EDT Eurodima Braxx WB12T User Manual

User Manual

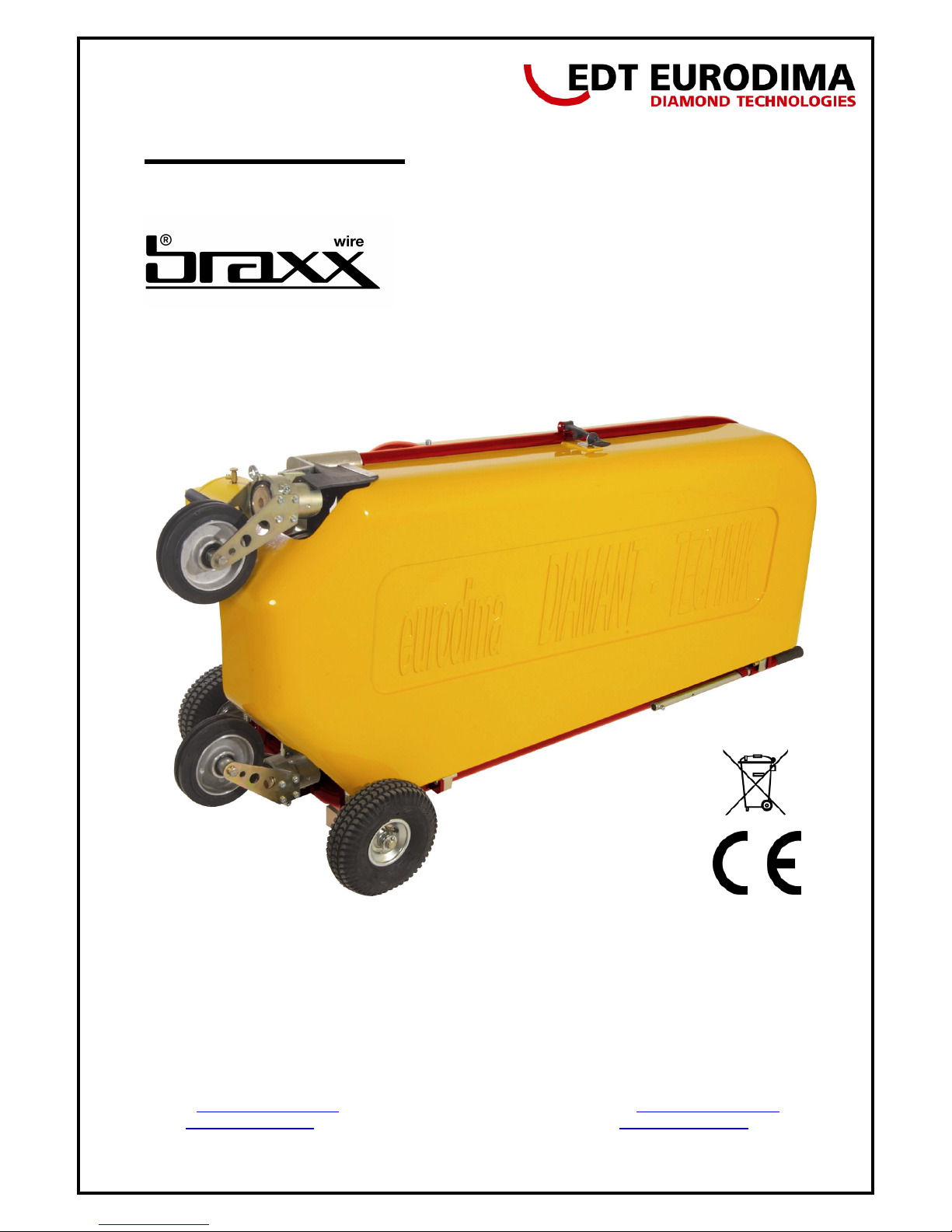

Electric Wire Saw WB12T

EDT EURODIMA GMBH

Diamond Technologies Branch in Germany:

Lagerstrasse 6 Oberheinrieter Straße 30 - 32

A-5071 Wals bei Salzburg D-74199 Unterheinriet

Tel.: +43 (0) 662 / 42 42 48 Tel.: +49 (0) 7130 / 40095 0

Fax: +43 (0) 662 / 42 42 48-20 Fax: +49 (0) 7130 / 40095 20

e-Mail: office@eurodima.com e-Mail: office@eurodima.com

www.eurodima.com www.eurodima.com

WB12T

2

Table of Contents

1

Introduction ..................................................................................................................... 3

2

EU Declaration of Compliance ....................................................................................... 4

3

Intended Use.................................................................................................................... 5

4

Specifications.................................................................................................................. 5

5

General notes electric pneumatic saw WB12T.............................................................. 6

6

Safety ............................................................................................................................... 7

6.1 Dangerousness of the wire saw WB12T............................................................................ 7

6.2 Intended use ..................................................................................................................... 7

6.3 Danger .............................................................................................................................. 8

6.4 Emissions.......................................................................................................................... 8

6.5 Sources of danger............................................................................................................. 8

6.6 Workplace ......................................................................................................................... 9

6.7 Approved Operators.......................................................................................................... 9

6.8 Personal safety measures................................................................................................. 9

6.9 Safety measures at the installation place .......................................................................... 9

6.10 Emergency measures ..................................................................................................... 10

7

Safety Equipment.......................................................................................................... 10

8

Mounting the System .................................................................................................... 10

8.1 Positioning ...................................................................................................................... 10

8.2 Electrical connection ....................................................................................................... 10

8.3 Compressed air supply – pneumatic unit......................................................................... 11

9

Initial operation ............................................................................................................. 11

9.1 User Manual.................................................................................................................... 11

9.2 Turn on/off the machine .................................................................................................. 11

10 Operation ....................................................................................................................... 12

11 Mounting the cutting tools ........................................................................................... 12

12 Functional description.................................................................................................. 12

13 Maintenance and service of wire saw WB12T............................................................ 14

14 Maintenance and service of the control panel ............................................................ 14

14.1 Condensation water ........................................................................................................ 14

14.2 Cleaning.......................................................................................................................... 14

14.3 Compressor..................................................................................................................... 15

15 Liability and Warranty................................................................................................... 15

16 Drawings and Pictures.................................................................................................. 16

WB12T

3

1 I

NTRODUCTION

This user manual is intended for the operators and maintenance personnel of this machine.

The manual is not intended to replace correct training in operating the machine. We

recommend training by qualified employees of EDT EURODIMA GMBH or by one of our

authorized dealers. A protocol of receipt and training is then set up.

All persons employed in the operation, maintenance and/or repair

of this machine must read and understand these instructions

completely.

Please direct inquiries to the manufacturer or an authorized dealer.

Please observe our safety features and safety precautions which are

highlighted by a at the respective locations

in the manual.

The wire braxx sawing system is equipped with safety features; however, various dangers

can result from errors and misuse. Anyone involved in the setup, start-up, operation or

maintenance of the machine must read and observe the safety precautions.

Non-observance of these safety precautions may result in

-

the injury or death of the operator or third persons

-

damage to the machine and other assets

-

damage to the building

- inefficient operation of the wall saw.

WB12T

4

2 EU D

ECLARATION OF COMPLIANCE

Manufacturer : EDT EURODIMA GMBH

Lagerstraße 6

A-5071 Wals bei Salzburg

Description: wire saw system, consisting of remote control panel,

wire saw storage unit and wire guiding device

Type: Wire saw system WB12T

Serial number: ____________________

We herewith confirm that the design and construction of the aforementioned machine

complies with the following EU guidelines and its basic safety and health regulations:

Machine Guideline 89/392/CEE, i.d.F. 91/368/CEE

Guideline - Electromagnetic Compatibility (EMC) 89/336/EG, i.d.F. 93/31/CEE

Low Voltage Guideline 73/23/CEE

The following harmonized standards were applied

EN 292-1

EN 292-2

EN 294

EN 60204

The following documentation is completely included in the user manual

Description of precautions to prevent machine-related dangers

Operator instructions for the machine

Spare parts list

This declaration is no longer valid if the machine is modified in any way without prior

consultation with us and without our prior approval.

Wals, 03.08.2009 ____________________________

Dipl.-Ing. Wolfgang Stangassinger

Managing Director

WB12T

5

3 I

NTENDED USE

Important safety note

The EDT EURODIMA machines may not be used in conjunction

with other brands of machines unless recommended or

approved by EDT EURODIMA GMBH. Non-observance will void

the warranty and any product liability.

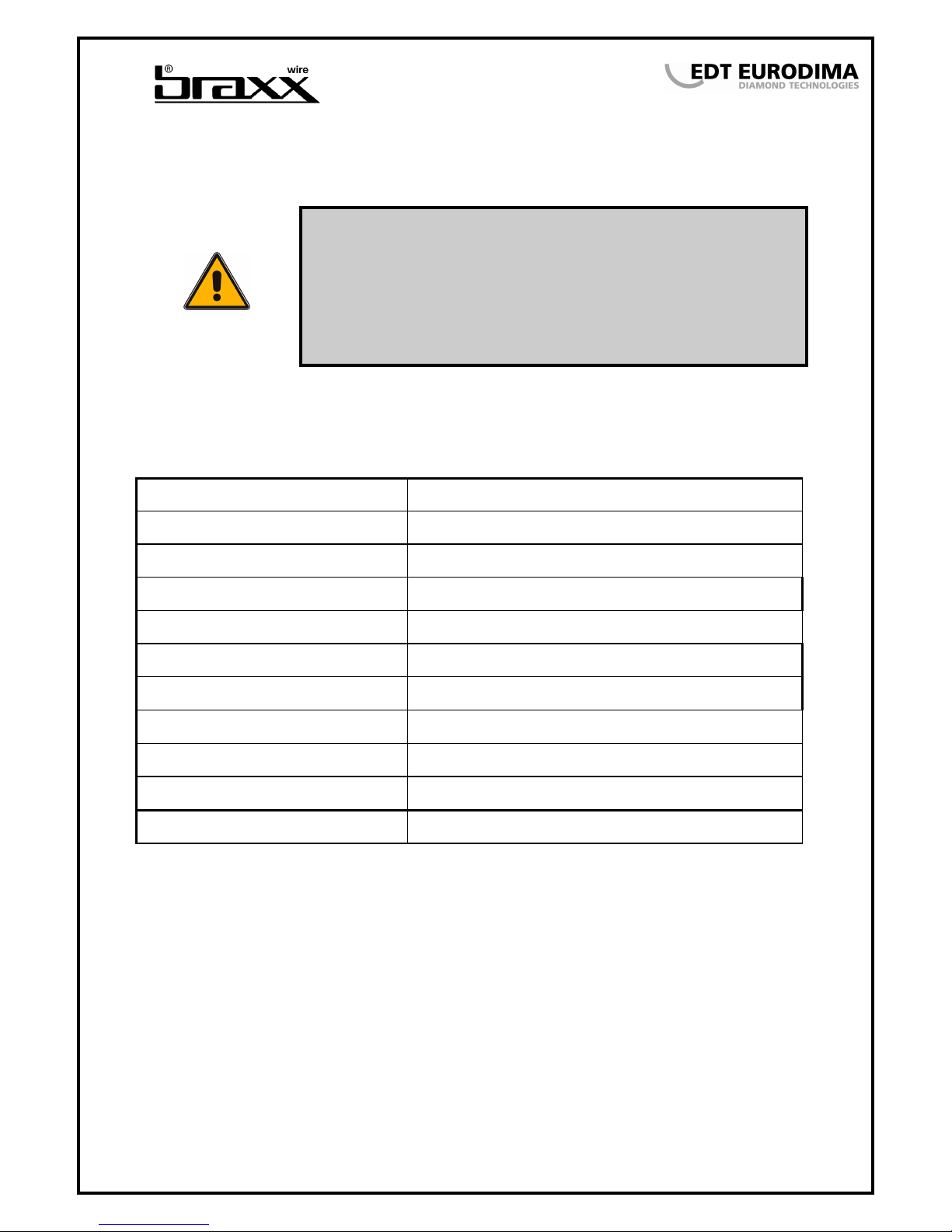

4 S

PECIFICATIONS

Rated voltage 230/400 V

Current consumption 63 A, 3PH/N/PE

Power 32 kW, water cooled

Frequency 1000 Hz

Revolutions 0 – 2200 min-1

Protection class IP67

Cutting speed 2 - 30 m/sec, frequency controlled up to 1000 Hz

Pressure 8 bar

Dimensions 1875 x 620 x 820 mm

Weight 192 kg without control unit

Maximum wire storage 4 + 12 m

WB12T

6

5 G

ENERAL NOTES ELECTRIC PNEUMATIC SAW

WB12T

The wire saw system consists of a wire guiding device that is mounted at the cut. The wire

saw unit wb12 is then positioned and/or mounted considering the specific application.

The saw system is made up of the following components:

stable machine frame; at the same time compressed-air store

(Pict. 1 pos. 1) see p. 16

electric drive motor; dismountable by quick separation system

(Pict. 1 pos. 2) see p. 16

dismountable saw head with special drive gear, offset rolley, two counterrotating

guide rollers and two swivel rollers

(Pict. 1 pos. 3) see p. 16

feed unit

dismountable protection device

(Pict. 2 pos. 1) see p. 16

dismountable transport wheels

(Pict. 1 transport wheels) see p. 16

two handles

(Pict. 1 handles) see p. 16

mobile control unit with integrated air compressor

electric cable set from control unit to drive motor of the wire saw

air hose 3-parts from control unit to wire saw

WB12T

7

6 S

AFETY

Warning

Check the compatibility of the voltage and the frequency with the

data on the rating plate prior to use. Repairs must be carried out

only by qualified personnel.

6.1 Dangerousness of the wire saw WB12T

The wire saw system wb12T is equipped with protection devices, however, there is danger

when operating it faultily or misuse it. All persons that are concerned with the set-up, the

initial operation, the handling and maintenance of the system, have to carefully read and

adhere to the following notes.

6.2 Intended use

The wire saw wb12T is built state-of-the-art. If the machine is used in an other than the

intended way, it is dangerous for the user.

The system is suitable only for wire saw works, using wire saws up to Ø 12 mm.

Without the drive unit protective cover (Pict. 2 pos. 1) see p. 16, no cut may be done.

If the air is affected by the cutting process, provide fresh air for the user for his

protection (mainly when dry cutting).

Spare wire lengtsh can be covered by safety guards. However, staying in the

direction of the alignment or in the danger area (Pict. 3, see page 16) during

operation is strictly forbidden.

All used wires must be approved for a cutting speed of 30 m/sec.

Wires may only be used if the following data is known:

o Applicability of use (concrete, masonry, steel, cast iron etc.)

o Dimensions

o Allowed cutting speed

o Allowed wire connector (preferent. EDT EURODIMA bwc9 quick wire connector)

Chapped or deformed wires may not be used.

Prior to every use, the diamond wire and the wire connector must be checked for

damages. When defect, the wire resp. the wire connector must be renewed.

Dry and wet cut: The wire saw system wb12 is designed for both dry and wet cuts.

Caution high-voltage current!

Danger to life, when lines are cut or defect!

All system use beyond is classified as not complying with the regulations. For damages

resulting from this misuse, the manufacturer cannot be held liable. The risk is borne by the

user himself.

WB12T

8

6.3 Danger

Through wire sawing, particles are torn out of the material and the grinding medium with high

speed. Due to the different workpiece forms, it is not possible to fit the safety guard exactly to

the workpiece. Provide appropriate workwear (see personal protection measures). Always

consider the safety safety clearance – the danger area is the idle wire length (Pict. 3, see

page 16).

Fire hazard:

Never cut near flammable substances or in rooms with explosives!

Never cut workpieces from aluminium, magnesium, or any aluminium or magnesium

alloys!

Aluminium and magnesium chipping is readily flammable!

Do not cut any material where harmful dust or vapours are produced in the grinding

process (e.g. asbestos at renovations etc.)!

Do not cut any material where explosive dust is produced in the grinding process!

If above-mentioned work is done, clarify separately which further safety measures are to be

conducted. Your contact is your regulatory authority and your professional association.

6.4 Emissions

The A-rated equivalent continuous sound pressure level of this system is lower than 75 dbA,

thus no ear protection is needed. Hence, this wire saw is especially suitable for the use in

construction of public social institutions such as hospitals and nursing homes.

6.5 Sources of danger

High wire speed

Danger at a potential wire crack, by whipping of the wire and consequenly flying wire

or closure parts, being able to cause heavy chip or crush injuries.

If any limbs come between the wire and the roller guides, they can be pinched or cut

off. Loose clothes can be trapped inbetween the operating wheels, too. Thus,

absolutely avoid the danger area (Pict. 3, see page 16) during machine operation.

Prior to maintenance and cleaning, the motor must be switched off and the voltage

supply must be disconnected (pull out power plug)

Turn off the motor before you leave the machine.

Leave the machine only when it is brought to a halt.

Never remove safety equipment, or never change the system so that the safety

devices do not function anymore.

During the cutting operation, never stay in the alignment of the idle wire (Pict. 3, see

page 16).

Danger through high voltage current – danger to life!

Loading...

Loading...