EDTM ETEKT+ AE1601 User Manual

ETEKT+ IMPROPER OPERATING CONDITIONS

The ETEKT+ is the only thing that should be in contact with the glass while

the reading is being taken. The operator may have their hand on the

meter itself, but should not allow any part of their hand to overlap the meter

and come into contact with the glass during testing.

If the window area under test is excessively

dirty or contaminated, the ETEKT+ may

give improper results. The window area

under test must be RELATIVELY CLEAN.

Clean the test area or move the ETEKT+ to

a clean location on the window.

The ETEKT+ must be used with the surface

opposite the POWER button pushed flat

against the window. Using the small end

surface of the unit or tilting the unit away

from the window surface will give

improper results.

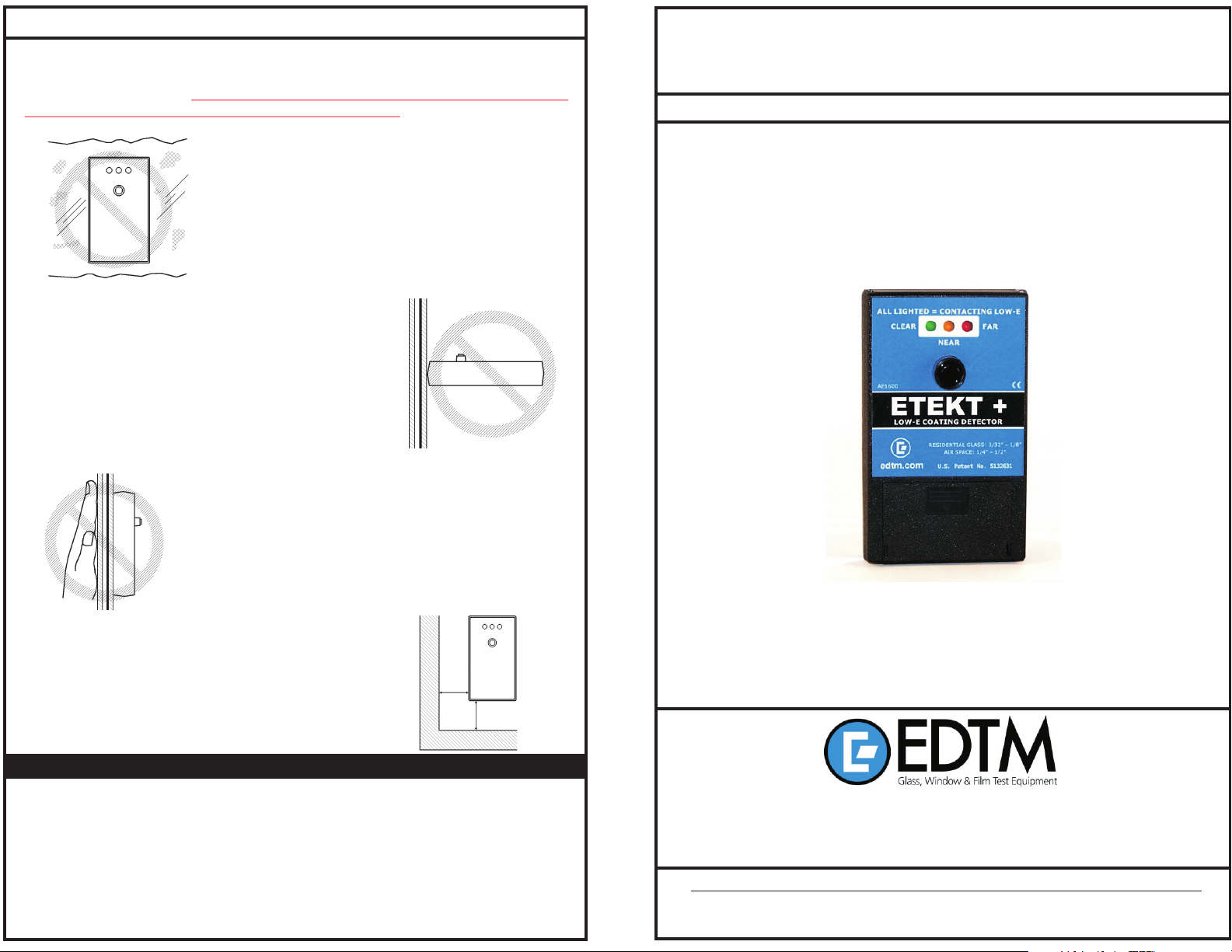

ETEKT+

DUAL PANE LOW-E COATING DETECTOR

MODEL# AE1601

GENERAL DESCRIPTION:

The "ETEKT+" is a portable instrument using a patented method to detect the

presence and location of Low-E coatings or any other conductive coating

on or within a window assembly. The ETEKT+ is designed to test single or

double pane windows from a single side. The instrument is optimized for

windows containing 3/32” and 1/8” glass with air spaces up through ½",

HOWEVER the AE1601 can test many other window sizes as explained in this

operating manual.

Placing your hand or an object on the

opposite side of the window may cause

improper results. Remove hand or object.

IMPORTANT:

Do not operate the ETEKT+ within two (2) inches

of a window frame or any other metallic window

2"

component. Extraneous conductive materials

may impact the accuracy of your test results

2"

AE1601 WARRANTY

The manufacturer warrants all models of the AE1601 to be free from defects in material and

workmanship under normal use and service as specified within the operator's manual. The

manufacturer shall repair or replace the unit within twelve (12) months from the original date of

shipment after the unit is returned to the manufacturers factory, prepaid by the user, and the unit is

disclosed to the manufacturers satisfaction, to be thus defective. This warranty shall not apply to any

unit that has been repaired or altered other than by the manufacturer. The aforementioned provisions

do not extend the original warranty period of the unit which has been repaired or replaced by the

manufacturer. Batteries are not covered by warranty.

EDTM, Inc. assumes no liability for the consequential damages of any kind through the use or misuse of

the AE1601 product by the purchaser or others. No other obligations or liabilities are expressed or

implied. All damage or liability claims will be limited to an amount equal to the sale price of the

AE1601, as established by EDTM, Inc.

manual_edtm AE1601

This instrument detects the presence of all electrically conductive coatings

in/on a window, including Low-E coatings. Make sure the window is

reasonably clean before testing. The “FAR” and “CLEAR” indicators are

dependent on the window being within the thickness specifications listed

above. If in doubt about the thickness of the window being tested, always

test both sides of the window and look for the side that yields the “NEAR”

indication. The “NEAR” indication works for any glass thickness.

745 Capital Commons Drive

Toledo, Ohio 43615 USA

PHONE: (419) 861-1030 FAX: (419) 861-1031

www.EDTM.com Email: sales@edtm.com

KEEP THE COMPETITIVE EDGE WITH PRODUCTS FROM EDTM, INC.

glass & air space laser meters, tempered glass detectors, SHGC, solar, visible, & uv meters

low-e type detectors, 4 point sheet resistance meters, tin side detectors,

self-clean coating detectors, sales kits, temperature guns & accessories

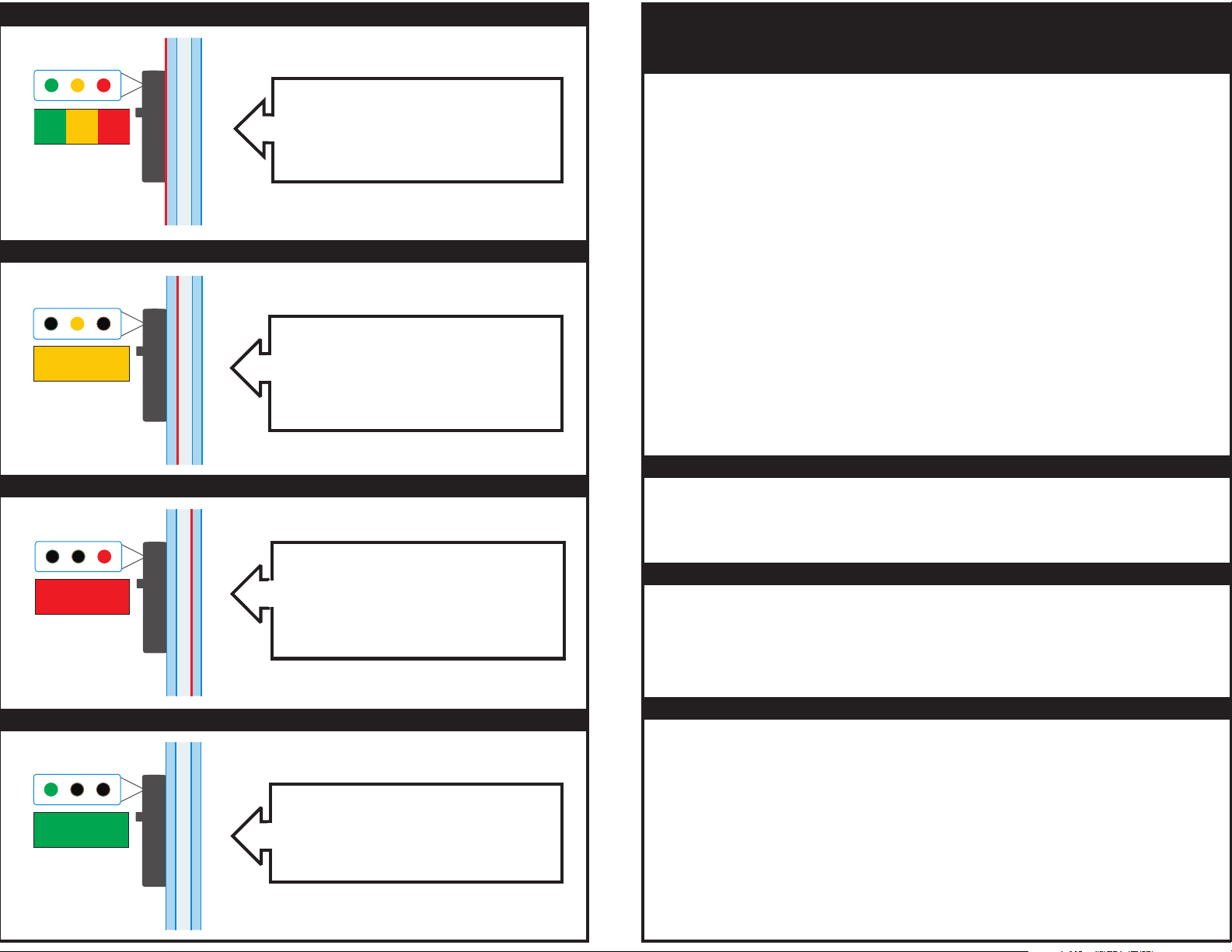

CONTACTING LOW E = SURFACE 1 DETECTION

WHAT IF I DON’T KNOW THE THICKNESS OF GLASS I AM TESTING?

All Indicators

CONTACTING

(SURFACE 1)

Meter is contacting the

coated surface.

NEAR INDICATION = SURFACE 2 DETECTION

Yellow Indicator

NEAR

(SURFACE 2)

The Low-E coating is

on the near pane.

FAR INDICATION = SURFACE 3/4 DETECTION

Red Indicator

FAR

(SURFACE 3)

The Low-E coating is

on the far pane.

Green Indicator

CLEAR

(No Low-E)

The window has no

coating.

When the ETEKT+ is in direct

contact with a LOW-E coating

the GREEN, YELLOW and RED

PANE 1

AIR SPACE

PANE 2

indicators will all be lighted.

The YELLOW light indicates that

a LOW-E coating exists on the

NEAR surface of the window.

The near surface of the window

PANE 1

AIR SPACE

PANE 2

is surface #2 as you look at the

window.

The RED light indicates that a

LOW-E coating exists on a FAR

surface of the window. The far

surfaces of the window are

PANE 1

AIR SPACE

PANE 2

surface #3 or #4 as you look at

the window.

CLEAR INDICATION

The GREEN light indicates that the

window is CLEAR of any LOW-E

COATING. NO LOW-E coating

exists on any of the surfaces

PANE 1

PANE 2

"SINGLE PANE MODE"

The ETEKT+ RED/FAR and GREEN/CLEAR lights are optimized for single pane or IG

window assemblies manufactured with 3/32" (2.5mm) or 1/8" (3mm) glass with an air

space between 1/4" and ½". Whenever you are operating on glass or air spaces

BEYOND this range, DISREGARD the and indicators--they have NO

RED GREEN

meaning.

Therefore to fully test an IG unit when the thickness is not known, you must take a

reading from both sides of the window, measuring each piece of glass

individually. Watch ONLY for the NEAR/YELLOW indicator. If you do not obtain a

NEAR indication on either side of the IG unit, it is a CLEAR IG assembly. If you do

obtain a NEAR indication on one side of the window, that piece of glass contains

the low e, and it is on the second surface of the glass as explained on the

previous page.

SUMMARIZING:

1. Test both sides of the window looking for the NEAR indication ONLY.

2. If you do not get a NEAR indication on either side of the window, the

window does not contain any LOW-E coatings (it is a clear window).

3. If the YELLOW/NEAR indicator lights on one of the sides of the window,

then that pane of glass contains the LOW-E coating.

4. Totally disregard the FAR and CLEAR indicators, as they are not valid in

this application.

5. The "CONTACTING" coating indication is valid for ALL applications,

regardless of thickness or air space.

OTHER APPLICATIONS

The AE1601 instrument can be used to identify ANY conductive coatings, even if

they are not low e coatings. Other known applications for the AE1601 include

identifying non-ceramic window films and also Pilkington’s “Optiview” antireflective coating. In most cases the ETEKT+ is able to identify other coatings even if

they are protected by an insulating coating over the top of the conductive surface.

MULTIPLE LOW E SURFACES or TRIPLE PANE

The AE1601 instrument will only detect the nearest low e coating it encounters.

Therefore if you have a window with more than one low e coating, the AE1601 will

only show the presence of the coating that is closest to the meter. If you believe

there is more than one coating, you will need to test the other side of the window to

confirm this. Remember, the instrument will only identify the nearest coating it

encounters. For triple pane applications, it is necessary to test both sides of the

window.

LOW BATTERY INDICATION

The AE1601 is equipped with a low battery indicator that will indicate when it is

necessary to replace the battery. The low battery condition is indicated by blinking

the LED that gives the results of the test. Typically the LED result is shown in a

“constant-on” style. However when the battery needs replaced, the LED result will

be blinked. This is the warning indication that a new battery should be installed

sometime soon. The instrument will continue to operate correctly for a given time

after the warning is indicated. It is recommended that you replace the battery

soon. Once the battery voltage drops to a dangerously low level, the instrument

will NOT operate and the LED indicators will go into a continuous blinking pattern,

NOT allowing you to use the meter.

AIR SPACE

The AE1601 is powered by a 9 volt alkaline battery. Please replace the battery with

an alkaline battery when necessary.

Loading...

Loading...