The

pressure

drop

across

the

TEV

causes

the

refrigerant

to

change

from

a

liquidtoa

mixtureofliquid

and

gas.

2.

The

liquid

and

gas

mixture

enters

the

heat

exchanger

whereitbecomes

entirely

a

gas.

The

process

of

expansion

fromaliquidtoa

gas

reduces

the

temperature

by

absorbing

energy.

3.

The

refrigerant

leaving

the

heat

exchanger

returnstothe

compressor

through

the

subcooler

and

a

crankcase

pressure

regulator.

The

subcoolcr

further

cools

the

refrigerant

entering

the

TEV.

TCU

40/80

Temperature

Control

Unit

Page 16

4.2.2Ifcoolingisnot

required:

1.

Solenoid

valve

SVl

closes

(coil

de-energized).

2.

Hot

refrigerant

from

the

compressor

is

passed

through

SV2

(coil

energized)

andahot

gas

bypass

valve

before

returning

to

the

compressor

suction

line.

This

bypassing

allows

the

compressor

to

run

continuously.

3.

Cooling,

requiredtoprevent

the

compressor

from

overheating,

is

providedbyallowing

someofthe

liquid

from

the

condensertopass

through

the

safety

cooling

automatic

expansion

valve

into

the

suction

line,

thus

maintaining

the

discharge

gas

temperature

below99°C.

4.3

Coolant

circuit

Coolantispulled

from

the

reservoir

by

the

circulation

pump

and

transferred

to

the

heat

exchanger

where

itiscooledbythe

refrigeration

systemasrequired.

It

then

flowstothe

process

equipmentbymeansofthe

coolant

supply

hose.

The

coolant

returnstothe

TCU

40/80

reservoirbymeansofthe

coolant

return

hose.

The

coolant

system

requires8litersofcoolant

for

the

reservoir,

plus

the

volumeofthe

circulation

lines

and

any

other

spaces

filled

with

coolant

that

are

attachedtothe

TCU

40/80.

To

increase

the

coolant

temperature,

the

reservoir

usesanelectrical

resistance

heater

thatiscontrolled

by

the

temperature

controller.

The

heater

mustbefully

submergedatall

times,

andifthe

coolantinthe

reservoir

falls

below

3.S

liters,alevel

switch causes

the

status

alarm

signaltoautomatically

shut

down

the

TCU

40/80.

A

three-float

level

switch,athermostat,

andaflow

sensor

provide

coolant

status

signalstothe

TCU

40/80

control

system.

4.4

Temperature

monitoring

A

Resistance

Temperature

Device

(RTD)

monitors

the

temperatureofthe

coolant

leaving

the

TCU

40/80

and

transmits

this

information

to

the

temperature

controller.

The

TCU

40/80

compares

the

outputofthe

RTDtothe

selected

process

temperature

(SVl)

and

determines

if

the

coolant

needstobe

cooledorheated.

The

temperature

controller

then

operates

the

main

cooling

solenoid

valveorheater.

The

coolant

temperature

at

the

supply

portonthe

rear

panelismeasuredbya

local,

internally

connected

RTD.Ifsensingofprocess

equipment

temperature

is

needed,

connectanRTDtoJ72J3atthe

rear

panel

(see

Figure5on page

13).

For

remote

connection

schematic

details,

see

FigureISon

page

56.

^WIITV

10

TCU

40/80

Temperature

Control

Unit

Page 17

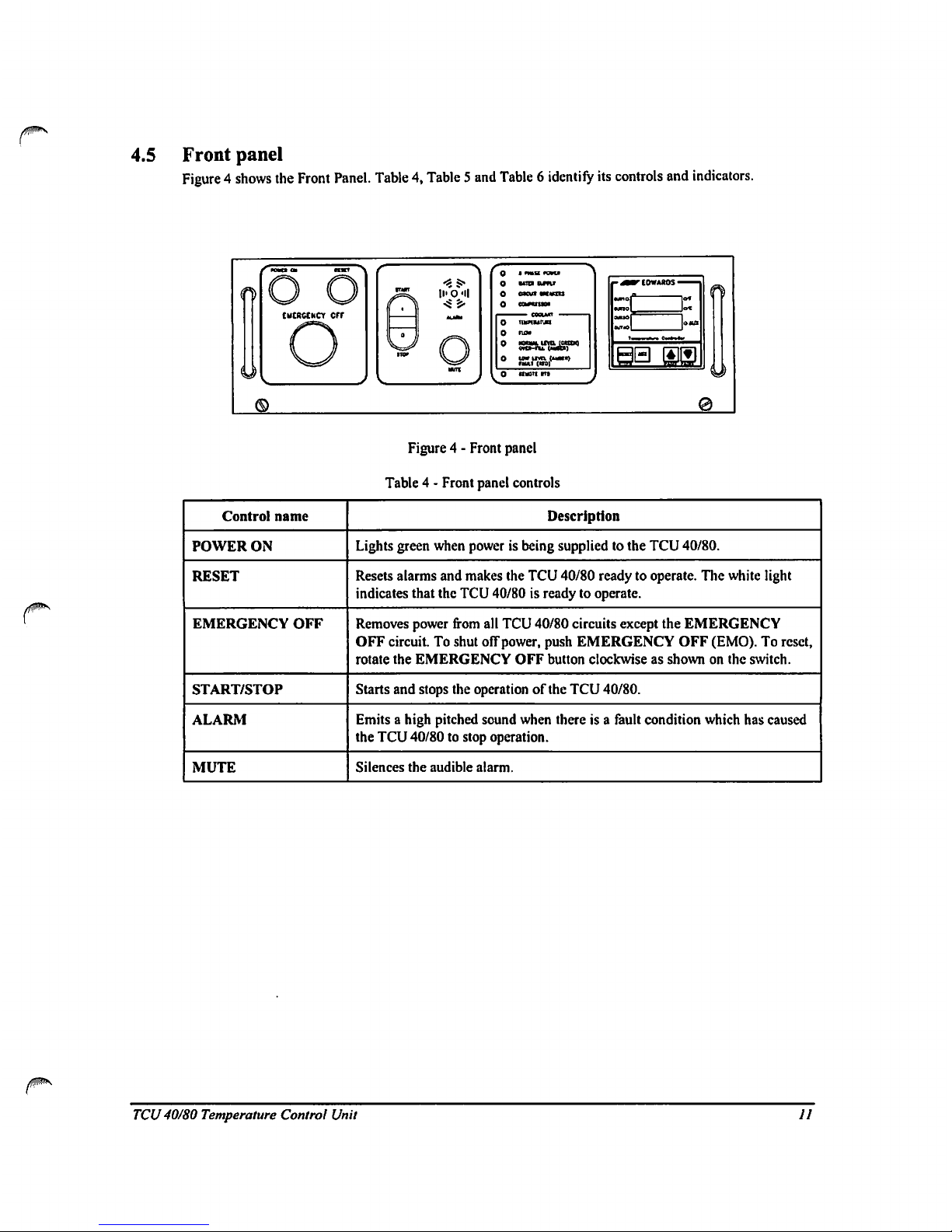

4.5

Front

panel

Figure

4 shows

the

Front

Panel.

Table4,Table5and

Table6identify

its

controls

and

indicators.

|MO<

?

5

>

mat

mu

0

aw-"

Figure4-

Front panel

Table4-

Front panel

controls

Control

name

POWER

ON

RESET

EMERGENCY

OFF

START/STOP

ALARM

MUTE

Description

Lights

green

when

powerisbeing

suppliedtothe

TCU

40/80.

Resets

alarms

and

makes

the

TCU

40/80

readytooperate.

The

white

light

indicates

that

the

TCU

40/80isreadytooperate.

Removes

power

from

all

TCU

40/80

circuits

except

the

EMERGENCY

OFF

circuit.Toshut

off

power,

push

EMERGENCY

OFF

(EMO).Toreset,

rotate

the

EMERGENCY

OFF

button

clockwiseasshownonthe

switch.

Starts

and

stops

the

operationofthe

TCU

40/80.

Emitsahigh

pitched

sound

when

thereisa

fault

condition

which

has

caused

the

TCU

40/80tostop operation.

Silences

the

audible

alarm.

TCU

40/80

Temperature

Control

Unit

II

Page 18

Table5-

Front

panel

LED

indicators

LED

name

FACILITY

POWER

FACILITY

WATER

CIRCUIT

BREAKERS

COMPRESSOR

COOLANT

TEMPERATURE

COOLANT

FLOW

COOLANT

NORMAL

LEVEL

COOLANT

LOW

LEVEL

REMOTE

RTD

Condition

Green

Red

Green

Red

Green

Red

Green

Red

Green

Red

Green

Red

Green

Amber

Off

Amber

Red

Off

Green

Description

Power

phases

are

normal.

Power

phases

are

reversedorlow

line

voltage.

Water

pressure

and

flow

are

normal.

Water

pressureorflow

are

not

adequate.

(See

Specifications

on page

14.

Rear

panel

circuit

breakers

2, 3,

and4are

on.

Oneormoreofthese

breakersistrippedoroff.

Compressorisoperating

normally.

Compressor

has

stopped

operating.

Coolant

reservoir

temperature

is

normal.

Coolant

temperature

is

above

the

operating

range.

Coolant

flowisnormal.

Coolant

flowisnot

adequate.

Coolant

levelisnormal.

Coolant

levelisover

filled.

Coolant

levelisnormal

Coolant

levelislow.

Coolant

levelisvery

low.

Remote

RTD

not

connected.

Remote

RTD

temperature

probeisin

use.

Table6-

Temperature

controller

Controls

and

indicators

Process

Value

(PV)

Setpoint

Value

(SP)

Pushbuttons

Remote

Mode

LED

(Aux)

Description

The

present

temperature

of

the

coolant,asindicatedbythe

internal

RTD

or

the

remote

RTD.

The

TCU

40/80

regulates

to this

temperature,

as

setbythe

operator.

Usedtoprogram

the

controller.

Indicates

modeofoperation:

Off

indicates

local

operation.

On

indicates

remote

operation.

12

TCU

40/80

Temperature

Control

Unit

Page 19

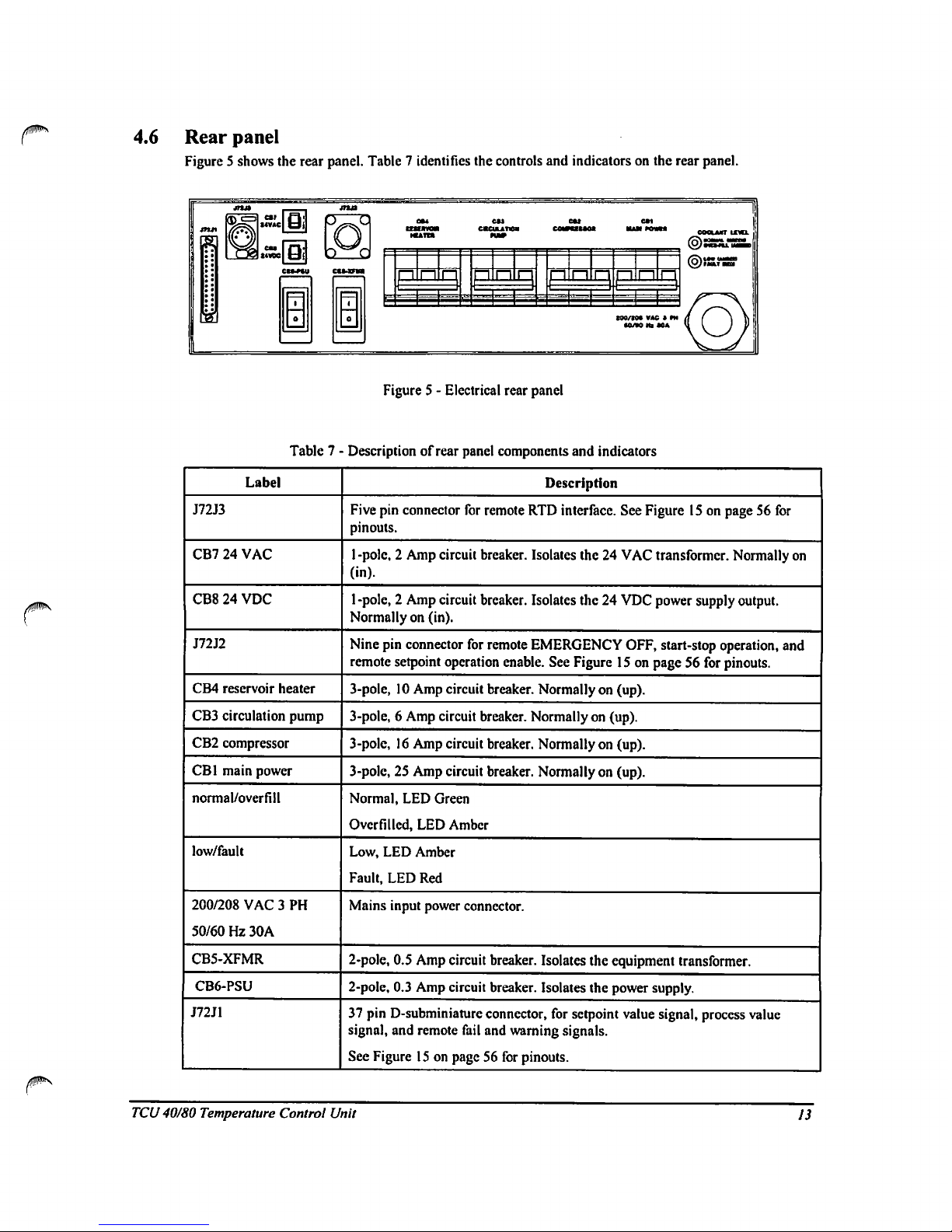

4.6

Rear

panel

Figure5shows

the

rear

panel.

Table7identifies

the

controls

and

indicators

on

the

rear

panel.

D

G

t

Fj

cocuurr

iml

p

n

n

pi

n

p!

=

H

t90/t0*

VAC

» *M

•0/WHi*0A

Figure5-

Electrical

rear

panel

Table7■

Label

J72J3

CB724VAC

CB824VDC

J72J2

CB4

reservoir

heater

CB3

circulation

pump

CB2

compressor

CB1

main

power

normal/overfill

low/fault

200/208

VAC3PH

50/60Hz30A

CB5-XFMR

CB6-PSU

J72J1

■

Description

of

rear

panel

components

and

indicators

Description

Five

pin

connector

for

remote

RTD

interface.

See

Figure15on

page56for

pinouts.

1

-pole,2Amp

circuit

breaker.

Isolates

the24VAC

transformer.

Normally

on

(in).

l-pole,2Amp

circuit

breaker.

Isolates

the24VDC

power

supply

output.

Normallyon(in).

Nine

pin

connector

for

remote

EMERGENCY

OFF,

start-stop

operation,

and

remote

setpoint

operation

enable.

See

Figure15on

page56for

pinouts.

3-pole,10Amp

circuit

breaker.

Normallyon(up).

3-pole,6Amp

circuit

breaker.

Normallyon(up).

3-pole,16Amp

circuit

breaker.

Normallyon(up).

3-pole,25Amp

circuit

breaker.

Normallyon(up).

Normal,

LED

Green

Overfilled,

LED

Amber

Low,

LED

Amber

Fault,

LED

Red

Mains

input

power

connector.

2-pole,

0.5

Amp

circuit

breaker.

Isolates

the

equipment

transformer.

2-poIe,

0.3

Amp

circuit

breaker.

Isolates

the

power

supply.

37

pin

D-subminiature

connector,

for

setpoint

value

signal,

process

value

signal,

and

remote

fail

and

warning

signals.

See

Figure15on

page56for

pinouts.

TCU

40/80

Temperature

Control

Unit

13

Page 20

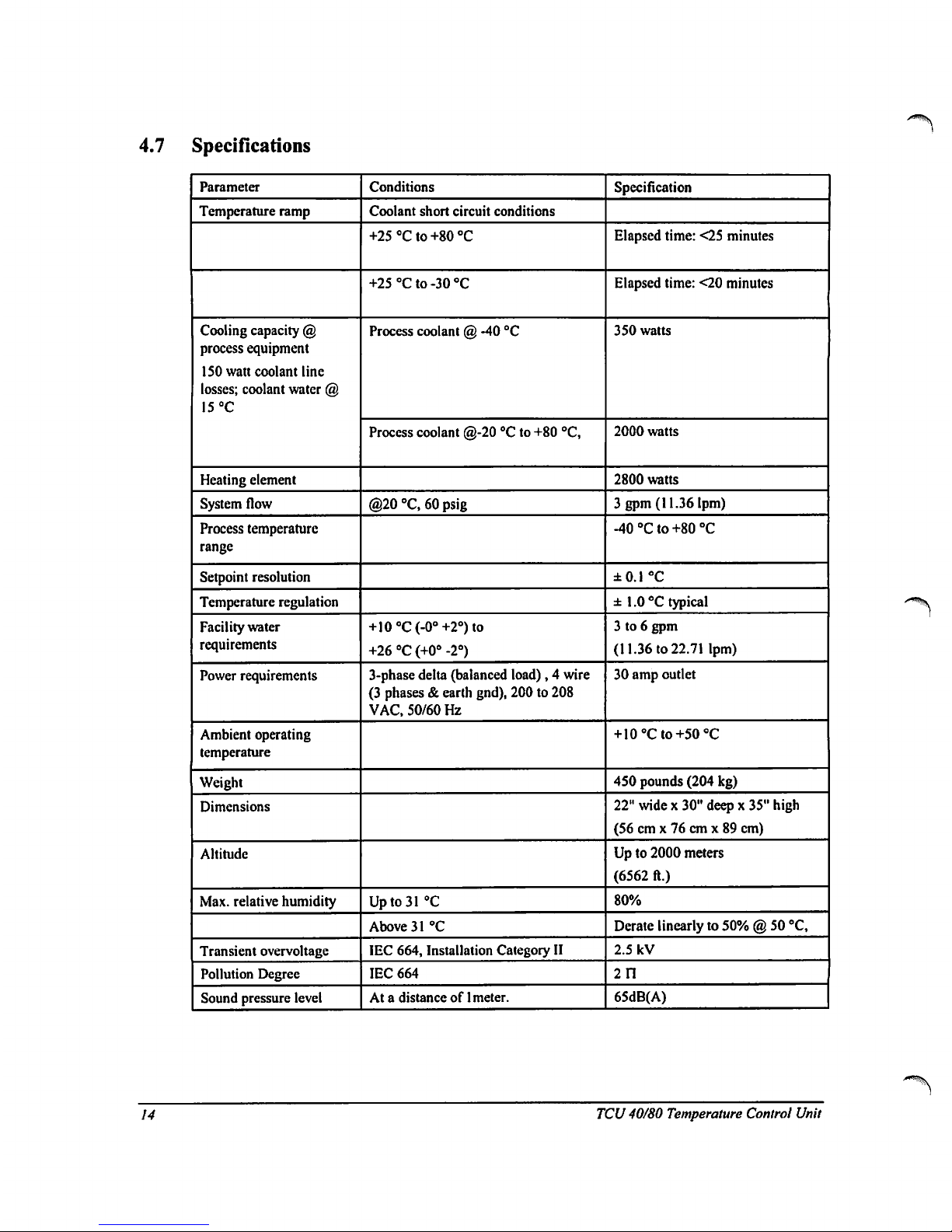

4.7

Specifications

Parameter

Temperature

ramp

Cooling

capacity

@

process

equipment

ISO

watt

coolant

line

losses;

coolant

water

@

15

°C

Heating element

System

flow

Process

temperature

range

Setpoint

resolution

Temperature

regulation

Facility

water

requirements

Power

requirements

Ambient

operating

temperature

Weight

Dimensions

Altitude

Max.

relative

humidity

Transient

overvoltage

Pollution

Degree

Sound

pressure

level

Conditions

Coolant

short

circuit

conditions

+25°Cto+80°C

+25°Cto-30°C

Process

coolant@-40

°C

Process

coolant

@-20°Cto

+80

"C,

@20

°C,60psig

+10oC(-0°+2°)to

+26"C(+0°

-2°)

3-phase

delta

(balanced

load),4wire

(3

phases&earth

gnd),

200to208

VAC,

50/60

Hz

Upto31

"C

Above31°C

IEC

664,

Installation

Category

II

IEC

664

Atadistanceof1

meter.

Specification

Elapsed

time:

<25

minutes

Elapsed

time:

<20

minutes

350

watts

2000

watts

2800

watts

3

gpm

(11.36

lpm)

-40°Cto+80°C

±0.1

°C

±

1.0°Ctypical

3to6

gpm

(11.36to22.71

lpm)

30

amp

outlet

+

10°Cto+50°C

450

pounds

(204

kg)

22"

widex30"

deepx35"

high

(56cmx76cmx89

cm)

Upto2000

meters

(6562

ft.)

80%

Derate

linearlyto50%@50

°C,

2.5

kV

211

65dB(A)

14

TCU

40/80

Temperature

Control

Unit

Page 21

4.8

Dimensions

TCU

40/80

TCU

40/80

inches

(millimeters)

Figure6-

TCU

dimensions

TCU

40/80

Temperature

Control

Unit

15

Page 22

5

INSTALLATION

5.1

Receiving

and

unpacking

Doacomplete

visual

inspection

of

the

TCU

40/80

for

any

damage.Donot

use

the

TCU

40/80ifphysical

damageisevident.Ifthereisany

damage,

notify

your

supplier

and

the

carrierinwriting

within

three

days;

state

the

item

numberofthe

TCU

40/80

together

with

your

order

number

and

supplier's

invoice

number.

Retain

all

packing

materials

for

inspection.

Caution

When

usingaforklift

to

moveorposition

the

TCU

40/80,donot

install

the

secondary

containment

receptacle

until

the

TCU

40/80isin

position.

Failuretofollow

these

instructions

may

lead

to

damageofthe

secondary

containment

receptacle

causedbythe

forksofthe

forklift.

5.2

Location

Allowaspace

46"

widex54"

deep

for

the

TCU

40/80

cable

and

coolant

connections.

The

TCU

40/80

should

haveatleast

two

feetofclearance

at

the

rear

and

one

foot

along

the

sidesofthe

unit.Besure

that

the

mounting

surface

can

safely

support

the

weightofthe

TCU

40/80

(450

pounds

evenly

distributed).

The

centerofgravityisapproximately

the

centerofthe

refrigeration

compartment.

When

usingafork-lift

to

move

the

TCU

40/80,

position

the

forks

from

the

sideofthe

unit.

The

TCU

40/80

weighs

450

pounds

(204

kg).

Failuretotake

proper

careinmovingorlifting

these

units

can

resultinserious

bodily

injury.

A3foot

(1m)

service

lengthofthe

power

cableisrequiredtofully

open

the

electrical

drawer.

Therefore,

do

not

install

the

TCU

40/80

further

than7feet

(2.1m)from

the

power

source.

5.2.1

Securing

the

unit

The

four

lockable

castersofthe

TCU

40/80

swiveltoprovide

maximum

maneuverability.

Make

sure

that

all

four

casters

are

turned

inward

and

lockedinposition

once

Ihe

TCU

40/80issituated.

5.2.2

Installing

the

secondary

containment

receptacle

The

secondary

containment

receptacle

slides

into

the

base

from

the

rearofthe

unit.

5.2.3

Floor

levelers

An

optional

floor

leveler

kitisavailable

to

compensate

for

uneven

surfaces.

See

Table15on

page52for

ordering

information.

16

TCU

40/80

Temperature

Control

Unit

Page 23

5.3

Stacking

The

TCU

40/80

maybestacked

two

high.Besure

that

the

mounting

surface

can

safely

support

the

weight

of

the

two

units

(900

pounds,

408

kg).

Be

sure

that

the

castersofthe

top

unit

are

turned

inwards,

but

are

not

locked,

until

the

top

unitisfully

seated.

5.3.1

Tie-bolts

An

optional

tie-bolt

kitisavailable

for

attaching

stacked

units.

See

Table15on

page52for

ordering

information.

TCU

40/80

inches

(millimeters)

Figure7-Stacked

TCU

40/80

systems

5.4

Facilities

The

TCU

40/80

requires

a

water

supply

flow

rate

between

3 to6gallons

per

minuteata

maximum

pressureof100

psig,

andaninlet

temperature

rangeof10°Cto26°C

Power

inputisbyafused,

suitable

isolating

electrical

outlet,

208

VAC,

50/60

Hz,30amp,

3-phase

delta

(balanced

load),

3-wire

and

earth.

The

required

receptacle

typeisHubbell

P/N

L21-30R2810-A,

or

equivalent.

TCU

40/80

Temperature

Control

Unit

17

Page 24

5.4.1

Water

and

coolant

connections

Figure8showsarear

viewofthe

TCU

40/80

with

its

water

and

coolant

connections.

inches

(millimeters)

Figure8-System

rear

view

18

j

TCU

40/80

Temperature

Control

Unit

Page 25

5.4.2

Water

/JWN

Connections

to

the

water

supply

and

return

are

madetoeither

Vi"

brass

barb

fittingsorVi"

compression

fittings.

For

bare

hose

connections

("A"

nominal

I.D.):

1.

Slip

the

hose

over

the

barb

fitting

and

tighten

the

hose

clamp.

2.

Turnonthe

water

supply

and

check

for

leaks.

For

connections

using

hose

with

tube

adaptersortubing

('/i"

nominal

O.D.):

1.

Remove

the

adapter

coupledtothe

hose

barb.

2.

Insert

the

tube

adapterortubing

with

the

appropriate

ferrule

and

compression

nut.

3.

Tighten

the

compression

nut,

turnonthe

water

supply,

and

check

for

leaks.

Rear

Acctii

Pantl

F»rrulo

•

1/2'

Compr.jslon

Nut

•

1/2"

O.O.

Tubing

or

Hose

Tuba

Adaptor

Supplied

Adaptor

With

Hoie

Barb

♦NOT

INCLUDED

Figure 9

Water

connections

5.4.3

Coolant

Note:Ifthis

TCU

40/80isbeing

installed

on

process

equipment

that

has

been used

mthacoolant

other

than

Fluorinert.

contact

process

equipment

supplier

for

retrofit

instructions.

Connections

to

the

coolant

supply

and

return

are

madeonthe

rear

panel

(see

Figure8on

page

18).

The

maximum

distance

between

the

process

equipment

and

the

TCU

40/80is50

feet

(100

feet

total

hose

length).

1.

Attach

the

hosestothe

supply

and

return

compression

fittings.

Follow

the

hose

manufacturers

recommendations

for

appropriate

adapters.

2.

Insulate

the

hoses

with

closed

cell

insulation

in

ordertominimize

heat

loss.

3.

Tape

and

glue

the

insulated

jointstoavoid

condensation

and

icing.

5.4.4

Remote

connections

Wiring

details

for

remote

connections

are

showninFigure15on

page

56.

Remote

connections

should

not

be

run nearorparalleltoa.c.

power

linesorin

the

vicinity

of

equipment

that

generates

large

electric

fields.

TCU

40/80

Temperature

Control

Unit

19

Page 26

6

OPERATION

6.1

Preparation

Verify

that

water

and

coolant

connections

are

madeatboth

ends,

that

the

drain

valveisclosed

and

the

coolant

supply

and

return

valves

are

open.

Connect

the

remote

interfaces

if

required.

1.Touseanexternal

RTD

probe,

attachitto

connector

J72J3.

RefertoFigure15on

page

56.

Verify

that

the

plug

J72J2isinstalled.

2.

Press

the

EMERGENCY

OFF

buttononthe

front

panel.

3.

Plug

the

TCU

40/80

power

cord

intoafused,

switchable,

30

amp,

3-phase,

208

VAC

outlet.

4.

Ensure

that

all

circuit

breakersonthe

rear

panel

areintheONposition.

CB7

and

CB8

are

non-

switchable

circuit

breakers

and

will

trip

when

thereisa

problem.

They

cannotbeturnedonor

off,

but

they

are

re-settablc.

6.2

Poweringupthe

TCU

40/80

1.

Verify

that

the

POWERONlamponthe

front

panelisilluminated.

2.

Release

the

EMERGENCY

OFF

button.

If

the

Facility

Power

LED

illuminates,

the

line

voltageislow,

or the

phaseofthe

main

power

supplyisreversed.

Adjust

the

line

voltage,ifitislow.

Correct

the

phasesbyswapping

two

phasesinthe

electrical

outlet.

3.

Press

the

RESET

button

and

verify

the

front

panel

indicators

are asinthe

Reset

Condition

column

of

Table

8.

Table8-

Front

panel

power up

indicator

conditions

Indicator

POWER

ON

RESET

FACILITY

POWER

FACILITY

WATER

CIRCUIT

BREAKERS

COMPRESSOR

TEMPERATURE

FLOW

NORMAL

LEVEL

LOW

LEVEL

REMOTE

RTD

(if

used)

Reset

condition

Green

Off

Green

Green

Green

Off

Green

Off

Off

Red

Green

Start

condition

Green

White

Green

Green

Green

Green

Green

Green

Green

Off

Green

20

TCU

40/80

Temperature

Control

Unit

Page 27

4.

Press

MUTEtosilence

the

alarm.

The

TCU

40/80isshipped

without

coolant.

The

coolant

level

alarm

will

sound

and

the

front

panel

Reservoir

Coolant

Low

Level

LED

willbered

indicating

that

the

reservoir

mustbefilled.

5.

Fill

the

coolant

reservoir

using

the

procedure

Filling

the

Reservoir

on page

26.

6.

Press

the

START

button

and

verify

the

front

panel

indicators

areasin

the

Start

Condition

column

of

Table

8.

7.

Useahalogen

leak detectortocheck

all

supply

and

return

line

connections

at

both

the

TCU

and

process

equipment,

around

the

pump

head

assembly,

drain

valve,

heater,

flow

switch,

vent

line,

fill

line,

and

reservoir

pressure

relief

valve.

6.3

Changing

the

setpoint

value

(SV1)

The

following

instructions

are

for

local

temperature

control

only.

Do

not

exceed

the

temperature

range

of-40°Cto

+80

Thisisthe

normal

operating

rangeofthe

TCU

40/80.

To

change

the

temperature

settings

press

pageupor

page

downtocither

increaseordecrease

the

temperature.

The

red

display

"PV"

indicates

the

process

value.

The

green

display

"SP"

indicates

the

current

setpoint.

Note:

The

temperature

controller

has

been

programmedtoprevent

the

setpoint

from

exceeding

the

normal

operating

rangeofthe

TCU

40/80.

The

controller

is

also

protected

from

unauthorized

changes

to

the

Pid

and

other

settings,

Contact

the

process

equipment

supplier

for

accesstothese

settings

and

other

information.

'P

EDWARDS

0UT1O

OUT

tO

OUH.

F-j-71

-■

HUBI

MB

4

:

mb

Figure10-

Temperature

controller

6.4

Temperature

controller

Pid

settings

Edwards

default

settings

are:

PID1-heating

Pbl

Arl

rAtl

dbl

value

8.0

0.43

7.0

1.0

PID2-cooling

Pb2

Ar2

rAt2

db2

value

12.5

0.7

9.0

1.0

parameter

proportional

band

automatic

reset

rate

deadband

TCU

40/80

Temperature

Control

Unit

21

Page 28

6.5

Remote

set-point

To

use

the

remote

set-point,

wire

the

J72J2

mating

connectorasillustrated

on

page

56.

24vac

mustbeappliedtopins3and

4.

The

AUX

LEDonthe

temperature

controller

will

illuminate

indicating

remote

setpoint

enable

mode

as

soonasthe

mating

connectorisinstalled.

6.6

Flow

rate

adjustment

Caution

Do

not

exceed

coolant

pressureof100

psi.

Exceeding

the

coolant

pressure

may

resultindamage

to

the

pump.

The

Fluorinert

flow

rateofthe

TCU

40/80isfactory

settoprovide

approximately

3

gpmat60

psig/20°C

foraunit

operatingat208vac/3-ph/60Hz.

If

the

flow

rate

requires

adjustmenttoaccommodate

the

process

equipment

suppliers

recommendations,

follow

the

steps

below.

The

flow

rate

maybemeasured

usingaflow

meter

externaltothe

TCU

40/80.

1.

Open

the

left

side

access

door.

2.

Peel

back

the

insulation

covering

the

by-pass

valve.

RefertoFigure1on

page

6.

3.

The

valve

handle

canbefoundinthe

plastic

bag

securedtothe

pump.

Reduce

the

flowbyturning

the

valve

stem

clockwise.Toincrease

the

flow,

turn

the

stem

counter

clockwise.

The

valveisa

1/4

turn

valve.

4.

Once

the

required

flow

rate

has

been

achieved,

return

the

valve

handletothe

bag

for

future

use,

glue

the

insulation

backinplace,

and

secure

the

access

door.

22

TCU40/80

Temperature

Control

Unit

Page 29

7

MAINTENANCE

This

section

contains

information

that

will

allow

youtosafely

keep

your

TCU

40/80inworking

order.

It

contains

important

Hazard

Warnings,aPreventive

Maintenance

Scheduleonpage

27,

and

a

Troubleshooting

Guideonpage

41.

Maintenance

to

the

electrical

systemofthe

TCU40/80

shouldbeperformedbyqualified

personnel

only.

Warning

The

refrigeration

units

are

scaled

and

are

not

user

serviceable.

Only

trained

and

licensed

refrigeration

personnel

should

perform

repairs

on

this

equipment.

All

applicable

EPA

regulations

apply.

7.1

Hazard

warnings

High

Pressure

Water and

the

coolant

arc

pressurized

within

this

equipment.

Water

pressure

will

depend

upon

utility

supply,

but

usuallyisupto60

psig.

The

coolant

canbeat

pressuresupto

100

psig.

Refrigerant

pressures

canbeupto300

psig.

Do

not

open

lines

with

pressure

present.

Toxic

Gases

The

coolant

breaks

down

above

215

°C.Ifthe

coolantisallowedtoreach

these

temperatures,

toxic

gasses

maybedischarged

from

the

unit.

Refertothe

Appendix

for

Material

Safety

Data

Sheets

for

the

coolant

and

refrigerant

usedinthis

system.

High

Pressure

The

reservoir

may

become

pressurized

due

to

changesintemperature.

Undernocircumstances

should

the

reservoir

pressure

relief

valveberemovedorcapped

off.

TCU

40/80

Temperature

Control

Unit

23

Page 30

High

Pressure

The

refrigerant

lines

areathigh

pressure.

Undernocircumstances

should

the

refrigerant

pressure

relief

valveberemovedorcapped

off.

Eye

Protection

Hand

Protection

Leakageorfailureofhigh

pressure

circuits

may

cause

injuryorirritation

of

the

eyes.

Eye

protection

shouldbeworn

when

working

with

fluid

systems.

Hotorcold

fluids

and

surfaces

can

cause

injury or

irritation

of

the

hands.

Hand

protection

shouldbeworn

when

working

with

these

fluid

systems.

Electric

Shock

Ensure

that

all

electrical

power

has

been

removed

and

the

main

circuit

breaker

has

been

turned

off

priortoopening

the

electrical

drawer.

The

EMERGENCY

OFF

circuit

(EMO)

does

not

disconnect

all

power

from

the

electrical

drawer.

Extreme

caution

mustbeobservedifperforming

maintenance

operations

with

the

drawer

open.

Hot

Surface

Refrigeration

and

circulating

fluid lines

can

attain

temperatures

as

highas110

°C.

Caution

mustbeobserved.

24

TCU

40/80

Temperature

Control

Unit

Page 31

7.2

Hazards

Table9gives

the

classifications

of

electrical

hazards.

This

number

indicates

the

severityofthe

hazard

as

definedbySEMI

S2-93.

Table9-

Electrical

hazards

classifications

Classification

Typel

Type

2

Type

3

Type

4

Type

5

Description

Equipmentisfully

de-energized.

Equipmentisenergized.

Live

circuits

are

covered

or

insulated.

Workisperformedata

remote

location

to

preclude

accidental

shock.

Equipmentisenergized.

Live

circuits

are

exposed

and

accidental

contactispossible.

Potential

exposures

are

less

than30volts

RMS,

42.2

volts

peak,

240

volt-amps,

20

Joules.

(See

NFPA

79-14.3,

IEC

204,UL1950&1262,

IEC

950.)

Equipmentisenergized.

Live

circuits

are

exposed

and

accidental

contactispossible.

Potential

exposures

are

greater

than30volts

RMS,

42.2

volts

peak,

240

volt-amps,

20

Joulesorradio

frequency

(rf)ispresent.

Equipmentisenergized

and

measurements

and

adjustments

require

physical

entry

into

the

equipment,

or

equipment

configuration

will

not

allow

the

useofclamp-on

probes.

Comment

None

called

out.

None

called

out.

Called

out as

Type

3.

Called

outasType

4.

None

called

out.

TCU

40/80

Temperature

Control

Unit

25

Page 32

7.3

Filling

the

reservoir

Warning

When

retrofitting

a

TCU

40/80inplaceofa

water/glycol

unit,

the

coolant

lines

mustbeflushed

with

nitrogentoremove

moisture

prior

to

installation.

1.

Open

the

vent

port

valve

(see

Figure8on

page

18)toavoid

air

locks

that

may

slow

filling.

2.

Remove

the

plug

and

fasten

the

funnel

accessory

to

the

Vi"

fill

port

locatedatthe

rearofthe

unit (see

Figure8on

page

18).

3.

Fill

the

reservoir

with

Fluorinert

heat

transfer

fluid.

The

amount

needed

foranew

installation

is

approximately

44

pounds

for

the

TCU

andanadditional

amount

for

process

lines

(approx.

.15

lbs/ft.;

1/2"

tube)

and

other

external

volumes.

Fill

the

reservoir

until

the

Coolant

Normal

Level

LEDonthe

rear

electrical

panel

turns

green.

4.Inthe

eventofover-filling,

the

Coolant

Normal

LED

will

change

from

greentoamber.

Drain

excess

fluid

until

the

Coolant

Normal

Level

LED

turns

green.

RefertoDraining/Bleeding

the

Coolant

Reservoir,

below.

7.4

Draining/bleeding

the

coolant

reservoir

It

maybenecessarytodrain

the

coolant

reservoir

for

storageofthe

TCU

40/80orduetomoisture

contamination

of

the

coolant.

v

It

maybenecessarytobleed

the

coolant

reservoir

to

correctanoverfill

condition.

Note:

The

unit

may

continue

running

during

this

procedure.

Follow

the

procedure

below

wheneveritbecomes

necessarytodrainorbleed

the

system.

Firtreme

Temnerature

Hot

or

cold

coolant

may

reach

"40

°C

t0

+80

°C

during

UXtreme1emperature

operation.

Hot

or

cold

fluid

can

cause

burns.

Coolant

shouldbeat

ambient

temperature

before

handling.

1.

Open

the

vent

valve

locatedatthe

topofthe

unit.

2.

Placeanappropriate

container

beneath

the

drain

valve.

The

capacityofthe container

used

needstobe

10

liters

plus

the

volumeofthe

hoses

and

the

volumeofthe

process

equipment.

3.

Remove

the

cap

fitting

from

the

endofthe

drain

valve.

4.

Open

the

reservoir

drain

valve.

5a.Tocorrectanoverfill

condition,

drain

the

reservoir

until

the

Coolant

Level

Normal

LEDonthe

rear

electrical

panel

turns

green.

Close

the

reservoir

drain

and

vent

valves

when

the

LED

turns

green.

5b.Toempty

the

reservoir,

remove

powertothe

TCU

and

allow

the

unittodrain

until

all

coolant

has

been

removed.

6.

Close

the

reservoir

drain

and

vent

valves.

7.

For

proper

disposalofthe

coolant,

follow

the

manufacturers

recommendations.

Note:

Uncontaminated

Fluorinert

maybereused.

The

Fluorinert

shouldbestoredina

compatible

and

sealed

container.

26

TCU

40/80

Temperature

Control

Unit

Page 33

7.5

Temperature

probe

calibration

The

Edwards

Temperature

Controller

comes

equipped

withafactory

calibrated

internal

+10V

remote

input/output

option

making

calibration

unnecessary.

7.6

Preventive

maintenance

schedule

Table10shows

the

maintenance

requiredtokeep

the

TCU

40/80ingood

working

order.

Failuretofollow

this

schedule

may

resultindegradationofsystem

performance.

Table10-

Preventive

maintenance

schedule

Frequency

Semi

annual

ly

Annually

Operation

Verify

system

status

Check

coolant

level

Check

lamps

Coolant

leak

check

Refrigeration

leak

check

Insulation

repair

Water

leak

check

Replace

solenoid

coils

SV1

and

SV2

System

check

Lamp

replacement

Hazard

(Type

3)

(Type

3)

(Type

3)

(Type

3)

(Type

3)

(Type

3)

(Type

3)

(Type

3)

Note:

All

maintenance

should be

recordedonthe

Preventative

Maintenance

Record

label

locatedonthe

insideofthe

left-hand

side

access

panel.

TCU

40/80

Temperature

Control

Unit

27

Page 34

1

7.7

Semi-annual

preventative

maintenance

Refertothe

Troubleshooting

sectiononpage42when

results

for

anyofthe

following

checkpoints

are

notasexpected.

7.7.1

Required

equipment

•

12"

slotted

screwdriver

•

Spare

lamps

(24

vac/60

mA)

•4"slotted

screwdriver

•

Fluorinert

•

Two

10"

adjustable

wrenches•Insulation

Tape

•

Halogen

leak

detector

7.7.2

Preparation

•

Locate

the

two

screws

securing

eachofthe

side

access

panels

and

loosentoopen

doors.

•

Listen

for

excessiveorquestionable

noiseorsounds

coming

from

the

pump

assembly, motor,

compressor,orsolenoid

valves

(SV1

and

SV2).

7.7.3

Verify

system

status

•

Verify

system

status

led

indicators

on

the

front

electrical

panel.

(See-Front

panel

power

up

indicator

conditions

tableonpage

20.)

7.7.4

Refrigeration

leak

check

•

Visually

check

for

signsofcompressor

oilonthe

base,

insulation,

andonall

refrigeration

pipework.

•

Usingahalogen

leak

detector

check around

the

discharge

and

suction

service

valvesofthe

compressor,

and

all

accessible

refrigeration

pipework.

7.7.5

Fluorinert

leak

check

•

Useahalogen

leak

detectortocheck

all

supply

and

return

line

connections

at

both

the

TCU

and

process

equipment,

around

the

pump

head

assembly,

drain

valve,

heater,

flow

switch,

vent

line,

fill

line,

and

reservoir

pressure

relief

valve.

7.7.6

Water

leak

check

•

Visually

check

for

signsofwater

leaksatall

water

line

connections

externaltothe

TCU

andatthe

condenser

connections

inside

the

unit.

7.7.7

Insulation

repair

Note:Ifice

formationisexcessive,

it

maybenecessarytocorrect

this

condition

before

insulation

can

be

repaired.

•

Visually

inspect

refrigeration

and

process

fluid

lines

both

inside

the

TCU

cabinet

andatthe

supply

and

return

line

connections

for

signsofice

formation.

Correct

insulation

as

necessary.

28

TCU

40/80 Temperature

Control

Unit

Page 35

7.7.8

Lamp

check/replacement

Electric

Shock

Ensure

all

electrical

power

has

been

removed

and

the

main

circuit

breaker

has

been

turned

off

due

to

the

presenceofhigh

voltageorcurrent.

Caution

Shouldalamp

require

replacement,

notify

the

appropriate

personnel

thatanEMO

condition

will

occur.

Failuretofollow

these

instructions

may

result

in

the

shut-downofthe

process

tool

and

associated

equipment.

Visually

verify

that

the

POWERONand

RESET

lamps

are

working.

If either

lamp

needs

replacement

and

the

proper

authorization

has

been

obtained:

1.

Press

STOP.

2.

Turn

off

the

main

circuit

breaker

(CB1).

3.

Disconnect

power

cord

from

mains

power

supply.

4.

Locate

the

two

securing

screwsonthe

front

electrical

panel

and

loosen.Open

the

electrical

drawer.

5.Ifreplacing

the

POWERONlamp,

locate

contactor

block

(LPl)onthe

back

sideofthe

front

electrical

panel.Ifreplacing

the

RESET

lamp,

locate

contactor

block

(PBl)onthe

back

sideofthe

front

electrical

panel.

6.

Pryupthe

metal

retaining

ring attachedtothe

coupling

plate.

Remove

the

contact

block

assembly.

7.

Replace

the

defective

lamp.

8.

Reinstall

the

contact

block

assemblybysnappingitback

onto

the

front

clement.

9.

Close

the

electrical

drawer

and

tighten

securing

screws.

10.

Reconnect

mains

power

and

turnonthe

main

circuit

breaker

(CBI)..

The

POWERONlamp

should

be

illuminated.

11.

Press

RESET.

The

lamp

should

illuminate.

Press

STARTtoreactivate

the

TCU.

Figure11-

Lamp

replacement

TCU40/80