Page 1

User’s Guide

VisionLink RCX

Remote Camera Link extender

for use with Camera Link cameras

Date: 2016 August 30

Rev.: 0002

Page 2

EDT | Engineering Design Team, Inc.

3423 NE John Olsen Ave.

Hillsboro, OR 97124

U.S.A.

Tel: +1-503-690-1234 | Toll free (in U.S.A.): 800-435-4320

Fax: +1-503-690-1243

www.edt.com

EDT

TM

and Engineering Design Team are trademarks of Engineering Design Team, Inc. All other trademarks, service marks,

TM

and copyrights are the property of their respective owners†.

© 1997-2019 Engineering Design Team, Inc. All rights reserved.

EDT, Inc. 2

Page 3

Terms of Use Agreement

Definitions. This agreement, between Engineering Design Team, Inc. (“Seller”) and the user or distributor (“Buyer”), covers the

use and distribution of the following items provided by Seller: a) the binary and all provided source code fo r any and all device

drivers, software libraries, utilities, and example applications (collectively, “Software”); b) the binary and all provided source code

for any and all configurable or programmable devices (collectively, “Firmware”); and c) the computer boards and all other physical

components (collectively, “Hardware”). Software, Firmware, and Hardware are collectively referred to as “Products.” This

agreement also covers Seller’s published Limited Warranty (“Warranty”) and all other published manuals and product information

in physical, electronic, or any other form (“Documentation”).

License. Seller grants Buyer the right to use or distribute Seller’s Software and Firmware Products solely to enable Seller’s

Hardware Products. Seller’s Software and Firmware must be used on the same computer as Seller’s Hardware. Seller’s Products

and Documentation are furnished under, and may be used only in accordance with, the terms of this agreement. By using or

distributing Seller’s Products and Documentation, Buyer agrees to the terms of this agreement, as well as any additional

agreements (such as a nondisclosure agreement) between Buyer and Seller.

Export Restrictions. Buyer will not permit Seller’s Software, Firmware, or Hardware to be sent to, or used in, any other country

except in compliance with applicable U.S. laws and regulations. For clarification or advice on such laws and regulations, Buyer

should contact: U.S. Department of Commerce, Export Division, Washington, D.C., 20230, U.S.A.

Limitation of Rights. Seller grants Buyer a royalty-free right to modify, reproduce, and distribute executable files using the

Seller’s Software and Firmware, provided that: a) the source code and executable files will be used only with Seller’s Hardware;

b) Buyer agrees to indemnify, hold harmless, and defend Seller from and against any claims or lawsuits, including attorneys’ fees,

that arise or result from the use or distribution of Buyer’s products containing Seller’s Products. Seller’s Hardware may not be

copied or recreated in any form or by any means without Seller’s express written consent.

No Liability for Consequential Damages. In no event will Seller, its directors, officers, employees, or agents be liable to Buyer

for any consequential, incidental, or indirect damages (including damages for business interruptions, loss of business profits or

information, and the like) arising out of the use or inability to use the Products, even if Seller has been advised of the possibility

of such damages. Because some jurisdictions do not allow the exclusion or limitation of liability for consequential or incidental

damages, the above limitations may not apply to Buyer. Seller’s liability to Buyer for actual damages for any cause whatsoever,

and regardless of the form of the action (whether in contract, product liability, tort including negligence, or otherwise) will be

limited to fifty U.S. dollars ($50.00).

Limited Hardware Warranty. Seller warrants that the Hardware it manufactures and sells shall be free of defects in materials

and workmanship for a period of 12 months from date of shipment to initial Buyer. This warranty does not apply to any product

that is misused, abused, repaired, or otherwise modified by Buyer or others. Seller’s sole obligation for breach of this warranty

shall be to repair or replace (F.O.B. Seller’s plant, Beaverton, Oregon, USA) any goods that are found to be non-conforming or

defective as specified by Buyer within 30 days of discovery of any defect. Buyer shall bear all installation and transportation

expenses, and all other incidental expenses and damages.

Limitation of Liability.

whether such damages arise from, or are a result of, breach of contract, warranty, tort (including negligence), strict liability, or

otherwise. All references to damages herein shall include, but not be limited to: loss of profit or revenue; loss of use of the goods

or associated equipment; costs of substitute goods, equipment, or facilities; downtime costs; or claims for damages. Seller shall

not be liable for any loss, claim, expense, or damage caused by, contributed to, or arising out of the acts or omissions of Buyer,

whether negligent or otherwise.

No Other Warranties. Seller makes no other warranties, express or implied, including without limitation the implied warranties

of merchantability and fitness for a particular purpose, regard ing Seller’s Products or Documentation. Seller does not warrant,

guarantee, or make any representations regarding the use or the results of the use of the Products or Documentation or their

correctness, accuracy, reliability, currentness, or otherwise. All risk related to the results and performance of the Products and

Documentation is assumed by Buyer. The exclusion of implied warranties is not permitted by some jurisdictions. The above

exclusion may not apply to Buyer.

Disclaimer. Seller’s Products and Documentation, including this document, are subject to change without notice. Documentation

does not represent a commitment from Seller.

In no event shall Seller be liable for any type of special consequential, incidental, or penal damages,

EDT, Inc. 3

Page 4

Contents

Overview........................................................................................................................................................................................5

Care and Cautions ...............................................................................................................................................................5

Related Products..................................................................................................................................................................5

Related Resources...............................................................................................................................................................6

Setup .............................................................................................................................................................................................7

Adapter Cabling, Mounting, Safetying...........................................................................................................................................9

Status, Configuration, Operating Mode........................................................................................................................................10

Status.................................................................................................................................................................................10

Configuration......................................................................................................................................................................10

Operating Mode Details .....................................................................................................................................................11

Resetting or Changing the Operating Mode.......................................................................................................................11

Firmware......................................................................................................................................................................................12

Transceivers................................................................................................................................................................................12

Pin Assignments..........................................................................................................................................................................13

Camera Link.......................................................................................................................................................................13

Power Connector ...............................................................................................................................................................13

Cable assembly – Lemo to loose wire......................................................................................................................14

Cable assembly – Lemo to male DB9 ......................................................................................................................14

Cable assembly – Lemo to female DB9 RS232.......................................................................................................14

Power Supply...............................................................................................................................................................................15

Dimensions..................................................................................................................................................................................16

Revision Log................................................................................................................................................................................17

EDT, Inc. 4

Page 5

VisionLink RCX Remote Camera Extender

Overview

The VisionLink RCX is a base-mode extender which adapts Camera Link over fiber, providing electrical isolation and

extended range. It supports most base-mode cameras from 20 to 85 MHz, at serial data rates of up to 19.2 Kb/s.

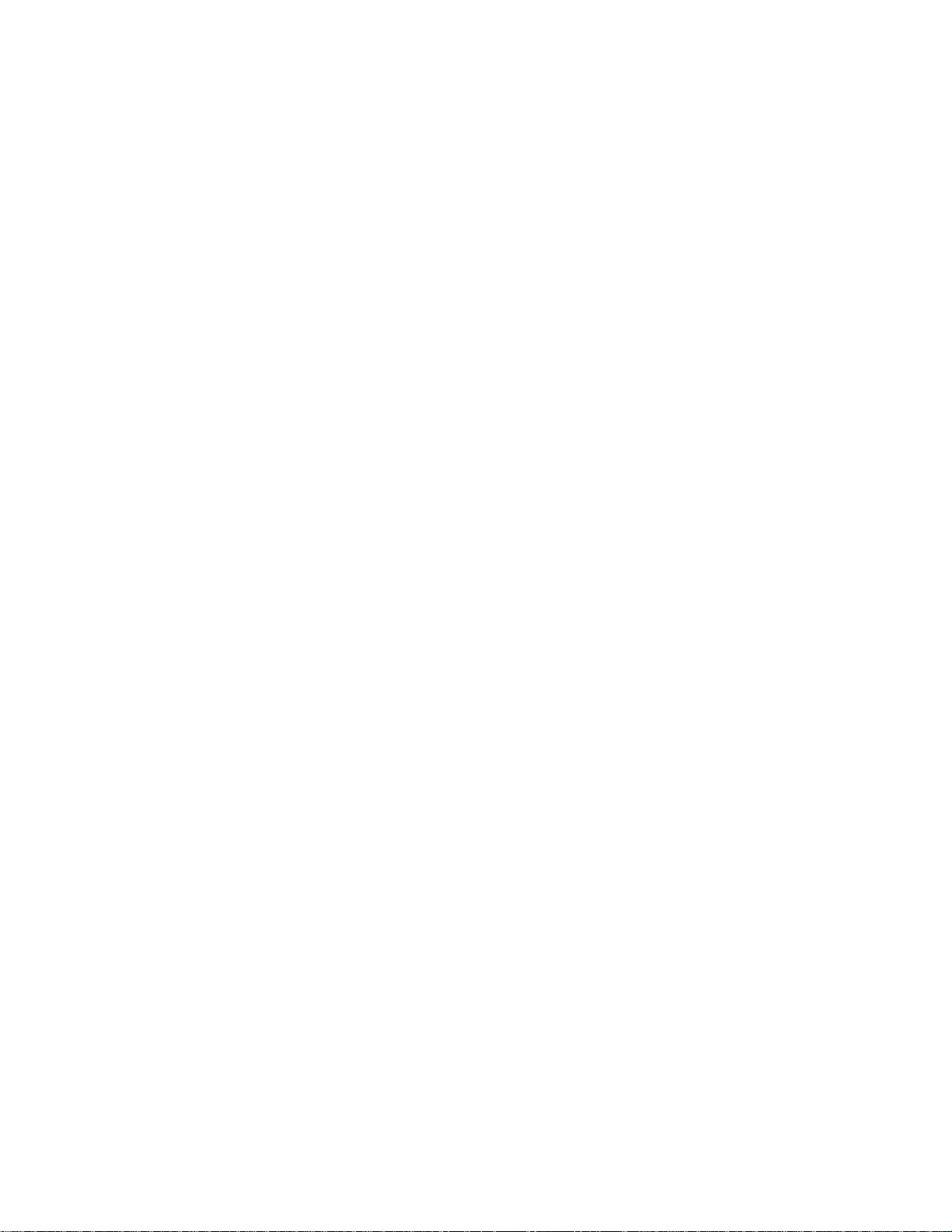

A pair of VisionLink RCX extenders, with fiberoptic cable, replaces standard Camera Link cable as shown in Figure 1.

Figure 1. Two VisionLink RCX extenders with fiber

Care and Cautions

When opening and handling EDT products, always follow electrostatic dissipative procedures (see edt.com/static).

Your EDT extender, though built to withstand a wide range of conditions as listed in its datasheet specifications, is still

a high-performance component which must be treated with care for optimal results.

In particular, the connectors – especially the fiberoptic transceivers – must be kept clean and dry. If you suspect the

presence of moisture or debris in the connectors, you should blast a burst of compressed air...

• directly into the ports to dislodge any debris there; and

• away from the electronic components to blow out any moisture in the air nozzle.

CAUTION To avoid damaging your eyesight, never look directly into any fiberoptic transceiver.

Related Products

The base-mode VisionLink RCX is compatible with the earlier RCX C-Link extender. For other modes, use a set of RCX

C-Link medium- or full-mode extenders. To find details on these extenders and other EDT vision products (for example,

framegrabbers), see Related Resources.

EDT, Inc. 5

Page 6

VisionLink RCX Overview

Related Resources

The resources below may be helpful or necessary for your applications.

NOTE For complete resources and documentation on any EDT product – visit edt.com and navigate to the product page,

or go to the download hub (edt.com/download-hub) and look under the product name.

EDT Resources

• Installation instructions edt.com/download-hub

• VisionLink RCX datasheet / specifications “

• VisionLink RCX quick start guide “

• Block diagrams “

• Videos and tutorials “

• RCX C-Link user’s guide and datasheet / specifications edt.com/product/rcx-c-link

Third-Party Resources

• PCI Express (PCIe) specifications www.pcisig.com

• Camera Link specifications www.visiononline.org

• Timecode (IRIG-B) specifications irigb.com

EDT, Inc. 2016 August 30 6

Page 7

VisionLink RCX Setup

VisionLink RCX

LC duplex

fiberoptic

transceiver:

- transmit

- receive

Power (Lemo

or Switchcraft)

Hirose (future use)

LED

thumbscrews

MDR26

Setup

Each extender unit is preset and prelabeled to connect to either a camera or a framegrabber (Figure 2). Each unit, in

order to work properly, must be connected to the type of device for which it is set.

NOTE If you reconfigure an extender, relabel it immediately to avoid confusion later.

Figure 2. Fiberoptic extender, labeled with factory presets

The label at the far right shows the unit’s factory presets, including:

• the device (camera or framegrabber) for which the unit is preset;

• the operating mode (blink code) for which the unit is preset (see

Configuration on page 10).

After you have checked the labeling, you can connect each extender as explained below.

• Device end: Attach the correct device (camera or framegrabber) to the extender’s MDR26 connector.

• Cable end: Attach the correct cabling to the extender’s cable connectors.

Figure 3 shows the extender connectors and other features, including the LED (explained in Status, Configuration,

Operating Mode on page 10).

Figure 3. VisionLink RCX – connectors and features

a. Cable end – connectors b. Cable end – other features

c. Device end – connector

d. Extender connected to camera

EDT, Inc. 2016 August 30 7

Page 8

VisionLink RCX Setup

Base mode requires two extenders: one at the camera end, and the other at the framegrabber end.

To set up this system...

1. Install the framegrabber according to its user’s guide (for EDT user’s guides, see edt.com/download-hub).

2. Verify the extenders are configured properly (see Configuration on page 10) – one for the camera end, and one for

the framegrabber end.

3. Turn off power to all devices.

4. Connect the extender labeled “Camera End” to the MDR26 connector on the camera and the extender labeled

“Framegrabber End” to the MDR26 connector on the framegrabber, as shown in Figure 4 below.

NOTE An adapter may be required in some setups, such as those with devices using SDR connectors; for details, see

Figure 5 below and Adapter Cabling, Mounting, Safetying on page 9.

Figure 4. Base mode setup with devices using MDR26 connectors

Figure 5. Base mode setup with MDR26-SDR26 adapter at camera end

5. Connect the two extenders’ transceivers to each other with fiberoptic cabling (see Transceivers on page 12).

6. Connect each extender’s power connector to the power supply (see Power Supply on page 15).

7. Turn on power to all devices.

8. Verify each LED shows a steady light (for LED details, see Status, Configuration, Operating Mode on pag e 10).

EDT, Inc. 2016 August 30 8

Page 9

VisionLink RCX Adapter Cabling, Mounting, Safetying

Mounting holes

Safety wire

running through

hole,

notch, no

and bale strap

Adapter Cabling, Mounting, Safetying

You may need adapter cabling, either from EDT or from a third party, in some cases – for example...

• To connect the extender in applications with limited space or other constraints.

• To connect the extender to an EDT VisionLink framegrabber or any other device using an SDR connector.

Table 1 shows the adapter cabling available from EDT and how to attach it to the extender.

Table 1. Using adapter cabling from EDT

Part # Description Attachment instructions

016-13740 MDR26 female to SDR26 male, 2.0M Secure the

016-13779 MDR26 female to SDR26 male, 1.0M

016-14199 MDR26 female to SDR26 male, 0.5M

016-02563 MDR26 female to MDR26 male, 0.5M

extender to

the adapter

cable via the

extender’s

thumbscrews.

In most cases, mounting the extender to the device via the thumbscrews is sufficient. However, some settings – e.g., a

high vibration environment on an aircraft – may require additional methods to secure the extender and fiberoptic cable.

In such settings you can mount the extender by using the two 4-40 thread mounting holes with a custom (user-provided)

bracket – for the precise locations of these holes, see Dimensions on page 16. Also, you can secure the fiberoptic

transceiver’s bale strap with safety wire. For details on mounting holes and safety wire, see Figure 6.

Figure 6. Using the mounting holes and safety wire

a. Mounting holes b. Safety wire

To use the 4-40 thread mounting holes:

Add your own custom bracket, designed to match the exact

location of the holes (see Dimensions on page 16).

CAUTION – To avoid damage to the extender, the mounting

screws cannot extend more than 0.2" into the case.

To use safety wire:

Thread the safety wire through the bale strap and the hole and

notch in the backshell. EDT recommends using .022 gauge

aviation safety wire and other supplies from an aviation

supplier – for example, www.aircraftspruce.com (Aircraft

Spruce and Specialty). For aviation applications, follow

relevant Federal Aviation Administration (FAA) guidelines and

best practices for safetying items on aircraft; see FAA

Advisory Circular (AC) 43.13-1B at www.faa.gov.

EDT, Inc. 2016 August 30 9

Page 10

VisionLink RCX Status, Configuration, Operating Mode

Status, Configuration, Operating Mode

Each extender has a light-emitting diode (LED), as in Figure 3b. By displaying various patterns of blinks, the LED

communicates information about the extender’s configuration and status, as follows.

• At power-on, the LED blinks a one-time configuration code to indicate the operating mode for which the extender

is configured, and then blinks rapidly as the firmware loads.

• After power-on, the LED continuously displays a status code which shows steady green if the unit is working properly, or shows a different blink pattern if there is an error.

This section explains the status and configuration codes, as well as the related operating modes.

Status

As stated above, at power-on the LED will blink the extender’s configuration code on e time, Then it will blink quickly

while the firmware loads. After power-on, the LED continuously displays the extender’s status code, which indica tes

whether the unit is working properly or has errors (see Table 2).

Table 2. Status codes

LED behavior Significance

Steady light All OK – everything is working properly.

Slow blinks (1Hz) There is an error from the other end. The typical causes are:

• The extender at the other end has no power, or its operating mode does not match the operating mode on

this extender (see Configuration on page 10).

• The cable connection is compromised, either by incorrect or damaged cabling, or by moisture or debris in the

extender’s cable connectors (see Care and Cautions on page 5).

Fast blinks (10Hz) There is an error from the camera to the extender, related to the camera’s pixel clock.

Both slow and fast

blinks

2 fast + 2 slow + 2

fast blinks

No light The extender has no power or is faulty.

Configuration

Each extender is preset and prelabeled for the operating mode you specified in your product order. The operating mode

is selected and indicated through a blink pattern, displayed once at power-on, called the LED configuration (blink) code.

The LED configuration code consists of two digits, each represented by a certain number of blinks. The two digits are

separated by a pause, shown in this guide as a hyphen. For example, a configuration code of “one blink, pause, one

blink” is shown in this guide as 1-1.

A first digit of 1 means the unit is configured for the camera end; a first digit of 2 indicates that the unit is configured for

the framegrabber end. The second digit must be the same for both ends (camera and framegrabber). With an EDT FOX

framegrabber, there is no extender at the framegrabber end, so the configuration code is set at the camera end only.

For a typical base-mode system, a configuration code of 1-1 at the camera end and 2-1 at the framegrabber end permits

standard base-mode operation at clock frequencies of 20–40 MHz.

If the fast blink is on the camera-end extender: either the camera has no power, or the operating mode on the

extender does not match the operating mode on the camera (see Configuration on page 10).

If the fast blink is on the framegrabber-end extender: either the extender or the resync cable is faulty.

There is at least one slow-blink error and at least one fast-blink error.

The extender is configured with an unsupported operating mode (see Configuration on page 10).

EDT, Inc. 2016 August 30 10

Page 11

VisionLink RCX Status, Configuration, Operating Mode

Table 3 shows the configuration blink codes for standard usage and RCX C-Link emulation.

Table 3. Configuration codes

Standard usage RCX C-Link emulation

Unit

connects

to

camera 1-1 20–40 MHz 24 1.250 Gb/s 3-1-1 20–40 MHz 24 1.250 Gb/s

camera 1-2 20–80 MHz 24 2.500 Gb/s 3-1-2 20–60 MHz 16 1.250 Gb/s

camera 1-3 20–85 MHz 24 3.125 Gb/s 3-1-3 20–60 MHz 24 2.500 Gb/s

camera 1-4 20–80 MHz 24 2.500 Gb/s 3-1-4 60–80 MHz 24 2.500 Gb/s

framegrabber 2-1 40 MHz 24 1.250 Gb/s 3-2-1 40 MHz 24 1.250 Gb/s

framegrabber 2-2 80 MHz 24 2.500 Gb/s 3-2-2 60 MHz 16 1.250 Gb/s

framegrabber 2-3 85 MHz 24 3.125 Gb/s 3-2-3 60 MHz 24 2.500 Gb/s

framegrabber 2-4 80 MHz 24 2.500 Gb/s 3-2-4 80 MHz 24 2.500 Gb/s

Blink

code

(N-N)

Pixel

clock

rate

Bits

per

clock

Link rate

between

units

Blink

code

(3-N-N)

Pixel

clock

rate

Bits

per

clock

Link rate

between

units

Operating Mode Details

In base mode, each pixel clock transfers up to 24 bits of video data from the camera’s X channel. The extender can

transfer four camera control signals and has a bidirectional serial interface between framegrabber and camera. The

extender generates its own pixel clock, so the clock rate into the framegrabber may exceed the rate of the camera. Thus,

the amount of time spent in blanking will vary from line to line and frame to frame.

At reset (and whenever the extender cannot lock to the camera clock), the extender initializes to assume that the

Camera Link data-valid signal is never asserted, and ignores it. Many Pulnix cameras do not assert data-valid, so this

behavior is useful for those using such cameras. The first occurrence of data-valid true from the camera causes the

extender to use data-valid to qualify video data from that point on.

In the case of a dual-tap camera, the Camera Link pixel clock is half the camera’s pixel rate. For example, a dual-tap

12-bit camera with a 40 MHz Camera Link clock sends 80 million pixels per second. This camera is compatible with the

extender in configuration code 1-1.

For instructions on verifying and updating the firmware, see Firmware on page 12.

Resetting or Changing the Operating Mode

Your extender is preset and prelabeled for the operating mode you specified in your product order. However, if you need

to reset or change the operating mode, follow the steps below (see edt.com/download-hub for a video tutorial).

1. Determine in advance which configuration code you want (see Table 3, Configuration codes) so you will be ready

to enter it quickly in step 5 below.

2. Power on the extender.

3. Push and hold the recessed button on the bottom of the extender with a ballpoint pen or a similar fine, blunt point

(Figure 7); hold the button until the LED stops blinking and stays steady green.

EDT, Inc. 2016 August 30 11

Figure 7. Pushing the recessed button

Page 12

VisionLink RCX Firmware

4. Release the button and allow the LED to turn off.

5. Push and hold the button, allow the LED to start blinking, and release the button after the correct number of blinks

for the first digit; repeat for each digit.

For example, for a configuration code of 2-1:

a) First, hold the button for two blinks and release it.

b) Then, hold the button for one blink and release it.

6. Watch what happens after you enter the configuration code. If the code is valid, the extender will display the code

as a pattern of blinks. If the pattern is not what you want, or if the pattern is two fast, two slow, and two fast blinks

(an error code), start over from Step 1.

7. To verify that the extender is working properly, watch the status code (see Status on page 10).

8. If you changed the operating mode, relabel the extender to prevent confusion later.

Firmware

Each extender is preconfigured with EDT firmware which controls its operation. EDT provides periodic firmware updates

which currently must be performed onsite at EDT. If you are notified that an update is available or needed, contact EDT.

Transceivers

The VisionLink RCX extender supports various types of small form-factor pluggable (SFP) transceivers with matching

multimode fiber (MMF) or single mode fiber (SMF), as shown in Table 4.

NOTE To secure the transceiver and its cabling – e.g., in high vibration settings – see Adapter Cabling, Mounting,

Safetying on page 9.

Table 4. Transceiver + fiber combinations

Wavelength Cable Range at

1.250 Gb/s

1310 nm 4 kilometers

Alternatively, the following transceivers are available as options...

• Single fiber (bidirectional) transceivers – distances up to 60 km: These have an integrated passive optical multiplexer and transmit data in each direction over one fiber using different colors of light – especially useful when going

through an optical rotary joint.

• CWDM transceivers – extended range of 5 km or more, 1310 nm, single-fiber PON: These use up to 16 different

colors of light, with the light split and combined by passive optical multiplexers that are external to the extender.

They support up to twelve different cameras simultaneously over a single fiber.

• DualTX and DualRX transceivers: In full mode, these are used on the secondary Camera Link connector because

it must carry twice as much data as the primary connector.

Typically, it is easiest to connect all transceivers using LC duplex fiber. However, if you wish to use fewer fibers, in some

atypical cases it is possible to do so – for example, when using single-fiber (bi-directional) transceivers, as above.

62.5-micron MMF (OM1)

50-micron MMF (OM3)

9-micron SMF

300 meters

550 meters

10 kilometers

Range at

2.500 Gb/s

150 meters

300 meters

5 kilometers

Range at

3.125 Gb/s

70 meters850 nm

150 meters850 nm

122016 August 30EDT, Inc.

Page 13

VisionLink RCX Pin Assignments

1

(Switchcraft)

5

6

7

1

4

2

3

(Lemo)

Pin Assignments

This section provides pin assignments for each connector.

Camera Link

Table 5 shows the Camera Link MDR26 pin assignments for base mode.

Table 5. Pin assignments – Camera Link MDR26 connector

Framegrabber

end

1 inner shield 1 7 SerTC– 20

14 inner shield 14 19 SerTFG– 8

25 X0– 2 6 SerTFG+ 21

12 X0+ 15 18 CC1– 9

24 X1– 3 5 CC1+ 22

11 X1+ 16 17 CC2+ 10

23 X2– 4 4 CC2– 23

10 X2+ 17 16 CC3– 11

22 Xclk– 5 3 CC3+ 24

9 Xclk+ 18 15 CC4+ 12

21 X3– 6 2 CC4– 25

8 X3+ 19 13 inner shield 13

20 SerTC+ 7 26 inner shield 26

Camera Link

Power Connector

Figure 8 shows pin assignments for the power connector – either a standard coaxial Switchcraft or an optional Lemo.

Figure 8. Pin assignments – standard Switchcraft or optional Lemo connector

signal

Camera

end

Framegrabber

end

Camera Link

signal

Camera

end

Outer ring is

ground.

Pin 1 is power to

extender (+4.75 to

+28 V DC).

Key in connector barrel (at top).

Pin 2 is power to extender (+4.75 to +28 V DC).

Pin 7 is ground (for signals and power).

Pins 1, 3, 4, 5, 6 (defined by firmware used in extender)

typically are used at CMOS +3.3 V signal levels, though

pins 1,6 and 3,4 can be configured as LVDS pairs.

With the Lemo, you can use various cables that allow auxiliary signals. (On medium- and full-mode systems using the

resync cable option, the extenders at the framegrabber end must use Lemo connectors.)

EDT, Inc. 2016 August 30 13

Page 14

VisionLink RCX Pin Assignments

Cable assembly – Lemo to loose wire

The Lemo to loose wire cable assembly (EDT part #016-02650) can be wired as needed or connected to various types

of connectors, depending on your application.

Table 6. Pin assignments – Lemo to loose wire

Lemo pin Wire color Standard firmware Signal level Comments

1 (output) green AUX_TX, primary auxiliary transmit UART CMOS +3.3 V

2 red power to extender +4.75 to +28 V

3 (output) orange AUX2_TX, secondary auxiliary transmit CMOS +3.3 V

4 (input) brown AUX2_RX, secondary auxiliary receive CMOS +3.3 V

5 white SYNC, can be configured as an outgoing copy of

the camera’s frame-valid signal

6 (input) blue AUX_RX, primary auxiliary receive UART CMOS +3.3 V

7 black ground ground

CMOS +3.3 V

All five CMOS 3.3 V signals go to

FPGA I/O 3.3V pins using series

100-ohm resistors.

Custom firmware can be used to

configure these pins as input or

output.

Cable assembly – Lemo to male DB9

The Lemo to male DB9 cable assembly (EDT part #016-02718) supports signals that can be used as an auxiliary

signaling system for a variety of purposes.

For example, with custom firmware you could control the camera’s pan and servo motors, or set up a hardware trigger

that is local to either end. If you wish to explore these options, contact EDT.

Unlike the DB9 in the female assembly, this DB9 has no looped-back signals or integrated level conversion.

Table 7 shows the pin assignments and how the standard firmware uses each wire.

Table 7. Pin assignments – male DB9 cable

Lemo pin Color DB9 pin Standard firmware Signal level Comments

––1[unused] –

––6[unused] –

1 (output) green 2 AUX_TX, primary auxiliary transmit UART CMOS +3.3 V

2 red 9 power to extender +4.75 to +28 V

3 (output) orange 7 AUX2_TX, secondary auxiliary transmit CMOS +3.3 V

4 (input) brown 8 AUX2_RX, secondary auxiliary receive CMOS +3.3 V

5 white 4 SYNC, can be configured as an outgoing copy of

the camera’s frame-valid signal

6 (input) blue 3 AUX_RX, primary auxiliary receive UART CMOS +3.3 V

7 black 5 ground ground

CMOS +3.3 V

All five CMOS 3.3 V

signals go to FPGA I/O

3.3V pins using series

100-ohm resistors.

Custom firmware can be

used to configure these

pins as input or output.

Cable assembly – Lemo to female DB9 RS232

The Lemo to female DB9 cable assembly (EDT part #016-02445) supports integrated CMOS +3.3 V to RS232 level

converters on a small circuit board inside the DB9 connector shell.

This cable is designed to plug in directly to a host computer serial port. The cable offers an auxiliary serial UART

connection over the fiber, in addition to the UART normally associated with the Camera Link standard. This auxiliary

UART can be used, for example, to control the camera’s pan and zoom servo motors from the host at 19.2 Kb/s or less.

Alternatively, it can be used for other low bandwidth signals.

EDT, Inc. 2016 August 30 14

Page 15

VisionLink RCX Power Supply

Unlike the DB9 in the male assembly, this DB9 does not supply power to the extender. Instead, a red wire (power) and

a black wire (ground), each 24 inches long, are left loose so you can hook up your own power source. The required

power is 4.75 to 28 V DC.

Table 8 shows the pinout and how the standard firmware uses each wire. DB9 pins 1, 4, and 6 are wired together and

unconnected, 7 and 8 also are wired together, and 9 also is unconnected; these signals are not otherwise used.

Table 8. Pin assignments – female DB9 cable

Lemo pin Wire color DB9 pin Standard firmware Signal level

––1[unused] –

––6[unused] –

1 (output) green 2 AUX_TX, primary auxiliary transmit UART RS232 (at DB9) to CMOS +3.3 V (at Lemo)

2 red – power to extender +4.75 to +28 V (red wire out)

3 orange 7 reserved –

4brown8reserved –

5 white 4 reserved –

6 (input) blue 3 AUX_RX, primary auxiliary receive UART RS232 (at DB9) to CMOS +3.3 V (at Lemo)

7 black – ground ground (black wire out)

Power Supply

Each extender has an internal switching regulator that supports voltages of 4.75 to 28 V DC. For pin information and

polarity on the standard Switchcraft and optional Lemo power connector, see Power Connector on page 13.

Table 9 shows the base-mode power supply requirements.

Table 9. Power supply requirements

U.S. International

Voltage in 100–240 V, 50–60 Hz

Voltage out 5 V, 1 A DC; power supply

Connector,

standard

Connector,

Lemo option

from AC mains

includes a U.S.-standard

power plug

Switchcraft 760K Switchcraft 760K

FGG.0B.307.CLAD.56 FGG.0B.307.CLAD.56

100–240 V, 50–60 Hz

from AC mains

5 V, 2A DC; power supply

includes four international

power plug adapters

EDT, Inc. 2016 August 30 15

Page 16

VisionLink RCX Dimensions

Dimensions

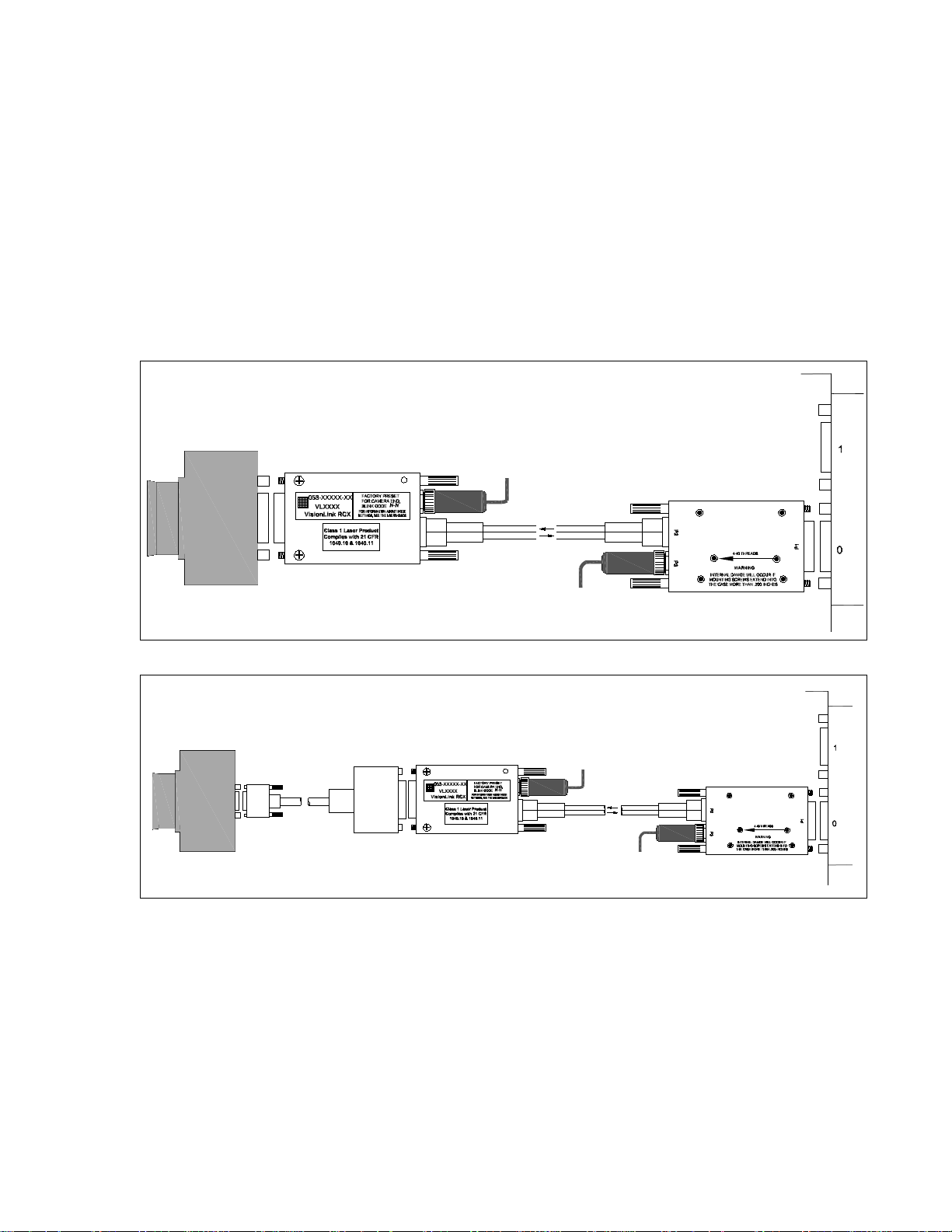

Figure 9 shows typical VisionLink RCX dimensions. The power connector dimension of 0.31 inch is for the standard

power connector; the optional Lemo connector on the fiber version is approximately 0.35 inch.

NOTE Connector dimensions are approximate; for precise dimensions, see the manufacturer’s specificati ons.

Figure 9. Extender dimensions

Figure 10 shows a typical value for cable clearance; the exact value is dependent upon the cable used.

Figure 10. Cable clearance

EDT, Inc. 2016 August 30 16

Page 17

VisionLink RCX Dimensions

Revision Log

Below is a history of modifications to this guide.

Date Rev By Pg(s) Detail

20150521 0000 PH,RH All • Created new guide.

20160812 0001 PH,CH 11-12 • In Resetting or Changing the Operating Mode: Suggested updates (20160722~11:42a,

20160812 0001 PH,CH 13-15 • In Pin Assignments and Power Supply sections, updated power spec from “+4.75 to +24

20160830 0002 PH,CH 15 • Under Pin Assignments > Cable assembly - Lemo to female DB9 RS232 > Table 8 > DB9

from CH, “VL RCX - changing the blink code) were made and ok’d by CH.

V DC” (and, for Lemo to loose wire, “+4.75 to +18 VDC”) to “+4.75 to +28 V DC.”

pin column, deleted “9” and “5.”

EDT, Inc. 2016 August 30 17

Loading...

Loading...