Page 1

User’s Guide

VisionLink XF

Camera Link fiber extender

for base mode through 80-bit operation

Date: 2019 March 19

Rev.: 0001

Page 2

EDT | Engineering Design Team, Inc.

3423 NE John Olsen Ave

Hillsboro, OR 97124

U.S.A.

Tel: +1-503-690-1234 | Toll free (in U.S.A.): 800-435-4320

Fax: +1-503-690-1243

www.edt.com

EDT

TM

and Engineering Design Team are trademarks of Engineering Design Team, Inc. All other trademarks, service marks,

TM

and copyrights are the property of their respective owners†.

© 1997-2019 Engineering Design Team, Inc. All rights reserved.

EDT, Inc. 2

Page 3

Terms of Use Agreement

Definitions. This agreement, between Engineering Design Team, Inc. (“Seller”) and the user or distributor (“Buyer”), covers the

use and distribution of the following items provided by Seller: a) the binary and all provided source code fo r any and all device

drivers, software libraries, utilities, and example applications (collectively, “Software”); b) the binary and all provided source code

for any and all configurable or programmable devices (collectively, “Firmware”); and c) the computer boards and all other physical

components (collectively, “Hardware”). Software, Firmware, and Hardware are collectively referred to as “Products.” This

agreement also covers Seller’s published Limited Warranty (“Warranty”) and all other published manuals and product information

in physical, electronic, or any other form (“Documentation”).

License. Seller grants Buyer the right to use or distribute Seller’s Software and Firmware Products solely to enable Seller’s

Hardware Products. Seller’s Software and Firmware must be used on the same computer as Seller’s Hardware. Seller’s Products

and Documentation are furnished under, and may be used only in accordance with, the terms of this agreement. By using or

distributing Seller’s Products and Documentation, Buyer agrees to the terms of this agreement, as well as any additional

agreements (such as a nondisclosure agreement) between Buyer and Seller.

Export Restrictions. Buyer will not permit Seller’s Software, Firmware, or Hardware to be sent to, or used in, any other country

except in compliance with applicable U.S. laws and regulations. For clarification or advice on such laws and regulations, Buyer

should contact: U.S. Department of Commerce, Export Division, Washington, D.C., 20230, U.S.A.

Limitation of Rights. Seller grants Buyer a royalty-free right to modify, reproduce, and distribute executable files using the

Seller’s Software and Firmware, provided that: a) the source code and executable files will be used only with Seller’s Hardware;

b) Buyer agrees to indemnify, hold harmless, and defend Seller from and against any claims or lawsuits, including attorneys’ fees,

that arise or result from the use or distribution of Buyer’s products containing Seller’s Products. Seller’s Hardware may not be

copied or recreated in any form or by any means without Seller’s express written consent.

No Liability for Consequential Damages. In no event will Seller, its directors, officers, employees, or agents be liable to Buyer

for any consequential, incidental, or indirect damages (including damages for business interruptions, loss of business profits or

information, and the like) arising out of the use or inability to use the Products, even if Seller has been advised of the possibility

of such damages. Because some jurisdictions do not allow the exclusion or limitation of liability for consequential or incidental

damages, the above limitations may not apply to Buyer. Seller’s liability to Buyer for actual damages for any cause whatsoever,

and regardless of the form of the action (whether in contract, product liability, tort including negligence, or otherwise) will be

limited to fifty U.S. dollars ($50.00).

Limited Hardware Warranty. Seller warrants that the Hardware it manufactures and sells shall be free of defects in materials

and workmanship for a period of months from date of shipment to initial Buyer. This warranty does not apply to any product that

is misused, abused, repaired, or otherwise modified by Buyer or others. Seller’s sole obligation for breach of this warranty shall

be to repair or replace (F.O.B. Seller’s plant, Beaverton, Oregon, USA) any goods that are found to be non-conforming or

defective as specified by Buyer within 30 days of discovery of any defect. Buyer shall bear all installation and transportation

expenses, and all other incidental expenses and damages.

Limitation of Liability. In no event shall Seller be liable for any type of special consequential, incidental, or penal damages,

whether such damages arise from, or are a result of, breach of contract, warranty, tort (including negligence), strict liability, or

otherwise. All references to damages herein shall include, but not be limited to: loss of profit or revenue; loss of use of the goods

or associated equipment; costs of substitute goods, equipment, or facilities; downtime costs; or claims for damages. Seller shall

not be liable for any loss, claim, expense, or damage caused by, contributed to, or arising out of the acts or omissions of Buyer,

whether negligent or otherwise.

No Other Warranties. Seller makes no other warranties, express or implied, including without limitation the implied warranties

of merchantability and fitness for a particular purpose, regard ing Seller’s Products or Documentation. Seller does not warrant,

guarantee, or make any representations regarding the use or the results of the use of the Products or Documentation or their

correctness, accuracy, reliability, currentness, or otherwise. All risk related to the results and performance of the Products and

Documentation is assumed by Buyer. The exclusion of implied warranties is not permitted by some jurisdictions. The above

exclusion may not apply to Buyer.

Disclaimer. Seller’s Products and Documentation, including this document, are subject to change without notice. Documentation

does not represent a commitment from Seller.

EDT, Inc. 3

Page 4

Contents

Overview.........................................................................................................................................................................5

Care and Cautions ................................................................................................................................................ 5

Related Resources................................................................................................................................................6

Cabling............................................................................................................................................................................ 7

Camera Link.......................................................................................................................................................... 7

Fiberoptic ..............................................................................................................................................................7

Power and Auxiliary ..............................................................................................................................................7

Setup .............................................................................................................................................................................. 8

DIP Switches and LEDs........................................................................................................................................ 9

Mounting and Safetying................................................................................................................................................ 10

Firmware.......................................................................................................................................................................10

Transceivers................................................................................................................................................................. 11

Pin Assignments........................................................................................................................................................... 12

Camera Link Connectors..................................................................................................................................... 12

Power Connector ................................................................................................................................................ 13

Cable Assembly – Lemo to Loose Wire..................................................................................................... 13

Cable Assembly – Lemo to Male DB9.......................................................................................................13

Cable Assembly – Lemo to Female DB9 RS232.......................................................................................14

Power Supply................................................................................................................................................................ 15

Dimensions................................................................................................................................................................... 16

EDT, Inc. 4

Page 5

VisionLink XF Camera Link Fiber Extender

Overview

The VisionLink XF extends Camera Link (base through 80-bit mode) over fiber, providing electrical isolation and

extended range. It supports cameras from 20 to 85 MHz, and serial data rates up to 115.2 kb/s.

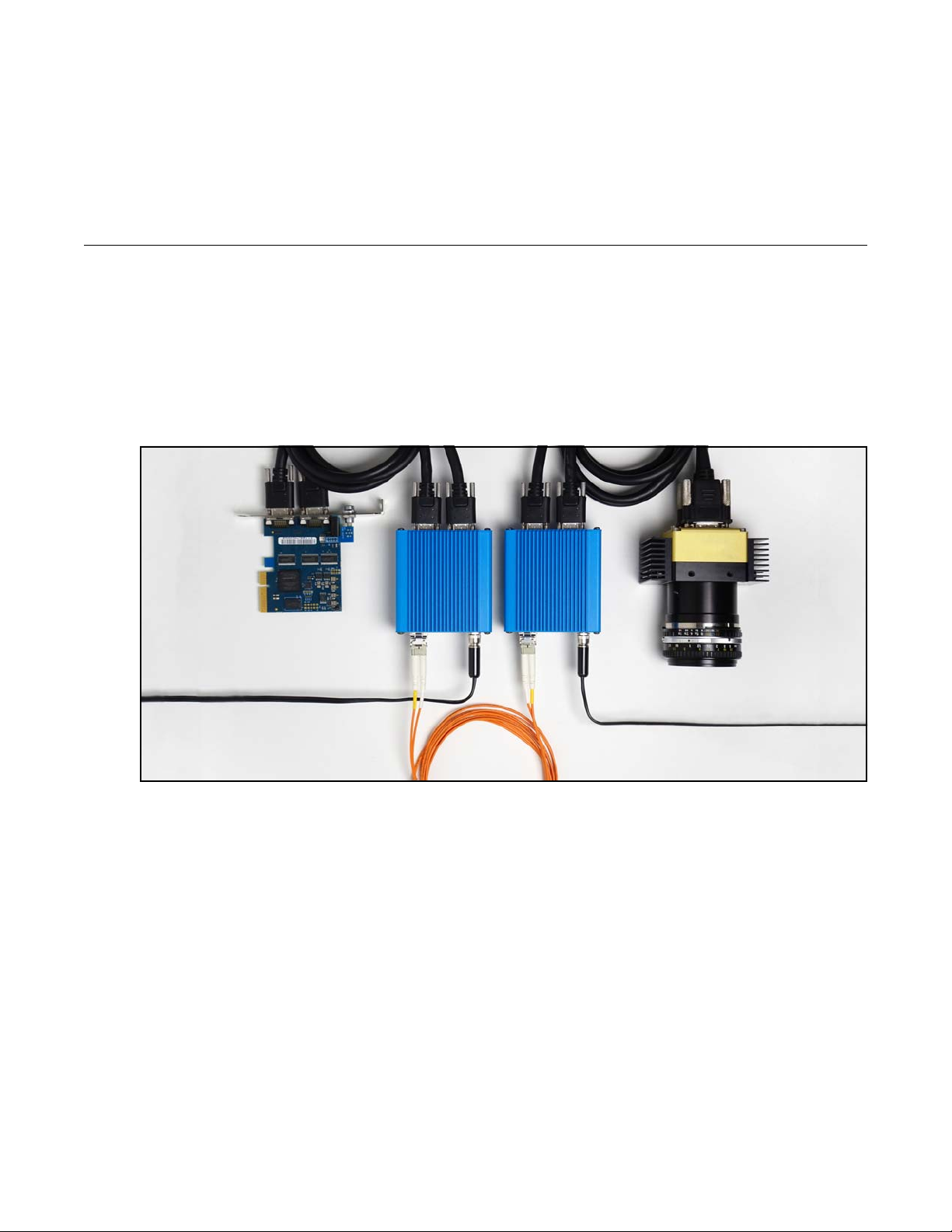

The VisionLink XF extender works with EDT or third-party framegrabbers (see Related Resources). The extender units

are designed to work in pairs: one unit connects to the camera and the other to the framegrabber with Camera Link

cabling; then the two units connect to each other with fiberoptic cabling. Figure 1 shows an example setup.

Figure 1. VisionLink XF extender pair – example setup (medium or 80-bit mode)

Care and Cautions

When opening and handling EDT products, always follow electrostatic dissipative procedures (see edt.com/static).

Each EDT product, though built to withstand a wide range of conditions as listed in its datasheet specifications, is still a

high-performance component which requires proper care for best results.

In particular, the connectors – especially the fiberoptic transceivers – must be kept clean and dry. If you suspect the

presence of moisture or debris in the connectors, use compressed air to do the following...

1) Blow the compressed air away from the equipment to clear any moisture or debris from the air nozzle.

2) Blow the compressed air directly into each connecto r to clear any moisture or debris there.

CAUTION To avoid damaging your eyesight, never look directly into any fiberoptic transceiver.

EDT, Inc. 5

Page 6

VisionLink XF Overview

Related Resources

The resources below may be helpful or necessary for your applications. For complete resources and documentation on

any EDT product, visit edt.com and navigate to the product page.

EDT resources

• VisionLink XF datasheet / specifications edt.com/product-data

• VisionLink XF quick start guide “

• Videos and tutorials “

• All EDT extenders edt.com/product-lines/camera-link-extenders/

• All EDT frame grabbers edt.com/product-lines/camera-link-frame-grabbers/

Third-party resources

• Camera Link specifications visiononline.org

• Providers of fiberoptic cabling assemblies:

– Borg Technologies borg-tech.com

– Cypress Industries cypressindustries.com

– Molex molex.com

EDT, Inc.

2019 March 19

6

Page 7

VisionLink XF Cabling

Cabling

The VisionLink XF requires Camera Link, fiberoptic, and power cables, as explained below.

Camera Link

Use standard Camera Link cables (SDR-to-SDR or SDR-to-MDR) to connect the VisionLink XF units to the camera and

the framegrabber. EDT recommends that these cables should be one meter or less in length. You may use longer

cables, but they may introduce noise into your image data – particularly if you use a camera with a high pixel clock rate.

For Camera Link pin assignments, see Pin Assignments on page 12.

Fiberoptic

Use fiberoptic cabling to connect the two VisionLink XF units to each other. The type of cabling you need will depend

on where you install the system, and which transceivers you use (for transceiver specifications, see Transceivers on

page 11). EDT stocks a small number of options for fiberoptic cable assemblies; if these options do not meet your

needs, you should contact a provider of such assemblies (see Related Resources for some of these providers).

Power and Auxiliary

EDT ships your VisionLink XF extenders with a power adapter and a connecting cable. For options and pin

assignments, see Power Supply on page 15 and (under Pin Assignments) Power Connector on page 13.

EDT, Inc.

2019 March 19

7

Page 8

VisionLink XF Setup

Setup

To set up your VisionLink XF extender pair...

1. Power off all devices.

In the host computer, install the

2.

P0 is connected to the base, or primary, port of the camera or framegrabber. P1 is connected to the medium/full,

3.

or secondary, port of the camera or framegrabber. Connect the camera-end unit to the camera and the

framegrabber-end unit to the framegrabber with appropriate cables. See Figure 2.

Figure 2. Connecting Camera Link cables to the VisionLink XF

a. SDR-to-SDR, part #016-15341 b. SDR-to-MDR, part #016-15340

framegrabber according to its user’s guide (for EDT framegrabbers, see

edt.com

).

4. In each unit, insert a fiberoptic transceiver into the SFP+ port; then connect the two units with fiberoptic cabling and

close the bale straps on the transceivers.

5. Verify that each DIP switch is set correctly (see DIP Switches and LEDs on page 9).

6. Connect each extender to its power supply (see Power Supply on page 15).

EDT, Inc.

7. Power on, in this order: the framegrabber (in the host computer); the framegrabber-end extender; the camera-end

extender; the camera.

8. Verify that each LED is steady green (see

DIP Switches and LEDs on page 9

2019 March 19

).

8

Page 9

VisionLink XF Setup

SDR ports (“P0” and “P1”) with LEDs

transmit / receive DIP switches

Power (“P4”)

SFP+ port

(“P3”) with

LED:

DIP Switches and LEDs

Figure 3 shows the extender’s ports and features, including the DIP switches and LEDs.

Figure 3. Ports and features

a. Camera Link end b. Fiberoptic end

• The DIP switches indicate which device (camera or framegrabber, as labeled on the Camera Link end of the unit);

whether Power over Camera Link (PoCL) is on or off; and whether the unit is set for program mode or normal mode.

• The LEDs indicate the status of each port.

Table 1 and Table 2 explain the details.

Table 1. DIP switch settings

# Function On Off Details

1 Which device to connect camera framegrabber System reads this switch at boot time only.

2 Port 1 (P1): PoCL P1: PoCL on P1: PoCL off Valid for camera-end units only. This switch always should be “off”

3 Port 0 (P0): PoCL P0: PoCL on P0: PoCL off Valid for camera-end units only. This switch always should be “off”

4 Program vs. normal mode program normal System reads this switch at boot time only.

5 undefined -- -- -6 undefined -- -- --

for the framegrabber-end unit (that is, whenever switch 1 is “off”).

for the framegrabber-end unit (that is, whenever switch 1 is “off”).

Table 2. LED behaviors

Unit LED location Behavior Meaning

Camera SDR Green, no flash Good; the camera (pixel clock) is detected

Green, quick flash (10Hz) Error; the camera (pixel clock) is not detected

Red, no flash Good; PoCL is enabled

Red, quick flash (10Hz) Error; PoCL is enabled, but a non-PoCL device is connected to

SFP+ Green, no flash Good; the other unit is detected at the framegrabber end

Red, slow flash (1Hz) Error; the other unit is not detected at the framegrabber end

Red, quick flash (10Hz) Error; the other unit is detected, but it is a camera-end unit (it

Framegrabber SDR Green, no flash Good; data is transferring between the unit and the framegrabber

SFP+ Green, no flash Good; the other unit is detected at the camera end

Red, slow flash (1Hz) Error; the other unit is not detected at the camera end

Red, quick flash (10Hz) Error; the other unit is detected, but it is a framegrabber-end unit

the unit (SafePower circuit is open)

should be a framegrabber-end unit)

(it should be a camera-end unit)

EDT, Inc.

2019 March 19

9

Page 10

VisionLink XF Mounting and Safetying

Mounting holes

Safety wire

running through

hole,

notch, no

and bale strap

Mounting and Safetying

In some applications – for example, aircraft or other high-vibration environments – you may need to mount the extender,

safety the transceiver, or do both.

• To mount the extender, you can attach a custom (user-provided) bracket via the two 4-40 mounting posts on the

bottom of the case; for the precise locations of these holes, see Dimensions on page 16.

• To safety the fiberoptic transceiver, you can use aviation safety wire.

For details on how to use the mounting holes and safety wire, see Figure 4.

Figure 4. Mounting and safetying

a. Mounting holes b. Transceiver with safety wire

Firmware

To use the 4-40 thread mounting holes:

Add your own custom bracket, designed to match the exact

location of the holes (see Dimensions on page 16).

CAUTION – Internal damage will occur if 4-40 mounting

screws extend into the case more than 0.250 inches from

standoff.

To safety the transceiver:

Thread the safety wire through the bale strap and the hole and

notch in the backshell. EDT recommends .020 dia. aviation

safety wire from an aviation supplier – for example, Aircraft

Spruce and Specialty (www.aircraftspruce.com). For aviation

applications, follow relevant Federal Aviation Administration

(FAA) guidelines and best practices; see the FAA Advisory

Circular (AC) 43.13-1B at www.faa.gov.

Each extender is preconfigured with EDT firmware which controls its operation. EDT provides periodic firmware updates

which currently must be performed onsite at EDT. If you are notified that an update is available or needed, contact EDT.

EDT, Inc.

2019 March 19

10

Page 11

VisionLink XF Transceivers

Transceivers

The VisionLink XF extender supports various types of small form-factor pluggable (SFP+) transceivers with matching

multimode fiber (MMF) or single mode fiber (SMF), as shown in Table 3.

Table 3. Transceiver + fiber combinations

Wavelength Cable Range at 10 Gb/s *

33 meters62.5-micron MMF (OM1)850 nm

300 meters50-micron MMF (OM3)850 nm

Up to 10 kilometers9-micron SMF1310 nm

Alternatively, the following transceivers are available as options...

• Bidirectional transceivers – These support data transmit and receive over a single fiber using two separate wavelengths (for example, 1310 nm and 1550 nm). They can be used in a matched pair, 1310/1550 and 1550/1310.

Typical usage is with an optical rotary joint.

• CWDM transceivers – These support data transmission on a specific wavelength (1270 nm to 1610 nm). They can

be used with a CWDM multiplexer and demultiplexer which can support up to 16 wavelengths over a duplex fiber

between the multiplexer and demultiplexer. Typical usage is with an optical network of devices to be served by one

duplex fiber.

Typically, it is easiest to connect all transceivers using LC duplex fiber; but if you want to use fewer fibers, in some

atypical cases it is possible to do so – for example, when using single-fiber (bidirectional) transceivers, as above.

EDT, Inc.

2019 March 19

11

Page 12

VisionLink XF Pin Assignments

Pin Assignments

This section provides pin assignments for each connector.

Camera Link Connectors

Below are the pin assignments for the Camera Link SDR26 connectors.

Camera

or simulator

end

Frame

grabber

end

Camera Link signal

(base mode,

primary connector)

Camera Link signal

(medium mode,

secondary connector)

Camera Link signal

(full mode,

secondary connector)

inner shield / ground*inner shield / ground*inner shield / ground*1*1*

inner shield / ground*inner shield / ground*inner shield / ground*14*14*

Y0–Y0–X0–252

Y0+Y0+X0+1215

Y1–Y1–X1–243

Y1+Y1+X1+1116

Y2–Y2–X2–234

Y2+Y2+X2+1017

Yclk–Yclk–Xclk–225

Yclk+Yclk+Xclk+918

Y3–Y3–X3–216

Y3+Y3+X3+819

100 ohmsunusedSerTC+207

terminatedunusedSerTC–720

Z0–unusedSerTFG–198

Z0+unusedSerTFG+621

Z1–unusedCC1–189

Z1+unusedCC1+522

Z2–unusedCC2+1710

Z2+unusedCC2–423

Zclk–unusedCC3–1611

Zclk+unusedCC3+324

Z3–unusedCC4+1512

Z3+unusedCC4–225

inner shield / ground*inner shield / ground*inner shield / ground*13*13*

inner shield / ground*inner shield / ground*inner shield / ground*26*26*

EDT, Inc.

* With PoCL enabled, pins 1 and 26 change to +12 V DC power, while pins 13 and 14 change to +12 V DC power return.

2019 March 19

12

Page 13

VisionLink XF Pin Assignments

1

(Switchcraft)

5

6

7

1

4

2

3

(Lemo)

Power Connector

Below are the pin assignments for the power connector – either a standard coaxial Switchcraft or an optional Lemo.

Figure 5. Pin assignments – standard Switchcraft or optional Lemo connector

Outer ring is

ground.

Pin 1 is power

to the extender

(+12 V DC).

With the Lemo, you can use various cables that allow auxiliary signals.

Cable Assembly – Lemo to Loose Wire

The Lemo to loose wire cable assembly (EDT part #016-12650) can be wired as needed or connected to various types

of connectors, depending on your application.

Key in connector barrel (at top).

Pin 2 is power to the extender (+12 V DC).

Pin 7 is ground (for signals and power).

Pins 1, 3, 4, 5, 6 (defined by firmware used in extender)

typically are used at CMOS +3.3 V signal levels, though

pins 1,6 and 3,4 can be configured as LVDS pairs.

Table 4. Pin assignments – Lemo to loose wire

Lemo pin Wire color Standard firmware Signal level Comments

CMOS +3.3 VAUX_TX, primary auxiliary transmit UARTgreen1 (output)

All five CMOS 3.3 V signals go to

FPGA I/O 3.3V pins using series

100-ohm resistors.

Custom firmware can be used to

configure these pins as input or

output.

AUX2_TX, secondarorange3 (output) CMOS +3.3 Vy auxiliary transmit

SYNC, can be configured as an outgoing copy ofwhite5

the camera’s frame-valid signal

+12 Vpower to extenderred2

CMOS +3.3 VAUX2_RX, secondary auxiliary receivebrown4 (input)

CMOS +3.3 V

CMOS +3.3 VAUX_RX, primary auxiliary receive UARTblue6 (input)

groundgroundblack7

Cable Assembly – Lemo to Male DB9

The Lemo to male DB9 cable assembly (EDT part #016-12718) supports signals that can be used as an auxiliary

signaling system for a variety of purposes.

For example, with custom firmware you could control the camera’s pan and servo motors, or set up a hardware trigger

that is local to either end. If you wish to explore these options, contact EDT.

Unlike the DB9 in the female assembly, this DB9 has no looped-back signals or integrated level conversion.

EDT, Inc.

2019 March 19

13

Page 14

VisionLink XF Pin Assignments

Table 5 shows the pin assignments and how the standard firmware uses each wire.

Table 5. Pin assignments – male DB9 cable

Lemo pin Color DB9 pin Standard firmware Signal level Comments

–[unused]1––

All five CMOS 3.3 V

signals go to FPGA I/O

3.3V pins using series

100-ohm resistors.

Custom firmware can be

used to configure these

pins as input or output.

SYNC, can be configured as an outgoing copy of4white5

the camera’s frame-valid signal

–[unused]6––

CMOS +3.3 VAUX_TX, primary auxiliary transmit UART2green1 (output)

+12 Vpower to extender9red2

CMOS +3.3 VAUX2_TX, secondary auxiliary transmit7orange3 (output)

CMOS +3.3 VAUX2_RX, secondary auxiliary receive8brown4 (input)

CMOS +3.3 V

CMOS +3.3 VAUX_RX, primary auxiliary receive UART3blue6 (input)

groundground5black7

Cable Assembly – Lemo to Female DB9 RS232

The Lemo to female DB9 cable assembly (EDT part #016-12445) supports integrated CMOS +3.3 V to RS232 level

converters on a small circuit board inside the DB9 connector shell.

This cable is designed to plug in directly to a host computer serial port. The cable offers an auxiliary serial UART

connection over the fiber, in addition to the UART normally associated with the Camera Link standard. This auxiliary

UART can be used, for example, to control the camera’s pan and zoom servo motors from the host at 115.2 kb/s or less.

Alternatively, it can be used for other low bandwidth signals.

Unlike the DB9 in the male assembly, this DB9 does not supply power to the extender. Instead, a red wire (power) and

a black wire (ground), each 24 inches long, are left loose so you can hook up your own power source. The required

power is 12 V DC.

Table 6 shows the pinout and how the standard firmware uses each wire. DB9 pins 1, 4, and 6 are wired together and

unconnected, 7 and 8 also are wired together, and 9 also is unconnected; these signals are not otherwise used.

EDT, Inc.

Table 6. Pin assignments – female DB9 cable

Lemo pin Wire color DB9 pin Standard firmware Signal level

–[unused]1––

–[unused]6––

AUX_TX, primary auxiliary transmi2green1 (output) RS232 (at DB9) to CMOS +3.3 V (at Lemo)t UART

+12 Vpower to extender–red2

–reserved7orange3

–reserved8brown4

–reserved4white5

RS232 (at DB9) to CMOS +3.3 V (at Lemo)AUX_RX, primary auxiliary receive UART3blue6 (input)

groundground–black7

2019 March 19

14

Page 15

VisionLink XF Power Supply

Power Supply

Each extender has an internal switching regulator which supports 12 V DC. For pin information and polarity on the

standard Switchcraft or optional Lemo power connector, see Power Connector on page 13.

Table 7 shows the base-mode power supply requirements.

Table 7. Power supply requirements – base mode

U.S. International

Voltage in 100–240 V, 50–60 Hz

from AC mains

100–240 V, 50–60 Hz

from AC mains

Voltage out 12 V DC; power supply

includes a U.S.-standard

power plug

Connector,

standard

Connector,

Lemo option

Switchcraft 760K Switchcraft 760K

FGG.0B.307.CLAD.56 FGG.0B.307.CLAD.56

12 V DC; power supply

includes four international

power plug adapters

EDT, Inc.

2019 March 19

15

Page 16

VisionLink XF Dimensions

Dimensions

This section shows the dimensions of the VisionLink XF.

The Switchcraft power connector has an outside diameter of 0.31 inch; the optional Lemo power conne ctor has an

outside diameter of 0.35 inch.

NOTE Connector dimensi ons are approximate; for precise dimensions, see the manufacturer’s specifications.

Figure 6. Extender dimensions

EDT, Inc.

2019 March 19

16

Page 17

VisionLink XF Dimensions

Revision Log

Below is a history of modifications to this guide.

Date Rev By Pg(s)

20170215

20190319 0001 BB et al.

0000 PH et al. All

Detail

• Created new guide.

• Added details to cable connections in Setup section.

8

EDT, Inc.

2019 March 19

17

Loading...

Loading...