Operating Instruction

Segmental Type Pumps

Please keep your Operating Instruction in a safe place!

Type

Serial No.

EDUR-Pumpenfabrik

Eduard Redlien GmbH & Co. KG

E-mail: info@edur.de · http://www.edur.de

Postfach 1949 · D-24018 Kiel

Tel. (+431) 689868 · Fax (+431) 6898800

2

Contents

1 Security 3

1.1 Identification of Safety Instructions in the

Operating Manual 3

1.2 Qualification and Training of Operating

Personnel 3

1.3 Hazards in the Event of Non-Compliance

with the Safety Instructions 3

1.4 Compliance with Regulations Pertaining to

Safety at Work 4

1.5 Safety Instructions relevant for Operation 4

1.6 Safety Instructions relevant for Maintenance,

Inspection and Assembly Work 4

1.7 Unauthorized Alterations and Production of

Spare Parts 4

1.8 Unauthorized Modes of Operation 4

2 Transport and Intermediate Storage 4

2.1 Transport 4

2.2 Intermediate Storage 5

2.2.1 Internal Preservation 5

2.2.2 Preservation Control 5

2.2.3 Removal of Preservation 5

3 Description 5

3.1 Design 5

3.2 Place of Operation 6

4 Mounting 6

4.1 Installation 6

4.2 Connected Loads 6

4.3 Direction 6

4.4 Coupling Protection 7

4.5 Piping 7

4.5.1 General Remarks 7

4.5.2 Suction Pipeline 7

4.5.3 Pressure Pipeline 7

4.5.4 Additional Connections 7

4.6 Low-Noise Installation 7

5 Starting Operation/ Stopping Operation 7

5.1 Preparations for Initial 7

5.2 Initial Starting 7

5.3 Restarting 8

5.4 Stopping Operation 8

6 Service/Maintenance 8

6.1 Supervision of Operation 8

6.1.1 Shaft Bearing 8

6.1.2 Mechanical Seal 8

6.1.3 Gland Packing 8

6.2 Maintance 9

6.2.1 Preparation 9

6.2.2 Dismounting 9

6.2.2.1 Pump 9

6.2.2.2 Dismounting of Mechanical Seal 9

6.2.2.3 Motor 9

6.2.3 Mounting 9

6.2.3.1 General Remarks 9

6.2.3.2 Mounting of the Motor 10

6.2.3.3 Replacing the Gland Packing 10

6.2.3.4 Mounting of Mechanical Seal 10

7 Disturbance 12

8 Pump View and List of Spare Parts 13

8.1 LBU 13

8.1 VBU 14

3

General

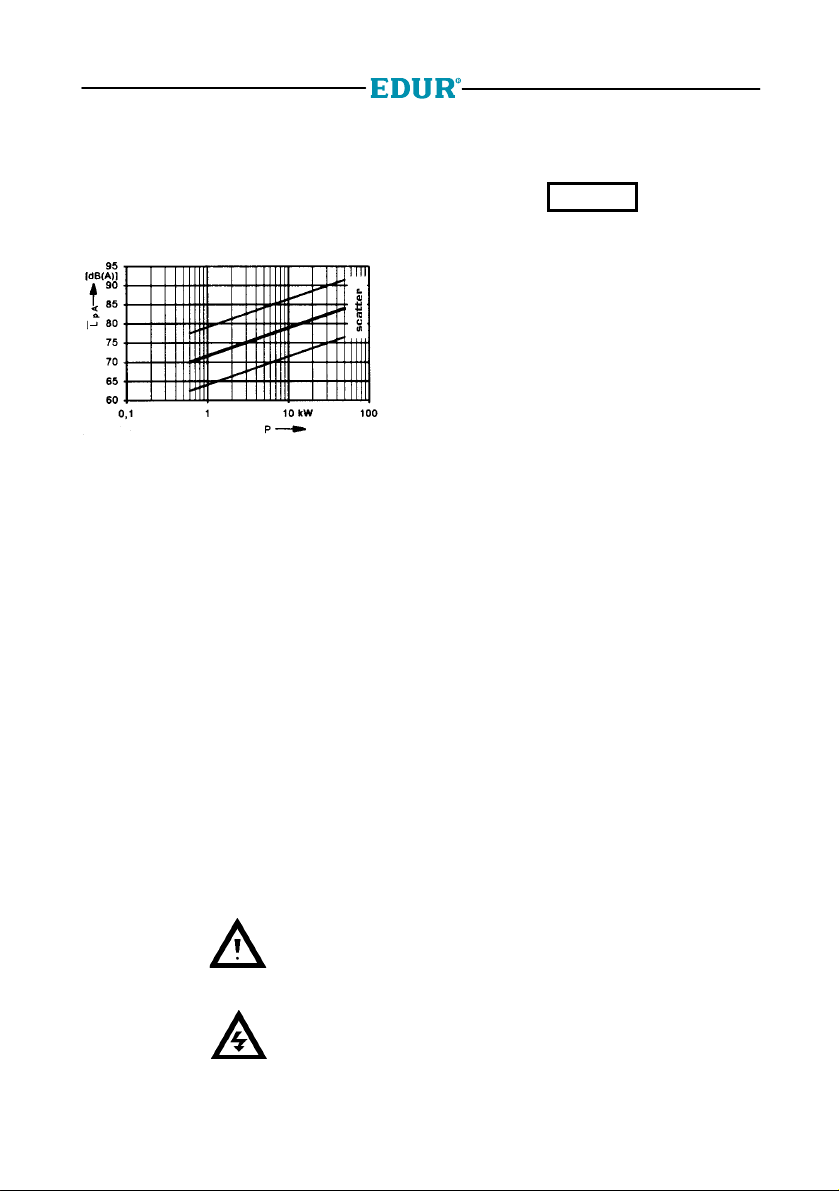

The most important operational data are

mentioned on the type label. The sound

pressure L

depending on the nominal pump power input P

will be seen from the diagram underneath.

Fig. Noise emission

The actual sound level ascertained at place of

installation will possibly differ considerably from

these values due to the operating conditions and

the conditions of installation.

following VDI-guidelines 3743 sheet 1

pA

1 Security

This operating manual gives basic instructions

which are to be observed during installation,

operation and maintenance of the pump. it is

therefore imperative that this manual be read by

the responsible personnel/operator prior to

assembly and commissioning. It is always to be

kept available at the installation site.

It is not only the general safety instructions

contained under this main heading safety that are

to be observed but also the specific information

provided under the other main headings.

1.1 Identification of Safety

Instructions in the Operating

Manual

Safety instructions given in this manual

non-compliance with which would affect safety are

identified by the following symbol:

or where electrical safety is involved, with

see DIN 4844-W9

Instructions non-compliance with which would

give rise to malfunctioning of the machinery are

identify by the word

CAUTION

It is imperative that signs affixed to the machine,

e. g.

- arrow indicating the direction of rotation

- symbols indicating fluid connections

be observed and kept legible.

1.2 Qualification and Training of

Operating Personnel

The personnel responsible for operation,

maintenance, inspection and assembly must be

adequately qualified. Scope of responsibility and

supervision of the personnel must be exactly

defined by the plant operator. If the staff does not

have the necessary knowledge, they must be

trained and instructed, which may be performed

by the machine manufacturer or supplier on

behalf of the plant operator. Moreover the plant

operator is to make sure that the contents of the

operating manual are fully understood by the

personnel.

1.3 Hazards in the Event of

Non-Compliance with the Safety

Instructions

Non-compliance with the safety instructions may

produce a risk to the personnel as well as to the

environment and the machine and results in a

loss of any right to claim damages.

For example, non-compliance may involve the

following hazards:

- Failure of important functions of the

machine/plant

- Failure of specified procedures of

maintenance and repair

- Exposure of people to electrical, mechanical

and chemical hazards

- Endangering the environment owing to

hazardous substances being released

see DIN 4844-W8

4

1.4 Compliance with Regulations

Pertaining to Safety at Work

When operating the pump, the safety instructions

contained in this manual, the relevant national

accident prevention regulations and any other

service and safety instructions issued by the plant

operator are to be observed.

1.5 Safety Instructions relevant for

Operation

-

If hot or cold machine components involve

hazards, they must be guarded against

accidental contact.

- Guards for moving parts (e.g. coupling)

must not be removed from the machine

while in operation.

- Any leakage of hazardous (e.g. explosive,

toxic, hot) fluids (e.g. from the shaft seal)

must be drained away so as to prevent any

risk occurring to persons or the environment.

Statutory regulations are to be complied

with.

- Hazards resulting from electricity are to be

precluded (see, for example, the

VDE Specifications and the bye-laws of the

local power supply utilities).

1.6 Safety Instructions relevant for

Maintenance, Inspection and

Assembly Work

It shall be the plant operator's responsibility to

ensure that all maintenance, inspection and

assembly work is performed by authorized and

qualified personnel who have adequately

familiarized themselves with the subject matter by

studying this manual in detail.

Any work on the machine shall only be performed

when it is at a standstill, it being imperative that

the procedure for shutting down the machine

described in this manual be followed.

Pumps and pumps units which convey hazardous

media must be decontaminated.

On completion of work all safety and protective

facilities must be re-installed and made operative

again.

Prior to restarting the machine, the instructions

listed under Initial commissioning are to be

observed.

Unauthorized Alterations and Production of Spare

Parts

Any modifications may be made to the machine

only after consultation with the manufacturer.

Using spare parts and accessories authorised by

the manufacturer is in the interest of safety. Use

of other parts may exempt the manufacturer from

any liability.

1.7 Unauthorized Modes of

Operation

The reliability of the machine delivered will be only

guaranteed if it is used in the manner intended, in

accordance with our order documentation,

especially with the order confirmation.

The limit values specified in the data sheet must

under no circumstances be exceeded.

2 Transport and Intermediate Storage

2.1 Transport

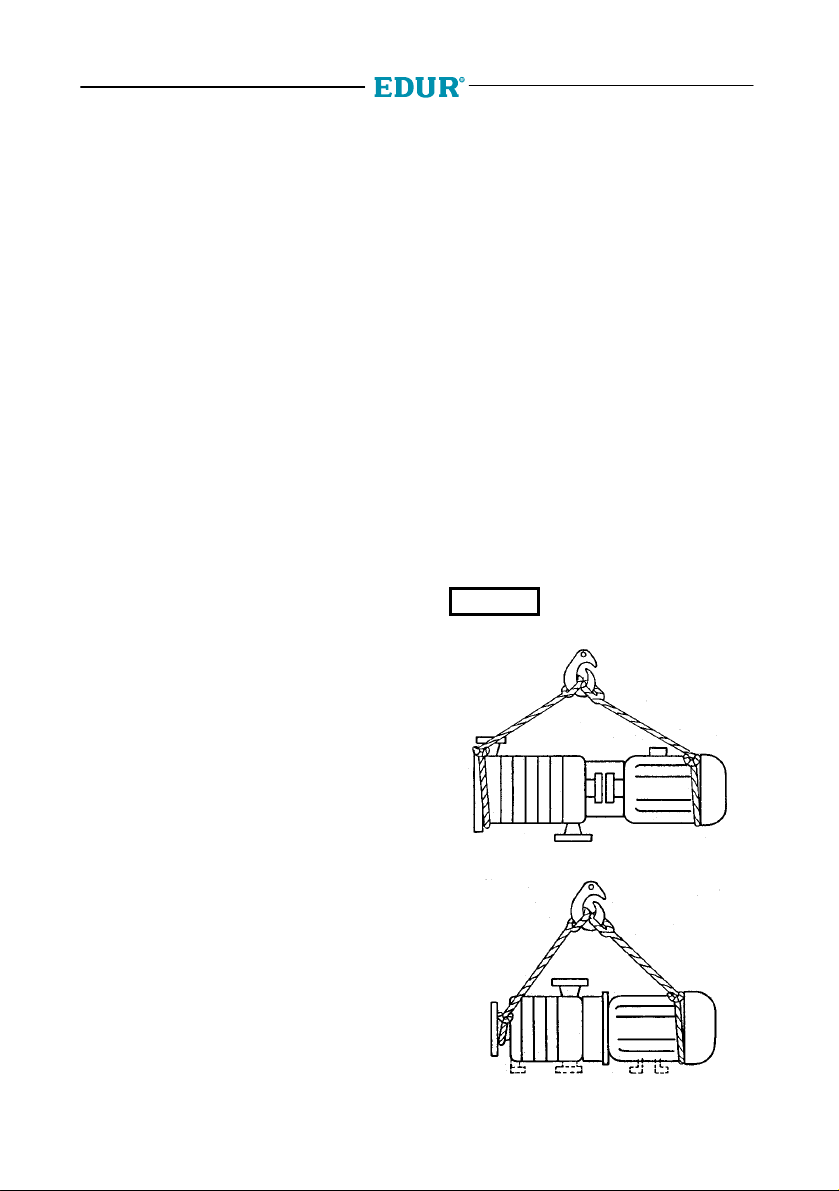

When transporting the complete pump unit by

crane, mount the ropes as shown in the figure.

The crane facility and the ropes must be of

CAUTION

for transport of the complete pump unit.

Fig. 2.1a Pumps of structural form V

sufficient capacity. The ring loop

of the motor must not be used

Fig. 2.1b Pumps of structural form L

5

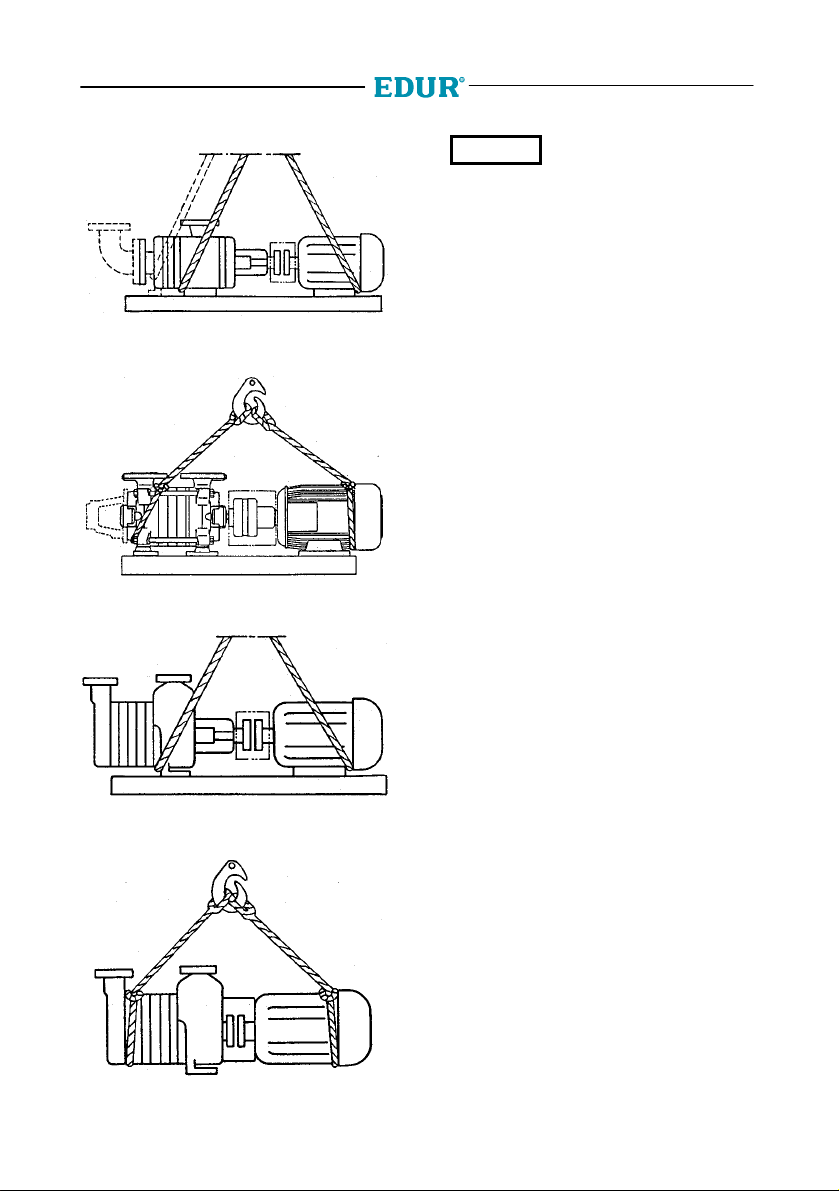

Fig. 2.1c Pumps of structural forms N, S and

N1-N9

Fig. 2.1d Pumps of structural form Z

CAUTION

and base plate are tightened at our works. Please

take care that before setting into operation the

screws have to be released by all means resp. in

case of a transport again have to be tightened.

In this regard also see section 4.1

For transport only the screws

between foot of suction casing

2.2 Intermediate Storage

On delivery, all pumps are preserved. Thus, they

can be stored for 6-12 months. If the storage time

is longer or the pumps are not in operation, they

must receive additional preservation on the inside.

The preservation means (please consult us)

depends on the used materials and conditions of

operation.

The storage room must be roofed and well

ventilated. Avoid temperatures below zero and

high humidity.

2.2.1 Internal Preservation

Close the suction branch securely. Fill the pump

with the preservation means and slowly turn the

rotor manually. Close the pressure branch

securely.

2.2.2 Preservation Control

Check the filling level of the pump and turn the

rotor by hand at regular intervals of 3 months.

Refill preservation means, if necessary.

Fig. 2.1e Pumps of structural forms V1-V6, E1-E6,

E11-E16

Fig. 2.1f Pumps of structural forms

NVB(K)1-NVB(K)9, V1-V6, E1-E6,

E11-E16, NuV25

2.2.3 Removal of Preservation

Prior to operation, the pump must be rinsed

thoroughly. In the case of additional preservation,

the preservation means on the inside must at first

be removed.

3 Description

3.1 Design

Horizontal and vertical, single-stage or multi-stage

ring section pumps, with or without an electric

drive unit, on a common bed-plate or unitconstruction pumps, available in different

construction materials, sizes and with different

shaft sealings.

Self-priming pumps are provided with an inlet

bend fitted at the suction branch.

6

3.2 Place of Operation

The pump unit must be freely accessible for the

purpose of supervision, servicing, maintenance,

mounting and dismounting.

Avoid using it in corrosive and very dusty

surroundings.

The limiting values of the electric drive unit with

regard to the insulation material class and the

types of protection must be observed.

For other drive units supplied, see the enclosed

separate operating instructions.

4 Mounting

4.1 Installation

The complete pump unit is generally mounted on

a pedestal. The pedestal must be even and must

have fasteners and a sufficient load capacity.

Instead of the pump being secured by means of

fasteners, the bed-plate of horizontal pumps or

the suction casing of vertical pumps can be

sealed in the pedestal by a depth of about 20 mm.

The complete pump unit must be adjusted by

means of a spirit level when it is being mounted

on the pedestal. The levelling plates are to be

installed between the bed-plate or suction casing

and the pedestal as well as close to any existing

fasteners. All levelling plates must be well set.

The fasteners must be tightened steadily after the

complete pump unit has been adjusted.

In the case of self-priming pumps, the pipe bend

must not be removed or distorted.

CAUTION

plate, the coupling must be checked thoroughly

after the piping has been connected and the

bed-plate secured. If necessary, pump and motor

must be readjusted.

When checking the coupling and adjusting the

unit, first loosen the pump footings and then

retighten them but without stresses.

CAUTION

the suction casing must never be screwed to the

bed-plate in order to avoid axial distortion.

Pump and motor are correctly adjusted if the

distance between a straight-edge which is placed

on the coupling halves and the relevant shaft is

the same for the entire circumference of the shaft.

The coupling rubber must have free motion of

1 to 2 mm between the coupling halves for the

entire circumference on both sides (Fig. 4.1a).

Even if the pump unit is delivered

completely mounted on the bed-

If the pump has two pump

footings, the pump footing below

Fig. 4.1a Adjustment of the Coupling

The permissible axial and radial deviation

measured at the front end and the circumference

of the coupling is 0.1 mm. If this is not the case,

the pump unit of the motor must be readjusted.

Subsequently, the motor footing must also be

tightened without stresses and the adjustment of

the coupling must be checked once again.

CAUTION

shaft and shaft sealings.

Errors in adjustment can

increase the load on the bearing,

4.2 Connected Loads

Work must only be executed when

electricity is switched off. Make sure

that the system cannot be powered

on accidentally.

CAUTION

pumped liquid. The pump must by no means be

operated without liquid!

The pump must be connected according to

international national requirements as well as

according to the requirements of the local mains

system. Voltage and frequency must correspond

to the winding of the electric drive. For details of

the respective winding, see the type label.

The motor must not be operated without motor

protection facility.

For motors with explosion protection, the range of

temperature of the motor indicated on the type

label must correspond to the range of the fuel

gas.

Prior to connecting the pump to

the power system, fill it with

4.3 Direction

Switch on the motor briefly in order to check the

direction of rotation. The motor must not reach its

operational speed. The direction of rotation must

correspond to the arrow indicating the direction of

rotation on top of the pump. If the direction of

rotation is not correct, perform the relevant

modifications at the phase-sequence.

7

4.4 Coupling Protection

The pump must not be operated if

coupling protection is not fitted. If this

coupling protection is not supplied by

the manufacturer, the operator of the pump must

supply it himself.

4.5 Piping

4.5.1 General Remarks

The nominal widths of the pipes must be at least

as wide as those of the pump connection joints.

For adapters, use extension angles of 8°, if

possible.

The pipes must be gathered and secured right in

front of the pump so that their weight does not

affect the pump. The negative effects of variations

in temperature and occurring oscillation may be

reduced by installing a suitable bellow expansion

joint (see section 4.6).

Measuring equipment for supervision of the pump

operation is required.

Prior to operation, all parts in contact with liquids

must be thoroughly cleaned.

4.5.2 Suction Pipeline

The suction pipeline must be as short as possible.

Variations in diameter and additional piping must

be kept to a minimum. The suction pipeline

towards the pump must be rising, the inlet must

be descending to prevent an air pocket from being

formed. For non-self-priming pumps, installation

of a foot valve into the suction pipeline is

compulsory in order to avoid that, in case of a

standstill, the pump and the suction pipeline run

out of liquid during suction operation.

Contamination of the pumped liquid is to be

avoided by using a suction hose or a filter. By no

means must air penetrate through the liquid level

via the suction hose or dirt be whirled up from the

liquid pool. Clean the suction hose and filter

regularly.

To close the suction pipeline in the case of

mounting or maintenance work, a stop valve must

be provided near the pump. The stop valve must

not be used for adjustment and must be

completely open during operation.

4.5.4 Additional Connections

For the position and dimension of required

additional connections as e.g. for rinse, stop and

quench liquid, refer to the labels supplied with the

pump or to the drawings in the operating

instructions. The rinse, stop and quench liquids

must be checked at regular intervals.

Connections for ventilation and release of the

leakage liquid are also described in the drawings.

4.6 Low-Noise Installation

A reduction in noise (Fig. 4.6a) can be achieved

by isolating the pedestal (1) from the ground by

means of an appropriate insulation board (2) and

by using suitable bellow expansion joints between

the piping and the pump. The pedestal (1) must

not be secured to the ground or to the walls.

Fig. 4.6a Low-Noise Installation

Another possibility to reduce the noise is the use

of oscillation absorbers. In this case, you need to

install a frame under the base of the pump.

Bellow expansion joints must be

checked regularly for brittle and

cracks.

5 Starting Operation/ Stopping

Operation

5.1 Preparations for Initial

Prior to the start, the pump and the suction

pipeline must be drained of air and be completely

filled with the pumped liquid. The stop valve in the

suction or inlet pipeline must be completely open,

if there is one. For self-priming pumps, the pump

must only be completely drained of air and filled

with the pumped liquid.

4.5.3 Pressure Pipeline

For adjustment, repair and mounting of the pump,

a stop valve is to be provided near the pressure

joint.

5.2 Initial Starting

The pump must not be started until the outlet stop

valve is closed so as to avoid overload of the

motor. Immediately after reaching the operational

speed, slowly open the stop valve of the pressure

pipeline and adjust the operating point.

8

Until the liquid starts moving against atmospheric

pressure, the hydrostatic pressure for self-priming

pumps must not exceed 1 bar with reference to

the difference in height between suction and

outlet liquid level and to the density of the pumped

liquid.

The pump must never be operated for

a longer period if the outlet stop valve

damaged if the pumped liquid exceeds the

permitted temperature.

is closed. The pump unit will be

5.3 Restarting

Do not restart the pump until the pump shaft

stands still.

CAUTION

rotation of the pump. If this is the case,

mechanical seals dependent on direction of

rotation may be damaged.

Backflow of liquid must not result

in a change of direction of

5.4 Stopping Operation

Close stop valve of the pressure pipeline. If there is

a backflow stop and sufficient counter pressure in

the pipeline, the stop valve can remain open.

Switch off the motor and observe that it slows down

smoothly. Close stop valve of the pressure pipeline.

If the pumped liquid reaches temperatures below

zero and/or if longer periods of standstill occur,

the pump must be drained completely and be

preserved (see section 2.2.1).

6 Service/Maintenance

6.1 Supervision of Operation

Ensure that the pump runs free of vibration and

smoothly

The pump must by no means be operated without

liquid.

There is only a minimal or invisible loss of leakage

(steam) if the mechanical seals function correctly.

Gland packings should drip slightly.

Do not operate the pump for a longer period with

a closed stop valve.

The maximum permitted environmental

temperature is 40oC. The storing temperature

measured at the motor or pump casing may

exceed the environmental temperature by 50oC. It

must not exceed 90oC. Only operate the pump at

a higher temperature with the manufacturer's

approval.

We have to point out that an increased wear may

occur in case of transport of abrasive / corrosive

media.

CAUTION

components have to be checked regularly in order

to detect wear in time - before a damage occurs.

The intervals have to comply with the liquids to be

pumped and initially have to be carried out more

frequently, until perceptions about the progress of

wear are attained.

Installed pumps must be powered on and off

briefly once a week in order to guarantee that they

are ready for operation.

In case of corrosive / abrasive

media to be pumped pressurized

6.1.1 Shaft Bearing

Under normal operation conditions, replace the

motor bearings after 20.000 hours of operation or

at the latest after 2,5 years. In the case of bad

operation conditions, as e.g. a high environmental

temperature or a corrosive and dusty

environment, the motor bearings must be checked

at an earlier date and, if necessary, be replaced.

Pump bearings with a lubrication device must be

checked every 5000 hours of operation. Dirty

bearings must be cleaned and filled with new

lubricant. The free space in the bearing and

casing should be filled by 30-50% with lubricant.

Do not use resinous or acid lubricants. Its

consistencies (NLGI grade) should correspond to

a worked penetration of 265 to 295 mm/10.

Lithium-base soap lubricants with a drop point of

more than 185°C are to be used for pumped

liquids which have a maximum temperature of

110°C. For pumped liquid with a higher

temperature, use silicon lubricants with a lithiumbase soap and with a drop point of more than

215°C.

If necessary, the bearings can also be lubricated

with lubricants of a different soap base. For this

based on different soaps must not be mixed. The

required re-lubrication periods must then be

adapted to the type of lubricant used.

6.1.2 Mechanical Seal

The mechanical seals are maintenance-free. If

leakages occur after a longer period of operation,

replace the complete seal.

6.1.3 Gland Packing

Gland packings are low-maintenance parts and

must leak slightly during operation. Do not tighten

a gland packing after its first operation.

Considerable leakage at the beginning disappears

by itself.

If greater leakages occur during operation, the

gland lid or insert must be slightly tightened,

however it must never be tightened at a slant.

9

It must be possible to rotate the slide slightly after

having tightened the lid or insert. If tightening of

the gland lid or insert results in the pump being

heated excessively or if it is not possible to tighten

the gland lid or insert any further, the gland

packing must be replaced completely.

CAUTION

If the gland lid or insert is

tightened too much the shaft will

be damaged.

6.2 Maintenance

6.2.1 Preparation

In order to make sure that the pump

cannot be started, separate the power

cable from the motor. Secure the unit

against accidental switch-on.

Close the stop valve of the pressure and suction

pipelines. The pump casing must have reached

the environmental temperature and be drained of

liquid and pressure. In the case of pumps in

unit-construction with mounting flange, the

container must be drained completely.

6.2.2 Dismounting

By no means use force while dismounting the

pump.

Proceed as follows for the different pump types:

Unit-construction pumps:

- Separate the pump from the piping and any

additional connections

- Loosen the fasteners

Pumps with a motor on a common bed-plate:

- Separate the pump from the piping and any

additional connections

- Remove the coupling protection

- Loosen the pump from the bed-plate and

remove it from the motor

For fixed parts of the casings, impellers and

couplings, use appropriate dismounting facilities.

Impellers, which cannot easily be removed from

the shaft, can be pushed back from the shaft by

means of two hexagon screws.

6.2.2.1 Pump

The pump is always dismounted on the suction

side and with the shaft in a horizontal position.

Refer to enclosed drawings on page 13 to 14

(only pumps of structural forms LBU and VBU) or

in the supplementary sheet for the dismounting

sequence.

For unit-construction pumps, the pump and motor

must not be separated for the axial fixing of the

pump shaft.

To prevent the partially mounted pump or the

complete pump unit from tilting, put blocks as a

mounting aid under the step casing and, if

necessary, under the drive unit.

Mark the position and sequence of the pump parts

for later mounting.

6.2.2.2 Dismounting of Mechanical

Seal

In order to replace the mechanical seal, the pump

must be dismounted (s

ee Fig. 6.2.2) first. After that the pump must be

dismantled before the seal can be removed.

Dismantle the pump in the sequence shown in the

exploded view diagrams, pages 13 or 14. Remove

impeller (230), casing (108,117), key (940.1) and

the circlip (932), pull the delivery casing (107) off

the shaft with the mechanical seal (433).

6.2.2.3 Motor

For vertical pumps and unit-construction pumps, it

is not necessary to dismount the pump unit. The

pump can remain in the piping. First, remove the

coupling protection and loosen the hexagon

screws of the coupling. After having loosened the

hexagon screws at the motor flange, remove the

motor from the pump.

For pumps with a motor on a common bed-plate,

first remove the coupling protection. Then, loosen

the mounting screws of the motor and separate

the motor from the pump.

6.2.3 Mounting

6.2.3.1 General Remarks

Prior to mounting, all parts must be cleaned

thoroughly. Remove remaining parts of the seals.

Slight scratches and grooves on the shaft near

the shaft seal and on other sealing surfaces of the

casings are to be polished with linen.

CAUTION

damage and replace them, if necessary.

Mounting is effected in the reverse order of

dismounting. Heat up the coupling joints of rigid

couplings to approximately 250°C prior to

mounting them onto the shaft.

In the case of flexible

on the pump shaft must be tightened thoroughly

If this is not possible, replace the

parts. Gaskets must always be

renewed. Check O-rings for

couplings, the coupling half

10

by means of the shaft nut and/or the hexagon nut.

If this is not observed, the bearings will be

damaged.

The starting torques for the tie bolts and locking

screws non lubricated condition are displayed in

fig. 6.2.3.1a.

thread M 10 M 12 M 14 M16 M20

torque

Nm

* for pumps with more than 4 tie bolts

Abb. 6.2.3.1a Starting torque

30 40 50 110

70*

120

6.2.3.2 Mounting of the Motor

For initial mounting of motor and pumps with rigid

coupling, first of all, remove the transport

safeguards of the lantern or of the intermediate

flange, then remove the motorside coupling half.

Subsequently, put this part onto the motor shaft.

This coupling half must be next to the motor shaft

collar. Tighten screws, join motor and pump

centrically without tilting them. Tighten screws

between motor and lantern or intermediate flange

and then coupling screws.

CAUTION

are connected and the motorside or pumpside

coupling half has been installed incorrectly or not

at all.

The inner parts of the pump will

be damaged if motor and pump

6.2.3.3 Replacing the Gland Packing

Remove gland lid or insert and remove the old

packing rings. Clean gland packing compartment

of any remaining packing material. Insert new

gland packing, ring by ring with staggered open

butt joint, see Fig. 6.2.3.3a and slightly tighten it

with gland lid or insert. No lubricant must touch

the gland packing.

6.2.3.4 Mounting of Mechanical Seal

CAUTION

carefully and with precision.

Do not touch the surfaces of the seal. Do not

damage the sealing parts. To facilitate the

mounting, moisten elastomer with low-surface

tension water.

The shape of spare mechanical seals may differ

from those of the installed mechanical seal.

However, the dimensions of the spare mechanical

seal are the same and for that reason it can be

replaced.

To avoid distortion of the counter-ring, mechanical

seals with doubled PTFE-wrapped sealing O rings

are additionally secured by a leading pin inside

the casing. The pin must be removed when

replacing the type of mechanical seals and when

using a type with different O-ring material.

For details of the individual types of mechanical

seals observe the following procedures.

When mounting the mechanical

seals, you must proceed very

Mechanical seals and sealingparts

with elastomer made of EP rubber

must by no means come in contact

with oil or grease.

Fig. 6.2.3.3a Gland packing

During the first hours of operation, watch out for

any considerable increase in heat or leakage.

11

Observe the enclosed, separate mounting

instructions for those types of mechanical seals

which are not listed.

1. Stressed mechanical seal independent of

direction of rotation with elastomer bellows

(fig. 6.2.3.4a)

Fig. 6.2.3.4a

Carefully press angle collar (1) together with

counter ring (2) into the counter ring fit.

Twist the rotating unit (3,4,5) onto the shaft

as far as the counter ring. Put on supporting

ring and mount circlip (932*) and/or push

shaft sleeve for mechanical seal (516*) onto

the shaft.

For suction-side mechanical seals (only

pumps of type Z), mount circlip (932.1*).

Push rotating unit (5,4,3) on to the shaft up

to the circlip (932.1*).

2. Stressed mechanical seal dependent on

direction of rotation with conical springs

(fig. 6.2.3.4b)

Fig. 6.2.3.4b

Insert O-Ring (1) into counter ring fit and

carefully press counter ring (2) into it. Push

mechanical seal (3) onto the shaft as far as

the counter ring. Press O Ring (4) into the

mechanical seal by means of the supporting

ring. The pivot of the pressure spring (6)

must be situated in the groove of the

mechanical seal ring. Put on locking

ring (7). Mount circlip (932*) and/or shaft

sleeve for mechanical seal (516*).

For suction-side mechanical seals (only

pumps of type Z), mount circlip (932.1*).

Push locking ring (7), pressure spring (6),

supporting ring (5), O ring (4) and

mechanical seal ring (3) separately onto the

shaft.

*

see sectional drawing in the operating

instruction (only pumps of structural

forms LBU and VBU) or sectional

drawing in supplementary sheet.

12

7 Disturbance

Pump is blocked

Coupling fault

Heads too low

Rates of flow too low

Bearing temperature too high

Pump operates badly

Leakages at the casing

Overload of the drive

Shaft seal leaks badly

z z

z z z

z

z

z z

z

z z

z

z

z

z

z

z

1)

Please consult us

2)

Only pumps with lubricator

z z z

z z

z z z

z z

z z

z z z

z z

z z

z

z z

z z

To eliminate disturbance, the pump must have

CAUTION

reached the environmental temperature and must

be drained of air and pressure.

The chart shows a list of potential errors and their possible causes. For

errors which are not listed here or which have other reasons, please

consult us.

Motor protection activated

Pump is becoming too hot

Cause Elimination

Pump and/or suction pipeline is not

completely drained of air/filled

Suction level too high, NPSH value of

the unit too high

z

Air inclusion in the pumped liquid too

high

z

Formation of air bag in suction pipeline Change suction pipeline/attach drain valve

z

Direction of rotation incorrect Check and change phase sequence, if

Rates of flow too low Readjust operating point

z

Wear of inner parts Replace inner parts

Pump operates out of tolerance Readjust operating point

Shaft seal damaged Replace shaft seal

Stuffing box gland jammed or tightened

too heavily

Air entry through shaft sealing on

suction side

Speed too low Increase speed

Speed too high Reduce speed

Connecting screws, seals Tighten connecting screws, replace seals

Pump/motor not adjusted Replace defective parts, adjust pump/motor

Problems via piping Check pipe connections/pump

Insufficient, excessive or wrong

lubrication grease

Incorrect coupling gap Readjust motor

Defective bearing Replace bearing

Density/viscosity of pumped liquid

higher than indicated in the order

Motor protection unit set incorrectly or

defective

Impeller blocked Clean interior parts from particles and

Drain of air and fill

Completely open stop slide in the suction

pipeline, check suction bag/footing valve, if

necessary, increase liquid level, if

necessary

Seal suction pipeline once again, check

suction bag, increase liquid level, if

necessary

necessary

Correct

Check liquid sealing or replace packing

1)

1)

fasteners/bearing distance of pipe clips,

installation with oscillation absorbers

Add, remove or change grease2)

1)

Check motor protection unit, replace it, if

necessary

impurities

y

13

210 932.1 844

341 681 901.2 844.1 904

903

117108

920 nut

930/.1-.2 tooth lock washer

932/.1 circlip

940/.1 ke

When ordering spare parts, please

indicate serial no., type no. and

parts no. by all means.

904940 930.1 901.1

901.4

part no. designation 903 screwed plug

904 hexagon socket set screw

905 tie bolt

B

C

411 903 722554.1 901 930.2

part no. designation 554/.1 washer

592/.1 base

681 coupling guard

930

412

412 592 182 531 901.3

part no. designation 230 impeller

341 lantern

411 joint ring

722 intermediate flange

844/.1 disc type coupling

412 o-ring

433 mechanical seal

901/.1-.5 hexagon screw

531/.1 locking sleeve

545

A

930 531.1 412

A: Screwed plug G¼ for vent connection and pressure gauge connection

8 Pump View and List of Spare Parts

8.1 LBU

905 411 903 106 230 940.1 230 940.1 932 433 107 554 920 411

592.1 182.1901.5

part no. designation 106 suction casing

107 delivery casing

108 stage casing

117 endstage casing

182/.1 foot

B: Screwed plug G¼ for vent connection and pressure gauge connection

210 shaft

C: Screwed plug G¼ for drain

14

p

y

901.1930.1940 904

all means.

901.2 210 932.1 844 844.1 904

341 681

903

920 411

107 554

901.4

part no. designation 930/.1 tooth lock washer

932/.1 circlip

940/.1 key

930.2901554.1 722903411

When ordering spare parts, please

arts no. b

indicate serial no., type no. and

B

C

part no. designation 722 intermediate flange

844/.1 disc type coupling

901/.1-.3 hexagon screw

903 screwed plug

904 hexagon socket set screw

905 tie bolt

920 nut

412412

part no. designation 341 lantern

411 joint ring

412 o-ring

433 mechanical seal

554/.1 washer

230 230 433

412

681 coupling guard

905411

903 940.1 108 117940.1 932

106

545

C

part no. designation 106 suction casing

107 delivery casing

108 stage casing

8.2 VBU

117 endstage casing

B: Screwed plug G¼ for vent connection and pressure gauge connection

210 shaft

230 impeller

C: Screwed plug G¼ for drain

15

As defined by machinery directive 98/37/EC Annex II A

Declaration of Conformity

Herewith we declare that the pump unit supplied with mounted electric drive

complies with the following provisions applying to it

EC-machinery directive (98/37/EC, Annex I No. 1)

EC-low voltage directive (73/23/EEC)

Applied harmonized standards

EN 809 EN 953

EN 292-1 EN 60204-1 section 16

EN 292-2 EN 60034-5

EN 294

In case of a modification of the pump unit without being coordinated with us this declaration will not longer be

valid.

i.A.

(QM-Supervisor)

1) other driving motor see separate declaration of c onformity

1)

As defined by machinery directive 98/37/EC, Annex II B

Herewith we declare that the pump supplied without driving motor is intended to be incorporated into

machinery or assembled with other machinery to constitute machinery covered by this directive and must not

be put into service until the machinery into which it is to be incorporated has been declared in conformity with

the provisions of the directive, version 98/37/EC.

Applied harmonized standards

In case of a modification of the pump without being coordinated with us this declaration will not longer be

valid.

i.A.

(QM-Supervisor)

Declaration by the manufacturer

EN 809

EN 292-1

EN 292-2

BE1 17102,8 / 071001

Loading...

Loading...